wiring diagram MERCEDES-BENZ ML320 1997 Complete Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2060 of 4133

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

See CHARGING SYSTEM in appropriate SYSTEM WIRING DIAGRAMS article in ELECTRICAL.

ApplicationFt. Lbs. (N.m)

Generator Mounting Bolts30 (42)

Generator Pulley Nut52 (70)

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 26 © 2006 Mitchell Repair Information Company, LLC.

Page 2672 of 4133

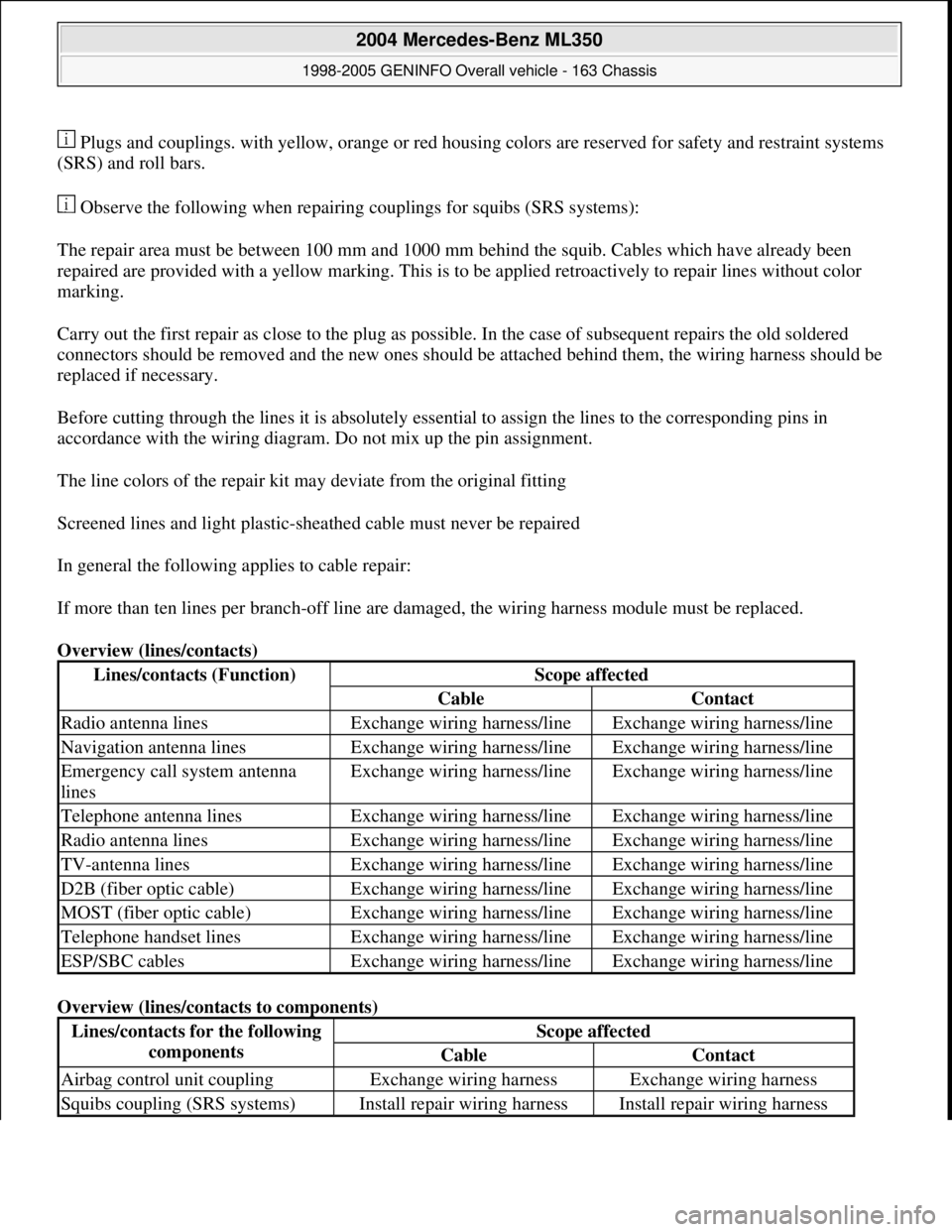

Plugs and couplings. with yellow, orange or red housing colors are reserved for safety and restraint systems

(SRS) and roll bars.

Observe the following when repairing couplings for squibs (SRS systems):

The repair area must be between 100 mm and 1000 mm behind the squib. Cables which have already been

repaired are provided with a yellow marking. This is to be applied retroactively to repair lines without color

marking.

Carry out the first repair as close to the plug as possible. In the case of subsequent repairs the old soldered

connectors should be removed and the new ones should be attached behind them, the wiring harness should be

replaced if necessary.

Before cutting through the lines it is absolutely essential to assign the lines to the corresponding pins in

accordance with the wiring diagram. Do not mix up the pin assignment.

The line colors of the repair kit may deviate from the original fitting

Screened lines and light plastic-sheathed cable must never be repaired

In general the following applies to cable repair:

If more than ten lines per branch-off line are damaged, the wiring harness module must be replaced.

Overview (lines/contacts)

Overview (lines/contacts to components)

Lines/contacts (Function)Scope affected

CableContact

Radio antenna linesExchange wiring harness/lineExchange wiring harness/line

Navigation antenna linesExchange wiring harness/lineExchange wiring harness/line

Emergency call system antenna

linesExchange wiring harness/lineExchange wiring harness/line

Telephone antenna linesExchange wiring harness/lineExchange wiring harness/line

Radio antenna linesExchange wiring harness/lineExchange wiring harness/line

TV-antenna linesExchange wiring harness/lineExchange wiring harness/line

D2B (fiber optic cable)Exchange wiring harness/lineExchange wiring harness/line

MOST (fiber optic cable)Exchange wiring harness/lineExchange wiring harness/line

Telephone handset linesExchange wiring harness/lineExchange wiring harness/line

ESP/SBC cablesExchange wiring harness/lineExchange wiring harness/line

Lines/contacts for the following

componentsScope affected

CableContact

Airbag control unit couplingExchange wiring harnessExchange wiring harness

Squibs coupling (SRS systems)Install repair wiring harnessInstall repair wiring harness

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 27 © 2006 Mitchell Repair Information Company, LLC.

Page 3213 of 4133

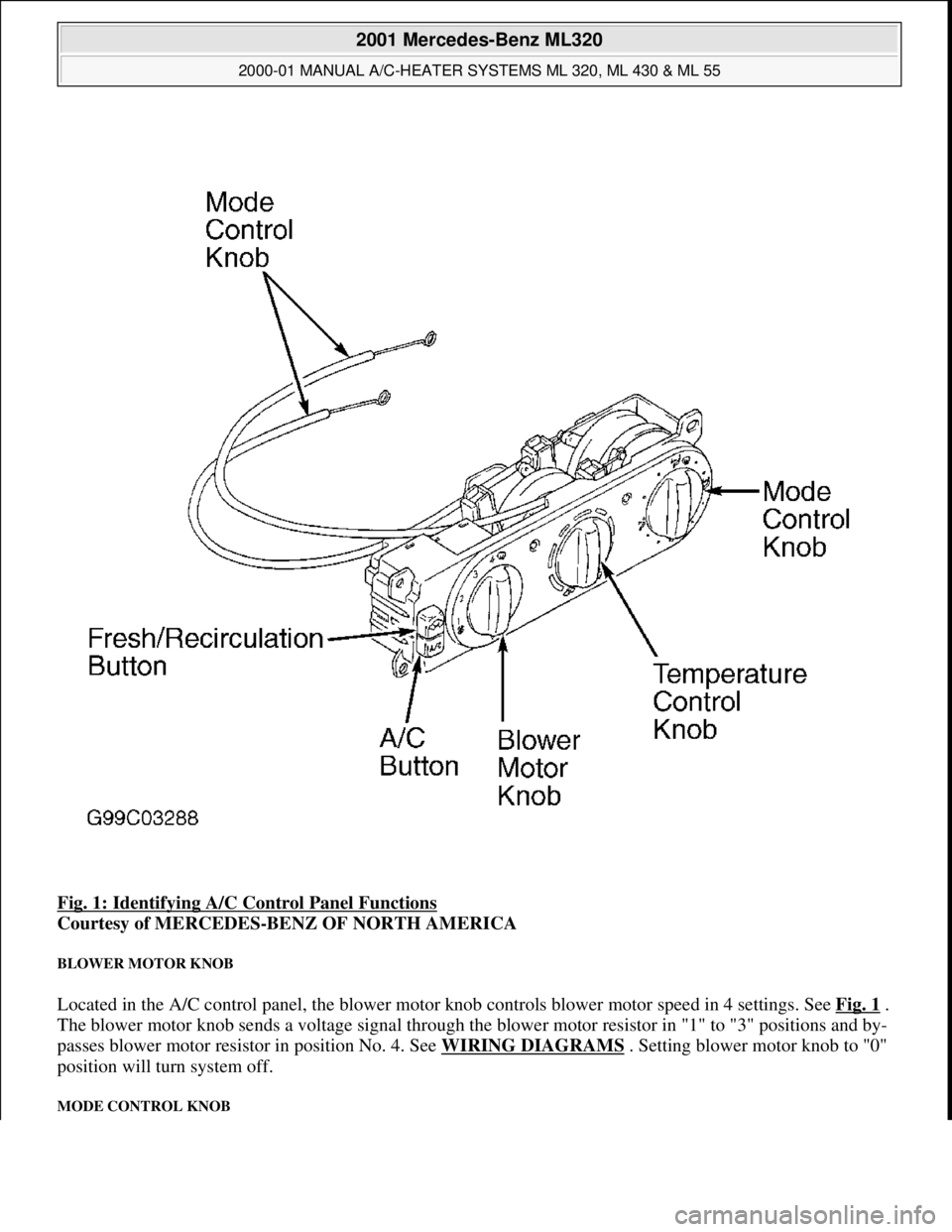

Fig. 1: Identifying A/C Control Panel Functions

Courtesy of MERCEDES-BENZ OF NORTH AMERICA

BLOWER MOTOR KNOB

Located in the A/C control panel, the blower motor knob controls blower motor speed in 4 settings. See Fig. 1 .

The blower motor knob sends a voltage signal through the blower motor resistor in "1" to "3" positions and by-

passes blower motor resistor in position No. 4. See WIRING DIAGRAMS . Setting blower motor knob to "0"

position will turn system off.

MODE CONTROL KNOB

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 2 © 2006 Mitchell Repair Information Company, LLC.

Page 3220 of 4133

FUNCTIONAL TEST PREPARATION

1. Check condition of fuses F16, F41, F43 and F44. See WIRING DIAGRAMS . Repair and/or replace

fuses and necessary.

2. Turn ignition on. Locate in-vehicle temperature sensor aspirator blower vent grille above anti-theft

indicator light. Place a half-inch square of tissue paper over aspirator blower vent grille. If paper stays on

vent grille, go to next step. If paper does not stay on vent grille, correct insufficient aspirator blower

ventilation.

3. Put shift lever in "P" and engage parking brake. Run engine at idle until it reaches normal operating

temperature, about 176°F (80°C). Ensure ambient (outside) temperature is greater than 58°F (15°C).

4. Manually open center and side air outlets. Ensure recirculation button is not depressed. Set blower speed

knob to position No. 1.

FUNCTION TEST

Defrost Mode

To check operation in defrost mode, set temperature selector knob to White range (vertical). Set mode control

knob to 12-o'clock position (vertical). Ensure A/C button indicator is illuminated. Air will vent from defrost and

center outlets and A/C compressor will engage. If operation is not as specified, perform the following in order:

Check voltage supply circuit Z50/2 between No. 16 fuse (15-amp) and connected components. See

VOLTAGE SUPPLY CIRCUIT Z50/2

under ELECTRICAL TESTS.

Check ground circuit. See GROUND CIRCUIT Z50/4 under ELECTRICAL TESTS.

Check in-vehicle temperature sensor signal voltage. See IN-VEHICLE TEMPERATURE SENSOR

under ELECTRICAL TESTS.

Check in-vehicle temperature sensor signal resistance. See IN-VEHICLE TEMPERATURE SENSOR

under ELECTRICAL TESTS.

Check icing protection temperature sensor signal voltage. See ICING PROTECTION

TEMPERATURE SENSOR under ELECTRICAL TESTS.

Check icing protection temperature sensor resistance. See ICING PROTECTION TEMPERATURE

SENSOR under ELECTRICAL TESTS.

Check activation voltage during temperature reduction. See ACTIVATION VOLTAGE

TEMPERATURE under ELECTRICAL TESTS.

Check activation voltage during temperature increase. See ACTIVATION VOLTAGE

TEMPERATURE under ELECTRICAL TESTS.

Check blend air flap actuator motor operation voltage. See BLEND AIR FLAP ACTUATOR MOTOR

under ELECTRICAL TESTS.

Check blend air flap actuator motor resistance. See BLEND AIR FLAP ACTUATOR MOTOR under

ELECTRICAL TESTS.

Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

Check A/C pressure switch. See A/C REFRIGERANT PRESSURE SWITCH under ELECTRICAL NOTE: Function test steps must be performed in order given.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 9 © 2006 Mitchell Repair Information Company, LLC.

Page 3221 of 4133

TESTS.

Normal Ventilation In Regulating Mode

To check normal ventilation in regulating mode, set temperature selector knob to White range (vertical). Set

mode control knob to 4-o'clock position. Ensure A/C button indicator is illuminated. Air will vent from upper

and lower outlets and A/C compressor will engage. Ambient air will flow from center outlet and coolant

circulation pump will operate. If operation is not as specified, perform the following in order:

Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

Check A/C pressure switch. See A/C REFRIGERANT PRESSURE SWITCH under ELECTRICAL

TESTS.

Economy Setting Not In Heating Mode

To check economy setting without heating mode activated, set temperature selector knob to Blue range. Set

mode control knob to the 9-o'clock position. Ensure A/C button indicator is not illuminated. Ambient air will

flow from center outlet and A/C compressor will NOT be engaged. If operation is not as specified, perform the

following:

Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

Economy Setting In Heating Mode

To check economy setting with heating mode activated, set temperature selector knob to Red range. Set mode

control knob to the 4-o'clock position. Ensure A/C button indicator is not illuminated. Heated air will flow from

lower, upper and center outlets and A/C compressor will NOT be engaged. If operation is not as specified,

perform the following:

Check A/C button activation. See A/C BUTTON under ELECTRICAL TESTS.

Recirculation Mode

To check recirculation mode, press fresh/recirculation button. Ensure fresh/recirculation indicator is

illuminated. Set blower speed knob to position No. 4. Blower fan noise will increase noticeably. If operation is

not as specified, check wiring between recirculated air flap element, heater-A/C switch and No. 16 fuse (15-

amp).

ELECTRICAL TESTS

Voltage Supply Circuit Z50/2

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Turn ignition on, with engine off. Connect voltmeter positive lead to socket box terminal

No. 7 and negative lead to terminal No. 9.

2. Voltage should be 11-14 volts. If voltage is not as specified, check voltage supply circuit Z50/2 between

No. 16 fuse (15-amp) and connected components. See WIRING DIAGRAMS

. Repair as necessary.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 10 © 2006 Mitchell Repair Information Company, LLC.

Page 3222 of 4133

Ground Circuit Z50/4

1. Connect socket box to A/C push button control unit wiring harness connector. See CONNECTING

TEST EQUIPMENT . Turn ignition off. Ensure A/C push button control unit is not connected to socket

box.

2. Connect ohmmeter positive lead to socket box terminal No. 9 and negative lead to body ground.

Resistance should be zero. If resistance is not as specified, check control unit ground circuit Z50/4. See

WIRING DIAGRAMS

. Repair as necessary.

In-Vehicle Temperature Sensor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 12 and negative lead to

terminal No. 9.

2. Turn ignition on. Turn temperature control knob to Red range detent. Voltage should be 1.9 volts at 68°F

(20°C). If voltage is as specified, go to next step. If voltage is not as specified, check in-vehicle

temperature sensor circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay,

replace in-vehicle temperature sensor.

3. Turn ignition off. Disconnect test cable from A/C push button control unit. Connect ohmmeter positive

lead to socket box terminal No. 2 and negative lead to terminal No. 12. Measure temperature sensor

resistance at specified temperatures. See IN

-VEHICLE TEMPERATURE SENSOR RESISTANCE

table.

4. If resistance is not as specified, check wiring harness and connectors between A/C push button control

unit, in-vehicle temperature sensor, blend air flap actuator position sensor and temperature regulator

switch. Repair as necessary.

IN-VEHICLE TEMPERATURE SENSOR RESISTANCE

Icing Protection Temperature Sensor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 11 and negative lead to

terminal No. 9.

2. Turn ignition on. Voltage should be 2.0-2.4 volts at 32°F (0°C) and 1.4-1.8 volts at 59°F (15°C). If

voltage is as specified, go to next step. If voltage is not as specified, check icing protection temperature

sensor circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace icing

protection temperature sensor.

3. Turn ignition off. Disconnect test cable from A/C push button control unit. Connect ohmmeter positive

lead to socket box terminal No. 3 and negative lead to terminal No. 11. Measure temperature sensor

resistance at specified temperatures. See ICING PROTECTION TEMPERATURE SENSOR

RESISTANCE table.

Sensor Temperature - °F (°C)Ohms

68 (20)2100

77 (25)1700

104 (40)900

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 11 © 2006 Mitchell Repair Information Company, LLC.

Page 3223 of 4133

4. If resistance is not as specified, check wiring harness between temperature sensor and control unit. Repair

as necessary. If wiring harness is okay, replace icing protection temperature sensor.

ICING PROTECTION TEMPERATURE SENSOR RESISTANCE

Activation Voltage Temperature

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 2 and negative lead to

terminal No. 9.

2. Turn ignition on. Turn temperature control knob to Blue range detent. Voltage should be more than 2.0

volts. Turn temperature control knob from Blue range detent to Red range detent. Voltage should be more

than 3.0 volts.

3. If voltage is as specified, go to next step. If voltage is not as specified, check recirculated air switch

circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace recirculated air

switch.

4. Connect voltmeter positive lead to socket box terminal No. 5 and negative lead to terminal No. 9. Turn

ignition on. Turn temperature control knob to Blue range detent. Voltage should be more than 3.0 volts.

Turn temperature control knob from Blue range detent to Red range detent. Voltage should be more than

4.0 volts.

5. If voltage is not as specified, check recirculated air switch circuits. See WIRING DIAGRAMS

. Repair

as necessary. If circuits are okay, replace recirculated air switch.

Blend Air Flap Actuator Motor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 1 and negative lead to

terminal No. 9.

2. Turn ignition on. Turn temperature control knob to Blue range detent. Voltage should be less than one

volt. Turn temperature control knob from Blue range detent to Red range detent. Voltage should be 11.0-

14.0 volts.

3. If voltage is as specified, go to next step. If voltage is not as specified, check blend air flap actuator motor

wiring harness circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace

blend air flap actuator motor.

4. Connect voltmeter positive lead to socket box terminal No. 8 and negative lead to terminal No. 9. Turn

ignition on. Turn temperature control knob to Red range detent. Voltage should be less than one volt.

Turn temperature control knob from Red range detent to Blue range detent. Voltage should be 11.0-14.0

volts.

5. If voltage is as specified, go to next step. If voltage is not as specified, check blend air flap actuator motor

wiring harness circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace

Sensor Temperature - °F (°C)Ohms

43 (6)3600

59 (15)2300

72 (22)1700

77 (25)1500

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 12 © 2006 Mitchell Repair Information Company, LLC.

Page 3224 of 4133

blend air flap actuator motor.

6. Turn ignition off. Disconnect test cable from A/C push button control unit. Connect ohmmeter positive

lead to socket box terminal No. 1 and negative lead to terminal No. 8. Resistance should be 120 ohms.

7. If resistance is not as specified, check blend air flap actuator motor circuits. See WIRING DIAGRAMS

.

Repair as necessary. If circuits are okay, replace blend air flap actuator motor.

A/C Button

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Connect voltmeter positive lead to socket box terminal No. 10 and negative lead to

terminal No. 9.

2. Turn ignition on. Depress A/C button switch to on position and set blower speed knob to position No. 4.

Ensure A/C button indicator is illuminated. Voltage should be less than one volt. Depress A/C button

switch to off position with A/C button indicator not illuminated or set blower speed knob to off position.

Voltage should be 11-14 volts.

3. If voltage is as specified, go to next step. If voltage is not as specified, check A/C button wiring harness

circuits. See WIRING DIAGRAMS

. Repair as necessary. If circuits are okay, replace A/C button

switch.

4. Turn ignition on. Depress A/C button switch to on position and set blower speed knob to position No. 4.

Ensure A/C button indicator is illuminated. Connect voltmeter positive lead to socket box terminal No. 4

and negative lead to terminal No. 9. Voltage should be more than 3.0 volts.

5. Connect Fused Jumper Wire (124 589 37 63 00) between socket box terminals No. 4 and 11. Depress A/C

button switch to on position and set blower speed knob to position No. 4. Ensure A/C button indicator is

illuminated. Measure voltage. Voltage should be less than one volt.

6. If voltage is not as specified, check A/C button wiring harness circuits. See WIRING DIAGRAMS

.

Repair as necessary. If circuits are okay, replace A/C button switch.

A/C Refrigerant Pressure Switch

1. Turn ignition off. Disconnect refrigerant pressure sensor connector. Turn ignition on. Connect voltmeter

positive lead to pressure sensor harness connector terminal "B" (Pink wire) and negative lead to terminal

"A" (Tan wire). Voltage should be 4.75-5.25 volts.

2. If voltage is as specified, replace A/C refrigerant pressure sensor. If voltage is not as specified, check

wiring harness between refrigerant pressure sensor and All Activity Module (AAM). See WIRING

DIAGRAMS . Repair as necessary. If circuits are okay, replace AAM and retest A/C system.

Outside Temperature Sensor

1. Connect socket box to A/C push button control unit and wiring harness. See CONNECTING TEST

EQUIPMENT . Turn ignition off. Connect ohmmeter positive lead to socket box terminal No. 12 and

negative lead to terminal No. 3.

2. Disconnect test cable from A/C push button control unit. See OUTSIDE TEMPERATURE SENSOR

RESISTANCE table. If resistance is not as specified, check wiring harness between outside temperature

sensor and A/C push button control unit. See WIRING DIAGRAMS

. Repair as necessary. If wiring

harness is okay, replace outside temperature sensor.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 13 © 2006 Mitchell Repair Information Company, LLC.

Page 3236 of 4133

Fig. 9: Replacing Intake Air Dust Filter

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

RECEIVER-DRIER

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Remove headlight

units. Remove headlight units. Remove upper frame crossmember, release hood release control cable and

remove crossmember. See Fig. 6

.

2. Remove bolts from receiver-drier refrigerant lines. See Fig. 5

. Disconnect refrigerant lines from receiver-

drier. Plug exposed openings to protect A/C system from debris and moisture. Discard "O" rings. Loosen

receiver-drier clamp bolt. Remove receiver-drier. To install, reverse removal procedure.

3. When installing a new receiver-drier, add 0.34 ounce of NEW refrigerant oil to receiver-drier. Use NEW

"O" rings. Tighten refrigerant line bolts to specification. See TORQUE SPECIFICATIONS

.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

ApplicationFt. Lbs. (N.m)

Compressor Mounting Bolts15 (20)

Refrigerant Line-To-Compressor Bolt15 (20)

Refrigerant Line-To-Condenser Bolt15 (20)

Steering Column Bolt15 (20)

Steering Column Nut13 (18)

INCH Lbs. (N.m)

Expansion Valve Self-Locking Nut89 (10)

Refrigerant Line-To-Receiver-Drier Bolt89 (10)

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 25 © 2006 Mitchell Repair Information Company, LLC.

Page 3238 of 4133

Fig. 10: Manual A/C-Heater Systems Wiring Diagram (2000-01 ML 320 Without Cooling Fan Control

Module - 1 Of 2)

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 27 © 2006 Mitchell Repair Information Company, LLC.