brake fluid MERCEDES-BENZ ML320 1997 Complete Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3049 of 4133

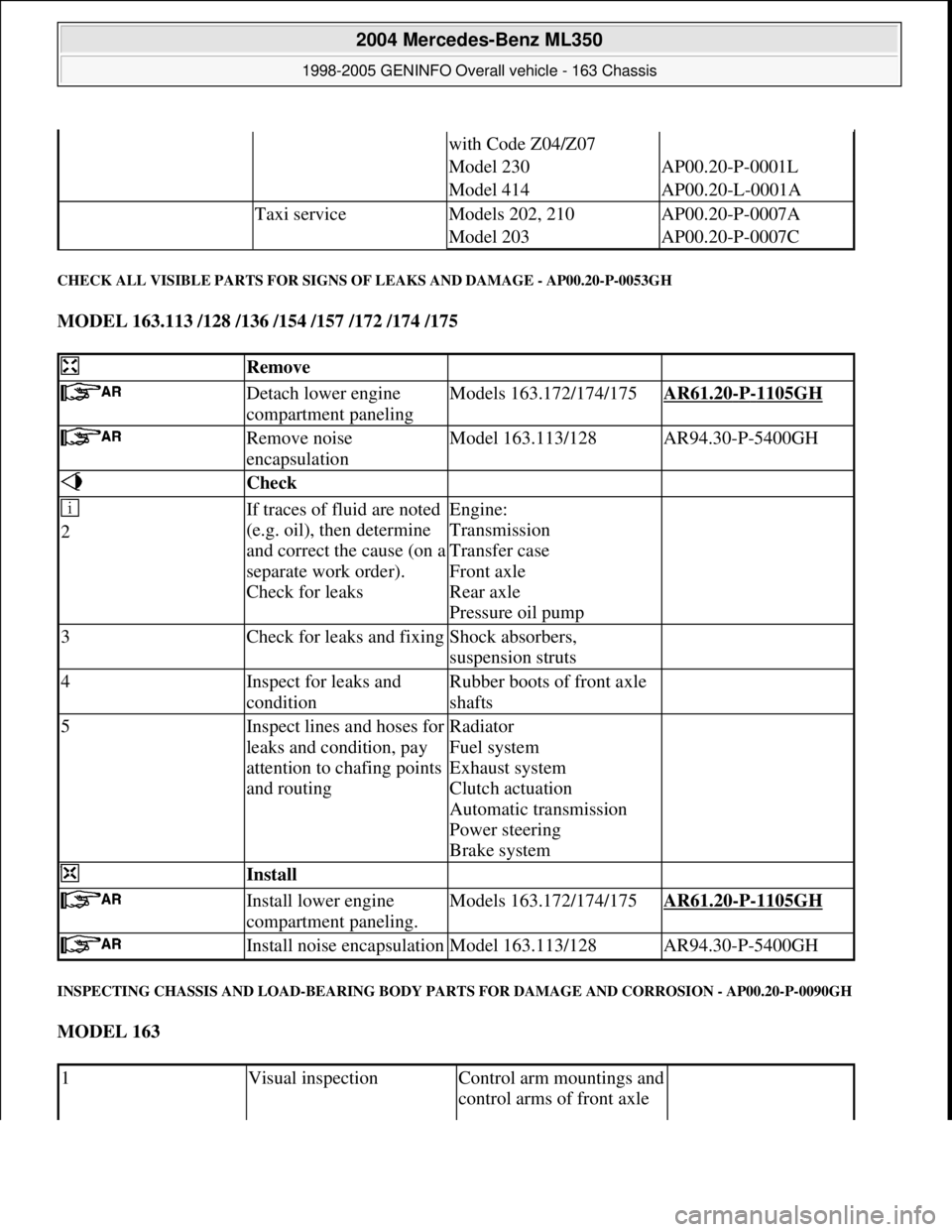

CHECK ALL VISIBLE PARTS FOR SIGNS OF LEAKS AND DAMAGE - AP00.20-P-0053GH

MODEL 163.113 /128 /136 /154 /157 /172 /174 /175

INSPECTING CHASSIS AND LOAD-BEARING BODY PARTS FOR DAMAGE AND CORROSION - AP00.20-P-0090GH

MODEL 163

with Code Z04/Z07

Model 230AP00.20-P-0001L

Model 414AP00.20-L-0001A

Taxi serviceModels 202, 210AP00.20-P-0007A

Model 203AP00.20-P-0007C

Remove

Detach lower engine

compartment panelingModels 163.172/174/175AR61.20-P-1105GH

Remove noise

encapsulationModel 163.113/128AR94.30-P-5400GH

Check

2If traces of fluid are noted

(e.g. oil), then determine

and correct the cause (on a

separate work order).

Check for leaksEngine:

Transmission

Transfer case

Front axle

Rear axle

Pressure oil pump

3Check for leaks and fixingShock absorbers,

suspension struts

4Inspect for leaks and

conditionRubber boots of front axle

shafts

5Inspect lines and hoses for

leaks and condition, pay

attention to chafing points

and routingRadiator

Fuel system

Exhaust system

Clutch actuation

Automatic transmission

Power steering

Brake system

Install

Install lower engine

compartment paneling.Models 163.172/174/175AR61.20-P-1105GH

Install noise encapsulationModel 163.113/128AR94.30-P-5400GH

1Visual inspectionControl arm mountings and

control arms of front axle

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 404 © 2006 Mitchell Repair Information Company, LLC.

Page 3052 of 4133

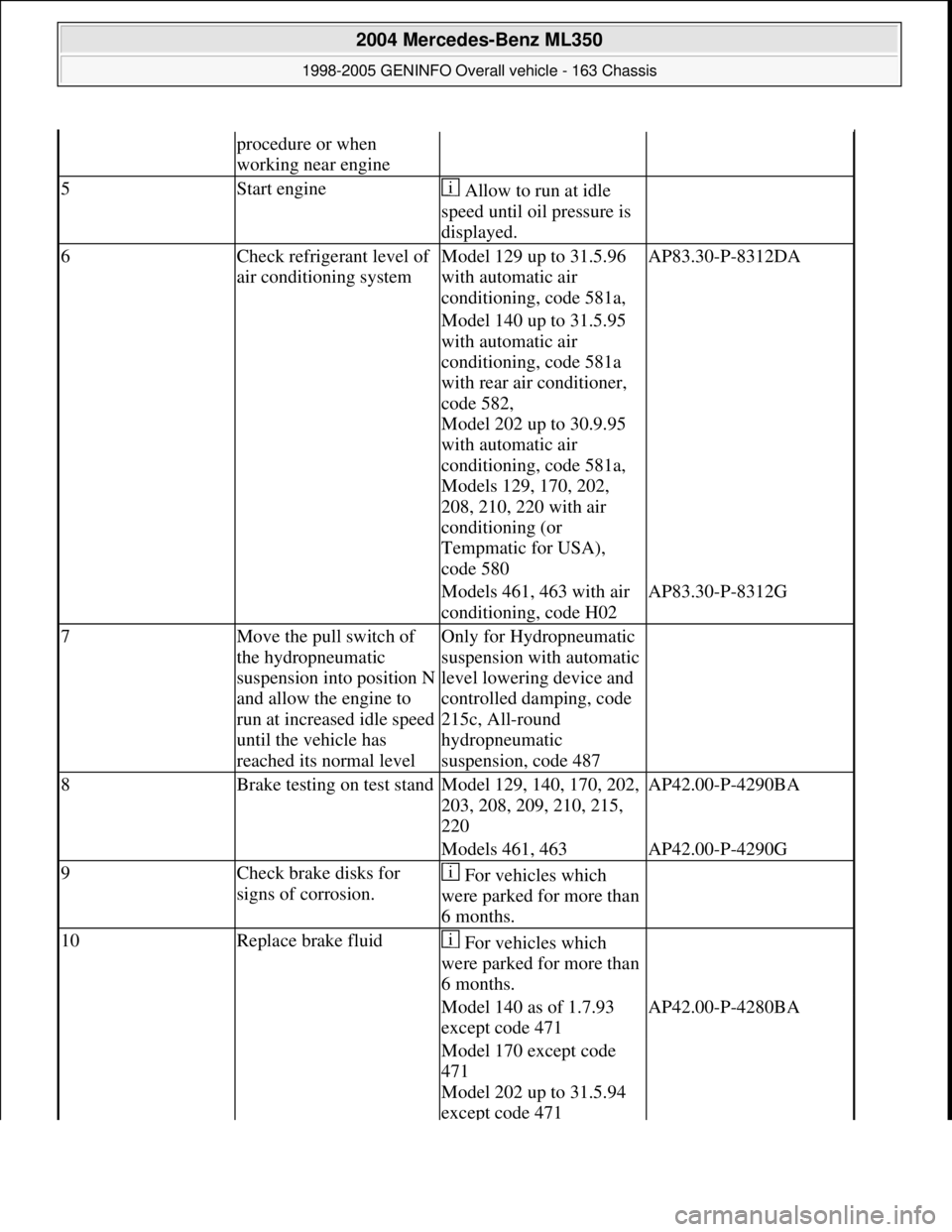

procedure or when

working near engine

5Start engine Allow to run at idle

speed until oil pressure is

displayed.

6Check refrigerant level of

air conditioning systemModel 129 up to 31.5.96

with automatic air

conditioning, code 581a,AP83.30-P-8312DA

Model 140 up to 31.5.95

with automatic air

conditioning, code 581a

with rear air conditioner,

code 582,

Model 202 up to 30.9.95

with automatic air

conditioning, code 581a,

Models 129, 170, 202,

208, 210, 220 with air

conditioning (or

Tempmatic for USA),

code 580

Models 461, 463 with air

conditioning, code H02AP83.30-P-8312G

7Move the pull switch of

the hydropneumatic

suspension into position N

and allow the engine to

run at increased idle speed

until the vehicle has

reached its normal levelOnly for Hydropneumatic

suspension with automatic

level lowering device and

controlled damping, code

215c, All-round

hydropneumatic

suspension, code 487

8Brake testing on test standModel 129, 140, 170, 202,

203, 208, 209, 210, 215,

220AP42.00-P-4290BA

Models 461, 463AP42.00-P-4290G

9Check brake disks for

signs of corrosion. For vehicles which

were parked for more than

6 months.

10Replace brake fluid For vehicles which

were parked for more than

6 months.

Model 140 as of 1.7.93

except code 471AP42.00-P-4280BA

Model 170 except code

471

Model 202 up to 31.5.94

except code 471

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 407 © 2006 Mitchell Repair Information Company, LLC.

Page 3175 of 4133

GENERAL BRAKE FLUID - BB00.40-P-0330-01A

These specifications are valid for the Mercedes-Benz and smart brands.

General

The brake fluid in the brake system and in the hydraulic clutch operating system fulfills hydraulic tasks. Due to

the high heat build-up during braking, these tasks can only be fulfilled by brake fluids which comply with all of

today's technical requirements in terms of their various properties (viscosity-temperature-characteristic, boiling

point, corrosion protection, oxidation resistance, etc.).

The most important properties which a brake fluid must exhibit are:

High boiling point, to ensure that the brake fluid does not form vapor locks at high temperatures. Vapor

locks reduce the operating pressure and thus the braking effect and may ultimately lead to brake failure.

The boiling point should remain as constant as possible throughout the duration of use of the coolant and

not drop under varying atmospheric influences or operating conditions (pressure, temperature), i.e. the

"wet boiling point" should be as high as possible.

Low compressibility, in particular at high temperatures.

The low-temperature characteristic of the fluid - even when at 40°C - must permit operation, i.e.

primarily, the viscosity must not become too high in the cold.

Compatibility with the materials used in the brake units and clutch operating systems, e.g. the rubber

boots or any other seal materials (elastomers) included in the brake components may only swell to a

controlled extent, any shrinkage must be avoided.

Sufficient corrosion protection for all metals present in the brake system.

The brake fluids released for use in MB vehicle models are listed on Sheet 331.0. These brake fluids not only

comply with our requirements, but also those of the US safety specifications FMVSS 116, DOT 4. The released

"DOT 4 plus" brake fluids (internal designation) are more advanced DOT 4 brake fluids with higher wet boiling

point, standard change interval: 2 years. In order to be able to comply with this useful period without any

problem, we strongly advise the use of released products as per Sheet 331.0, during the warranty phase this is a

precondition for any acceptance of customer claims.

The brake fluid listed on Sheet 331.1 "DOT 4 Type 200" is released for special applications in the UNIMOG

range with more stringent thermal requirements. For this type of use, a brake fluid change interval of 1 year

must be adhered to.

Handling brake fluid

Brake fluid based on polyhydric alcohols in oligomer or polymer form and/or their

Esters are hygroscopic and thus absorbs moisture from the air. Water, however, reduces the boiling point of the

brake fluid, whereby the danger of vapor lock formation is present. Therefore it should be noted that brake fluid

is always stored in sealed vessels. Brake fluid that has been stored unsealed can absorb so much moisture in a

few hours that it is rendered unusable.

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 530 © 2006 Mitchell Repair Information Company, LLC.

Page 3176 of 4133

Because the brake fluid also absorbs moisture through the vent bore on the expansion reservoir, the wheel brake

cylinder and the brake hoses, the brake fluid has to be changed for safety reasons at regular intervals, best done

in the spring. When performing this change, make sure that the old fluid is also drained off the clutch system.

Generally, it is vital for the brake/clutch system to be completely drained before being filled with new fluid!

For the above-mentioned reasons, used brake fluid must not be used again.

The brake fluid is amber in color and thus can be easily confused with mineral products.

Therefore, brake fluids should always only be taken from original containers and stored separately from other

mineral oils and fluids.

When performing maintenance operations and repairs on brake parts, make sure that fuel, mineral oil, grease or

suchlike do not enter the brake system. Hydrocarbon-based materials will lead to swelling of the elastomers in

the brake and clutch system and - even in low concentrations - will suffice to cause total failure of the systems.

Only new brake fluid may be used as a rinsing and cleaning agent for the cylinders, lines and the expansion

reservoir of the hydraulic brake system.

Experience shows that before handling brake fluid, the hands must be cleaned and any oil and grease removed.

Brake fluid acts aggressively towards paint and color. In the event of any brake fluid spills or splashes, it must

be rinsed away immediately using copious amounts of water (do not rub it away).

Brake fluid disposal

When disposing of brake fluid, the relevant national specifications must be observed. It is advisable to try to

have the brake fluid disposed of as economic good; this is contingent on

Strict separation of used brake fluid from other materials;

Presence of a disposal channel, which justifies its classification as an economic good, i.e. a proper

alternate usage must be assured.

If this procedure is not possible, used brake fluid is to be disposed of together with any, e.g. paint residue,

solvents and suchlike. Any adding of used oil must be avoided, as it will result in difficulties, if the used oil is to

be recycled; in several countries this is prohibited by the legislators.

MISCELLANEOUS NOTES

NOTES ON SCRAPPING GAS-FILLED HYDRAULIC COMPONENTS - OS00.00-P-1000-01A

all

Unusable gas pressure dampers, spring accumulators, pressure reservoirs and impact absorbers have to be

depressurized before being scrapped according to the respective valid accident prevention regulations. These

safety measures are necessary because gas pressurized hydraulic parts can explode if heat is applied. A risk of

explosion is

given, e.g. when scrapping with cutting torches, smelting or if gas pressurized parts in landfills start

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 531 © 2006 Mitchell Repair Information Company, LLC.

Page 3480 of 4133

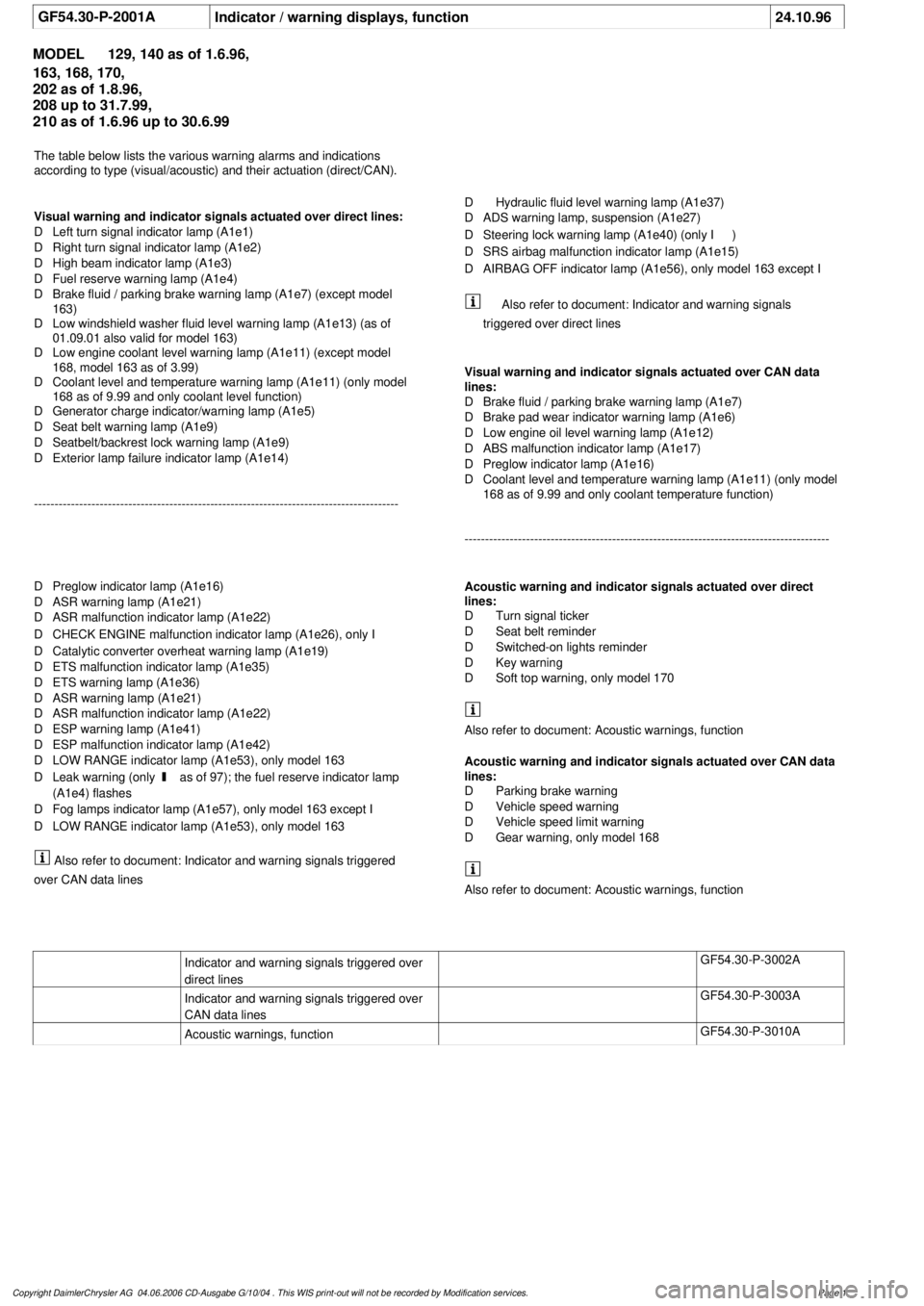

GF54.30-P-2001A

Indicator / warning displays, function

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

The table below lists the various warning alarms and indications

according to type (visual/acoustic) and their actuation (direct/CAN).

Visual warning and indicator signals actuated over direct lines:

D

Left turn signal indicator lamp (A1e1)

D

Right turn signal indicator lamp (A1e2)

D

High beam indicator lamp (A1e3)

D

Fuel reserve warning lamp (A1e4)

D

Brake fluid / parking brake warning lamp (A1e7) (except model

163)

D

Low windshield washer fluid level warning lamp (A1e13) (as of

01.09.01 also valid for model 163)

D

Low engine coolant level warning lamp (A1e11) (except model

168, model 163 as of 3.99)

D

Coolant level and temperature warning lamp (A1e11) (only model

168 as of 9.99 and only coolant level function)

D

Generator charge indicator/warning lamp (A1e5)

D

Seat belt warning lamp (A1e9)

D

Seatbelt/backrest lock warning lamp (A1e9)

D

Exterior lamp failure indicator lamp (A1e14)

-----------------------------------------------------------------------------------------

D

Hydraulic fluid level warning lamp (A1e37)

D

ADS warning lamp, suspension (A1e27)

D

Steering lock warning lamp (A1e40) (only

I

)

D

SRS airbag malfunction indicator lamp (A1e15)

D

AIRBAG OFF indicator lamp (A1e56), only model 163 except

I

Also refer to document: Indicator and warning signals triggered

over CAN data lines

Acoustic warning and indicator signals actuated over direct

lines:

D

Turn signal ticker

D

Seat belt reminder

D

Switched-on lights reminder

D

Key warning

D

Soft top warning, only model 170

Also refer to document: Acoustic warnings, function

Acoustic warning and indicator signals actuated over CAN data

lines:

D

Parking brake warning

D

Vehicle speed warning

D

Vehicle speed limit warning

D

Gear warning, only model 168

Also refer to document: Acoustic warnings, function

Indicator and warning signals triggered over

direct lines

GF54.30-P-3002A

Indicator and warning signals triggered over

CAN data lines

GF54.30-P-3003A

Acoustic warnings, function

GF54.30-P-3010A

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3481 of 4133

GF54.30-P-2001A

Indicator / warning displays, function

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

The table below lists the various warning alarms and indications

according to type (visual/acoustic) and their actuation (direct/CAN).

Visual warning and indicator signals actuated over direct lines:

D

Left turn signal indicator lamp (A1e1)

D

Right turn signal indicator lamp (A1e2)

D

High beam indicator lamp (A1e3)

D

Fuel reserve warning lamp (A1e4)

D

Brake fluid / parking brake warning lamp (A1e7) (except model

163)

D

Low windshield washer fluid level warning lamp (A1e13) (as of

01.09.01 also valid for model 163)

D

Low engine coolant level warning lamp (A1e11) (except model

168, model 163 as of 3.99)

D

Coolant level and temperature warning lamp (A1e11) (only model

168 as of 9.99 and only coolant level function)

D

Generator charge indicator/warning lamp (A1e5)

D

Seat belt warning lamp (A1e9)

D

Seatbelt/backrest lock warning lamp (A1e9)

D

Exterior lamp failure indicator lamp (A1e14)

-----------------------------------------------------------------------------------------

D

Hydraulic fluid level warning lamp (A1e37)

D

ADS warning lamp, suspension (A1e27)

D

Steering lock warning lamp (A1e40) (only

I

)

D

SRS airbag malfunction indicator lamp (A1e15)

D

AIRBAG OFF indicator lamp (A1e56), only model 163 except

I

Also refer to document: Indicator and warning signals triggered

over CAN data lines

Acoustic warning and indicator signals actuated over direct

lines:

D

Turn signal ticker

D

Seat belt reminder

D

Switched-on lights reminder

D

Key warning

D

Soft top warning, only model 170

Also refer to document: Acoustic warnings, function

Acoustic warning and indicator signals actuated over CAN data

lines:

D

Parking brake warning

D

Vehicle speed warning

D

Vehicle speed limit warning

D

Gear warning, only model 168

Also refer to document: Acoustic warnings, function

Indicator and warning signals triggered over

direct lines

GF54.30-P-3002A

Indicator and warning signals triggered over

CAN data lines

GF54.30-P-3003A

Acoustic warnings, function

GF54.30-P-3010A

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3482 of 4133

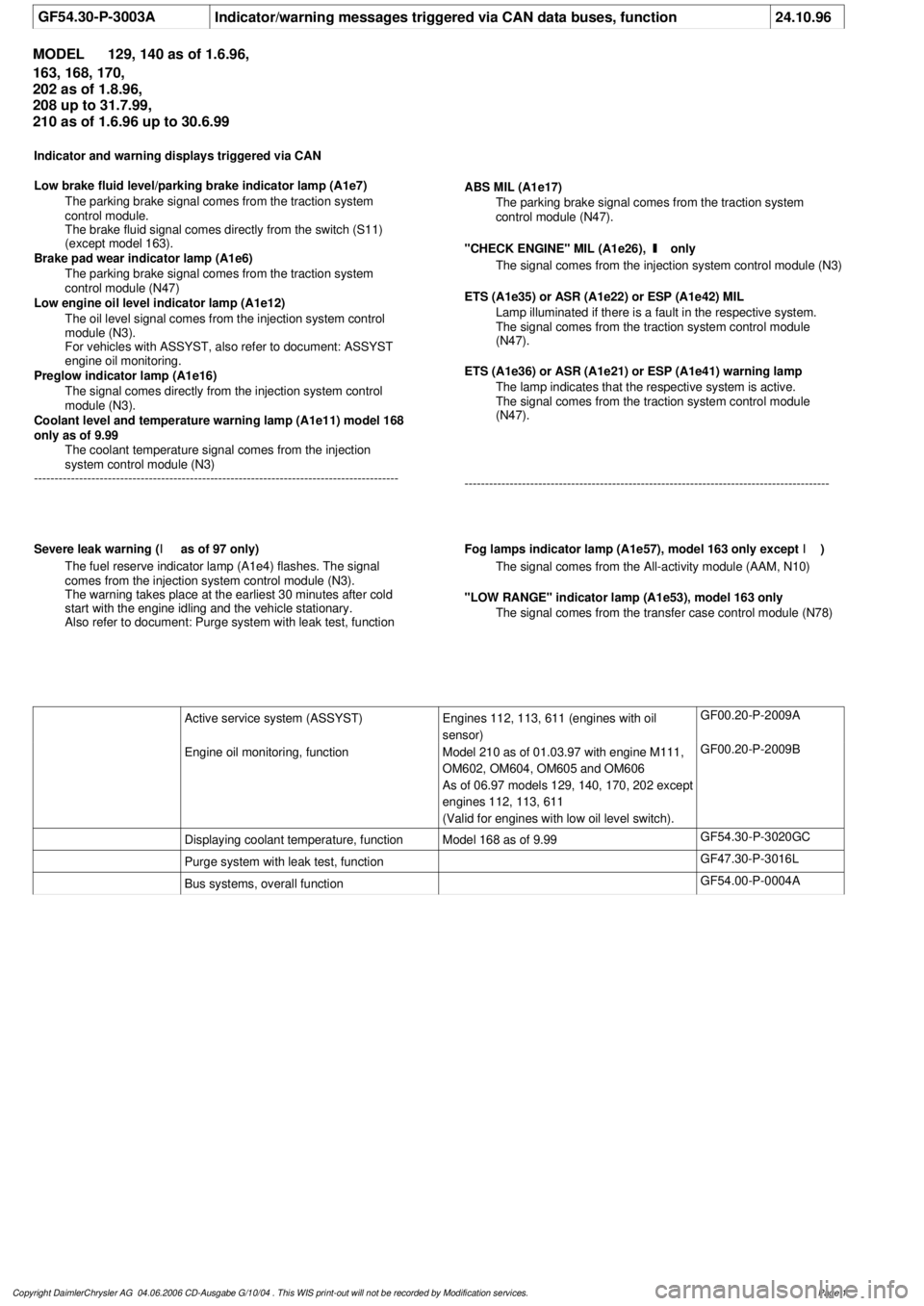

GF54.30-P-3003A

Indicator/warning messages triggered via CAN data buses, function

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

Indicator and warning displays triggered via CAN

Low brake fluid level/parking brake indicator lamp (A1e7)

The parking brake signal comes from the traction system

control module.

The brake fluid signal comes directly from the switch (S11)

(except model 163).

Brake pad wear indicator lamp (A1e6)

The parking brake signal comes from the traction system

control module (N47)

Low engine oil level indicator lamp (A1e12)

The oil level signal comes from the injection system control

module (N3).

For vehicles with ASSYST, also refer to document: ASSYST

engine oil monitoring.

Preglow indicator lamp (A1e16)

The signal comes directly from the injection system control

module (N3).

Coolant level and temperature warning lamp (A1e11) model 168

only as of 9.99

The coolant temperature signal comes from the injection

system control module (N3)

-----------------------------------------------------------------------------------------

ABS MIL (A1e17)

The parking brake signal comes from the traction system

control module (N47).

"CHECK ENGINE" MIL (A1e26),

I

only

The signal comes from the injection system control module (N3)

ETS (A1e35) or ASR (A1e22) or ESP (A1e42) MIL

Lamp illuminated if there is a fault in the respective system.

The signal comes from the traction system control module

(N47).

ETS (A1e36) or ASR (A1e21) or ESP (A1e41) warning lamp

The lamp indicates that the respective system is active.

The signal comes from the traction system control module

(N47).

-----------------------------------------------------------------------------------------

Severe leak warning (

I

as of 97 only)

The fuel reserve indicator lamp (A1e4) flashes. The signal

comes from the injection system control module (N3).

The warning takes place at the earliest 30 minutes after cold

start with the engine idling and the vehicle stationary.

Also refer to document: Purge system with leak test, function

Fog lamps indicator lamp (A1e57), model 163 only except

I

)

The signal comes from the All-activity module (AAM, N10)

"LOW RANGE" indicator lamp (A1e53), model 163 only

The signal comes from the transfer case control module (N78)

Active service system (ASSYST)

Engines 112, 113, 611 (engines with oil

sensor)

GF00.20-P-2009A

Engine oil monitoring, function

Model 210 as of 01.03.97 with engine M111,

OM602, OM604, OM605 and OM606

As of 06.97 models 129, 140, 170, 202 except

engines 112, 113, 611

(Valid for engines with low oil level switch).

GF00.20-P-2009B

Displaying coolant temperature, function

Model 168 as of 9.99

GF54.30-P-3020GC

Purge system with leak test, function

GF47.30-P-3016L

Bus systems, overall function

GF54.00-P-0004A

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3483 of 4133

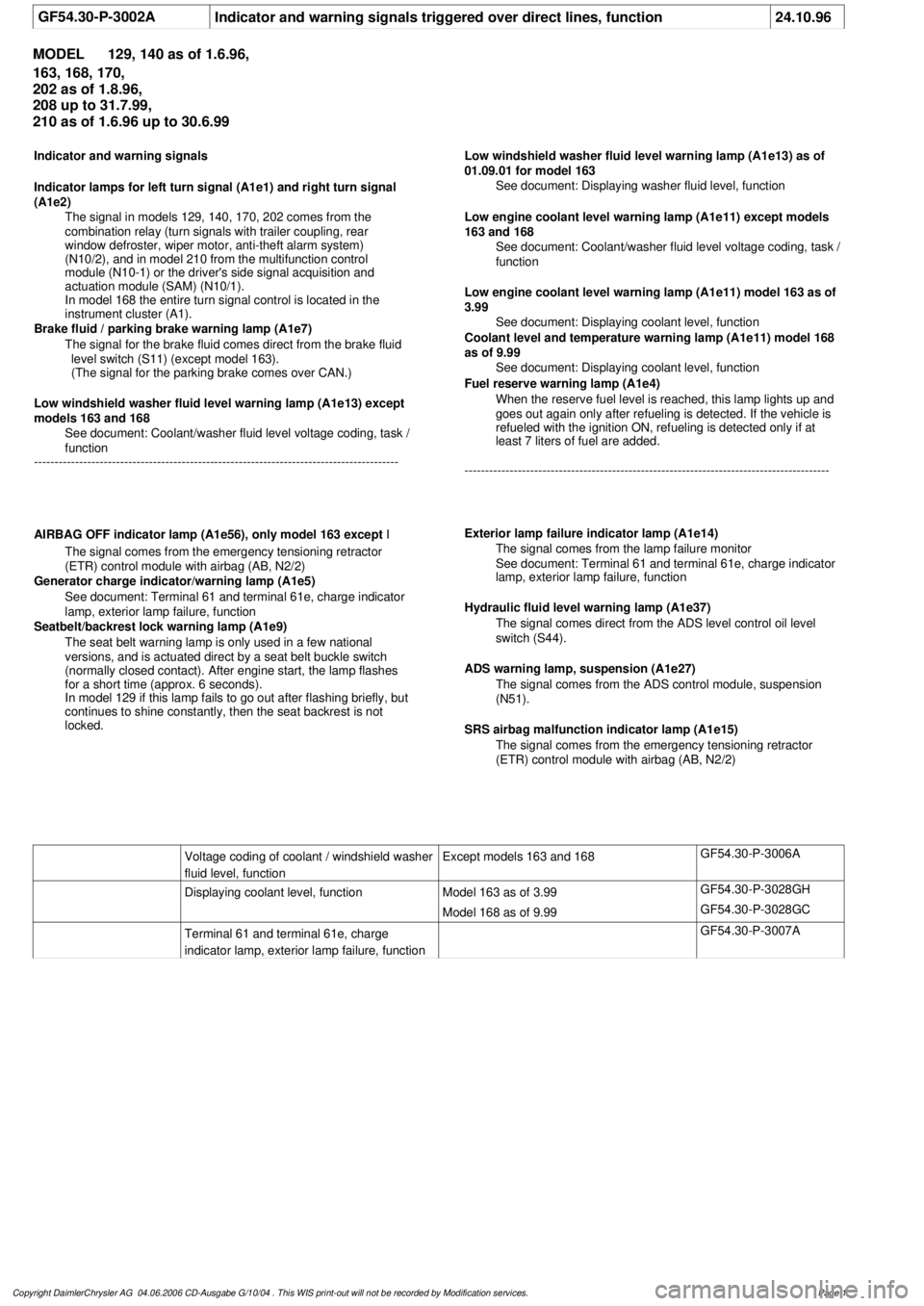

GF54.30-P-3002A

Indicator and warning signals triggered over direct lines, function

24.10.96

MODEL

129, 140 as of 1.6.96,

163, 168, 170,

202 as of 1.8.96,

208 up to 31.7.99,

210 as of 1.6.96 up to 30.6.99

Indicator and warning signals

Indicator lamps for left turn signal (A1e1) and right turn signal

(A1e2)

The signal in models 129, 140, 170, 202 comes from the

combination relay (turn signals with trailer coupling, rear

window defroster, wiper motor, anti-theft alarm system)

(N10/2), and in model 210 from the multifunction control

module (N10-1) or the driver's side signal acquisition and

actuation module (SAM) (N10/1).

In model 168 the entire turn signal control is located in the

instrument cluster (A1).

Brake fluid / parking brake warning lamp (A1e7)

The signal for the brake fluid comes direct from the brake fluid level switch (S11) (except model 163).

(The signal for the parking brake comes over CAN.)

Low windshield washer fluid level warning lamp (A1e13) except

models 163 and 168

See

document: Coolant/washer fluid level voltage coding, task /

function

-----------------------------------------------------------------------------------------

Low windshield washer fluid level warning lamp (A1e13) as of

01.09.01 for model 163

See document: Displaying washer fluid level, function

Low engine coolant level warning lamp (A1e11) except models

163 and 168

See

document: Coolant/washer fluid level voltage coding, task /

function

Low engine coolant level warning lamp (A1e11) model 163 as of

3.99

See

document: Displaying coolant level, function

Coolant level and temperature warning lamp (A1e11) model 168

as of 9.99

See

document: Displaying coolant level, function

Fuel reserve warning lamp (A1e4)

When the reserve fuel level is reached, this lamp lights up and

goes out again only after refueling is detected. If the vehicle is

refueled with the ignition ON, refueling is detected only if at

least 7 liters of fuel are added.

-----------------------------------------------------------------------------------------

AIRBAG OFF indicator lamp (A1e56), only model 163 except

I

The signal comes from the emergency tensioning retractor

(ETR) control module with airbag (AB, N2/2)

Generator charge indicator/warning lamp (A1e5)

See document: Terminal 61 and terminal 61e, charge indicator

lamp, exterior lamp failure, function

Seatbelt/backrest lock warning lamp (A1e9)

The seat belt warning lamp is only used in a few national

versions, and is actuated direct by a seat belt buckle switch

(normally closed contact). After engine start, the lamp flashes

for a short time (approx. 6 seconds).

In model 129 if this lamp fails to go out after flashing briefly, but

continues to shine constantly, then the seat backrest is not

locked.

Exterior lamp failure indicator lamp (A1e14)

The signal comes from the lamp failure monitor

See document: Terminal 61 and terminal 61e, charge indicator

lamp, exterior lamp failure, function

Hydraulic fluid level warning lamp (A1e37)

The signal comes direct from the ADS level control oil level

switch (S44).

ADS warning lamp, suspension (A1e27) The signal comes from the ADS control module, suspension

(N51).

SRS airbag malfunction indicator lamp (A1e15)

The signal comes from the emergency tensioning retractor

(ETR) control module with airbag (AB, N2/2)

Voltage coding of coolant / windshield washer

fluid level, function

Except models 163 and 168

GF54.30-P-3006A

Displaying coolant level, function

Model 163 as of 3.99

GF54.30-P-3028GH

Model 168 as of 9.99

GF54.30-P-3028GC

Terminal 61 and terminal 61e, charge

indicator lamp, exterior lamp failure, function

GF54.30-P-3007A

Copyright DaimlerChrysler AG 04.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3489 of 4133

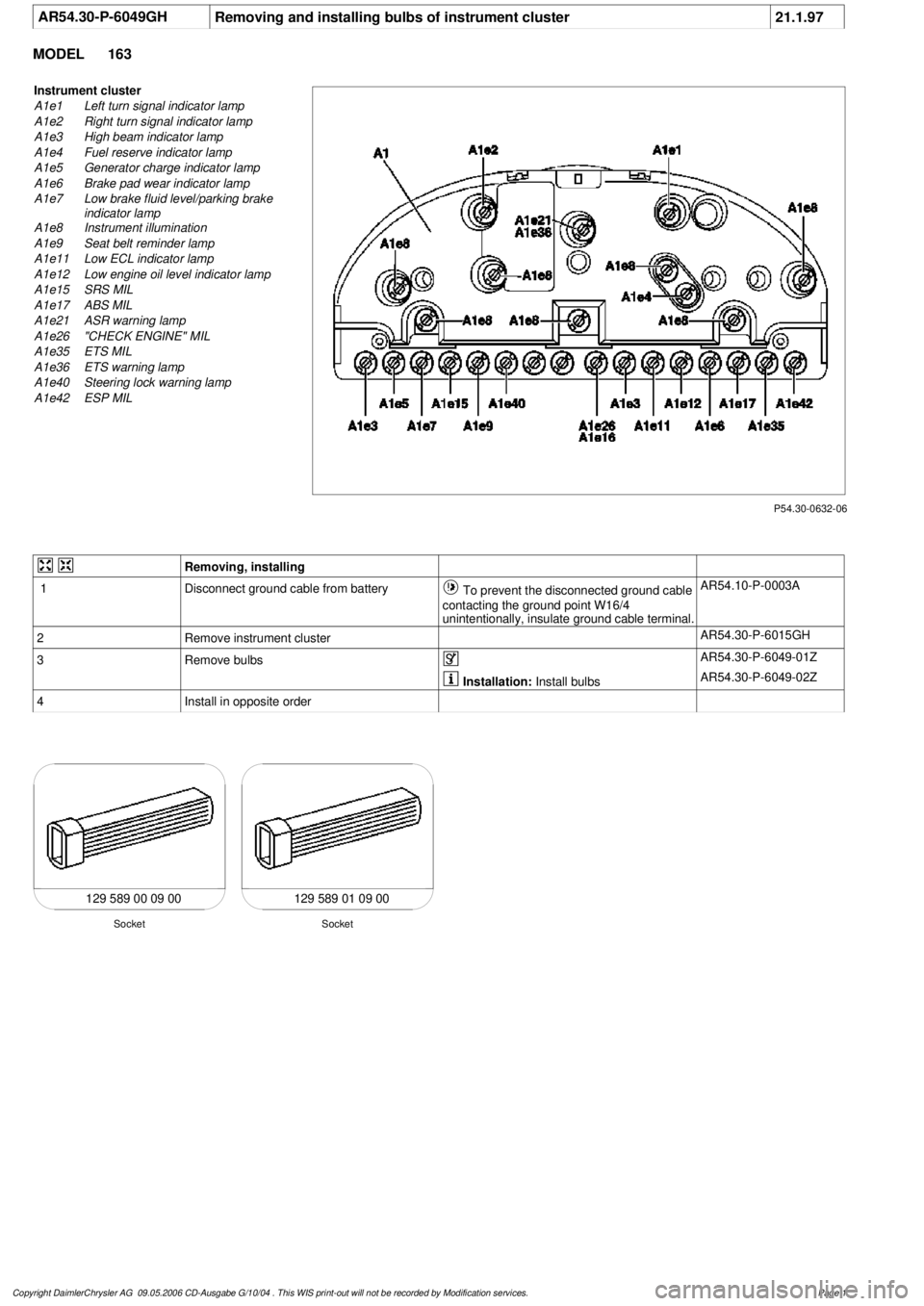

AR54.30-P-6049GH

Removing and installing bulbs of instrument cluster

21.1.97

MODEL

163

P54.30-0632-06

Instrument cluster

A1e1

Left turn signal indicator lamp

A1e2

Right turn signal indicator lamp

A1e3

High beam indicator lamp

A1e4

Fuel reserve indicator lamp

A1e5

Generator charge indicator lamp

A1e6

Brake pad wear indicator lamp

A1e7

Low brake fluid level/parking brake

indicator lamp

A1e8

Instrument illumination

A1e9

Seat belt reminder lamp

A1e11

Low ECL indicator lamp

A1e12

Low engine oil level indicator lamp

A1e15

SRS MIL

A1e17

ABS MIL

A1e21

ASR warning lamp

A1e26

"CHECK ENGINE" MIL

A1e35

ETS MIL

A1e36

ETS warning lamp

A1e40

Steering lock warning lamp

A1e42

ESP MIL

Removing, installing

1

Disconnect ground cable from battery

To prevent the disconnected ground cable

contacting the ground point W16/4

unintentionally, insulate ground cable terminal.

AR54.10-P-0003A

2

Remove instrument cluster

AR54.30-P-6015GH

3

Remove bulbs

AR54.30-P-6049-01Z

Installation:

Install bulbs

AR54.30-P-6049-02Z

4

Install in opposite order

129 589 00 09 00 129 589 01 09 00

Socket

Socket

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

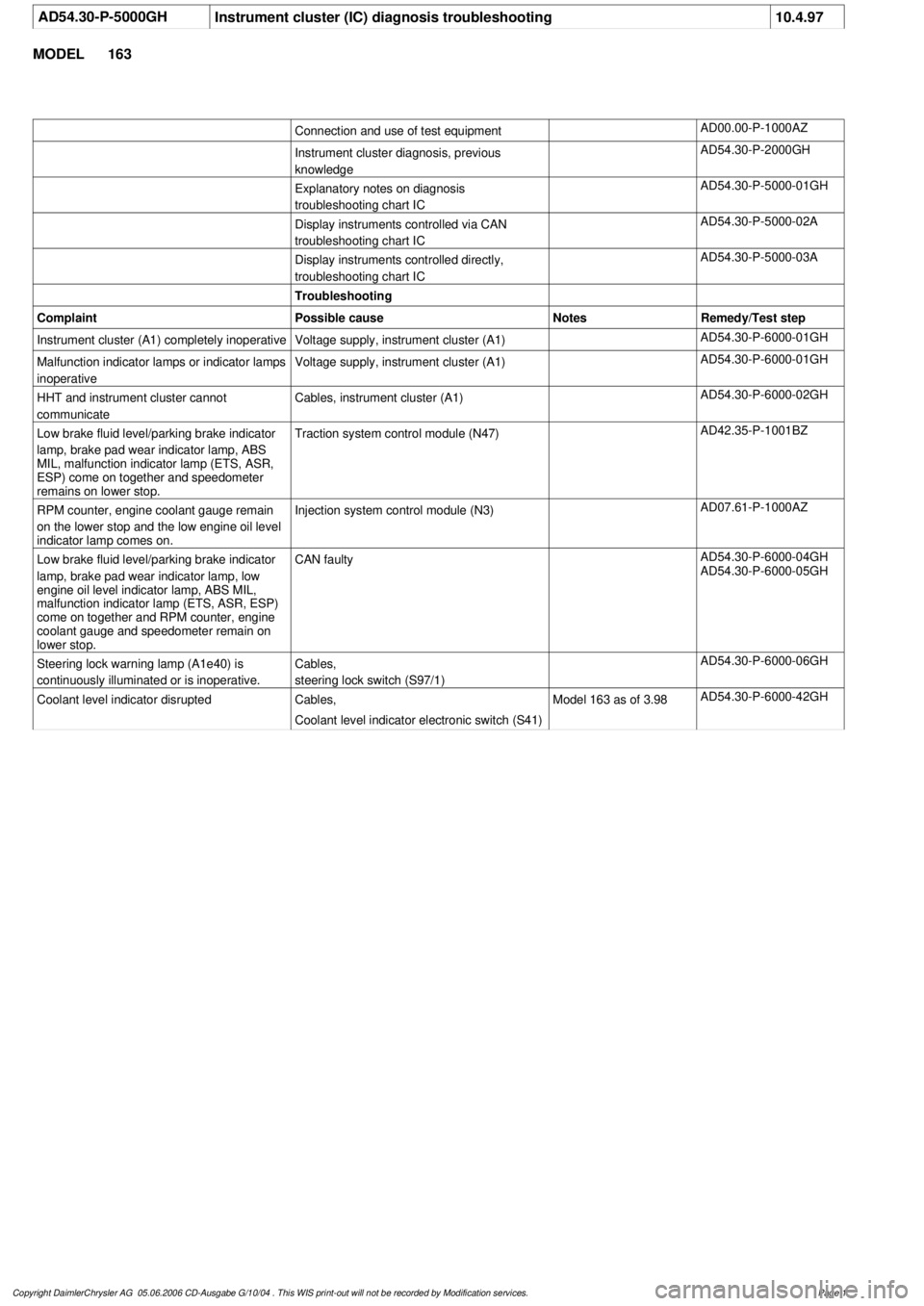

Page 3496 of 4133

AD54.30-P-5000GH

Instrument cluster (IC) diagnosis troubleshooting

10.4.97

MODEL

163

Connection and use of test equipment

AD00.00-P-1000AZ

Instrument cluster diagnosis, previous

knowledge

AD54.30-P-2000GH

Explanatory notes on diagnosis

troubleshooting chart IC

AD54.30-P-5000-01GH

Display instruments controlled via CAN

troubleshooting chart IC

AD54.30-P-5000-02A

Display instruments controlled directly,

troubleshooting chart IC

AD54.30-P-5000-03A

Troubleshooting

Complaint

Possible cause

Notes

Remedy/Test step

Instrument cluster (A1) completely inoperative

Voltage supply, instrument cluster (A1)

AD54.30-P-6000-01GH

Malfunction indicator lamps or indicator lamps

inoperative

Voltage supply, instrument cluster (A1)

AD54.30-P-6000-01GH

HHT and instrument cluster cannot

communicate

Cables, instrument cluster (A1)

AD54.30-P-6000-02GH

Low brake fluid level/parking brake indicator

lamp, brake pad wear indicator lamp, ABS

MIL, malfunction indicator lamp (ETS, ASR,

ESP) come on together and speedometer

remains on lower stop.

Traction system control module (N47)

AD42.35-P-1001BZ

RPM counter, engine coolant gauge remain

on the lower stop and the low engine oil level

indicator lamp comes on.

Injection system control module (N3)

AD07.61-P-1000AZ

Low brake fluid level/parking brake indicator

lamp, brake pad wear indicator lamp, low

engine oil level indicator lamp, ABS MIL,

malfunction indicator lamp (ETS, ASR, ESP)

come on together and RPM counter, engine

coolant gauge and speedometer remain on

lower stop.

CAN faulty

AD54.30-P-6000-04GH

AD54.30-P-6000-05GH

Steering lock warning lamp (A1e40) is

continuously illuminated or is inoperative.

Cables,

steering lock switch (S97/1)

AD54.30-P-6000-06GH

Coolant level indicator disrupted

Cables,

Coolant level indicator electronic switch (S41)

Model 163 as of 3.98

AD54.30-P-6000-42GH

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1