ignition MERCEDES-BENZ ML320 1997 Complete Manual Online

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1207 of 4133

Operation

The steering lock interlock prevents the ignition key being removed when the parking lock is not engaged.

The locking pawl (39) is positioned on the exterior contour of the detent plate (38) if the parking lock is not

engaged and if the brake pedal is not depressed. See Fig. 20

.

The cables (53, 54) hold the locking valve (60) in its position in front of the locking cam (61) against the force

of the pressure spring. Therefore, the ignition key cannot be turned to the "0" position.

In selector lever position "P" and with the brake pedal in the rest position, the force of the return spring (57) can

pull the locking pawl (39) under the stop at the detent plate (38) and the pressure spring (62) simultaneously

pulls the locking valve (60) away from the locking cam (61).

The ignition key can now be turned to the "0" position and removed from the ignition.

The design of the parking lock interlock is the same as for the steering lock interlock and it functions with

reciprocal action to the steering lock interlock.

Parking Lock, Location/Task/Design/Function

See PARKING LOCK, LOCATION/TASK/DESIGN/FUNCTION

.

Parking Lock, Location/Task/Design/Function

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 38 © 2006 Mitchell Repair Information Company, LLC.

Page 1405 of 4133

See MODULATING PRESSURE, FUNCTION

.

Shift Valve Pressure, Function

See SHIFT VALVE PRESSURE, FUNCTION

.

Lubricating Pressure, Function

See LUBRICATING PRESSURE, FUNCTION

.

Regulating Valve Pressure, Function

See REGULATING VALVE PRESSURE, FUNCTION

.

Limp-Home Mode, Function

Operation

In order to ensure a safe driving state and to prevent damage to the automatic transmission, the ECT control

module (N15/3) switches to limp-home mode in the event of critical faults. A fault code assigned to the fault is

stored in memory.

All solenoid and regulating valves are thus de-energized.

Effect

The gear last engaged remains engaged.

The modulating pressure and shift pressure rise to the maximum levels.

The torque converter lockup clutch is switched off.

In order to preserve the operability of the vehicle to some extent, the hydraulic control can be used to engage

2nd gear or reverse:

Stop Vehicle

Switch Off Engine

Move Selector Lever To "P"

Wait At Least 10 Seconds

Start Engine

Move Selector Lever To "D": 2Nd Gear

Move Selector Lever To "R"

The limp-home function remains active until the fault is rectified or the stored fault code is erased. Sporadic

faults can be reset via ignition OFF/ON.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:29 PMPage 236 © 2006 Mitchell Repair Information Company, LLC.

Page 1457 of 4133

When the kick-down switch (S16/6) is operated via the accelerator pedal a signal is passed on to the ETC

control module (N15/3). Based on this information the ETC control module (N15/3) actuates the solenoid

valves so that the upshifts and downshifts take place at higher engine speed.

Shift-Lock Function

Operation

The term shift lock combines the functions which, in addition to the parking brake, offer an additional safeguard

for the vehicle to prevent it moving off unintentionally.

These include the functions of locking the selector lever position "P" and locking the ignition lock as well as the

parking lock in the transmission.

The shift lock function only allows shifting out of selector lever position "P" if the transmitter key (A8/1) has

been turned into the position "Ignition: ON" and the brake pedal is depressed.

In order to ensure that after parking the vehicle the selector lever is shifted into selector lever position "P", the

transmitter key (A8/1) can only be turned towards "0" in this position and removed from the EZS control

module (N73) (ignition lock locking, function).

The vehicle is secured mechanically by blocking the park pawl gear.

In the event of mechanical or electrical/electronic faults it is possible to unlock selector lever position "P"

manually (shift lock override function).

Function Of Locking Of Selector Lever Position "P"

See FUNCTION OF LOCKING OF SELECTOR LEVER POSITION "P"

.

Ignition Lock Locking, Function

See IGNITION LOCK INTERLOCK

.

Function Of Shift Lock Override

See FUNCTION OF SHIFT LOCK OVERRIDE

.

Function Of Locking Of Selector Lever Position "P" (With Touch Shift)

Operation

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 288 © 2006 Mitchell Repair Information Company, LLC.

Page 1459 of 4133

ignition key position Ignition "ON" when the brake pedal is depressed and therefore when the brake lamp

switch (S9/1) is actuated and when selector lever position "P" is recognized.

The R/P locking magnet (89) releases the selector lever thus allowing the selector lever to be moved away from

position "P".

Parking Lock, Location/Task/Design/Function - See PARK PAWL,

LOCATION/TASK/DESIGN/FUNCTION.

Ignition Lock Interlock

Operation

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 290 © 2006 Mitchell Repair Information Company, LLC.

Page 1460 of 4133

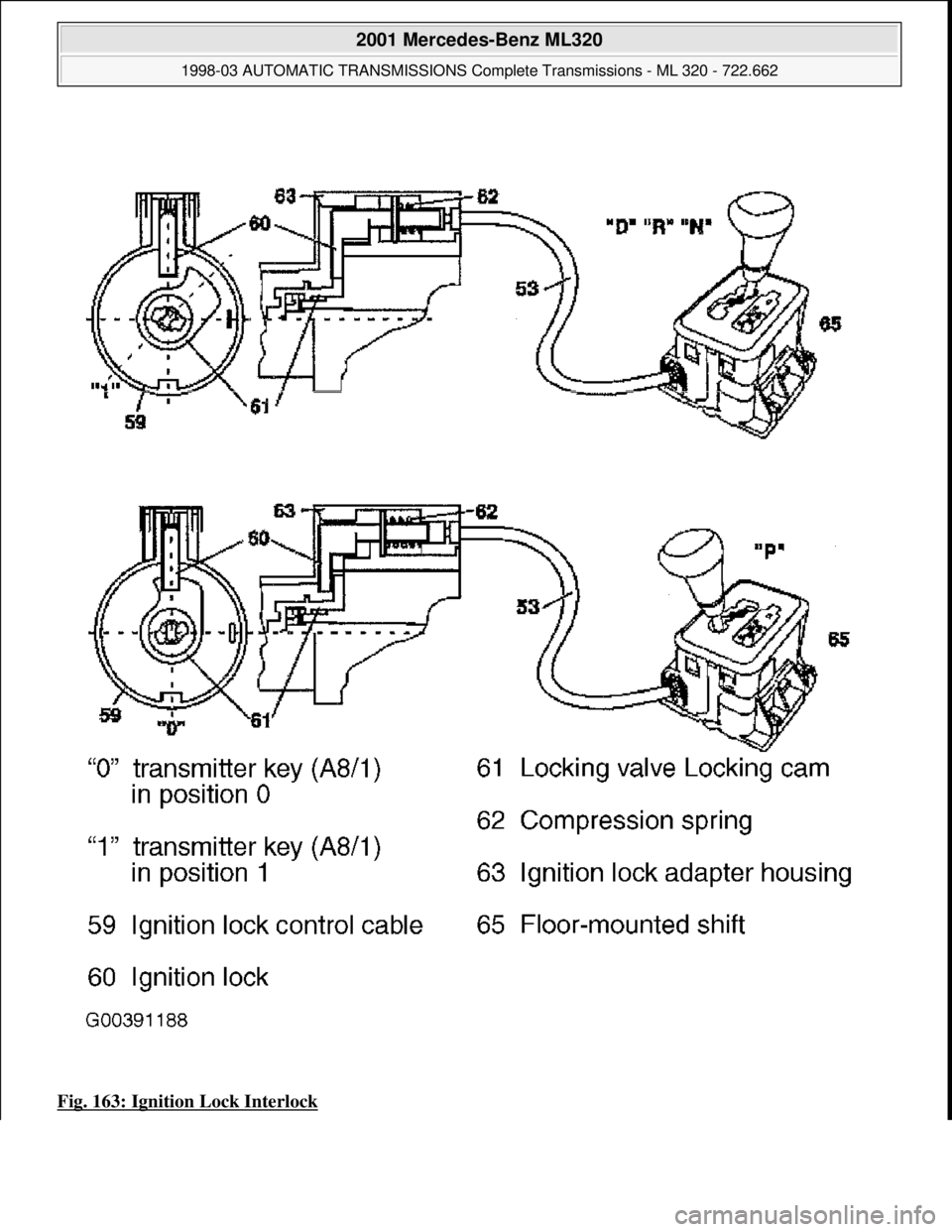

Fig. 163: Ignition Lock Interlock

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMI SSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 291 © 2006 Mitchell Repair Information Company, LLC.

Page 1461 of 4133

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

The mechanism of the ignition lock interlock connects the selector lever of the floor shift with the ETC control

module (N73). See Fig. 163

. It prevents the transmitter key (A8/1) from being withdrawn when the selector

lever is not at position "P".

When the parking lock is not engaged (selector lever position "D", "R", "N"), the locking valve (60) locks the

locking cam (61). The compression spring (62) only pulls the locking valve (60) away from the locking cam

(61) in selector lever position "P". The transmitter key (A8/1) can now be turned to position "0" and removed

from the ignition.

Parking Lock, Location/Task/Design/Function

See PARK PAWL, LOCATION/TASK/DESIGN/FUNCTION

.

Function Of Shift lock Override

Transmission with touch shift 722.6 in MODEL 163

Operation

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 292 © 2006 Mitchell Repair Information Company, LLC.

Page 1473 of 4133

See OIL LEVEL CONTROL, FUNCTION

.

Function of Torque Converter Lockup Clutch Control

See FUNCTION OF TORQUE CONVERTER LOCKUP CLUTCH CONTROL

.

Torque Converter Lockup Clutch Control Pressure, Function

See TORQUE CONVERTER LOCKUP CLUTCH CONTROL PRESSURE, FUNCTION

.

Function Of Locking Of Selector Lever Position "P"

See FUNCTION OF LOCKING OF SELECTOR LEVER POSITION "P"

.

Ignition Lock Locking, Function

See IGNITION LOCK INTERLOCK

.

Function Of Shift Lock Override

See FUNCTION OF SHIFT LOCK OVERRIDE

.

Survey Of System Components, Automatic Transmission, Location/Task/Design/Function

See SURVEY OF SYSTEM COMPONENTS, AUTOMATIC TRANSMISSION,

LOCATION/TASK/DESIGN/FUNCTION.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 304 © 2006 Mitchell Repair Information Company, LLC.

Page 1489 of 4133

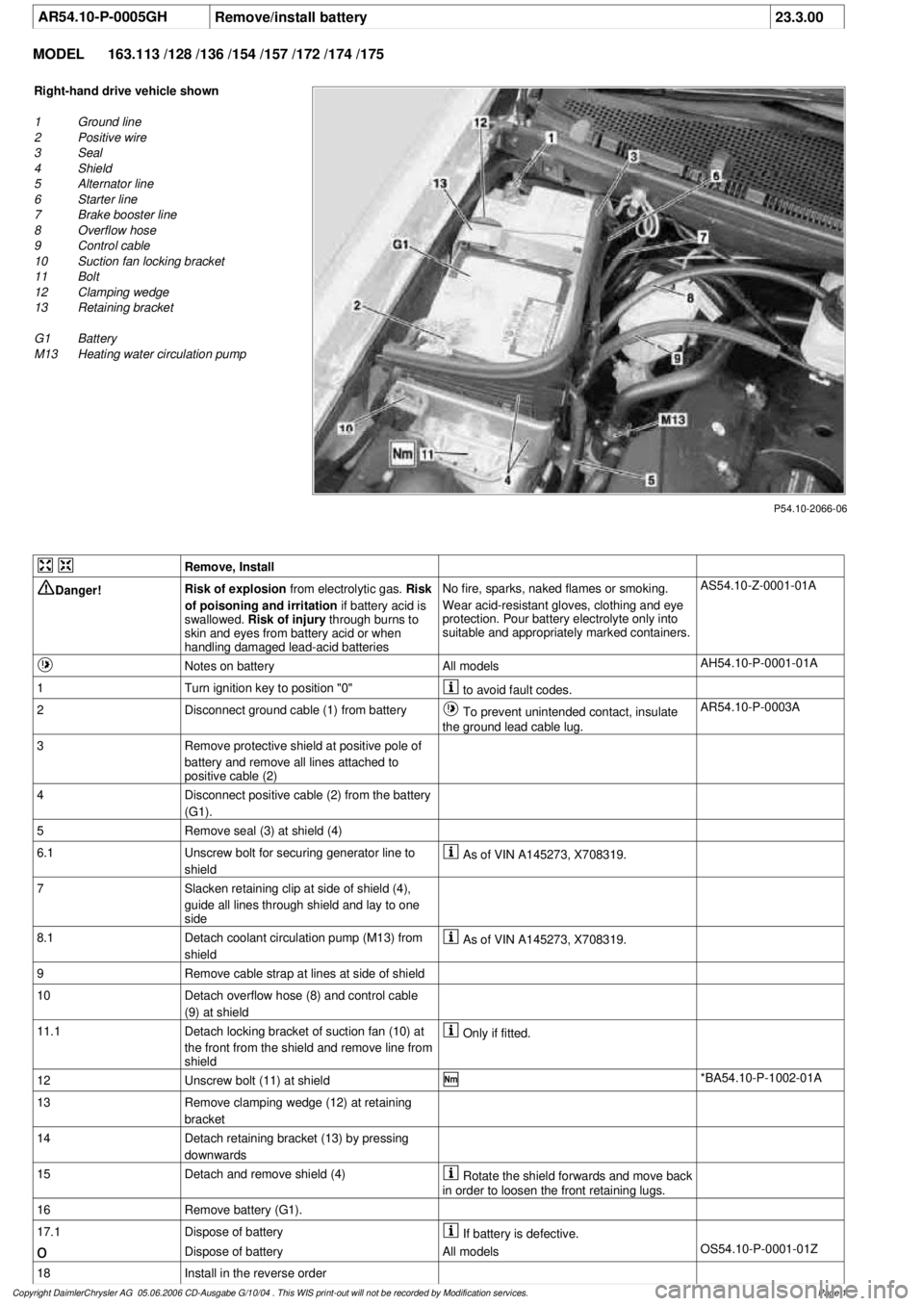

AR54.10-P-0005GH

Remove/install battery

23.3.00

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P54.10-2066-06

Right-hand drive vehicle shown

1

Ground line

2

Positive wire

3

Seal

4

Shield

5

Alternator line

6

Starter line

7

Brake booster line

8

Overflow hose

9

Control cable

10

Suction fan locking bracket

11

Bolt

12

Clamping wedge

13

Retaining bracket

G1 Battery

M13

Heating water circulation pump

Remove, Install

Danger!

Risk of explosion

from electrolytic gas.

Risk

of poisoning and irritation

if battery acid is

swallowed.

Risk of injury

through burns to

skin and eyes from battery acid or when

handling damaged lead-acid batteries

No fire, sparks, naked flames or smoking.

Wear acid-resistant gloves, clothing and eye

protection. Pour battery electrolyte only into

suitable and appropriately marked containers.

AS54.10-Z-0001-01A

Notes on battery

All models

AH54.10-P-0001-01A

1

Turn ignition key to position "0"

to avoid fault codes.

2

Disconnect ground cable (1) from battery

To prevent unintended contact, insulate

the ground lead cable lug.

AR54.10-P-0003A

3

Remove protective shield at positive pole of

battery and remove all lines attached to

positive cable (2)

4

Disconnect positive cable (2) from the battery

(G1).

5

Remove seal (3) at shield (4)

6.1

Unscrew bolt for securing generator line to

shield

As of VIN A145273, X708319.

7

Slacken retaining clip at side of shield (4),

guide all lines through shield and lay to one

side

8.1

Detach coolant circulation pump (M13) from

shield

As of VIN A145273, X708319.

9

Remove cable strap at lines at side of shield

10

Detach overflow hose (8) and control cable

(9) at shield

11.1

Detach locking bracket of suction fan (10) at

the front from the shield and remove line from

shield

Only if fitted.

12

Unscrew bolt (11) at shield

*BA54.10-P-1002-01A

13

Remove clamping wedge (12) at retaining

bracket

14

Detach retaining bracket (13) by pressing

downwards

15

Detach and remove shield (4)

Rotate the shield forwards and move back

in order to loosen the front retaining lugs.

16

Remove battery (G1).

17.1

Dispose of battery

If battery is defective.

o

Dispose of battery

All models

OS54.10-P-0001-01Z

18

Install in the reverse order

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 1515 of 4133

XENON HEADLAMPS, FUNCTION - GF82.10-P-2007-01GH

Function

The combustion chamber of the xenon lamp is filled with xenon and a mixture of metal halide salts. This

mixture is ignited by high voltage. The color of the light has a characteristic similar to daylight.

When the low beam lamps are switched on the xenon headlamp control module (E1 n1, E2n1) activates the

xenon headlamp control module and ignition module (E1n2, E2n2) via the control voltage within a few

milliseconds.

As a result of a high voltage surge (approx. 20 kV) of the ignition device, an arc forms between the electrodes,

and the xenon lamp is ignited.

When an arc of sufficient stability is detected, the control electronics of the xenon lamp control module (E1n1,

E2n1) switches over to power-limiting mode. The electric power is regulated to 35 W. A voltage converter

generates the voltage of approx. 85 V (~) necessary for the reliable function of the xenon lamp. For technical

reasons the xenon lamp has a timed startup characteristic. After switching on, 50 % of the luminosity is reached

within 1 to 2 seconds and full luminosity is reached after approx. 30 seconds.

Model 163, up to

31.08.01GF82.10-P-0001GH

Model 163 as of

1.09.01GF82.10-P-

0001GHA

Xenon headlamps, functionModel 163, up to

31.08.01GF82.10-P-2007-

01GH

Model 163 as of

1.09.01GF82.10-P-2007-

01GHA

Automatic driving light actuation,

functionModel 163 as of

01.09.01GF82.10-P-3003GH

Daytime running light control, functionModel 163 as of

01.09.01GF82.10-P-3005GH

Locator lighting, functionModel 163 as of

01.09.01GF80.20-P-2008GH

Headlamp cut-in, functionModel 163 as of

01.09.01GF80.20-P-2003GH

Daytime running lights, functionModel 202 with

Code 236a special

lamp circuit for

daytime running

lampsGF82.10-P-2002A

Contents - Function description of

exterior lighting,

location/task/design/functionModels 129, 140,

163, 202, 208, 210

with code 612b

xenon headlamp unitGF82.10-P-9999B

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:04 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 1516 of 4133

XENON HEADLAMPS, FUNCTION - GF82.10-P-2007-01GHA

The lighting technology, known as bi-xenon 70 , is located in the outer headlamps.

When the low beam lamps are switched on the xenon headlamp control module (E1 n1, E2n1) activates the

xenon headlamp control module and ignition module (E1n2, E2n2) via the control voltage within a few

milliseconds.

A high-voltage surge from the ignition device ignites the xenon lamps, and in doing so an electric arc is formed

between the electrodes. When an arc of sufficient stability is detected, the control electronics of the control

module (E1 n1, E2n1) switches over to power-limiting mode.

The light generated previously in a gas discharge lamp (D2S lamp) is not reflected in bi-xenon 70 headlamps,

but instead it is sent directly through a lens optical system with a lens diameter of 70 mm.

Using the mask (B), which is positioned between the gas discharge lamp and the lens optical system, the beam

of light is partially masked for the low beam so that oncoming traffic is not blinded.

For the high beam, the mask (B) is electro-mechanically folded to the side using the solenoid (M).

If the solenoid (M) should fail or a supply line breaks, the mask (B) remains mechanically held in the low

beam position, always between the gas discharge lamp and the lens optical system.

In order to make the extremely bright light more acceptable to other road users, the lens aperture area with its

dotted characteristic is optically enlarged.

This is possible on account of the specially formed areas which surround the lens. In addition, the light can pass

through a number of chrome-plated strips from the rear. A portion of the diffused light is intercepted by the

lower section of the surface area and reflected to the upper section of the chrome-plated longitudinal strips.

For technical reasons the xenon lamp has a timed startup characteristic. After switch on, 50 % of the luminosity

is reached within 1 to 2 seconds and full luminosity is achieved after another approx. 30 seconds.

XENON HEADLAMP, LOCATION/DESIGN/FUNCTION - GF82.10-P-2007GH

MODELS 163.113 /136 /154 /172 up to 31.08.01 with CODE (612b) xenon headlamp unit with CODE

(U47) conversion package

MODELS 163.174 up to 31.08.01, 163.113 /128 /136 /154 /172 as of 01.09.01

Design:

From model

year 2002 (as of 1.9.01) the xenon headlamps are installed as standard.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:04 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.