engine MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3165 of 4133

COOLANT SPECIFICATIONS - BB00.40-P-0310-01A

1.Coolant

1.1 Coolant composition

1.1.1 Passenger car and commercial vehicle engines (normal case)

50 vol.-% Water

50 vol.-% Anticorrosion/antifreeze agents (see Sheet 325.0 or 325.2, 325.3) antifreeze protection down to

approx. -37°C

Pre-mixed products in accordance with sheets 326.x can also be used.

1.1.2 Commercial vehicle engines (without antifreeze specification)

Blend of water and coolant additive in accordance with Sheet 312.0, for prescribed mixture ratio refer to

Sheet 312.0.

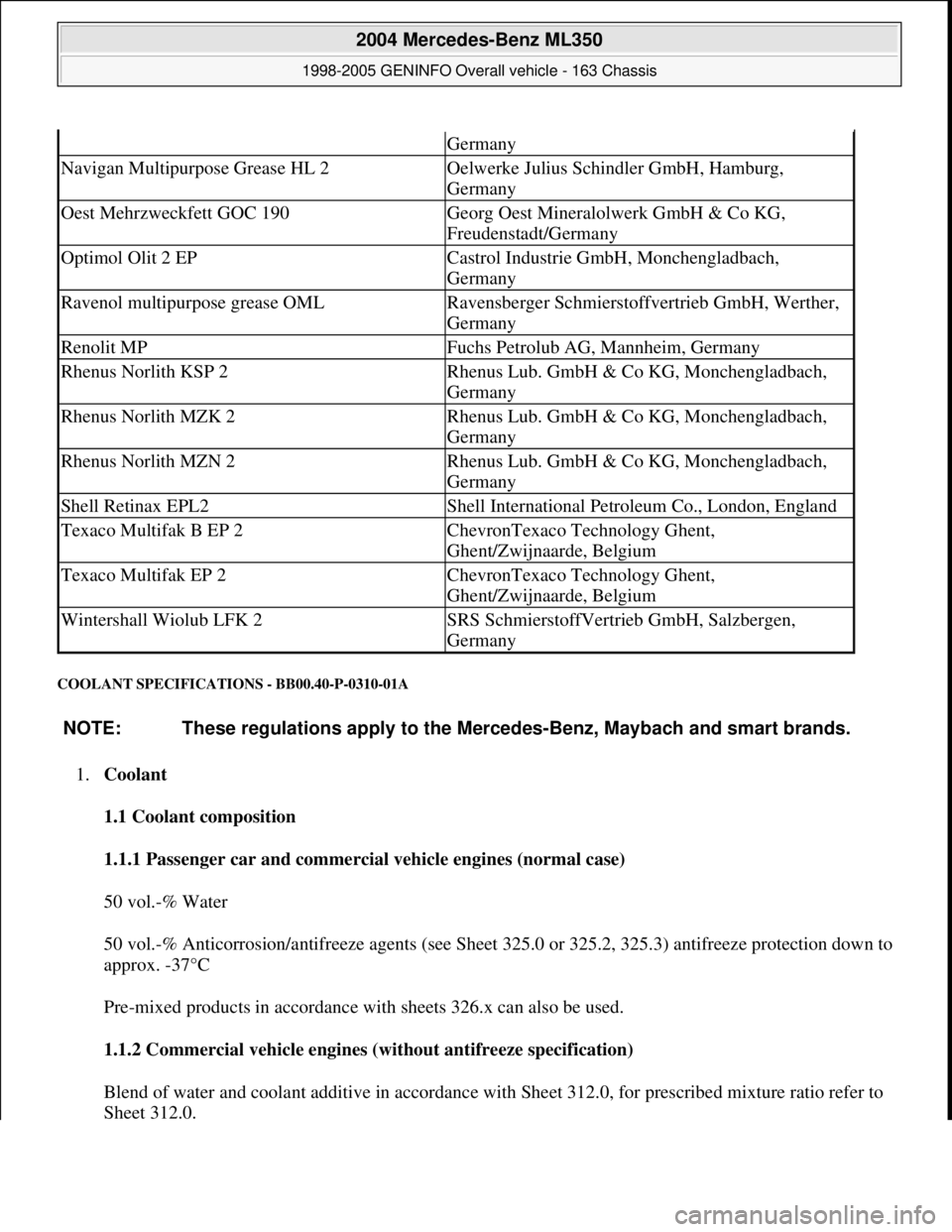

Germany

Navigan Multipurpose Grease HL 2Oelwerke Julius Schindler GmbH, Hamburg,

Germany

Oest Mehrzweckfett GOC 190Georg Oest Mineralolwerk GmbH & Co KG,

Freudenstadt/Germany

Optimol Olit 2 EPCastrol Industrie GmbH, Monchengladbach,

Germany

Ravenol multipurpose grease OMLRavensberger Schmierstoffvertrieb GmbH, Werther,

Germany

Renolit MPFuchs Petrolub AG, Mannheim, Germany

Rhenus Norlith KSP 2Rhenus Lub. GmbH & Co KG, Monchengladbach,

Germany

Rhenus Norlith MZK 2Rhenus Lub. GmbH & Co KG, Monchengladbach,

Germany

Rhenus Norlith MZN 2Rhenus Lub. GmbH & Co KG, Monchengladbach,

Germany

Shell Retinax EPL2Shell International Petroleum Co., London, England

Texaco Multifak B EP 2ChevronTexaco Technology Ghent,

Ghent/Zwijnaarde, Belgium

Texaco Multifak EP 2ChevronTexaco Technology Ghent,

Ghent/Zwijnaarde, Belgium

Wintershall Wiolub LFK 2SRS SchmierstoffVertrieb GmbH, Salzbergen,

Germany

NOTE: These regulations apply to the Mercedes-Benz, Maybach and smart brands.

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 520 © 2006 Mitchell Repair Information Company, LLC.

Page 3166 of 4133

Scope: With constant ambient temperatures above freezing point.

1.1.3 Commercial vehicle engines (exception, not for engines OM 500, OM 900, OM 457 and OM

460)

99 vol % Water

1 vol % Refining agent (see Sheet 311.0)

Scope: For constant ambient temperatures above freezing point, e.g. in tropical regions, in which it can be

proven that no approved anticorrosion/antifreeze agents and coolant additives according to Sheet 312.0

are available.

Passenger-car engines, which are installed in a commercial vehicle, must always be filled up as for a

passenger-car engine, refer to points 2.1/2.2.

A quick-glance overview of the fields of application for the approved coolant additives and the

prescribed change intervals are available in Section 5. Please note the mixing prohibition for Sheets 325.3

and 326.3!

1.2 Water

1.2.1 Fresh-water regulations/water treatment

Clean, and where possible, not too hard water should be used for processing the coolant. Drinking water

frequently, although not always, complies with the given specifications.

Sea water, brackish water, brine and industrial waters are not suitable. The level of water containing

dissolved substances can vary greatly depending upon its origin (ground, spring, surface water) and it is

of major significance regarding the presence of corrosion.

Water that is too hard is disadvantageous because of the possibility of scaling or sludging occurring. Salt

content, predominantly chloride, greatly promotes corrosion. If in doubt, analyze the water.

Information concerning the water quality of drinking water is available from the local water-plant

authorities or the official water utilities on request.

If there is no available information regarding the quality of the drinking water then distilled or deionized

water should be used.

If the water fails to comply with the approved analysis values, then it is be processed in a suitable

manner, because even excellent anticorrosion/antifreeze agents are greatly impaired in their ability to

protect against corrosion if water quality is poor.

Should it not be possible to soften the water then the water should be brought up to an approved hardness

by an admixture of soft or distilled (deionized) water.

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 521 © 2006 Mitchell Repair Information Company, LLC.

Page 3167 of 4133

If the chloride or total ionic content of the water is too high, then the level can be reduced through the

admixture of demineralized, in other words, ion-exchanged or distilled water.

Particular treatment processes will need to be used (desalination and demineralization or subprocesses)

depending upon the contaminants present in the water. Information on how to conduct water treatment is

available from water plants or water utilities as well as several companies and engineering consultants

who are experienced in this area.

Depending upon the coolant composition, the analysis values for the water should lie within the following

limits:

1.2.2 Fresh-water quality for coolant composition as under item 1.1.1 (passenger-cars and

commercial-vehicle engines)

Sum total of alkalis (water hardness): 0 to 3.6 mmol/l (0 up to 20° d)*

pH value at 20°C: 6.5 up 8.5

Chlorine ion content: max. 100 mg/l

Total chlorides and sulfates: max. 200 mg/l

1.2.3 Fresh-water quality for coolant composition as under item 1.1.2/1.1.3 (commercial-vehicle

engines)

Sum total of alkalis (water hardness): 0 to 2.7 mmol/l (0 up to 15° d)*

pH value at 20°C: 6.5 to 8.0

Chlorine ion content: max. 80 mg/l

Total chlorides and sulfates: max. 160 mg/l

If in doubt, contact DaimlerChrysler AG, department EP/MOR (operating fluids), C 405, D-70546

Stuttgart, Germany.

* Customary designations for water hardness in various countries: 1 mmol/l=5.6° d=10° f=7.02° e=100

mg/kg Ca CO.

3.

1° d (German degree =1° dGH)=1.78° (French degree)=1.25° e (English degree )=17.9 mg/kg Ca CO

3

(USA hardness).

1.3 Premixed coolant

Several providers have water with premixed coolant in their product range. Provided they are approved

(see below), the

y can also be used; the regulations relating to application, composition, change intervals,

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 522 © 2006 Mitchell Repair Information Company, LLC.

Page 3168 of 4133

etc. of these coolant specifications also apply. It is imperative that the correct concentration (50/50) is

used in their application and, of course, further dilution is not permitted!

Approval status:

Coolants for all vehicle and engines (Basis 325.0) Sheet 326.0

Coolants for commercial vehicle and industrial engines (Basis 325.2) Sheet 326.2

Coolants for commercial vehicle and industrial engines (Basis 325.3) Sheet 326.3

The regulations for each respective Sheet 325.x are to be transferred correspondingly to Sheet

326.x.

At the time of compiling these regulations it is possible that not all the Sheets 326.x are represented with

approved products.

2.Coolant additives (General information)

Normally, coolant consists of water and anticorrosion/antifreeze agents. The anticorrosion/antifreeze

agents (ethylene glycol with corrosions inhibitors) in the cooling system have to fulfill, among other

things, the following functions:

to provide sufficient corrosion and cavitation protection for all cooling system components

freezing point depression (antifreeze)

increasing boiling point

For corrosion protection purposes the coolant

approx. 50 vol.-% Anticorrosion/antifreeze agents are added if the expected ambient temperatures do not

require an even higher concentration. This concentration (50 vol %) offers frost protection up to approx. -

37°C. A higher concentration is only necessary if the ambient temperatures are even lower.

Even with extremely low ambient temperatures, not more than 55 vol.-% anticorrosion/antifreeze agent

should be used, because at this level the maximum antifreeze protection is reached and a greater

concentration reduces the antifreeze protection again and decreases the heat dissipation (55 vol.-%

corresponds to antifreeze protection down to approx. -45°C).

Should these coolant regulations fail to be observed then corrosion and damage to the cooling

system are inevitable.

The admixture of anticorrosion/antifreeze agent serves to increase the boiling point. By raising the

pressure the boiling temperature can be increased yet further. Both physical relationships are put to use in

modern cooling systems - the maximum coolant temperature is raised, without increasing the danger of

boiling. In keeping with the higher temperature level the cooling performance is also greater. Only

approved products (Sheet 325.0/326.0 or 325.2 or 326.2, 325.3 or 326.3 as well as 312.0 or 311.0)

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 523 © 2006 Mitchell Repair Information Company, LLC.

Page 3169 of 4133

provide reliable cooling system protection. In special cases (commercial-vehicle engines, no antifreeze

specification) coolant additives can be used that are primarily corrosion protection additives. In this case

item 2.3 is valid.

As an exception, if neither anticorrosion/antifreeze agent conforming to Sheet 325.0 nor coolant additives

without addition of antifreeze conforming to Sheet 312.0 are available, proceed according to point 2.4

(exception: OM 500 and OM 900). The systems described under items 2.2/2.3/2.4 are not compatible

with each other. It is recommended to mix the entire coolant quantity outside the engine.

2.1 Anticorrosion/antifreeze agent for passenger-car engines

Alongside the correct constitution of the cooling water (point 1.2.2), care must be taken to ensure that

only anticorrosion/antifreeze agents as approved for all engines in accordance with Sheet 325.0 are used.

These products serve to guarantee that, in particular, an effective protection against corrosion is provided

for all light-alloy parts in the cooling system and they are also specified for all passenger-car engines.

In order to ensure that the protection against corrosion is effective, the anticorrosion/antifreeze agent must

remain in the cooling system throughout the year - including when in tropical climates - and regardless of

the operating conditions. In countries with high outside temperatures this is also important in terms of

raising the boiling point.

In the event that these regulations are not observed the cooling system may suffer from damage by

corrosion. As a consequence of corrosion deposits there is a danger that ducts in the radiators (engine

overheating) and heat exchangers (poor heat output) get plugged up thus causing damage to the engine.

As a result of the optimizations we have carried out on the system of engine/coolant/cooling system, in

the majority of our newer passenger cars, a replacement of coolant is not necessary until reaching 15

operating years or 250,000 km (whichever comes first). This may not apply to some models; in these

cases the maintenance booklet will stipulate another regulation.

2.2 Anticorrosion/antifreeze agent for commercial-vehicle engines (normal case)

(not: BR 600, BR 100 and BR 200)

The coolant in commercial-vehicle engines is made up of both water and anticorrosion/antifreeze agent

(refer to item 1.1.1) and as such offers ideal protection against corrosion and cavitation.

All the approved products on the Sheets 325.2, 325.3 or 325.0 which are part of the Specifications for

Operating Fluids can be used to select an anticorrosion/antifreeze agent. However, it should be noted that

passenger vehicle engines built into commercial vehicles must be filled like passenger vehicles (e.g. OM

601 in T1), i.e. a product conforming to Sheet 325.0 and 326.0 must be used.

Products that are not listed in Sheets 325.0 and 326.0, or 325.2 and 326.2, or 325.3 and 326.3 are not

approved and are therefore not to be used under any circumstances.

Anticorrosion/antifreeze agents or coolants conforming to Sheet 325.3 or 326.3 may be used for

longer than other products due to their composition. The change interval is set at 5 years (refer to

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 524 © 2006 Mitchell Repair Information Company, LLC.

Page 3170 of 4133

Overview Section 5). However, it should always be remembered that anticorrosion/antifreeze

a

gents or coolants conforming to Sheet 325.3 and 326.3 must not be mixed with those conforming to

Sheet 325.0 or 326.0 or 325.2 and 326.2.

2.3 Coolant additives for commercial-vehicle en

gines without antifreeze specifications (refer to item

1.1.2) (not: BR 600, BR 100 and BR 200)

In those application cases where no antifreeze is necessary, coolant for commercial-vehicle engines as

under item 1.1.2 can be mixed to suit. It is impossible to cite generalized mixing proportions because the

application concentrations of products included in Sheet 312.0 may be different. If the tolerances exceed

or fall below those given in Sheet 312.0, then appropriate adjustments must be made. The coolant's

boiling point is only insignificantly increased by these additives. The starting-off water underlies the

more stringent regulations as under point 1.2.3. The usage period for this coolant is shorter than usual (see

position 3). If it is necessary to refill, the same product must be used and at the same concentration level.

The blending of different products is not permitted as stated in Sheet 312.0.

2.4 Coolant regulations for commercial vehicle engines (exception, not for engines OM 500, OM

900, OM 457 and OM 460)

In the event that neither an approved anticorrosion/antifreeze agent is available, nor a coolant additive in

accordance with sheet 312.0 and if temperatures do not drop below freezing then it is possible in this

exceptional case to use a coolant refining agent to 1 vol % if it is approved in sheet 311.0 (soluble

corrosion protection oil). This will not raise the boiling point. The starting-off water itself underlies the

more stringent regulations as under point 1.2.3.

The period of usage for this coolant, which may only be used in exceptional circumstances, is shorter than

usual (refer to position 3).

Water that is too hard may impair the emulsion resistance, with the result that the emulsion

breaks down (oil separation) and the engine's water jackets are contaminated.

2.4.1 Applying water refining mixture

When carrying out a new filling (initial filling or filling after a cleansing operation) an emulsion of 1.0-

1.5 vol % should be used. When refilling, an emulsion of 0.5-1.0 vol % should be used. Concentrations

that are too high (>1.5 vol %) do not improve the corrosion protection capability and may exert a negative

influence on seals and hoses.

3.Monitoring coolant operation

It is very important to monitor the coolant constantly if the engine is to run trouble free.

The concentration level should be checked every six months.

The inspection should be conducted with suitable apparatus. If, when monitoring the concentration of the

coolant, it is determined that the concentration of anticorrosion/antifreeze agent has reached 40 vol.% or

less or an antifreeze protection of -28°C is no lon

ger guaranteed, the concentration must be increased to

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 525 © 2006 Mitchell Repair Information Company, LLC.

Page 3171 of 4133

the regulation filling of 50 vol.% (-37°C). When topping up (after coolant loss), an anticorrosion/

antifreeze agent content in the coolant of at least 50 vol. % (antifreeze protection down to -37°C) must be

ensured, or the concentration regulations according to point 2.3/2.4.1 must be observed. In closing an

example is given in Overview Section 5.

Non observance a observance of these regulations or the use of non-approved products will

result in serious damage.

The corrosion inhibitors diminish during operation and lose their protective capability. Coolant that is too

old, and has lost its important inhibitors and anti-aging additives, becomes strongly corrosive. The

coolant additives as under Sheets 311.0 and 312.0 will also age. This causes a deterioration in the level of

protection capability, and with regard to coolant refining agents this will also cause the emulsion to break

down.

For this reason it is important to replace the coolant, in order to ensure that its corrosion protection

capability is retained. If necessary the cooling system should be thoroughly cleansed before refilling with

the new coolant. A sufficient level of heat dissipation will only be given if the cooler surfaces are clean.

The maximum permissible period of usage for coolant is cited in Overview Section 5.

The use of approved operatin

g fluids, which naturally include the anticorrosion/antifreeze agents, is

a well-known constituent of the warranty conditions.

4.Disposal of coolants

The coolants are biologically-degradable material.

All statutory regulations or waste water regulations in each individual country with regard to the disposal

of used coolant must be observed.

It is recommended to have the possibilities available for disposing of materials explained by the local

responsible water authorities.

Currently in Germany methods are being compiled for the purification of used coolant. The separate

collection of all used operating fluids is highly recommended.

However, as a consequence of the complex tasks asked of a modern coolant, it is on no account advisable

to use an improperly "recycled" coolant, which has only undergone a mechanical pre-purification process

5.Overview

Which coolant additive, what change interval for which engines?

Passenger cars engines

Sheet No.Engine seriesChange interval

years/km

M100/M200OM600

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 526 © 2006 Mitchell Repair Information Company, LLC.

Page 3172 of 4133

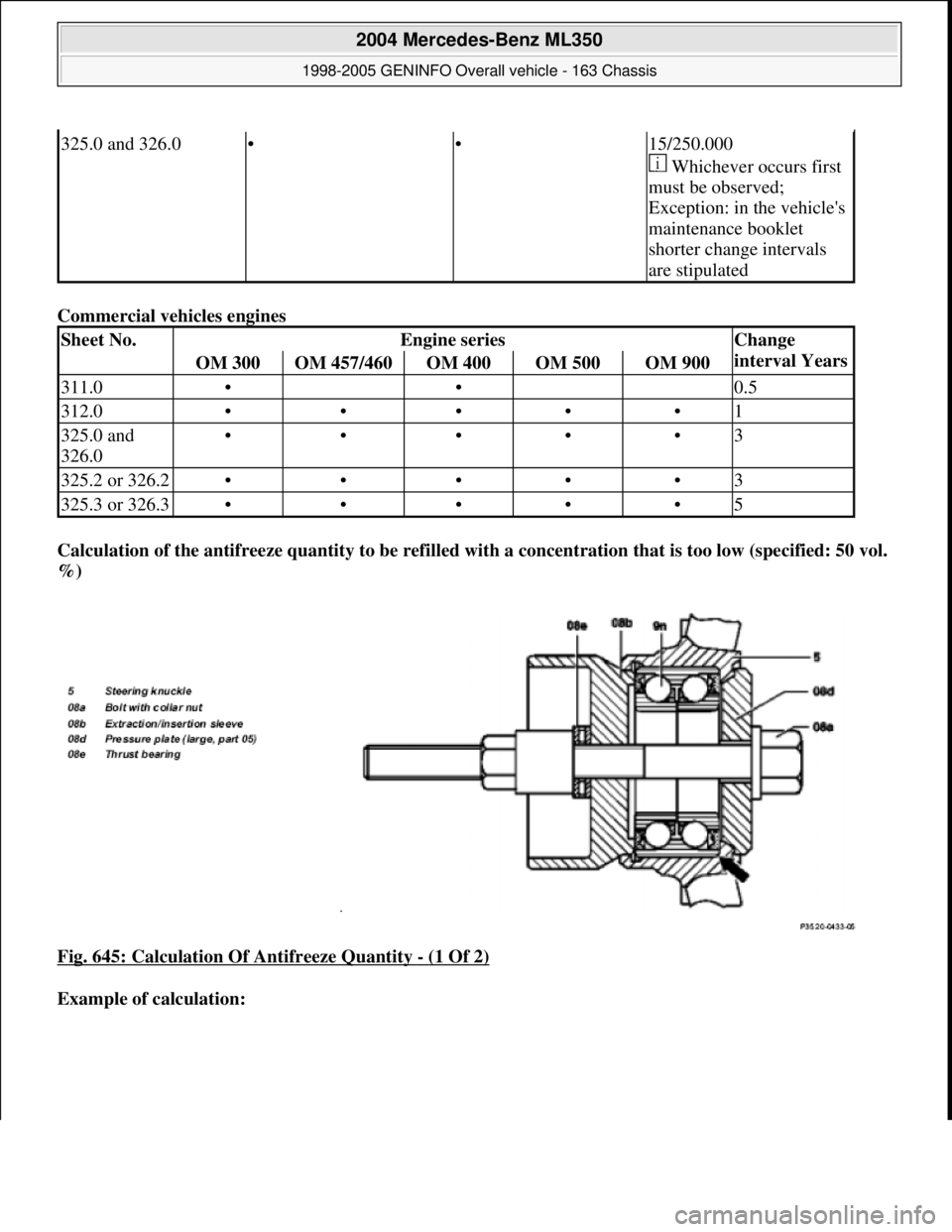

Commercial vehicles engines

Calculation of the antifreeze quantity to be refilled with a concentration that is too low (specified: 50 vol.

%)

Fig. 645: Calculation Of Antifreeze Quantity

- (1 Of 2)

Example of calculation:

325.0 and 326.0••15/250.000

Whichever occurs first

must be observed;

Exception: in the vehicle's

maintenance booklet

shorter change intervals

are stipulated

Sheet No.Engine seriesChange

interval Years

OM 300OM 457/460OM 400OM 500OM 900

311.0• • 0.5

312.0•••••1

325.0 and

326.0•••••3

325.2 or 326.2•••••3

325.3 or 326.3•••••5

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 527 © 2006 Mitchell Repair Information Company, LLC.

Page 3173 of 4133

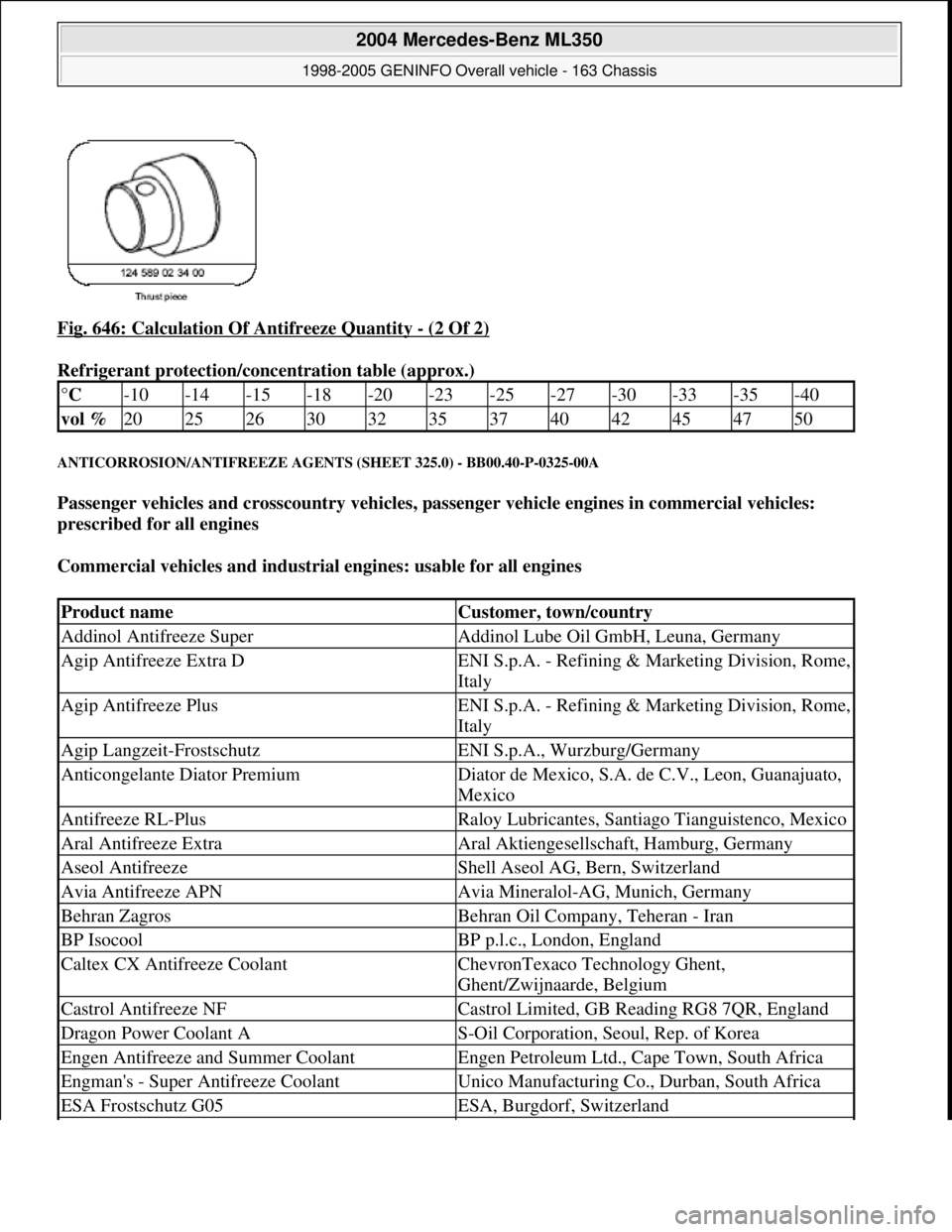

Fig. 646: Calculation Of Antifreeze Quantity - (2 Of 2)

Refrigerant protection/concentration table (approx.)

ANTICORROSION/ANTIFREEZE AGENTS (SHEET 325.0) - BB00.40-P-0325-00A

Passenger vehicles and crosscountry vehicles, passenger vehicle engines in commercial vehicles:

prescribed for all engines

Commercial vehicles and industrial engines: usable for all engines

°C -10-14-15-18-20-23-25-27-30-33-35-40

vol % 202526303235374042454750

Product nameCustomer, town/country

Addinol Antifreeze SuperAddinol Lube Oil GmbH, Leuna, Germany

Agip Antifreeze Extra DENI S.p.A. - Refining & Marketing Division, Rome,

Italy

Agip Antifreeze PlusENI S.p.A. - Refining & Marketing Division, Rome,

Italy

Agip Langzeit-FrostschutzENI S.p.A., Wurzburg/Germany

Anticongelante Diator PremiumDiator de Mexico, S.A. de C.V., Leon, Guanajuato,

Mexico

Antifreeze RL-PlusRaloy Lubricantes, Santiago Tianguistenco, Mexico

Aral Antifreeze ExtraAral Aktiengesellschaft, Hamburg, Germany

Aseol AntifreezeShell Aseol AG, Bern, Switzerland

Avia Antifreeze APNAvia Mineralol-AG, Munich, Germany

Behran ZagrosBehran Oil Company, Teheran - Iran

BP IsocoolBP p.l.c., London, England

Caltex CX Antifreeze CoolantChevronTexaco Technology Ghent,

Ghent/Zwijnaarde, Belgium

Castrol Antifreeze NFCastrol Limited, GB Reading RG8 7QR, England

Dragon Power Coolant AS-Oil Corporation, Seoul, Rep. of Korea

Engen Antifreeze and Summer CoolantEngen Petroleum Ltd., Cape Town, South Africa

Engman's - Super Antifreeze CoolantUnico Manufacturing Co., Durban, South Africa

ESA Frostschutz G05ESA, Burgdorf, Switzerland

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:57 PMPage 528 © 2006 Mitchell Repair Information Company, LLC.

Page 3185 of 4133

AD54.30-P-2000-02GC

Notes on HHT previous knowledge diagnosis

IC

HHT :

The instrument cluster and active service system (ASSYST) sub-

function are checked with HHT, there being the choice of the

following functions for this:

1. Control module version

2. Fault memory

3. Actual values

4. Actuations

5. Control module adaptation

Additional information on test items 2, 3 and 5 can be called up using

the INPUT key

Control module adaptation

The following alternatives are available in the HHT under control

module adaptation:

1.)

Read out coding and transfer to new instrument cluster. IC and

ASSYST.

2.)

Read out/change codings e.g.:

Engine and national variants,

version of fuel tank,

special equipment etc.

3.)

Settings:

1

Clock

2

Put forward kilometer reading

3

Put back kilometer reading

4

Oil change

5

Reset oil change initiated inadvertently

6

Active Service System

7

Enter times with battery disconnected

8

Set minimum oil warning

Before replacing a defective instrument cluster, readout the existing

variant codings (driving data and instrument cluster data) and store in

the HHT on an interim basis. Read in the values stored on an interim

basis again after installing the new instrument cluster.

If it is not possible to read out the stored variant coding, all variant

codings must be input manually (menu-assistance in HHT).

When installing an instrument cluster on an experimental basis, do

not put forward the kilometer reading as it cannot be put back later.

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1