MERCEDES-BENZ ML320 2002 W163 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: ML320, Model: MERCEDES-BENZ ML320 2002 W163Pages: 342, PDF Size: 13.75 MB

Page 281 of 342

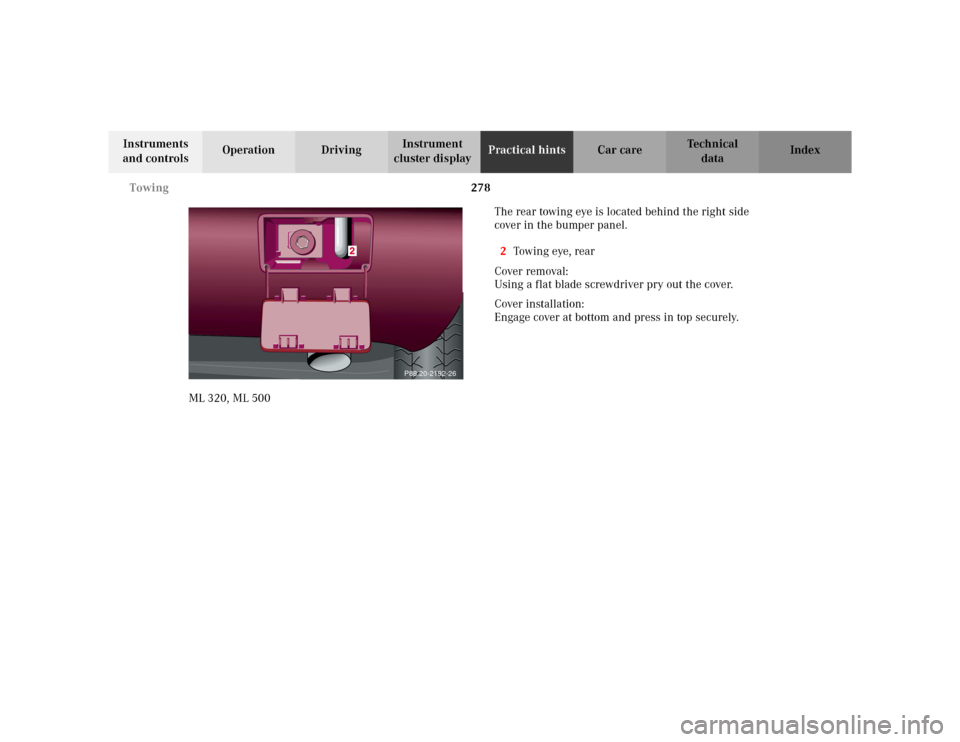

278 Towing

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

ML 320, ML 500The rear towing eye is located behind the right side

cover in the bumper panel.

2Towin g eye, rea r

Cover removal:

Using a flat blade screwdriver pry out the cover.

Cover installation:

Engage cover at bottom and press in top securely.

P88.20-2192-26

Page 282 of 342

279 Towing

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index ML 55 AMG and vehicles with optional sport package.

The rear towing eye is located behind the right side

cover (1) in the bumper panel.

3Cover

4Tow i n g eye , r e a rCover removal:

Grip cover at bottom and securely pull out.

Cover installation:

Engage cover and press in securely.

We recommend that the vehicle be transported using

flat bed equipment. This method is preferable to other

types of towing.

The vehicle may be towed with all wheels on the ground

and the selector lever in position “N” for distances up to

30 miles (50 km) and at a speed not to exceed 30 mph

(50 km / h). The key must be in steering lock position 2.

Note:

The steering lock cannot be locked or unlocked and the

selector lever remains in position “P” if the battery is

disconnected or discharged (see page 273). See

page 281 for transmission selector lever, manually

unlocking.

Wa r n i n g !

In order to avoid possible serious burns or injury,

use extreme caution when removing the cover,

because the rear exhaust pipe is extremely hot.

Page 283 of 342

280 Towing

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

To be certain to avoid additional damage to the vehicle

powertrain, however you should do the following:

•With damage to front axle, raise front axle. Remove

flexible drive shaft between rear axle and transfer

case

•With damage to rear axle, raise rear axle and tow

vehicle with wheel lift or dolly placed under front

wheels.

•With damage to transfer case, remove flexible drive

shafts to the drive axles.

Note:

Always install new self-locking nuts when reinstalling

the flexible drive shaft.Caution!

If the vehicle is towed with the front axle raised, the

engine must be shut off (key in steering lock position 1).

Otherwise, the 4-ETS+ may become engaged which may

cause loss of towing control. Switch off the tow-away

alarm (see page 37) as well as the ESP (see page 225).

Note:

To signal turns while being towed with hazard warning

flasher in use, turn key in steering lock to position 2

and activate combination switch for left or right turn

signal in usual manner. Now deactivate the hazard

warning flasher, only the selected turn signal will

operate. Upon canceling the turn signal, the hazard

warning flasher must be activated again.

Wa r n i n g !

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort is necessary to

brake and steer the vehicle.

Page 284 of 342

281 Towing

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

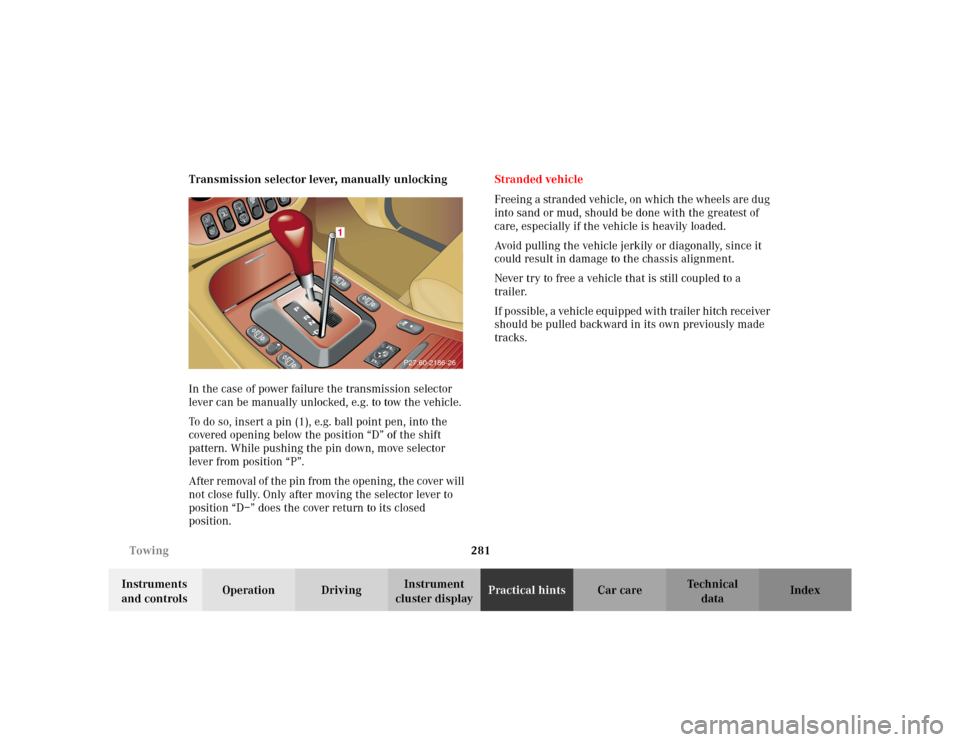

cluster displayPractical hintsCar care Index Transmission selector lever, manually unlocking

In the case of power failure the transmission selector

lever can be manually unlocked, e.g. to tow the vehicle.

To do so, insert a pin (1), e.g. ball point pen, into the

covered opening below the position “D” of the shift

pattern. While pushing the pin down, move selector

lever from position “P”.

After removal of the pin from the opening, the cover will

not close fully. Only after moving the selector lever to

position “D–” does the cover return to its closed

position.Stranded vehicle

Freeing a stranded vehicle, on which the wheels are dug

into sand or mud, should be done with the greatest of

care, especially if the vehicle is heavily loaded.

Avoid pulling the vehicle jerkily or diagonally, since it

could result in damage to the chassis alignment.

Never try to free a vehicle that is still coupled to a

trailer.

If possible, a vehicle equipped with trailer hitch receiver

should be pulled backward in its own previously made

tracks.

P27.60-2186-26

1

Page 285 of 342

282 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Exterior lamps

Headlamp adjustment

Correct headlamp adjustment is extremely important.

Check and readjust headlamps at regular intervals and

when a bulb has been replaced.

For adjusting headlamp aim see page 290.Replacing bulbs

To prevent a possible electrical short circuit, switch off

lamp prior to replacing a bulb.

When replacing bulbs, install only 12 volt bulbs with

the specified watt rating.

When replacing halogen bulbs do not touch glass

portion of bulb with bare hands. Use plain paper or a

clean cloth.

Wa r n i n g !

Bulbs and bulb holders can be very hot. Allow the

lamp to cool down before changing a bulb.

Halogen lamps contain pressurized gas. A bulb can

explode if you:

• touch or move it when hot,

•drop the bulb,

• scratch the bulb.Wear eye and hand protection.

Wa r n i n g !

Because of high voltage in BiXenon lamps, it is

dangerous to replace the bulb of repair the lamp

and its components. We recommend that you have

such work done by a qualified technician.

Page 286 of 342

283 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

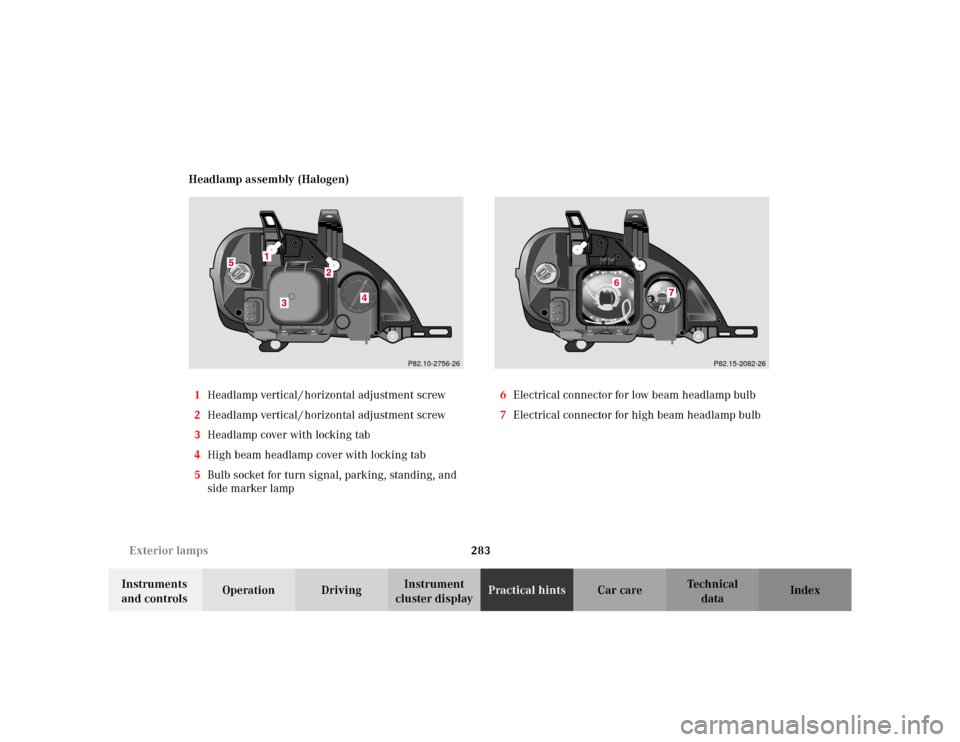

cluster displayPractical hintsCar care Index Headlamp assembly (Halogen)

1Headlamp vertical / horizontal adjustment screw

2Headlamp vertical / horizontal adjustment screw

3Headlamp cover with locking tab

4High beam headlamp cover with locking tab

5Bulb socket for turn signal, parking, standing, and

side marker lamp6Electrical connector for low beam headlamp bulb

7Electrical connector for high beam headlamp bulb

P82.10-2756-26

6

P82.15-2082-26

Page 287 of 342

284 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

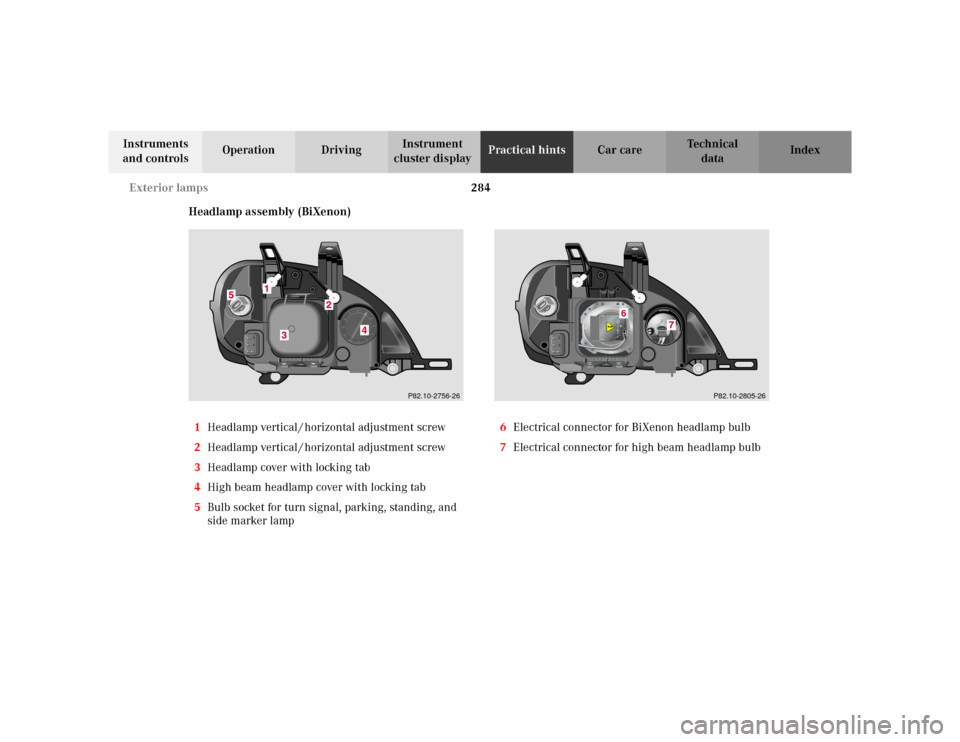

Headlamp assembly (BiXenon)

1Headlamp vertical / horizontal adjustment screw

2Headlamp vertical / horizontal adjustment screw

3Headlamp cover with locking tab

4High beam headlamp cover with locking tab

5Bulb socket for turn signal, parking, standing, and

side marker lamp6Electrical connector for BiXenon headlamp bulb

7Electrical connector for high beam headlamp bulb

P82.10-2756-26

P82.10-2805-26

6

Page 288 of 342

285 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

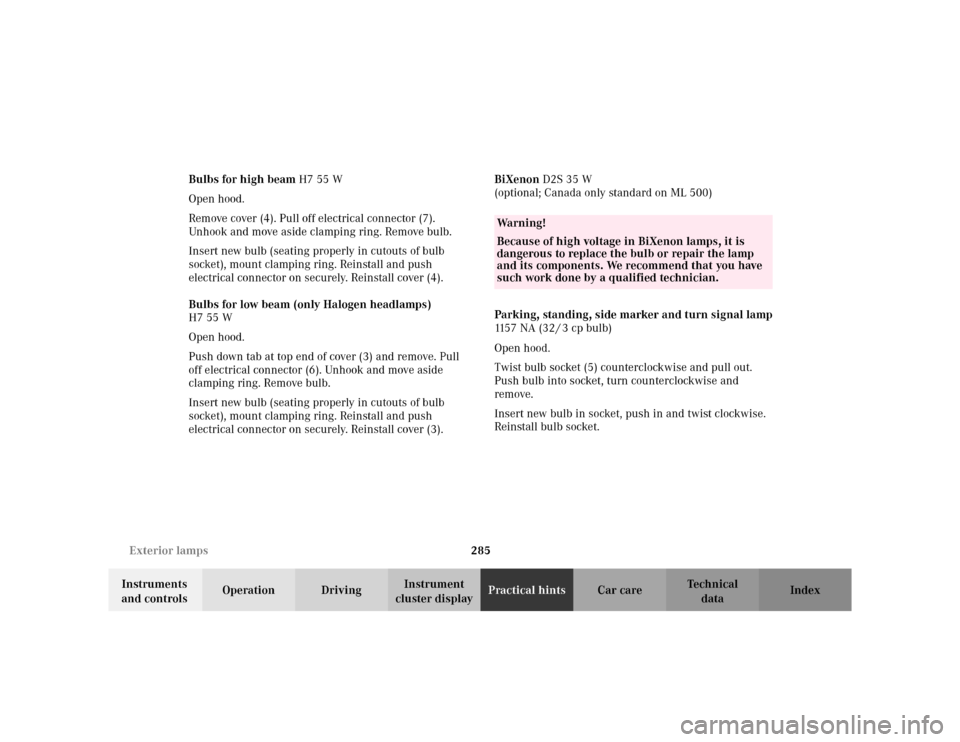

cluster displayPractical hintsCar care Index Bulbs for high beam H7 55 W

Open hood.

Remove cover (4). Pull off electrical connector (7).

Unhook and move aside clamping ring. Remove bulb.

Insert new bulb (seating properly in cutouts of bulb

socket), mount clamping ring. Reinstall and push

electrical connector on securely. Reinstall cover (4).

Bulbs for low beam (only Halogen headlamps)

H7 55 W

Open hood.

Push down tab at top end of cover (3) and remove. Pull

off electrical connector (6). Unhook and move aside

clamping ring. Remove bulb.

Insert new bulb (seating properly in cutouts of bulb

socket), mount clamping ring. Reinstall and push

electrical connector on securely. Reinstall cover (3).BiXenon D2S 35 W

(optional; Canada only standard on ML 500)

Parking, standing, side marker and turn signal lamp

115 7 N A ( 3 2 / 3 c p b u l b )

Open hood.

Twist bulb socket (5) counterclockwise and pull out.

Push bulb into socket, turn counterclockwise and

remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb socket.

Wa r n i n g !

Because of high voltage in BiXenon lamps, it is

dangerous to replace the bulb or repair the lamp

and its components. We recommend that you have

such work done by a qualified technician.

Page 289 of 342

286 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

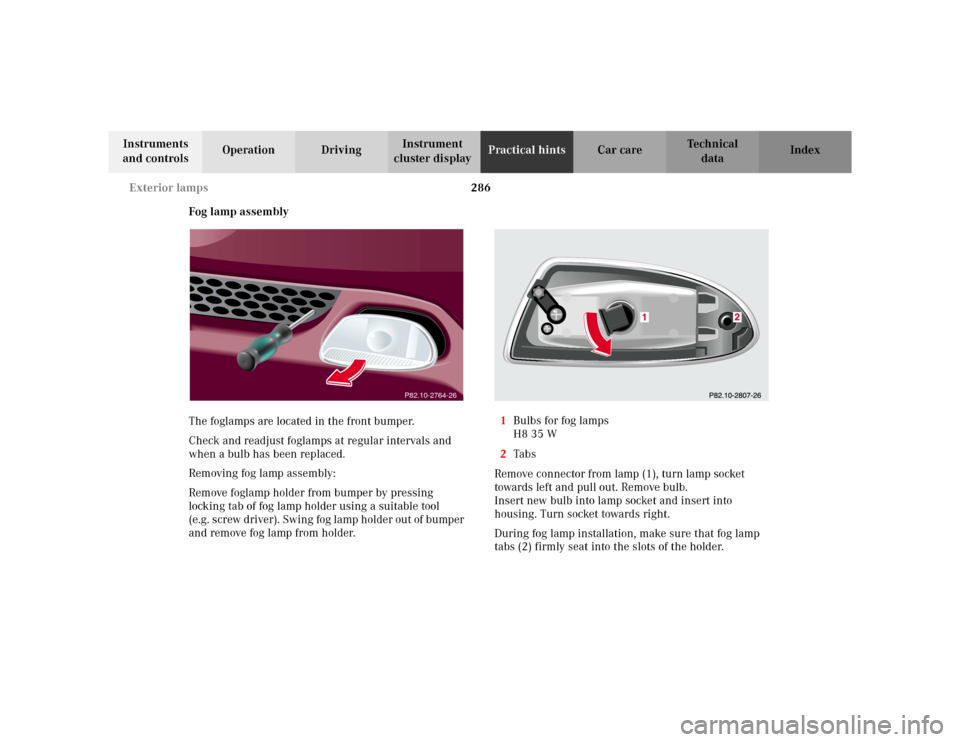

Fog lamp assembly

The foglamps are located in the front bumper.

Check and readjust foglamps at regular intervals and

when a bulb has been replaced.

Removing fog lamp assembly:

Remove foglamp holder from bumper by pressing

locking tab of fog lamp holder using a suitable tool

(e.g. screw driver). Swing fog lamp holder out of bumper

and remove fog lamp from holder.1Bulbs for fog lamps

H8 35 W

2Ta b s

Remove connector from lamp (1), turn lamp socket

towards left and pull out. Remove bulb.

Insert new bulb into lamp socket and insert into

housing. Turn socket towards right.

During fog lamp installation, make sure that fog lamp

tabs (2) firmly seat into the slots of the holder.

P82.10-2764-26

Page 290 of 342

![MERCEDES-BENZ ML320 2002 W163 Owners Manual 287 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Taillamp assemblies

1Stop lamp (1073 [32 cp bulb])

2Backup la MERCEDES-BENZ ML320 2002 W163 Owners Manual 287 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Taillamp assemblies

1Stop lamp (1073 [32 cp bulb])

2Backup la](/img/4/3367/w960_3367-289.png)

287 Exterior lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Taillamp assemblies

1Stop lamp (1073 [32 cp bulb])

2Backup lamp (1073 [32 cp bulb])

3Turn signal lamp (P Y 21 W bulb)

4Tail, parking, standing lamp, driver’s side rear fog

lamp (P 21 / 4 W bulb)

5Side marker lamp W 5 WOpen liftgate.

Remove screws (1).

Remove taillamp.

Note.

Spacers are used under the taillamp mounting tabs.

During reinstallation make sure that the spacers are

properly installed onto the screws.

P82.10-2755-26