MERCEDES-BENZ ML350 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML350, Model: MERCEDES-BENZ ML350 1997Pages: 4133, PDF Size: 88.89 MB

Page 2151 of 4133

X18.

Z52/11In passenger harness, in breakout to dash connector

X18.

Z52/14In passenger harness, in main harness breakout for

left side of vehicle.

Z52/15In passenger harness, near breakout to radio & SRS

control module.

Z53/1In passenger harness, in main harness breakout for

left side of vehicle.

Z53/2In passenger harness, in main harness breakout for

left side of vehicle.

Z53/4In passenger harness, near breakout to trailer

connector X52.

Z53/5In passenger harness, in main harness breakout for

right side of vehicle.

Z53/6In passenger harness, near breakout to trailer

connector X52.

Z53/7In passenger harness, near breakout to dash

connector X18.

Z53/8In passenger harness, in main harness breakout for

right side of vehicle.

Z53/9In passenger harness, under center console in plastic

harness channel.

Z53/16Under right front seat.

Z53/17In passenger harness, in main harness breakout for

right side of vehicle.

Z53/18In passenger harness, in E-box.

Z53/20Under front of center console.

Z53/21In passenger harness, near breakout to dash

connector X18.

Z53/23In passenger harness, in breakout to ABS module.

Z53/24In passenger harness, in breakout to ABS module.

Z54/1In headliner harness, in breakout for right sun visor

connector.

Z54/2In headliner harness, in breakout for right sun visor

connector.

Z54/3In headliner harness, in breakout for rear dome

light.

Z54/7In headliner harness, near breakout to left sun visor

connector.

Z54/8In headliner harness, near breakout to left sun visor

connector.

Z54/9In headliner harness, in breakout for W7.

2001 Mercedes-Benz ML320

2001 MERCEDES-BENZ ML320 & ML430

me

Saturday, October 02, 2010 3:21:17 PMPage 11 © 2006 Mitchell Repair Information Company, LLC.

Page 2152 of 4133

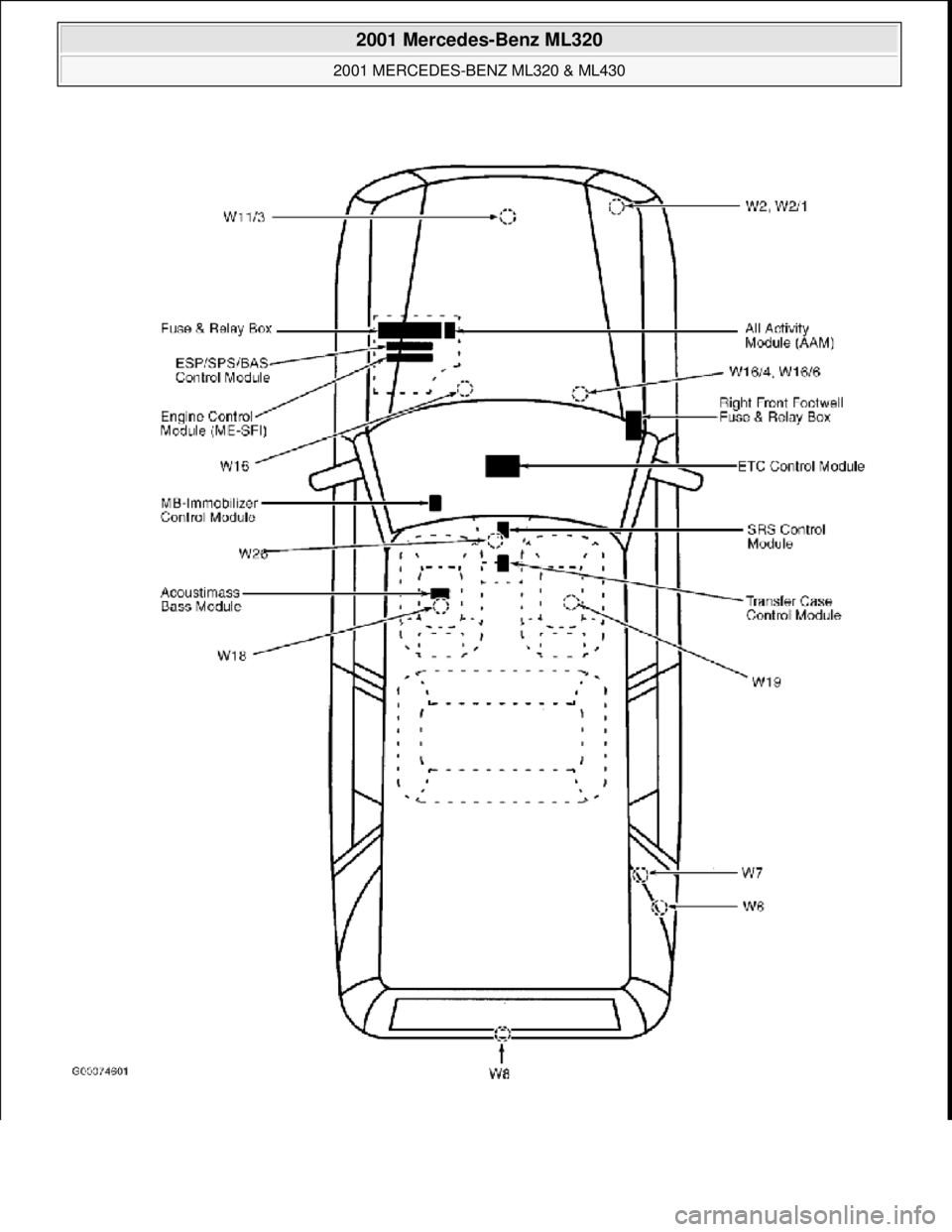

COMPONENT LOCATION GRAPHICS

Z54/10In headliner harness, in breakout for W7.

Z55/1In tailgate harness, near breakout to tailgate CL

actuating motor, rear wiper motor & license plate

lights.

Z56/1Behind left headlight.

Z56/2Behind left headlight.

Z56/4Behind left headlight.

Z56/5Behind left headlight.

Z56/6Behind left headlight.

Z56/7In breakout to fanfare horns.

Z57/1Behind right headlight.

Z57/2In E-box.

Z57/3In right engine harness, near breakout to wiper

motor.

Z57/7In E-box.

Z58/1In trailer harness.

Z58/8In trailer harness.

Z59/1In door mounted spare tire harness.

Z59/2In door mounted spare tire harness.

Z59/3In left/right door harness.

Z59/4In left/right rear door harness.

Z60/4In foglight harness.

Z60/5In foglight harness.

Z61In dash harness, near breakout to parking brake

switch.

Z61/5Under center console, near breakout for lower

control field control module connector C3.

Z61/6Under center console, near breakout for lower

control field control module connector C3.

Z87/17Behind radio.

Z87/18Behind radio.

Z99/6In motor harness, in E-box.

Z99/7In motor harness, in E-box.

NOTE: Figures may show multiple component locations. Refer to appropriate table for

proper figure references.

2001 Mercedes-Benz ML320

2001 MERCEDES-BENZ ML320 & ML430

me

Saturday, October 02, 2010 3:21:17 PMPage 12 © 2006 Mitchell Repair Information Company, LLC.

Page 2153 of 4133

2001 Mercedes-Benz ML320

2001 MERCEDES-BENZ ML320 & ML430

me

Saturday, October 02, 2010 3:21:17 PMPage 13 © 2006 Mitchell Repair Information Company, LLC.

Page 2154 of 4133

Fig. 1: Plan View Of Vehicle

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

2001 Mercedes-Benz ML320

2001 MERCEDES-BENZ ML320 & ML430

me

Saturday, October 02, 2010 3:21:17 PMPage 14 © 2006 Mitchell Repair Information Company, LLC.

Page 2155 of 4133

1998-2005 ENGINE

Electrical System - Engine - 163 Chassis

GENERAL INFORMATION

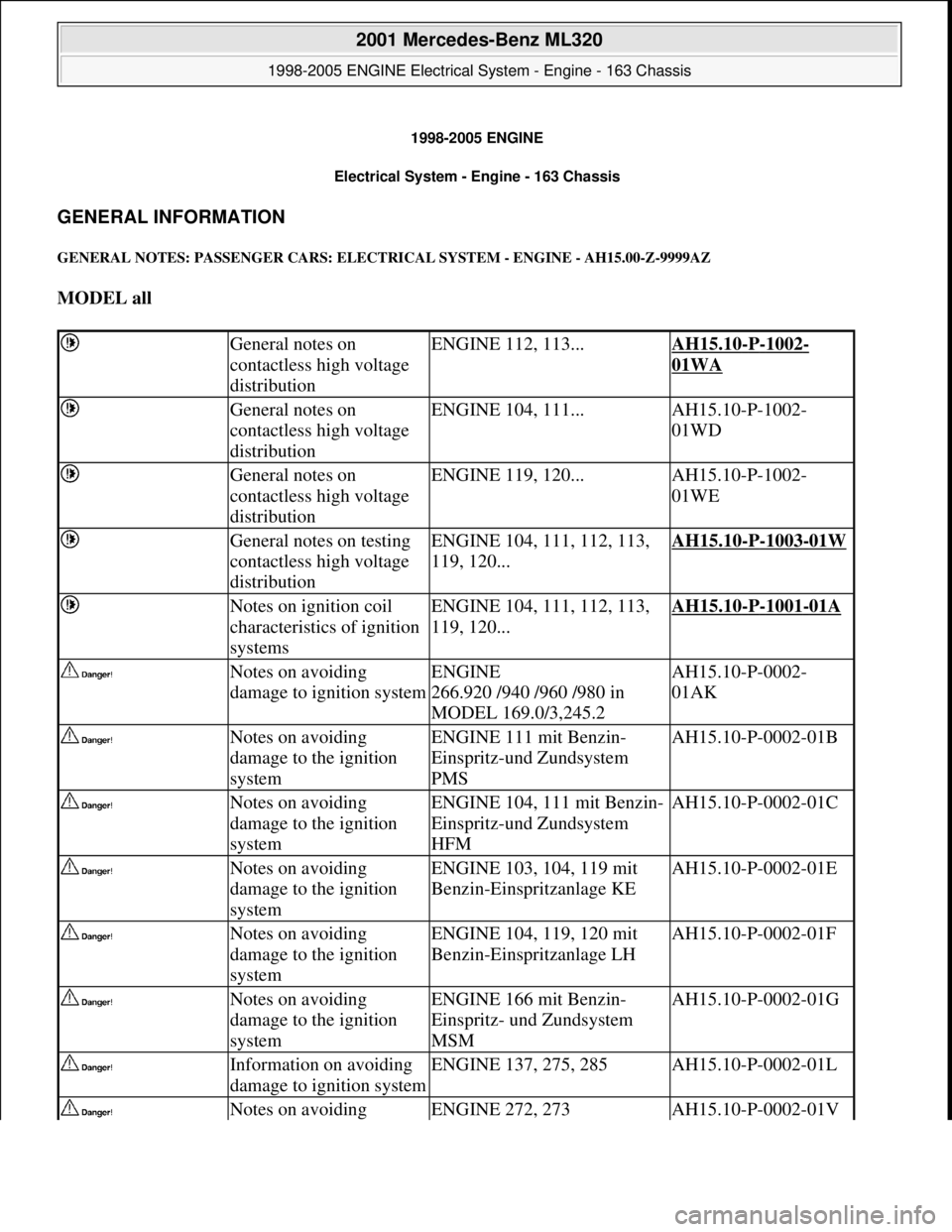

GENERAL NOTES: PASSENGER CARS: ELECTRICAL SYSTEM - ENGINE - AH15.00-Z-9999AZ

MODEL all

General notes on

contactless high voltage

distributionENGINE 112, 113...AH15.10-P-1002-

01WA

General notes on

contactless high voltage

distributionENGINE 104, 111...AH15.10-P-1002-

01WD

General notes on

contactless high voltage

distributionENGINE 119, 120...AH15.10-P-1002-

01WE

General notes on testing

contactless high voltage

distributionENGINE 104, 111, 112, 113,

119, 120...AH15.10-P-1003-01W

Notes on ignition coil

characteristics of ignition

systemsENGINE 104, 111, 112, 113,

119, 120...AH15.10-P-1001-01A

Notes on avoiding

damage to ignition systemENGINE

266.920 /940 /960 /980 in

MODEL 169.0/3,245.2AH15.10-P-0002-

01AK

Notes on avoiding

damage to the ignition

systemENGINE 111 mit Benzin-

Einspritz-und Zundsystem

PMSAH15.10-P-0002-01B

Notes on avoiding

damage to the ignition

systemENGINE 104, 111 mit Benzin-

Einspritz-und Zundsystem

HFMAH15.10-P-0002-01C

Notes on avoiding

damage to the ignition

systemENGINE 103, 104, 119 mit

Benzin-Einspritzanlage KEAH15.10-P-0002-01E

Notes on avoiding

damage to the ignition

systemENGINE 104, 119, 120 mit

Benzin-Einspritzanlage LHAH15.10-P-0002-01F

Notes on avoiding

damage to the ignition

systemENGINE 166 mit Benzin-

Einspritz- und Zundsystem

MSMAH15.10-P-0002-01G

Information on avoiding

damage to ignition systemENGINE 137, 275, 285AH15.10-P-0002-01L

Notes on avoiding ENGINE 272, 273AH15.10-P-0002-01V

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

me

Saturday, October 02, 2010 3:18:57 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

Page 2156 of 4133

NOTES ON AVOIDING DAMAGE TO IGNITION SYSTEM - AH15.10-P-0002-01D

Engine 104, 111, 112, 113, 119, 120, 156, 271

To avoid damage to control unit connect and disconnect the two connectors on control unit only when

ignition is switched off.

Terminal 1 of ignition coils must not be short-circuited to GND, e.g. as anti-theft protection.

Install only original ignition system components.

Do not operate ignition system at starting speed unless all of the ignition cables are connected.

No tests such as holding ignition cable 4 at a distance to GND, unplugging a spark plug connector or

pulling cable 4 out of the ignition coils, may be performed at starting speed or when the engine is

running.

Every high voltage circuit must be loaded with at least 2 kohms (spark plug connector).

If it is necessary to test the ignition spark when providing roadside assistance, this must only be done with

a spark plug at a cylinder ignition cable. Ensure that the spark plug has good contact to ground.

Before working at cranking speed, e.g. checking compression pressure, switch off ignition and disconnect

connector "2" from control unit.

Engine 120 has two fuel injection and ignition systems.

Use of testers

Only connect and disconnect secondary measuring sensor to corresponding ignition cables when vertical

engine and ignition are switched off.

If the shot-circuit protection is operated (cylinder comparison) and the engine stays upright, it is not

possible to conduct the test with this test instrument.

Do not connect test lamp to ignition coil terminals 1 and 15.

NOTES ON IGNITION COIL CHARACTERISTICS OF IGNITION SYSTEMS - AH15.10-P-1001-01A

Engine 104, 111, 112, 113, 119, 120

In the case of the twin-spark ignition coil with kV pickup in ignition systems ME-SFI 2.1 and HFM-SFI, no

measurement facilit

y exists at the ignition coil using the kV pickup although a kV pickup is fitted. It is only

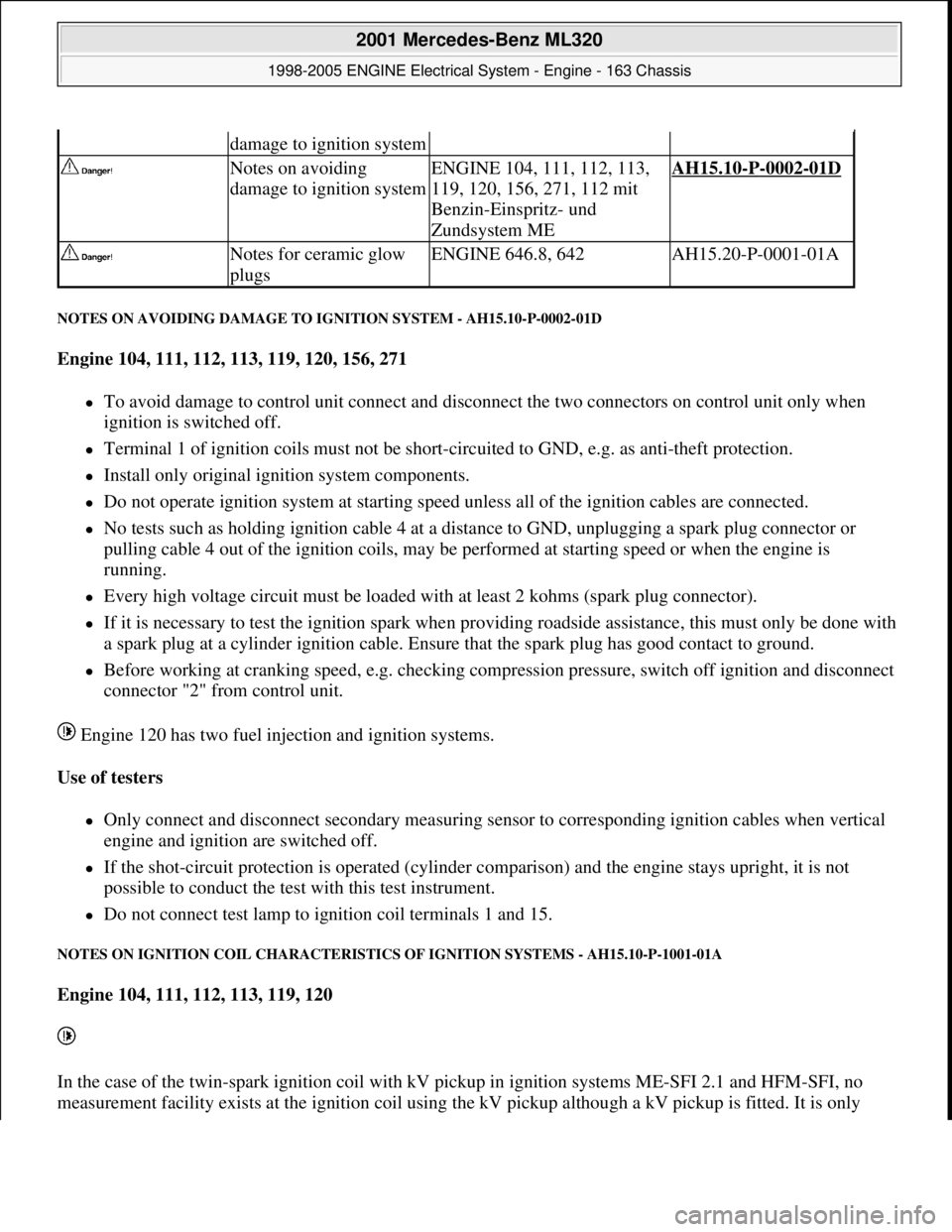

damage to ignition system

Notes on avoiding

damage to ignition systemENGINE 104, 111, 112, 113,

119, 120, 156, 271, 112 mit

Benzin-Einspritz- und

Zundsystem MEAH15.10-P-0002-01D

Notes for ceramic glow

plugsENGINE 646.8, 642AH15.20-P-0001-01A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 2 © 2006 Mitchell Repair Information Company, LLC.

Page 2157 of 4133

possible to test the primary ignition circuit with adapter cable A.

Ignition coil characteristics of ignition systems

EngineModelHFM-SFIME-SFIPECTwin-spark

i

gnition coil

without kV

pickup

Twin-spark

i

gnition coil

with kV

pickup

Single-

spark

i

gnition coil

with kV

pickup

104129 up to 05/96X X

104129 as of 06/96 2.1 X

104140 up to 05/96X X

104140 as of 06/96 2.1 X

104202 up to 07/96X X

104202 as of 08/96 2.1 X

104210X X

104210 up

to 05/96X X

104210 as

of 06/96 2.1 X

111163X X

111170.435X X

111170.445 2.1 X

111170.447 2.1 X

111202.018/020 up

to 07/96 XX

111202.018/020 as

of 08/96X X

111202.025 up to

07/96X X

111202.025 as of

08/96 2.1 X

111202.022 up to

07/96X X

111202.023 as of

08/96X X

111202.023 as of

08/96 2.1 X

111202.024 up to

07/96X X

111202.024 as of

08/96 2.1 X

111210 up to 05/96X X

111210 as of 06/96X X

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 3 © 2006 Mitchell Repair Information Company, LLC.

Page 2158 of 4133

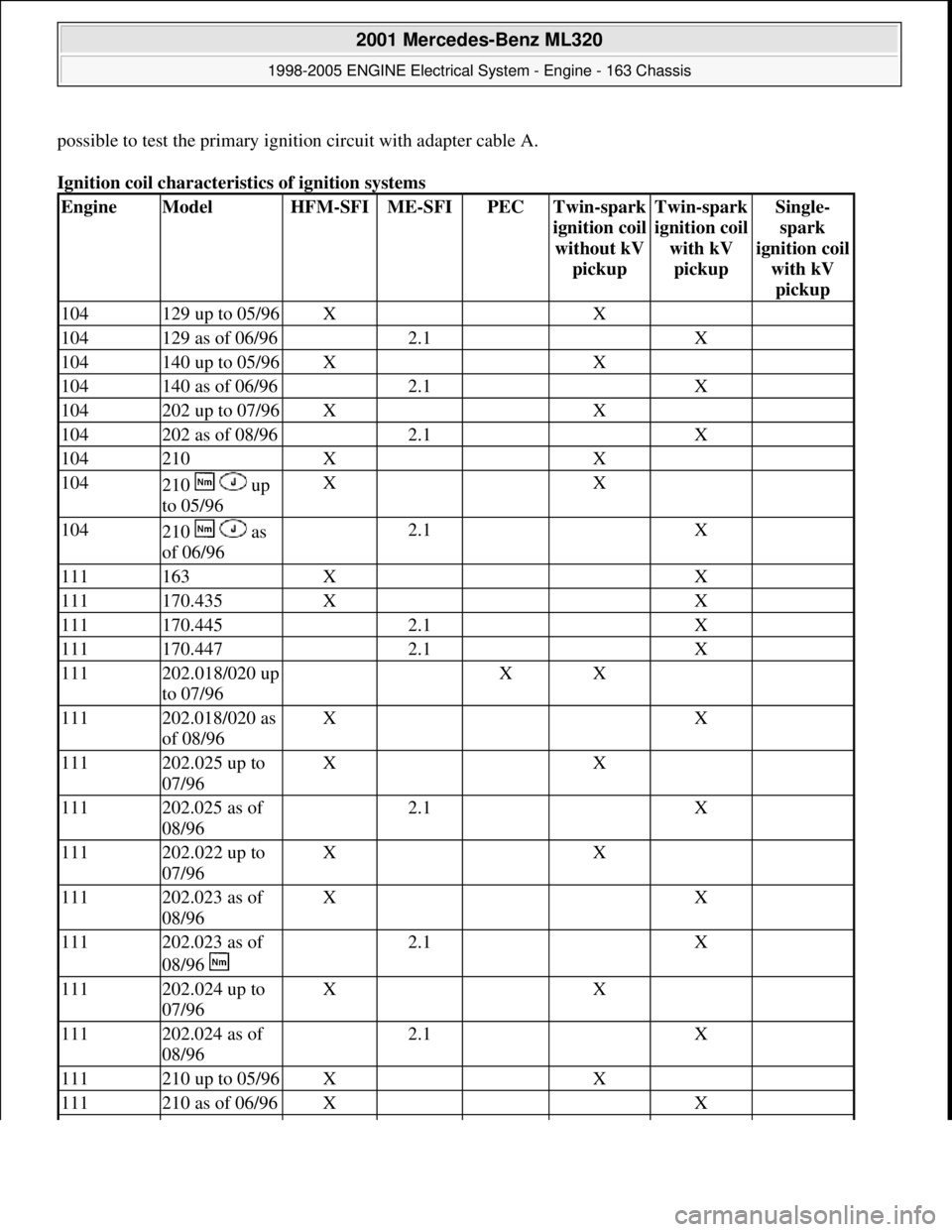

GENERAL NOTES ON CONTACTLESS HIGH VOLTAGE DISTRIBUTION - AH15.10-P-1002-01WA

Engine 112, 113 with ME-SFI fuel injection and ignition system

The ignition system can be tested at the primary side and secondary side. It is only possible to test ignition

circuit a and ignition circuit b one after the other.

The ignition coils are fitted as standard with cast mounts for the secondary adapters (kV pickup C). The primary

i

gnition voltage curve can be plotted with a primary adapter cable (D).

112163 2.0 X

112202 2.0 X

112208 2.0 X

112210 2.0 X

112220 2.0 X

113163 2.0 X

113202 2.0 X

113208 2.0 X

113210 2.0 X

113220 2.0 X

119.982129 1.0 X

119.980140 1.0 X

119.981140 1.0 X

119210 1.0 X

120.983129 1.0 X

120.982140 1.0 X

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 4 © 2006 Mitchell Repair Information Company, LLC.

Page 2159 of 4133

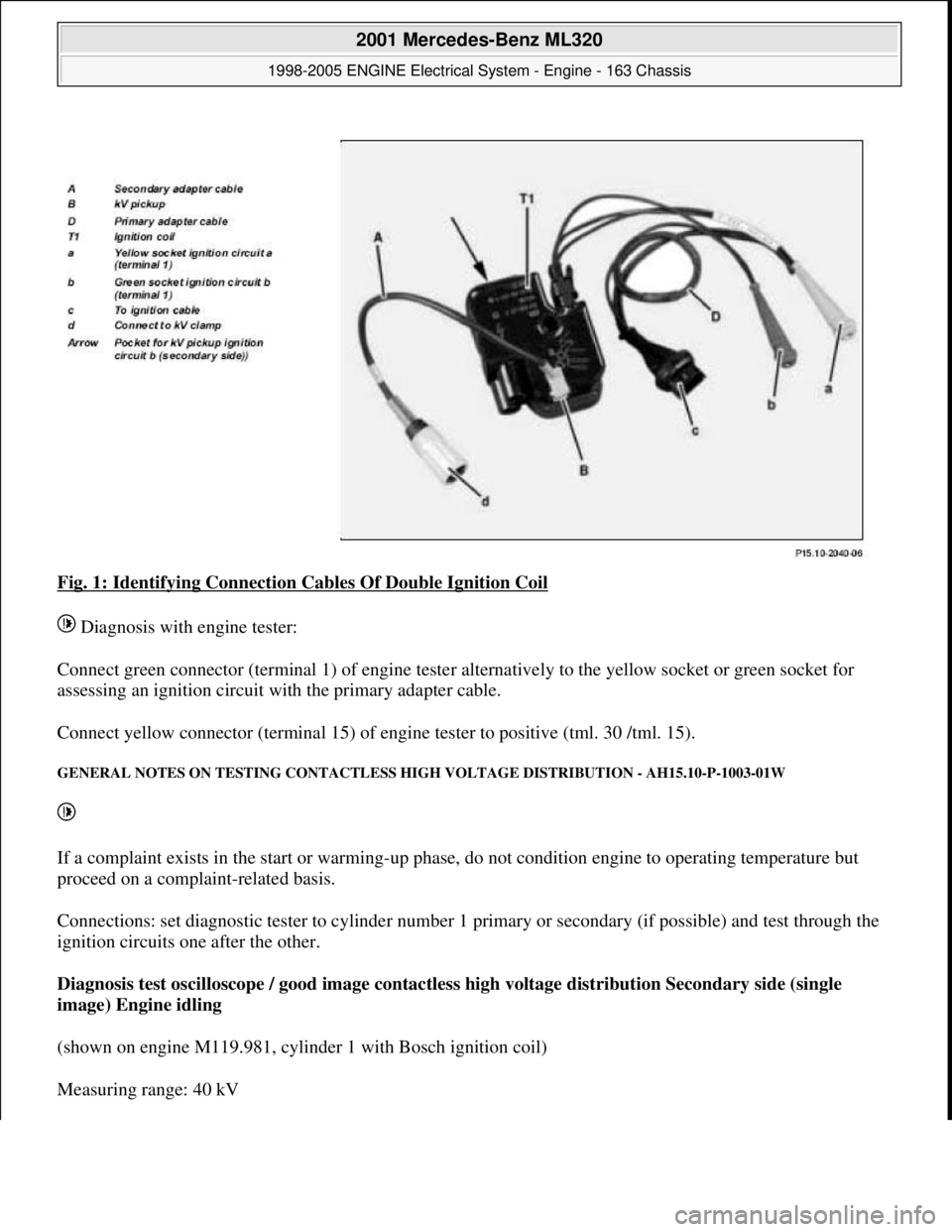

Fig. 1: Identifying Connection Cables Of Double Ignition Coil

Diagnosis with engine tester:

Connect green connector (terminal 1) of engine tester alternatively to the yellow socket or green socket for

assessing an ignition circuit with the primary adapter cable.

Connect yellow connector (terminal 15) of engine tester to positive (tml. 30 /tml. 15).

GENERAL NOTES ON TESTING CONTACTLESS HIGH VOLTAGE DISTRIBUTION - AH15.10-P-1003-01W

If a complaint exists in the start or warming-up phase, do not condition engine to operating temperature but

proceed on a complaint-related basis.

Connections: set diagnostic tester to cylinder number 1 primary or secondary (if possible) and test through the

ignition circuits one after the other.

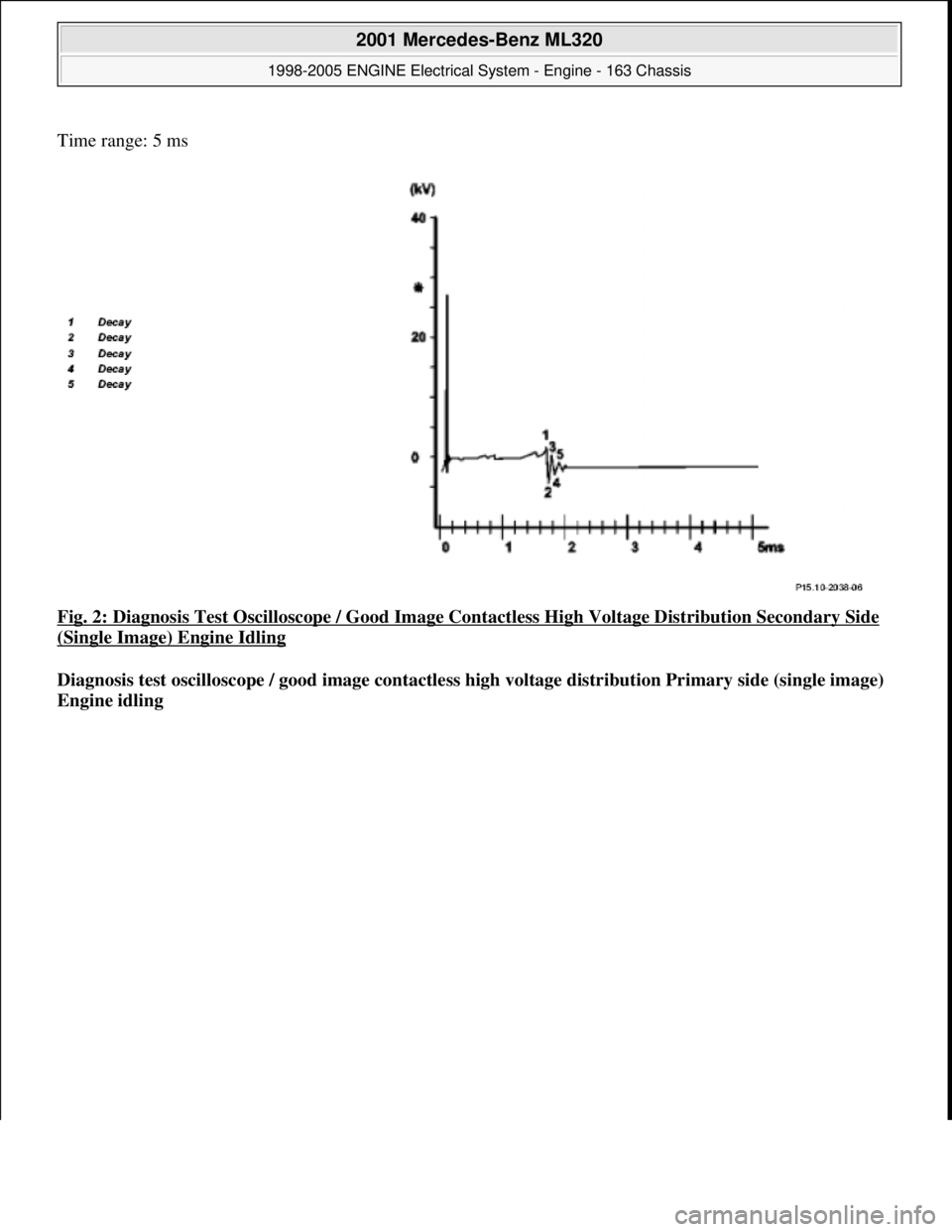

Diagnosis test oscilloscope / good image contactless high voltage distribution Secondary side (single

image) Engine idling

(shown on engine M119.981, cylinder 1 with Bosch ignition coil)

Measurin

g range: 40 kV

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 5 © 2006 Mitchell Repair Information Company, LLC.

Page 2160 of 4133

Time range: 5 ms

Fig. 2: Diagnosis Test Oscilloscope / Good Image Contactless High Voltage Distribution Secondary Side

(Single Image) Engine Idling

Diagnosis test oscilloscope / good image contactless high voltage distribution Primary side (single image)

Engine idling

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 6 © 2006 Mitchell Repair Information Company, LLC.