MERCEDES-BENZ ML350 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML350, Model: MERCEDES-BENZ ML350 1997Pages: 4133, PDF Size: 88.89 MB

Page 3191 of 4133

Valve seal not okay :

#

3

Remove/install/replace valve seal.

AR05.30-P-3500B

Cause 6:

Remedy 6:

00 001 70

1.5 mm hole missing on individual right

cylinder head covers at connection to

crankcase ventilation.

1

Check cylinder head cover

Up to production 06/1999.

Crankcase ventilation out of order, engine can

sludge up and consume oil as a result

Cylinder head cover not okay:

#

2

Remove/install/replace cylinder head

cover.

ENGINE

112

Air cleaner positioned on engine

side.

ENGINE

113

Air cleaner positioned on engine

side.

AR01.20-P-5014BV

ENGINE

112

Air cleaner positioned on engine side

ENGINE

113

Air cleaner positioned on engine side

AR01.20-P-5014B

Cause 7:

Remedy 7:

00 001 70

Engine oil sludging due to excessively long

engine oil change intervals

Service information: Oil sludge

SI18.00-P-0010A

If the service interval according to

ASSYST is exceeded, the engine oil sludges

up sooner or later depending on the oil

quality, type of operation and operating time.

Engine consumes oil.

See Service Information.

1

Print out ASSYST printout.

2

Check oil change intervals

3

Inform vehicle owner.

4

Remove/install/replace piston rings.

AR03.10-P-7311BV

Disassemble and clean sludged engines

completely because dirty oil usually gets into

clean-oil side due to clogged oil filter.

Cause 8:

Remedy 8:

00 001 70

Piston rings sticky or have coke deposits from

engine oils (e.g. API-S in USA) in connection

with regionally poor fuel quality.

Always use engine oils according to

Specifications for Operating Fluids 229.3, do

not add special additives to engine oil and fuel

BB00.40-P-0229-03A

1

Remove/install/replace piston rings.

AR03.10-P-7311BV

Cause 9:

Remedy 9:

00 001 70

Piston ring wear due to excessive

contamination/dust (model 163) through air

intake system.

1

Remove/install/replace gaskets on air

intake line and distribution element of

partial load ventilation.

e.g. due to incorrect assembly after

workshop visit or embrittlement of gaskets

The distribution element with optimized

material will be available as of 11/ 2000 as a

standard feature.

2

Remove/install/replace intake module.

Exterior oil loss, e.g. due to cast iron

porosity on left side of crankcase in area of

engine support is not considered to be oil

consumption

In the event of a customer complaint

regarding the engine oil consumption, always

determine the oil consumption definitely

because the oil indicator lamp can come on

due to other causes (e.g. defective oil sensor).

Commercially available tools

(see Workshop Equipment Manual)

Number

Designation

Make (e. g.)

Order number

WH58.30-Z-1009-05A

Flexible inspection light

Scope of supply 1 (complete unit):

-glass fiber optical fiber

-light projector

-230 V, storage case

-operating instructions

-graphics protocol

Richard Wolf GmbH

Pforzheimerstr. 32

D-75438 Knittlingen

Karl Storz GmbH

Mittelstr. 8

D-78532 Tuttlingen

1.00565.00

80902

WH58.30-Z-1010-05A

Flexible inspection light

Scope of delivery 2 (for workshops which already have an approved

Wolf or Storz inspection light):

-storage case

-operating instructions

-pictures protocol

Richard Wolf GmbH

Pforzheimerstr. 32

D-75438 Knittlingen

Karl Storz GmbH

Mittelstr. 8

D-78532 Tuttlingen

7.05065.00

K03506AJ

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3192 of 4133

WH58.30-Z-1027-05A

Cylinder inspection light

Motoskop MB (cold light) with 560 mm and 200 mm lens probes

Karl Storz GmbH

D-78512 Tuttlingen

80 900

Parts ordering notes

Part no.

Designation

Quantity

112 141 01 80

Gaskets

As required

112 141 02 80

Gaskets

As required

112 018 02 09

Distributor fitting

As required

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 3193 of 4133

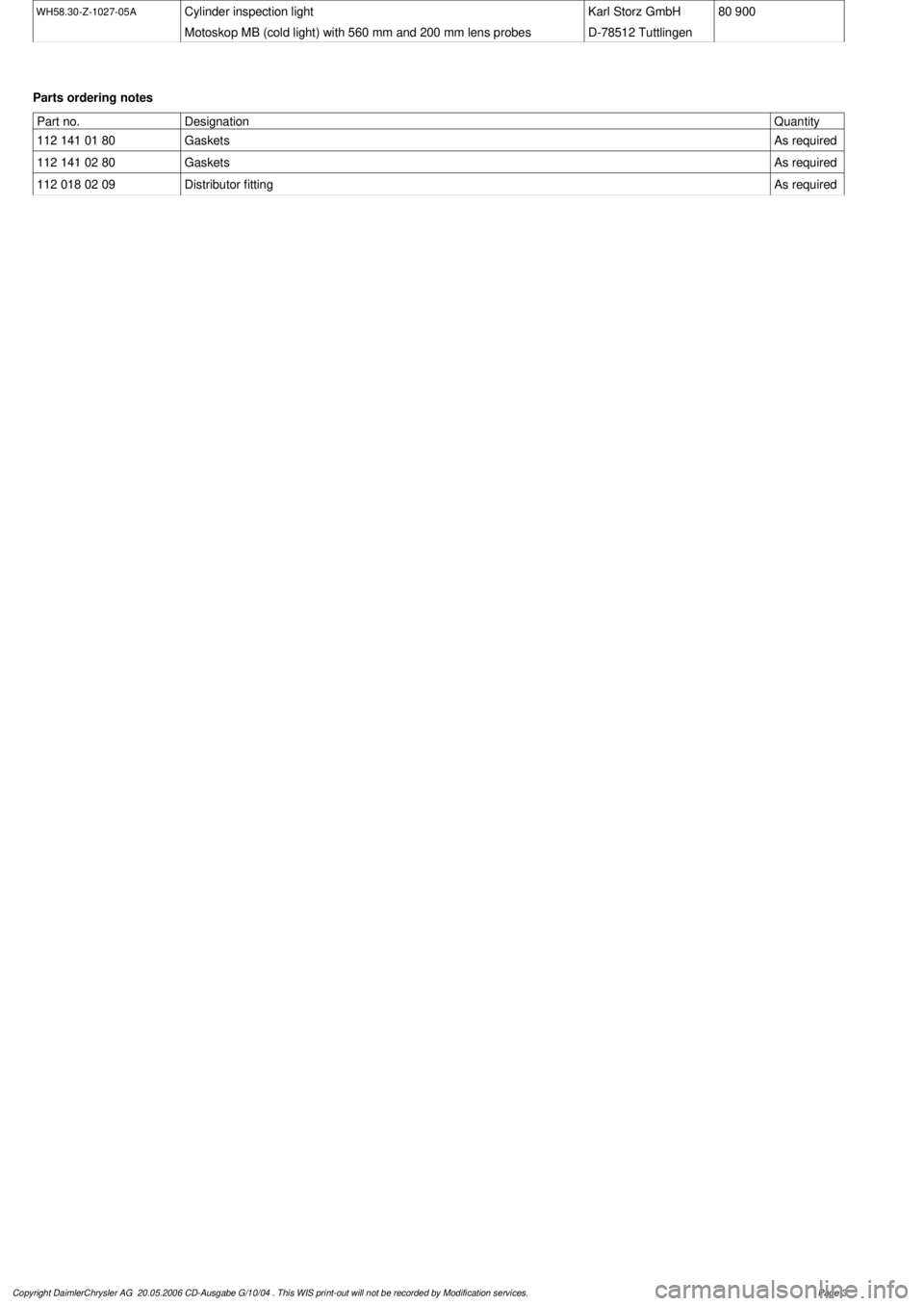

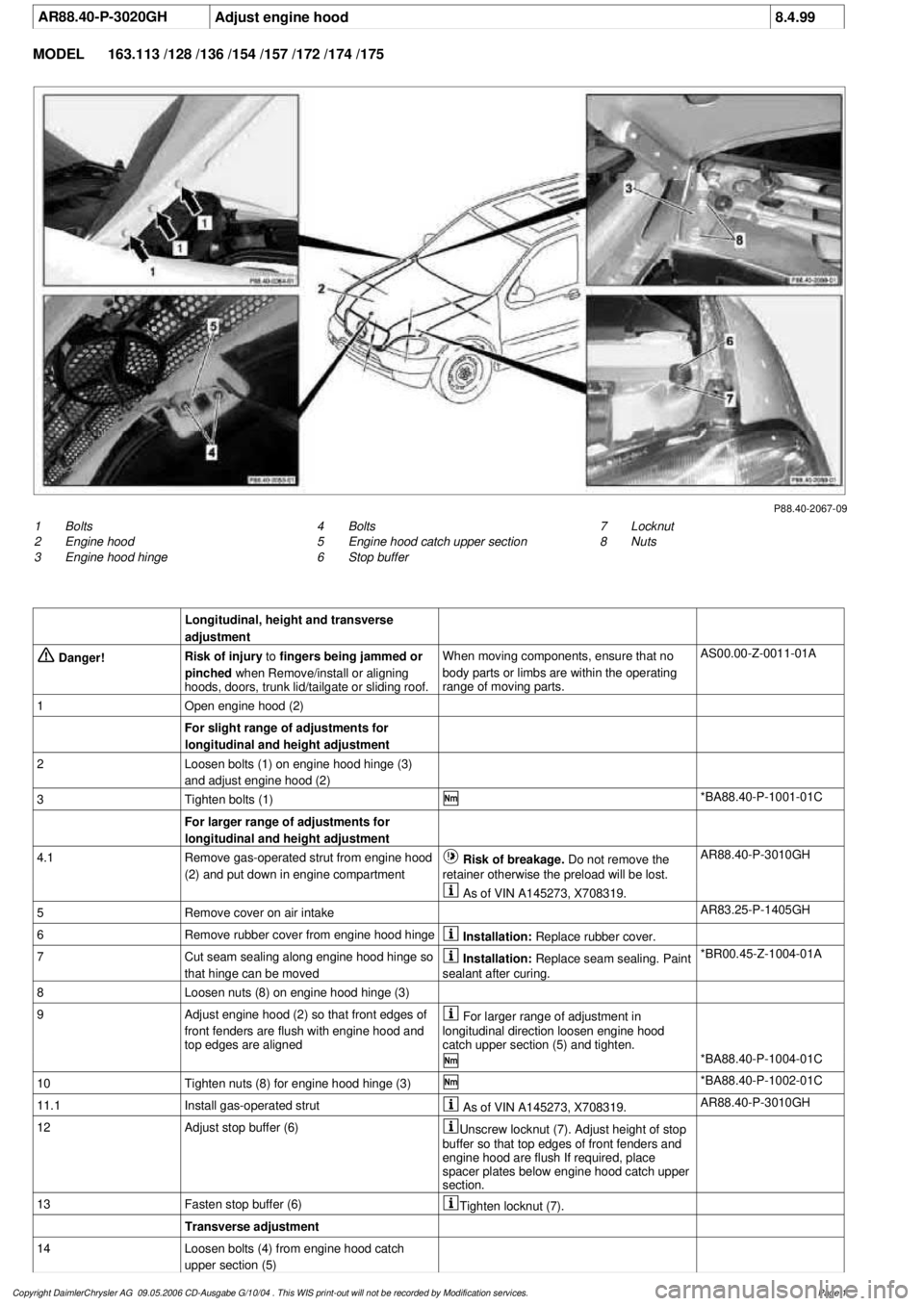

AR88.40-P-3020GH

Adjust engine hood

8.4.99

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P88.40-2067-09

1

Bolts

2

Engine hood

3

Engine hood hinge

7

Locknut

8

Nuts

4

Bolts

5

Engine hood catch upper section

6

Stop buffer

Longitudinal, height and transverse

adjustment

Danger!

Risk of injury

to

fingers being jammed or

pinched

when Remove/install or aligning

hoods, doors, trunk lid/tailgate or sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

1

Open engine hood (2)

For slight range of adjustments for

longitudinal and height adjustment

2

Loosen bolts (1) on engine hood hinge (3)

and adjust engine hood (2)

3

Tighten bolts (1)

*BA88.40-P-1001-01C

For larger range of adjustments for

longitudinal and height adjustment

4.1

Remove gas-operated strut from engine hood

(2) and put down in engine compartment

Risk of breakage. Do not remove the

retainer otherwise the preload will be lost.

AR88.40-P-3010GH

As of VIN A145273, X708319.

5

Remove cover on air intake

AR83.25-P-1405GH

6

Remove rubber cover from engine hood hinge

Installation:

Replace rubber cover.

7

Cut seam sealing along engine hood hinge so

that hinge can be moved

Installation:

Replace seam sealing. Paint

sealant after curing.

*BR00.45-Z-1004-01A

8

Loosen nuts (8) on engine hood hinge (3)

9

Adjust engine hood (2) so that front edges of

front fenders are flush with engine hood and

top edges are aligned

For larger range of adjustment in

longitudinal direction loosen engine hood

catch upper section (5) and tighten.

*BA88.40-P-1004-01C

10

Tighten nuts (8) for engine hood hinge (3)

*BA88.40-P-1002-01C

11.1

Install gas-operated strut

As of VIN A145273, X708319.

AR88.40-P-3010GH

12

Adjust stop buffer (6)

Unscrew locknut (7). Adjust height of stop

buffer so that top edges of front fenders and

engine hood are flush If required, place

spacer plates below engine hood catch upper

section.

13

Fasten stop buffer (6)

Tighten locknut (7).

Transverse adjustment

14

Loosen bolts (4) from engine hood catch

upper section (5)

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3194 of 4133

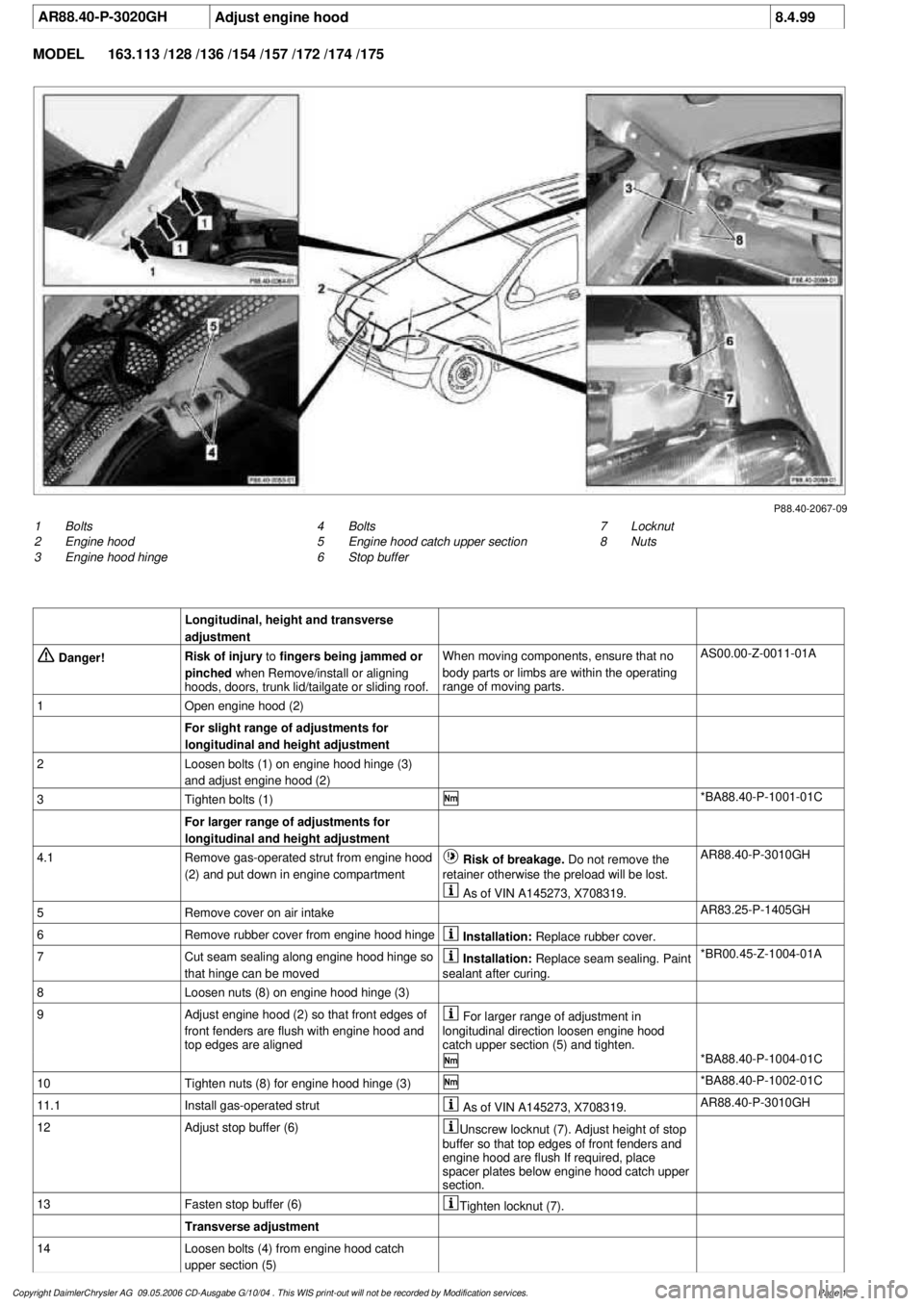

15

Adjust gap dimensions

Gap dimensions

*BE60.00-P-1001-01D

Feeler gage

*129589032100

16

Align engine hood catch upper section (5)

centered in longitudinal and transverse

direction to engine hood catch lower section

and tighten

*BA88.40-P-1004-01C

17

Ensure that engine hood catch catches

properly

For this purpose, close engine hood and

pull upward with a jerk.

18

Release engine hood and ensure that safety

hook catches on radiator crossmember

19

Close engine hood (2)

Test and adjustment values, gap dimensions at hoods, doors and covers

Number

Designation

Model 163

BE60.00-P-1001-01D

Gap

dimension

Engine hood to fender

Dimension "A"

mm

5.0 (

F

0.5)

Engine hood to headlamp

Dimension "R"

mm

5.0 (

F

0.5)

Engine hood to radiator grille

Dimension "O"

mm

5.0 (

F

0.5)

Radiator grill to headlamp

Dimension "N"

mm

-

Fig., see

AR60.00-P-0700-

01GH

Engine hood

Number

Designation

Model 163

BA88.40-P-1001-01C

Bolt, engine hood hinge on engine hood

Nm

10

BA88.40-P-1002-01C

Nut, engine hood hinge to body

Nm

18

BA88.40-P-1004-01C

Bolt, engine hood catch upper section to engine

hood

Nm

12

129 589 03 21 00

Feeler gage

Auxiliary repair materials

Number

Designation

Order number

BR00.45-Z-1004-01A

MB body sealant for sealing seams (suitable for painting)

001 989 63 20

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3195 of 4133

AR88.40-P-3020GH

Adjust engine hood

8.4.99

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P88.40-2067-09

1

Bolts

2

Engine hood

3

Engine hood hinge

7

Locknut

8

Nuts

4

Bolts

5

Engine hood catch upper section

6

Stop buffer

Longitudinal, height and transverse

adjustment

Danger!

Risk of injury

to

fingers being jammed or

pinched

when Remove/install or aligning

hoods, doors, trunk lid/tailgate or sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

1

Open engine hood (2)

For slight range of adjustments for

longitudinal and height adjustment

2

Loosen bolts (1) on engine hood hinge (3)

and adjust engine hood (2)

3

Tighten bolts (1)

*BA88.40-P-1001-01C

For larger range of adjustments for

longitudinal and height adjustment

4.1

Remove gas-operated strut from engine hood

(2) and put down in engine compartment

Risk of breakage. Do not remove the

retainer otherwise the preload will be lost.

AR88.40-P-3010GH

As of VIN A145273, X708319.

5

Remove cover on air intake

AR83.25-P-1405GH

6

Remove rubber cover from engine hood hinge

Installation:

Replace rubber cover.

7

Cut seam sealing along engine hood hinge so

that hinge can be moved

Installation:

Replace seam sealing. Paint

sealant after curing.

*BR00.45-Z-1004-01A

8

Loosen nuts (8) on engine hood hinge (3)

9

Adjust engine hood (2) so that front edges of

front fenders are flush with engine hood and

top edges are aligned

For larger range of adjustment in

longitudinal direction loosen engine hood

catch upper section (5) and tighten.

*BA88.40-P-1004-01C

10

Tighten nuts (8) for engine hood hinge (3)

*BA88.40-P-1002-01C

11.1

Install gas-operated strut

As of VIN A145273, X708319.

AR88.40-P-3010GH

12

Adjust stop buffer (6)

Unscrew locknut (7). Adjust height of stop

buffer so that top edges of front fenders and

engine hood are flush If required, place

spacer plates below engine hood catch upper

section.

13

Fasten stop buffer (6)

Tighten locknut (7).

Transverse adjustment

14

Loosen bolts (4) from engine hood catch

upper section (5)

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3196 of 4133

15

Adjust gap dimensions

Gap dimensions

*BE60.00-P-1001-01D

Feeler gage

*129589032100

16

Align engine hood catch upper section (5)

centered in longitudinal and transverse

direction to engine hood catch lower section

and tighten

*BA88.40-P-1004-01C

17

Ensure that engine hood catch catches

properly

For this purpose, close engine hood and

pull upward with a jerk.

18

Release engine hood and ensure that safety

hook catches on radiator crossmember

19

Close engine hood (2)

Test and adjustment values, gap dimensions at hoods, doors and covers

Number

Designation

Model 163

BE60.00-P-1001-01D

Gap

dimension

Engine hood to fender

Dimension "A"

mm

5.0 (

F

0.5)

Engine hood to headlamp

Dimension "R"

mm

5.0 (

F

0.5)

Engine hood to radiator grille

Dimension "O"

mm

5.0 (

F

0.5)

Radiator grill to headlamp

Dimension "N"

mm

-

Fig., see

AR60.00-P-0700-

01GH

Engine hood

Number

Designation

Model 163

BA88.40-P-1001-01C

Bolt, engine hood hinge on engine hood

Nm

10

BA88.40-P-1002-01C

Nut, engine hood hinge to body

Nm

18

BA88.40-P-1004-01C

Bolt, engine hood catch upper section to engine

hood

Nm

12

129 589 03 21 00

Feeler gage

Auxiliary repair materials

Number

Designation

Order number

BR00.45-Z-1004-01A

MB body sealant for sealing seams (suitable for painting)

001 989 63 20

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3197 of 4133

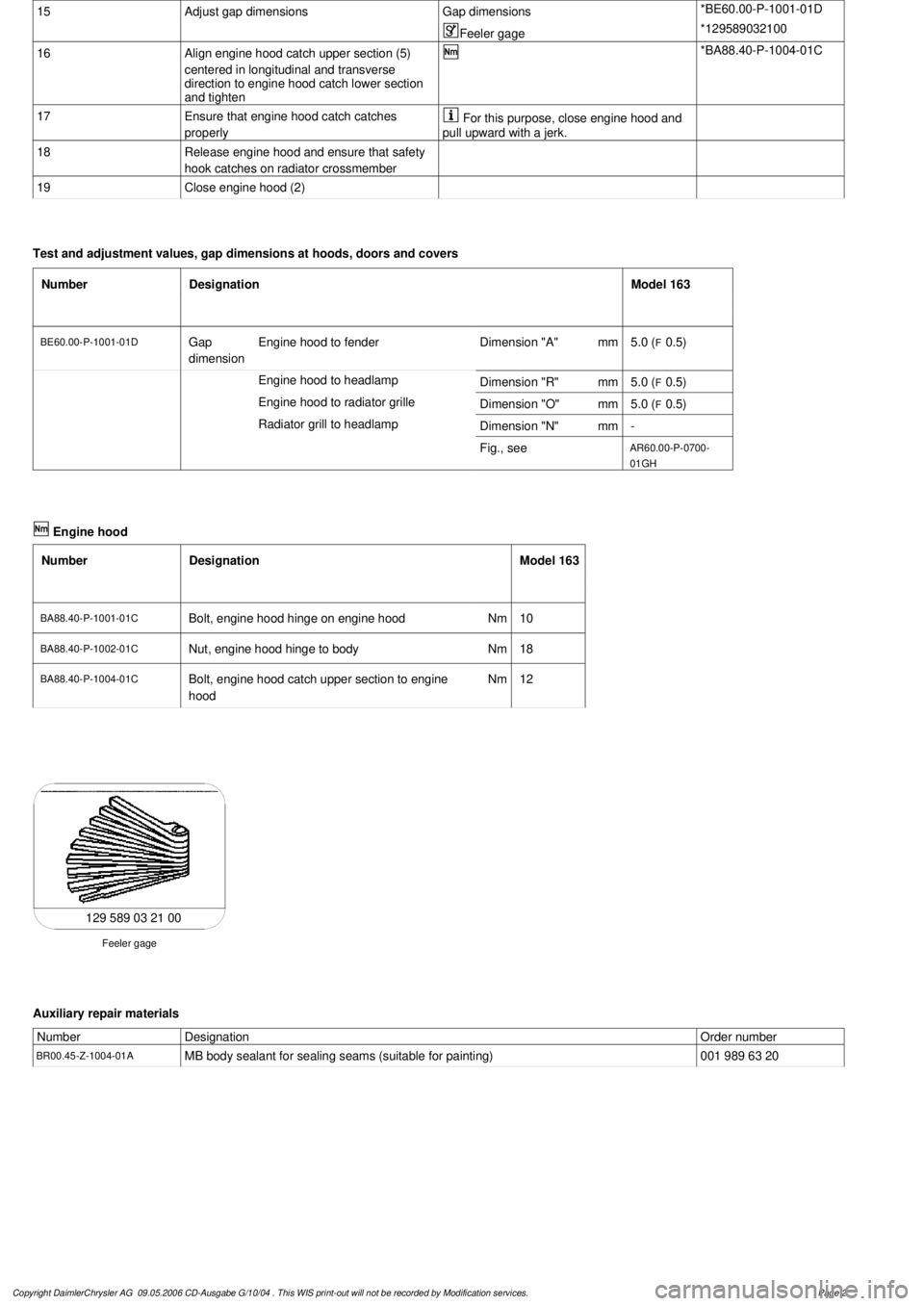

AR88.40-P-3100GH

Remove/install control cable for engine hood

5.5.00

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P88.40-2140-06

Illustrated up to VIN A145272, X708318

1

Clips

2

Rubber grommet

3

Engine hood control cable

Removing and installing

1

Open engine hood and raise to vertical position

Up to VIN A145272, X708318.

AR88.40-P-1000GH

As of VIN A145273, X708319.

AR88.40-P-1000GI

2.1

Remove upper frame cross member

Only up to VIN A145272, X708318

AR62.30-P-2300GH

2.2Remove engine hood lock

Only as of VIN A145273, X708319.

AR88.40-P-3200GI

3.1

Unhook engine hood control cable from clip at

bottom of radiator cross member

Only as of VIN A145273, X708319.

4

Remove cover from fuse and relay box

5 screws.

5

Unhook clips (1) from body

6

Remove left cover below instrument panel

Left hand drive vehicle.

AR68.10-P-1500GH

Vehicles with right-hand steering up to

VIN A145272, X708318.

AR68.10-P-1520GH

Vehicles with right-hand steering as of

VIN A145273, X708319.

AR68.10-P-1520GI

7

Remove paneling in left footwell

AR68.30-P-4010GH

8

Unhook engine hood control cable at side at

clip in footwell

9

Remove rubber grommet (2) from fuse and

relay box

10

Pull out engine hood control cable (3) through

firewall on engine side and remove

Installation:

Ensure that engine hood

control cable is routed cleanly along fuse and

relay box.

11

Install in the reverse order

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3198 of 4133

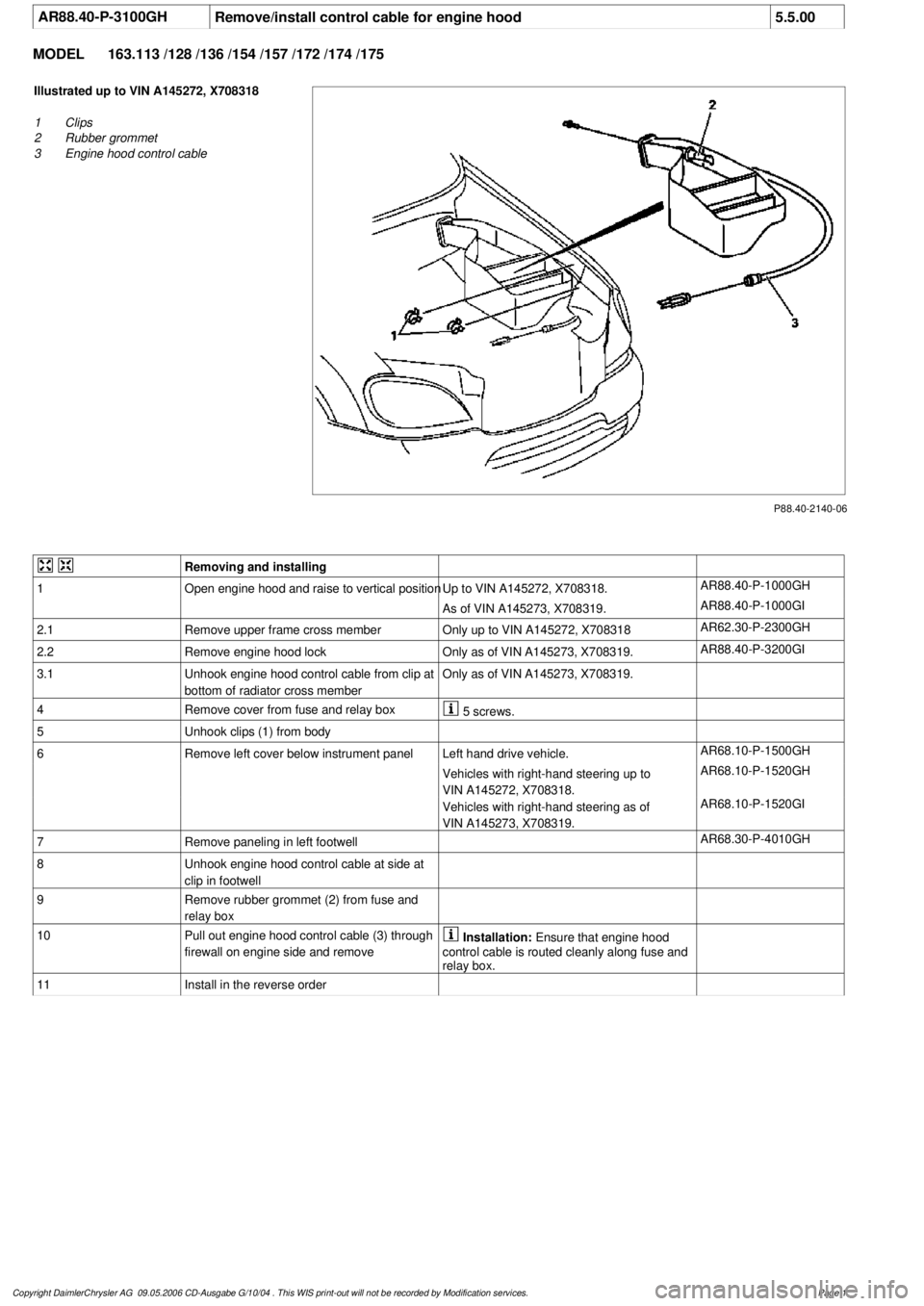

AR88.40-P-4050R

Remove/install Mercedes star

30.3.01

MODEL

163, 203.7, 215, 230.467 /474 /475 /476 /479

P88.40-2291-11

Shown on model 230

1

Mercedes star

2

Grommets

Remove/Install

1

Remove Mercedes star (1) from engine hood

upward with long wedge (1)

Protect engine hood around Mercedes

star (1) with adhesive tape to avoid damaging

paint.

Long wedge

*115589035900

2

Remove grommets (2)

Check grommets (2) and replace if

required.

3

Install in the reverse order

Long wedge

115 589 03 59 00

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3199 of 4133

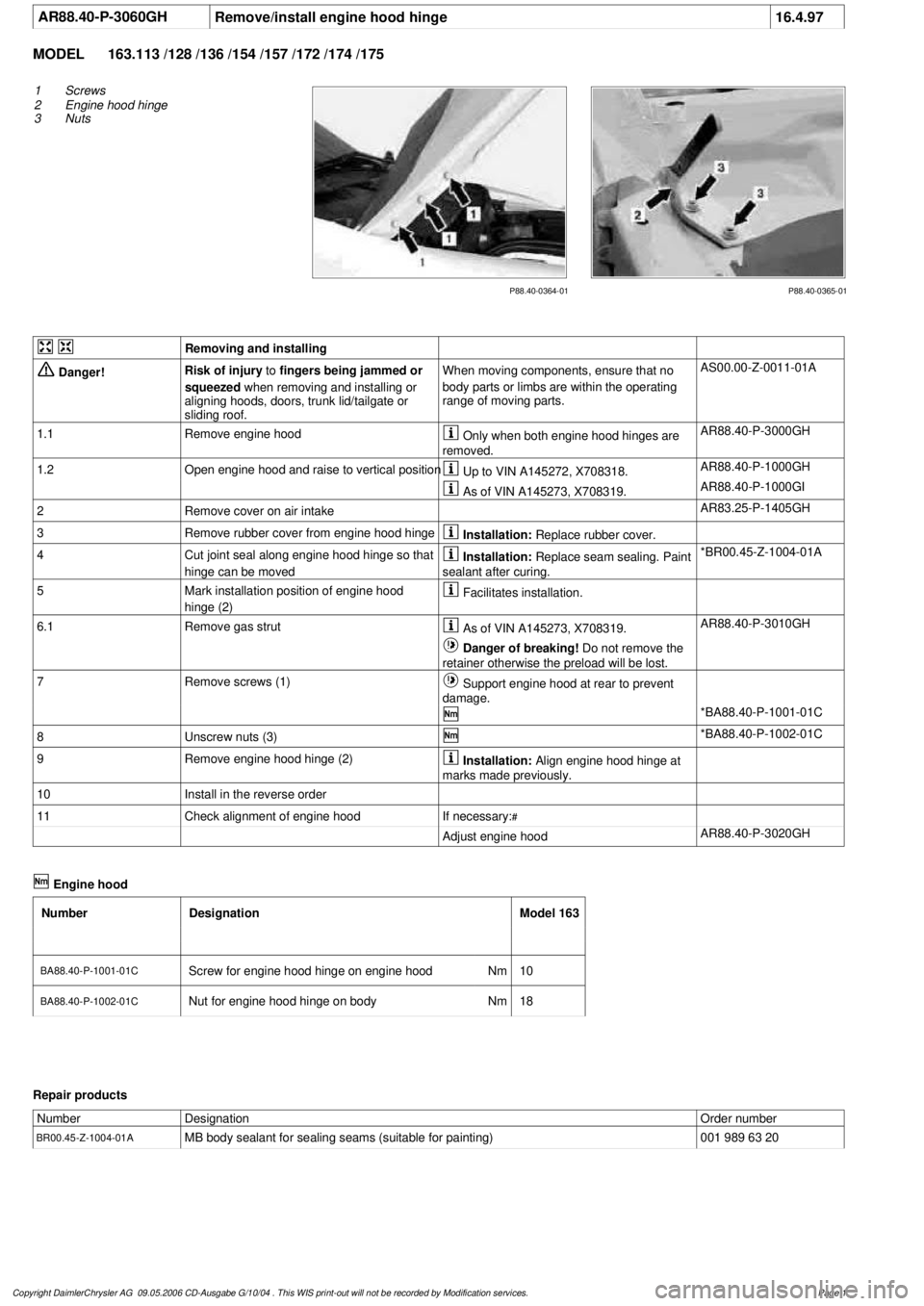

AR88.40-P-3060GH

Remove/install engine hood hinge

16.4.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P88.40-0365-01

P88.40-0364-01

1

Screws

2

Engine hood hinge

3

Nuts

Removing and installing

Danger!

Risk of injury

to

fingers being jammed or

squeezed

when removing and installing or

aligning hoods, doors, trunk lid/tailgate or

sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

1.1

Remove engine hood

Only when both engine hood hinges are

removed.

AR88.40-P-3000GH

1.2

Open engine hood and raise to vertical position

Up to VIN A145272, X708318.

AR88.40-P-1000GH

As of VIN A145273, X708319.

AR88.40-P-1000GI

2

Remove cover on air intake

AR83.25-P-1405GH

3

Remove rubber cover from engine hood hinge

Installation:

Replace rubber cover.

4

Cut joint seal along engine hood hinge so that

hinge can be moved

Installation:

Replace seam sealing. Paint

sealant after curing.

*BR00.45-Z-1004-01A

5

Mark installation position of engine hood

hinge (2)

Facilitates installation.

6.1

Remove gas strut

As of VIN A145273, X708319.

AR88.40-P-3010GH

Danger of breaking!

Do not remove the

retainer otherwise the preload will be lost.

7

Remove screws (1)

Support engine hood at rear to prevent

damage.

*BA88.40-P-1001-01C

8

Unscrew nuts (3)

*BA88.40-P-1002-01C

9

Remove engine hood hinge (2)

Installation:

Align engine hood hinge at

marks made previously.

10

Install in the reverse order

11

Check alignment of engine hood

If necessary:

#

Adjust engine hood

AR88.40-P-3020GH

Engine hood

Number

Designation

Model 163

BA88.40-P-1001-01C

Screw for engine hood hinge on engine hood

Nm

10

BA88.40-P-1002-01C

Nut for engine hood hinge on body

Nm

18

Repair products

Number

Designation

Order number

BR00.45-Z-1004-01A

MB body sealant for sealing seams (suitable for painting)

001 989 63 20

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3200 of 4133

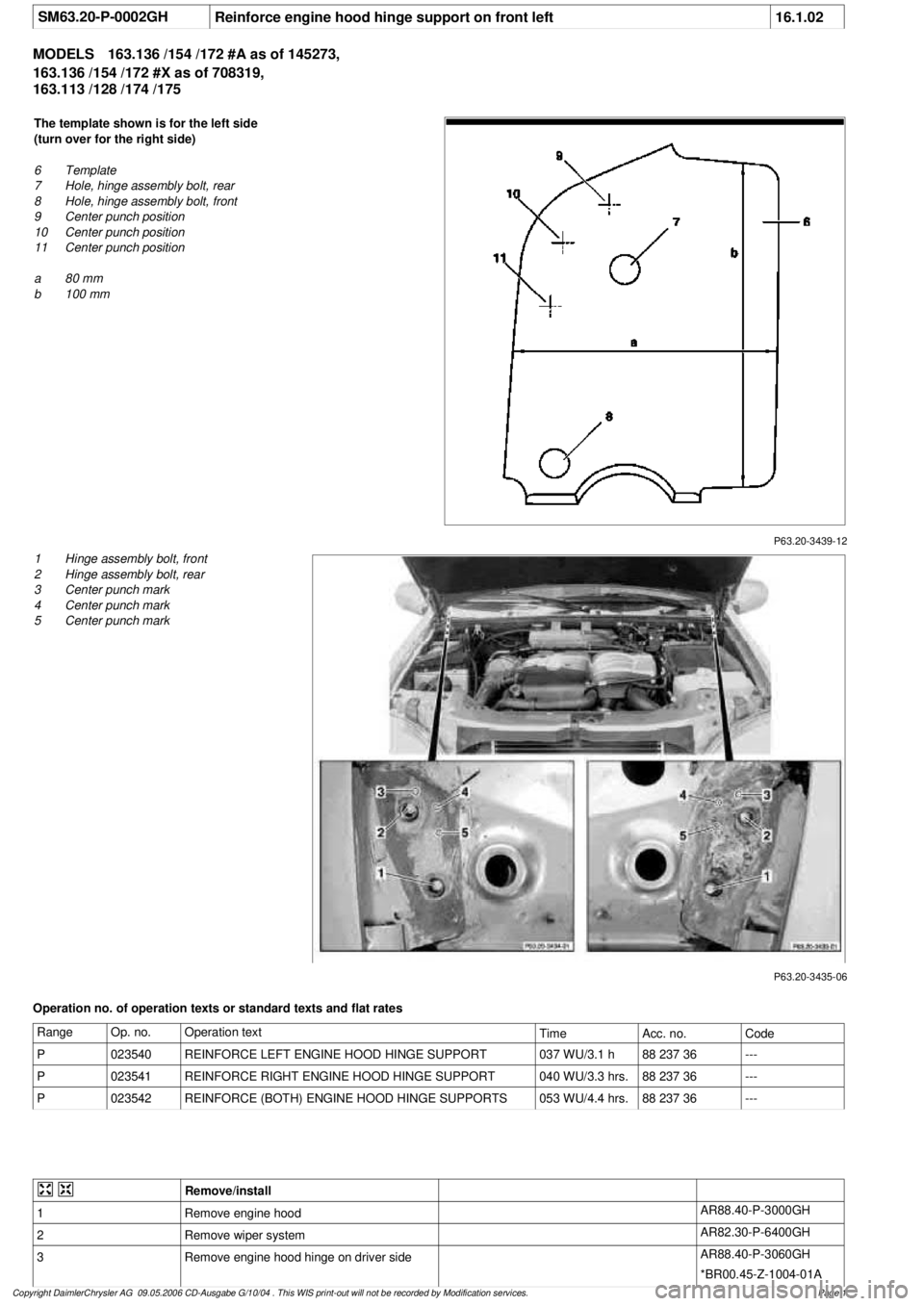

SM63.20-P-0002GH

Reinforce engine hood hinge support on front left

16.1.02

MODELS

163.136 /154 /172 #A as of 145273,

163.136 /154 /172 #X as of 708319,

163.113 /128 /174 /175

P63.20-3439-12

The template shown is for the left side

(turn over for the right side)

6

Template

7

Hole, hinge assembly bolt, rear

8

Hole, hinge assembly bolt, front

9

Center punch position

10

Center punch position

11

Center punch position

a

80 mm

b

100 mm

P63.20-3435-06

1

Hinge assembly bolt, front

2

Hinge assembly bolt, rear

3

Center punch mark

4

Center punch mark

5

Center punch mark

Operation no. of operation texts or standard texts and flat rates

Range

Op. no.

Operation text

Time

Acc. no.

Code

P

023540

REINFORCE LEFT ENGINE HOOD HINGE SUPPORT

037 WU/3.1 h

88 237 36

---

P

023541

REINFORCE RIGHT ENGINE HOOD HINGE SUPPORT

040 WU/3.3 hrs.

88 237 36

---

P

023542

REINFORCE (BOTH) ENGINE HOOD HINGE SUPPORTS

053 WU/4.4 hrs.

88 237 36

---

Remove/install

1

Remove engine hood

AR88.40-P-3000GH

2

Remove wiper system

AR82.30-P-6400GH

3

Remove engine hood hinge on driver side

AR88.40-P-3060GH

*BR00.45-Z-1004-01A

Copyright DaimlerChrysler AG 09.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1