oil viscosity MERCEDES-BENZ ML350 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML350, Model: MERCEDES-BENZ ML350 1997Pages: 4133, PDF Size: 88.89 MB

Page 231 of 4133

181 Driving instructions

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index Winter driving

Have your vehicle winterized at your authorized

Mercedes-Benz Light Truck Center before the onset of

winter.

•Change the engine oil if the engine contains an oil

which is not approved for winter operation. For

viscosity (SAE / CCMC class) and filling quantity,

see page 292.

•Check engine coolant anticorrosion / antifreeze

concentration.

•Additive for the windshield washer and headlamp

cleaning system: Add MB Concentrate “S” to a

premixed windshield washer solvent / antifreeze

which is formulated for below freezing temperatures

see page 237.

•Test battery: Battery capacity drops with decreasing

ambient temperature. A well charged battery helps

to ensure that the engine can be started, even at low

ambient temperatures.

•Tires: We recommend M+S rated radial-ply tires on

all four wheels for the winter season. Observe

permissible maximum speed for M+S rated

radial-ply tires and the legal speed limit.In winter operation, the maximum effectiveness of the

antilock brake system (ABS), the four wheel electronic

traction system (4-ETS+), the electronic stability

program (ESP), and electronic brake proportioning

(EBP) can only be achieved with M+S rated radial-ply

tires and / or snow chains recommended by

Mercedes-Benz. Snow chains maximize performance.

For driving instructions using snow chains see

page 179.

Deep water

Caution!

Do not drive through flooded areas or water of unknown

depth. Before driving through water, determine its

depth. It should not be deeper than approximately

20 inches (50 cm).

If you must drive through deep water, drive slowly to

prevent water from entering the engine compartment or

passenger compartment, being ingested by the air

intake, possibly causing damage to electrical

components or wiring, to engine or transmission that is

not covered by the Mercedes-Benz Limited Warranty.

Page 648 of 4133

181

Driving instructions

Te ch n ica l

data

Instruments

and controls Operation

Driving Instrument

cluster display Practical hints Car care Index

Winter driving

Have your vehicle winterized at your authorized

Mercedes-Benz Light Truck Center before the onset of

winter.

• Change the engine oil if the engine contains an oil

which is not approved for winter operation. For

viscosity (SAE / CCMC class) and filling quantity,

see page 292.

• Check engine coolant anticorrosion / antifreeze

concentration.

• Additive for the windshield washer and headlamp

cleaning system: Add MB Concentrate “S” to a

premixed windshield washer solvent / antifreeze

which is formulated for below freezing temperatures

see page 237.

• Test battery: Battery capacity drops with decreasing

ambient temperature. A well charged battery helps

to ensure that the engine can be started, even at low

ambient temperatures.

• Tires: We recommend M+S rated radial-ply tires on

all four wheels for the winter season. Observe

permissible maximum speed for M+S rated

radial-ply tires and the legal speed limit. In winter operation, the maximum effectiveness of the

antilock brake system (ABS), the four wheel electronic

traction system (4-ETS+), the electronic stability

program (ESP), and electronic brake proportioning

(EBP) can only be achieved with M+S rated radial-ply

tires and / or snow chains recommended by

Mercedes-Benz. Snow chains maximize performance.

For driving instructions using snow chains see

page 179.

Deep water

Caution!

Do not drive through flooded areas or water of unknown

depth. Before driving through water, determine its

depth. It should not be deeper than approximately

20 inches (50 cm).

If you must drive through deep water, drive slowly to

prevent water from entering the engine compartment or

passenger compartment, being ingested by the air

intake, possibly causing damage to electrical

components or wiring, to engine or transmission that is

not covered by the Mercedes-Benz Limited Warranty.

Page 1116 of 4133

312 Technical termsEngine oil viscosity

Measurement for the inner friction (vis-

cosity) of the oil at different tempera-

tures. The higher the temperature an

oil can tolerate without becoming thin,

or the lower the temperature it can tol-

erate without becoming viscous, the

better the viscosity.

ESP

(E

lectronic S

tability Pr

ogram)

Improves vehicle handling and direc-

tional stability.

ETD

(E

mergency T

ensioning D

evice)

Device which deploys in certain frontal

and rear collisions exceeding the sys-

tem's threshold to tighten the seat

belts.

->SRSFSS

(F

lexible S

ervice S

ystem)

Service indicator in the speedometer

display that informs the driver when

the next vehicle maintenance service is

due.

Gear range

Number of gears which are available to

the automatic transmission for shifting.

The automatic gear shifting process

can be adapted to specific operating

conditions using the gear selector

lever.

GPS

(G

lobal P

ositioning S

ystem)

Satellite-based system for relaying

geographic location information to and

from vehicles equipped with special re-

ceivers. Employs CD or DVD digital

maps for navigation.GAWR

(G

ross A

xle W

eight R

ating)

The GAWR is the maximum permissible

axle weight. The gross vehicle weight

on each axle must never exceed the

GAWR for the front and rear axle indi-

cated on the certification label located

on the driver’s door pillar.

GVW

(G

ross V

ehicle W

eight)

The GVW comprises the weight of the

vehicle including fuel, tools, spare

wheel, installed accessories, passen-

gers and cargo. The GVW must never

exceed the GVWR, indicated on the

certification label located on the driv-

er’s door pillar.

Page 1128 of 4133

324 IndexEmergency calls

Initiating an emergency call 175

With Tele Aid* 173

Emergency operation (Limp Home

Mode) 124

Emergency operations

Closing sliding/pop-up roof* 265

Locking the vehicle 262

Opening sliding/pop-up roof* 265

Remote door unlock 179

Unlocking the vehicle 261

Emergency tensioning device see

ETD 67, 312

Emission control 212

Emission control label 292

Engine

Starting 46

Technical data 294

Turning off 54

Engine cleaning 236Engine compartment

Fuse box in 287

Hood 217

Engine malfunction indicator lamp 25,

248

Engine number 311

Engine oil 218, 302

Adding 221

Additives 302

Checking level 218

Consumption 218

Messages in display 219

Oil dipstick 221

Viscosity 312

Enlarged cargo area 99

Error

Display messages 256ESP 25, 80, 312

LOW RANGE mode 81

Malfunction indicator lamp 245, 246,

247

Switching off 81

Switching on 82

Synchronizing 246

Warning lamp 245, 246, 247, 251

ETD 312

Safety guidelines 62

ETD (Emergency tensioning device) 67

Exterior mirrors

Folding 128

Exterior rear view mirrors 40

Adjusting 40

Folding electrically 128

Page 1135 of 4133

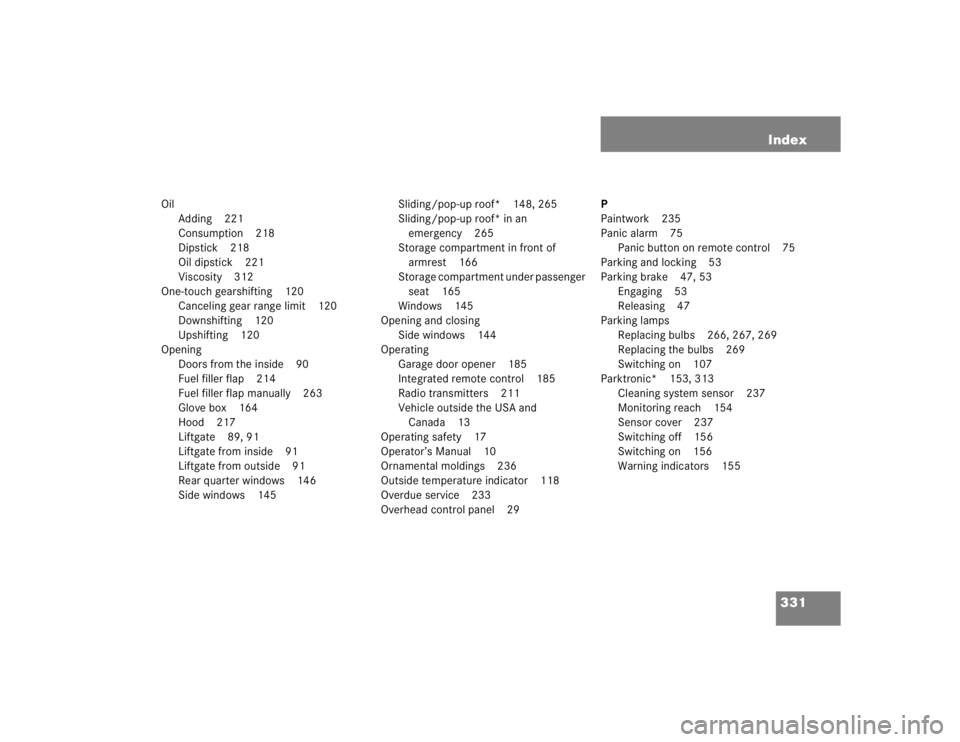

331 Index

Oil

Adding 221

Consumption 218

Dipstick 218

Oil dipstick 221

Viscosity 312

One-touch gearshifting 120

Canceling gear range limit 120

Downshifting 120

Upshifting 120

Opening

Doors from the inside 90

Fuel filler flap 214

Fuel filler flap manually 263

Glove box 164

Hood 217

Liftgate 89, 91

Liftgate from inside 91

Liftgate from outside 91

Rear quarter windows 146

Side windows 145Sliding/pop-up roof* 148, 265

Sliding/pop-up roof* in an

emergency 265

Storage compartment in front of

armrest 166

Storage compartment under passenger

seat 165

Windows 145

Opening and closing

Side windows 144

Operating

Garage door opener 185

Integrated remote control 185

Radio transmitters 211

Vehicle outside the USA and

Canada 13

Operating safety 17

Operator’s Manual 10

Ornamental moldings 236

Outside temperature indicator 118

Overdue service 233

Overhead control panel 29P

Paintwork 235

Panic alarm 75

Panic button on remote control 75

Parking and locking 53

Parking brake 47, 53

Engaging 53

Releasing 47

Parking lamps

Replacing bulbs 266, 267, 269

Replacing the bulbs 269

Switching on 107

Parktronic* 153, 313

Cleaning system sensor 237

Monitoring reach 154

Sensor cover 237

Switching off 156

Switching on 156

Warning indicators 155

Page 2232 of 4133

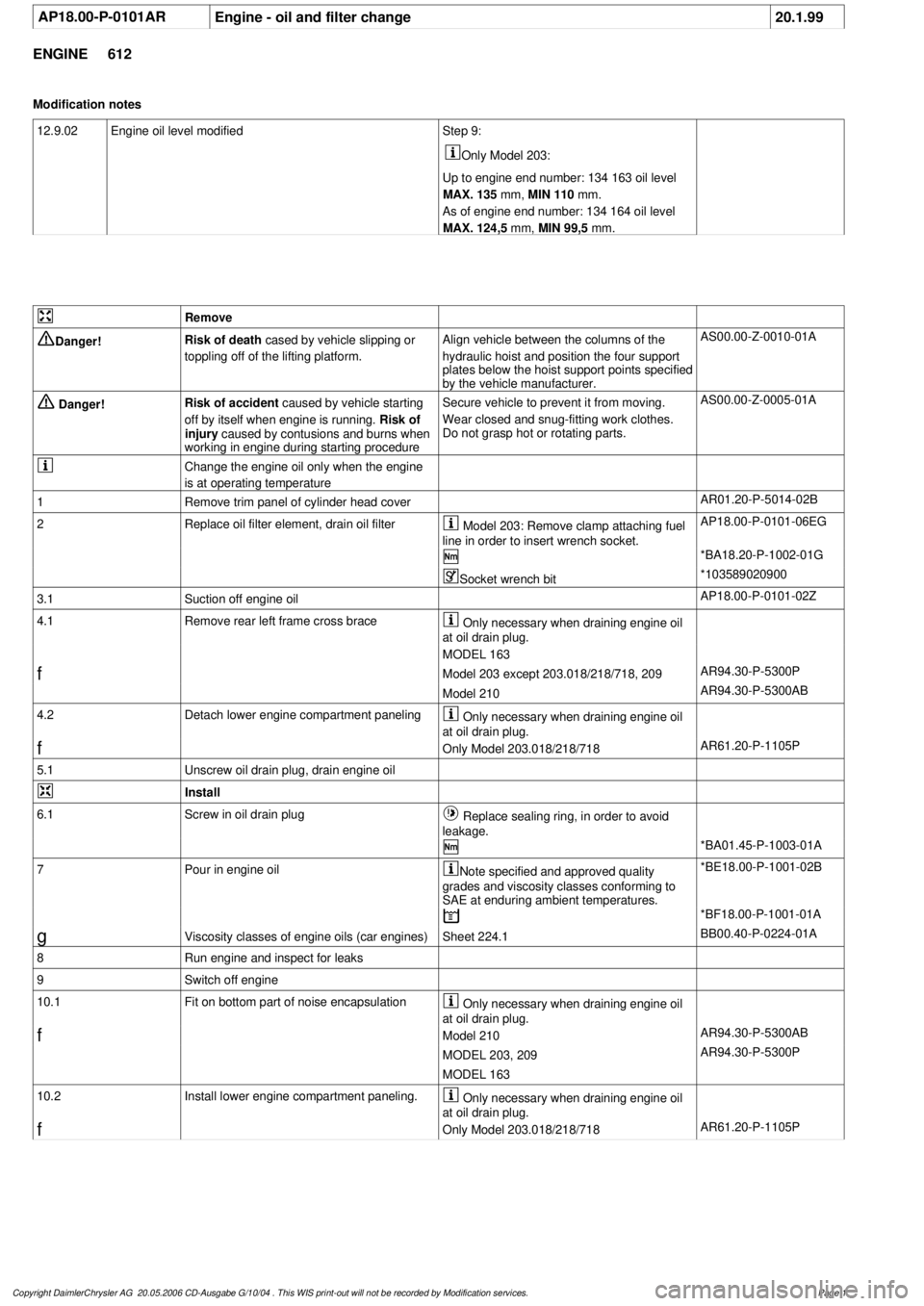

AP18.00-P-0101AR

Engine - oil and filter change

20.1.99

ENGINE

612

Modification notes

12.9.02

Engine oil level modified

Step 9:

Only Model 203:

Up to engine end number: 134 163 oil level

MAX. 135

mm,

MIN 110

mm.

As of engine end number: 134 164 oil level

MAX. 124,5

mm,

MIN 99,5

mm.

Remove

Danger!

Risk of death

cased by vehicle slipping or

toppling off of the lifting platform.

Align vehicle between the columns of the

hydraulic hoist and position the four support

plates below the hoist support points specified

by the vehicle manufacturer.

AS00.00-Z-0010-01A

Danger!

Risk of accident

caused by vehicle starting

off by itself when engine is running.

Risk of

injury

caused by contusions and burns when

working in engine during starting procedure

Secure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

AS00.00-Z-0005-01A

Change the engine oil only when the engine

is at operating temperature

1

Remove trim panel of cylinder head cover

AR01.20-P-5014-02B

2

Replace oil filter element, drain oil filter

Model 203: Remove clamp attaching fuel

line in order to insert wrench socket.

AP18.00-P-0101-06EG

*BA18.20-P-1002-01G

Socket wrench bit

*103589020900

3.1

Suction off engine oil

AP18.00-P-0101-02Z

4.1

Remove rear left frame cross brace

Only necessary when draining engine oil

at oil drain plug.

MODEL 163

f

Model 203 except 203.018/218/718, 209

AR94.30-P-5300P

Model 210

AR94.30-P-5300AB

4.2

Detach lower engine compartment paneling

Only necessary when draining engine oil

at oil drain plug.

f

Only Model 203.018/218/718

AR61.20-P-1105P

5.1

Unscrew oil drain plug, drain engine oil

Install

6.1

Screw in oil drain plug

Replace sealing ring, in order to avoid

leakage.

*BA01.45-P-1003-01A

7

Pour in engine oil

Note specified and approved quality

grades and viscosity classes conforming to

SAE at enduring ambient temperatures.

*BE18.00-P-1001-02B

*BF18.00-P-1001-01A

g

Viscosity classes of engine oils (car engines)

Sheet 224.1

BB00.40-P-0224-01A

8

Run engine and inspect for leaks

9

Switch off engine

10.1

Fit on bottom part of noise encapsulation

Only necessary when draining engine oil

at oil drain plug.

f

Model 210

AR94.30-P-5300AB

MODEL 203, 209

AR94.30-P-5300P

MODEL 163

10.2

Install lower engine compartment paneling.

Only necessary when draining engine oil

at oil drain plug.

f

Only Model 203.018/218/718

AR61.20-P-1105P

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3058 of 4133

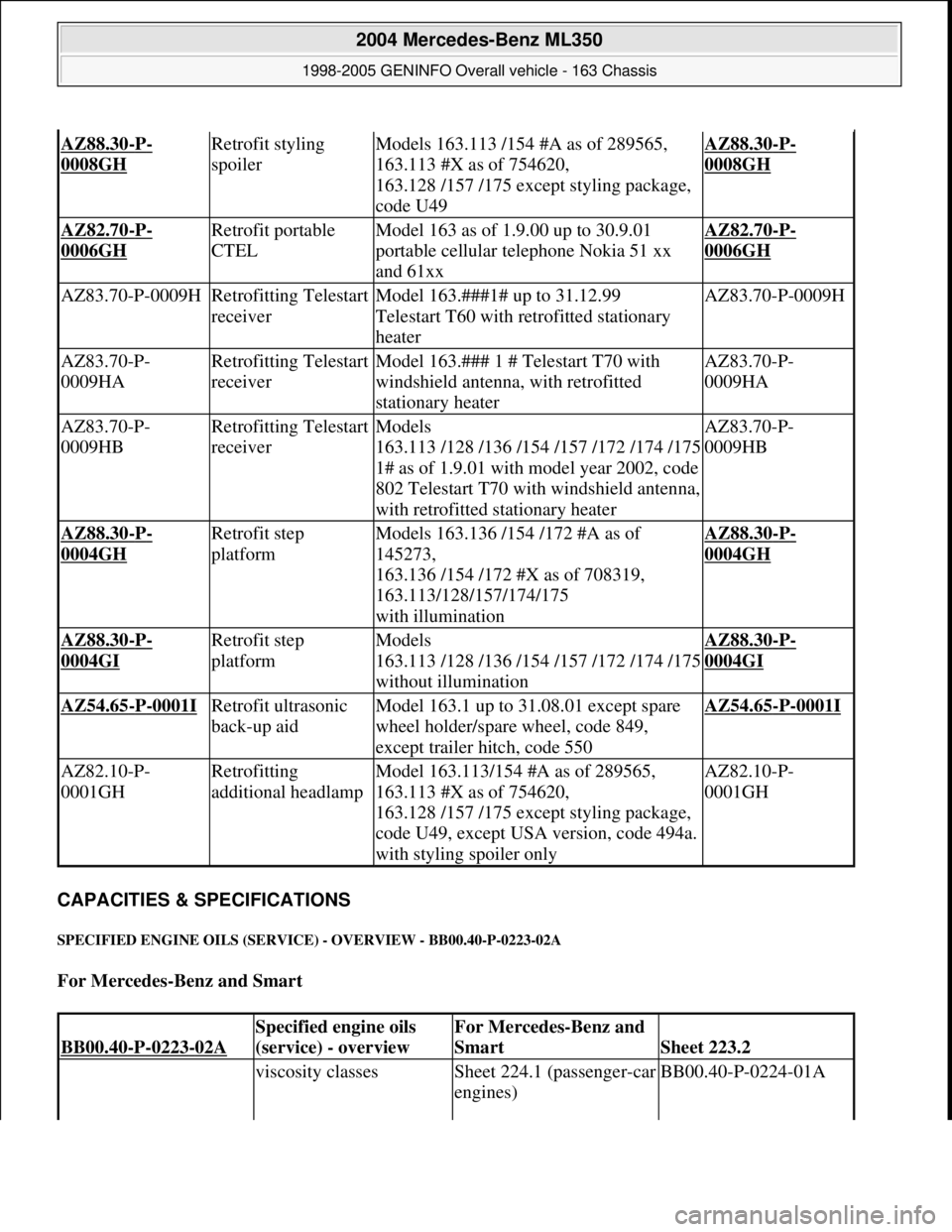

CAPACITIES & SPECIFICATIONS

SPECIFIED ENGINE OILS (SERVICE) - OVERVIEW - BB00.40-P-0223-02A

For Mercedes-Benz and Smart

AZ88.30-P-

0008GH

Retrofit styling

spoilerModels 163.113 /154 #A as of 289565,

163.113 #X as of 754620,

163.128 /157 /175 except styling package,

code U49AZ88.30-P-

0008GH

AZ82.70-P-

0006GH

Retrofit portable

CTELModel 163 as of 1.9.00 up to 30.9.01

portable cellular telephone Nokia 51 xx

and 61xxAZ82.70-P-

0006GH

AZ83.70-P-0009HRetrofitting Telestart

receiverModel 163.###1# up to 31.12.99

Telestart T60 with retrofitted stationary

heaterAZ83.70-P-0009H

AZ83.70-P-

0009HARetrofitting Telestart

receiverModel 163.### 1 # Telestart T70 with

windshield antenna, with retrofitted

stationary heaterAZ83.70-P-

0009HA

AZ83.70-P-

0009HBRetrofitting Telestart

receiverModels

163.113 /128 /136 /154 /157 /172 /174 /175

1# as of 1.9.01 with model year 2002, code

802 Telestart T70 with windshield antenna,

with retrofitted stationary heaterAZ83.70-P-

0009HB

AZ88.30-P-

0004GH

Retrofit step

platformModels 163.136 /154 /172 #A as of

145273,

163.136 /154 /172 #X as of 708319,

163.113/128/157/174/175

with illuminationAZ88.30-P-

0004GH

AZ88.30-P-

0004GI

Retrofit step

platformModels

163.113 /128 /136 /154 /157 /172 /174 /175

without illuminationAZ88.30-P-

0004GI

AZ54.65-P-0001I Retrofit ultrasonic

back-up aidModel 163.1 up to 31.08.01 except spare

wheel holder/spare wheel, code 849,

except trailer hitch, code 550AZ54.65-P-0001I

AZ82.10-P-

0001GHRetrofitting

additional headlampModel 163.113/154 #A as of 289565,

163.113 #X as of 754620,

163.128 /157 /175 except styling package,

code U49, except USA version, code 494a.

with styling spoiler onlyAZ82.10-P-

0001GH

BB00.40-P-0223-02A

Specified engine oils

(service) - overviewFor Mercedes-Benz and

Smart

Sheet 223.2

viscosity classesSheet 224.1 (passenger-car

engines)BB00.40-P-0224-01A

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 413 © 2006 Mitchell Repair Information Company, LLC.

Page 3059 of 4133

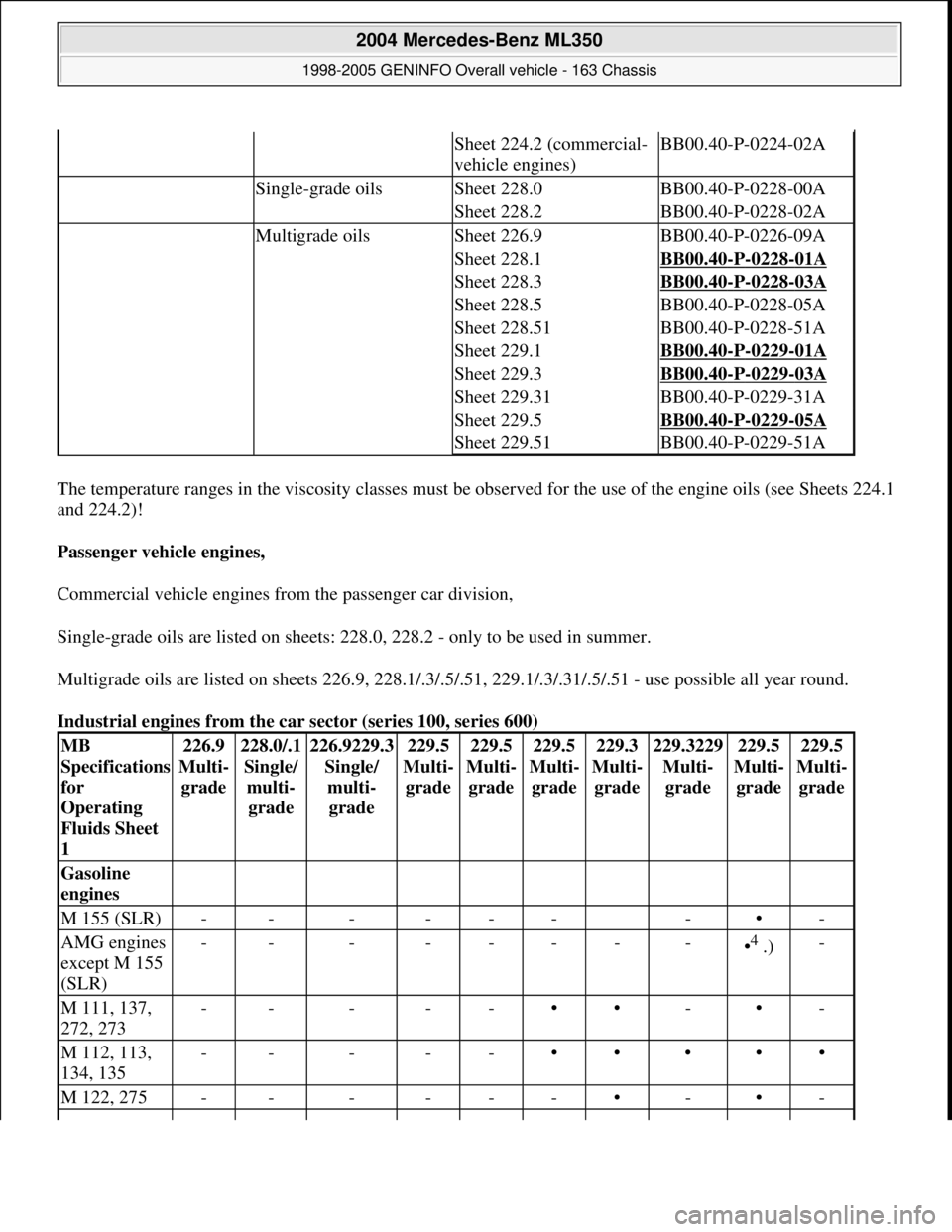

The temperature ranges in the viscosity classes must be observed for the use of the engine oils (see Sheets 224.1

and 224.2)!

Passenger vehicle engines,

Commercial vehicle engines from the passenger car division,

Single-grade oils are listed on sheets: 228.0, 228.2 - only to be used in summer.

Multigrade oils are listed on sheets 226.9, 228.1/.3/.5/.51, 229.1/.3/.31/.5/.51 - use possible all year round.

Industrial engines from the car sector (series 100, series 600)

Sheet 224.2 (commercial-

vehicle engines)BB00.40-P-0224-02A

Single-grade oilsSheet 228.0BB00.40-P-0228-00A

Sheet 228.2BB00.40-P-0228-02A

Multigrade oilsSheet 226.9BB00.40-P-0226-09A

Sheet 228.1BB00.40-P-0228-01A

Sheet 228.3BB00.40-P-0228-03A

Sheet 228.5BB00.40-P-0228-05A

Sheet 228.51BB00.40-P-0228-51A

Sheet 229.1BB00.40-P-0229-01A

Sheet 229.3BB00.40-P-0229-03A

Sheet 229.31BB00.40-P-0229-31A

Sheet 229.5BB00.40-P-0229-05A

Sheet 229.51BB00.40-P-0229-51A

MB

Specifications

for

Operating

Fluids Sheet

1226.9

Multi-

grade228.0/.1

Single/

multi-

grade226.9229.3

Single/

multi-

grade229.5

Multi-

grade229.5

Multi-

grade229.5

Multi-

grade229.3

Multi-

grade229.3229

Multi-

grade229.5

Multi-

grade229.5

Multi-

grade

Gasoline

engines

M 155 (SLR)------ -•-

AMG engines

except M 155

(SLR)--------•4 .)-

M 111, 137,

272, 273-----••-•-

M 112, 113,

134, 135-----•••••

M 122, 275------•-•-

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:52 PMPage 414 © 2006 Mitchell Repair Information Company, LLC.

Page 3146 of 4133

1. Hypoid gear oils

Hypoid gear oils contain a high level of EP/AW additives (Extreme Pressure/Antiwear) and a highly

viscous base oil to prevent seizure when the hypoid gears mesh (mixed and boundary friction conditions)

and to ensure a high degree of protection against wear. The compatibility with radial shaft seals is

regarded as critical with such high concentrations of additives because the P/S additive systems become

thermally unstable at temperatures from 130°C to 140°C and this may lead to sludging of the hypoid oil.

The resultant deposits on the radial shaft seals then generally lead to thermal overload and this in turn

leads to leakage in this component.

The tooth engagement conditions of the hypoid gears result in a high proportion of sliding and a low

hydrodynamic proportion of tooth engagement between the pinion and ring gear. Due to the high

tribological load compared to adhesive wear (seizure) and pitting, the performance of hypoid gear oils

must be particularly high with respect to these types of wear. The formula of the oils is therefore

determined by a high concentration of EP/AW additives and a highly viscous base oil. Alternative oils,

e.g. engine oils, cannot be used for these drive types. Proof of performance that an oil fulfills the

requirements of DaimlerChrysler AG is provided by internal tests. However, the hypoid gear oils must at

least correspond to the US military specification MIL-L-2105 B/C/D and must be classed GL-5 in the

quality grade according to API (American Institute of Petroleum).

1.7 Viscosity requirements

The cold flow behavior is only specified for SAE, ... oils. Here, the limits apply according to SAE J 306

c, according to which the dynamic viscosity may be max. 150,000 mPas at -40°C for oils and at -12°C for

oils. As a result of the tendency to form deposits in the transmission, the polymer content is limited to

max.

1 percent by weight for pour point reducers. Polymers as VI improvers for thickening low-viscosity base

oils are not permitted. The kinematic viscosity at 100°C must be at least 16.5 mm

2 /s.

2. Transmission oils, sheet 235.1

The additive and viscosity properties of the transmission oils are adjusted so that they meet all the

requirements placed on manual transmissions with steel/molybdenum synchronization, spur gear axles,

MB and ZF transfer cases and reversing gears. Among other things, this results in the fact that the oils

ensure a defined friction coefficient of the synchronizer elements, even after a high number of shift

operations, without crunching noises.

With gear drives and roller bearings, the adhesive wear (seizure) and pitting in particular should be

minimized as far as possible.

2.1 Viscosity requirements

The cold flow behavior is only specified for SAE, 80W, ...oils. Here, the limits according to SAE J 306 c

apply, according to which the dynamic viscosity may be max. 150,000 mPas at -40°C for oils, at -26°C

for oils and at -12°C for oils. Due to the formation of deposits in the transmission, the polymer content is

limited to max. 1 percent b

y weight for pour point reducers. Polymers as VI improvers for thickening

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:56 PMPage 501 © 2006 Mitchell Repair Information Company, LLC.

Page 3147 of 4133

low-viscosity base oils are not permitted. The kinematic viscosity at 100°C 2 must be at least 9.5 mm /s.

In hot zones, gear oils of SAE grade 90 are also permitted.

2.2 Alternative transmission lubricants for commercial vehicle synchromesh transmissions which are

operated with transmission oils as per sheets 235.1, 235.5.

If there are no gear oils according to Sheet 235.1 and 235.5 available, the following engine oils can also

be used as alternatives:

In a moderate climate, engine oils of SAE-grade 30 as per sheet 235.12

In tropical climate, engine oils of SAE-grade 40 as per sheet 235.12

2.3 Fully synthetic transmission oil, sheet 235.4

Completely synthetic gear oils are imperative for the Unimog manual transmission UG 3/40, UG 3/65 and

the PTO transmission -as of the vehicle end No. ...179909 -. Older vehicles can have their oils changed

from gear oils according to Sheet 235.1 to gear oils according to Sheet 235.4 when an oil change is due.

The gear oils correspond to the ZF lubricant specifications TE-ML01 and TE-ML02 and are consequently

alternatives to the gear oils according to Sheet 235.1 in all synchronized ZF manual transmissions

installed in MB vehicles, with and without intarders. Furthermore, the approval extends to the MB

transfer case VG 2400 without oil cooler. Due to the favorable viscosity/temperature characteristics, a

good cold-shifting response and, due to the composition of the transmission oil, a good thermal/oxidative

stability of the oil at high transmission oil temperatures can be expected.

2.4 Transmission oils, sheet 235.5

The gear oils are approved for MB and ZF manual transmissions with steel/molybdenum synchronization,

MB and ZF transfer cases and corner gears.

The transmission oils have a low chlorine content as well as a potential for lower oil temperatures under

certain operating conditions.

2.5 Transmission oils, sheet 235.10

The partly synthetic gear oils are approved for the commercial vehicle manual transmission Model

G16/G28, for the passenger vehicle front-wheel-drive manual transmission SG 150/180 (A class) as well

as for all passenger vehicle in-line transmissions of the model series 717.4 as of transmission serial

number 7 340 241.

Due to the favorable viscosity/temperature characteristics, a very good cold-shifting response and, due to

the composition of the transmission oil, a good thermal/oxidative stability of the oil at high transmission

oil temperatures can be expected.

With regard to the use in passenger vehicle front-wheel drive manual transmissions/in-line transmissions,

which are also installed in cross-countr

y vehicles, the approved gear oil is usually only used in the event

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:56 PMPage 502 © 2006 Mitchell Repair Information Company, LLC.