MERCEDES-BENZ ML350 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML350, Model: MERCEDES-BENZ ML350 1997Pages: 4133, PDF Size: 88.89 MB

Page 3431 of 4133

Commercially available tools

Workshop equipment

DRAINING, EVACUATING AND REFILLING AIR CONDITIONING, CHECKING FUNCTION AND CHECKING FOR

LEAKS - AR83.30-P-1760GH

MODELS 163.113 /128 /136 /154 /157 /172 /174 /175 with CODE (580) Air conditioning or Tempmatic for

USA

Replace refrigerant compressor RPM sensor

Models 901-904

Not in model 163AR83.55-D-

5320A

7

Set blower rotary

switch to maximum

blower setting

8Check that refrigerant

flows free of bubbles

If the system is filled sufficiently, the refrigerant must flow

through the inspection glass (2) free of bubbles. A newly-

filled system may initially reveal bubbles. In this case, wait

for approx. 10 min. and check inspection glass again.

Does not reveal bubble-free flow ?

Check entire air conditioning circuit for leaks using leak

detector (3).AR83.30-D-

1209-01A

Air conditioning system leak detector*WE58.40-Z-

1002-20A

9Determine air outlet

temperature

Switch blower rotary switch to stage "1".

Insert sensor of temperature measurement device (1) into the

air outlet of the center nozzles.

After running for a period of 5 min., the air outlet temperature

must not be less than 2°C and more than 12°C. After 5 min., at

the latest, the refrigerant compressor must also be connected

and disconnected.

If the refrigerant compressor is disconnected at below 2°C ?

Check evaporator temperature switch. If the air outlet

temperature is not achieved ?

Check the connection and disconnection of the refrigerant

compressor or the refrigerant pressure upstream and

downstream of the refrigerant compressor.

*WH58.30-Z-

1005-08A

10

Switch air conditioning

off and shut vehicle

engine off

NumberDesignation

WH58.30-Z-1005-08ATemperature measuring device

WE58.40-Z-1002-20AAir conditioning leak detector

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 187 © 2006 Mitchell Repair Information Company, LLC.

Page 3432 of 4133

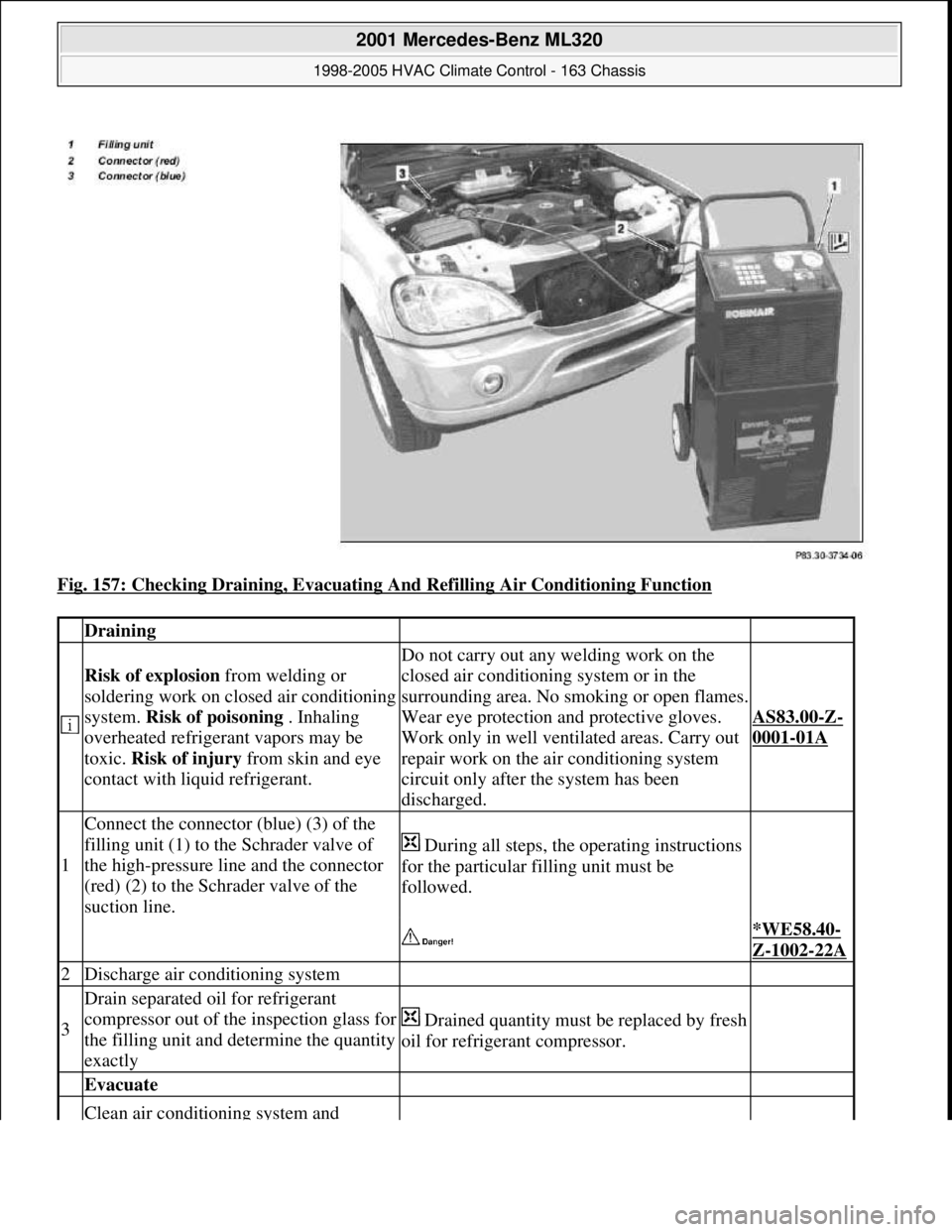

Fig. 157: Checking Draining, Evacuating And Refilling Air Conditioning Function

Draining

Risk of explosion from welding or

soldering work on closed air conditioning

system. Risk of poisoning . Inhaling

overheated refrigerant vapors may be

toxic. Risk of injury from skin and eye

contact with liquid refrigerant.

Do not carry out any welding work on the

closed air conditioning system or in the

surrounding area. No smoking or open flames.

Wear eye protection and protective gloves.

Work only in well ventilated areas. Carry out

repair work on the air conditioning system

circuit only after the system has been

discharged.

AS83.00-Z-

0001-01A

1

Connect the connector (blue) (3) of the

filling unit (1) to the Schrader valve of

the high-pressure line and the connector

(red) (2) to the Schrader valve of the

suction line.

During all steps, the operating instructions

for the particular filling unit must be

followed.

*WE58.40-

Z-1002-22A

2Discharge air conditioning system

3

Drain separated oil for refrigerant

compressor out of the inspection glass for

the filling unit and determine the quantity

exactly

Drained quantity must be replaced by fresh

oil for refrigerant compressor.

Evacuate

Clean air conditioning system and

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 188 © 2006 Mitchell Repair Information Company, LLC.

Page 3433 of 4133

Air conditioning system

Workshop equipment

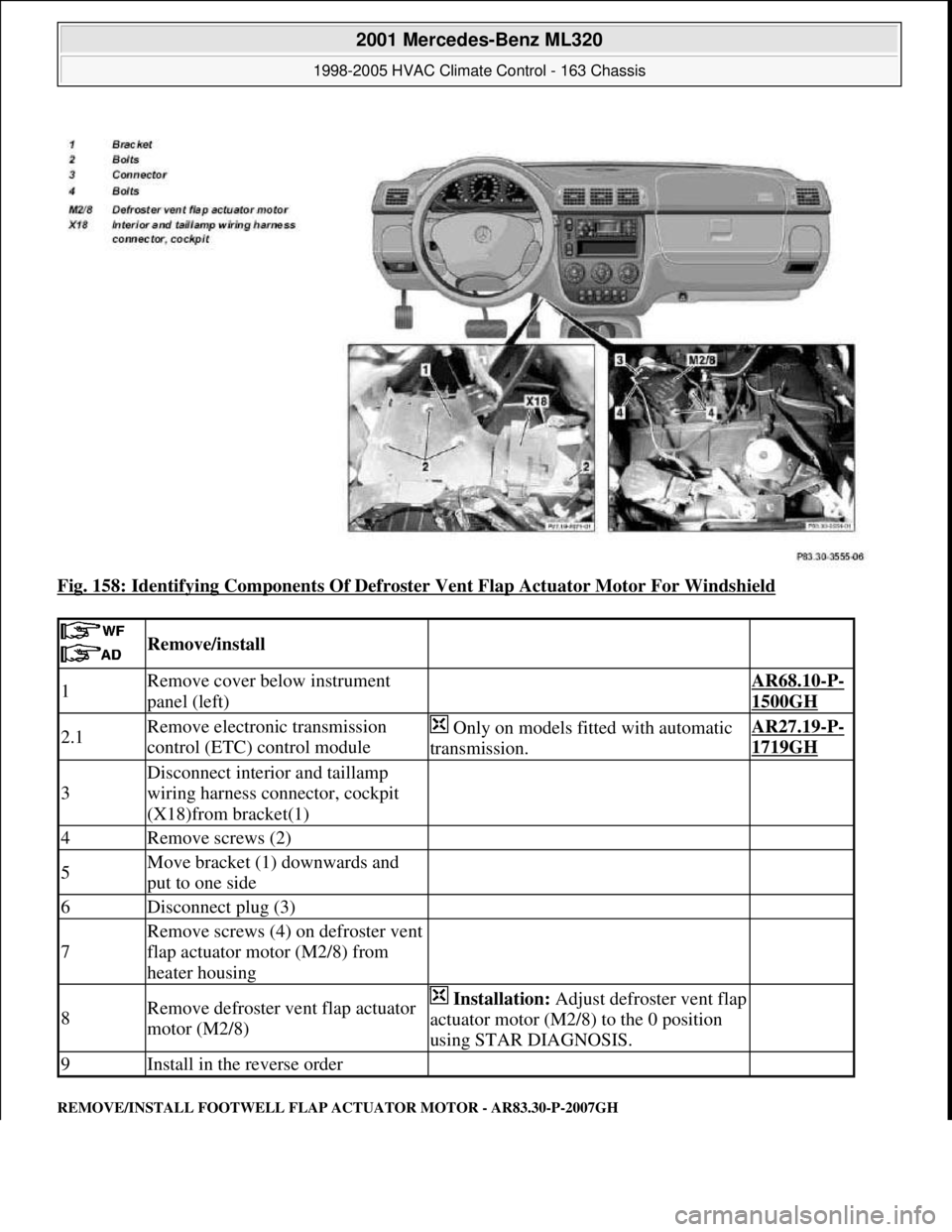

REMOVE/INSTALL DEFROSTER VENT FLAP ACTUATOR MOTOR FOR WINDSHIELD - AR83.30-P-2006GH

MODEL 163.113 /154 /174 #A as of 289565, 163.113 #X as of 754620, 163.128/157/175

4evacuate

Filling

5Supplement oil for refrigerant

compressor The exact quantity determined when

drained must be used.

6Fill air conditioning system *BF83.30-P-

1001-01B

Testing

7Inspect air conditioning system for leaks

with leak detector *WE58.40-

Z-1002-20A

8

Risk of accident. Accidents may result if

the vehicle starts off unintentionally with

the engine running. Risk of injury from

bruises and burns if you hold your hand

near engine when it is started or when it

is running. Check function of air

conditioningSecure vehicle to prevent it from moving.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.

Run engine at idle speed for about 4

minutes and check all the component

functions which are of relevance for proper

operation of the air conditioning system.

AS00.00-Z-

0005-01A

NumberDesignationModel Series 163

BF83.30-P-1001-01BRefrigerantsFilling quantityg750

Specifications for Operating FluidsSheetBB00.40-P-0361-00A

WE58.40-Z-1002-20AAir conditioning leak detector

WE58.40-Z-1002-22AAir conditioning service station

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 189 © 2006 Mitchell Repair Information Company, LLC.

Page 3434 of 4133

Fig. 158: Identifying Components Of Defroster Vent Flap Actuator Motor For Windshield

REMOVE/INSTALL FOOTWELL FLAP ACTUATOR MOTOR - AR83.30-P-2007GH

Remove/install

1Remove cover below instrument

panel (left) AR68.10-P-

1500GH

2.1Remove electronic transmission

control (ETC) control module Only on models fitted with automatic

transmission.AR27.19-P-

1719GH

3

Disconnect interior and taillamp

wiring harness connector, cockpit

(X18)from bracket(1)

4Remove screws (2)

5Move bracket (1) downwards and

put to one side

6Disconnect plug (3)

7

Remove screws (4) on defroster vent

flap actuator motor (M2/8) from

heater housing

8Remove defroster vent flap actuator

motor (M2/8) Installation:Adjust defroster vent flap

actuator motor (M2/8) to the 0 position

using STAR DIAGNOSIS.

9Install in the reverse order

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 190 © 2006 Mitchell Repair Information Company, LLC.

Page 3435 of 4133

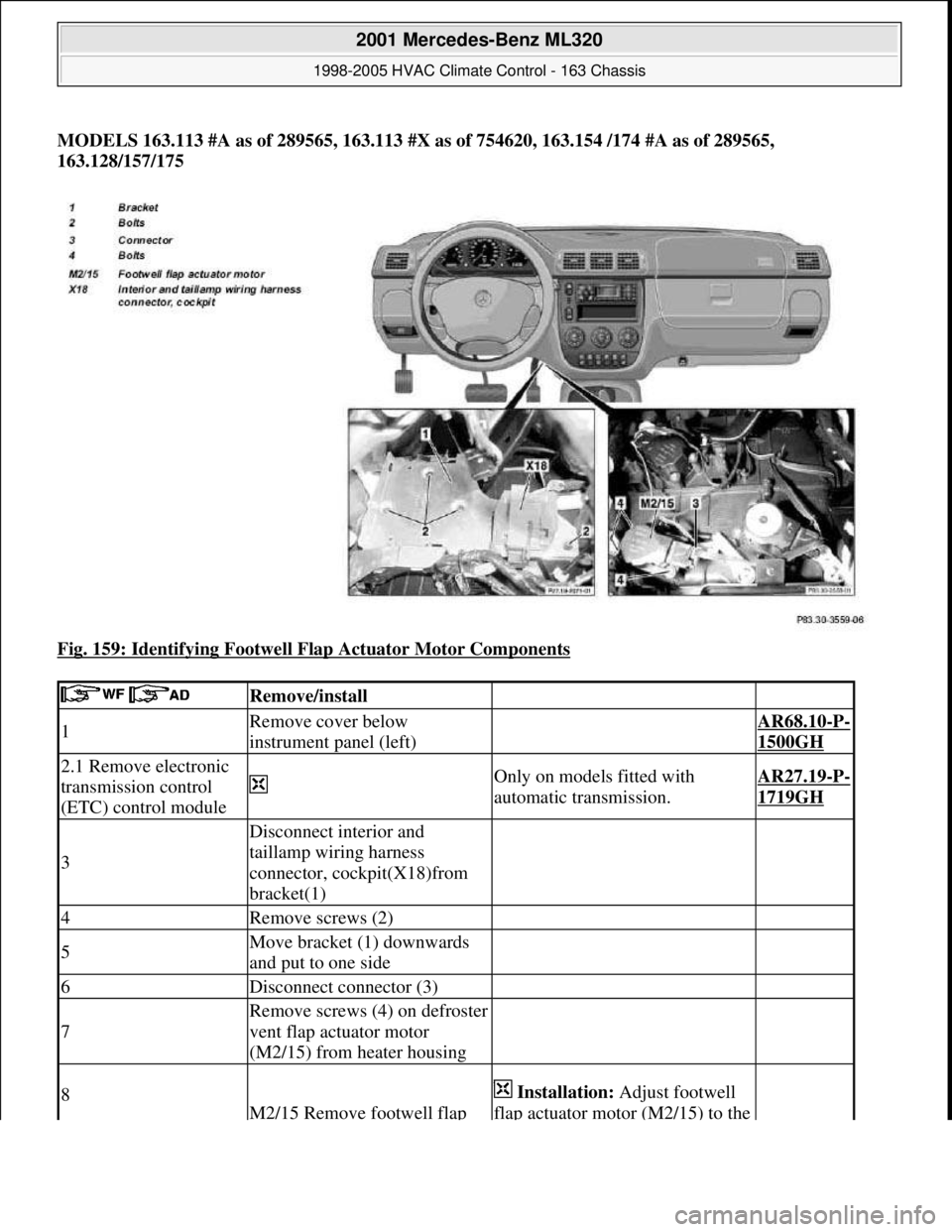

MODELS 163.113 #A as of 289565, 163.113 #X as of 754620, 163.154 /174 #A as of 289565,

163.128/157/175

Fig. 159: Identifying Footwell Flap Actuator Motor Components

Remove/install

1Remove cover below

instrument panel (left) AR68.10-P-

1500GH

2.1 Remove electronic

transmission control

(ETC) control module

Only on models fitted with

automatic transmission.AR27.19-P-

1719GH

3

Disconnect interior and

taillamp wiring harness

connector, cockpit(X18)from

bracket(1)

4Remove screws (2)

5Move bracket (1) downwards

and put to one side

6Disconnect connector (3)

7

Remove screws (4) on defroster

vent flap actuator motor

(M2/15) from heater housing

8

M2/15 Remove footwell flap

Installation: Adjust footwell

flap actuator motor (M2/15) to the

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 191 © 2006 Mitchell Repair Information Company, LLC.

Page 3436 of 4133

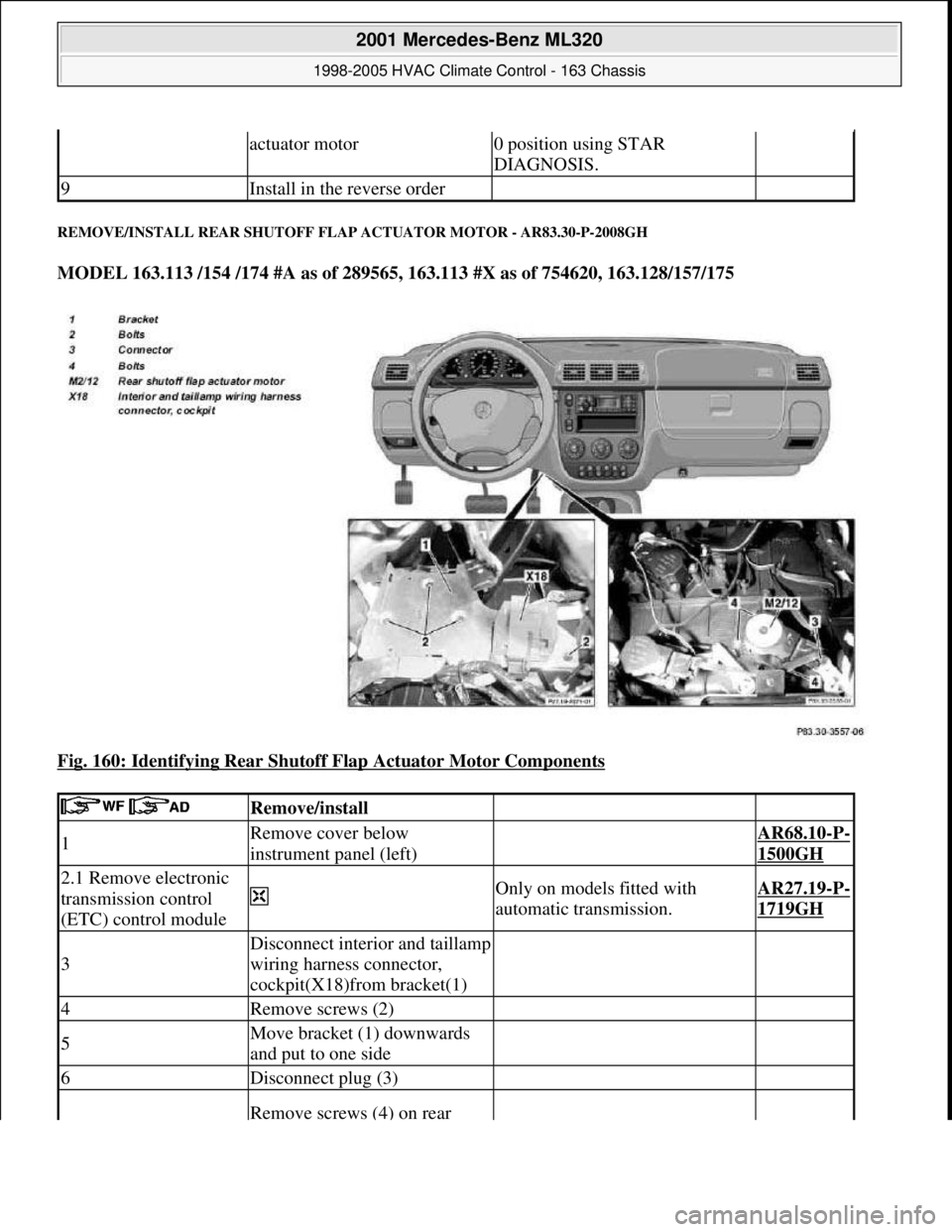

REMOVE/INSTALL REAR SHUTOFF FLAP ACTUATOR MOTOR - AR83.30-P-2008GH

MODEL 163.113 /154 /174 #A as of 289565, 163.113 #X as of 754620, 163.128/157/175

Fig. 160: Identifying Rear Shutoff Flap Actuator Motor Components

actuator motor0 position using STAR

DIAGNOSIS.

9Install in the reverse order

Remove/install

1Remove cover below

instrument panel (left) AR68.10-P-

1500GH

2.1 Remove electronic

transmission control

(ETC) control module

Only on models fitted with

automatic transmission.AR27.19-P-

1719GH

3

Disconnect interior and taillamp

wiring harness connector,

cockpit(X18)from bracket(1)

4Remove screws (2)

5Move bracket (1) downwards

and put to one side

6Disconnect plug (3)

Remove screws (4) on rear

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 192 © 2006 Mitchell Repair Information Company, LLC.

Page 3437 of 4133

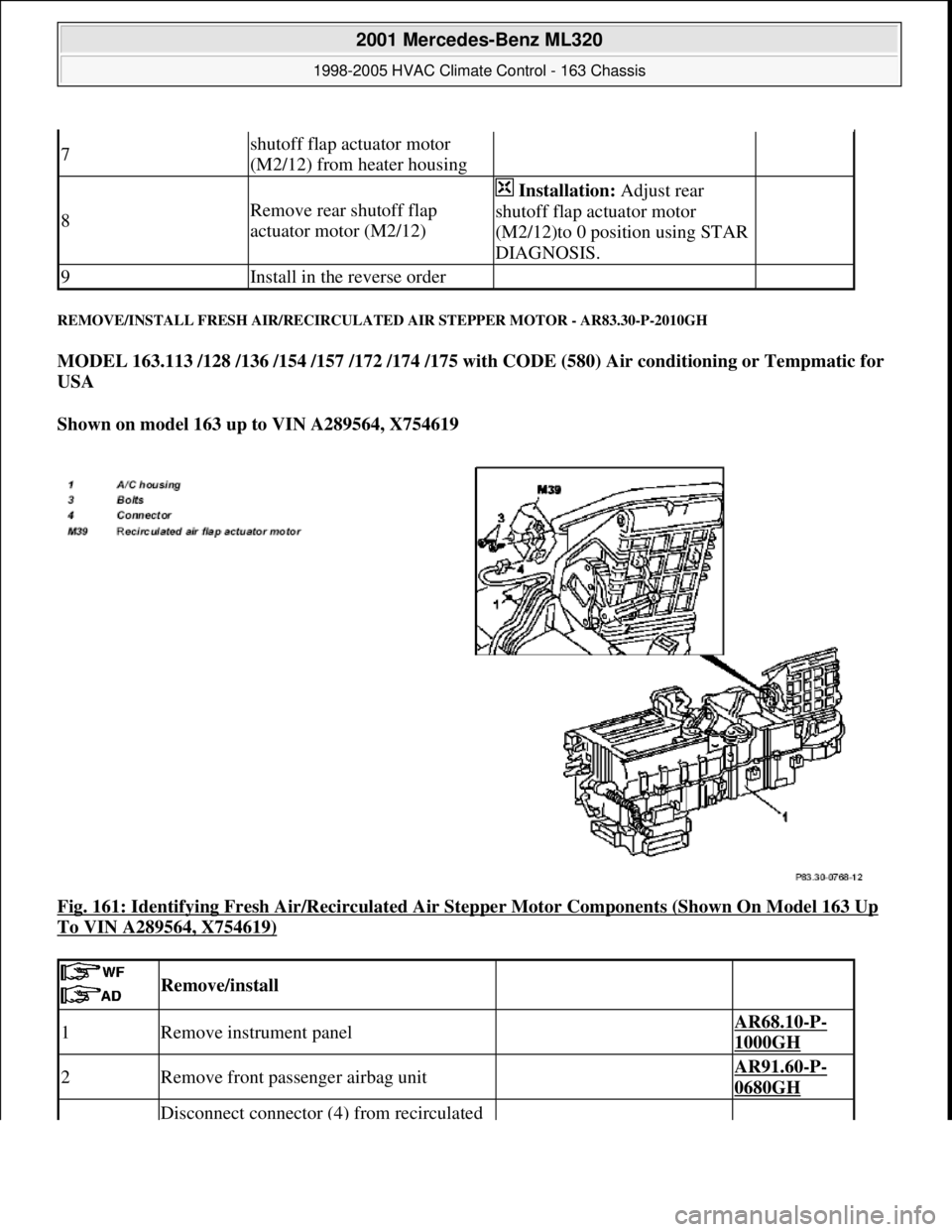

REMOVE/INSTALL FRESH AIR/RECIRCULATED AIR STEPPER MOTOR - AR83.30-P-2010GH

MODEL 163.113 /128 /136 /154 /157 /172 /174 /175 with CODE (580) Air conditioning or Tempmatic for

USA

Shown on model 163 up to VIN A289564, X754619

Fig. 161: Identifying Fresh Air/Recirculated Air Stepper Motor Components (Shown On Model 163 Up

To VIN A289564, X754619)

7shutoff flap actuator motor

(M2/12) from heater housing

8Remove rear shutoff flap

actuator motor (M2/12)

Installation: Adjust rear

shutoff flap actuator motor

(M2/12)to 0 position using STAR

DIAGNOSIS.

9Install in the reverse order

Remove/install

1Remove instrument panel AR68.10-P-

1000GH

2Remove front passenger airbag unit AR91.60-P-

0680GH

Disconnect connector (4) from recirculated

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 193 © 2006 Mitchell Repair Information Company, LLC.

Page 3438 of 4133

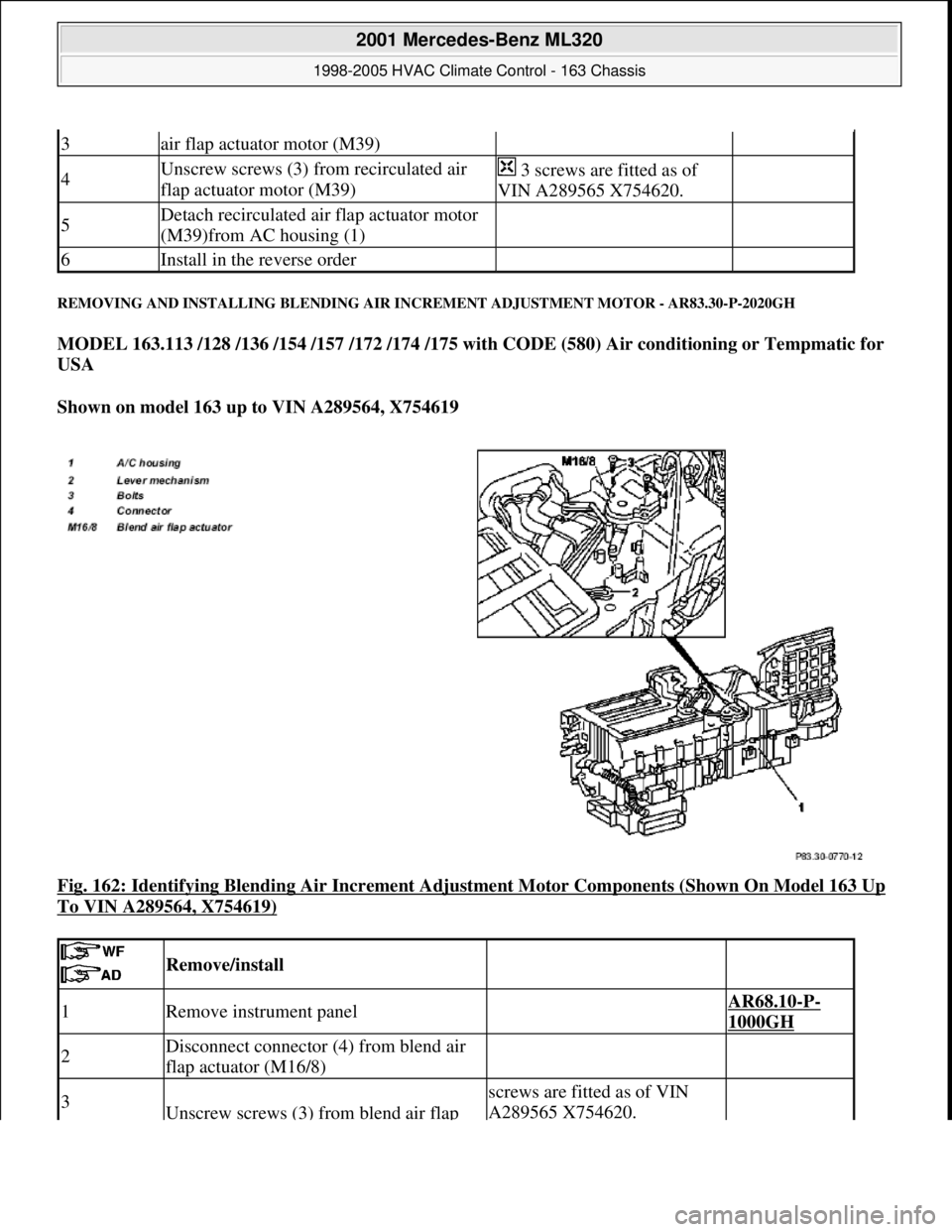

REMOVING AND INSTALLING BLENDING AIR INCREMENT ADJUSTMENT MOTOR - AR83.30-P-2020GH

MODEL 163.113 /128 /136 /154 /157 /172 /174 /175 with CODE (580) Air conditioning or Tempmatic for

USA

Shown on model 163 up to VIN A289564, X754619

Fig. 162: Identifying Blending Air Increment Adjustment Motor Components (Shown On Model 163 Up

To VIN A289564, X754619)

3air flap actuator motor (M39)

4Unscrew screws (3) from recirculated air

flap actuator motor (M39) 3 screws are fitted as of

VIN A289565 X754620.

5Detach recirculated air flap actuator motor

(M39)from AC housing (1)

6Install in the reverse order

Remove/install

1Remove instrument panel AR68.10-P-

1000GH

2Disconnect connector (4) from blend air

flap actuator (M16/8)

3Unscrew screws (3) from blend air flap

screws are fitted as of VIN

A289565 X754620.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 194 © 2006 Mitchell Repair Information Company, LLC.

Page 3439 of 4133

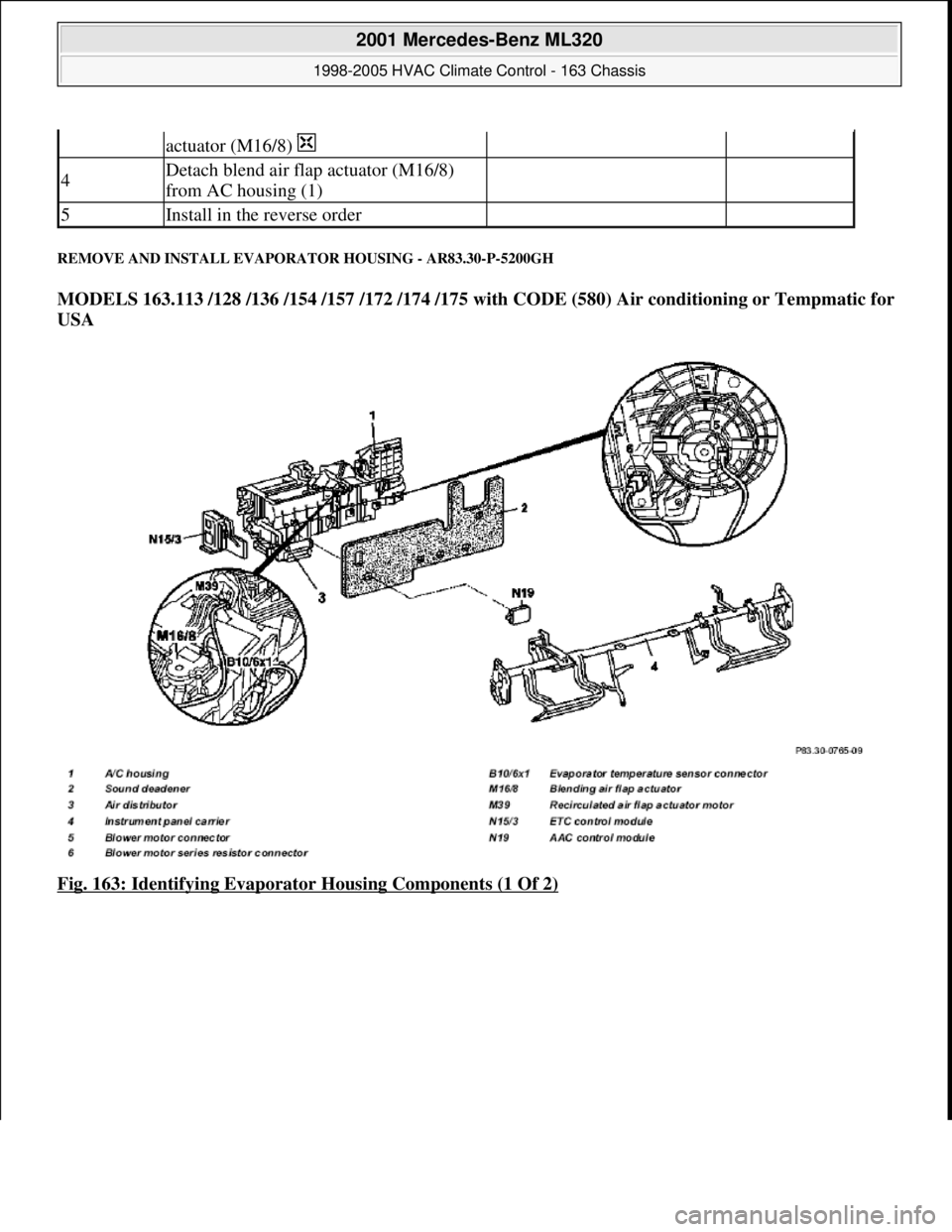

REMOVE AND INSTALL EVAPORATOR HOUSING - AR83.30-P-5200GH

MODELS 163.113 /128 /136 /154 /157 /172 /174 /175 with CODE (580) Air conditioning or Tempmatic for

USA

Fig. 163: Identifying Evaporator Housing Components (1 Of 2)

actuator (M16/8)

4Detach blend air flap actuator (M16/8)

from AC housing (1)

5Install in the reverse order

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 195 © 2006 Mitchell Repair Information Company, LLC.

Page 3440 of 4133

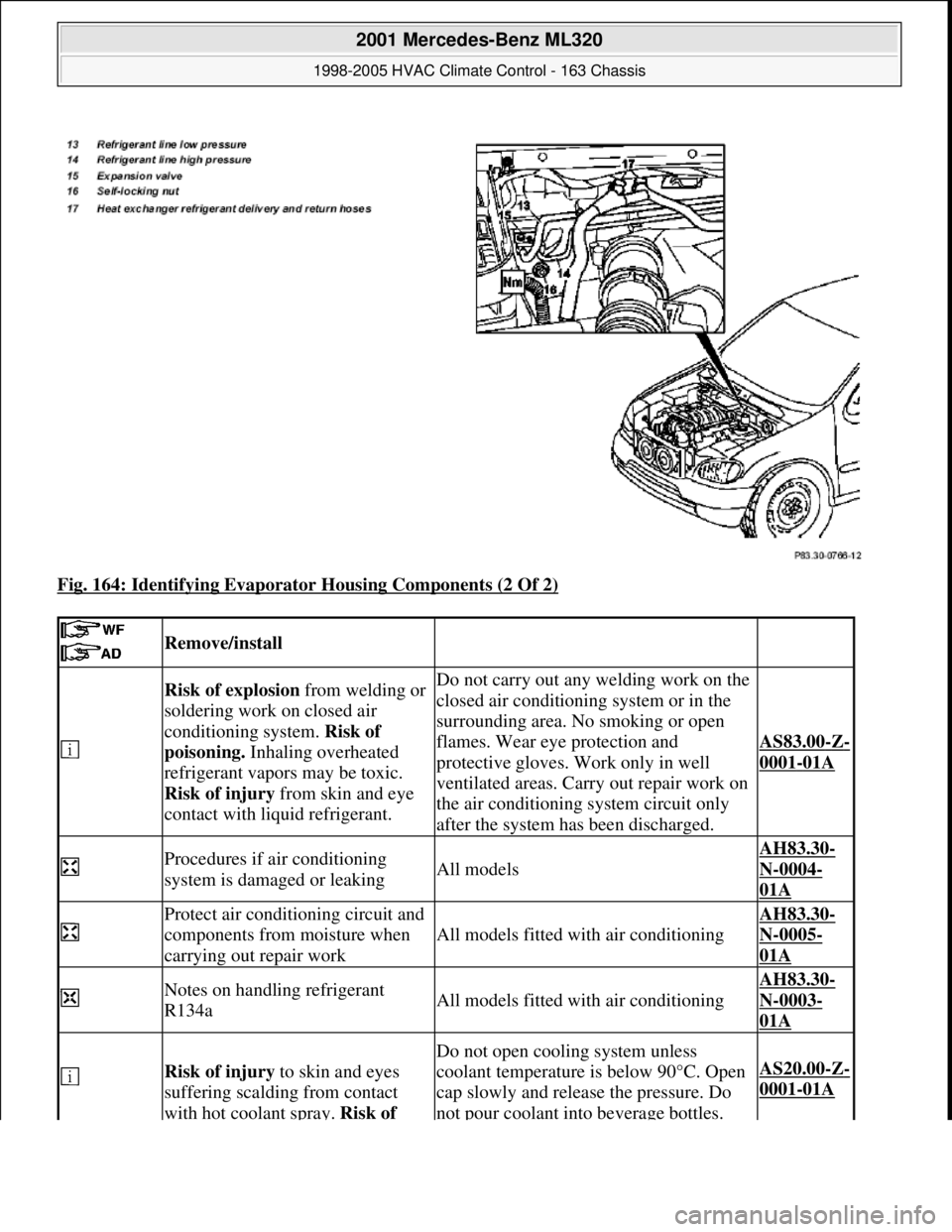

Fig. 164: Identifying Evaporator Housing Components (2 Of 2)

Remove/install

Risk of explosion from welding or

soldering work on closed air

conditioning system. Risk of

poisoning. Inhaling overheated

refrigerant vapors may be toxic.

Risk of injury from skin and eye

contact with liquid refrigerant.Do not carry out any welding work on the

closed air conditioning system or in the

surrounding area. No smoking or open

flames. Wear eye protection and

protective gloves. Work only in well

ventilated areas. Carry out repair work on

the air conditioning system circuit only

after the system has been discharged.

AS83.00-Z-

0001-01A

Procedures if air conditioning

system is damaged or leakingAll models

AH83.30-

N-0004-

01A

Protect air conditioning circuit and

components from moisture when

carrying out repair work

All models fitted with air conditioning

AH83.30-

N-0005-

01A

Notes on handling refrigerant

R134aAll models fitted with air conditioning

AH83.30-

N-0003-

01A

Risk of injury to skin and eyes

suffering scalding from contact

with hot coolant spray. Risk of

Do not open cooling system unless

coolant temperature is below 90°C. Open

cap slowly and release the pressure. Do

not pour coolant into beverage bottles.

AS20.00-Z-

0001-01A

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:18 PMPage 196 © 2006 Mitchell Repair Information Company, LLC.