MERCEDES-BENZ ML350 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML350, Model: MERCEDES-BENZ ML350 1997Pages: 4133, PDF Size: 88.89 MB

Page 3781 of 4133

B6 688 0819 Adapter kit for fender flares, bordeaux red1B6 688 0820 Adapter kit for fender flares, alabaster white1B6 688 0821 Adapter kit for fender flares, black opal1

B6 688 0822 Adapter kit for fender flares, tansanite blue1B6 688 0823 Adapter kit for fender flares, jaspis blue1

B6 688 0824 Adapter kit for fender flares, desert silver1B6 688 0825 Adapter kit for fender flares, andradite green1

az8830p0007ghRetrofit fender flares Page 3 of 3

Page 3782 of 4133

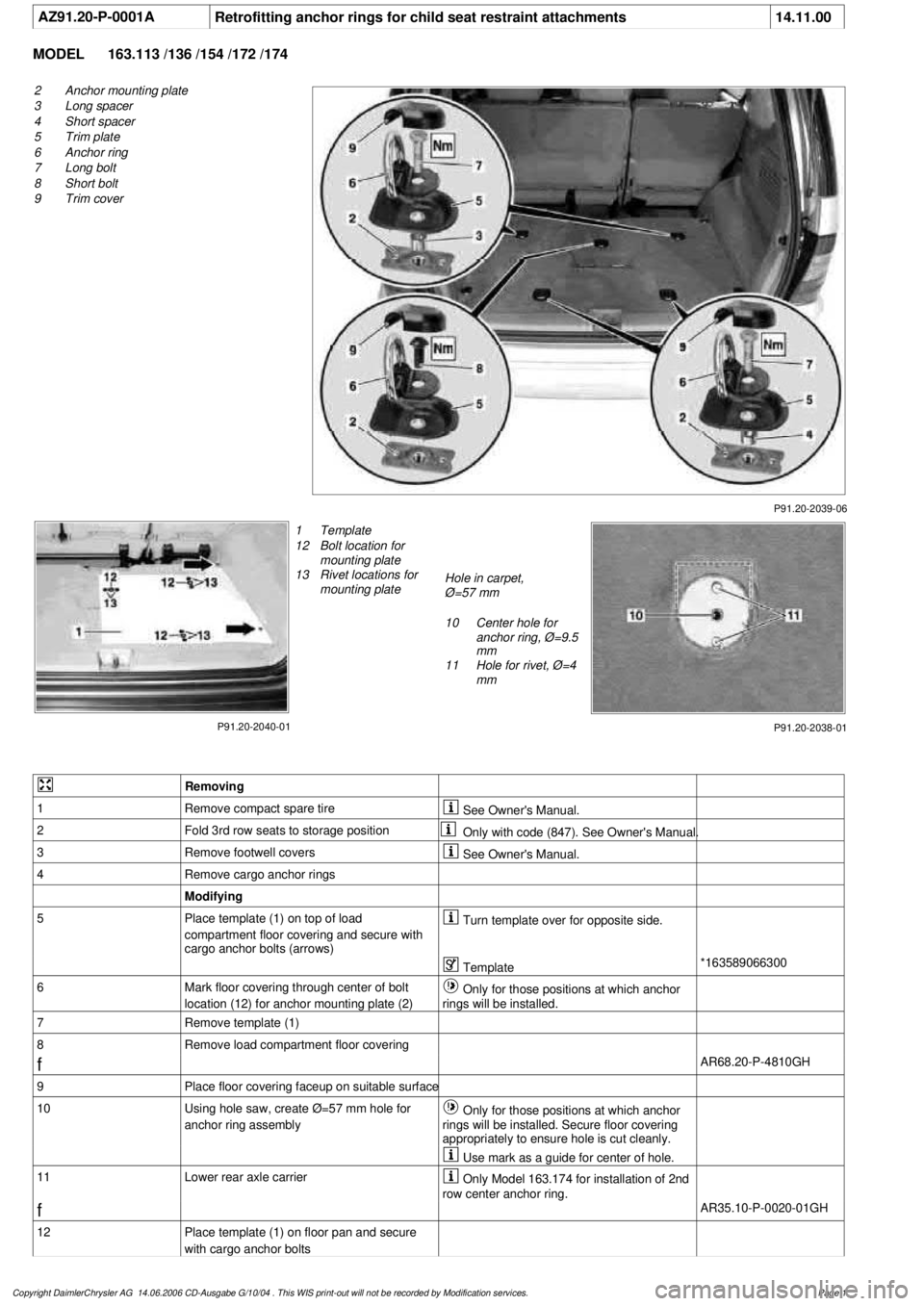

AZ91.20-P-0001A

Retrofitting anchor rings for child seat restraint attachments

14.11.00

MODEL

163.113 /136 /154 /172 /174

P91.20-2039-06

2

Anchor mounting plate

3

Long spacer

4

Short spacer

5

Trim plate

6

Anchor ring

7

Long bolt

8

Short bolt

9

Trim cover

P91.20-2040-01

1

Template

12

Bolt location for

mounting plate

13

Rivet locations for

mounting plate

Hole in carpet,

Ø=57 mm

10

Center hole for

anchor ring, Ø=9.5

mm

11

Hole for rivet, Ø=4

mm

P91.20-2038-01

Removing

1

Remove compact spare tire

See Owner's Manual.

2

Fold 3rd row seats to storage position

Only with code (847). See Owner's Manual.

3

Remove footwell covers

See Owner's Manual.

4

Remove cargo anchor rings

Modifying

5

Place template (1) on top of load

compartment floor covering and secure with

cargo anchor bolts (arrows)

Turn template over for opposite side.

Template

*163589066300

6

Mark floor covering through center of bolt

location (12) for anchor mounting plate (2)

Only for those positions at which anchor

rings will be installed.

7

Remove template (1)

8

Remove load compartment floor covering

f

AR68.20-P-4810GH

9

Place floor covering faceup on suitable surface

10

Using hole saw, create Ø=57 mm hole for

anchor ring assembly

Only for those positions at which anchor

rings will be installed. Secure floor covering

appropriately to ensure hole is cut cleanly.

Use mark as a guide for center of hole.

11

Lower rear axle carrier

Only Model 163.174 for installation of 2nd

row center anchor ring.

f

AR35.10-P-0020-01GH

12

Place template (1) on floor pan and secure

with cargo anchor bolts

Copyright DaimlerChrysler AG 14.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

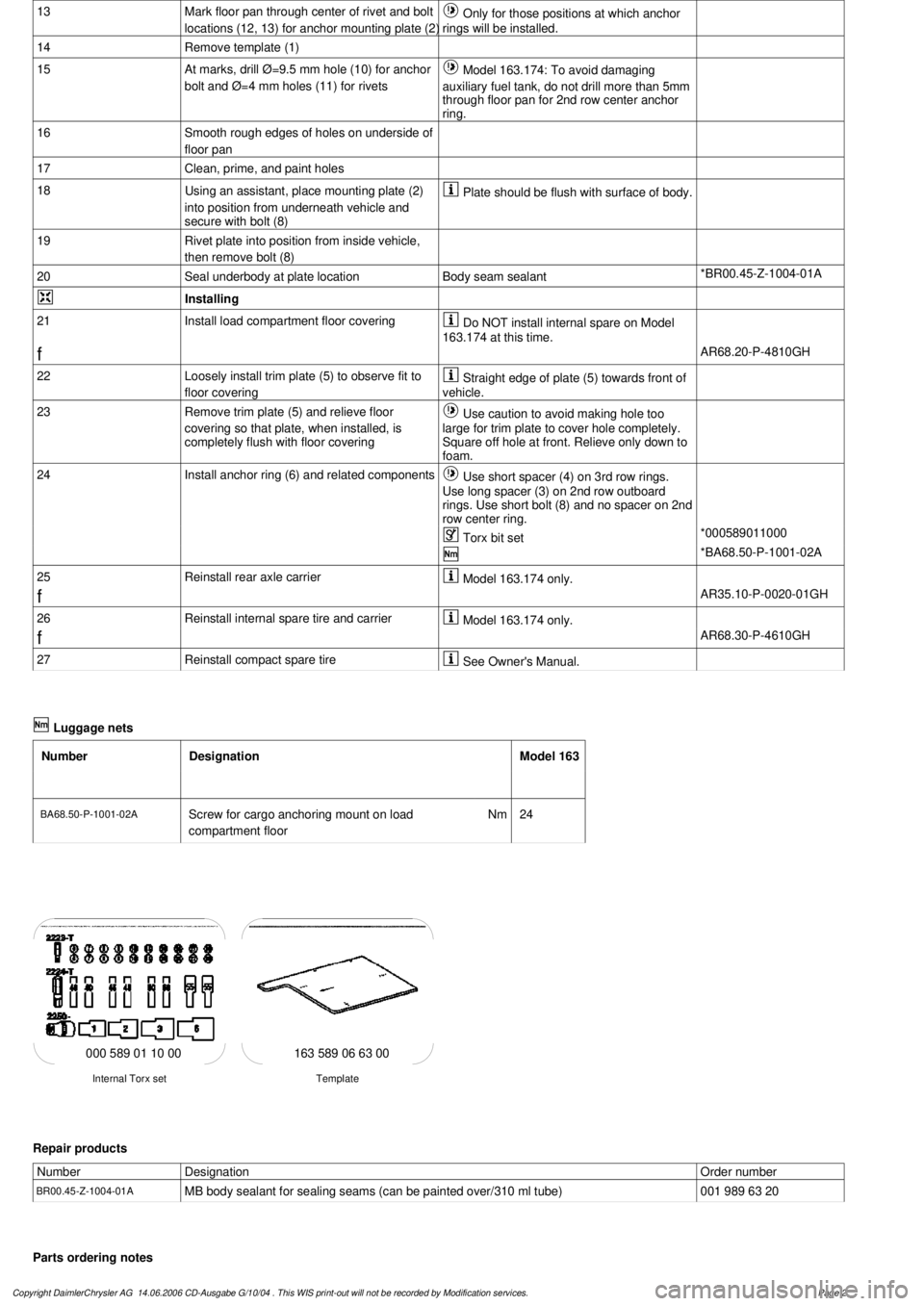

Page 3783 of 4133

13

Mark floor pan through center of rivet and bolt

locations (12, 13) for anchor mounting plate (2)

Only for those positions at which anchor

rings will be installed.

14

Remove template (1)

15

At marks, drill Ø=9.5 mm hole (10) for anchor

bolt and Ø=4 mm holes (11) for rivets

Model 163.174: To avoid damaging

auxiliary fuel tank, do not drill more than 5mm

through floor pan for 2nd row center anchor

ring.

16

Smooth rough edges of holes on underside of

floor pan

17

Clean, prime, and paint holes

18

Using an assistant, place mounting plate (2)

into position from underneath vehicle and

secure with bolt (8)

Plate should be flush with surface of body.

19

Rivet plate into position from inside vehicle,

then remove bolt (8)

20

Seal underbody at plate location

Body seam sealant

*BR00.45-Z-1004-01A

Installing

21

Install load compartment floor covering

Do NOT install internal spare on Model

163.174 at this time.

f

AR68.20-P-4810GH

22

Loosely install trim plate (5) to observe fit to

floor covering

Straight edge of plate (5) towards front of

vehicle.

23

Remove trim plate (5) and relieve floor

covering so that plate, when installed, is

completely flush with floor covering

Use caution to avoid making hole too

large for trim plate to cover hole completely.

Square off hole at front. Relieve only down to

foam.

24

Install anchor ring (6) and related components

Use short spacer (4) on 3rd row rings.

Use long spacer (3) on 2nd row outboard

rings. Use short bolt (8) and no spacer on 2nd

row center ring.

Torx bit set

*000589011000

*BA68.50-P-1001-02A

25

Reinstall rear axle carrier

Model 163.174 only.

f

AR35.10-P-0020-01GH

26

Reinstall internal spare tire and carrier

Model 163.174 only.

f

AR68.30-P-4610GH

27

Reinstall compact spare tire

See Owner's Manual.

Luggage nets

Number

Designation

Model 163

BA68.50-P-1001-02A

Screw for cargo anchoring mount on load

compartment floor

Nm

24

163 589 06 63 00

Template

Internal Torx set

000 589 01 10 00

Repair products

Number

Designation

Order number

BR00.45-Z-1004-01A

MB body sealant for sealing seams (can be painted over/310 ml tube)

001 989 63 20

Parts ordering notes

Copyright DaimlerChrysler AG 14.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

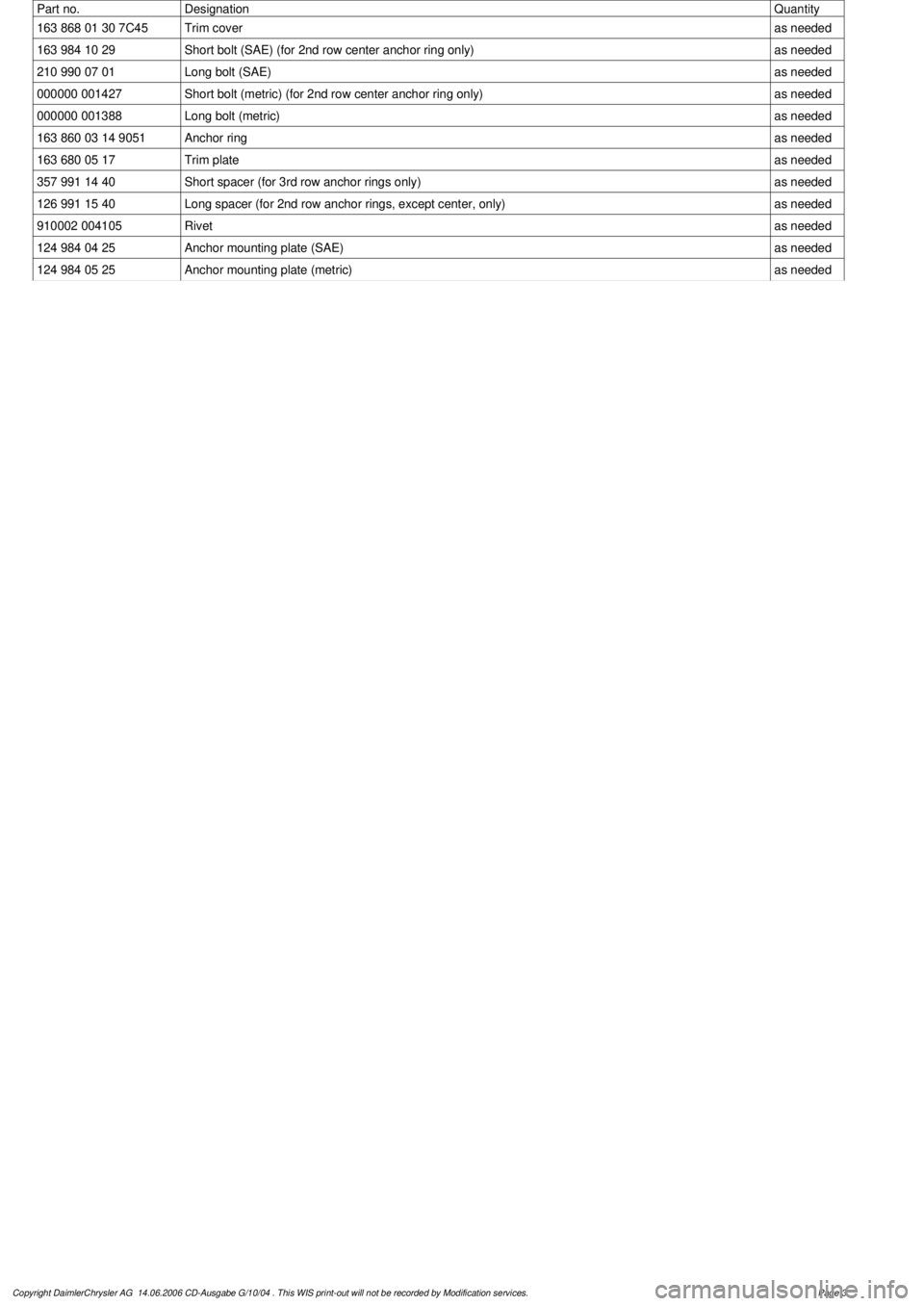

Page 3784 of 4133

Part no.

Designation

Quantity

163 868 01 30 7C45

Trim cover

as needed

163 984 10 29

Short bolt (SAE) (for 2nd row center anchor ring only)

as needed

210 990 07 01

Long bolt (SAE)

as needed

000000 001427

Short bolt (metric) (for 2nd row center anchor ring only)

as needed

000000 001388

Long bolt (metric)

as needed

163 860 03 14 9051

Anchor ring

as needed

163 680 05 17

Trim plate

as needed

357 991 14 40

Short spacer (for 3rd row anchor rings only)

as needed

126 991 15 40

Long spacer (for 2nd row anchor rings, except center, only)

as needed

910002 004105

Rivet

as needed

124 984 04 25

Anchor mounting plate (SAE)

as needed

124 984 05 25

Anchor mounting plate (metric)

as needed

Copyright DaimlerChrysler AG 14.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 3785 of 4133

AN68.30-P-0001-02B

Modify roof paneling for installing handle and

clamping strap mount

Model 163.113 /154 #A as of 289565,

Model 163.113 #X as of 754620,

Model 163.128/ 157/ 175

with code (847), 3rd seat row

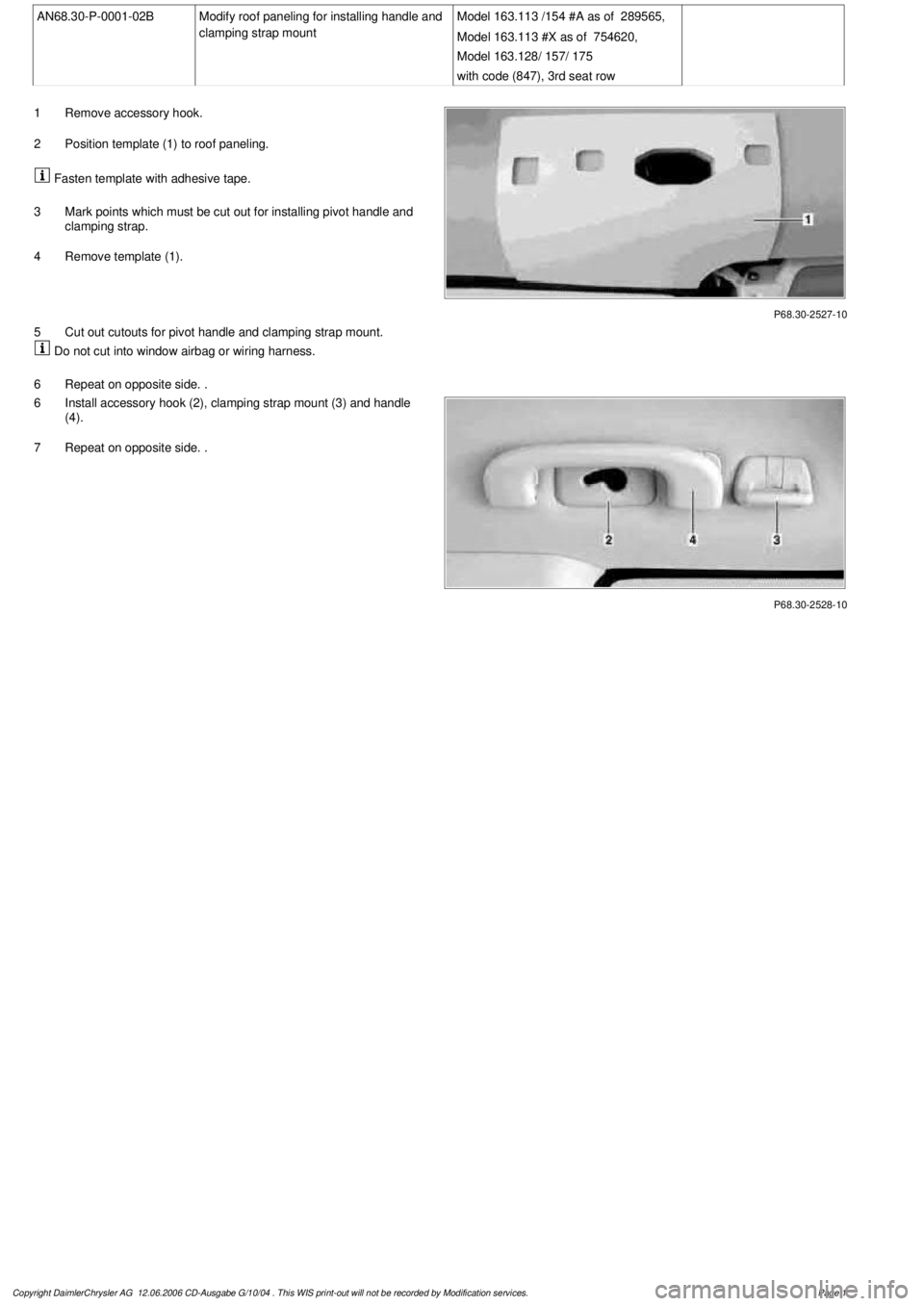

P68.30-2527-10

1

Remove accessory hook.

2

Position template (1) to roof paneling.

Fasten template with adhesive tape.

3

Mark points which must be cut out for installing pivot handle and

clamping strap.

4

Remove template (1).

5

Cut out cutouts for pivot handle and clamping strap mount.

Do not cut into window airbag or wiring harness.

6

Repeat on opposite side. .

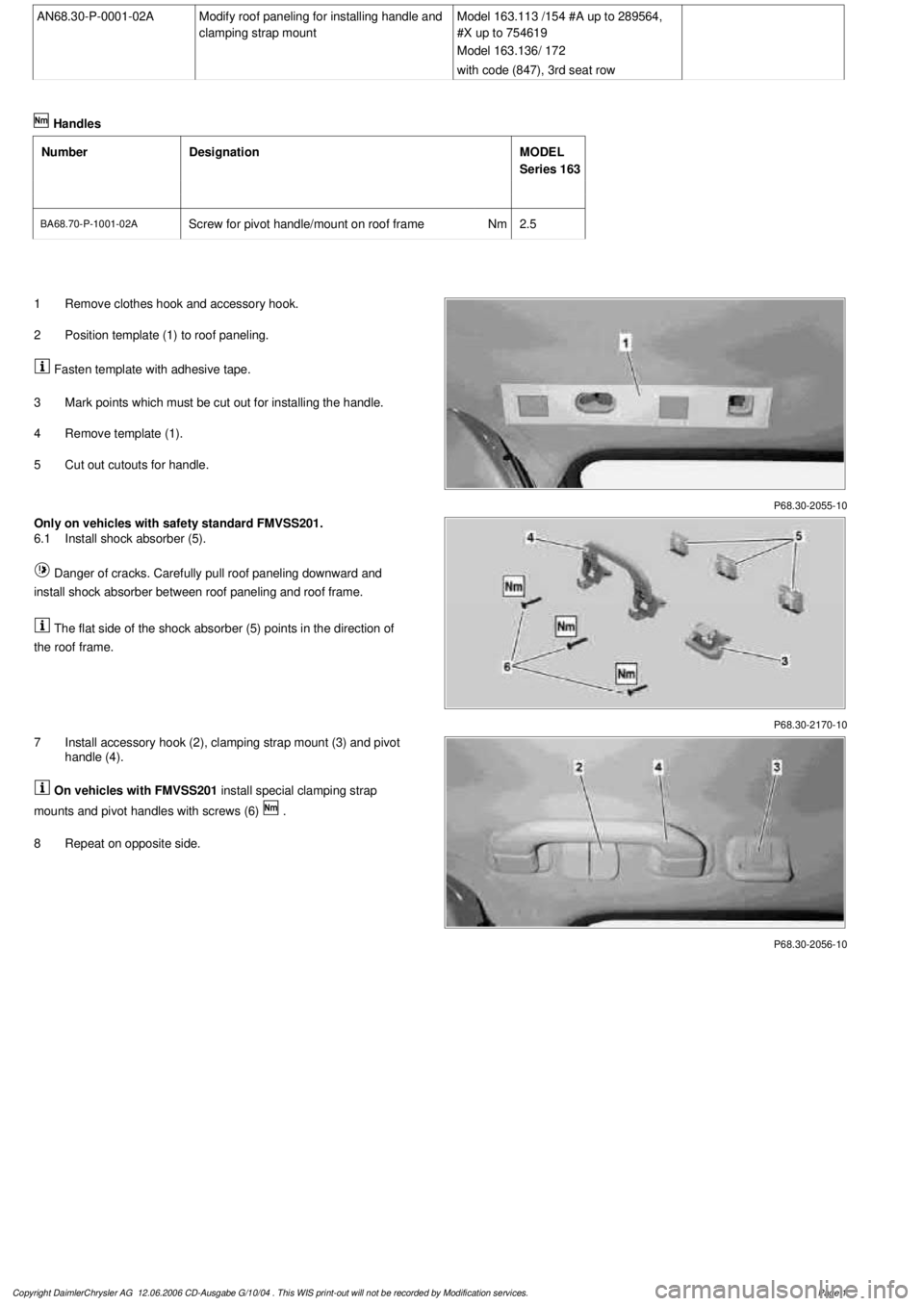

P68.30-2528-10

6

Install accessory hook (2), clamping strap mount (3) and handle

(4).

7

Repeat on opposite side. .

Copyright DaimlerChrysler AG 12.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3786 of 4133

AN68.30-P-0001-02A

Modify roof paneling for installing handle and

clamping strap mount

Model 163.113 /154 #A up to 289564,

#X up to 754619

Model 163.136/ 172

with code (847), 3rd seat row

Handles

Number

Designation

MODEL

Series 163

BA68.70-P-1001-02A

Screw for pivot handle/mount on roof frame

Nm

2.5

P68.30-2055-10

1

Remove clothes hook and accessory hook.

2

Position template (1) to roof paneling.

Fasten template with adhesive tape.

3

Mark points which must be cut out for installing the handle.

4

Remove template (1).

5

Cut out cutouts for handle.

P68.30-2170-10

Only on vehicles with safety standard FMVSS201.

6.1

Install shock absorber (5).

Danger of cracks. Carefully pull roof paneling downward and

install shock absorber between roof paneling and roof frame.

The flat side of the shock absorber (5) points in the direction of

the roof frame.

P68.30-2056-10

7

Install accessory hook (2), clamping strap mount (3) and pivot

handle (4).

On vehicles with FMVSS201

install special clamping strap

mounts and pivot handles with screws (6)

.

8

Repeat on opposite side.

Copyright DaimlerChrysler AG 12.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3787 of 4133

AR46.40-P-0400GH

Check and replace rubber boot

12.3.97

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P46.40-0263-12

10i

Clamp nut

11

Boot

11a

Inner clamp nut

11b

Outer clamp

23k

O-ring

Inspect

1

Check bellows (11)

Never check bellows by pressing in or

around the bead, as this leaves behind

damage to the plastic and results in leaks in

the long-term.

Because the seals on the rubber boots

must be absolutely tight and leak-free to

ensure that the steering rack continues to

provide reliable operation, a visual inspection

should be carried out as follows:

D

Raise vehicle at the front axle

D

Extend the bellows by turning the steering

onto left or right lock and in the process

check for damage (cracks, chafing marks

and intrusions) and replace if necessary.

Remove/Install

2

Remove track rod

AR46.40-P-0200GH

3

Unscrew clamping nut (10i)

4

Detach outer clamp (11b)

5

Detach inner clamp (11a)

AR46.40-P-0400-01GH

6

Pull off bellows (11)

7

Replace O-ring (23k)

8

Check steering rack and inner tie rod thrust

joint for corrosion and play

If the rack is already corroded and the

steering has a leak as a result, it is then

necessary to replace the complete rack-and-

pinion steering:

#

Remove/install rack-and-pinion steering

AR46.20-P-0600GH

If axial joint is worn, replace the inner

track rod:

#

Remove/install inner tie rod with axial joint

AR46.40-P-0201GH

9

Install in the reverse order

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3788 of 4133

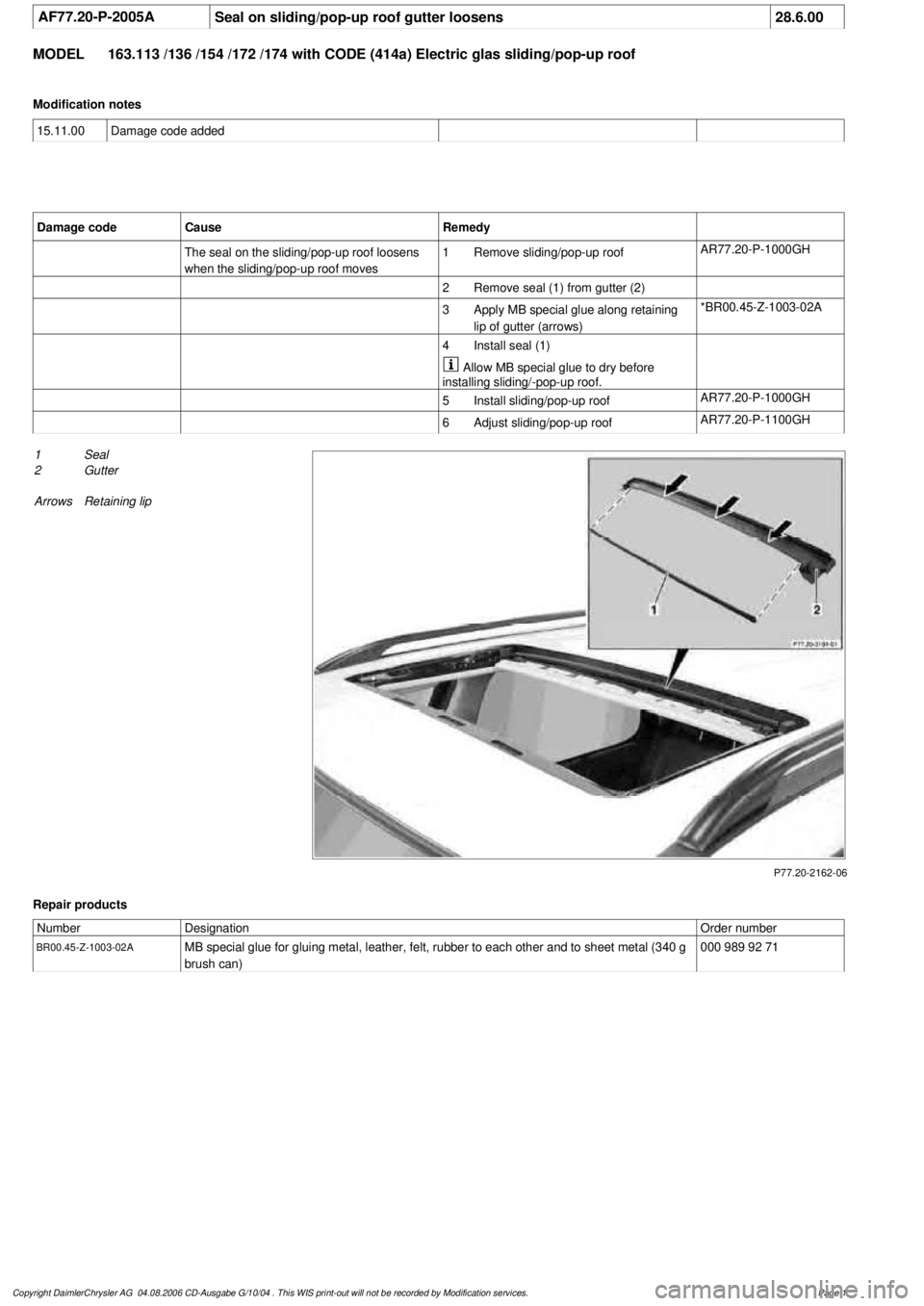

AF77.20-P-2005A

Seal on sliding/pop-up roof gutter loosens

28.6.00

MODEL

163.113 /136 /154 /172 /174 with CODE (414a) Electric glas sliding/pop-up roof

Modification notes

15.11.00

Damage code added

Damage code

Cause

Remedy

The seal on the sliding/pop-up roof loosens

when the sliding/pop-up roof moves

1

Remove sliding/pop-up roof

AR77.20-P-1000GH

2

Remove seal (1) from gutter (2)

3

Apply MB special glue along retaining

lip of gutter (arrows)

*BR00.45-Z-1003-02A

4

Install seal (1)

Allow MB special glue to dry before

installing sliding/-pop-up roof.

5

Install sliding/pop-up roof

AR77.20-P-1000GH

6

Adjust sliding/pop-up roof

AR77.20-P-1100GH

P77.20-2162-06

1

Seal

2

Gutter

Arrows

Retaining lip

Repair products

Number

Designation

Order number

BR00.45-Z-1003-02A

MB special glue for gluing metal, leather, felt, rubber to each other and to sheet metal (340 g

brush can)

000 989 92 71

Copyright DaimlerChrysler AG 04.08.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3789 of 4133

AR91.29-P-0008GH

Remove/install seat adjustment control module

23.6.99

MODEL

163.113 /128,

163.136 /154 as of 1.9.99,

163.157,

163.172 as of 1.9.99,

163.175

with CODE (241) Memory for electrically adjustable left front seat

with CODE (242a) Memory for electrically adjustable right front seat

MODEL

163.174

P91.29-2108-06

1

Coupling for left front seat

adjustment switch or right front seat

adjustment switch

2

Coupling for interior wiring harness

3

Coupling for height adjustment

motor for rear front seat cushion

4

Coupling for horizontal adjustment

motor for front seat

5

Coupling for height adjustment

motor for front front seat cushion

6

Coupling for electrical line for seat

belt buckle of front seat

P91.29-2108-06

7

Coupling for front seat backrest

angle motor

8

Coupling for automatic child seat

recognition

9

Coupling for heated seats

10

Bracket

11

Retaining lugs

N32/1

Left front seat adjustment control

module with memory

N32/2

Right front seat adjustment control

module with memory

Remove/Install

1

Move front seat forwards and adjust rear front

seat cushion upwards

2

Disconnect connector from coupling for left

front seat adjustment switch or right front seat

adjustment switch (1) and from the coupling

for interior wiring harness (2) on the left front

seat adjustment control module with memory

(N32/1) or right front seat adjustment control

module with memory (N32/2)

Copyright DaimlerChrysler AG 14.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3790 of 4133

3

Unscrew bolt (arrow) from bracket (10),

unhook front bracket and remove

4

Remove left front seat adjustment control

module with memory (N32/1) or right front

seat adjustment control module with memory

(N32/2) from bracket on front seat frame

Unhook two retaining lugs (11) on the side.

5

Disconnect the remaining connectors on the

left front seat adjustment control module with

memory (N32/1) or right front seat adjustment

control module with memory (N32/2)

6

Remove left front seat adjustment control

module with memory (N32/1) or right front

seat adjustment control module with memory

(N32/2)

7

Install in the reverse order

8

Perform function check

Copyright DaimlerChrysler AG 14.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2