heating MERCEDES-BENZ ML500 1997 Complete Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML500, Model: MERCEDES-BENZ ML500 1997Pages: 4133, PDF Size: 88.89 MB

Page 1489 of 4133

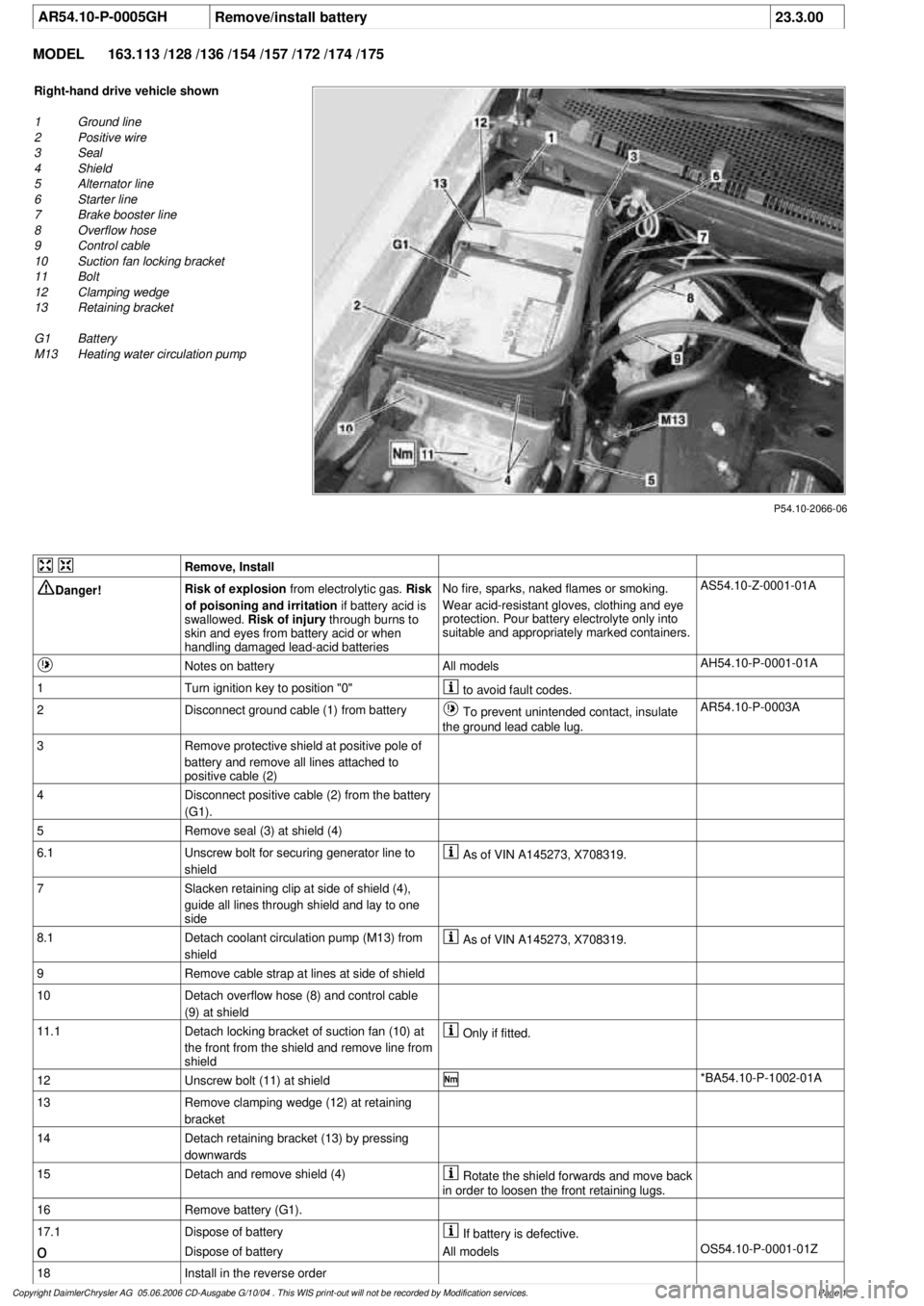

AR54.10-P-0005GH

Remove/install battery

23.3.00

MODEL

163.113 /128 /136 /154 /157 /172 /174 /175

P54.10-2066-06

Right-hand drive vehicle shown

1

Ground line

2

Positive wire

3

Seal

4

Shield

5

Alternator line

6

Starter line

7

Brake booster line

8

Overflow hose

9

Control cable

10

Suction fan locking bracket

11

Bolt

12

Clamping wedge

13

Retaining bracket

G1 Battery

M13

Heating water circulation pump

Remove, Install

Danger!

Risk of explosion

from electrolytic gas.

Risk

of poisoning and irritation

if battery acid is

swallowed.

Risk of injury

through burns to

skin and eyes from battery acid or when

handling damaged lead-acid batteries

No fire, sparks, naked flames or smoking.

Wear acid-resistant gloves, clothing and eye

protection. Pour battery electrolyte only into

suitable and appropriately marked containers.

AS54.10-Z-0001-01A

Notes on battery

All models

AH54.10-P-0001-01A

1

Turn ignition key to position "0"

to avoid fault codes.

2

Disconnect ground cable (1) from battery

To prevent unintended contact, insulate

the ground lead cable lug.

AR54.10-P-0003A

3

Remove protective shield at positive pole of

battery and remove all lines attached to

positive cable (2)

4

Disconnect positive cable (2) from the battery

(G1).

5

Remove seal (3) at shield (4)

6.1

Unscrew bolt for securing generator line to

shield

As of VIN A145273, X708319.

7

Slacken retaining clip at side of shield (4),

guide all lines through shield and lay to one

side

8.1

Detach coolant circulation pump (M13) from

shield

As of VIN A145273, X708319.

9

Remove cable strap at lines at side of shield

10

Detach overflow hose (8) and control cable

(9) at shield

11.1

Detach locking bracket of suction fan (10) at

the front from the shield and remove line from

shield

Only if fitted.

12

Unscrew bolt (11) at shield

*BA54.10-P-1002-01A

13

Remove clamping wedge (12) at retaining

bracket

14

Detach retaining bracket (13) by pressing

downwards

15

Detach and remove shield (4)

Rotate the shield forwards and move back

in order to loosen the front retaining lugs.

16

Remove battery (G1).

17.1

Dispose of battery

If battery is defective.

o

Dispose of battery

All models

OS54.10-P-0001-01Z

18

Install in the reverse order

Copyright DaimlerChrysler AG 05.06.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 1611 of 4133

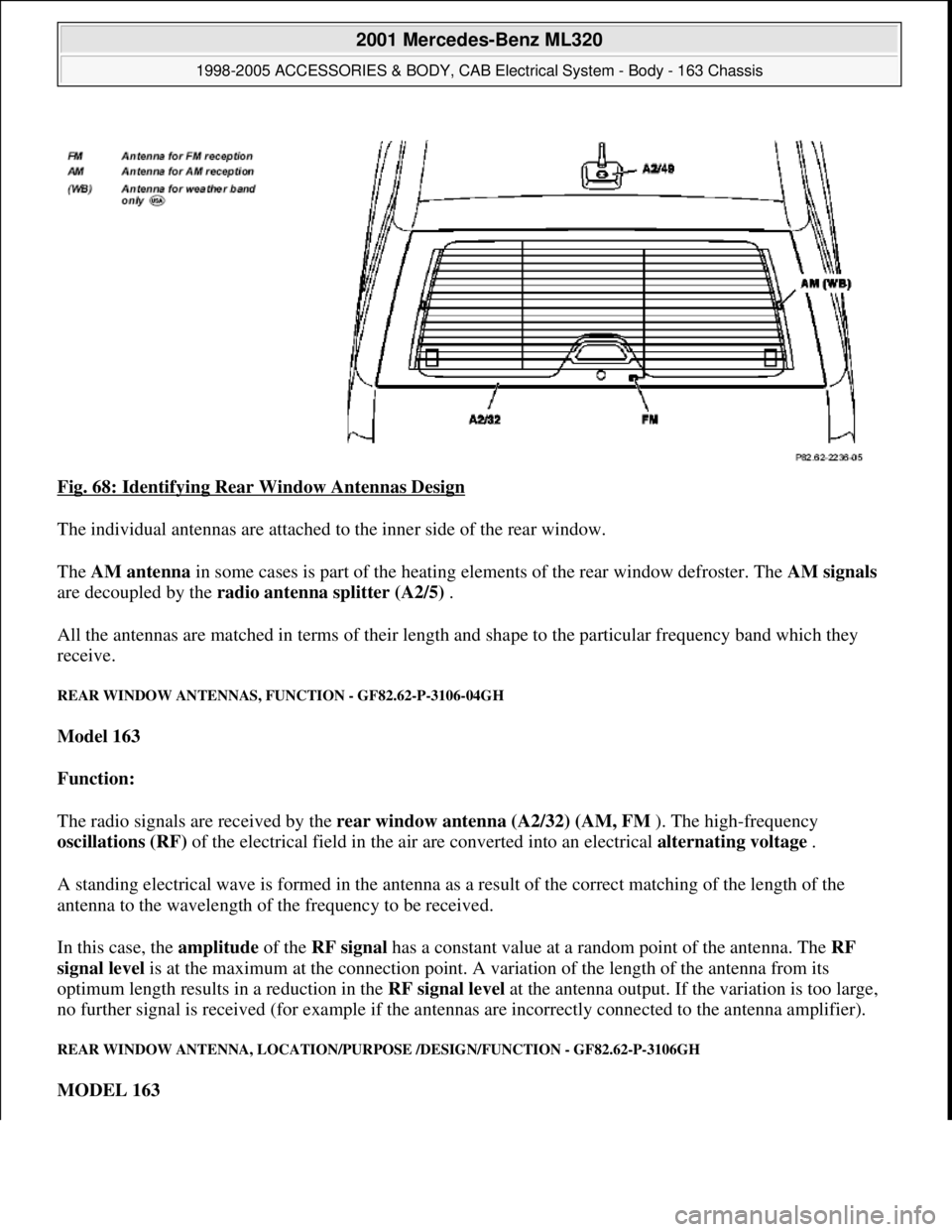

Fig. 68: Identifying Rear Window Antennas Design

The individual antennas are attached to the inner side of the rear window.

The AM antenna in some cases is part of the heating elements of the rear window defroster. The AM signals

are decoupled by the radio antenna splitter (A2/5) .

All the antennas are matched in terms of their length and shape to the particular frequency band which they

receive.

REAR WINDOW ANTENNAS, FUNCTION - GF82.62-P-3106-04GH

Model 163

Function:

The radio signals are received by the rear window antenna (A2/32) (AM, FM ). The high-frequency

oscillations (RF) of the electrical field in the air are converted into an electrical alternating voltage .

A standing electrical wave is formed in the antenna as a result of the correct matching of the length of the

antenna to the wavelength of the frequency to be received.

In this case, the amplitude of the RF signal has a constant value at a random point of the antenna. The RF

signal level is at the maximum at the connection point. A variation of the length of the antenna from its

optimum length results in a reduction in the RF signal level at the antenna output. If the variation is too large,

no further signal is received (for example if the antennas are incorrectly connected to the antenna amplifier).

REAR WINDOW ANTENNA, LOCATION/PURPOSE /DESIGN/FUNCTION - GF82.62-P-3106GH

MODEL 163

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:06 PMPage 116 © 2006 Mitchell Repair Information Company, LLC.

Page 1665 of 4133

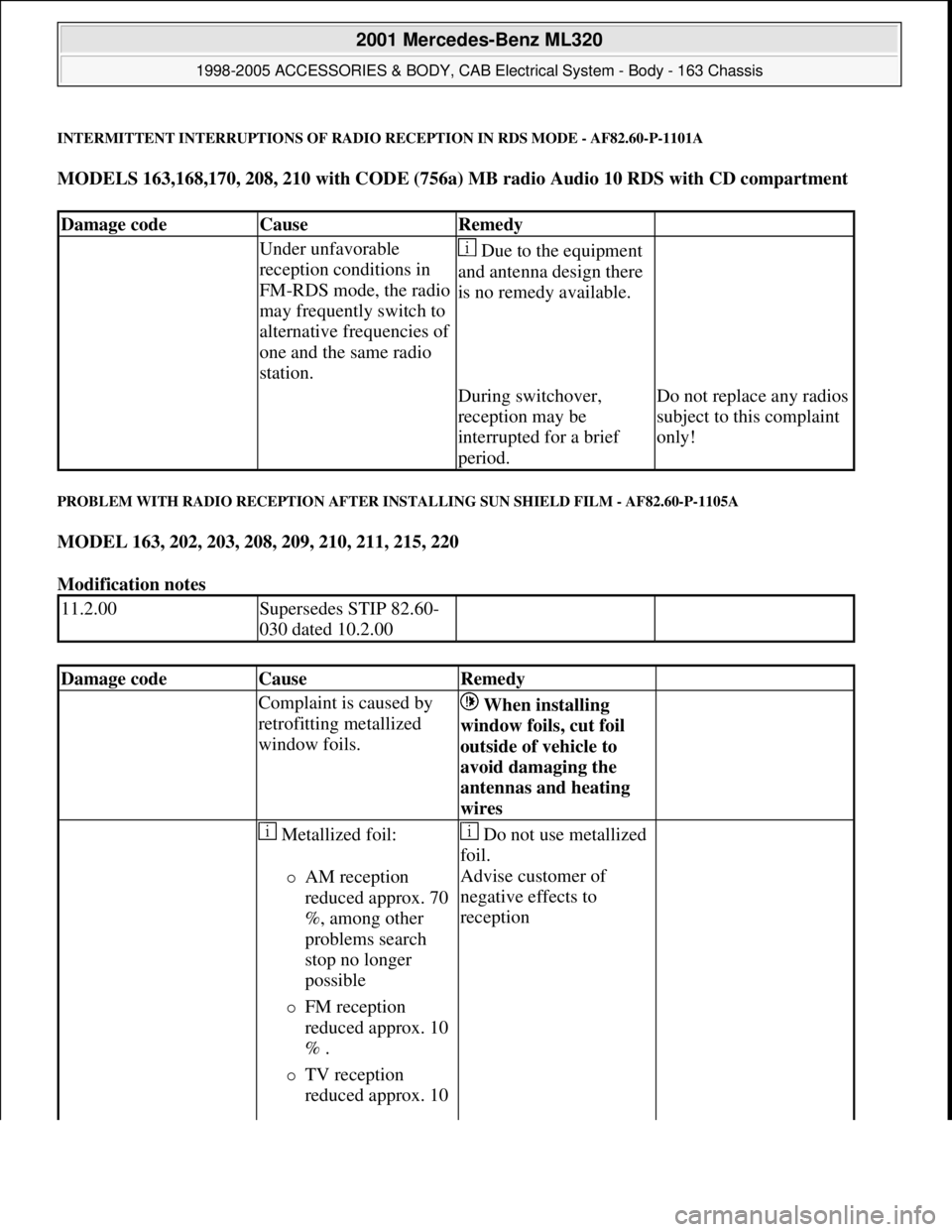

INTERMITTENT INTERRUPTIONS OF RADIO RECEPTION IN RDS MODE - AF82.60-P-1101A

MODELS 163,168,170, 208, 210 with CODE (756a) MB radio Audio 10 RDS with CD compartment

PROBLEM WITH RADIO RECEPTION AFTER INSTALLING SUN SHIELD FILM - AF82.60-P-1105A

MODEL 163, 202, 203, 208, 209, 210, 211, 215, 220

Modification notes

Damage codeCauseRemedy

Under unfavorable

reception conditions in

FM-RDS mode, the radio

may frequently switch to

alternative frequencies of

one and the same radio

station. Due to the equipment

and antenna design there

is no remedy available.

During switchover,

reception may be

interrupted for a brief

period.Do not replace any radios

subject to this complaint

only!

11.2.00Supersedes STIP 82.60-

030 dated 10.2.00

Damage codeCauseRemedy

Complaint is caused by

retrofitting metallized

window foils. When installing

window foils, cut foil

outside of vehicle to

avoid damaging the

antennas and heating

wires

Metallized foil:

AM reception

reduced approx. 70

%, among other

problems search

stop no longer

possible

FM reception

reduced approx. 10

% .

TV reception

reduced approx. 10

Do not use metallized

foil.

Advise customer of

negative effects to

reception

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:07 PMPage 170 © 2006 Mitchell Repair Information Company, LLC.

Page 1716 of 4133

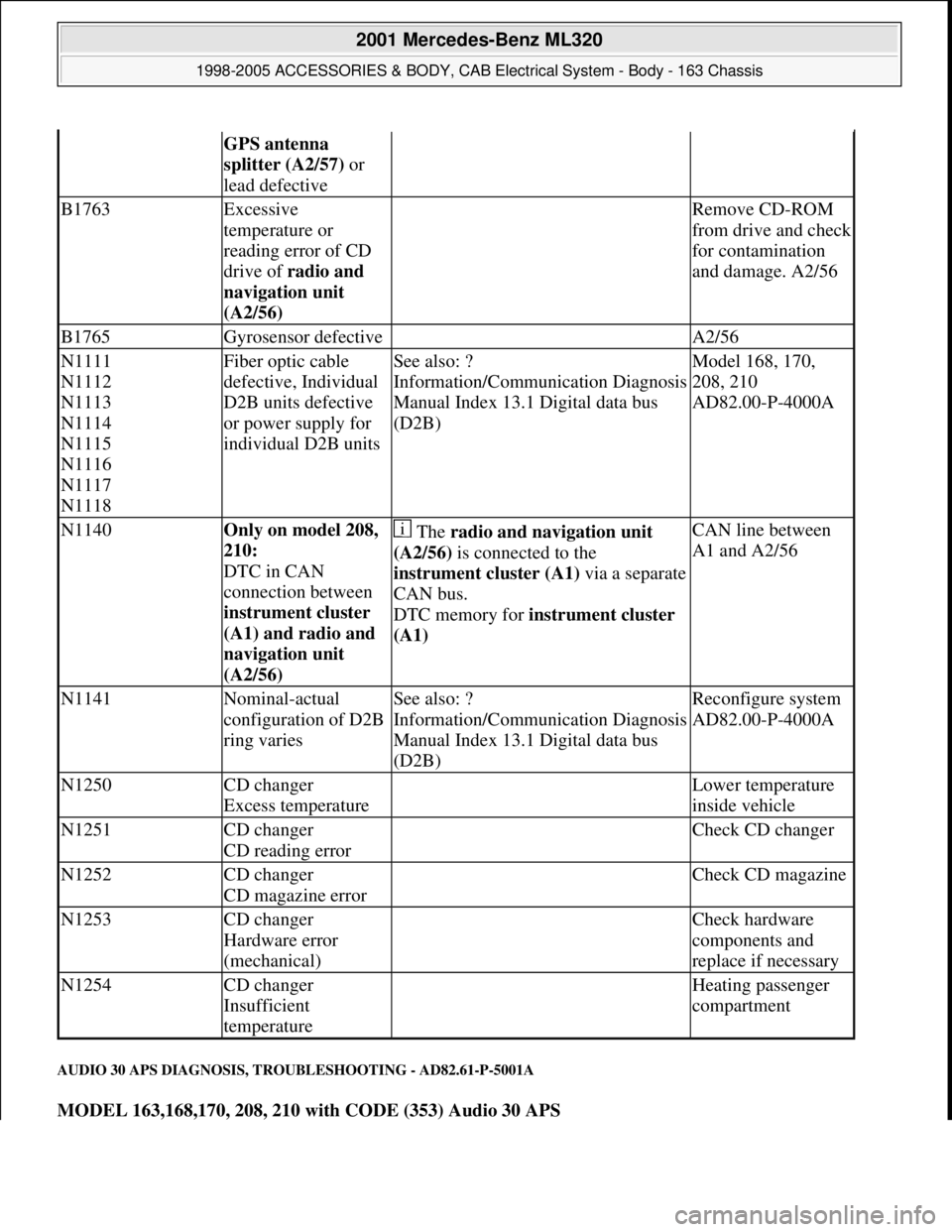

AUDIO 30 APS DIAGNOSIS, TROUBLESHOOTING - AD82.61-P-5001A

MODEL 163,168,170, 208, 210 with CODE (353) Audio 30 APS

GPS antenna

splitter (A2/57) or

lead defective

B1763Excessive

temperature or

reading error of CD

drive of radio and

navigation unit

(A2/56) Remove CD-ROM

from drive and check

for contamination

and damage. A2/56

B1765Gyrosensor defective A2/56

N1111

N1112

N1113

N1114

N1115

N1116

N1117

N1118Fiber optic cable

defective, Individual

D2B units defective

or power supply for

individual D2B unitsSee also: ?

Information/Communication Diagnosis

Manual Index 13.1 Digital data bus

(D2B)Model 168, 170,

208, 210

AD82.00-P-4000A

N1140Only on model 208,

210:

DTC in CAN

connection between

instrument cluster

(A1) and radio and

navigation unit

(A2/56) The radio and navigation unit

(A2/56) is connected to the

instrument cluster (A1)via a separate

CAN bus.

DTC memory for instrument cluster

(A1) CAN line between

A1 and A2/56

N1141Nominal-actual

configuration of D2B

ring variesSee also: ?

Information/Communication Diagnosis

Manual Index 13.1 Digital data bus

(D2B)Reconfigure system

AD82.00-P-4000A

N1250CD changer

Excess temperature Lower temperature

inside vehicle

N1251CD changer

CD reading error Check CD changer

N1252CD changer

CD magazine error Check CD magazine

N1253CD changer

Hardware error

(mechanical) Check hardware

components and

replace if necessary

N1254CD changer

Insufficient

temperature Heating passenger

compartment

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:08 PMPage 221 © 2006 Mitchell Repair Information Company, LLC.

Page 2068 of 4133

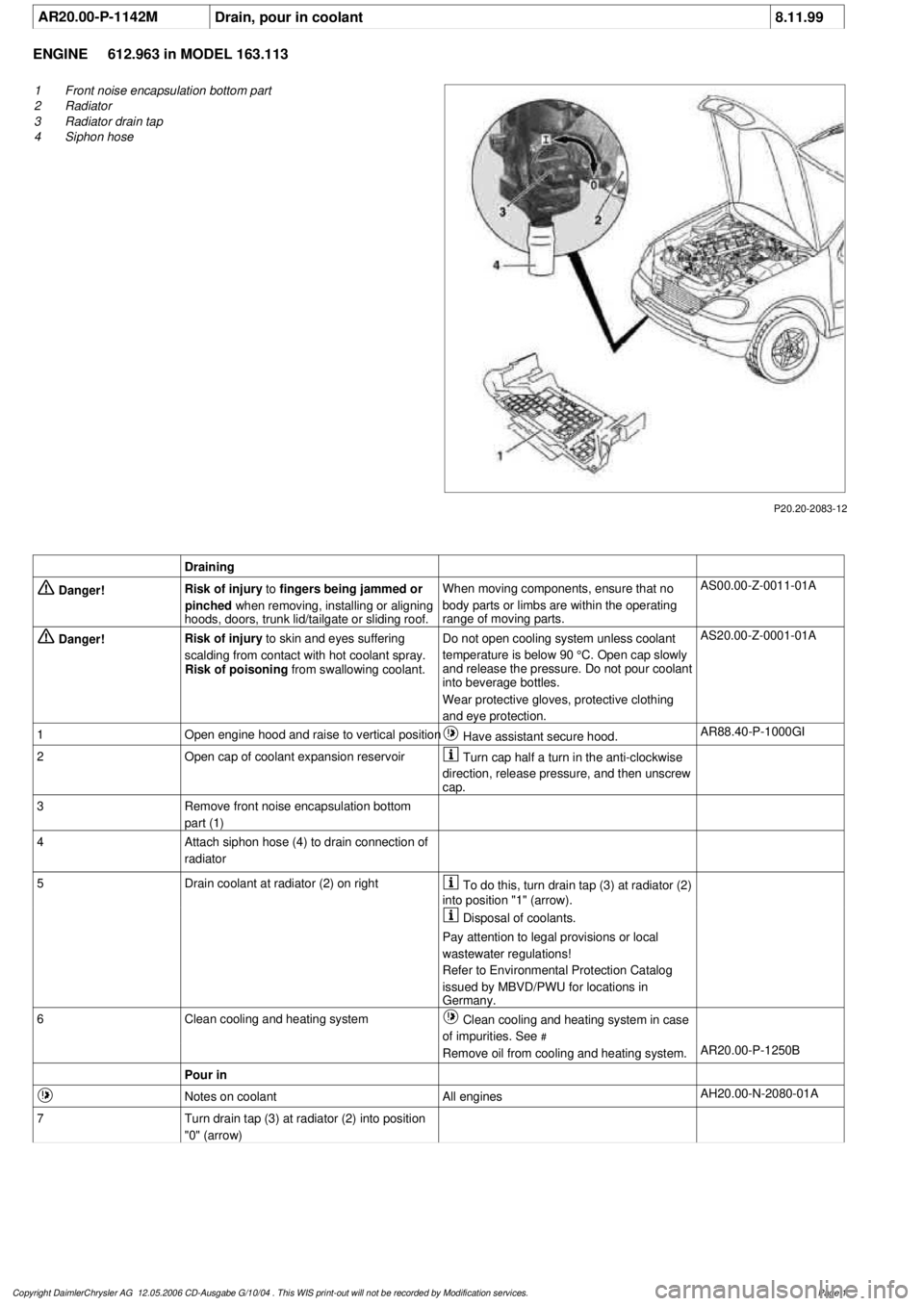

AR20.00-P-1142M

Drain, pour in coolant

8.11.99

ENGINE

612.963 in MODEL 163.113

P20.20-2083-12

1

Front noise encapsulation bottom part

2

Radiator

3

Radiator drain tap

4

Siphon hose

Draining

Danger!

Risk of injury

to

fingers being jammed or

pinched

when removing, installing or aligning

hoods, doors, trunk lid/tailgate or sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

Danger!

Risk of injury

to skin and eyes suffering

scalding from contact with hot coolant spray.

Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90 °C. Open cap slowly

and release the pressure. Do not pour coolant

into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-0001-01A

1

Open engine hood and raise to vertical position

Have assistant secure hood.

AR88.40-P-1000GI

2

Open cap of coolant expansion reservoir

Turn cap half a turn in the anti-clockwise

direction, release pressure, and then unscrew

cap.

3

Remove front noise encapsulation bottom

part (1)

4

Attach siphon hose (4) to drain connection of

radiator

5

Drain coolant at radiator (2) on right

To do this, turn drain tap (3) at radiator (2)

into position "1" (arrow).

Disposal of coolants.

Pay attention to legal provisions or local

wastewater regulations!

Refer to Environmental Protection Catalog

issued by MBVD/PWU for locations in

Germany.

6

Clean cooling and heating system

Clean cooling and heating system in case

of impurities. See

#

Remove oil from cooling and heating system.

AR20.00-P-1250B

Pour in

Notes on coolant

All engines

AH20.00-N-2080-01A

7

Turn drain tap (3) at radiator (2) into position

"0" (arrow)

Copyright DaimlerChrysler AG 12.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2075 of 4133

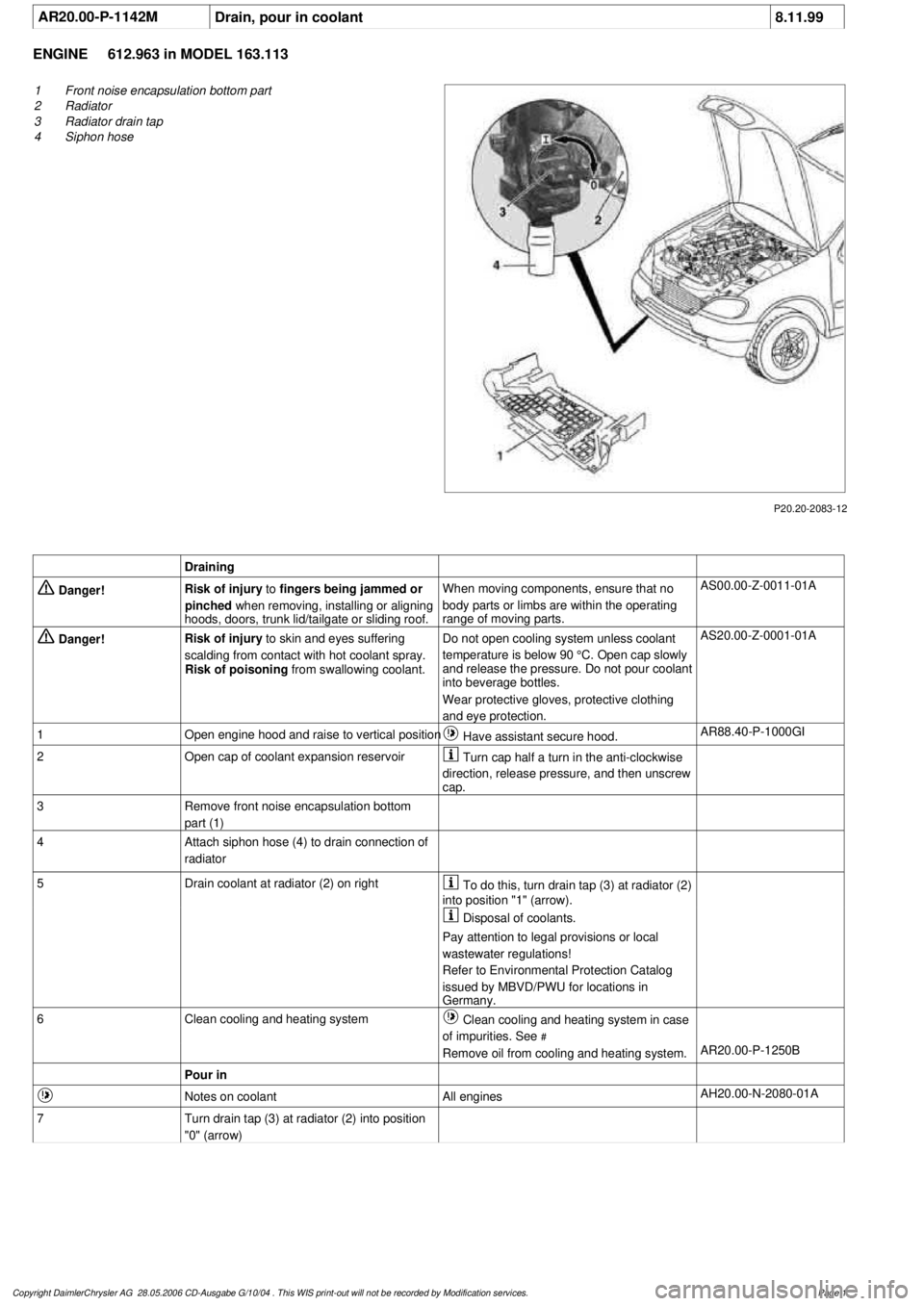

AR20.00-P-1142M

Drain, pour in coolant

8.11.99

ENGINE

612.963 in MODEL 163.113

P20.20-2083-12

1

Front noise encapsulation bottom part

2

Radiator

3

Radiator drain tap

4

Siphon hose

Draining

Danger!

Risk of injury

to

fingers being jammed or

pinched

when removing, installing or aligning

hoods, doors, trunk lid/tailgate or sliding roof.

When moving components, ensure that no

body parts or limbs are within the operating

range of moving parts.

AS00.00-Z-0011-01A

Danger!

Risk of injury

to skin and eyes suffering

scalding from contact with hot coolant spray.

Risk of poisoning

from swallowing coolant.

Do not open cooling system unless coolant

temperature is below 90 °C. Open cap slowly

and release the pressure. Do not pour coolant

into beverage bottles.

Wear protective gloves, protective clothing

and eye protection.

AS20.00-Z-0001-01A

1

Open engine hood and raise to vertical position

Have assistant secure hood.

AR88.40-P-1000GI

2

Open cap of coolant expansion reservoir

Turn cap half a turn in the anti-clockwise

direction, release pressure, and then unscrew

cap.

3

Remove front noise encapsulation bottom

part (1)

4

Attach siphon hose (4) to drain connection of

radiator

5

Drain coolant at radiator (2) on right

To do this, turn drain tap (3) at radiator (2)

into position "1" (arrow).

Disposal of coolants.

Pay attention to legal provisions or local

wastewater regulations!

Refer to Environmental Protection Catalog

issued by MBVD/PWU for locations in

Germany.

6

Clean cooling and heating system

Clean cooling and heating system in case

of impurities. See

#

Remove oil from cooling and heating system.

AR20.00-P-1250B

Pour in

Notes on coolant

All engines

AH20.00-N-2080-01A

7

Turn drain tap (3) at radiator (2) into position

"0" (arrow)

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2139 of 4133

GF54.21-P-4106-01GH

Extended Activity Module - Task

n

The primary tasks of the Extended Activity Module (EAM, N10/1) are

as follows:

D

To control the door sill lights

D

To suppress the auto-dimming mirror function

D

To control the headlight cleaning system (HCS)

D

To control the rear window defroster

D

To control seat heating

D

To control the power supply via control console to tilt/sliding or

louvered sunroof switch

D

To control the PTC heater booster (R22/3)

D

To control the auxiliary fan (M4)

D

To read the cruise control switch (S40) and relay data to control

module (DAS, N73/1)

D

To read the contacts for wiper speed settings 1 and 2 on

combination switch (S4) for diagnosis.

To perform these tasks the Extended Activity Module (EAM, N10/1)

reads various signals and switch settings directly.

The Extended Activity Module (EAM, N10/1) interfaces with other

control modules via the engine compartment CAN.

-----------------------------------------------------------------------------------------

Diagnosis

Diagnosis is performed using the Star diagnostic tool. To facilitate

this task, the Extended Activity Module (EAM, N10/1) is equipped

with its own diagnostics cable.

This cable is also used to diagnose the

All Activity Module (AAM,

N10)

and the

transfer case control module (N78)

.

The Extended Activity Module (EAM, N10/1) is linked to the All

Activity Module (AAM, N10) via the

engine compartment CAN

.

Data communication between the All Activity Module (AAM,

N10) and the Extended Activity Module (EAM, N10/1) is

assumed by the

CAN (N10 - N10/1)

when terminal 15 is off.

The CAN (N10 - N10/1)

is an independent CAN bus located

between the All Activity Module (AAM, N10) and the Extended

Activity Module (EAM, N10/1).

No other

control modules are

connected to the CAN (N10 - N10/1).

-----------------------------------------------------------------------------------------

Details:

Door sill lights

When the front interior light is on and one of the front doors is open,

or when the rear interior light is on and one of the back doors is open,

the door sill lights for the open door will illuminate.

Headlight cleaning system (HCS)

Activating a separate switch causes the EAM to send a turn-on signal

to the HCS pump relay.

EAM will send an additional turn-on signal to the HCS pump relay

only after the cleaning operation is completed and a "rest period" of

approximately 2.5 sec. has passed.

Auto-dimming mirror function

The auto-dimming mirror function is suppressed when the interior

light is on or reverse gear is engaged.

Auto-dimming suppression for the outside rearview mirror (slave) is

activated by the inside rearview mirror (master).

Heater booster/PTC air heater for diesel engines

EAM monitors system voltage and adjusts heater booster capacity to

minimize load on battery.

Rear window defroster

EAM sets maximum ON time for rear window defroster depending

on outdoor temperature and current vehicle speed.

D

Standard ON time:

10 min.

D

Outdoor temperature < 5

o

C:

Additional 5 min.

D

Speed >80 km/h:

Additional 3 min.

Seat heating

Sets maximum seat heating time.

D

Setting 1: max. 20 min.

D

Setting 2: max. 5 min.

Tilt/sliding or louvered sunroofs

Signal via AAM2 allows operation of tilt/sliding or louvered sunroofs

when ignition is on (standard mode) or off (keyless mode).

Ignition authorization via CAN

The EAM issues ignition authorization to AAM2 via the engine

compartment CAN depending on the requirements of the engine

control unit in connection with the FBM.

Copyright DaimlerChrysler AG 18.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 2171 of 4133

Engine load

Crankshaft position sensor

Camshaft Hall sensor

Coolant temperature sensor

Intake air temperature sensor/charge air.

Coil ignition: The ME control unit interrupts at the point of ignition timing at the ground end the ignition

coil primary circuit of the ignition coil.

ECI ignition system (engine 137): The ME control unit actuates the output stages in the ECI ignition

modules.

The ignition angle can only be checked with the HHT/STAR DIAGNOSIS.

2.Ignition angle adaptation

2.1 Catalytic converter heating-up (warming-up)

The ignition angle is continuously retarded for about 20 seconds in order to more rapidly warm up the catalytic

converter to its operating temperature if:

coolant temperature at start > 15 °C and < 40 °C

Selector lever position P or N

At the same time idle speed is increased by the idle speed control.

2.2 Idle speed

To assist the idle speed control, the ignition angle can be retarded by as much as 36° crank angle or advanced by

as much as 20° crank angle.

Altering the ignition angle provides a more rapid control than altering the position of the throttle valve (idle

speed control).

2.3 Deceleration fuel shutoff

The ignition angle is briefly retarded when combustion is resumed (fuel injectors actuated) in order to prevent a

sudden increase in torque.

2.4 Intake air temperature/coolant temperature

The ignition angle is retarded under load, as a function of the intake air temperature and coolant temperature, in

order to prevent an

y knocking tendency at high intake air and coolant temperatures. The ignition angle is

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 17 © 2006 Mitchell Repair Information Company, LLC.

Page 2174 of 4133

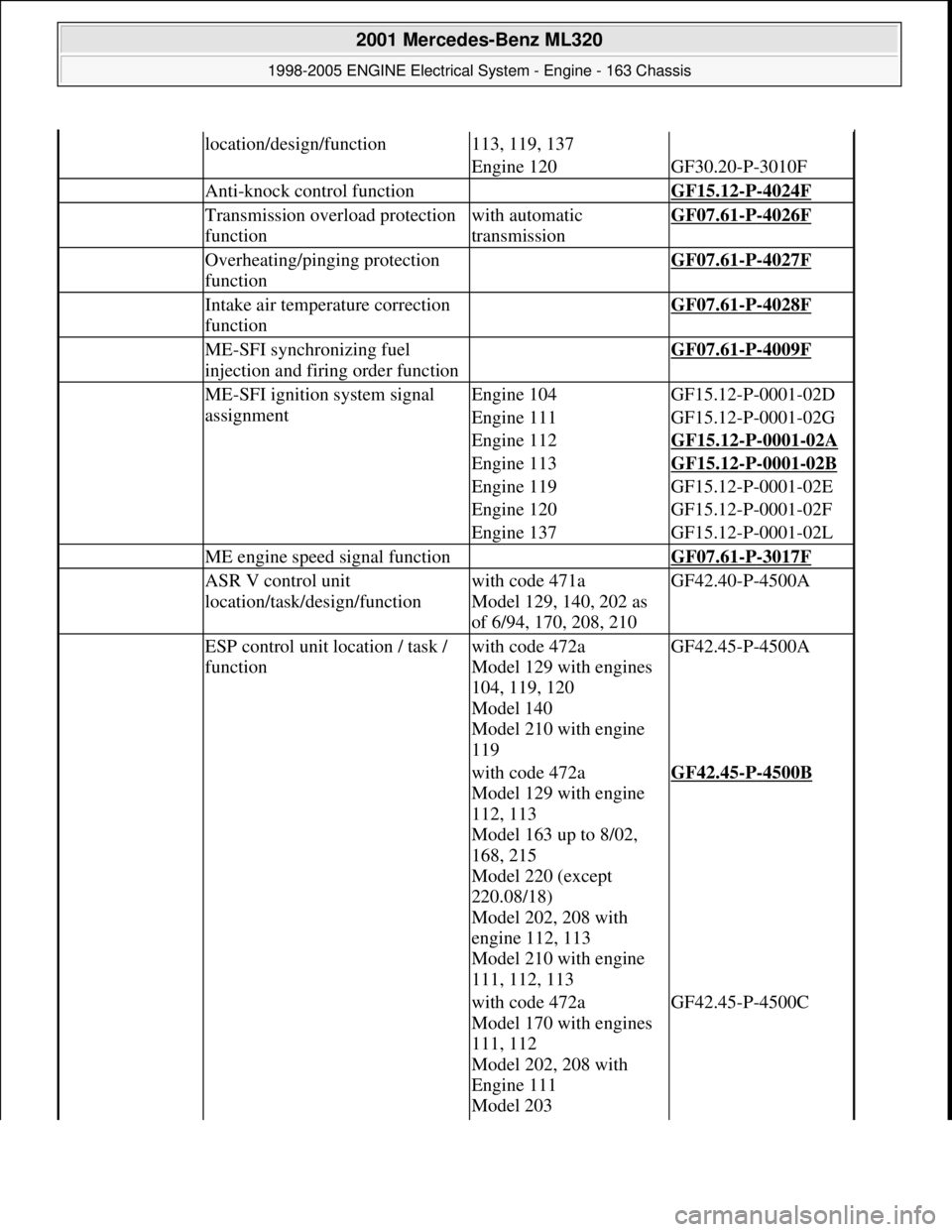

location/design/function113, 119, 137

Engine 120GF30.20-P-3010F

Anti-knock control function GF15.12-P-4024F

Transmission overload protection

functionwith automatic

transmissionGF07.61-P-4026F

Overheating/pinging protection

function GF07.61-P-4027F

Intake air temperature correction

function GF07.61-P-4028F

ME-SFI synchronizing fuel

injection and firing order function GF07.61-P-4009F

ME-SFI ignition system signal

assignmentEngine 104GF15.12-P-0001-02D

Engine 111GF15.12-P-0001-02G

Engine 112GF15.12-P-0001-02A

Engine 113GF15.12-P-0001-02B

Engine 119GF15.12-P-0001-02E

Engine 120GF15.12-P-0001-02F

Engine 137GF15.12-P-0001-02L

ME engine speed signal function GF07.61-P-3017F

ASR V control unit

location/task/design/functionwith code 471a

Model 129, 140, 202 as

of 6/94, 170, 208, 210GF42.40-P-4500A

ESP control unit location / task /

functionwith code 472a

Model 129 with engines

104, 119, 120

Model 140

Model 210 with engine

119GF42.45-P-4500A

with code 472a

Model 129 with engine

112, 113

Model 163 up to 8/02,

168, 215

Model 220 (except

220.08/18)

Model 202, 208 with

engine 112, 113

Model 210 with engine

111, 112, 113GF42.45-P-4500B

with code 472a

Model 170 with engines

111, 112

Model 202, 208 with

Engine 111

Model 203GF42.45-P-4500C

2001 Mercedes-Benz ML320

1998-2005 ENGINE Electrical System - Engine - 163 Chassis

me

Saturday, October 02, 2010 3:18:54 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 2291 of 4133

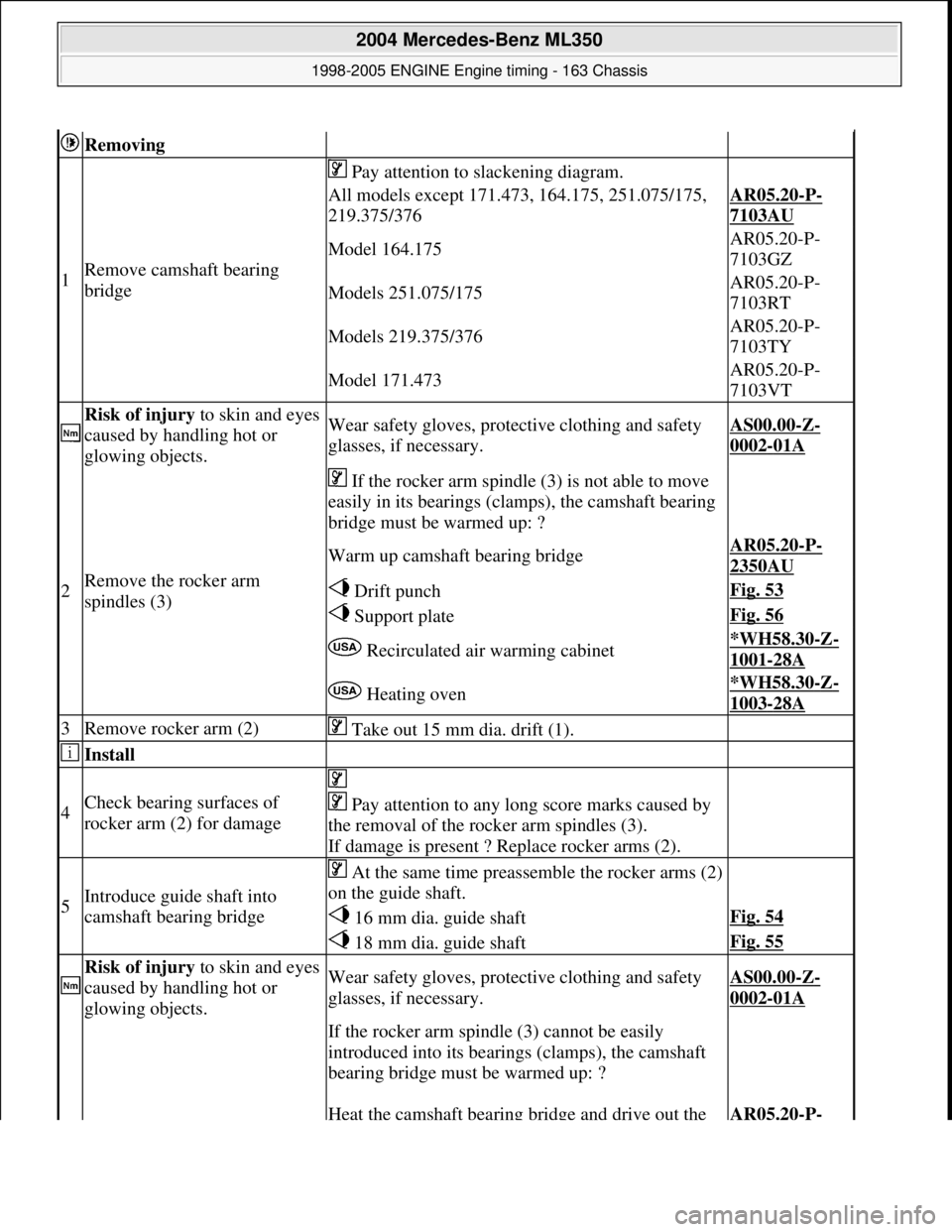

Removing

1Remove camsha ft bearing

bridge

Pay attention to slackening diagram.

All models except 171.473, 164.175, 251.075/175,

219.375/376AR05.20-P-

7103AU

Model 164.175AR05.20-P-

7103GZ

Models 251.075/175AR05.20-P-

7103RT

Models 219.375/376AR05.20-P-

7103TY

Model 171.473AR05.20-P-

7103VT

Risk of injury to skin and eyes

caused by handling hot or

glowing objects.Wear safety gloves, protec tive clothing and safety

glasses, if necessary.AS00.00-Z-

0002-01A

2Remove the rocker arm

spindles (3)

If the rocker arm spindle (3) is not able to move

easily in its bearings (clamps), the camshaft bearing

bridge must be warmed up: ?

Warm up camshaft bearing bridgeAR05.20-P-

2350AU

Drift punchFig. 53

Support plateFig. 56

Recirculated ai r warming cabinet*WH58.30-Z-

1001-28A

Heating oven*WH58.30-Z-

1003-28A

3Remove rocker arm (2) Take out 15 mm dia. drift (1).

Install

4Check bearing surfaces of

rocker arm (2) for damage

Pay attention to any l ong score marks caused by

the removal of the rocker arm spindles (3).

If damage is present ? Replace rocker arms (2).

5Introduce guide shaft into

camshaft bearing bridge

At the same time preassemble the rocker arms (2)

on the guide shaft.

16 mm dia. guide shaftFig. 54

18 mm dia. guide shaftFig. 55

Risk of injury to skin and eyes

caused by handling hot or

glowing objects.Wear safety gloves, protec tive clothing and safety

glasses, if necessary.AS00.00-Z-

0002-01A

If the rocker arm spindle (3) cannot be easily

introduced into its bearings (clamps), the camshaft

bearing bridge must be warmed up: ?

Heat the camshaft bearing bridge and drive out the AR05.20-P-

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:38 PMPage 50 © 2006 Mitchell Repair Information Company, LLC.