ECU MERCEDES-BENZ S CLASS 2017 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: S CLASS, Model: MERCEDES-BENZ S CLASS 2017Pages: 382, PDF Size: 12.12 MB

Page 351 of 382

Checking the tire pressures

Important safety notes Observe the notes on tire pressure

( Y

page 346).

Information on air pressure for the tires on your

vehicle can be found: R

on the vehicle's Tire and Loading Information

placard on the B-pillar ( Y

page 353)R

in the tire pressure table in the fuel filler flap

( Y

page 162) R

in the "Tire pressure" section

Checking tire pressures manually To determine and set the correct tire pressure,

proceed as follows: X

Remove the valve cap of the tire that is to be

checked. X

Press the tire pressure gage securely onto the

valve. X

Read the tire pressure and compare it to the

recommended value on the Tire and Loading

Information placard or the tire pressure table

( Y

page 346). X

If the tire pressure is too low, increase the tire

pressure to the recommended value. X

If the tire pressure is too high, release air. To

do so, press down the metal pin in the valve,

using the tip of a pen for example. Then check

the tire pressure again using the tire pressure

checker. X

Screw the valve cap onto the valve. X

Repeat these steps for the other tires.

Tire pressure monitor

General notes If a tire pressure monitor is installed, the vehi-

cle's wheels have sensors that monitor the tire

pressures in all four tires. The tire pressure mon-

itor warns you if the pressure drops in one or

more of the tires. The tire pressure monitor only

functions if the corresponding sensors are

installed in all wheels.

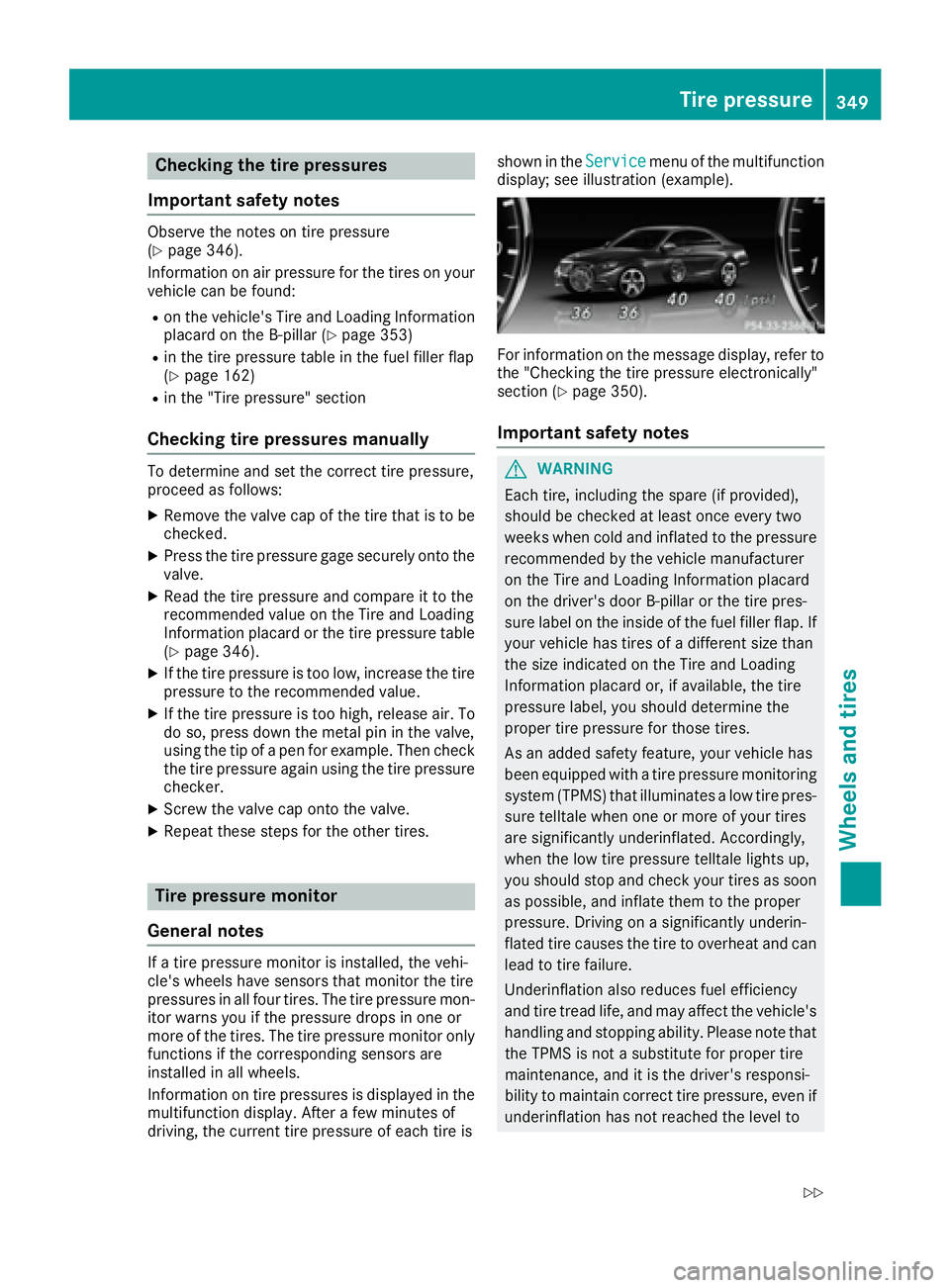

Information on tire pressures is displayed in the

multifunction display. After a few minutes of

driving, the current tire pressure of each tire is shown in the Service menu of the multifunction

display; see illustration (example).

For information on the message display, refer to

the "Checking the tire pressure electronically"

section ( Y

page 350).

Important safety notes

G WARNING

Each tire, including the spare (if provided),

should be checked at least once every two

weeks when cold and inflated to the pressure

recommended by the vehicle manufacturer

on the Tire and Loading Information placard

on the driver's door B-pillar or the tire pres-

sure label on the inside of the fuel filler flap. If

your vehicle has tires of a different size than

the size indicated on the Tire and Loading

Information placard or, if available, the tire

pressure label, you should determine the

proper tire pressure for those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire pres-

sure telltale when one or more of your tires

are significantly underinflated. Accordingly,

when the low tire pressure telltale lights up,

you should stop and check your tires as soon

as possible, and inflate them to the proper

pressure. Driving on a significantly underin-

flated tire causes the tire to overheat and can

lead to tire failure.

Underinflation also reduces fuel efficiency

and tire tread life, and may affect the vehicle's

handling and stopping ability. Please note that

the TPMS is not a substitute for proper tire

maintenance, and it is the driver's responsi-

bility to maintain correct tire pressure, eve

n if

un de rinflation has not reached the level toTire pressure 349

Wheels and tires Z

Page 364 of 382

Tire pressure This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected when

the tires are cold.

Cold tire pressure The tires are cold: R

if the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and R

if the vehicle has not been driven further than

1 mile (1.6 km)

Tread The part of the tire that comes into contact with

the road.

Bead The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall The part of the tire between the tread and the

bead.

Weight of optional extras The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 5 lbs (2.3 kg). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-per-

formance battery, are not included in the curb

weight and the weight of the accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be used by

a ti re manufacturer to identify tires, for example

fo r a product recall, and thus identify the pur-

chasers. The TIN is made up of the manufactur-

er's identity code, tire size, tire type code and

the manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire. Traction Traction is the result of friction between the tires

and the road surface.

Treadwear indicators Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of �

Page 365 of 382

Always observe the instructions and safety

notes in the "Mounting a wheel" section

( Y

page 363).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in

the center.

On vehicles that have the same size front and

rear wheels, you can rotate the wheels accord-

ing to the intervals in the tire manufacturer's

warranty book in your vehicle documents. If no

warranty book is available, the tires should be

rotate every 3,000 to 6,000 mile s (5,00 0 to

10,000 km). Earlier may be necessary, depend-

ing on the degree of tire wear. Do not change the

direction of wheel rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is rota-

ted. Check the tire pressure and, if necessary,

restart the tire pressure loss warning system

( Y

page 352) or the tire pressure monitor

( Y

page 351).

Direction of rotation Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. These advantages can only be gained if

the tires are installed corresponding to the

direction of rotation.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

Storing wheels Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from oil, grease, gasoline and diesel.

Mounting a wheel

Preparing the vehicle X

Stop the vehicle on solid, non-slippery and

level ground. X

Apply the electric parking brake manually. X

Bring the front wheels into the straight-ahead

position. X

Shift the transmission to position P . X

Make sure that the vehicle level is set to "Nor-

mal" for AIRMATIC ( Y

page 182) or Active

Body Control (ABC) ( Y

page 180).X

Switch off the engine. X

Open the driver's door.

The vehicle electronics now have status 0 .

This is the same as the SmartKey having been

removed. X

Remove Start/Stop button from ignition lock

( Y

page 145).

or, if the SmartKey is inserted in the ignition

lock: X

Remove the SmartKey from the ignition lock. X

Make sure that the engine cannot be started

via your smartphone ( Y

page 147).X

If included in the vehicle equipment, remove

the tire-change tool kit from the vehicle. X

Safeguard the vehicle against rolling away.

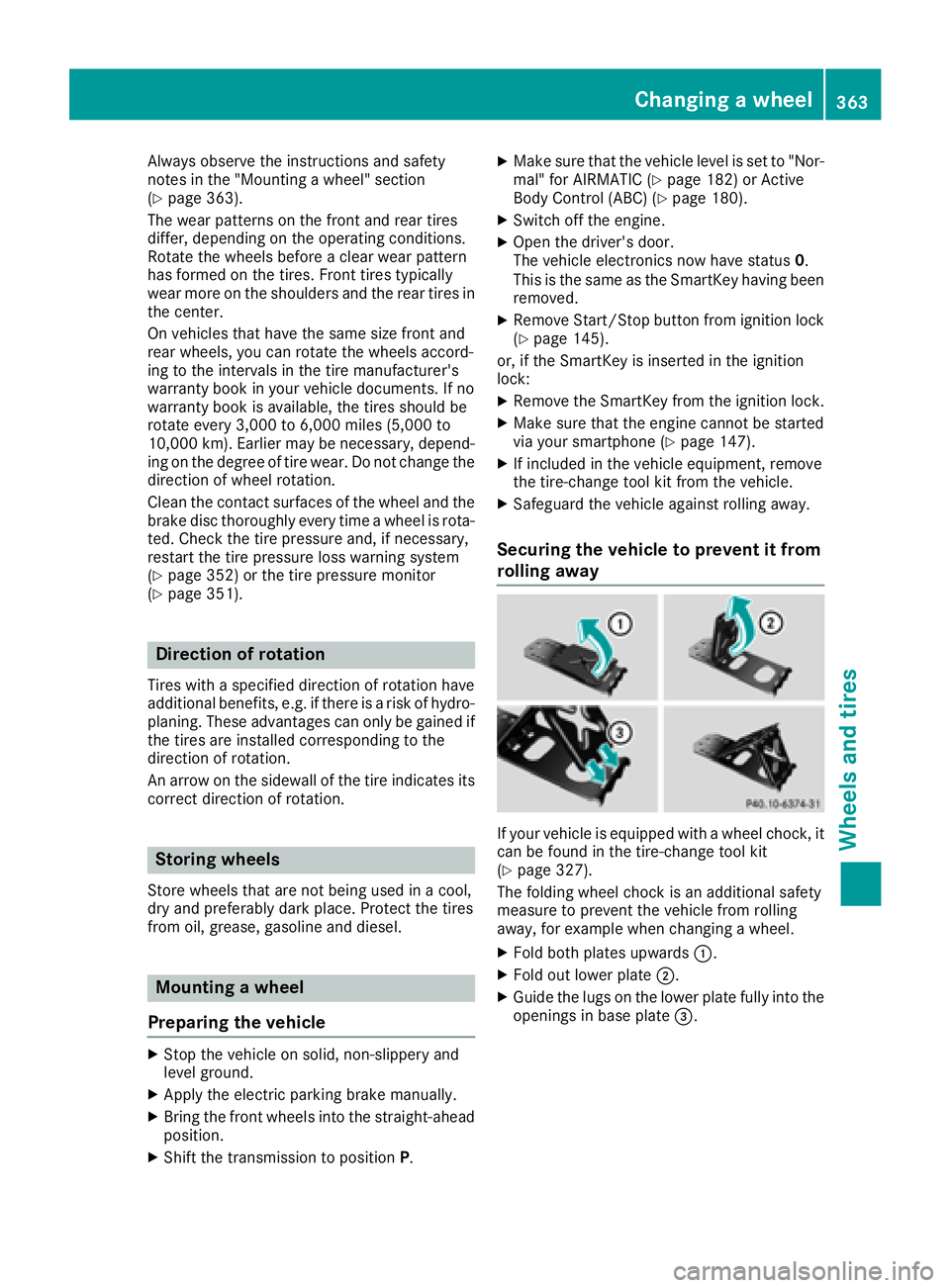

Securing the vehicle to prevent it from

rolling away

If your vehicle is equipped with a wheel chock, it

can be found in the tire-change tool kit

( Y

page 327).

The folding wheel chock is an additional safety

measure to prevent the vehicle from rolling

away, for example when changing a wheel. X

Fold both plates upwards �C .X

Fold out lower plate �D .X

Guide the lugs on the lower plate fully into the

openings in base plate �

Page 366 of 382

X

Place chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle

G WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

! The jack is designed exclusively for jacking

up the vehicle at the jacking points. Other-

wise, your vehicle could be damaged.

Observe the following when raising the vehi-

cle: R

To raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised. R

The jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle. R

Avoid changing the wheel on uphill and down-

hill slopes. R

Before raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised. R

The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a slippery surface, a non-slip underlay must be

used, e.g. rubber mats. R

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height. R

Make sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm). R

Do not place your hands or feet under the

raised vehicle. R

Do not lie under the vehicle. R

Do not start the engine when the vehicle is

raised. R

Do not open or close a door or the trunk lid

when the vehicle is raised. R

Make sure that no persons are present in the

vehicle when the vehicle is raised.

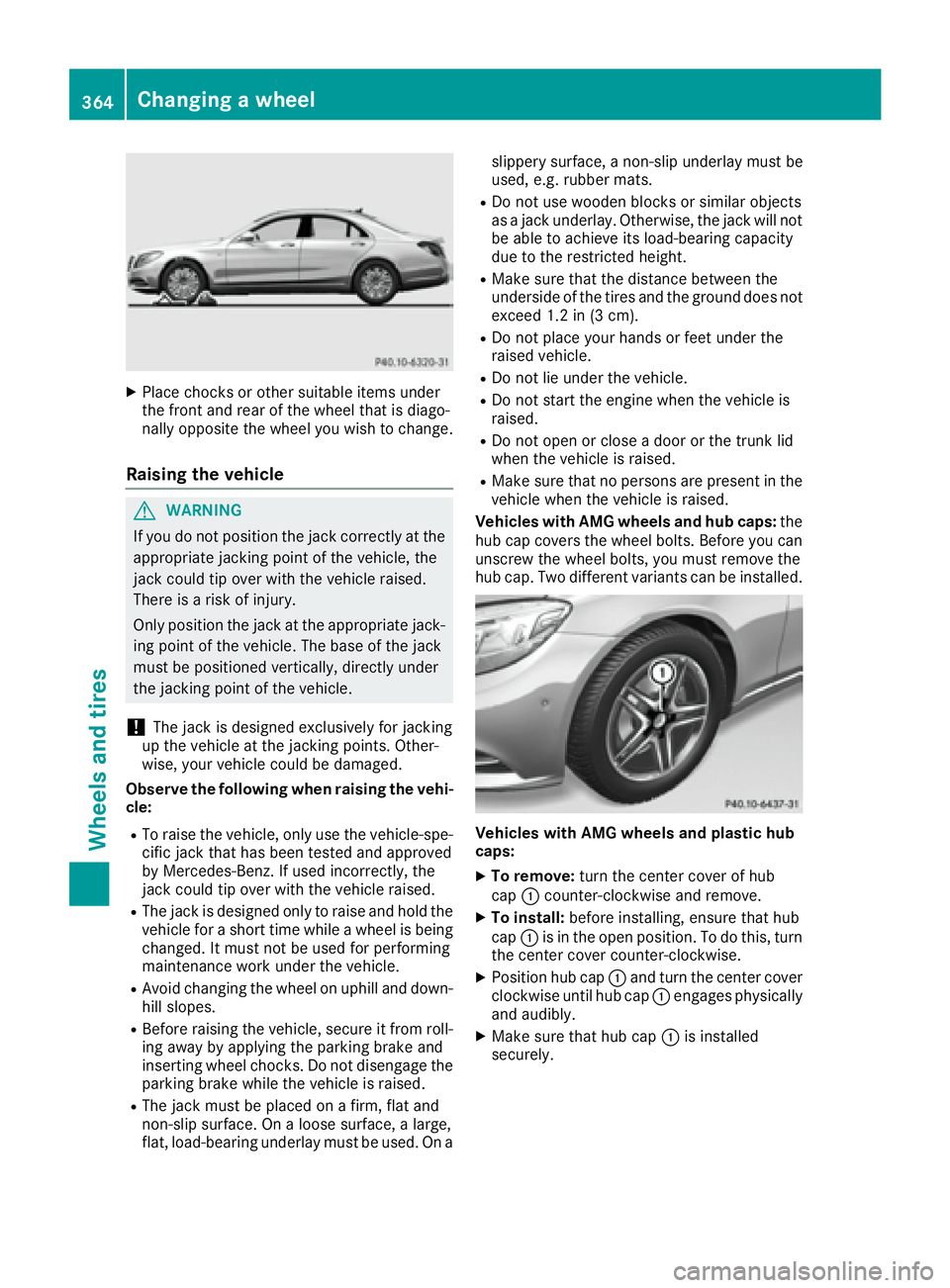

Vehicles with AMG wheels and hub caps: the

hub cap covers the wheel bolts. Before you can

unscrew the wheel bolts, you must remove the

hub cap. Two different variant s

can be installed.

Vehicles with AMG wheels and plastic hub

caps: X

To remove: turn the center cover of hub

cap �C counter-clockwise and remove. X

To install: before installing, ensure that hub

cap �C is in the open position. To do this, turn

the center cover counter-clockwise. X

Position hub cap �C and turn the center cover

clockwise until hub cap �C engages physically

and audibly. X

Make sure that hub cap �C is installed

securely.364

Changing a wheel

Wheels and tires