MERCEDES-BENZ S CLASS 2022 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2022, Model line: S CLASS, Model: MERCEDES-BENZ S CLASS 2022Pages: 610, PDF Size: 19.8 MB

Page 391 of 610

wheel

isbein gch ang edand notfo rmaint e‐

nance workund ertheve hicle.

R The jackmus tbe placed onafirm ,fl at and

no n-slip surface.

R The foot ofthejac kmus tbe position edverti‐

call yunder thejac ksuppor tpoint . Ru

les ofcon duct when theve hicle israised:

R Neverpla ceyour han dsand /or feet unde r

th eve hicle.

R Neverlie under theve hicle.

R Donotst ar tth eengine anddonotre lease

th eelectr icpar king brak e. R

Donotopen orclose anydoor sor thetrunk

lid. #

Using thelug wrenc h,loosen thewheel bolts

on thewheel youwish tochang eby about

on efull turn.Do notuns crew thebolts com‐

ple tely. Po

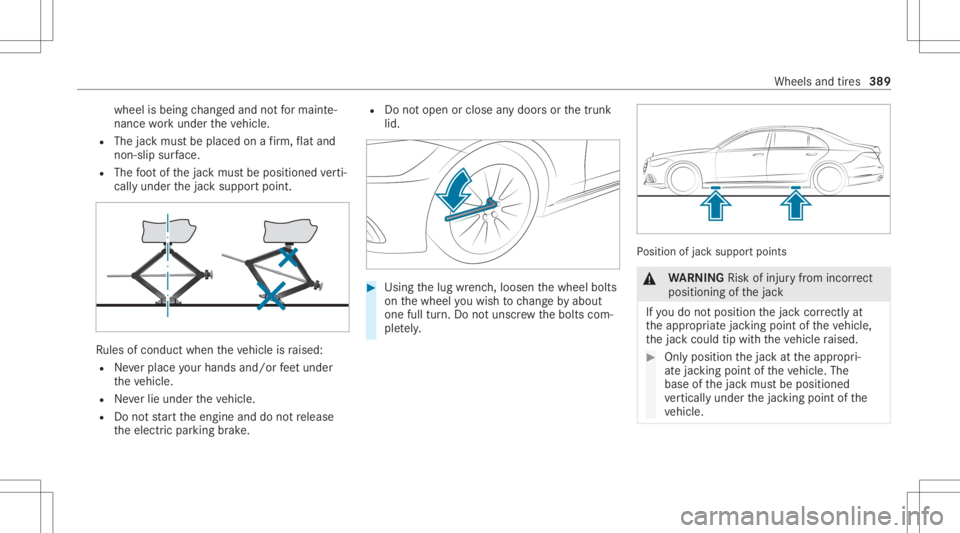

sition ofjac ksuppor tpoints &

WARNIN GRisk ofinju ryfrom incor rect

pos itioning ofthejac k

If yo udo notposi tionth ejac kcor rectly at

th eappr opriatejac king point oftheve hicle,

th ejac kcould tipwithth eve hicle raised. #

Onlyposit ionthejac kat theappr opri‐

at ejac king point oftheve hicle. The

base ofthejac kmus tbe position ed

ve rticall yunder thejac king point ofthe

ve hicle. Wheels

andtires 389

Page 392 of 610

*

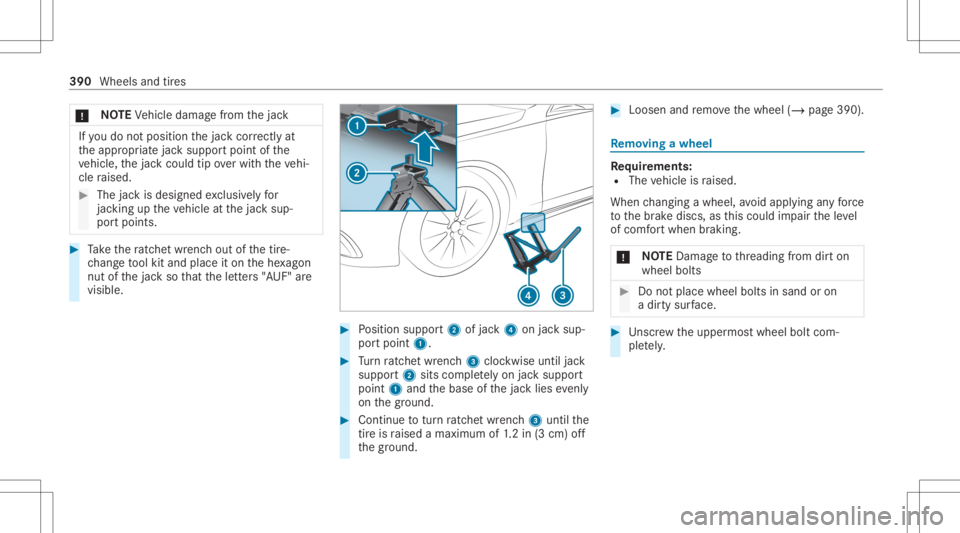

NO

TEVehicle damag efrom thejac k If

yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac ksuppor tpoint ofthe

ve hicle, thejac kcould tipove rwit hth eve hi‐

cle raised. #

The jackis design edexclu sively for

jac king uptheve hicle atthejac ksup‐

por tpoint s. #

Take thera tche twrenc hou tof thetir e-

ch ang eto ol kit and place iton thehe xagon

nut ofthejac kso that theletter s"A UF" are

visible. #

Position suppor t2 ofjac k4 onjacksup‐

por tpoint 1. #

Turn ratche twr enc h3 clockwise untiljac k

suppor t2 sitscom pletely on jacksuppor t

point 1and thebase ofthejac klies evenly

on thegr ound. #

Contin uetotur nra tche twr enc h3 unti lth e

tir eis raised amaxim umof1.2 in (3 cm) off

th egr ound. #

Loosen andremo vethewheel (/page390). Re

mo ving awh eel Re

quirement s:

R The vehicle israised.

When chang ingawheel, avoidappl ying anyfo rc e

to thebr ak ediscs, asthis could impair theleve l

of comf ortwhen braking.

* NO

TEDama getothre adin gfrom dirton

wheel bolts #

Donotplace wheel boltsin san dor on

a dir tysur face. #

Unscr ew theupper mostwheel boltcom‐

ple tely. 39

0

Wh eelsand tires

Page 393 of 610

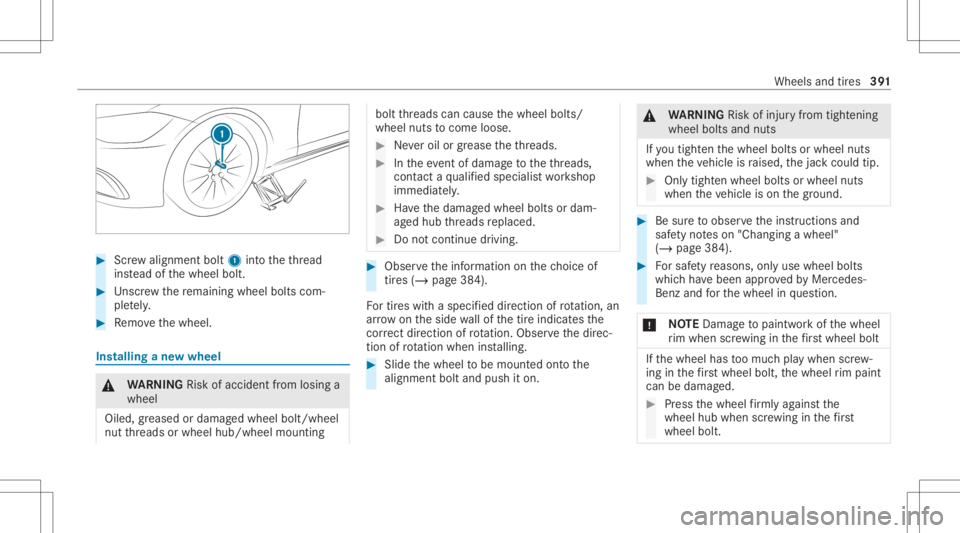

#

Screw align mentbolt 1intoth eth re ad

ins tead ofthewheel bolt. #

Unscr ew there maini ngwhee lbolts com‐

ple tely. #

Remo vethewheel. Ins

talling ane wwheel &

WARNIN GRisk ofacci dent from losing a

whe el

Oil ed, grea sed ordamag edwhe elbol t/whe el

nut thre ads orwheel hub/wheel mounting bolt

thre ads can caus eth ewheel bolts/

wheel nutstocome loose. #

Neveroil orgrease theth re ads. #

Intheeve ntofdama getotheth re ads,

con tact aqu alif ied spec ialistwo rkshop

immediat ely. #

Have thedamag edwheel boltsordam‐

ag ed hub thre ads replaced. #

Donotcon tinue driving. #

Obser vetheinf ormation onthech oice of

tir es (/ page38 4).

Fo rtir es wit haspecif ieddirection ofrotatio n,an

ar ro w on theside wallof thetir eindicat esthe

cor rect dire ction ofrotatio n.Ob serveth edir ec‐

tion ofrotatio nwh en installing. #

Slide thewheel tobe mount edont oth e

align mentbolt andpush iton . &

WARNIN GRisk ofinju ryfrom tight ening

whee lbol tsand nuts

If yo utig hten thewheel boltsorwheel nuts

when theve hicle israised, thejac kcould tip. #

Onlytight enwheel boltsorwheel nuts

when theve hicle ison thegr ound. #

Besureto obser vetheins truction sand

saf etyno teson "Cha nging awheel"

(/ page38 4). #

Forsaf etyre ason s,on lyuse wheel bolts

whic hha ve been approvedby Mer cedes-

Benz andforth ewheel inqu estion .

* NO

TEDama getopaintw orkof thewheel

ri m when screwing inthefirs twh eelbo lt If

th ewheel hastoomuc hpla ywhen screw‐

ing inthefirs twh eelbo lt, thewheel rim pai nt

can bedama ged. #

Press thewheel firm lyag ains tth e

wheel hubwhen screwing inthefirs t

wheel bolt. Wheels

andtires 39

1

Page 394 of 610

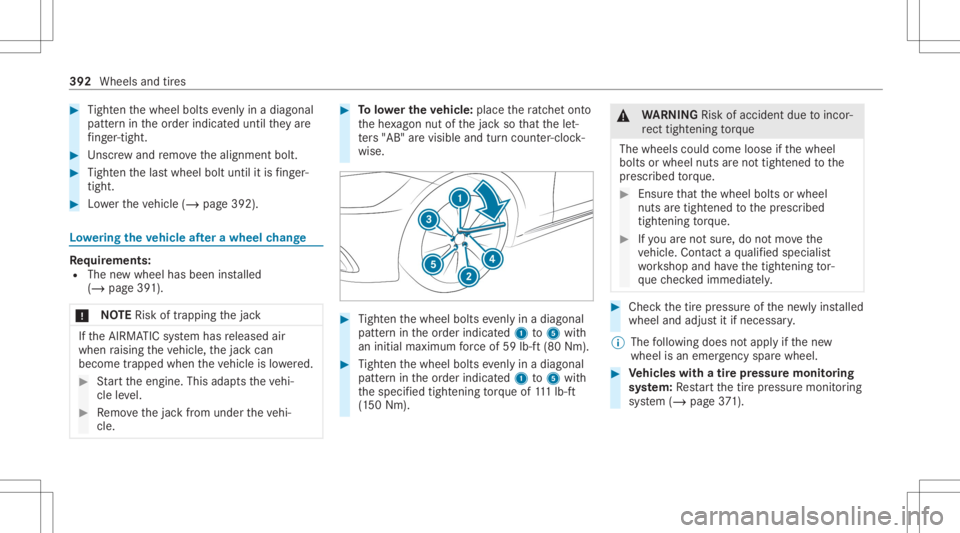

#

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat eduntil they are

fi ng er-tig ht. #

Unscr ew and remo vethealignment bolt. #

Tight enthelas twheel boltuntil itis fing er-

tig ht. #

Lowe rth eve hicle (/page392). Lo

we ring theve hicl eaf te ra wh eelch ang e Re

quirement s:

R The newwheel hasbeen installed

(/ page39 1).

* NO

TERisk oftrap ping thejac k If

th eAIRMA TICsystem has released air

when raising theve hicle, thejac kcan

become trapped whentheve hicle islowe red. #

Startth eengine. Thisadap tstheve hi‐

cle leve l. #

Remo vethejac kfrom under theve hi‐

cle. #

Tolowe rthe vehicl e:pla cethera tche tont o

th ehe xagon nutofthejac kso that thelet‐

te rs "AB "ar evis ible and turnco unt er-cloc k‐

wise. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed1 to5 with

an init ialmax imum forc eof 59 lb-ft(80 Nm). #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed1 to5 with

th especif iedtight ening torq ue of111 lb-ft

(1 50 Nm). &

WARNIN GRisk ofacci dent dueto inc or‐

re ct tigh tening torq ue

Th ewh eelscou ldcome looseifth ewheel

bolts orwheel nutsareno ttight ened tothe

pr escr ibed torq ue. #

Ensu rethat thewheel boltsorwheel

nuts aretight ened tothepr escr ibed

tight ening torq ue. #

Ifyo uar eno tsur e,do notmo vethe

ve hicle. Contactaqu alif ied spec ialist

wo rkshop andhave thetight ening tor‐

qu ech eckedimmediat ely. #

Chec kth etir epr essur eof thene wlyins talled

wheel andadjus tit ifnec essar y.

% The follo wing does notappl yif th ene w

wheel isan emer gency sparewheel. #

Vehicl eswith atir epr ess uremonit oring

sy stem: Restar tth etir epr essur emonit oring

sy stem (/ page37 1). 39

2

Wh eelsan dtir es

Page 395 of 610

Emer

gency spar ewheel No

teson theemer gency spar ewheel &

WARNIN GRisk ofacci dent caused by

inc orrect whe eland tiredimensi ons

The wheelor tiresize andthetir etype ofthe

emer gency sparewheel orspar ewheel and

th ewheel tobe replaced maydif fer. The

emer gency sparewheel orspar ewheel can

sign ifican tly im pair drivin gch aract eristic sof

th eve hicle.

To preve nthazardous situa tions: #

Adaptyo ur drivin gst yle accor dinglyand

dr ive car efull y. #

Neverins tallmor eth an oneemer gency

spa rewheel orspar ewheel that dif fers

in size . #

Onlyuse anemer gency sparewheel or

spar ewheel ofadif fere nt size briefly. #

Donotsw itchof fESP ®

. #

Have theemer gency sparewheel or

spar ewheel ofadif fere nt size replaced

at thenear estqu alif ied spec ialistwo rk‐ shop.

Thenewwheel mustha ve the

cor rect dimensi ons. %

The eme rgency sparewheel issec ured inthe

emer gency sparewheel baginthetrunk .

Obser vethefo llo wing noteson installing an

emer gency sparewheel:

R Chec kth etir epr essur eof theemer gency

spa rewheel installed. Correct thepr essur e

as neces sary.

R The maximum permissible speedwithan

emer gency sparewheel installed is50 mph

(80 km/ h).

R Donotins tallth eemer gency sparewheel

wit hsn ow chains .

R Replace theemer gency sparewheel afte rsix

ye arsat thelat est,re ga rdless ofwe ar.

R Use thewheel boltsthat areinc luded with

th eemer gency sparewheel.

Specif iedtigh tening torq ue: 96lb-ft

(1 30 Nm)

% Ve

hicl eswith atir epr ess uremonit oring

sy stem: Ifan emer gency sparewheel is ins

talled, thetir epr essur emonit oring sys‐

te m canno tfunction reliabl y.Fo ra fe w

minut esafte ran emerg encysparewhee lis

ins talled, thesy stem mayst ill displa yth etir e

pr essur eof there mo vedwheel. Onlyre star t

th esy stem again when theemer gency spare

wheel hasbeen replaced withane wwheel.

Be sureto also obse rveth efo llo wing further

re lat ed subje cts:

R Noteson tirepr essur e(/ page36 7)

R Tire and Loadi ngInfo rm atio nplacar d

(/ page37 2)

R Tire pressur eta ble (/ page368 )

R Noteson installing tires (/ page38 4) Wheels

andtires 393

Page 396 of 610

No

teson tech nical data

The datast at ed onlyapplies tovehicles with

st andar deq uipme nt.Yo ucan obtain further

inf ormation from anaut hor ized Mercedes- Benz

Cent er. Ve

hicl eele ctroni cs Tw

o-w ayradio s No

teson installing two-w ayradio s &

WARNIN GRisk ofacci dent dueto

im proper workon two-w ayradios

If tw o-w ayradios aremanipulat edorretrof it‐

te dincor rectl y,theelectr omagne ticradiation

fr om thetw o-w ayradios caninterfere wit h

th eve hicle electr onics andjeopar dizethe

oper ating safetyof theve hicle. #

Yousho uld have all workon electr ical

and electr oniccomponent scar ried out

at aqu alif ied spec ialistwo rkshop. &

WARNIN GRisk ofacci dent dueto

im proper opera tionoftwo-w ayradios

If yo uuse two-wa yra dios intheve hicle

im proper ly,th eir electr omagne ticradiation

can disruptth eve hicle's electronics. Thisis

th ecase inthefo llo wing situat ions,in par tic‐

ular :

R The two-w ayradio isno tcon nectedto an

ex terior ant enna.

R The exterior ant enna isins talled incor‐

re ctly orisno ta low- reflect ion antenn a.

This could jeopar dizetheoper ating safetyof

th eve hicle. #

Have thelow- reflect ion exterior

ant enna installed ataqu alif ied spec ial‐

is two rkshop. #

When operating two-w ayradios inthe

ve hicle, alwaysconn ectthem tothe

lo w- reflect ion exterior ant enna. *

NO

TEInva lidation oftheoper ating per‐

mit due tofailur eto com plywith the

ins truct ions forins tallation anduse The

oper atingper mit maybe inva lidat edif

th eins truction sfo rins tallation anduseof

tw o-w ayradios areno tobser ved. #

Onlyuse appr oved freq uency bands. #

Obser vethemaximum permissible out‐

put powe rin these freq uency bands. #

Onlyuse appr oved ant enn aposition s. 39

4

Tech nica lda ta

Page 397 of 610

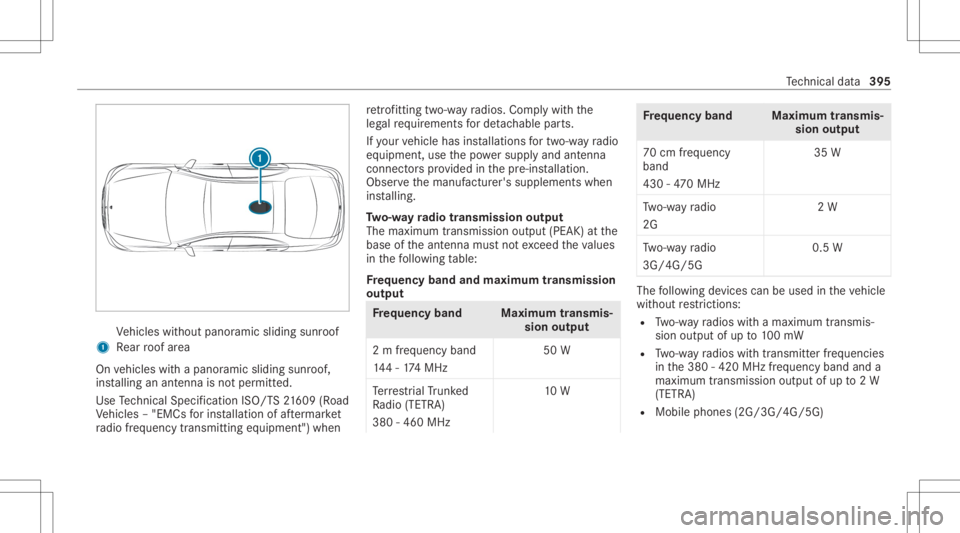

Ve

hicles without panor amicsliding sunroof

1 Rear roof area

On vehicles withapanor amicsliding sunroof,

ins talling anant enn ais no tper mitted.

Use Tech nica lSpe cifica tionISO/T S21 609 (Road

Ve hicles –"EMCs forins tallation ofafte rm arke t

ra dio freq uency transmit tingeq uipment ")when re

trof itti ng two-w ayradios. Complywithth e

leg alrequ iremen tsforde tach able parts.

If yo ur vehicle hasinstallation sfo rtw o-w ayradio

eq uipment ,use thepo we rsupp lyand antenn a

con nectors prov ided inthepr e-ins tallation .

Obser vethemanuf acturer'ssupplement swhen

ins talling.

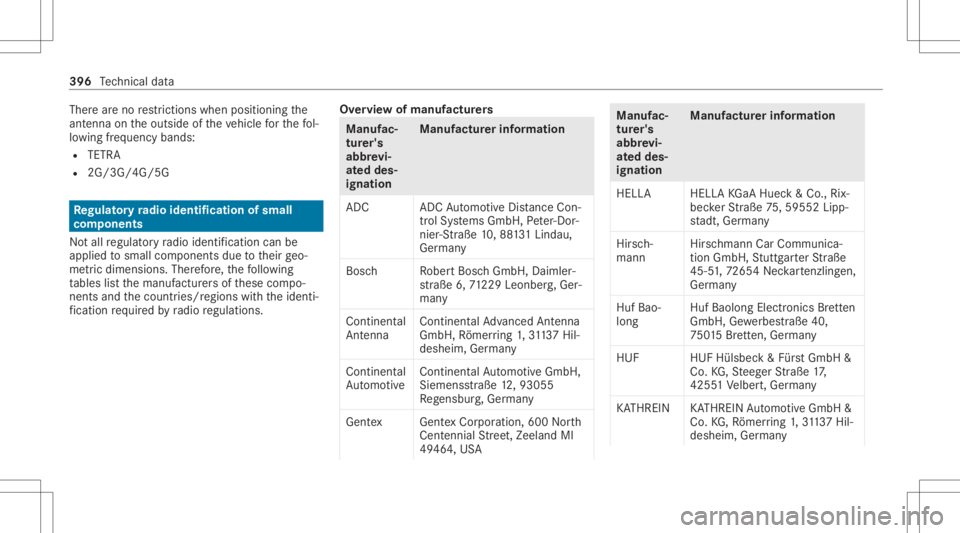

Tw o-w ayradio transmi ssion output

The maxi mum transm ission outpu t(PEAK) atthe

base oftheant enn amus tno texc eed theva lues

in thefo llo wing table:

Fr eq uency bandandmaxim um transm ission

out put Fr

eq uency band Maximumtransm is‐

sion output

2 m freq uenc yband

14 4-17 4MHz 50

W

Te rres trial Trunk ed

Ra dio (TETRA)

380 -460 MHz 10

W Fr

eq uency band Maximumtransm is‐

sion output

70 cm freq uenc y

band

43 0-47 0MHz 35

W

Tw o-w ayradio

2G 2

W

Tw o-w ayradio

3G/4G/ 5G 0.5

W The

follo wing device scan beused intheve hicle

wit hout restrictions :

R Two-w ayradios withamaximum transmis ‐

sion output ofup to100mW

R Two-w ayradios withtra nsm itter freq uencies

in the380 -420 MHz freq uency bandanda

maximum transmission outputofup to2W

(TETR A)

R Mobi lephones (2G/3G/4G/5G) Te

ch nica lda ta 395

Page 398 of 610

Ther

ear eno restrictions whenpos itioning the

ant enn aon theoutside oftheve hicle forth efo l‐

lo wing freq uenc ybands:

R TET RA

R 2G/3 G/4G/ 5G Re

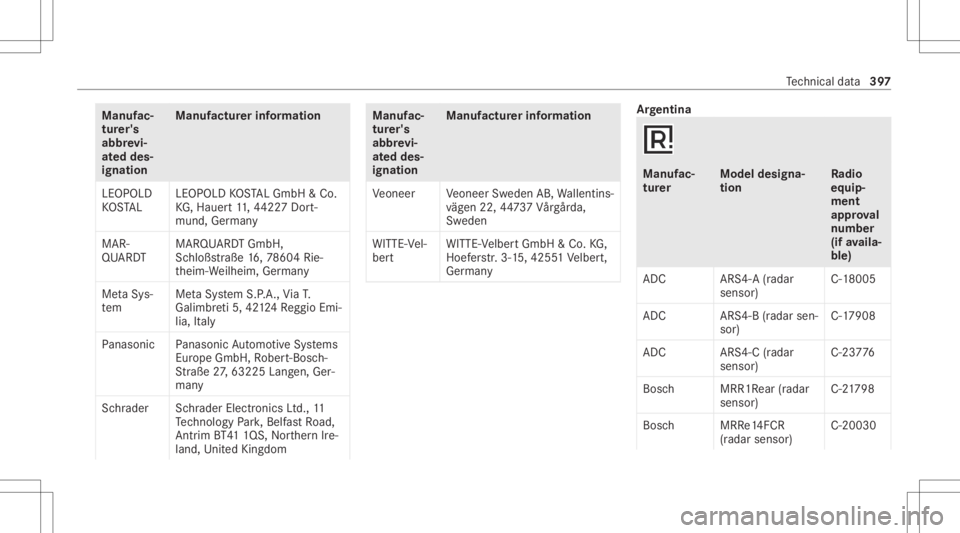

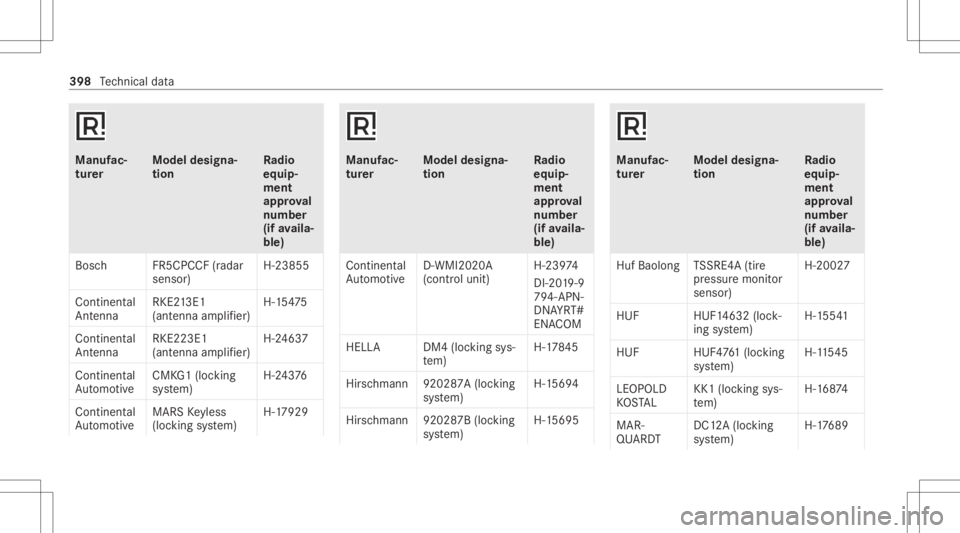

gulat oryra dio identif icatio nof small

co mp onent s

No tall regulat oryra dio ident ification canbe

applied tosmall components duetotheir geo‐

me tric dimensions. Therefor e, thefo llo wing

ta bles listth emanuf acturersof these com po‐

nen tsand thecount ries/r egions withth eidenti‐

fi cati onrequ ired byradio regulations. Ov

ervie wof manuf acturers Manuf

ac‐

tur er's

abbr evi‐

at ed des‐

ignat ion Manu

factu rerin fo rm ation

ADC ADCAutomo tiveDis tance Con‐

tr ol Sy stems GmbH, Peter-Dor‐

nie r-St raße 10,88 131Linda u,

Ger man y

Bosc hR obertBosc hGmbH, Daimler‐

st ra ße 6,71229 Leonbe rg,Ger‐

man y

Cont inental

Ant enna Co

ntine ntal Ad vanced Antenna

Gm bH, Römer ring 1,3113 7Hil‐

desh eim, German y

Continent al

Au tomo tive Continent

alAu tomo tiveGmbH,

Siemenss traße 12,930 55

Re gensbu rg,Ger man y

Gent ex GentexCor poratio n,60 0No rth

Cen tennia lSt reet,Zeeland MI

49 46 4,US A Manu

fac‐

tu rer's

abb revi‐

at ed des‐

ignation Manuf

acturerinformat ion

HELL AH ELLAKG aA Huec k& Co., Rix‐

bec kerSt raße 75,595 52Lipp‐

st adt ,Ger man y

Hir sch‐

man n Hir

schman nCar Comm unica‐

tio nGmbH ,St utt garter Straße

45- 51,72 65 4Nec kartenz ling en,

Ger man y

Huf Bao‐

long Huf

Baolong Electronics Brette n

GmbH ,Ge we rbes traße 40,

75 015Br ette n, Ge rmany

HUF HUFHülsbeck& Für stGmbH &

Co. KG,St eeg erStraße 17,

4255 1Ve lber t,Ger man y

KA THRE IN KATHRE INAutomo tiveGmbH &

Co. KG,Rö mer ring 1,3113 7Hil‐

desh eim, German y 396

Tech nica lda ta

Page 399 of 610

Manuf

ac‐

tur er's

abbr evi‐

at ed des‐

ignat ion Manu

factu rerin fo rm ation

LEOPOLD

KO STAL LEOP

OLDKOSTAL Gm bH &Co .

KG ,Hauer t11 ,44 227Dor t‐

mund, German y

MAR‐

QU ARD T MARQU

ARDTGmbH,

Sc hloß stra ße 16,78 604 Rie‐

th eim- Weilheim, German y

Me taSys‐

te m Me

taSystem S.P.A.,Vi aT.

Galimbr eti5, 42124Re ggio Emi‐

lia, Ital y

Pa nas onicP anasonicAu tomo tiveSy stems

Eur ope GmbH, Rober t-Bosc h-

St raße 27,632 25Lang en,Ger‐

man y

Sc hrader Schrader Electronic sLtd. ,11

Te ch nol ogy Park,Belf astRo ad,

An trim BT4 11Q S,Nor ther nIre‐

land, UnitedKingdom Manu

fac‐

tu rer's

abb revi‐

at ed des‐

ignation Manuf

acturerinformat ion

Ve oneer Veoneer Sweden AB,Wallent ins‐

vä ge n22, 44737Vår gårda,

Sw eden

WITT E-Ve l‐

ber t WITTE

-Velber tGmbH &Co. KG,

Hoef erstr. 3-1 5,4255 1Ve lber t,

Ger man y Ar

ge ntina Manuf

ac‐

tur er Model

designa‐

tion Ra

dio

eq uip‐

ment

appr oval

number

(if availa‐

ble )

ADC ARS4-A(rada r

sensor) C-1

8005

ADC ARS4-B(rada rsen‐

sor) C-1

7908

ADC ARS4-C(rada r

sensor) C-23

776

Bosc hM RR1Rear(radar

sen sor) C-2

1798

Bosc hM RRe14F CR

(r adar sensor) C-2

0030 Te

ch nica lda ta 39

7

Page 400 of 610

Manuf

ac‐

tur er Model

designa‐

tion Ra

dio

eq uip‐

ment

appr oval

number

(if availa‐

ble )

Bosc hF R5CPCCF(radar

sen sor) H-

23 855

Con tine ntal

An tenna RK

E213 E1

(a nt enna amplifie r) H-1

5475

Con tinental

Ant enna RK

E223E1

(a nt enna amplifie r) H-2

463 7

Co ntine ntal

Au tomo tive CMK

G1(loc king

sy stem) H-2

4376

Con tinental

Au tomo tive MARS

Keyless

(loc king system) H-1

7929 Manuf

ac‐

tur er Model

designa‐

tion Ra

dio

eq uip‐

ment

appr oval

number

(if availa‐

ble )

Contine ntal

Au tomo tive D-

WMI2020A

(contr olunit) H-239

74

DI-20 19-9

79 4-APN-

DN AYRT#

EN ACOM

HELL AD M4(locking sys‐

te m) H-1

7845

Hir schmann 920287A(locking

sy stem) H-1

569 4

Hir schmann 920287B(loc king

sy stem) H-1

5695 Manuf

ac‐

tur er Model

designa‐

tion Ra

dio

eq uip‐

ment

appr oval

number

(if availa‐

ble )

Huf Baol ong TSSRE4A (tire

pr essur emonit or

sensor ) H-2

002 7

HUF HUF14632 (lock‐

ing system) H-1

5541

HUF HUF4761(lo cking

sy stem) H-1

1545

LEOPOLD

KO STAL KK1

(loc king sys‐

te m) H-1

6874

MAR‐

QU ARD T DC1

2A(loc king

sy stem) H-1

7689 398

Tech nica lda ta