MERCEDES-BENZ S-CLASS CABRIOLET 2017 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: S-CLASS CABRIOLET, Model: MERCEDES-BENZ S-CLASS CABRIOLET 2017Pages: 521, PDF Size: 10.48 MB

Page 401 of 521

#

Attach wheel spanner 3tosoc ket 2and

tighten theh ub cap clockwise.

Specified tightening torq ue: 25 Nm. #

Raise thev ehicle (→ page400). Ra

ising thev ehicle when changing awheel Re

quirements:

R Ther eareno persons in thev ehicle.

R The vehicle has been prepared foraw heel

ch ang e(→pag e396).

R The hub caps ha vebeen remo ved

( → pag e397).

Impor tant no tesonu singthej ack:

R onlyusethev ehicle-specific jac kthat has

been tested and appr ovedbyM ercedes-Benz

to raise thev ehicle.

R thej ackiso nlyd esigned forr aising and hold‐

ing thev ehicle foras horttime while awheel

is being changed and no tfor maintenance

wo rkunder thev ehicle. R

thej ackm ustbep laced on afirm, flat and

non-slip sur face. If necessar y,use alarge,

load-bearing, non-slip underla y.

R thef ootoft he jac kmustbep ositioned verti‐

call yunder thej acking point. Ru

les of conduct when thev ehicle is raised:

R Neverp lace your hands or feet under the

ve hicle.

R Do no tlie under thev ehicle.

R Do no tstar tthe engine and do no trelease

th ee lectric parking brake.

R Do no topen or close an ydoor sort he boot

lid. #

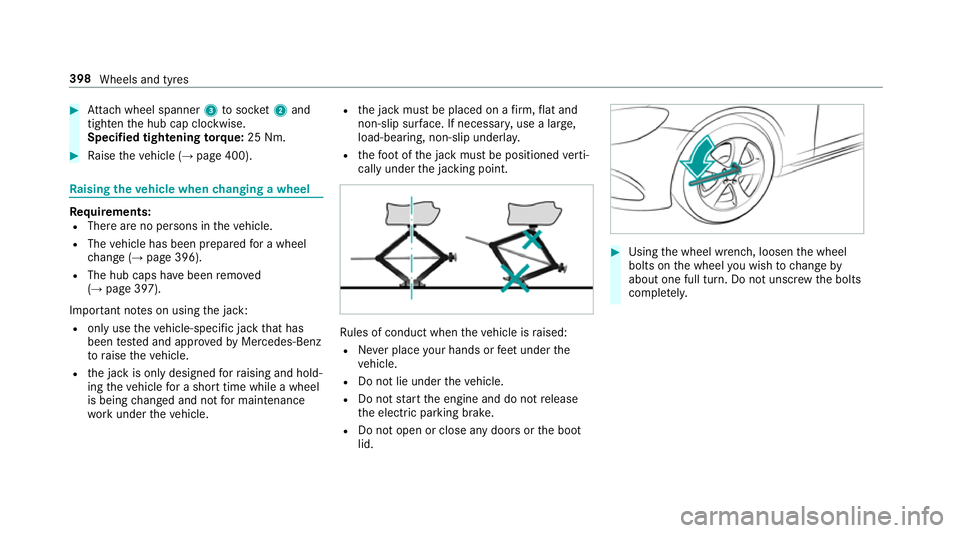

Using thew heel wrench, loosen thew heel

bolts on thew heel youw ish tochang eby

about on efull turn. Do no tunscr ewtheb olts

comple tely. 398

Wheels and tyres

Page 402 of 521

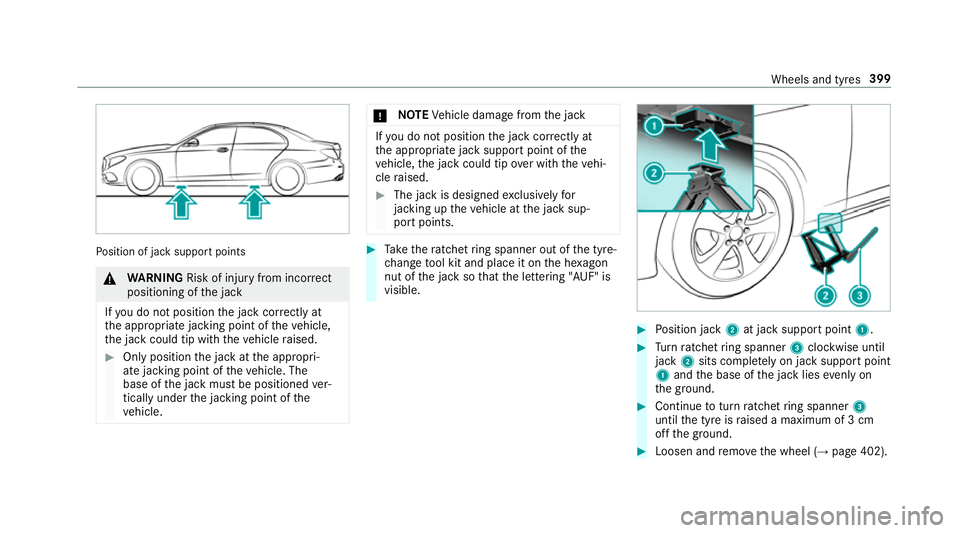

Po

sition of jac ksuppor tpoints &

WARNING Risk of inju ryfrom incor rect

positioning of thej ack

If yo udon otpositio nthe jac kcorrectly at

th ea ppropriat ejacking point of thev ehicle,

th ej ackc ould tip wit hthe vehicle raised. #

Onlyposition thej ackatt he appropri‐

at ej acking point of thev ehicle. The

base of thej ackm ustbep ositioned ver‐

tically under thej acking point of the

ve hicle. *

NO

TEVehicle damag efromt he jack If

yo udon otpositio nthe jac kcorrectl yat

th ea ppropriat ejacks uppor tpoint of the

ve hicle, thej ackc ould tip overwitht he vehi‐

cle raised. #

The jac kisdesigned exclusively for

jacking up thev ehicle at thej acks up‐

por tpoints. #

Take ther atche tring sp anner ou tofthe tyre-

ch ang etool kit and place it on theh exagon

nut of thej acksot hatthel ette ring "AUF" is

visible. #

Position jack 2at jac ksuppor tpoint 1. #

Turn ratche tring sp anner 3clockwise until

jack 2sitsc omple tely on ja cksuppor tpoint

1 and theb ase of thej ackl ies evenlyon

th eg round. #

Continue totur nratche tring sp anner 3

unti lthe tyr eisraised amaximum of 3cm

of ft he ground. #

Loosen and remo vethew heel (→ page402). Wheels and tyres

399

Page 403 of 521

Re

moving awheel Re

quirement:

R The vehicle is raised (→ page398).

When changing awheel, avoid applying an yforce

to theb rake discs, since this could impair the

le ve lofc omfort when braking.

* NO

TEDama getothre adin gfromd irton

wheel bolts #

Do no tplace wheel bolt sinsandoron

ad irty sur face. #

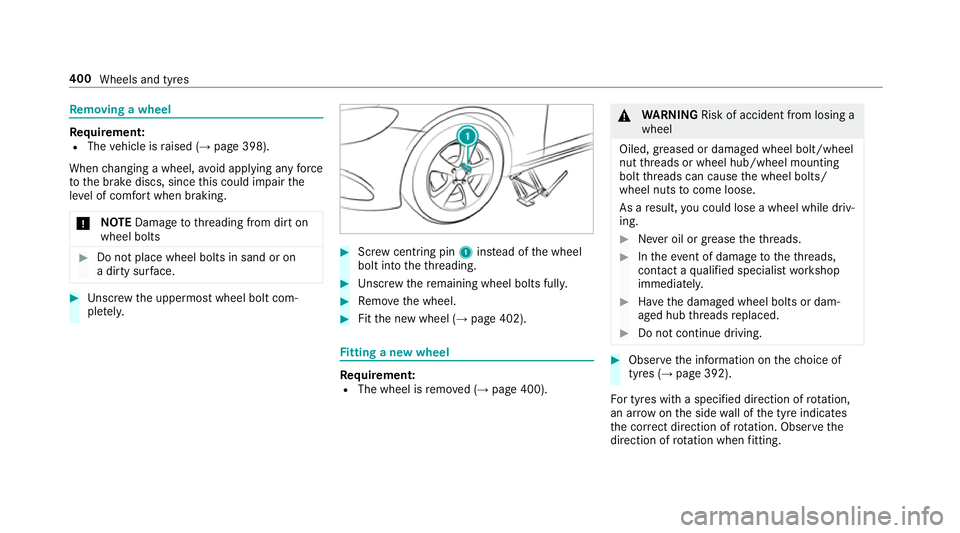

Unscr ew theu ppermos twheel bolt com‐

ple tely. #

Screw centring pin 1instead of thew heel

bolt int othe thre ading. #

Unscr ew ther emaining wheel bolt sfully. #

Remo vethew heel. #

Fitthen ew wheel (→ page402). Fi

ttin gan ewwheel Re

quirement:

R The wheel is remo ved( →pag e400). &

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can caus ethe wheel bolts/

wheel nuts tocome loose.

As aresult, youc ould lose awheel while driv‐

ing. #

Nevero il or grease thet hreads. #

Inthee vent of dama getothet hreads,

contact aqualified specialis tworks hop

immediatel y. #

Have thed amaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do no tcontinue driving. #

Obser vethei nformation on thec hoice of

tyres (→ page392).

Fo rtyres wit haspecified direction of rotation,

an ar rowonthes ide wall of thet yrei ndicates

th ec orrect di rection of rotation. Obse rvet he

direction of rotatio nw henf itting. 400

Wheels an dtyres

Page 404 of 521

#

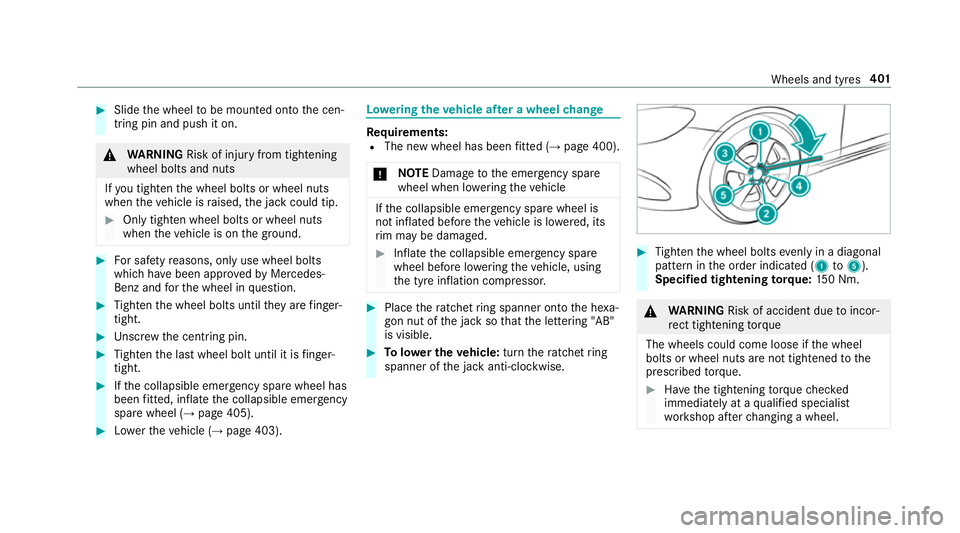

Slide thew heel tobe mounted ont othe cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

whee lbolts and nuts

If yo ut ighten thew heel bolts or wheel nuts

when thev ehicle is raised, thej ackc ould tip. #

Onlytighten wheel bolts or wheel nuts

when thev ehicle is on theg round. #

Fors afet yr easons, onl yuse wheel bolts

whic hhaveb een appr ovedbyM ercedes-

Benz and fort he wheel in question. #

Tighten thew heel bolts until they aref inger-

tight. #

Unscr ew thec ent ring pin. #

Tighten thel astw heel bolt until it is finger-

tight. #

Ifth ec ollapsible emer gency spa rewheel has

been fitted ,infla tethec ollapsible emer gency

spa rewheel (→ page405). #

Lowe rthe vehicle (→ page403). Lo

weri ngthev ehicle af teraw heelchange Re

quirements:

R The ne wwheel has been fitted (→ page 400).

* NO

TEDama getothee mer gency spa re

wheel when lo wering thev ehicle If

th ec ollapsible emer gency spa rewheel is

no tinflated befor ethe vehicle is lo wered, its

ri mm aybe dama ged. #

Inflat ethe collapsibl eemer gency spa re

wheel befor elowe ring thev ehicle, using

th et yrei nflation compressor. #

Place ther atche tring sp anner ont othe he xa‐

gon nut of thej acksot hatthel ette ring "AB"

is visible. #

Tolowe rthe vehicle: turnthe ratche tring

sp an ner of thej acka nti-clockwise. #

Tighten thew heel bolts evenlyinad iagonal

patter ninthe order indicated (1 to5 ).

Specified tightening torq ue: 150N m. &

WARNING Risk of accident du etoincor‐

re ct tigh tening torque

Th ew heel scould come loose if thew heel

bolts or wheel nuts ar enottightened tothe

prescribed torque. #

Have thet ightening torque checked

immediatel yataqualified specialist

wo rkshop af terc hanging awheel. Wheels and tyres

401

Page 405 of 521

#

Chec kthe tyr epressur eoft he newl ymoun‐

te dw heel and adjus taccording ly. #

Vehicles with tyr epressur elossw arning

sy stem: restar tt he tyr epressur eloss warn‐

ing sy stem (→ page392). #

Vehicles with atyrep ressur emonitoring

sy stem: restar tt he tyr epressur emonitoring

sy stem (→ page388).

Mak esuretoo bservethef ollowing fur ther rela‐

te ds ubjec t:

R Notesont yrep ressur e(→pag e385) Collapsible spar

ewheel Note

sont he collapsible spar ewheel &

WARNING Risk of accident caused by

incor rect wheel and tyr edimensions

The wheel or tyr esize and thet yret ype of

th ee mer gency spa rewheel or spar ewheel

and thew heel tobe replaced ma ydiffe r.

Mounting an emer gency spa rewheel/spare

wheel ma yseve rely impair thed riving char‐

acteristics. To

preve nt hazardous situations: #

Adapty our driving stylea ccording lyand

driv ecarefull y. #

Neverfit mo rethan on eemer gency

spa rewheel or spar ewheel that dif fers

in size. #

Onlyuse an emer gency spa rewheel or

spar ewheel of adiffe re nt size brie fly. #

Do no tswitcho ffESP ®

. #

>Ha vethee mer gency spa rewheel or

spar ewheel of adiffe re nt size replaced

at then eares tqualified specialis twork‐

shop. The ne wwheel mus thave the

cor rect dimensions. The collapsible spa

rewheel is an emer gency

whee lwhich is only suitable foru se foral imited

period of time and in arestricted manner in the

eve nt of aflat tyr e(e.g. until then eares twork‐

shop).

The tyr eside walls ar efolded when in transport

mode. Befor euse, thec ollapsible spar ewheel has

tobe inflated wit hthe accompanying com‐

pressor.

Chec kthe tyr epressur eoft he collapsibl espare

wheel oncef itted. Correct thep ressur easn ec‐

essar y.

The maximum permissible speed wit hacollapsi‐

ble spar ewheel fitted is 80 km/h.

Do no tfit sn ow ch ains wit hthe collapsibl espare

wheel.

Re place thec ollapsible spar ewheel af ters ix

ye arsatt he latest, rega rdless of wear.

% Ve

hicles with atyrep ressur elossw arn‐

ing sy stem: ifac ollapsible spar ewheel is

fi tted ,the tyr epressur eloss warning sy stem

cann otfunction reliabl y.Onl yrestart thes ys‐

te ma gain when thec ollapsible spar ewheel

has been replaced wit hanewwheel.

Ve hicles with atyrep ressur emonitoring

sy stem: ifac ollapsible spar ewheel is fitted

th et yrep ressur emonitoring sy stem cann ot

function reliably .Onlyr estart thes ystem

again when thec ollapsible spar ewheel has

been replaced wit hanewwheel. 402

Wheels and tyres

Page 406 of 521

Ve

hicles with atyrep ressur emonitoring

sy stem: foraf ewminutes af terac ollapsible

spar ewhee lisf itted, thes ystemm aystill

displa ythe tyr epressur eoft heremo ved

wheel.

Be sur etoalso obse rvet he following fur ther

re lated subjects:

R Notesont yrep ressur e(→pag e385)

R Tyre pressur etable (→ page386) Re

moving the collapsibl espar ew heel The collapsible spar

ewheel is secured in thec ol‐

lapsible spar ewheel bag in theb oot. #

Obser vethei nformation on mounting tyres

(→ pag e392). #

Open theb oot. #

Detach thef astening stra ps. #

Unhook ther etainin gspring hook softhefas‐

te ning stra ps from theb rack ets. #

Remo vethee mer gency spa rewheel bag

to ge ther wit hthe collapsibl espar ew heel. #

Open thee mer gency spa rewheel bag and

re mo vethec ollapsible spar ewheel. Inflating

thec ollapsible spa rewheel Re

quirements:

R Mount thec ollapsible spar ewheel as descri‐

bed. (→ page400)

R Remo vethet yrei nflation compressor from

th es towa ge well under theb ootfloor.

(→ pag e366)

* NO

TEDama getothec ollapsible spare

wheel when lo wering thev ehicle Lo

we ring thev ehicle without pr eviously

inflatin gthe collapsibl espar ew heel can

damag eits rim. #

Inflat ethe collapsibl espar ew heel using

th et yrei nflation compressor before

lo we ring thev ehicle. *

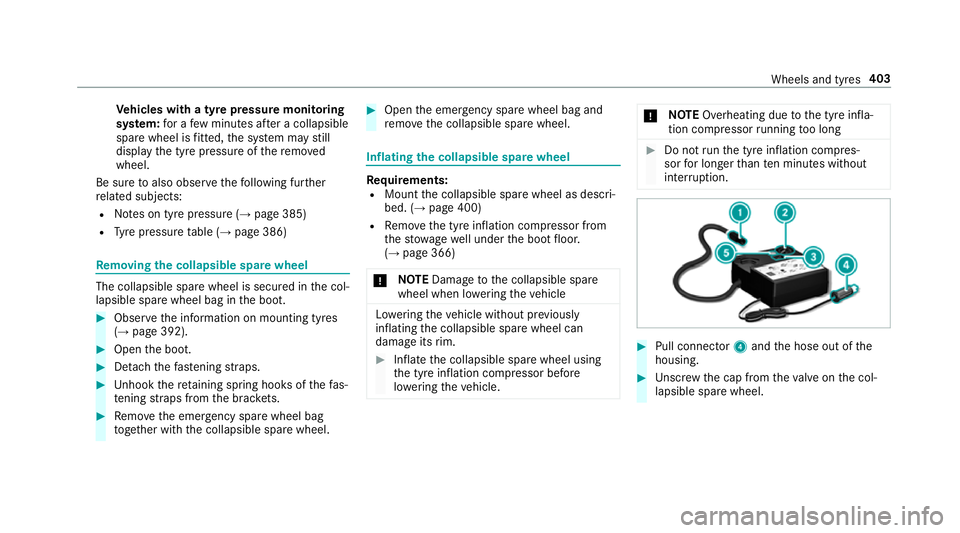

NO

TEOverheating du etothe tyr einfla‐

tion compressor running tool ong #

Do no trun thet yrei nflation compres‐

sor forl onger than tenm inutesw ithout

inter ruption. #

Pull connec tor4 and theh ose out of the

housing. #

Unscr ew thec ap from thev alveont he col‐

lapsible spar ewheel. Wheels and tyres

403

Page 407 of 521

#

Screw unio nnut1 oftheh ose ont othe

va lve.

Mak esureona nd offswitch 3ofthet yre

inflation compressor is se tto0. #

Inser tplug 4intot he cigar ette lighter

soc ket(→pa ge113) in your vehicle. #

Switc hont he powersupp ly (→pag e138). #

Press on and of fswitch 3onthet yrei nfla‐

tion compressor toI.

The tyr einflation compressor is switched on.

The tyr eisinflated. The tyr epressur eis

shown on manome ter2. #

Pum pthe tyr etothe specified tyr epressure.

The specified tyr epressur eisp rinted on the

ye llo wl abel of thec ollapsible spar ewheel. #

When thes pecified tyr epressur ehas been

re ached, press on and of fswit ch 3 onthe

tyr einflatio ncompressor to0. #

Ifth et yrep ressur eish igher than thes peci‐

fi ed pressure, press pressur erelease valve

bu tton 5unti lthe cor rect tyr epressur ehas

bee nreached. 404

Wheels and tyres

Page 408 of 521

Note

sont echnical data

Mercedes-AMG vehicles: observet he no tesin

th eS upplement .Otherwise, youm ayfailto rec‐

ognise dangers.

The tech nica ldataw as de term ined in accord‐

anc ewithEUD irectives. The dat astatedo nly

applies tovehicles wit hstandar dequipment .You

can obtain fur ther information from aMercedes-

Benz Service Centre.

Onl yfor certain count ries: youc an find vehi‐

cle-specific vehicle dat ainthe COC documents

(CERTIFIC ATEOFC ONFORMITY) .These docu‐

ments ar edelivered wi thyour vehicle. On-boar

delectronics Note

sont ampering with thee ngine elec‐

tronics *

NO

TEPremature wearthro ugh improper

main tenance Improper maintenance ma

ycause vehicle

componentstow ear morequickl yand the ve

hicle's operating permit ma ybeinvalida‐

te d. #

Alw aysh ave workon thee ngine elec‐

tronics and related component scarried

out at aqualified specialis tworks hop. *

NO

TEIncreased wear and tear or dam‐

ag ec aused bymeasu resu nder take nto

inc rease per form ance Engin

emanagemen tmeasures unde rtaken to

inc rease per form anc ecan lead toinc reased

we ar and tear or damag etothe driv esystem. #

Do no tunder take engine management

measures toinc rease per form ance. Tw

o-w ayradios Note

sonf itting two- wayradios &

WARNING Risk of accident du eto

improper workon two-w ayradios

The elect romagnetic radiation from two-w ay

ra dios can inter fere wit hthe on-boar delec‐

tronics if RF transmit ters arem anipulated or

re trofitted inco rrectly.

This could jeopardise theo perating saf etyof

th ev ehicle. #

Yous hould ha veall workon electrical

and electronic component scarried out

at aq ualified specialis tworks hop. &

WARNING Risk of accident from incor‐

re ct ope ratio noft wo-way radios

If yo uo perat etwo -way radios inco rrectly in

th ev ehicle, thee lectromagnetic radiation

could inter fere wit hthe on-boar delectronics,

e.g.: Te

ch nica ldata 405

Page 409 of 521

R

ifth et wo -way radio is no tconnec tedto

an exterior aerial

R ifth ee xterio raerial is no tcorrectly

mounted or is no toflowreflection

This could jeopardise theo perating saf etyof

th ev ehicle. #

Have thel ow -reflectio nexterio raerial

fi tted at aqualified specialis tworks hop. #

When operating two-w ayradios in the

ve hicle, alw aysc onnect them tothe

lo w- reflection exterior aerial. *

NO

TEInva lidation of theo perating per‐

mit due tofailur etoc omply wi th the

instructions fori ns tallation and use The operatin

gpermit ma ybeinvalidated if

th ei nstruction sfor ins tallation and use of

two-w ayradios ar enotobser ved. #

Onlyuse appr oved frequency bands. #

Obser vethem aximum permissible out‐

put po werint hese frequency bands. #

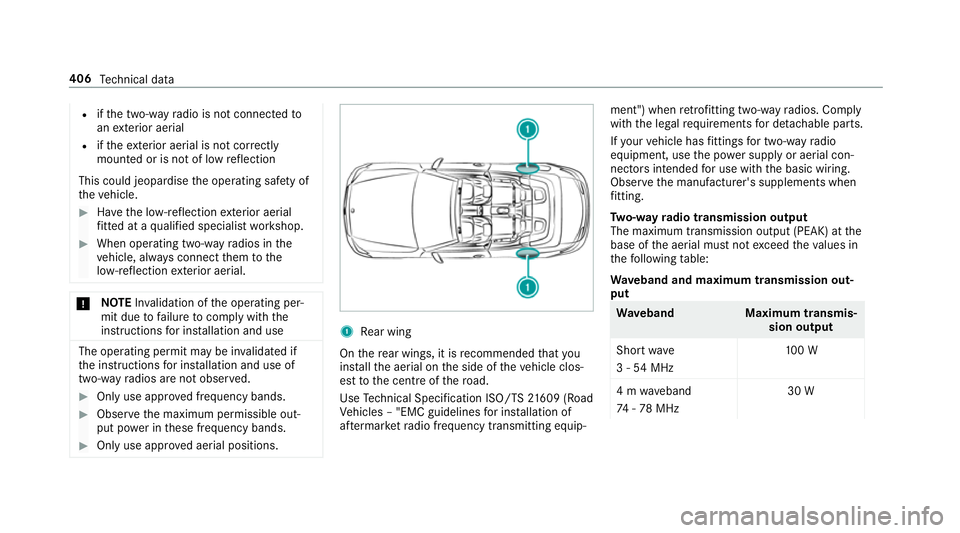

Onlyuse appr oved aerial positions. 1

Rear wing

On ther ear wings, it is recommended that you

ins tallth ea erial on thes ide of thev ehicle clos‐

es ttot he centre ofther oad.

Use Tech nica lSpecificatio nISO/T S21609 (Road

Ve hicles –"EMC guidelines fori ns tallation of

af te rm arke tradio frequency transmittin gequip‐ ment") when

retrofitting two-w ayradios. Comply

wit hthe legal requ irements ford etachable parts.

If yo ur vehicle has fitting sfor two-w ayradio

equipment ,use thep ower suppl yoraerial con‐

nector sintended foru se wit hthe basic wiring.

Obser vethem anufacturer's supplement swhen

fi tting.

Tw o-w ayradio transmission output

The maximum transmission outpu t(PEAK) at the

base of thea erial mus tnotexc eed thev alues in

th ef ollowing table:

Wa veband and maximum transmission out‐

put Wa

veband Maximum transmis‐

sion output

Shor twave

3-54M Hz 10

0W

4mw aveband

74 -78M Hz 30 W406

Tech nica ldata

Page 410 of 521

Wa

veband Maximum transmis‐

sion output

2mw aveband

14 4-1 74MHz 50 W

Tr unked radio sys‐

te m/T etra

380 -460 MHz 10 W

70 cm waveband

400 -460 MHz 35 W

Tw o-w ayradio

(2G/3G/4G) 10 WThe

following can be used in thev ehicle without

re strictions:

R RF transmitter switham aximum transmis‐

sion output of up to100mW

R RF transmitter switht ransmitter frequencies

in the3 80 -410 MHz waveband and amaxi‐

mum transmission output of up to2W

(trunked radio sy stem/T etra)

R Mobile phones (2G/3G/4G) Ther

eareno restrictions whe npositioning the

aerial on theo utside of thev ehicle fors ome

wav ebands.

This applies tothef ollowing wavebands:

R trunked radio sy stem/T etra

R 70 cm waveband

R 2G/3G/4G Ve

hicl eidentification plate, VIN and engine

number overview

Ve hicl eidentification plate Te

ch nica ldata 407