clock MERCEDES-BENZ SL-CLASS ROADSTER 2012 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SL-CLASS ROADSTER, Model: MERCEDES-BENZ SL-CLASS ROADSTER 2012Pages: 316, PDF Size: 7.21 MB

Page 227 of 316

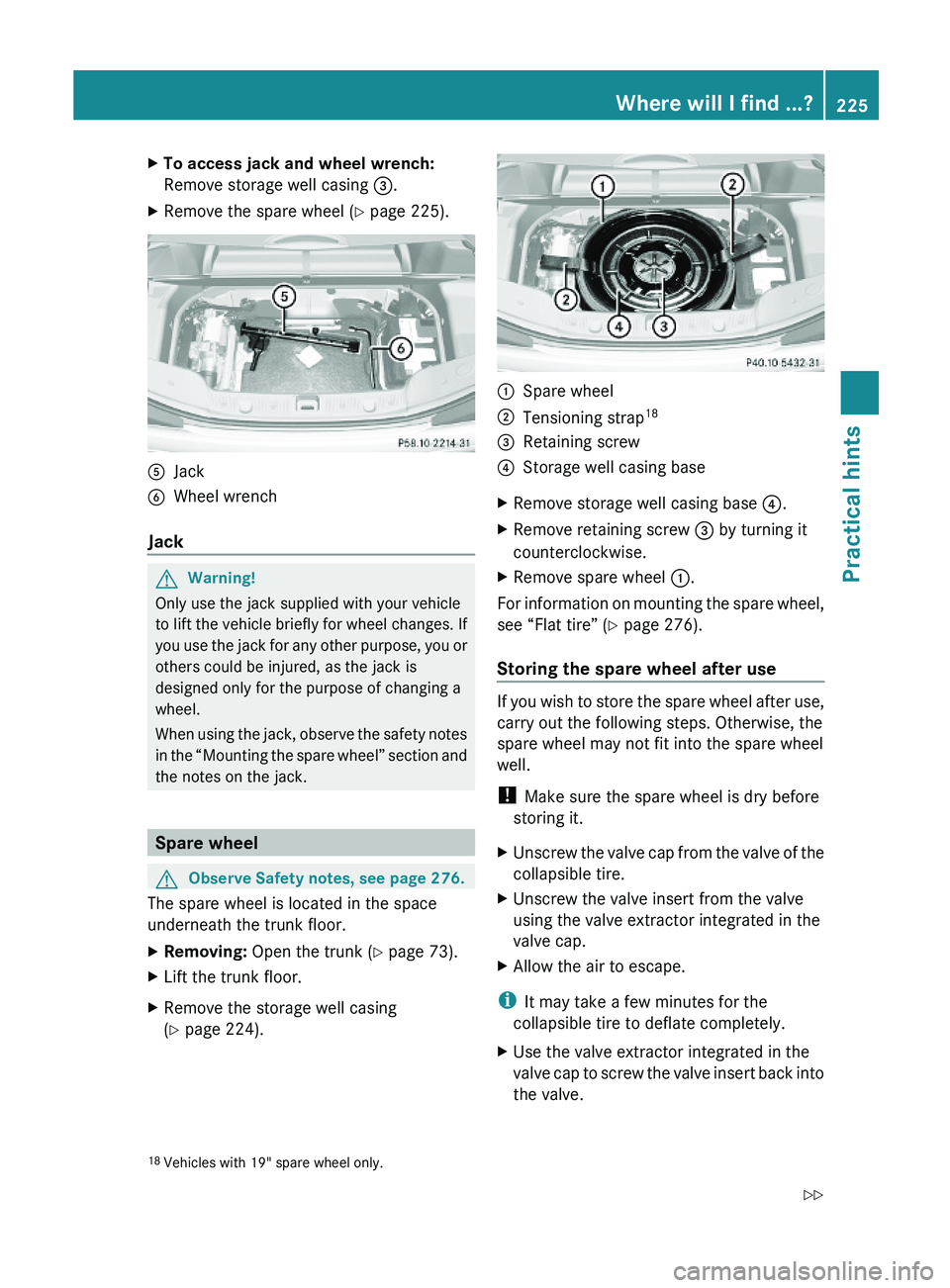

XTo access jack and wheel wrench:

Remove storage well casing =.

XRemove the spare wheel (Y page 225).AJackBWheel wrench

Jack

GWarning!

Only use the jack supplied with your vehicle

to lift the vehicle briefly for wheel changes. If

you use the jack for any other purpose, you or

others could be injured, as the jack is

designed only for the purpose of changing a

wheel.

When using the jack, observe the safety notes

in the “Mounting the spare wheel” section and

the notes on the jack.

Spare wheel

GObserve Safety notes, see page 276.

The spare wheel is located in the space

underneath the trunk floor.

XRemoving: Open the trunk (Y page 73).XLift the trunk floor.XRemove the storage well casing

(Y page 224).:Spare wheel;Tensioning strap18=Retaining screw?Storage well casing baseXRemove storage well casing base ?.XRemove retaining screw = by turning it

counterclockwise.

XRemove spare wheel :.

For information on mounting the spare wheel,

see “Flat tire” (Y page 276).

Storing the spare wheel after use

If you wish to store the spare wheel after use,

carry out the following steps. Otherwise, the

spare wheel may not fit into the spare wheel

well.

! Make sure the spare wheel is dry before

storing it.

XUnscrew the valve cap from the valve of the

collapsible tire.

XUnscrew the valve insert from the valve

using the valve extractor integrated in the

valve cap.

XAllow the air to escape.

iIt may take a few minutes for the

collapsible tire to deflate completely.

XUse the valve extractor integrated in the

valve cap to screw the valve insert back into

the valve.

18Vehicles with 19" spare wheel only.Where will I find ...?225Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 225Z

Page 228 of 316

XScrew the valve cap back onto the valve.

iVehicles with 19" spare wheel only:

Before placing the spare wheel in the spare

wheel well fasten tensioning straps, see

“Compressing the collapsible tire”

(Y page 226).

XPlace the spare wheel into the spare wheel

well.

XSecure the spare wheel by turning retaining

screw = clockwise.

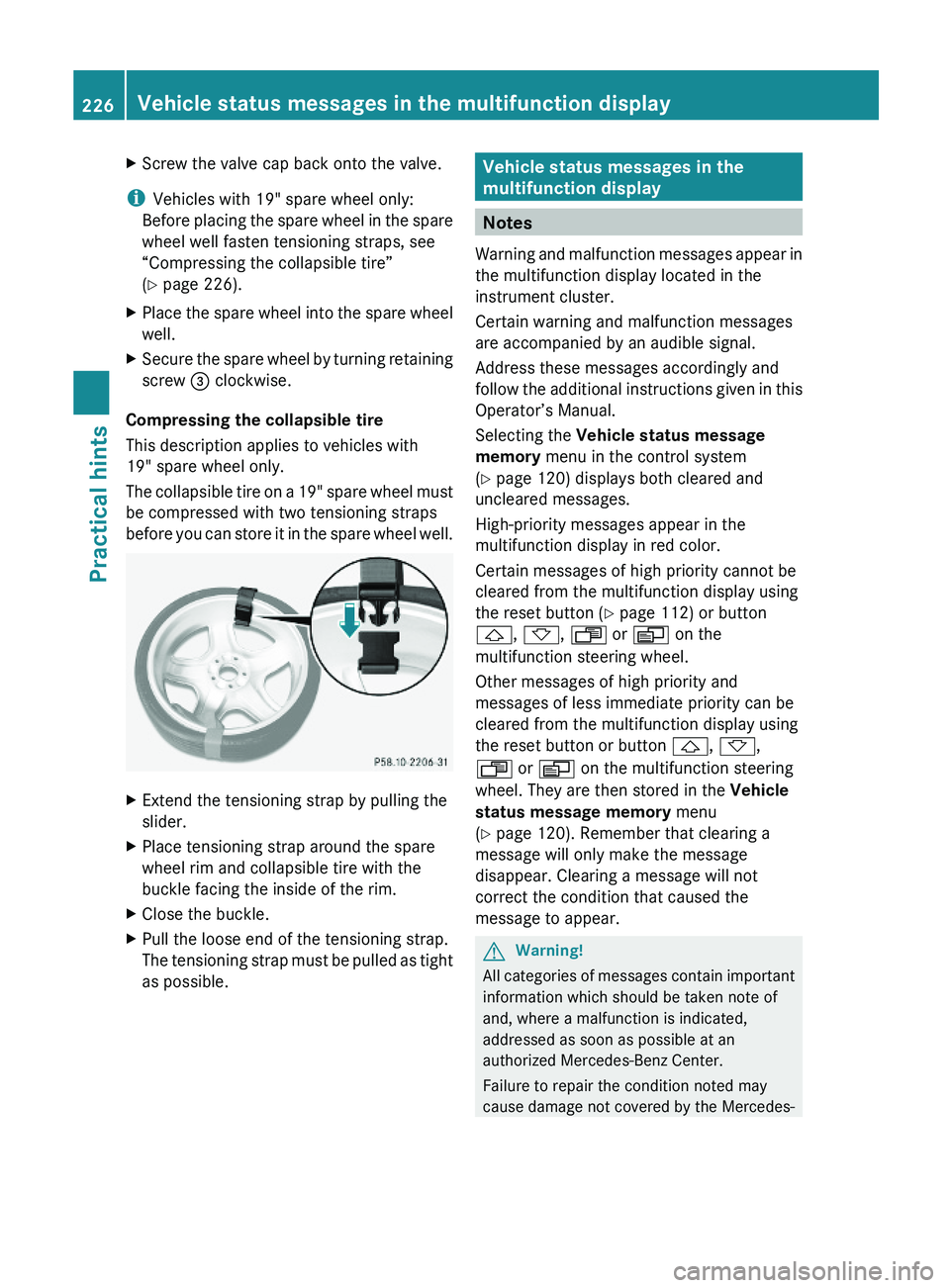

Compressing the collapsible tire

This description applies to vehicles with

19" spare wheel only.

The collapsible tire on a 19" spare wheel must

be compressed with two tensioning straps

before you can store it in the spare wheel well.

XExtend the tensioning strap by pulling the

slider.

XPlace tensioning strap around the spare

wheel rim and collapsible tire with the

buckle facing the inside of the rim.

XClose the buckle.XPull the loose end of the tensioning strap.

The tensioning strap must be pulled as tight

as possible.

Vehicle status messages in the

multifunction display

Notes

Warning and malfunction messages appear in

the multifunction display located in the

instrument cluster.

Certain warning and malfunction messages

are accompanied by an audible signal.

Address these messages accordingly and

follow the additional instructions given in this

Operator’s Manual.

Selecting the Vehicle status message

memory menu in the control system

(Y page 120) displays both cleared and

uncleared messages.

High-priority messages appear in the

multifunction display in red color.

Certain messages of high priority cannot be

cleared from the multifunction display using

the reset button (Y page 112) or button

&, *, U or V on the

multifunction steering wheel.

Other messages of high priority and

messages of less immediate priority can be

cleared from the multifunction display using

the reset button or button &, *,

U or V on the multifunction steering

wheel. They are then stored in the Vehicle

status message memory menu

(Y page 120). Remember that clearing a

message will only make the message

disappear. Clearing a message will not

correct the condition that caused the

message to appear.

GWarning!

All categories of messages contain important

information which should be taken note of

and, where a malfunction is indicated,

addressed as soon as possible at an

authorized Mercedes-Benz Center.

Failure to repair the condition noted may

cause damage not covered by the Mercedes-

226Vehicle status messages in the multifunction displayPractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 226

Page 270 of 316

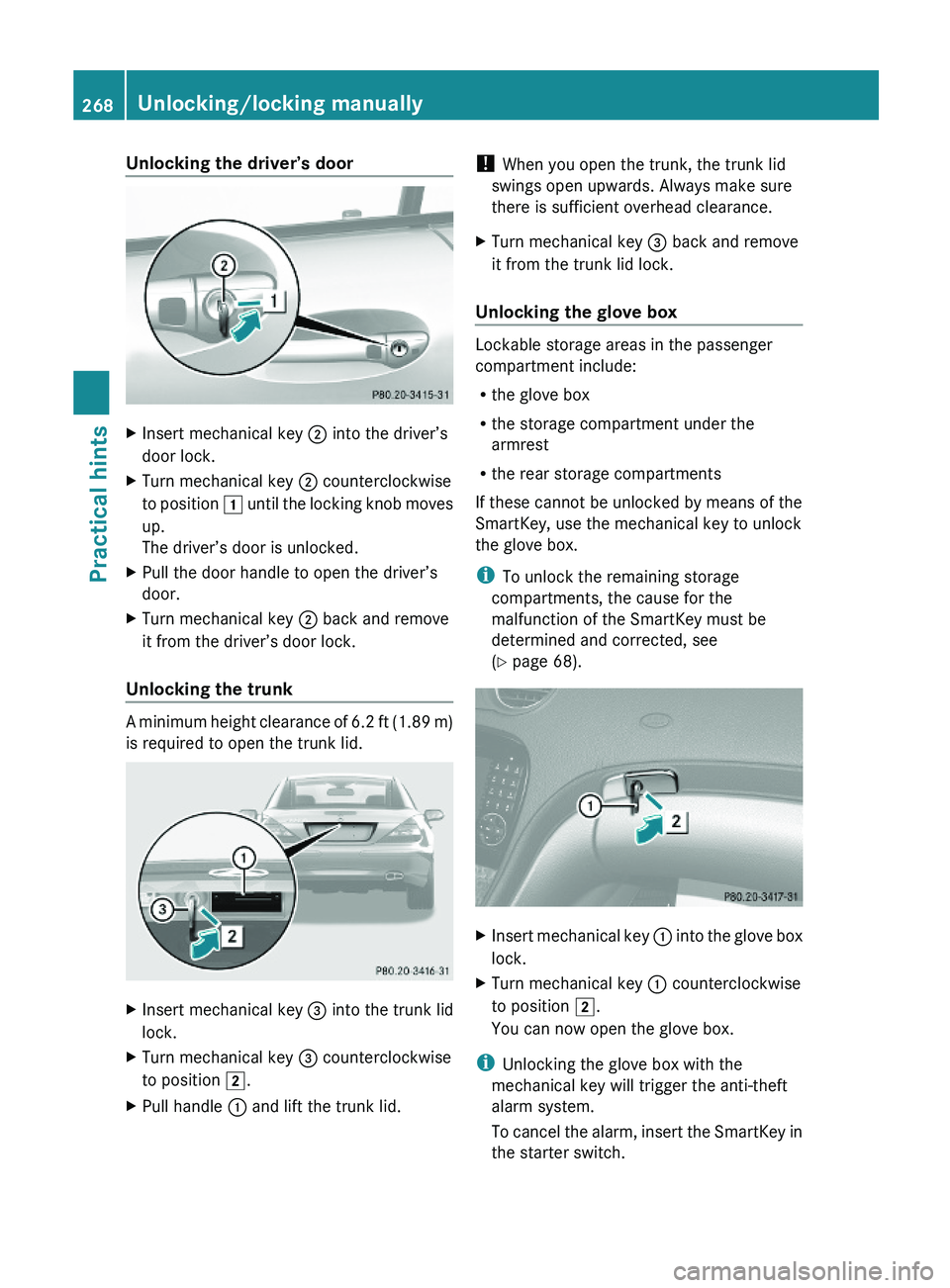

Unlocking the driver’s doorXInsert mechanical key ; into the driver’s

door lock.

XTurn mechanical key ; counterclockwise

to position 1 until the locking knob moves

up.

The driver’s door is unlocked.

XPull the door handle to open the driver’s

door.

XTurn mechanical key ; back and remove

it from the driver’s door lock.

Unlocking the trunk

A minimum height clearance of 6.2 ft (1.89 m)

is required to open the trunk lid.

XInsert mechanical key = into the trunk lid

lock.

XTurn mechanical key = counterclockwise

to position 2.

XPull handle : and lift the trunk lid.! When you open the trunk, the trunk lid

swings open upwards. Always make sure

there is sufficient overhead clearance.

XTurn mechanical key = back and remove

it from the trunk lid lock.

Unlocking the glove box

Lockable storage areas in the passenger

compartment include:

Rthe glove box

Rthe storage compartment under the

armrest

Rthe rear storage compartments

If these cannot be unlocked by means of the

SmartKey, use the mechanical key to unlock

the glove box.

iTo unlock the remaining storage

compartments, the cause for the

malfunction of the SmartKey must be

determined and corrected, see

(Y page 68).

XInsert mechanical key : into the glove box

lock.

XTurn mechanical key : counterclockwise

to position 2.

You can now open the glove box.

iUnlocking the glove box with the

mechanical key will trigger the anti-theft

alarm system.

To cancel the alarm, insert the SmartKey in

the starter switch.

268Unlocking/locking manuallyPractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 268

Page 271 of 316

Locking the vehicle

If you cannot lock the vehicle with the

SmartKey or with KEYLESS-GO, lock it as

follows:

XOpen the driver’s door.XClose the passenger door and the trunk.XPress the central locking switch

(Y page 73).

XCheck to see whether the locking knob on

the passenger door has moved down.

XIf necessary, push it down manually.XExit the vehicle and close the driver’s door.XRemove the mechanical key from the

SmartKey (Y page 267).

XCheck whether the trunk is locked.XIf it is not locked, lock it with the

mechanical key (Y page 77).

Except for the driver’s door, the vehicle

should now be locked.

XInsert mechanical key ; into the driver’s

door lock.

XTurn mechanical key ; clockwise to

position 1.

The driver’s door is locked.

XTurn mechanical key ; back and remove

it from the driver’s door lock.

iThis procedure does not arm the anti-

theft alarm system, nor does it lock the fuel

filler flap and the storage compartments.

The storage compartments can be locked

separately (Y page 161).

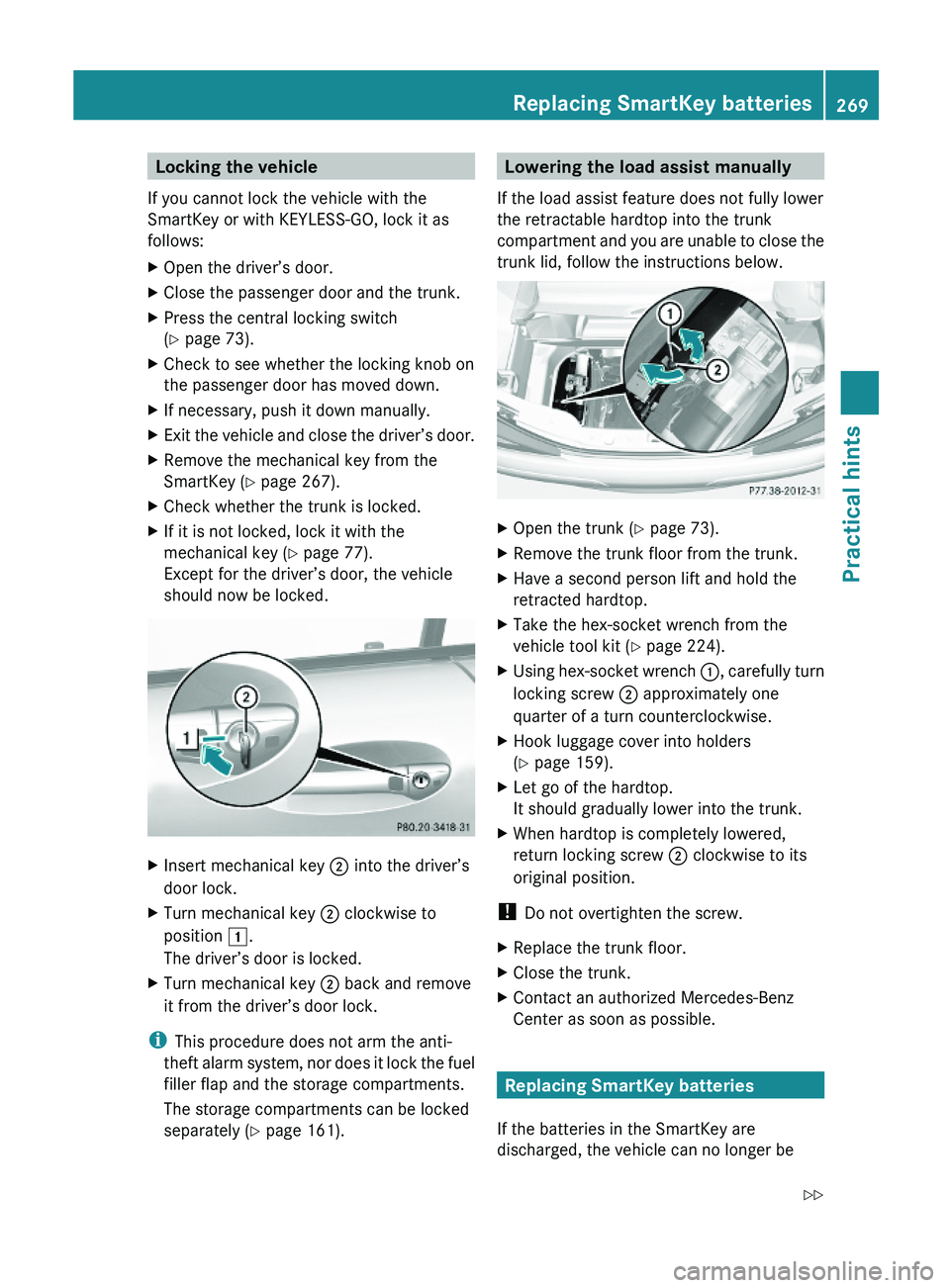

Lowering the load assist manually

If the load assist feature does not fully lower

the retractable hardtop into the trunk

compartment and you are unable to close the

trunk lid, follow the instructions below.

XOpen the trunk (Y page 73).XRemove the trunk floor from the trunk.XHave a second person lift and hold the

retracted hardtop.

XTake the hex-socket wrench from the

vehicle tool kit (Y page 224).

XUsing hex-socket wrench :, carefully turn

locking screw ; approximately one

quarter of a turn counterclockwise.

XHook luggage cover into holders

(Y page 159).

XLet go of the hardtop.

It should gradually lower into the trunk.

XWhen hardtop is completely lowered,

return locking screw ; clockwise to its

original position.

! Do not overtighten the screw.

XReplace the trunk floor.XClose the trunk.XContact an authorized Mercedes-Benz

Center as soon as possible.

Replacing SmartKey batteries

If the batteries in the SmartKey are

discharged, the vehicle can no longer be

Replacing SmartKey batteries269Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 269Z

Page 275 of 316

GObserve Safety notes, see page 271.

ROnly use 12-volt bulbs of the same type and

with the specified watt rating.

RSwitch the lights off before changing a bulb

to prevent short circuits.

RAlways use a clean lint-free cloth when

handling bulbs.

RYour hands should be dry and free of oil and

grease.

RIf the newly installed bulb does not come

on, contact an authorized Mercedes-Benz

Center.

iMercedes-Benz recommends using

Longlife (LL) bulbs.

Replacing bulbs for front lamps

GWarning!

Do not remove the cover for the Bi-Xenon

headlamp. Because of high voltage in Xenon

lamps, it is dangerous to replace the bulb or

repair the lamp and its components. It is

recommended to have such work done by a

qualified technician.

Before you start to replace a bulb for a front

lamp, do the following:

XSwitch off the ignition.XTurn the exterior lamp switch to position

$.

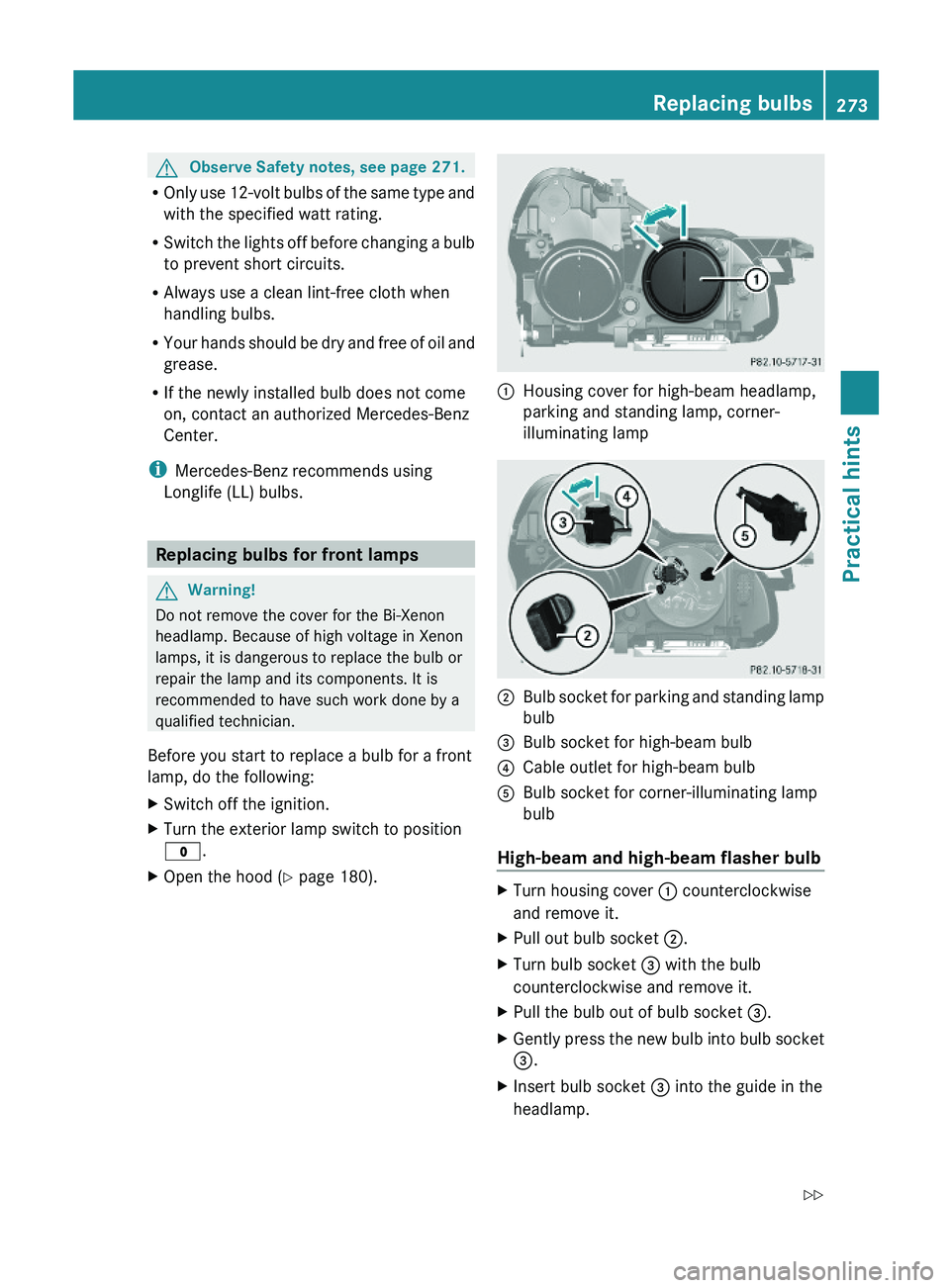

XOpen the hood (Y page 180).:Housing cover for high-beam headlamp,

parking and standing lamp, corner-

illuminating lamp

;Bulb socket for parking and standing lamp

bulb

=Bulb socket for high-beam bulb?Cable outlet for high-beam bulbABulb socket for corner-illuminating lamp

bulb

High-beam and high-beam flasher bulb

XTurn housing cover : counterclockwise

and remove it.

XPull out bulb socket ;.XTurn bulb socket = with the bulb

counterclockwise and remove it.

XPull the bulb out of bulb socket =.XGently press the new bulb into bulb socket

=.

XInsert bulb socket = into the guide in the

headlamp.

Replacing bulbs273Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 273Z

Page 276 of 316

XTurn bulb socket = clockwise until it

engages.

Driver’s side headlamp: Cable outlet ?

of bulb socket = must point towards the

lower right.

Passenger-side headlamp: Cable

outlet ? of bulb socket = must point

towards the lower left.

XPlace bulb socket ; back into the housing.XAlign housing cover : and turn it

clockwise until it engages.

Parking and standing lamp bulb

XTurn housing cover : counterclockwise

and remove it.

XPull out bulb socket ;.XPull the bulb out of bulb socket ;.XGently press the new bulb into bulb

socket ;.

XPlace bulb socket ; back into the housing.XAlign housing cover : and turn it

clockwise until it engages.

Corner-illuminating lamp bulbs

XTurn housing cover : counterclockwise

and remove it.

XTurn bulb socket A counterclockwise and

remove it.

XPull the bulb out of bulb socket A.XGently press the new bulb into bulb socket

A.

XInsert bulb socket A into the guide in the

headlamp.

XTurn bulb socket A clockwise until it

engages.

The handle of the bulb socket must be

vertical.

XAlign housing cover : and turn it

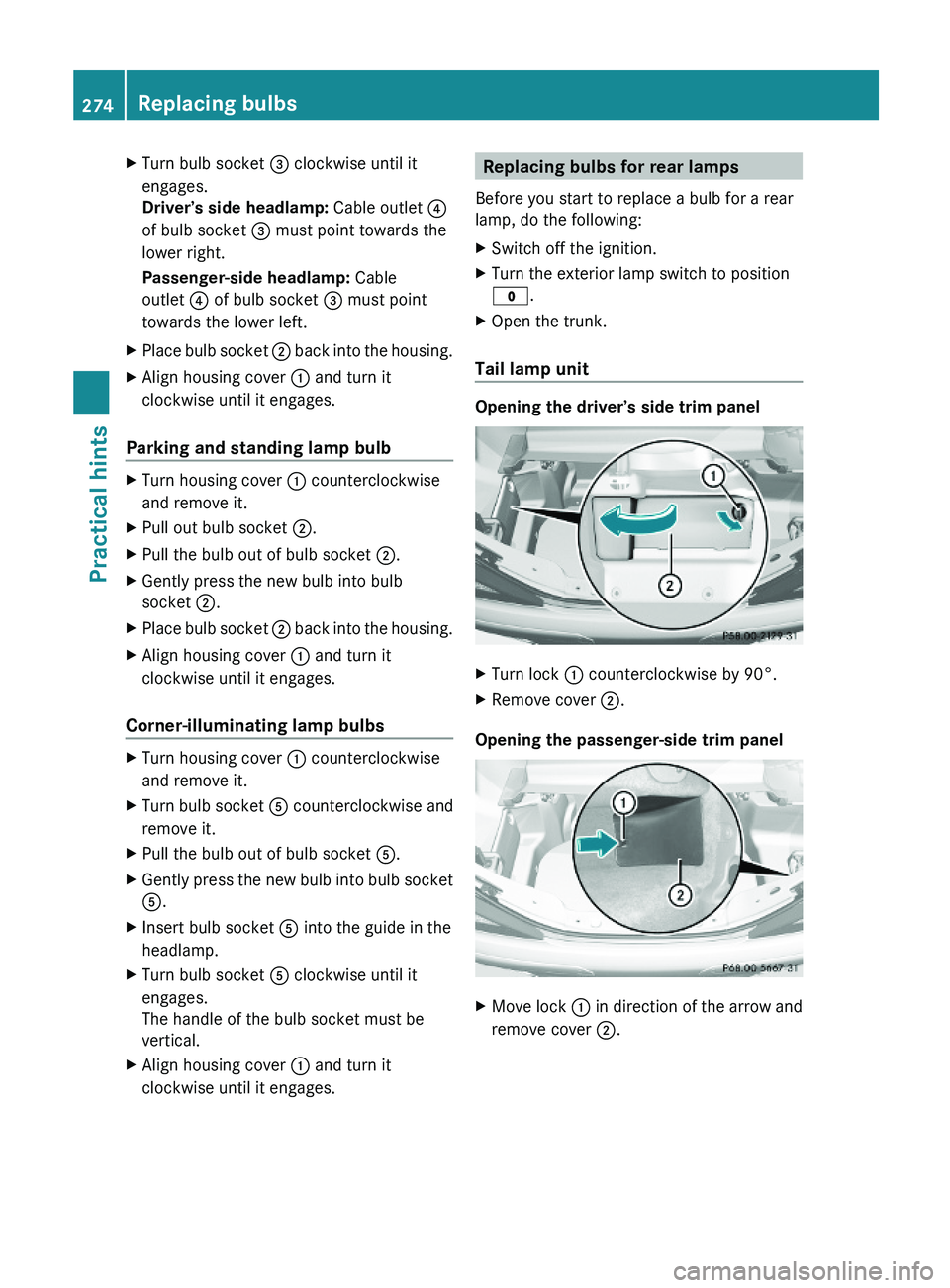

clockwise until it engages.Replacing bulbs for rear lamps

Before you start to replace a bulb for a rear

lamp, do the following:

XSwitch off the ignition.XTurn the exterior lamp switch to position

$.

XOpen the trunk.

Tail lamp unit

Opening the driver’s side trim panel

XTurn lock : counterclockwise by 90°.XRemove cover ;.

Opening the passenger-side trim panel

XMove lock : in direction of the arrow and

remove cover ;.

274Replacing bulbsPractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 274

Page 277 of 316

Replacing bulbs

Example illustration: Bulb socket passenger side

:Turn signal lamp;Backup lamp

iThe lamps on the driver’s side are

mirrored.

XDepending on which bulb needs to be

replaced, turn the respective bulb socket

counterclockwise and remove it.

XGently press onto the bulb and turn it

clockwise out of its bulb socket.

XGently press the new bulb into its bulb

socket and turn it counterclockwise until it

engages.

XAlign the respective bulb socket and press

it into the tail lamp unit until it audibly

engages.

XReinstall the trim.

License plate lamps

XLoosen screws : of lamp cover to be

removed.

XRemove lamp cover ;.XReplace the bulb.XReinstall lamp cover ;.XRetighten screws :.

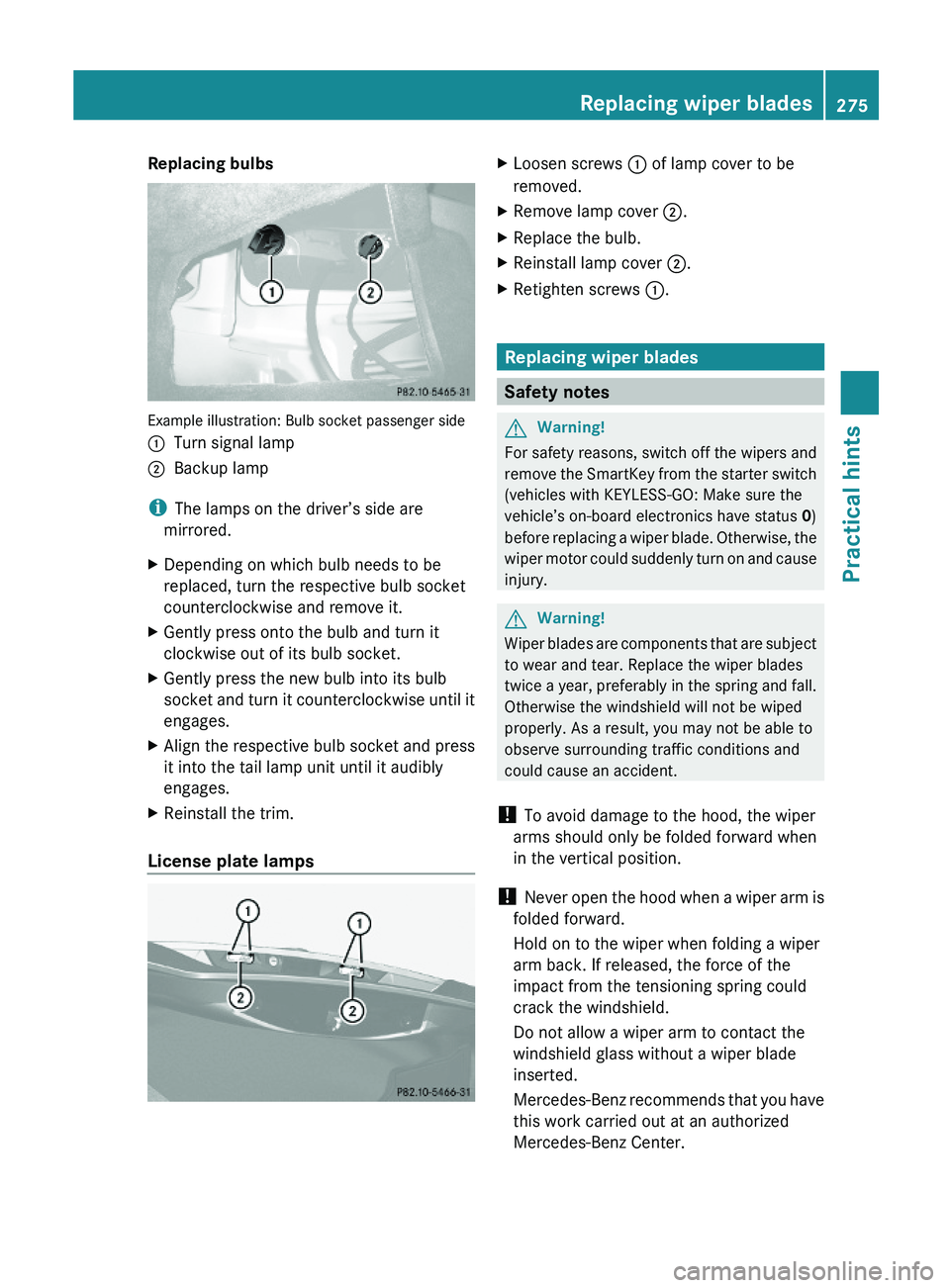

Replacing wiper blades

Safety notes

GWarning!

For safety reasons, switch off the wipers and

remove the SmartKey from the starter switch

(vehicles with KEYLESS-GO: Make sure the

vehicle’s on-board electronics have status 0)

before replacing a wiper blade. Otherwise, the

wiper motor could suddenly turn on and cause

injury.

GWarning!

Wiper blades are components that are subject

to wear and tear. Replace the wiper blades

twice a year, preferably in the spring and fall.

Otherwise the windshield will not be wiped

properly. As a result, you may not be able to

observe surrounding traffic conditions and

could cause an accident.

! To avoid damage to the hood, the wiper

arms should only be folded forward when

in the vertical position.

! Never open the hood when a wiper arm is

folded forward.

Hold on to the wiper when folding a wiper

arm back. If released, the force of the

impact from the tensioning spring could

crack the windshield.

Do not allow a wiper arm to contact the

windshield glass without a wiper blade

inserted.

Mercedes-Benz recommends that you have

this work carried out at an authorized

Mercedes-Benz Center.

Replacing wiper blades275Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 275Z

Page 281 of 316

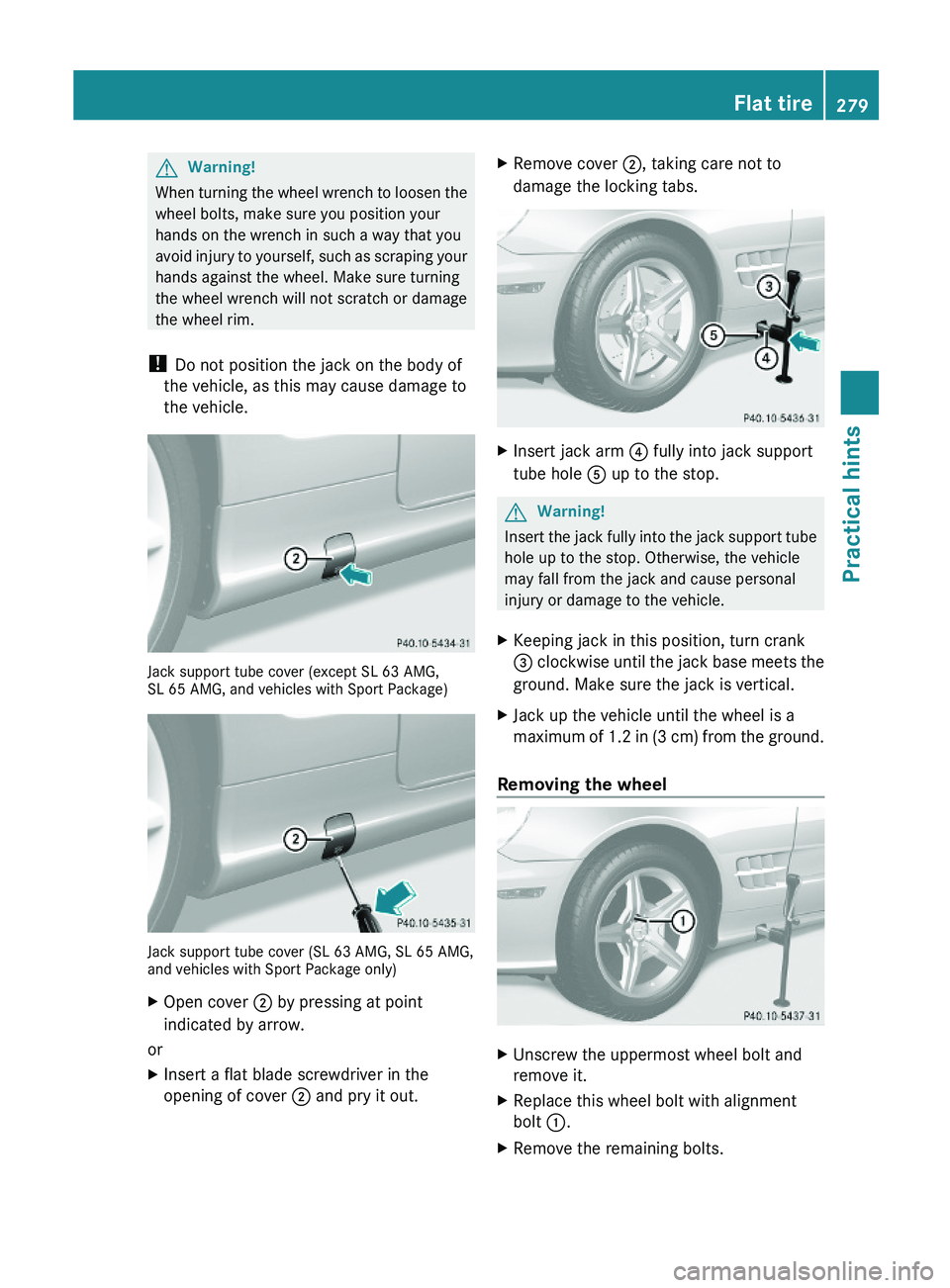

GWarning!

When turning the wheel wrench to loosen the

wheel bolts, make sure you position your

hands on the wrench in such a way that you

avoid injury to yourself, such as scraping your

hands against the wheel. Make sure turning

the wheel wrench will not scratch or damage

the wheel rim.

! Do not position the jack on the body of

the vehicle, as this may cause damage to

the vehicle.

Jack support tube cover (except SL 63 AMG,SL 65 AMG, and vehicles with Sport Package)

Jack support tube cover (SL 63 AMG, SL 65 AMG,and vehicles with Sport Package only)

XOpen cover ; by pressing at point

indicated by arrow.

or

XInsert a flat blade screwdriver in the

opening of cover ; and pry it out.

XRemove cover ;, taking care not to

damage the locking tabs.

XInsert jack arm ? fully into jack support

tube hole A up to the stop.

GWarning!

Insert the jack fully into the jack support tube

hole up to the stop. Otherwise, the vehicle

may fall from the jack and cause personal

injury or damage to the vehicle.

XKeeping jack in this position, turn crank

= clockwise until the jack base meets the

ground. Make sure the jack is vertical.

XJack up the vehicle until the wheel is a

maximum of 1.2 in (3 cm) from the ground.

Removing the wheel

XUnscrew the uppermost wheel bolt and

remove it.

XReplace this wheel bolt with alignment

bolt :.

XRemove the remaining bolts.Flat tire279Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 279Z

Page 284 of 316

pressure as specified for your vehicle

(Y page 303), decrease tire pressure using

the vent screw on air hose ?.

XVersion 2 only: If the tire inflation pressure

is above the recommended tire inflation

pressure as specified for your vehicle

(Y page 303), decrease tire pressure using

deflate button B.

GObserve Safety notes, see page 189.XDetach the electric air pump.XReinstall collapsible tire valve cap.XVersion 1 only: Store electrical plug =

and air hose ? behind flap :.

XVersion 2 only: Store electrical plug =

and the air hose back into the pump

housing bottom.

XPlace the electric air pump back in its

designated storage space.

XLower the vehicle.

Lowering the vehicle

GWarning!

Inflate collapsible tire only after the wheel is

properly attached.

Inflate the collapsible tire using the electric

air pump before lowering the vehicle.

XLower the vehicle by turning the crank

counterclockwise until the vehicle is

resting fully on its own weight.

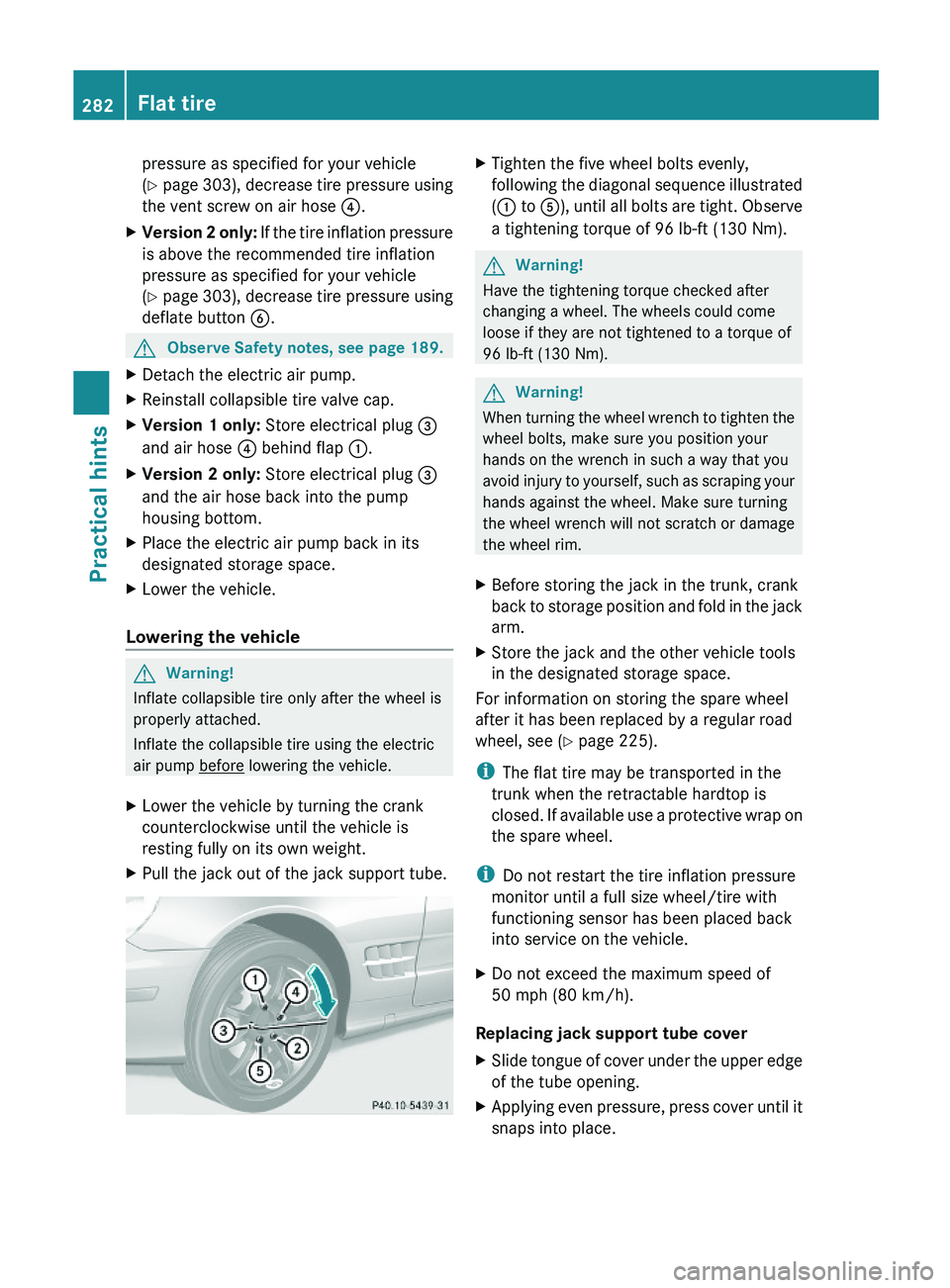

XPull the jack out of the jack support tube.XTighten the five wheel bolts evenly,

following the diagonal sequence illustrated

(: to A), until all bolts are tight. Observe

a tightening torque of 96 lb-ft (130 Nm).

GWarning!

Have the tightening torque checked after

changing a wheel. The wheels could come

loose if they are not tightened to a torque of

96 lb-ft (130 Nm).

GWarning!

When turning the wheel wrench to tighten the

wheel bolts, make sure you position your

hands on the wrench in such a way that you

avoid injury to yourself, such as scraping your

hands against the wheel. Make sure turning

the wheel wrench will not scratch or damage

the wheel rim.

XBefore storing the jack in the trunk, crank

back to storage position and fold in the jack

arm.

XStore the jack and the other vehicle tools

in the designated storage space.

For information on storing the spare wheel

after it has been replaced by a regular road

wheel, see (Y page 225).

iThe flat tire may be transported in the

trunk when the retractable hardtop is

closed. If available use a protective wrap on

the spare wheel.

iDo not restart the tire inflation pressure

monitor until a full size wheel/tire with

functioning sensor has been placed back

into service on the vehicle.

XDo not exceed the maximum speed of

50 mph (80 km/h).

Replacing jack support tube cover

XSlide tongue of cover under the upper edge

of the tube opening.

XApplying even pressure, press cover until it

snaps into place.

282Flat tirePractical hints

230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 282

Page 291 of 316

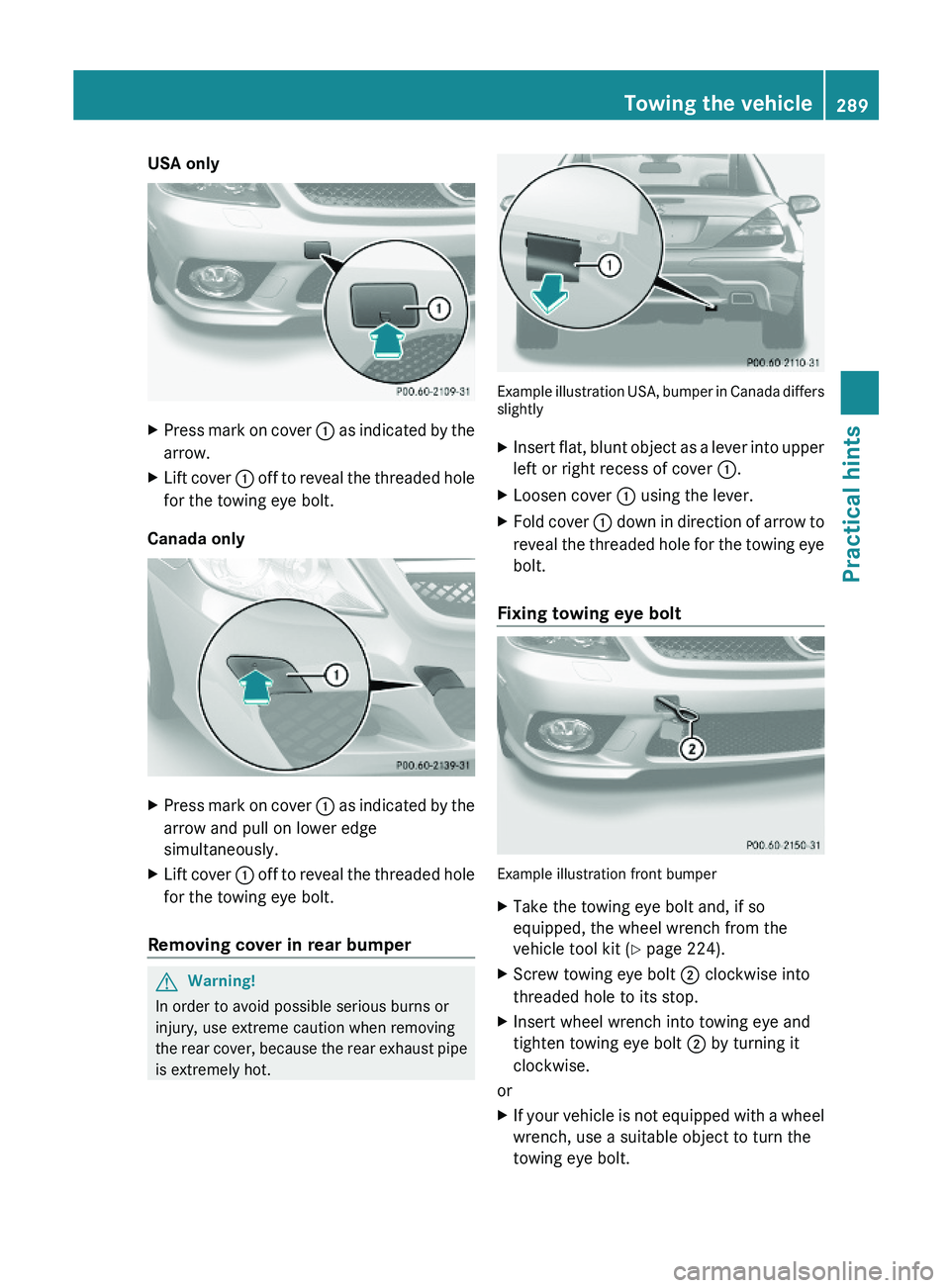

USA onlyXPress mark on cover : as indicated by the

arrow.

XLift cover : off to reveal the threaded hole

for the towing eye bolt.

Canada only

XPress mark on cover : as indicated by the

arrow and pull on lower edge

simultaneously.

XLift cover : off to reveal the threaded hole

for the towing eye bolt.

Removing cover in rear bumper

GWarning!

In order to avoid possible serious burns or

injury, use extreme caution when removing

the rear cover, because the rear exhaust pipe

is extremely hot.

Example illustration USA, bumper in Canada differsslightly

XInsert flat, blunt object as a lever into upper

left or right recess of cover :.

XLoosen cover : using the lever.XFold cover : down in direction of arrow to

reveal the threaded hole for the towing eye

bolt.

Fixing towing eye bolt

Example illustration front bumper

XTake the towing eye bolt and, if so

equipped, the wheel wrench from the

vehicle tool kit (Y page 224).

XScrew towing eye bolt ; clockwise into

threaded hole to its stop.

XInsert wheel wrench into towing eye and

tighten towing eye bolt ; by turning it

clockwise.

or

XIf your vehicle is not equipped with a wheel

wrench, use a suitable object to turn the

towing eye bolt.

Towing the vehicle289Practical hints230_AKB; 6; 22, en-USd2ureepe,Version: 2.11.8.12009-07-28T18:49:58+02:00 - Seite 289Z