clock MERCEDES-BENZ SL-CLASS ROADSTER 2013 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SL-CLASS ROADSTER, Model: MERCEDES-BENZ SL-CLASS ROADSTER 2013Pages: 572, PDF Size: 9.23 MB

Page 519 of 572

X

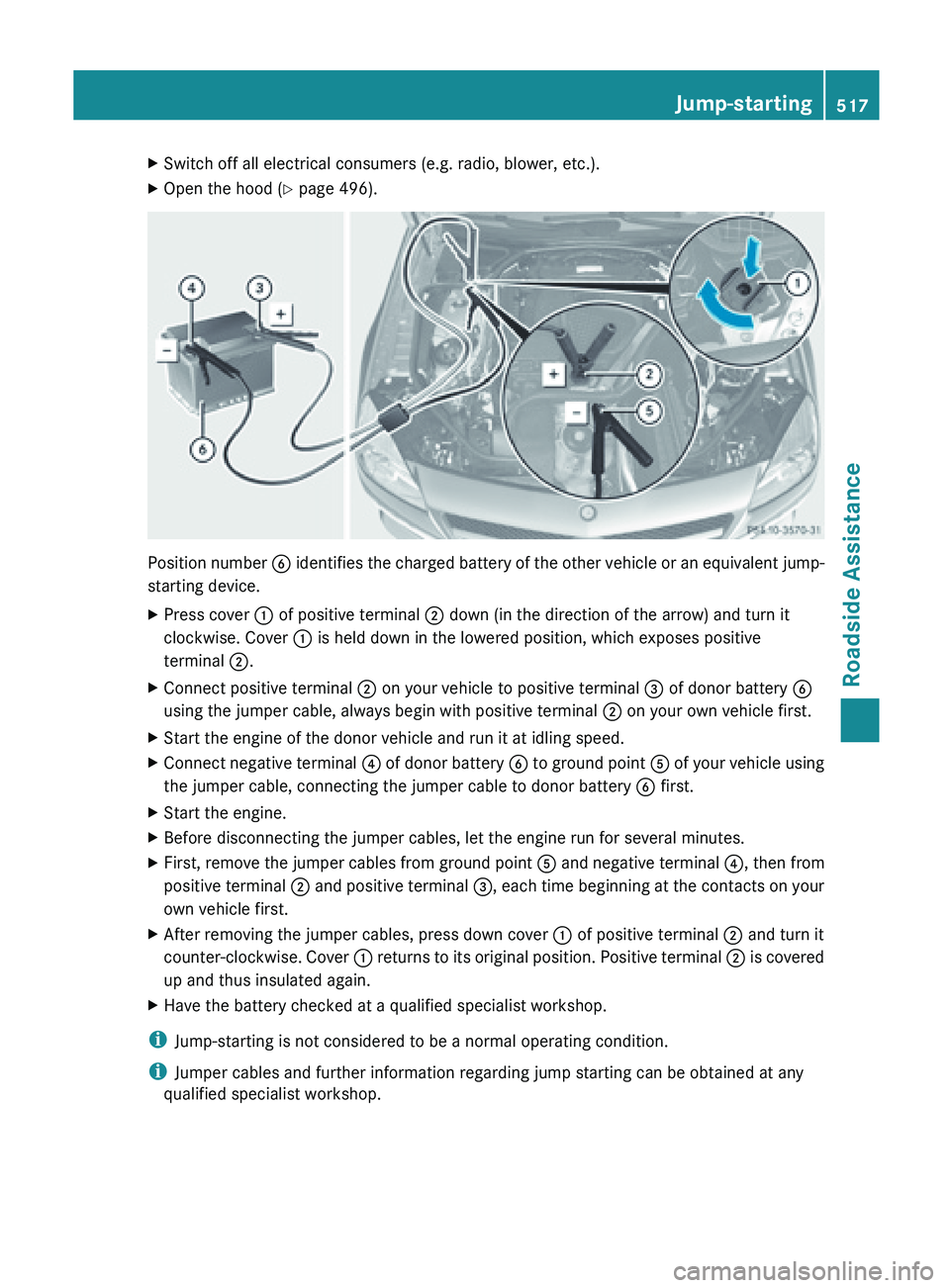

Switch off all electrical consumers (e.g. radio, blower, etc.).

X Open the hood (Y page 496). Position number

B identifies the charged battery of the other vehicle or an equivalent jump-

starting device.

X Press cover : of positive terminal ; down (in the direction of the arrow) and turn it

clockwise. Cover : is held down in the lowered position, which exposes positive

terminal ;.

X Connect positive terminal ; on your vehicle to positive terminal = of donor battery B

using the jumper cable, always begin with positive terminal ; on your own vehicle first.

X Start the engine of the donor vehicle and run it at idling speed.

X Connect negative terminal ? of

donor battery B to ground point A of your vehicle using

the jumper cable, connecting the jumper cable to donor battery B first.

X Start the engine.

X Before disconnecting the jumper cables, let the engine run for several minutes.

X First, remove the jumper cables from ground point A and

negative terminal ?, then from

positive terminal ; and positive terminal =, each time beginning at the contacts on your

own vehicle first.

X After removing the jumper cables, press down cover : of positive terminal ; and turn it

counter-clockwise. Cover

:

returns to its original position. Positive terminal ; is covered

up and thus insulated again.

X Have the battery checked at a qualified specialist workshop.

i Jump-starting is not considered to be a normal operating condition.

i Jumper cables and further information regarding jump starting can be obtained at any

qualified specialist workshop. Jump-starting

517

Roadside Assistance Z

Page 521 of 572

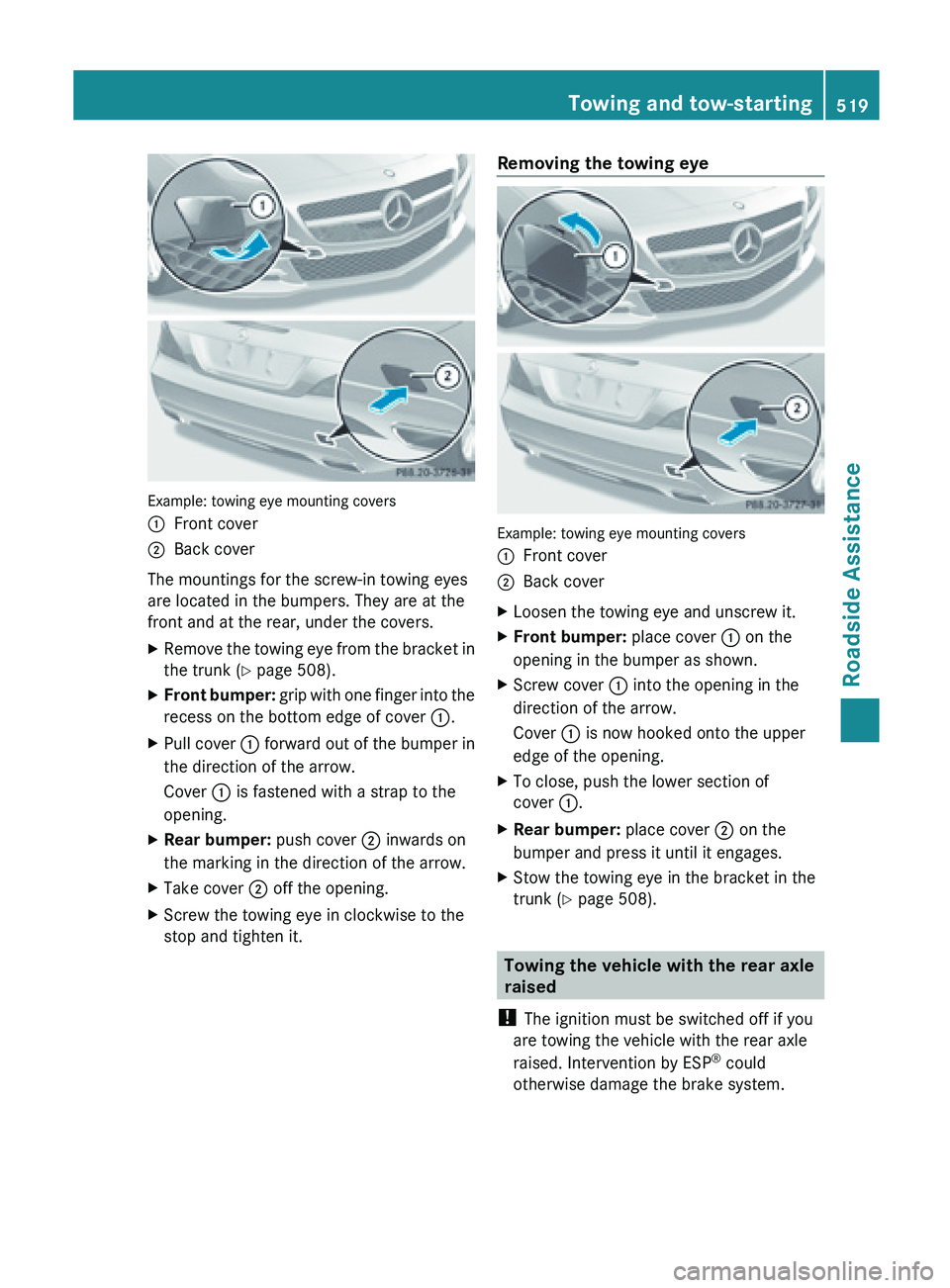

Example: towing eye mounting covers

:

Front cover

; Back cover

The mountings for the screw-in towing eyes

are located in the bumpers. They are at the

front and at the rear, under the covers.

X Remove the towing eye from the bracket in

the trunk (

Y page 508).

X Front bumper: grip

with one finger into the

recess on the bottom edge of cover :.

X Pull cover :

forward

out of the bumper in

the direction of the arrow.

Cover : is fastened with a strap to the

opening.

X Rear bumper: push cover ; inwards on

the marking in the direction of the arrow.

X Take cover ; off the opening.

X Screw the towing eye in clockwise to the

stop and tighten it. Removing the towing eye

Example: towing eye mounting covers

:

Front cover

; Back cover

X Loosen the towing eye and unscrew it.

X Front bumper: place cover : on the

opening in the bumper as shown.

X Screw cover : into the opening in the

direction of the arrow.

Cover : is now hooked onto the upper

edge of the opening.

X To close, push the lower section of

cover :.

X Rear bumper: place cover ; on the

bumper and press it until it engages.

X Stow the towing eye in the bracket in the

trunk (

Y page 508). Towing the vehicle with the rear axle

raised

! The ignition must be switched off if you

are towing the vehicle with the rear axle

raised. Intervention by ESP ®

could

otherwise damage the brake system. Towing and tow-starting

519

Roadside Assistance Z

Page 553 of 572

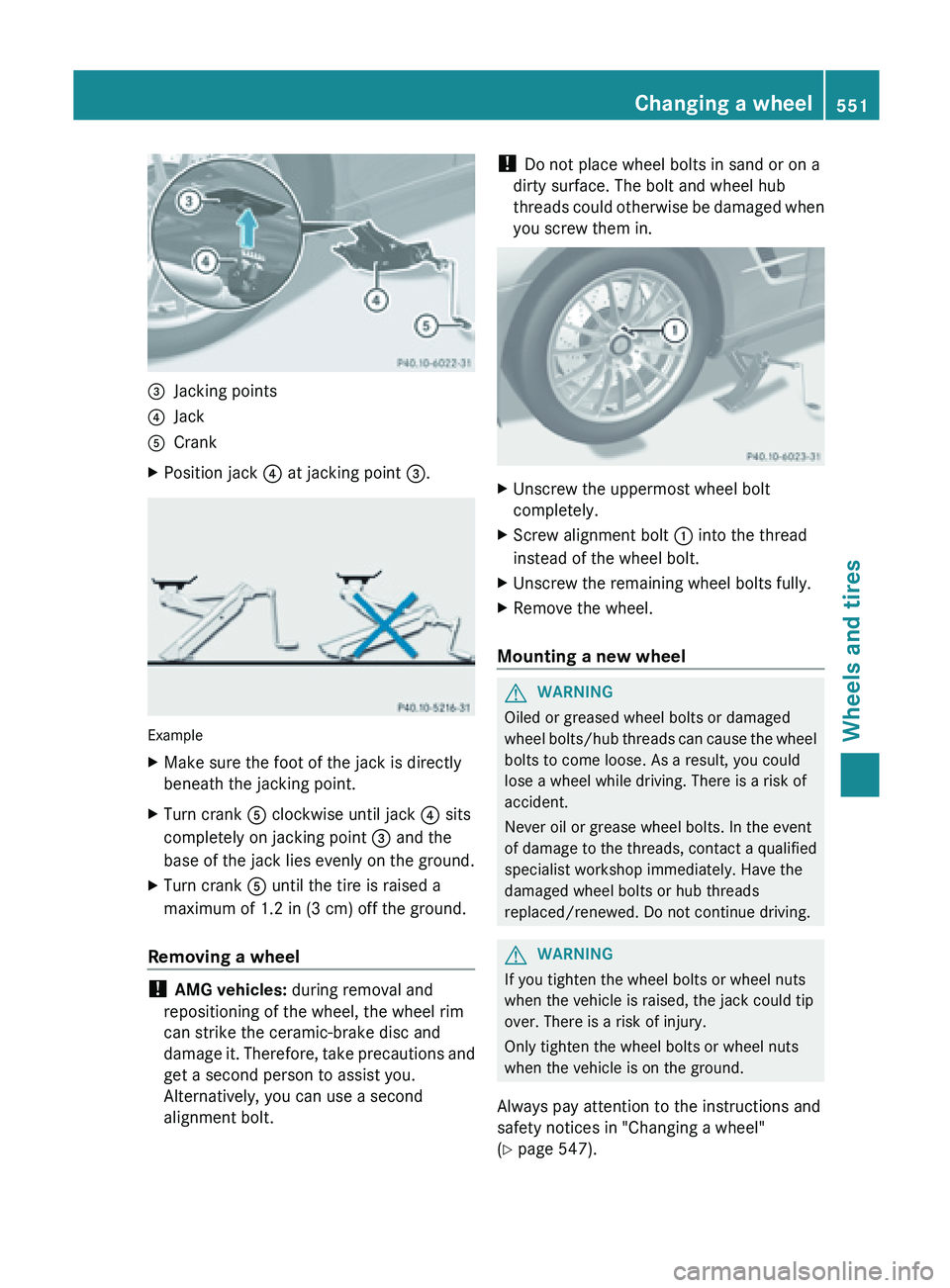

=

Jacking points

? Jack

A Crank

X Position jack ? at jacking point =.Example

X

Make sure the foot of the jack is directly

beneath the jacking point.

X Turn crank A clockwise until jack ? sits

completely on jacking point = and the

base of the jack lies evenly on the ground.

X Turn crank A until the tire is raised a

maximum of 1.2 in (3 cm ) off the ground.

Removing a wheel !

AMG vehicles: during removal and

repositioning of the wheel, the wheel rim

can strike the ceramic-brake disc and

damage it.

Therefore, take precautions and

get a second person to assist you.

Alternatively, you can use a second

alignment bolt. !

Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could

otherwise be damaged when

you screw them in. X

Unscrew the uppermost wheel bolt

completely.

X Screw alignment bolt : into the thread

instead of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub

threads can cause the wheel

bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notices in "Changing a wheel"

(Y page 547). Changing a wheel

551

Wheels and tires Z

Page 554 of 572

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety

reasons, Mercedes-Benz recommends that

you only use wheel bolts which have been

approved

for

Mercedes-Benz vehicles and the

respective wheel.

! AMG vehicles: during removal and

repositioning of the wheel, the wheel rim

can strike the ceramic-brake disc and

damage it. Therefore, take precautions and

get a second person to assist you.

Alternatively, you can use a second

alignment bolt.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

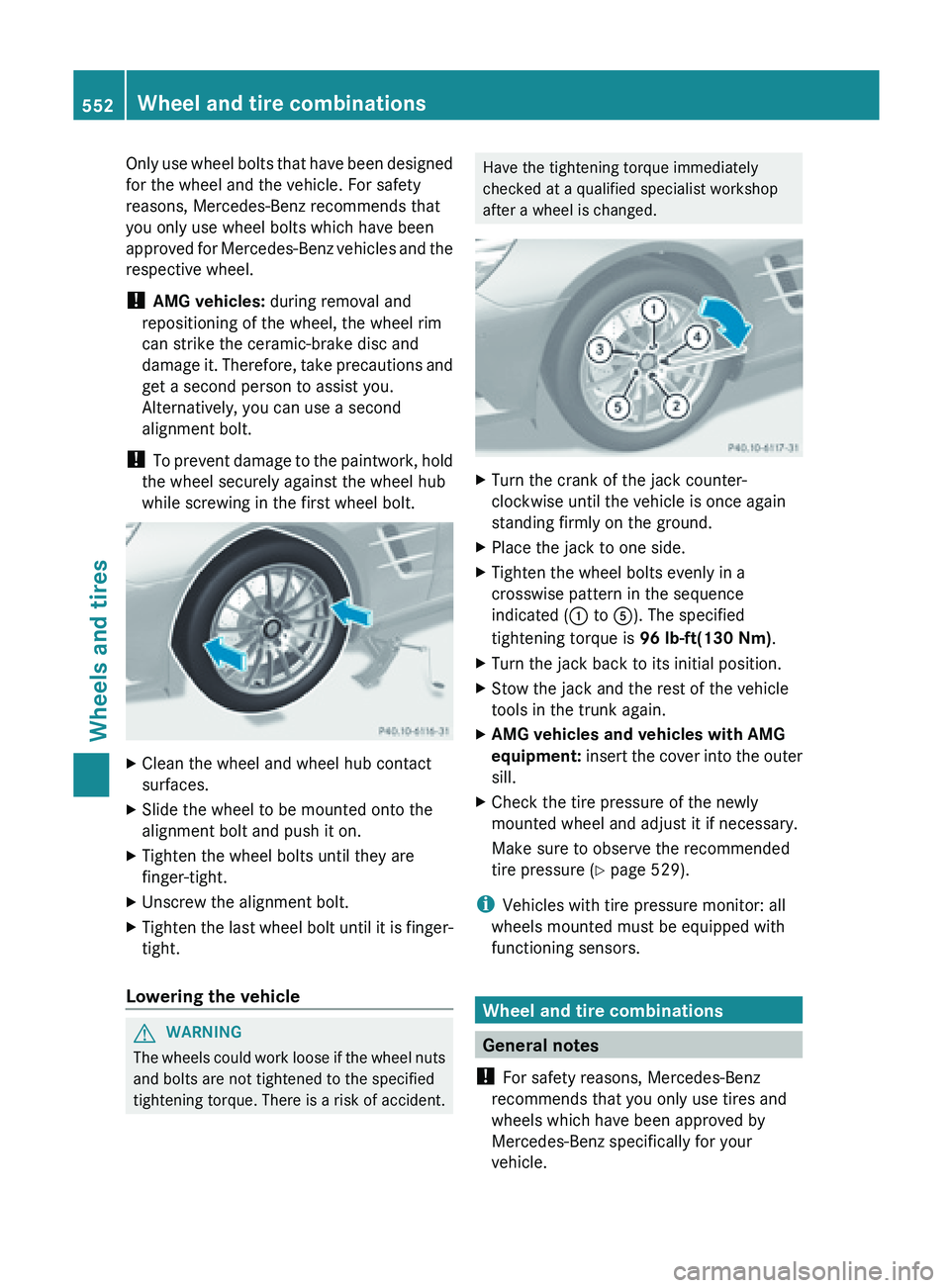

while screwing in the first wheel bolt. X

Clean the wheel and wheel hub contact

surfaces.

X Slide the wheel to be mounted onto the

alignment bolt and push it on.

X Tighten the wheel bolts until they are

finger-tight.

X Unscrew the alignment bolt.

X Tighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident. Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

X

Turn the crank of the jack counter-

clockwise until the vehicle is once again

standing firmly on the ground.

X Place the jack to one side.

X Tighten the wheel bolts evenly in a

crosswise pattern in the sequence

indicated ( : to A). The specified

tightening torque is 96 lb-ft(130 Nm).

X Turn the jack back to its initial position.

X Stow the jack and the rest of the vehicle

tools in the trunk again.

X AMG vehicles and vehicles with AMG

equipment: insert

the cover into the outer

sill.

X Check the tire pressure of the newly

mounted wheel and adjust it if necessary.

Make sure to observe the recommended

tire pressure ( Y page 529).

i Vehicles with tire pressure monitor: all

wheels mounted must be equipped with

functioning sensors. Wheel and tire combinations

General notes

! For safety reasons, Mercedes-Benz

recommends that you only use tires and

wheels which have been approved by

Mercedes-Benz specifically for your

vehicle. 552

Wheel and tire combinationsWheels and tires