inflation pressure MERCEDES-BENZ SL ROADSTER 2012 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SL ROADSTER, Model: MERCEDES-BENZ SL ROADSTER 2012Pages: 637, PDF Size: 20.68 MB

Page 583 of 637

G

WARNING

In the following situations, the tyre sealant is

unable to provide sufficient breakdown assis- tance, as it is unable to seal the tyre properly:

R there are cuts or punctures in the tyre

larger than those mentioned above.

R the wheel rim is damaged.

R you have driven at very low tyre pressures

or on a flat tyre.

There is a risk of an accident.

Do not drive any further. Contact a qualified

specialist workshop. G

WARNING

The tyre sealant is harmful and causes irrita-

tion. It must not come into contact with your

skin, eyes or clothing or be swallowed. Do not inhale TIREFIT fumes. Keep tyre sealant away

from children. There is a risk of injury.

If you come into contact with the tyre sealant,

observe the following:

R Rinse off the tyre sealant from your skin

immediately with water.

R If the tyre sealant comes into contact with

your eyes, immediately rinse them thor-

oughly with clean water.

R If tyre sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water. Do not induce vomiting,

and seek medical attention immediately.

R Immediately change out of clothing which

has come into contact with tyre sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

! Do not operate the tyre inflation com-

pressor for longer than eight minutes at a

time without a break. It may otherwise

overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

Comply with the manufacturer’s safety

instructions on the sticker on the tyre infla-

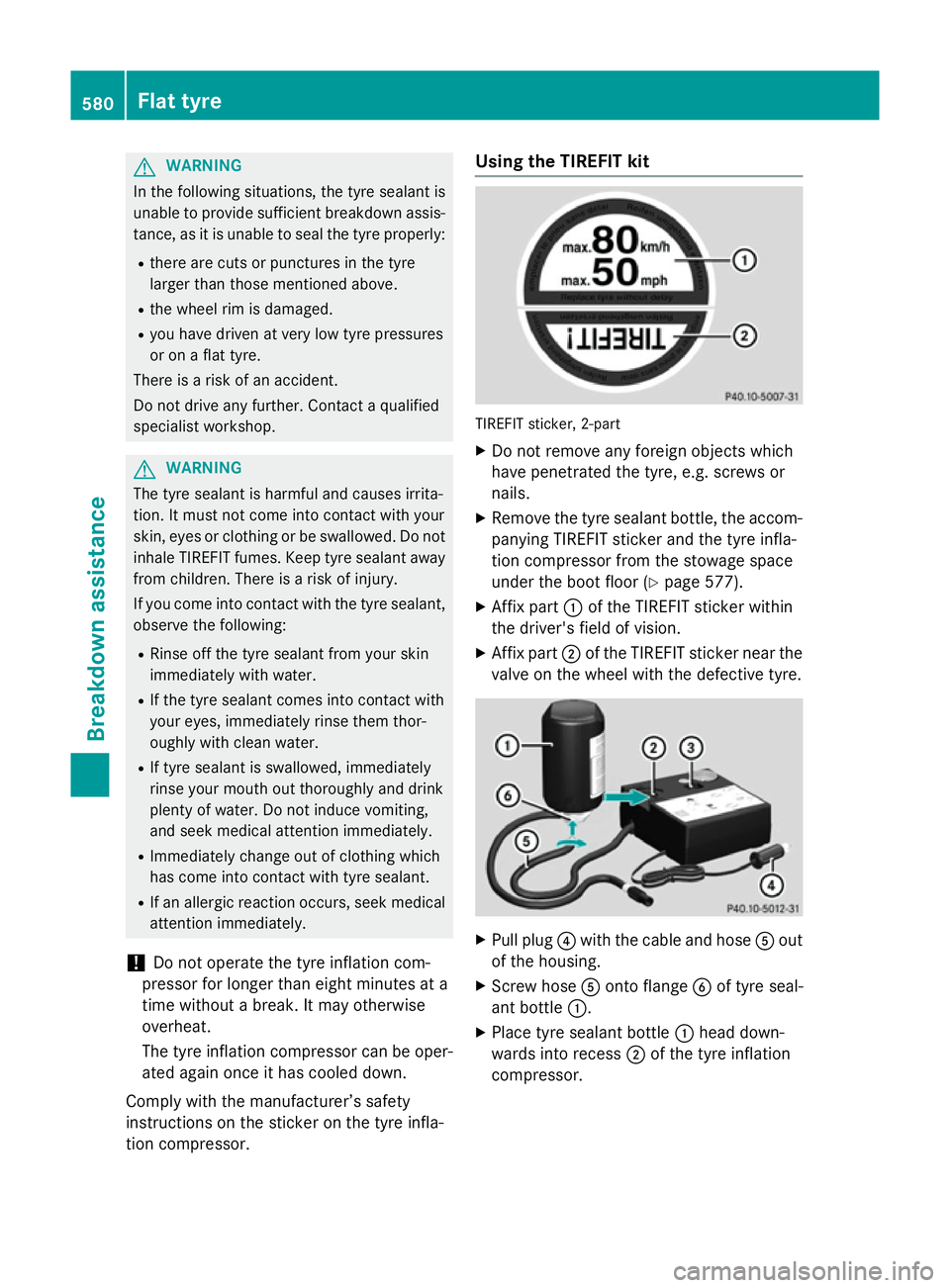

tion compressor. Using the TIREFIT kit

TIREFIT sticker, 2-part

X Do not remove any foreign objects which

have penetrated the tyre, e.g. screws or

nails.

X Remove the tyre sealant bottle, the accom-

panying TIREFIT sticker and the tyre infla-

tion compressor from the stowage space

under the boot floor (Y page 577).

X Affix part :of the TIREFIT sticker within

the driver's field of vision.

X Affix part ;of the TIREFIT sticker near the

valve on the wheel with the defective tyre. X

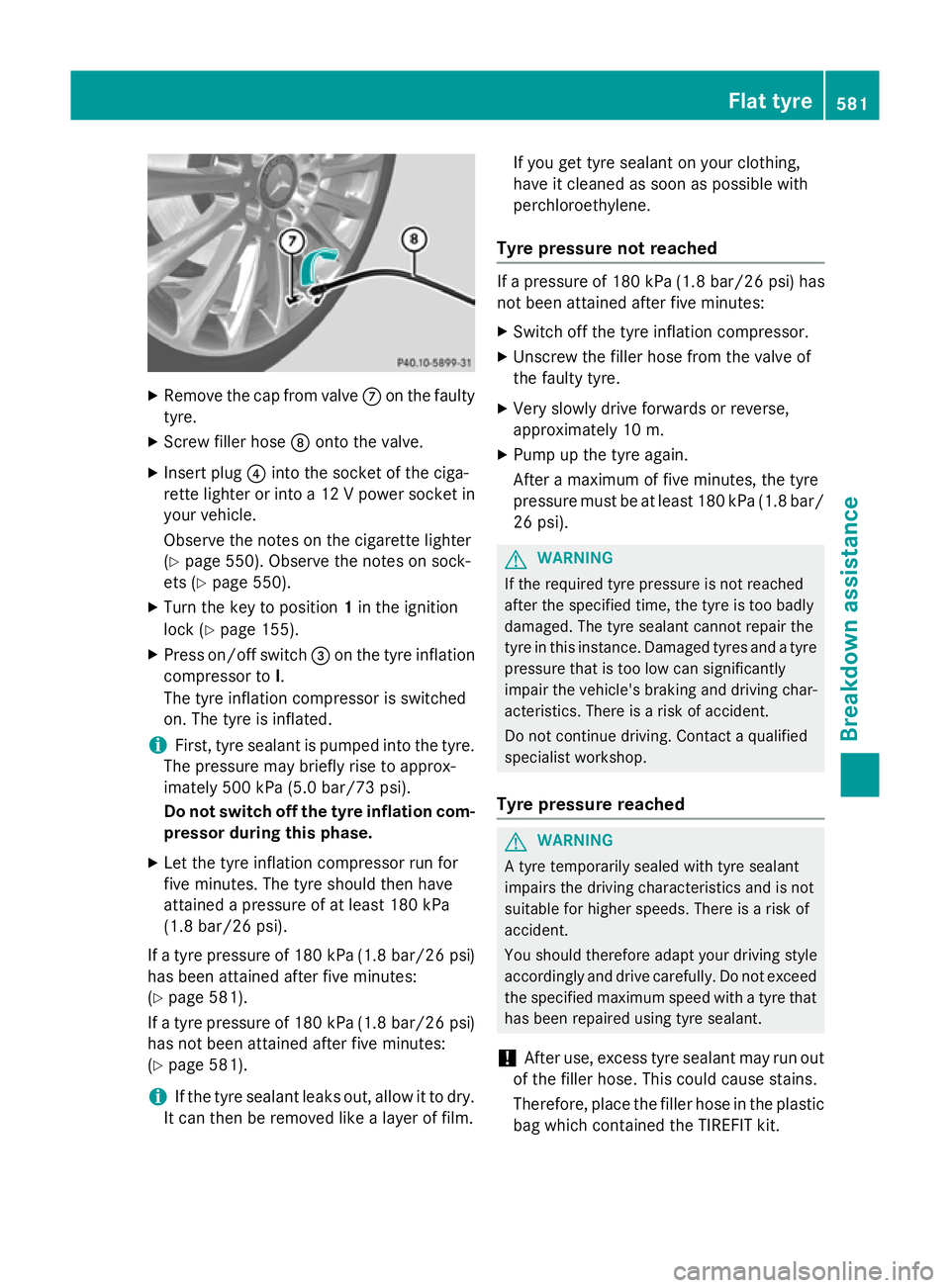

Pull plug ?with the cable and hose Aout

of the housing.

X Screw hose Aonto flange Bof tyre seal-

ant bottle :.

X Place tyre sealant bottle :head down-

wards into recess ;of the tyre inflation

compressor. 580

Flat tyreBreakdown assistance

Page 584 of 637

X

Remove the cap from valve Con the faulty

tyre.

X Screw filler hose Donto the valve.

X Insert plug ?into the socket of the ciga-

rette lighter or into a 12 V power socket in your vehicle.

Observe the notes on the cigarette lighter

(Y page 550). Observe the notes on sock-

ets (Y page 550).

X Turn the key to position 1in the ignition

lock (Y page 155).

X Press on/off switch =on the tyre inflation

compressor to I.

The tyre inflation compressor is switched

on. The tyre is inflated.

i First, tyre sealant is pumped into the tyre.

The pressure may briefly rise to approx-

imately 500 kPa (5.0 bar/73 psi).

Do not switch off the tyre inflation com-

pressor during this phase.

X Let the tyre inflation compressor run for

five minutes. The tyre should then have

attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

If a tyre pressure of 180 kP a(1.8 bar/26 psi)

has been attained after five minutes:

(Y page 581).

If a tyre pressure of 180 kPa (1.8 bar/26 psi)

has not been attained after five minutes:

(Y page 581).

i If the tyre sealant leaks out, allow it to dry.

It can then be removed like a layer of film. If you get tyre sealant on your clothing,

have it cleaned as soon as possible with

perchloroethylene.

Tyre pressure not reached If a pressure of 180 kPa (1.8 bar/26 psi) has

not been attained after five minutes:

X Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

X Very slowly drive forwards or reverse,

approximately 10 m.

X Pump up the tyre again.

After a maximum of five minutes, the tyre

pressure must be at least 180 kPa (1.8 bar/

26 psi). G

WARNING

If the required tyre pressure is not reached

after the specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this instance. Damaged tyres and a tyre pressure that is too low can significantly

impair the vehicle's braking and driving char-

acteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

Tyre pressure reached G

WARNING

A tyre temporarily sealed with tyre sealant

impairs the driving characteristics and is not

suitable for higher speeds. There is a risk of

accident.

You should therefore adapt your driving style

accordingly and drive carefully. Do not exceed the specified maximum speed with a tyre that

has been repaired using tyre sealant.

! After use, excess tyre sealant may run out

of the filler hose. This could cause stains.

Therefore, place the filler hose in the plastic

bag which contained the TIREFIT kit. Flat tyre

581Breakdown assistance Z

Page 585 of 637

H

Environmental note

Have the used tyre sealant bottle disposed of professionally, e.g. at a qualified specialist

workshop.

If a tyre pressure of 180 kPa (1.8 bar/26 psi) has been achieved after ten minutes:

X Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

X Stow the tyre sealant bottle, the tyre infla-

tion compressor and the warning triangle.

X Pull away immediately .

The maximum speed for a tyre sealed with

tyre sealant is 80 km/h. The upper part of

the TIREFIT sticker must be affixed to the

instrument cluster where it will be easily

seen by the driver.

X Stop after driving for approximately ten

minutes and check the tyre pressure with

the tyre inflation compressor.

The tyre pressure must now be at least

130 kPa (1.3 bar/19 psi). G

WARNING

If the required tyre pressure is not reached

after driving for a short period, the tyre is too badly damaged. The tyre sealant cannot

repair the tyre in this instance. Damaged tyres and a tyre pressure that is too low can signif-

icantly impair the vehicle's braking and driv-

ing characteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i In your vehicle, you will find a sticker with

the Mercedes-Benz Service24h telephone

number, e.g. on the B-pillar on the driver's

side.

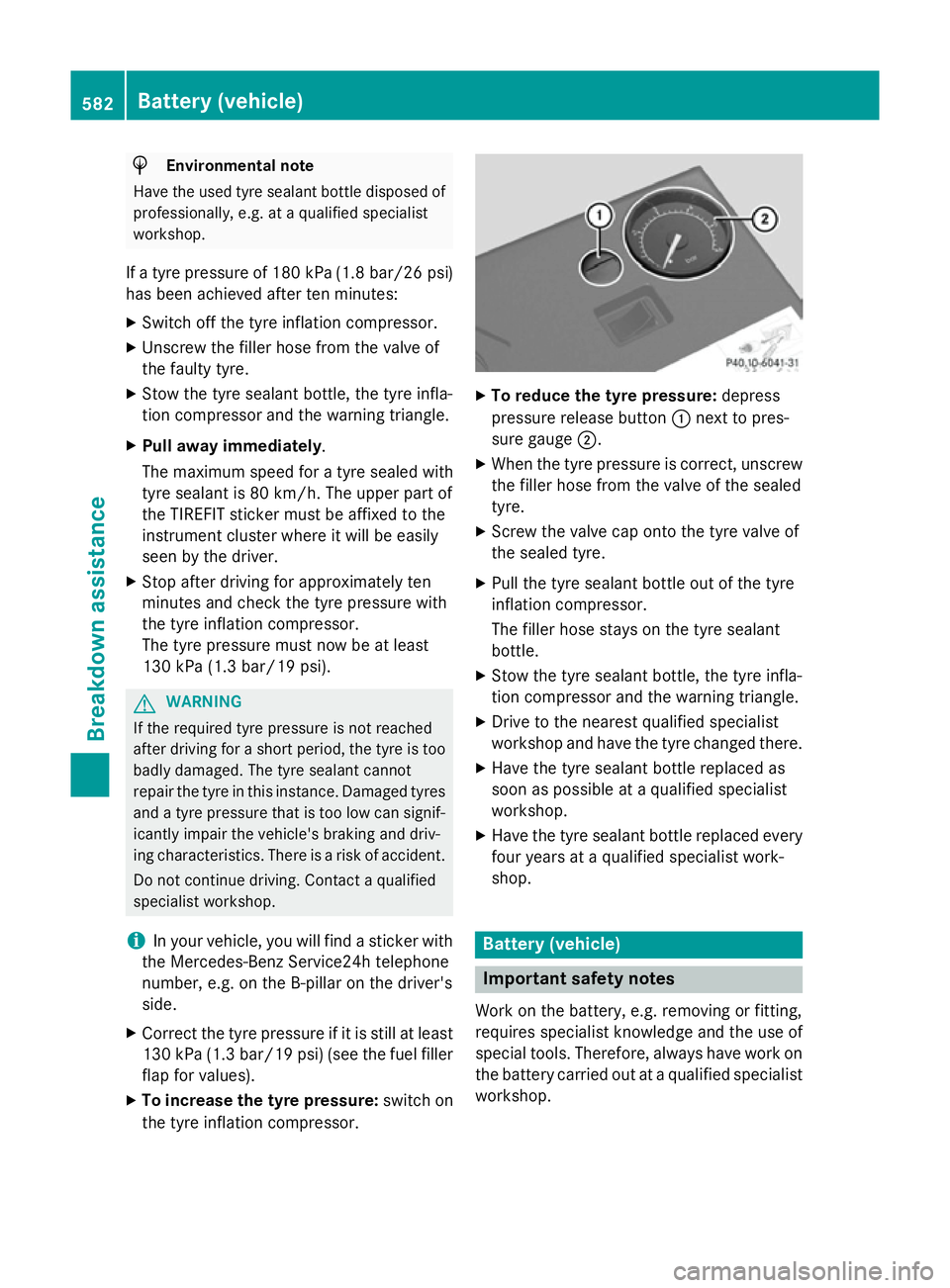

X Correct the tyre pressure if it is still at least

130 kPa (1.3 bar/19 psi) (see the fuel filler

flap for values).

X To increase the tyre pressure: switch on

the tyre inflation compressor. X

To reduce the tyre pressure: depress

pressure release button :next to pres-

sure gauge ;.

X When the tyre pressure is correct, unscrew

the filler hose from the valve of the sealed

tyre.

X Screw the valve cap onto the tyre valve of

the sealed tyre.

X Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filler hose stays on the tyre sealant

bottle.

X Stow the tyre sealant bottle, the tyre infla-

tion compressor and the warning triangle.

X Drive to the nearest qualified specialist

workshop and have the tyre changed there.

X Have the tyre sealant bottle replaced as

soon as possible at a qualified specialist

workshop.

X Have the tyre sealant bottle replaced every

four years at a qualified specialist work-

shop. Battery (vehicle)

Important safety notes

Work on the battery, e.g. removing or fitting,

requires specialist knowledge and the use of

special tools. Therefore, always have work on the battery carried out at a qualified specialist

workshop. 582

Battery (vehicle)Breakdown assistance

Page 600 of 637

damage. Hidden tyre damage could also be

causing the unusual handling characteristics. If you find no signs of damage, have the tyres

and wheels checked at a qualified specialist

workshop.

When parking your vehicle, make sure that

the tyres do not get deformed by the kerb or

other obstacles. If it is necessary to drive over

kerbs, speed humps or similar elevations, try

to do so slowly and at an obtuse angle. Oth-

erwise, the tyres, particularly the sidewalls,

may be damaged. Regular checking of wheels and tyres

G

WARNING

Damaged tyres can cause tyre inflation pres-

sure loss. As a result, you could lose control of your vehicle. There is a risk of accident.

Check the tyres regularly for signs of damage and replace any damaged tyres immediately.

Regularly check the wheels and tyres of your

vehicle for damage at least once a month, as well as after driving off-road or on rough

roads. Damaged wheels can cause a loss of

tyre pressure. Pay particular attention to

damage such as:

R cuts in the tyres

R punctures

R tears in the tyres

R bulges on tyres

R deformation or severe corrosion on wheels

Regularly check the tyre tread depth and the condition of the tread across the whole width

of the tyre (Y page 597). If necessary, turn

the front wheels to full lock in order to inspect

the inner side of the tyre surface.

All wheels must have a valve cap to protect

the valve against dirt and moisture. Do not fit

anything onto the valve other than the stand-

ard valve cap or other valve caps approved for

your vehicle by Mercedes-Benz. Do not fit any other valve caps or systems, e.g. tyre pres-

sure monitoring systems. Regularly check the pressure of all the tyres,

particularly prior to long trips. Adjust the tyre

pressure as necessary (Y page 600).

Observe the notes on the emergency spare

wheel (Y page 614).

The service life of tyres depends on various

factors, including the following:

R driving style

R tyre pressure

R mileage Important safety notes on the tyre

tread

G

WARNING

Insufficient tyre tread will reduce tyre trac-

tion. The tyre is no longer able to dissipate

water. This means that on wet road surfaces, the risk of aquaplaning increases, in particularwhere speed is not adapted to suit the driving

conditions. There is a risk of accident.

If the tyre pressure is too high or too low, tyres may exhibit different levels of wear at differ-

ent locations on the tyre tread. Thus, you

should regularly check the tread depth and

the condition of the tread across the entire

width of all tyres.

Minimum tyre tread depth for:

R summer tyres: 3 mm

R M+S tyres: 4 mm

For safety reasons, replace the tyres before

the legally prescribed limit for the minimum

tyre tread depth is reached. Selecting, fitting and replacing tyres

G

WARNING

Exceeding the stated tyre load-bearing capa-

city and the approved maximum speed could

lead to tyre damage or the tyre bursting. There is a risk of accident.

Therefore, only use tyre types and sizes

approved for your vehicle model. Observe the Operation

597Wheels and tyres

Z

Page 619 of 637

X

Turn the key to position 1in the ignition

lock (Y page 155).

X Press on/off switch Aon the tyre inflation

compressor to I.

The tyre inflation compressor is switched

on. The tyre is inflated. The tyre pressure is shown on pressure gauge =.

X Pump the tyre to the specified tyre pres-

sure.

The specified tyre pressure is printed on

the yellow label of the emergency spare

wheel.

X When the specified tyre pressure has been

reached, press on/off switch Aon the

electric air pump to 0.

The tyre inflation compressor is switched

off.

X Turn the key to position 0in the ignition

lock.

X If the tyre pressure is higher than the speci-

fied pressure, press pressure release but-

ton ;until the correct tyre pressure has

been reached.

X Unscrew union nut :on the air hose from

the valve.

X Screw the valve cap onto the collapsible

emergency spare wheel valve again.

X Stow plug ?and the air hose in the lower

section of the compressor housing.

X Stow the tyre inflation compressor in the

vehicle. 616

Emergency spare wheelWheels and tyres