MERCEDES-BENZ SLK 230 KOMPRESSOR 2002 R170 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: SLK 230 KOMPRESSOR, Model: MERCEDES-BENZ SLK 230 KOMPRESSOR 2002 R170Pages: 290, PDF Size: 20.03 MB

Page 211 of 290

208 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

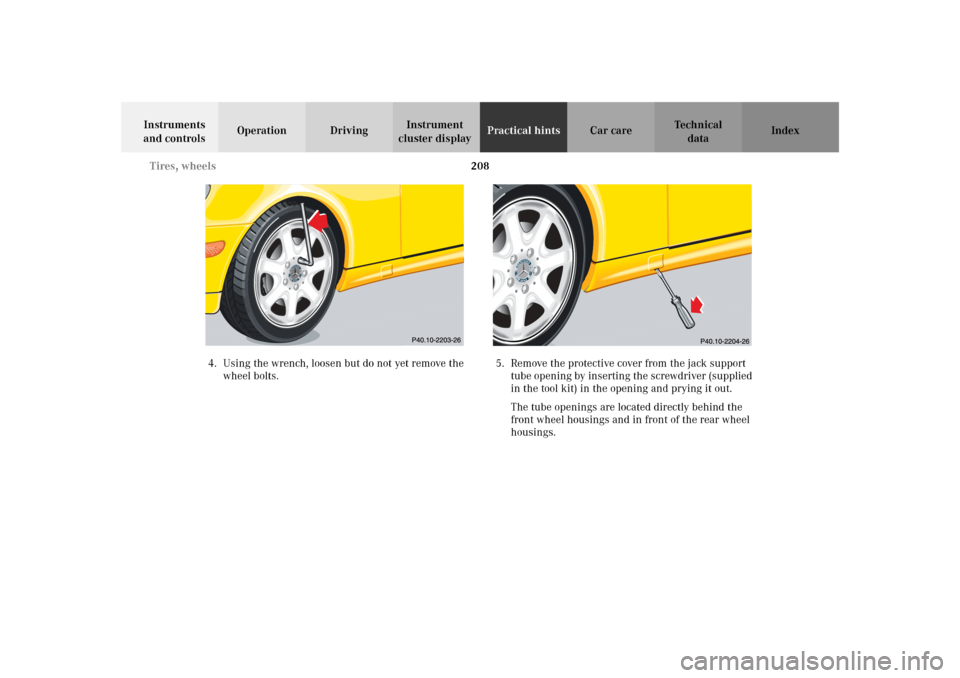

4. Using the wrench, loosen but do not yet remove the

wheel bolts.5. Remove the protective cover from the jack support

tube opening by inserting the screwdriver (supplied

in the tool kit) in the opening and prying it out.

The tube openings are located directly behind the

front wheel housings and in front of the rear wheel

housings.

Page 212 of 290

209 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

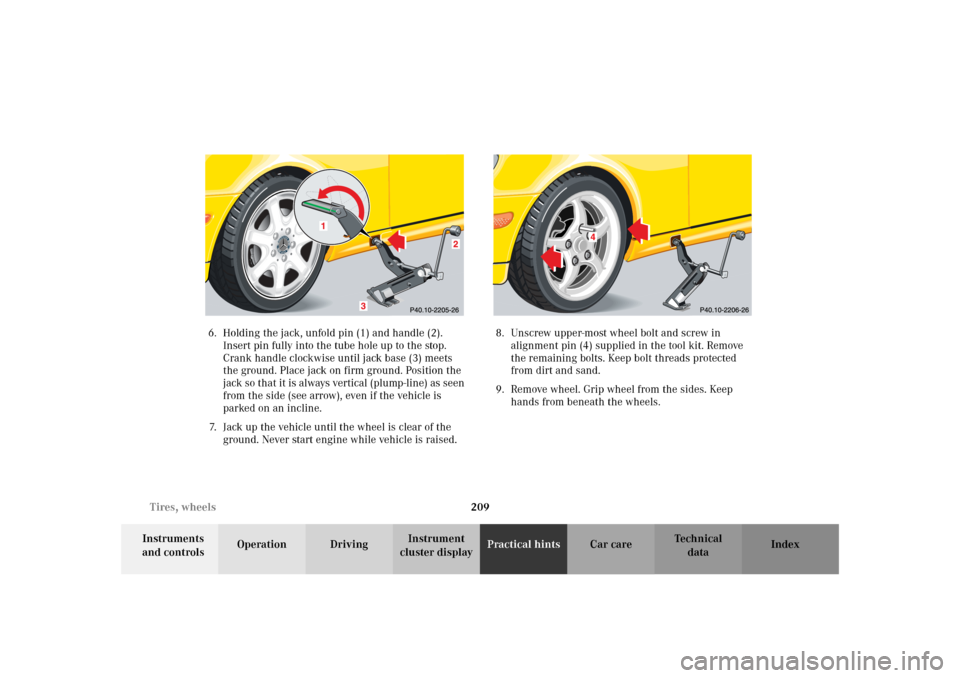

cluster displayPractical hintsCar care Index 6. Holding the jack, unfold pin (1) and handle (2).

Insert pin fully into the tube hole up to the stop.

Crank handle clockwise until jack base (3) meets

the ground. Place jack on firm ground. Position the

jack so that it is always vertical (plump-line) as seen

from the side (see arrow), even if the vehicle is

parked on an incline.

7. Jack up the vehicle until the wheel is clear of the

ground. Never start engine while vehicle is raised.8. Unscrew upper-most wheel bolt and screw in

alignment pin (4) supplied in the tool kit. Remove

the remaining bolts. Keep bolt threads protected

from dirt and sand.

9. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.

Page 213 of 290

210 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

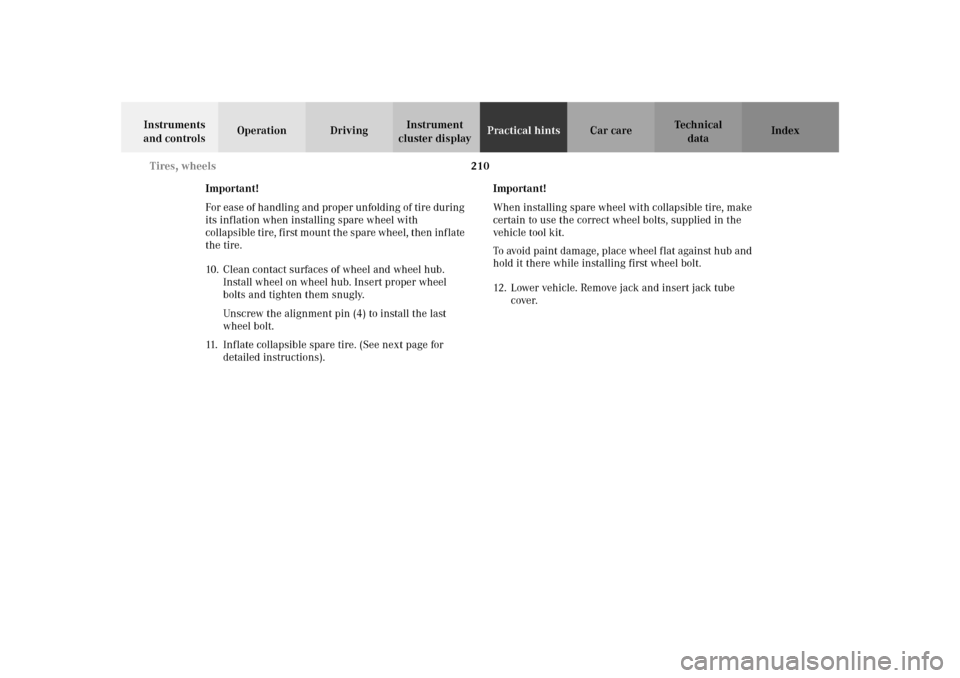

Important!

For ease of handling and proper unfolding of tire during

its inflation when installing spare wheel with

collapsible tire, first mount the spare wheel, then inflate

the tire.

10. Clean contact surfaces of wheel and wheel hub.

Install wheel on wheel hub. Insert proper wheel

bolts and tighten them snugly.

Unscrew the alignment pin (4) to install the last

wheel bolt.

11. Inflate collapsible spare tire. (See next page for

detailed instructions).Important!

When installing spare wheel with collapsible tire, make

certain to use the correct wheel bolts, supplied in the

vehicle tool kit.

To avoid paint damage, place wheel flat against hub and

hold it there while installing first wheel bolt.

12. Lower vehicle. Remove jack and insert jack tube

cover.

Page 214 of 290

211 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

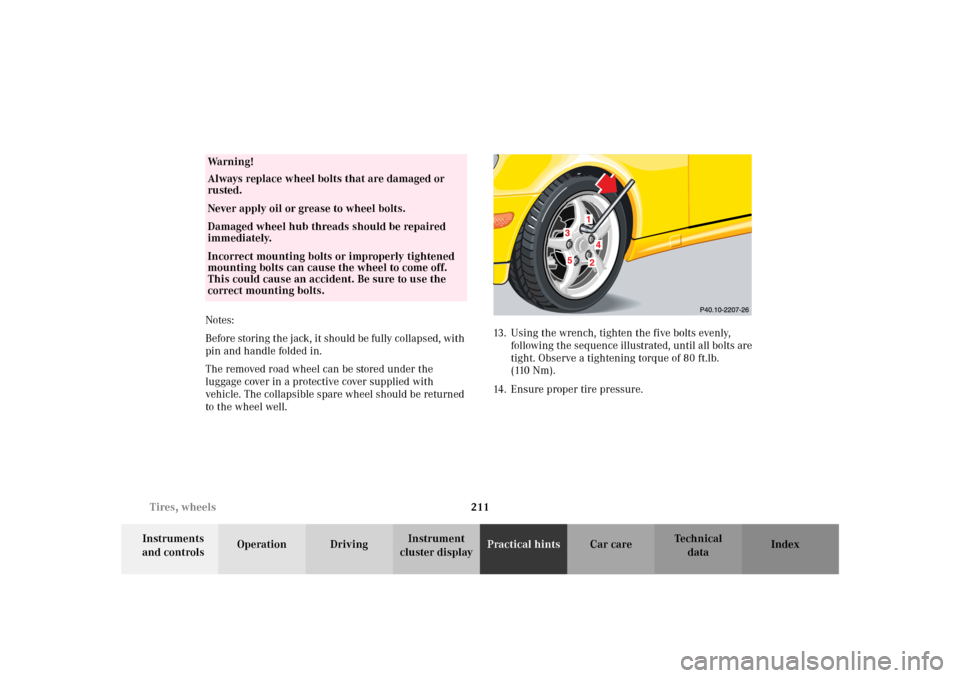

cluster displayPractical hintsCar care Index Notes:

Before storing the jack, it should be fully collapsed, with

pin and handle folded in.

The removed road wheel can be stored under the

luggage cover in a protective cover supplied with

vehicle. The collapsible spare wheel should be returned

to the wheel well.13. Using the wrench, tighten the five bolts evenly,

following the sequence illustrated, until all bolts are

tight. Observe a tightening torque of 80 ft.lb.

(110 Nm).

14. Ensure proper tire pressure.

Wa r n i n g !

Always replace wheel bolts that are damaged or

rusted.Never apply oil or grease to wheel bolts.Damaged wheel hub threads should be repaired

immediately.Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

This could cause an accident. Be sure to use the

correct mounting bolts.

Page 215 of 290

212 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

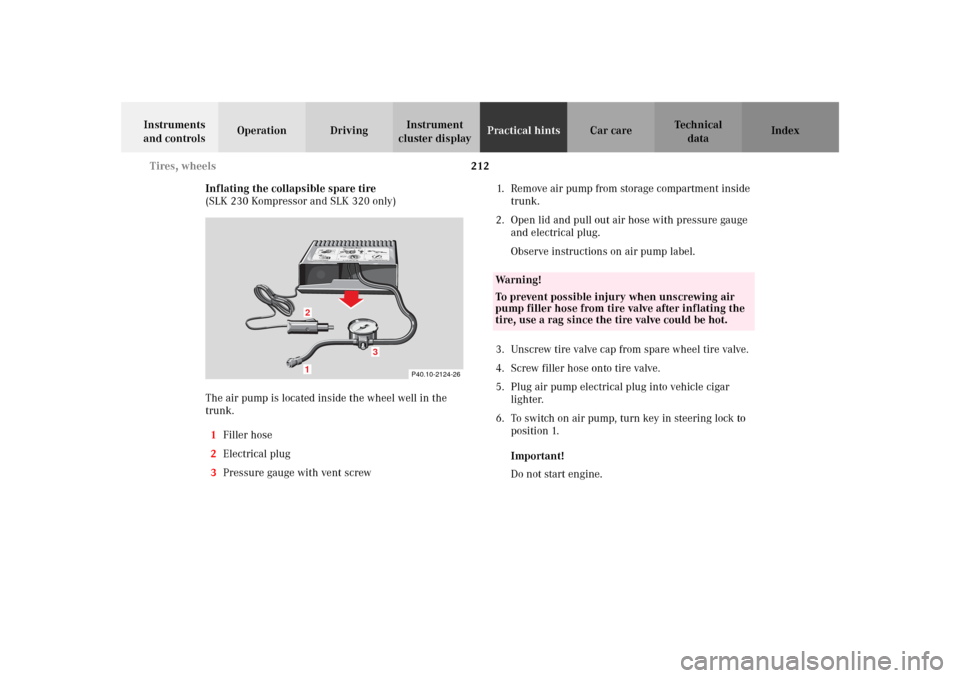

Inflating the collapsible spare tire

(SLK 230 Kompressor and SLK 320 only)

The air pump is located inside the wheel well in the

trunk.

1Filler hose

2Electrical plug

3Pressure gauge with vent screw1. Remove air pump from storage compartment inside

trunk.

2. Open lid and pull out air hose with pressure gauge

and electrical plug.

Observe instructions on air pump label.

3. Unscrew tire valve cap from spare wheel tire valve.

4. Screw filler hose onto tire valve.

5. Plug air pump electrical plug into vehicle cigar

lighter.

6. To switch on air pump, turn key in steering lock to

position 1.

Important!

Do not start engine.

P40.10-2124-26

1

0

45 6max. 6 min

A 170 584 01 38 AIR COMPRESSOR 23

Mercedes-Benz

2

3

2 1

1

2,5 bar

36 psi1

0 23

4

5

620PSI

BAR40

60

80

LUFTPRESSER12

12

3

Wa r n i n g !

To prevent possible injury when unscrewing air

pump filler hose from tire valve after inflating the

tire, use a rag since the tire valve could be hot.

Page 216 of 290

213 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index 7. Operate air pump (approximately 5 minutes) until

pressure gauge displays 36 psi (2.5 bar).

8. To switch off air pump, turn key in steering lock to

position 0.

9. Unscrew filler hose from tire. Reinstall tire valve

cap.

Note:

Excessive tire air pressure should be released using the

vent screw.Storing spare wheel in wheel well

Deflate spare tire:

1. Unscrew valve stem removal tool, which is a part of

the valve cap, from tire valve.

2. Using the valve stem removal tool, open tire valve

slightly by turning the tire valve insert

counterclockwise to release air pressure.

3. When the tire air pressure has been released,

remove tire valve insert (protect it from dirt and

sand) using the previously removed tire valve cap.

4. Once all air is out of the tire, and the tire has

collapsed to its original shape, reinstall the tire

valve insert and valve cap.

Place spare wheel in wheel well and secure it with air

pump holder. Turn pump holder clockwise to its stop.

Page 217 of 290

214 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

TIREFIT

(SLK 32 AMG only)

Small punctures, particularly those in the tread can be

sealed with TIREFIT.

Foreign objects (e.g. screws or nails) should not be

removed from the tire.

TIREFIT can be used in ambient temperatures down to

approx. - 4°F (- 20°C).

Wa r n i n g !

Cuts or punctures larger than approx. 0.16 in

(4 mm), tire damage caused by driving with

extremely low tire pressure or on a flat tire, or a

damaged wheel can pose a hazard while driving.

TIREFIT should not be used in such circumstances.Do not drive the vehicle under such circumstances.Contact your nearest Mercedes-Benz Center for

assistance.Take care not to allow the contents of TIREFIT to

come in contact with hair, eyes or clothing.

TIREFIT is harmful if inhaled, swallowed or

absorbed through the skin - causes skin, eye and

respiratory irritation.

Any contact with eyes or skin should be flushed

immediately with plenty of water.If clothing comes in contact with TIREFIT, change

clothing as soon as possible.In case of allergic reaction or rash, consult a

physician immediately.Keep TIREFIT out of reach of children.

If swallowed, rinse mouth immediately with plenty

of water and drink plenty of water.Do not induce vomiting!Consult a physician immediately.Keep away from open flame or heat source.

Page 218 of 290

215 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

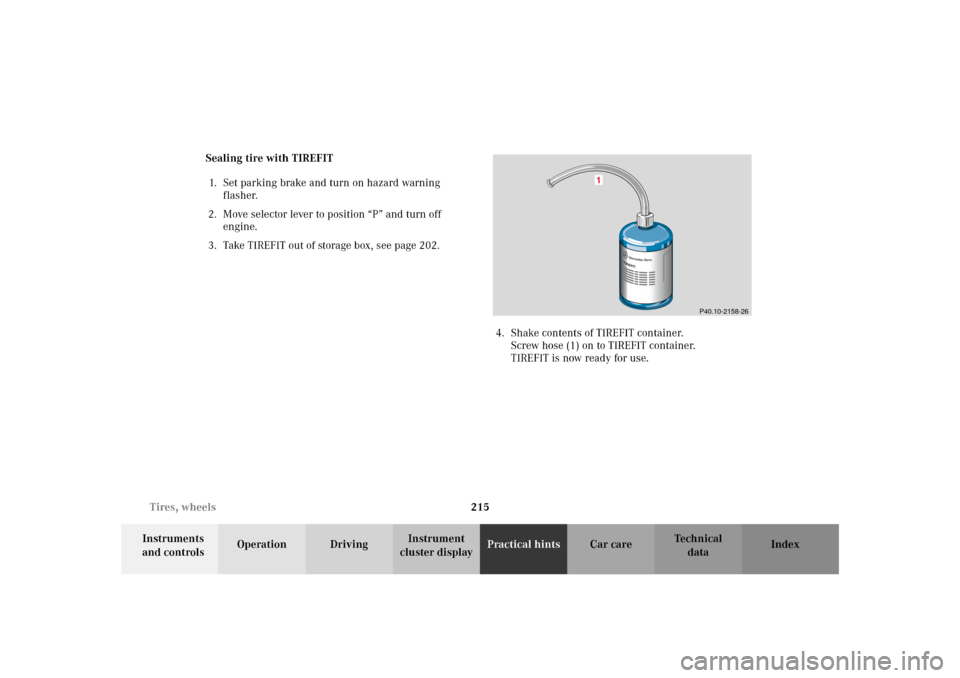

cluster displayPractical hintsCar care Index Sealing tire with TIREFIT

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Take TIREFIT out of storage box, see page 202.

4. Shake contents of TIREFIT container.

Screw hose (1) on to TIREFIT container.

TIREFIT is now ready for use.

1

P40.10-2158-26

Page 219 of 290

216 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

5. Unscrew valve tire cap. Remove tire valve (2) using

valve stem removal tool (3). Do not place tire valve in

sand or dirt.6. Remove plug (4) from end of hose (1) and push hose

(1) onto valve stem.

7. Hold container upside down (hose down) and

squeeze entire contents of container into tire.

8. Pull hose (1) off and screw tire valve (2) using valve

stem tool (3) into the valve stem.

Note:

A spare tire valve is stored with the valve stem tool.

9. Install plug (4) onto end of hose (1).

Page 220 of 290

217 Tires, wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

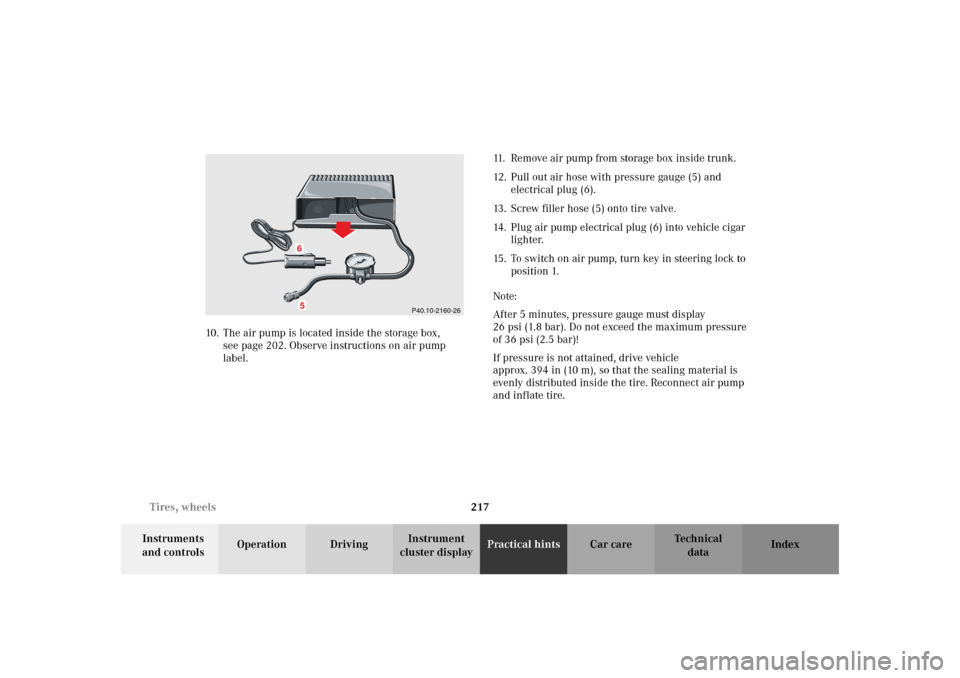

cluster displayPractical hintsCar care Index 10. The air pump is located inside the storage box,

see page 202. Observe instructions on air pump

label.11. Remove air pump from storage box inside trunk.

12. Pull out air hose with pressure gauge (5) and

electrical plug (6).

13. Screw filler hose (5) onto tire valve.

14. Plug air pump electrical plug (6) into vehicle cigar

lighter.

15. To switch on air pump, turn key in steering lock to

position 1.

Note:

After 5 minutes, pressure gauge must display

26 psi (1.8 bar). Do not exceed the maximum pressure

of 36 psi (2.5 bar)!

If pressure is not attained, drive vehicle

approx. 394 in (10 m), so that the sealing material is

evenly distributed inside the tire. Reconnect air pump

and inflate tire.

P40.10-2160-26

65