bolt pattern MERCEDES-BENZ SLK ROADSTER 2008 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2008, Model line: SLK ROADSTER, Model: MERCEDES-BENZ SLK ROADSTER 2008Pages: 273, PDF Size: 4.42 MB

Page 163 of 273

Winter driving

160 Interchanging the wheels

G

Risk of accident

Interchange the front and rear wheels only

if they have the same dimensions: for exam-

ple size, offset, etc.

After every wheel interchange/change,

have the tightening torque checked at a

qualified specialist workshop that has the

necessary specialist knowledge and tools

to carry out the work required. Mercedes-

Benz recommends that you use a

Mercedes-Benz Service Centre for this pur-

pose. In particular, work relevant to safety

or on safety-related systems must be car-

ried out at a qualified specialist workshop.

The wheels could work loose if they are not

tightened to a torque of 110 Nm.

For safety reasons, Mercedes-Benz recom -

mends that you only use wheel bolts of the

correct size which have been approved for

Mercedes-Benz vehicles.

The wheels may be interchanged every 5,000

km to 10,000 km depending on the degree of

tyre wear, provided that the vehicle has the

same size front and rear tyres. Do not reverse

the direction of tyre rotation.

The wear patterns on the front and rear tyres

differ depending on the operating conditions. Interchange the wheels before a clear wear

pattern has formed on the tyres. The fron

t

tyres typically wear more on the shoulders

and the rear tyres in the centre.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a whee l

is changed. Check the tyre pressure and, if

necessary, restart the tyre pressure loss

warning system*. Winter driving

Introduction to winter operation

Have your vehicle winterproofed at a qualified

specialist workshop, e.g. at a Mercedes-Ben z

Service Centre, at the onset of winter. Winter tyres

Use winter tyres at temperatures below +7 °

C and on snow or ice-covered roads. Only

then can the effect of the ABS and ES P®

driv-

ing systems be ensured in winter too.

Use winter tyres of the same make and tread

on all wheels to maintain safe handling char-

acteristics. G

Risk of accident

You must replace winter tyres with a trea d

depth of less than 4 mm immediately. They

are no longer suitable for winter use, in par-

ticular because they do not provide suffi-

cient grip. This could cause you to lose

control of your vehicle and cause an acci-

dent .

Always observe the maximum permitted

speed specified for the winter tyres you have

fitted. If you fit winter tyres which have a

lower maximum permitted speed than that of Operation

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 160

Page 232 of 273

Flat tyre

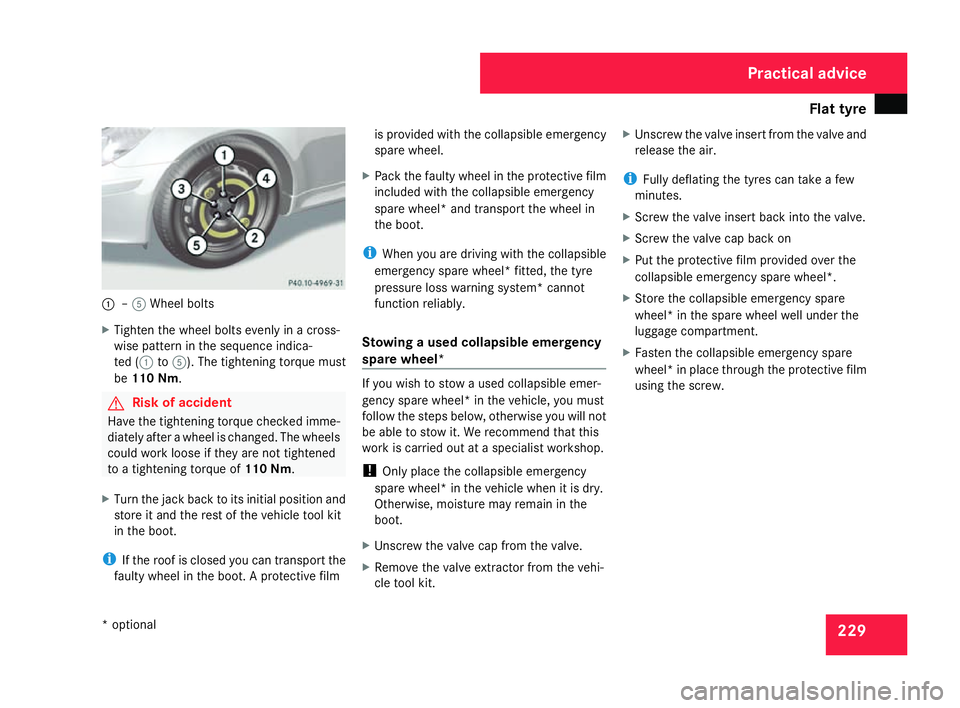

2291

–5 Wheel bolts

X Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indica-

ted (1 to5 ). The tightening torque must

be 110 Nm. G

Risk of acciden

t

Have the tightening torque checked imme-

diately after a wheel is changed. The wheels

could work loose if they are not tightened

to a tightening torque of 110 Nm.

X Turn the jack back to its initial position and

store it and the rest of the vehicle tool kit

in the boot.

i If the roof is closed you can transport the

faulty wheel in the boot. A protective film is provided with the collapsible emergency

spare wheel.

X Pack the faulty wheel in the protective film

included with the collapsible emergency

spare wheel* and transport the wheel in

the boot .

i When you are driving with the collapsible

emergency spare wheel* fitted, the tyre

pressure loss warning system* cannot

function reliably.

Stowing a used collapsible emergency

spare wheel* If you wish to stow a used collapsible emer-

gency spare wheel* in the vehicle, you must

follow the steps below, otherwise you will not

be able to stow it. We recommend that this

work is carried out at a specialist workshop.

!

Only place the collapsible emergency

spare wheel* in the vehicle when it is dry.

Otherwise, moisture may remain in the

boot.

X Unscrew the valve cap from the valve .

X Remove the valve extractor from the vehi -

cle tool kit. X

Unscrew the valve insert from the valve and

release the air.

i Fully deflating the tyres can take a few

minutes.

X Screw the valve insert back into the valve .

X Screw the valve cap back on

X Put the protective film provided over the

collapsible emergency spare wheel*.

X Store the collapsible emergency spar e

wheel* in the spare wheel well under the

luggage compartment.

X Fasten the collapsible emergency spar e

wheel* in place through the protective film

using the screw. Practical advice

* optional

171_AKB; 3; 4, en-GB

vpfaff7,

2007-11-13T10:50:25+01:00 - Seite 229