MERCEDES-BENZ SLK ROADSTER 2012 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SLK ROADSTER, Model: MERCEDES-BENZ SLK ROADSTER 2012Pages: 321, PDF Size: 6.9 MB

Page 261 of 321

!

Do not allow cosmetics, insect repellent

or sunscreen to come in contact with the

plastic trim. This maintains the high-quality

look of the surfaces.

X Wipe the plastic trim with a damp, lint-free

cloth, e.g. a microfibre cloth.

X Heavy soiling: use car care and cleaning

products recommended and approved by

Mercedes-Benz.

The surface may change colour tempora-

rily. Wait until the surface is dry again.

Cleaning the steering wheel and gear or

selector lever X

Thoroughly wipe with a damp cloth or use

leather care agents that have been recom-

mended and approved by Mercedes-Benz.

Cleaning wooden trim and trim ele-

ments X

Wipe the wooden trim and trim pieces with

a damp, lint-free cloth, e.g. a microfibre

cloth.

X Heavy soiling: use car care and cleaning

products recommended and approved by

Mercedes-Benz.

! Do not use solvent-based cleaning agents

such as tar remover, wheel cleaners, pol-

ishes or waxes. There is otherwise a risk of

damaging the surface.

Cleaning the seat covers !

Do not use microfibre cloths to clean gen-

uine leather, artificial leather or

Alcantara® covers. If used often, these can

damage the cover.

! Observe the following when cleaning:

R clean genuine leather covers carefully

with a damp cloth and then wipe the cov-

ers down with a dry cloth. Make sure that

the leather does not become soaked. It

may otherwise become rough and

cracked. Only use leather care agents that have been tested and approved by

Mercedes-Benz.Y

ou can obtain these

from a qualified specialist workshop.

R clean artificial leather covers with a cloth

moistened with a solution containing 1%

detergent (e.g. washing-up liquid).

R clean cloth covers with a microfibre cloth

moistened with a solution containing 1%

detergent (e.g. washing-up liquid). Rub

carefully and always wipe entire seat sec-

tions to avoid leaving visible lines. Leave

the seat to dry afterwards. Cleaning

results depend on the type of dirt and

how long it has been there.

R clean Alcantara® covers with a damp

cloth. Make sure that you wipe entire

seat sections to avoid leaving visible

lines.

i Note that regular care is essential to

make sure that the appearance and com-

fort of the covers are retained over time.

Cleaning the seat belts X

Use clean, lukewarm water and soap solu-

tion.

! Do not clean the seat belts using chemical

cleaning agents. Do not dry the seat belts

at temperatures above 80 † or in direct

sunlight.

Cleaning the roof lining and carpets X

Roof lining: use a soft brush or a cleaning

agent recommended and approved by

Mercedes-Benz to remove heavy soiling.

X Carpets: use the carpet and textile clean-

ing agents recommended and approved by

Mercedes-Benz. 258

CareMaintenance and care

Page 262 of 321

Useful information

............................260

Where will I find...? ...........................260

Flat tyre ............................................. 263

Battery ............................................... 273

Jump-starting .................................... 277

Towing and tow-starting ..................278

Electrical fuses ................................. 281 259Breakdown assistance

Page 263 of 321

Useful information

i This Owner's Manual describes all models

and all standard and optional equipment

available to your vehicle at the time of pub-

lication of the Owner's Manual. Country-

specific deviations are possible. Please

note that your vehicle may not be equipped

with all features described. This also

applies to safety-relevan tsystems and

functions.

i Please read the information on qualified

specialist workshops (Y page 22).Where will I find...?

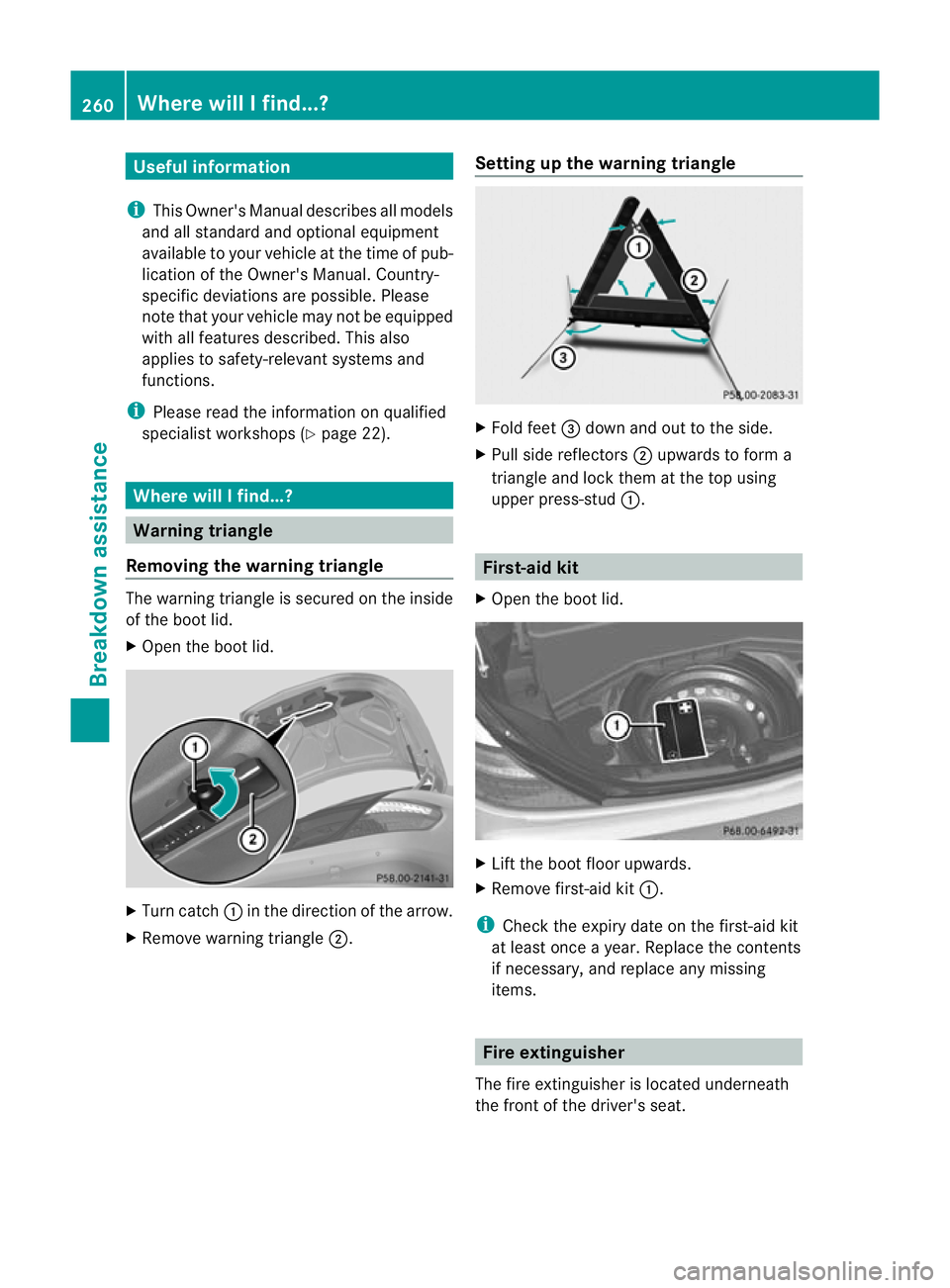

Warning triangle

Removing the warning triangle The warning triangle is secured on the inside

of the boo tlid.

X Open the boot lid. X

Turn catch :in the direction of the arrow.

X Remove warning triangle ;.Setting up the warning triangle X

Fold feet =down and out to the side.

X Pull side reflectors ;upwards to form a

triangle and lock the matthe top using

upper press-stud :. First-aid kit

X Open the boot lid. X

Lift the boot floor upwards.

X Remove first-aid kit :.

i Check the expiry date on the first-aid kit

at least once a year. Replace the contents

if necessary, and replace any missing

items. Fire extinguisher

The fire extinguisher is located underneath

the front of the driver's seat. 260

Where will I find...?Breakdown assistance

Page 264 of 321

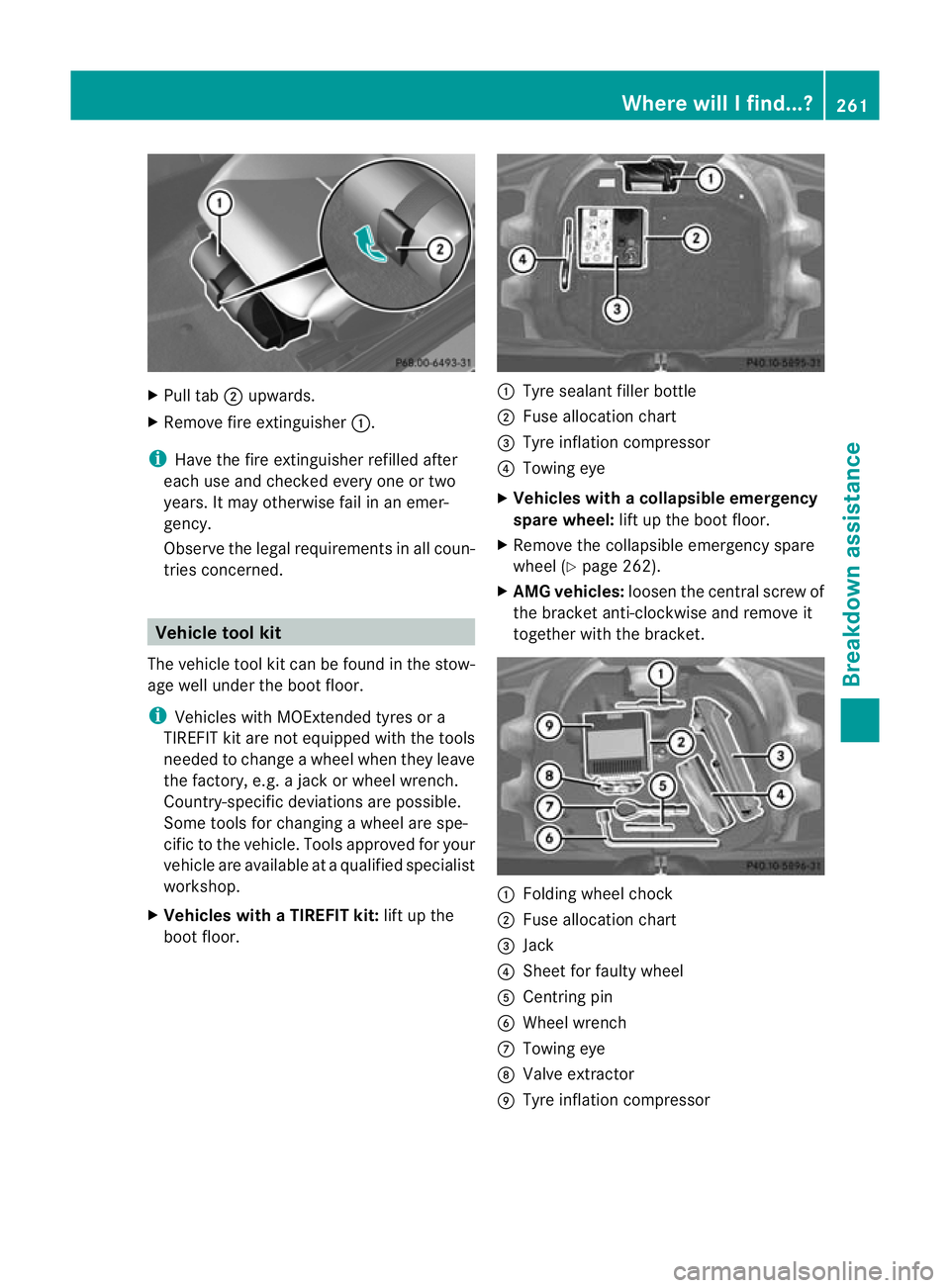

X

Pull tab ;upwards.

X Remove fire extinguisher :.

i Have the fire extinguisher refilled after

each use and checked every one or two

years. It may otherwise fail in an emer-

gency.

Observe the legal requirement sinall coun-

tries concerned. Vehicle tool kit

The vehicle tool kit can be found in the stow-

age well under the boot floor.

i Vehicles with MOExtended tyres or a

TIREFIT kit are not equipped with the tools

needed to change a wheel when they leave

the factory, e.g. a jack or wheel wrench.

Country-specific deviations are possible.

Some tools for changing awheel are spe-

cific to the vehicle. Tools approved for your

vehicle are available at a qualified specialist

workshop.

X Vehicles with a TIREFIT kit: lift up the

boot floor. :

Tyre sealant filler bottle

; Fuse allocation chart

= Tyre inflation compressor

? Towing eye

X Vehicles with acollapsible emergency

spare wheel: lift up the boot floor.

X Remove the collapsible emergency spare

wheel (Y page 262).

X AMG vehicles: loosenthe central screw of

the bracket anti-clockwise and remove it

together with the bracket. :

Folding wheel chock

; Fuse allocation chart

= Jack

? Sheet for faulty wheel

A Centring pin

B Wheel wrench

C Towing eye

D Valve extractor

E Tyre inflation compressor Where will I find...?

261Breakdown assistance

Page 265 of 321

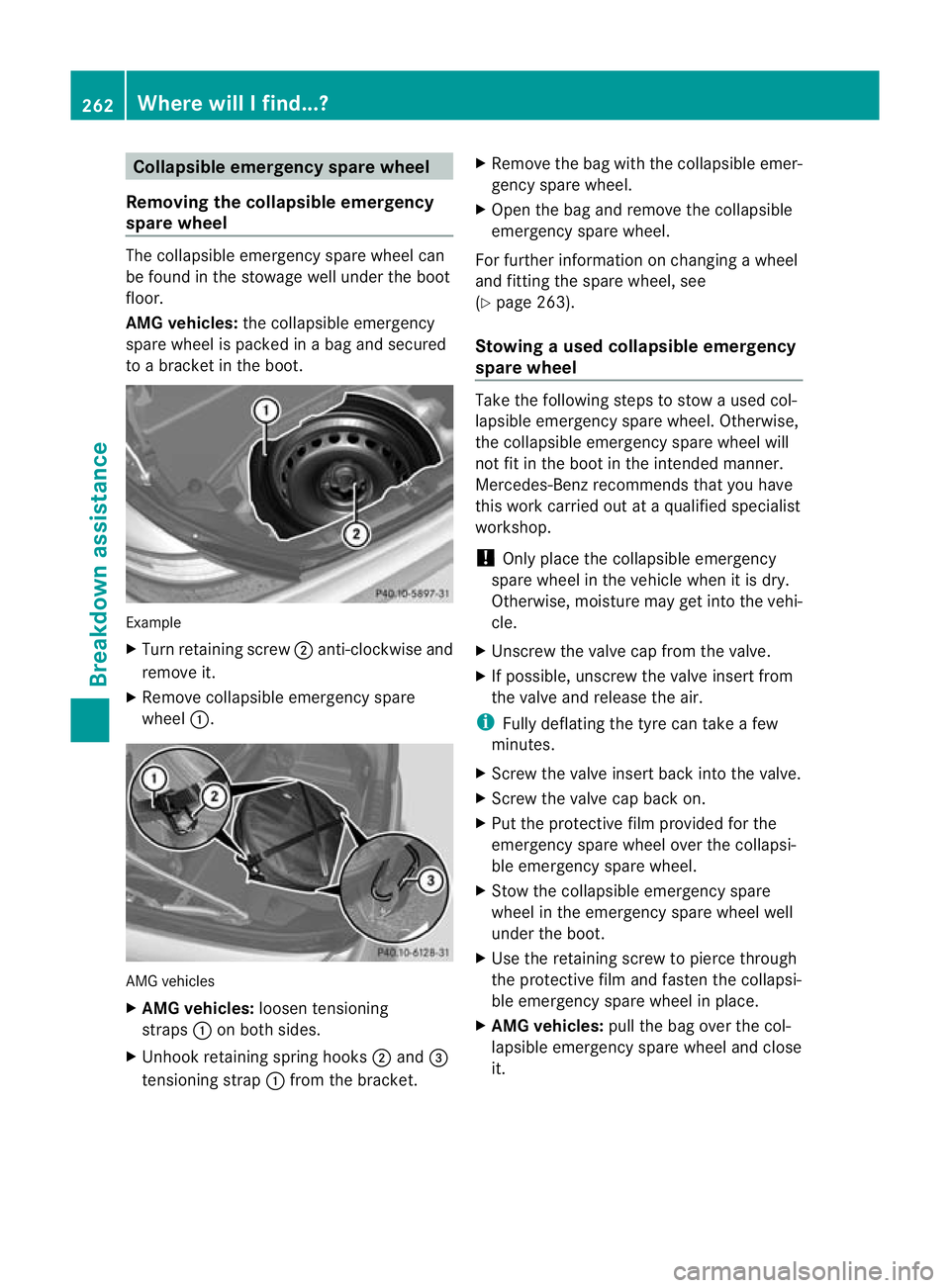

Collapsible emergency spare wheel

Removing the collapsible emergency

spare wheel The collapsible emergency spare wheel can

be found in the stowage well unde rthe boot

floor.

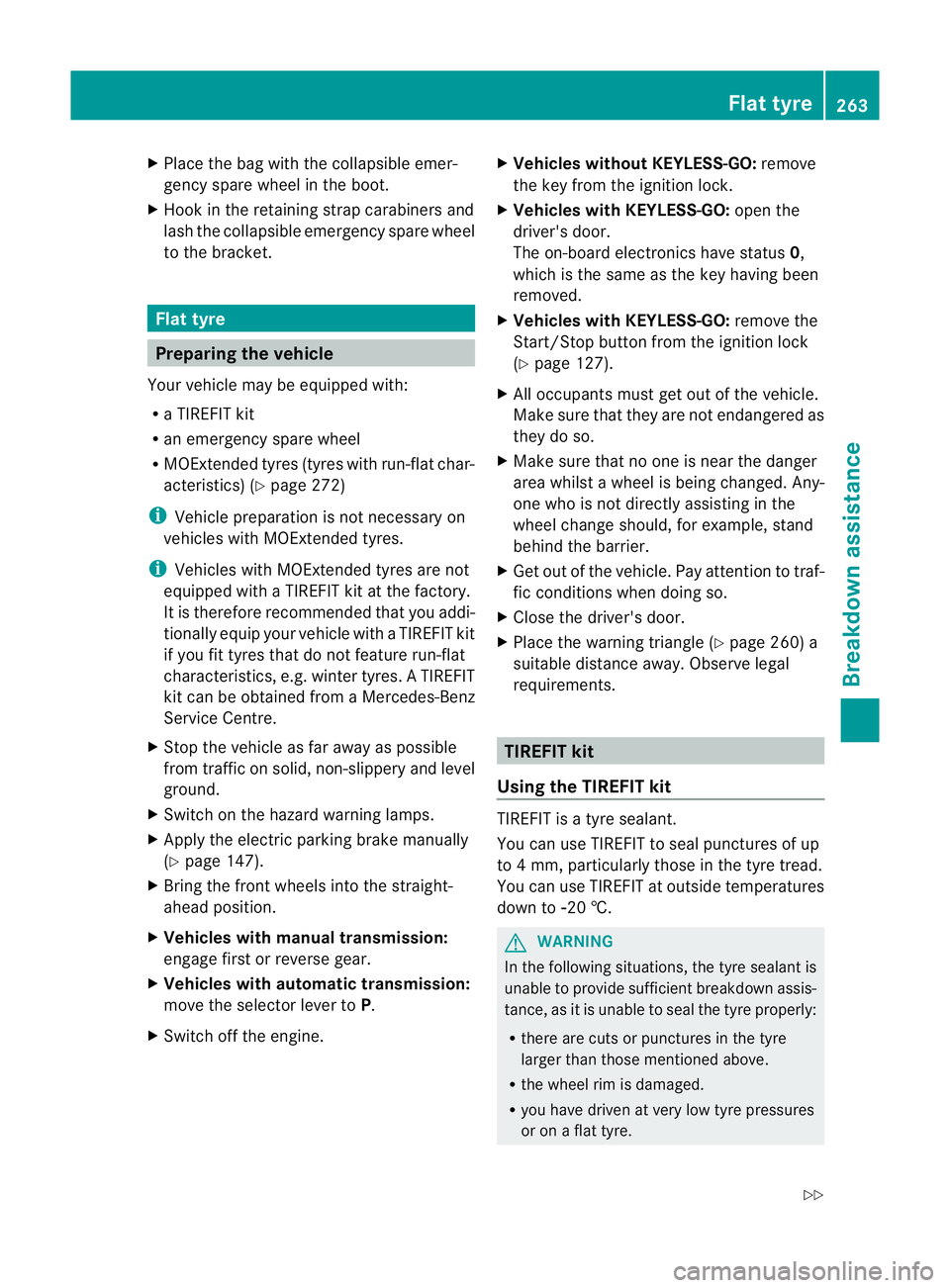

AMG vehicles: the collapsible emergency

spare wheel is packed in a bag and secured

to a bracket in the boot. Example

X

Turn retaining screw ;anti-clockwise and

remove it.

X Remove collapsible emergency spare

wheel :. AMG vehicles

X

AMG vehicles: loosen tensioning

straps :on both sides.

X Unhook retaining spring hooks ;and =

tensioning strap :from the bracket. X

Remove the bag with the collapsible emer-

gency spare wheel.

X Open the bag and remove the collapsible

emergency spare wheel.

For further information on changing a wheel

and fitting the spare wheel, see

(Y page 263).

Stowing aused collapsible emergency

spare wheel Take the following steps to stow a used col-

lapsible emergency spare wheel. Otherwise,

the collapsible emergency spare wheel will

not fit in the boot in the intended manner.

Mercedes-Benz recommends that you have

this work carried out at a qualified specialist

workshop.

!

Only place the collapsible emergency

spare wheel in the vehicle when it is dry.

Otherwise, moisture may get into the vehi-

cle.

X Unscrew the valve cap from the valve.

X If possible, unscrew the valve insert from

the valve and release the air.

i Fully deflating the tyre can take a few

minutes.

X Screw the valve insert back into the valve.

X Screw the valve cap back on.

X Put the protective film provided for the

emergency spare wheel over the collapsi-

ble emergency spare wheel.

X Stow the collapsible emergency spare

wheel in the emergency spare wheel well

under the boot.

X Use the retaining screw to pierce through

the protective film and fasten the collapsi-

ble emergency spare wheel in place.

X AMG vehicles: pull the bag over the col-

lapsible emergency spare wheel and close

it. 262

Where will I find...?Breakdown assistance

Page 266 of 321

X

Place the bag with the collapsible emer-

gency spare wheel in the boot.

X Hook in the retaining strap carabiners and

lash the collapsible emergenc yspare wheel

to the bracket. Flat tyre

Preparing the vehicle

Your vehicle may be equipped with:

R a TIREFIT kit

R an emergency spare wheel

R MOExtended tyres (tyres with run-flat char-

acteristics) (Y page 272)

i Vehicle preparation is not necessary on

vehicles with MOExtended tyres.

i Vehicles with MOExtended tyres are not

equipped with a TIREFIT kit at the factory.

It is therefore recommended that you addi-

tionally equip your vehicle with a TIREFIT kit

if you fit tyres that do not feature run-flat

characteristics, e.g. winter tyres. A TIREFIT

kit can be obtained from a Mercedes-Benz

Service Centre.

X Stop the vehicle as far away as possible

from traffic on solid, non-slippery and level

ground.

X Switch on the hazard warning lamps.

X Apply the electric parkin gbrake manually

(Y page 147).

X Bring the front wheels into the straight-

ahead position.

X Vehicles with manual transmission:

engage first or reverse gear.

X Vehicles with automatic transmission:

move the selector leve rtoP.

X Switch off the engine. X

Vehicles without KEYLESS-GO: remove

the key from the ignition lock.

X Vehicles with KEYLESS-GO: open the

driver's door.

The on-board electronics have status 0,

which is the same as the key having been

removed.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(Y page 127).

X All occupants must get out of the vehicle.

Make sure that they are not endangered as

they do so.

X Make sure that no one is near the danger

area whilst a wheel is being changed. Any-

one who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Get out of the vehicle. Pay attention to traf-

fic conditions when doing so.

X Close the driver's door.

X Place the warning triangle (Y page 260) a

suitable distance away.O bserve legal

requirements. TIREFIT kit

Using the TIREFIT kit TIREFIT is a tyre sealant.

You can use TIREFIT to seal punctures of up

to 4 mm, particularly those in the tyre tread.

You can use TIREFIT at outside temperatures

down to

Ò20 †. G

WARNING

In the following situations, the tyre sealant is

unable to provide sufficient breakdown assis-

tance, as it is unable to seal the tyre properly:

R there are cuts or punctures in the tyre

larger than those mentioned above.

R the wheel rim is damaged.

R you have driven at very low tyre pressures

or on a flat tyre. Flat tyre

263Breakdown assistance

Z

Page 267 of 321

There is a risk of accident.

Do not drive any further. Contact a qualified

specialist workshop.

X Do not remove any foreign objects which

have penetrated the tyre, e.g. screws or

nails.

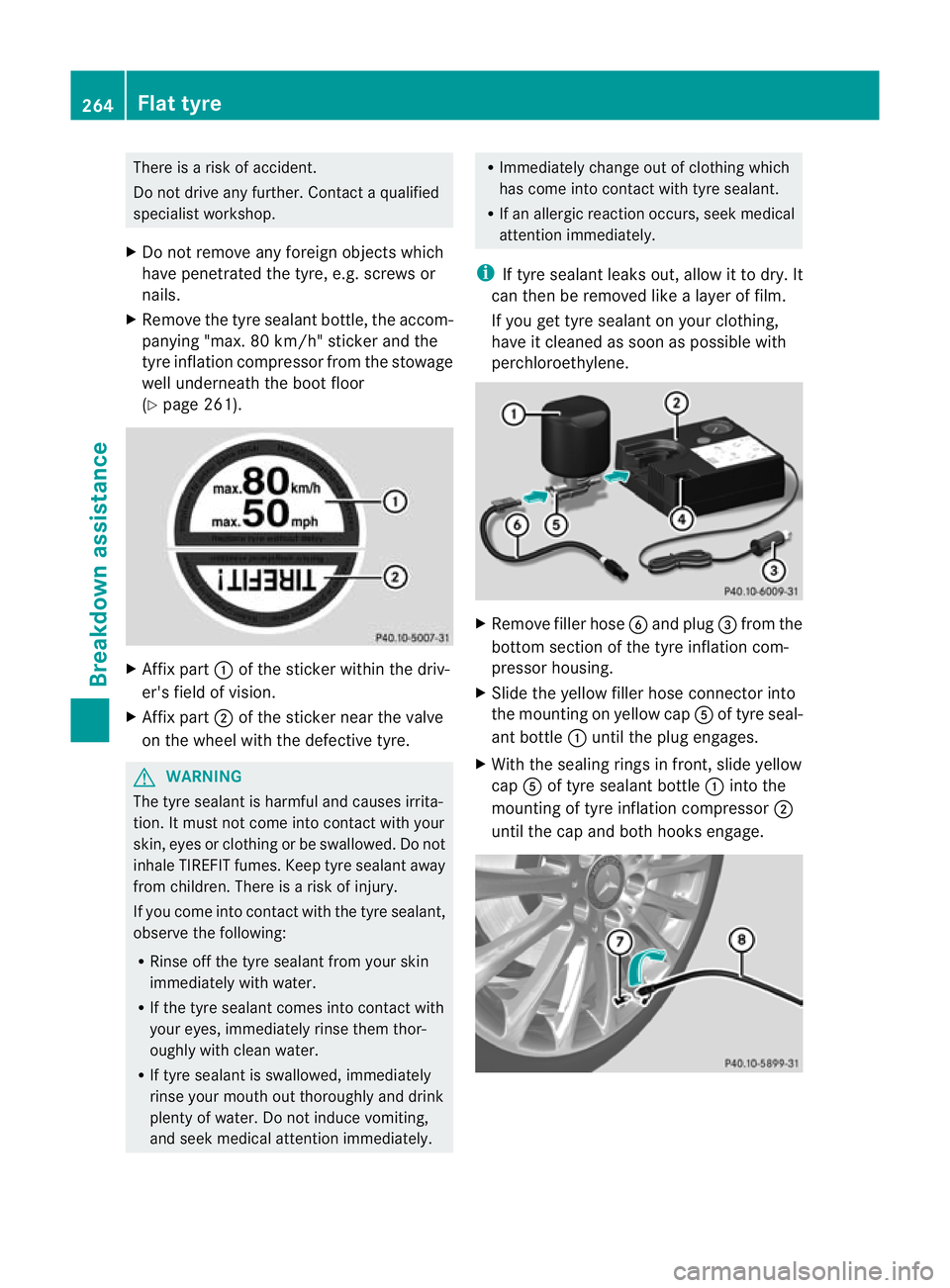

X Remove the tyre sealant bottle, the accom-

panying "max. 80 km/h" sticker and the

tyre inflation compressor from the stowage

well underneath the boot floor

(Y page 261). X

Affix part :of the sticker within the driv-

er's field of vision.

X Affix part ;of the sticker near the valve

on the wheel with the defective tyre. G

WARNING

The tyre sealant is harmful and causes irrita-

tion. It must not come into contact with your

skin, eyes or clothing or be swallowed. Do not

inhale TIREFIT fumes. Keep tyre sealant away

from children. There is a risk of injury.

If you come into contact with the tyre sealant,

observe the following:

R Rinse off the tyre sealant from your skin

immediately with water.

R If the tyre sealant comes into contact with

your eyes, immediately rinse them thor-

oughly with clean water.

R If tyre sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water. Do not induce vomiting,

and seek medical attention immediately. R

Immediately change out of clothing which

has come into contact with tyre sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

i If tyre sealant leaks out, allow it to dry. It

can then be removed like a layer of film.

If you get tyre sealant on your clothing,

have it cleaned as soon as possible with

perchloroethylene. X

Remove filler hose Band plug =from the

bottom section of the tyre inflation com-

pressor housing.

X Slide the yellow filler hose connector into

the mounting on yellow cap Aof tyre seal-

ant bottle :until the plug engages.

X With the sealing rings in front, slide yellow

cap Aof tyre sealant bottle :into the

mounting of tyre inflation compressor ;

until the cap and both hooks engage. 264

Flat tyreBreakdown assistance

Page 268 of 321

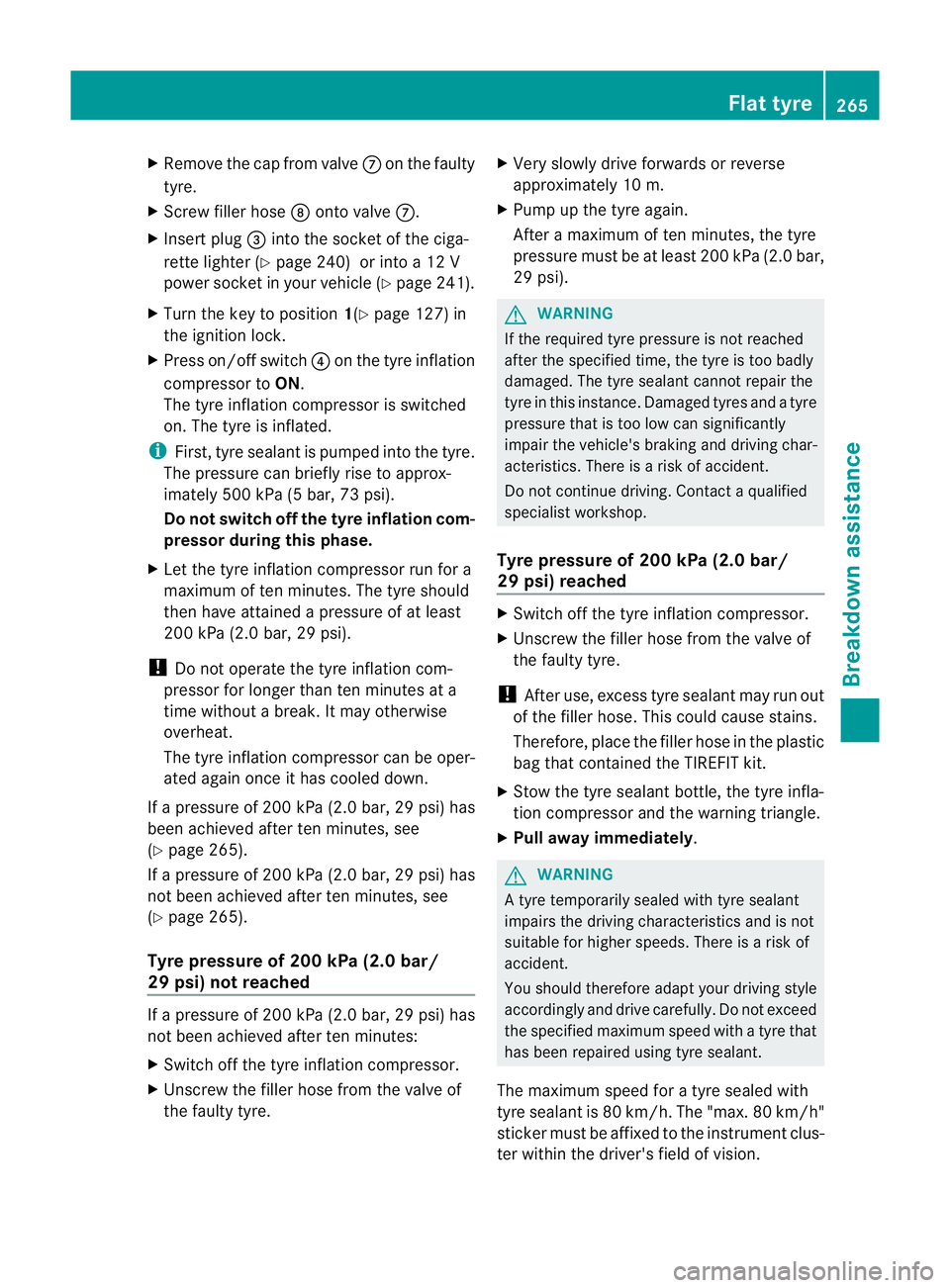

X

Remove the cap from valve Con the faulty

tyre.

X Screw filler hose Donto valve C.

X Inser tplug =into the socket of the ciga-

rette lighter (Y page 240) or into a 12 V

power socket in your vehicle (Y page 241).

X Turn the key to position 1(Ypage 127) in

the ignition lock.

X Press on/off switch ?on the tyre inflation

compressor to ON.

The tyre inflation compressor is switched

on. The tyre is inflated.

i First, tyre sealant is pumped into the tyre.

The pressure can briefly rise to approx-

imately 500 kPa (5 bar, 73 psi).

Do not switch off the tyre inflation com-

pressor during this phase.

X Let the tyre inflation compressor run for a

maximum of ten minutes. The tyre should

the nhave attained a pressure of at least

200 kPa (2.0 bar, 29 psi).

! Do not operate the tyre inflation com-

pressor for longer than ten minutes at a

time without a break .Itmay otherwise

overheat.

The tyre inflation compressor can be oper-

ated again once it has cooled down.

If a pressure of 200 kP a(2 .0 ba r,29 psi) has

bee nachieved afte rten minutes, see

(Y page 265).

If a pressure of 200 kPa (2.0 ba r,29 psi) has

not bee nachieved afte rten minutes, see

(Y page 265).

Tyre pressure of 200 kPa (2.0 bar/

29 psi) not reached If a pressure of 200 kPa

(2.0 ba r,29 psi) has

not been achieved after ten minutes:

X Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre. X

Very slowly drive forwards or reverse

approximately 10 m.

X Pump up the tyre again.

After a maximum of ten minutes, the tyre

pressure must be at least 200 kPa (2.0 bar,

29 psi). G

WARNING

If the required tyre pressure is not reached

after the specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this instance. Damaged tyres and a tyre

pressure that is too low can significantly

impair the vehicle's braking and driving char-

acteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

Tyre pressure of 200 kPa (2.0 bar/

29 psi) reached X

Switch off the tyre inflation compressor.

X Unscrew the filler hose from the valve of

the faulty tyre.

! After use, excess tyre sealant may run out

of the filler hose .This could cause stains.

Therefore, place the filler hose in the plastic

bag that contained the TIREFIT kit.

X Stow the tyre sealant bottle, the tyre infla-

tion compressor and the warning triangle.

X Pull away immediately. G

WARNING

At yre temporarily sealed with tyre sealant

impairs the driving characteristics and is not

suitable for higher speeds .There is a risk of

accident.

You should therefore adapt your driving style

accordingly and drive carefully. Do not exceed

the specified maximum speed with a tyre that

has been repaired using tyre sealant.

The maximum speed for a tyre sealed with

tyre sealant is 80 km/h. The "max. 80 km/h"

sticker must be affixed to the instrumentc lus-

ter within the driver's field of vision. Flat tyre

265Breakdown assistance Z

Page 269 of 321

X

Stop after driving for approximately ten

minutes and check the tyre pressure with

the tyre inflation compressor.

The tyre pressure mus tnow be at least

130 kPa (1.3 bar, 19 psi). G

WARNING

If the required tyre pressure is not reached

after driving for a short period, the tyre is too

badly damaged. The tyre sealant cannot

repair the tyre in this instance. Damaged tyres

and a tyre pressure that is too low can signif-

icantly impair the vehicle's braking and driv-

ing characteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i In your vehicle, you will find a sticker with

the Mercedes-Benz Service24h telephone

number, e.g. on the B-pillar on the driver's

side.

X Correct the tyre pressure if it is still at least

130 kPa (1.3 bar, 19 psi) (for the values,

see the fuel filler flap).

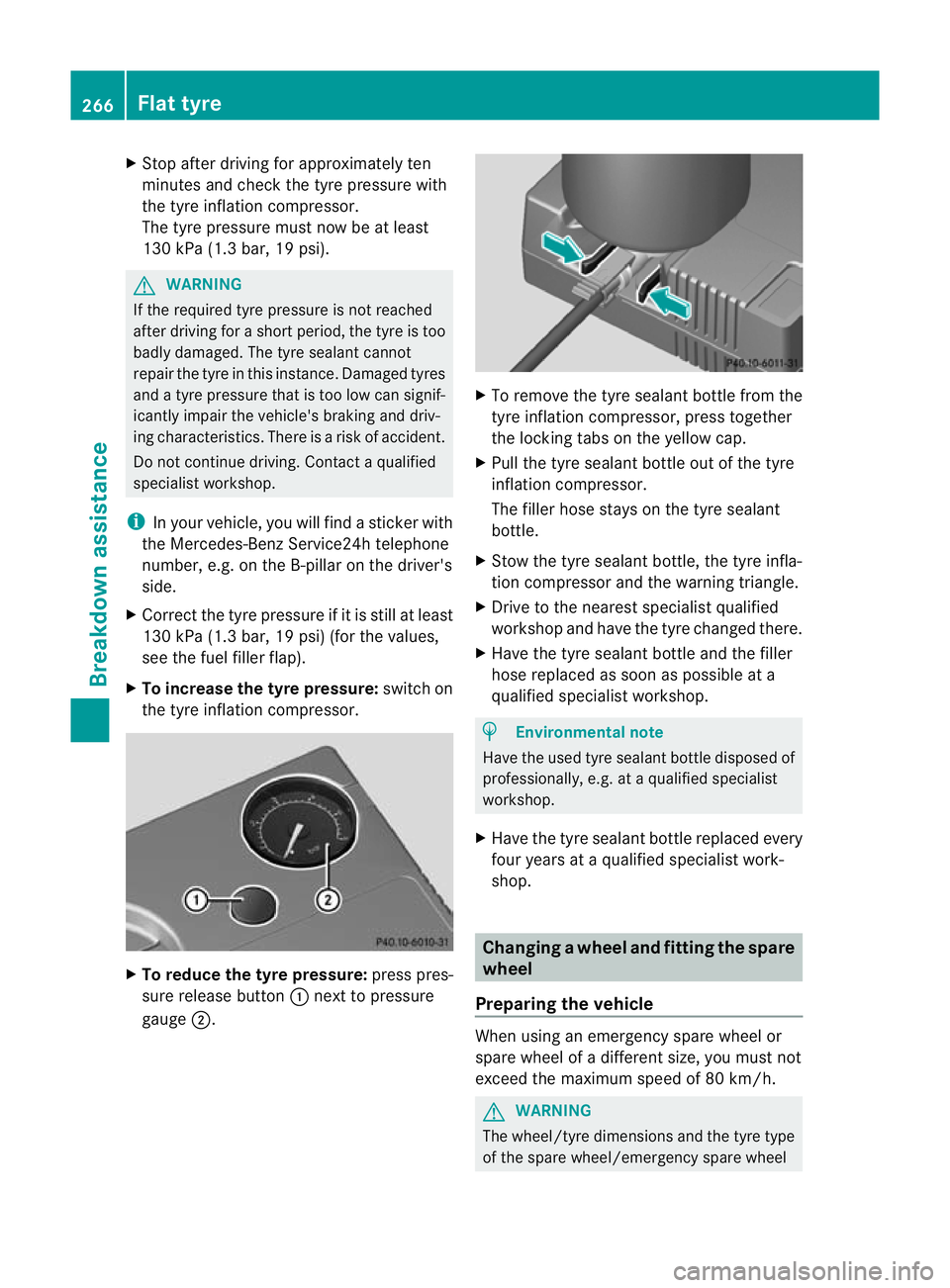

X To increase the tyre pressure: switch on

the tyre inflation compressor. X

To reduce the tyre pressure: press pres-

sure release button :next to pressure

gauge ;. X

To remove the tyre sealant bottle from the

tyre inflation compressor ,press together

the locking tabs on the yellow cap.

X Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filler hose stays on the tyre sealant

bottle.

X Stow the tyre sealant bottle, the tyre infla-

tion compresso rand the warning triangle.

X Drive to the neares tspecialist qualified

workshop and have the tyre changed there.

X Have the tyre sealant bottle and the filler

hose replaced as soon as possible at a

qualified specialist workshop. H

Environmental note

Have the used tyre sealant bottle disposed of

professionally, e.g. at aqualified specialist

workshop.

X Have the tyre sealan tbottle replaced every

four years at a qualified specialist work-

shop. Changing

awheel and fitting the spare

wheel

Preparing the vehicle When using an emergency spare wheel or

spare wheel of a different size, you must not

exceed the maximum speed of 80 km/h.

G

WARNING

The wheel/tyre dimensions and the tyre type

of the spare wheel/emergency spare wheel 266

Flat tyreBreakdown assistance

Page 270 of 321

and the wheel to be replaced may differ. Fit-

ting a spare wheel/emergency spare wheel

may severely impair the driving characteris-

tics. There is a risk of accident.

To prevent hazardous situations:

R Adap tyour driving style accordingly and

drive carefully.

R Never fit more than one spare wheel/emer-

gency spare wheel if the dimesions are dif-

ferent to those of the wheel being replaced.

R Only use a spare wheel/emergency spare

wheel briefly if the dimesions are different

to those of the wheel being replaced.

R Do not switch off ESP ®

.

R Have the spare wheel/emergency spare

wheel in question replaced at the nearest

qualified specialist workshop. Make sure

that the wheel/tyre dimensions and tyre

type are correct.

i Vehicles without an emergency spare

wheel/spare wheel are not equipped with

wheel-changing tools at the factory. For

more information on which tools are

required to perform a wheel change on your

vehicle, e.g. wheel chock, wheel wrench or

centring pin, consult a Mercedes-Benz

Service Centre.

X Prepare the vehicle as described

(Y page 263).

X Remove the following items (depending on

the vehicle's equipment) from the stowage

well under the boot floor:

R the emergency spare wheel

R the wheel wrench

R the folding wheel chock

R the jack

R the centring pin

R the tyre inflation compressor

X Secure the vehicle to prevent it from rolling

away. Securing the vehicle to prevent it from

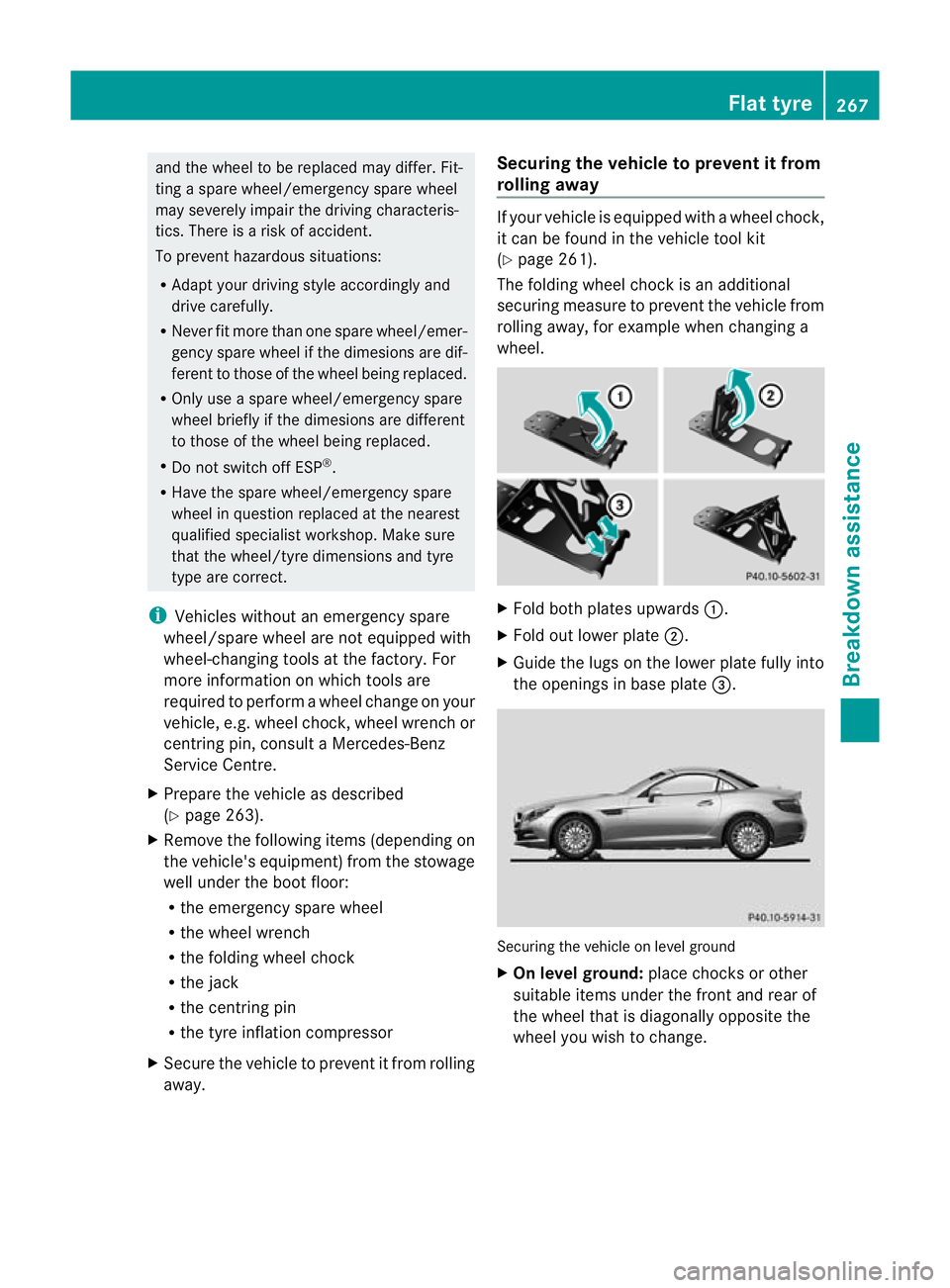

rolling away If your vehicle is equipped with a wheel chock,

it can be found in the vehicle tool kit

(Y

page 261).

The folding wheel chock is an additional

securing measure to prevent the vehicle from

rolling away, for example when changing a

wheel. X

Fold both plates upwards :.

X Fold out lower plate ;.

X Guide the lugs on the lower plate fully into

the openings in base plate =. Securing the vehicle on level ground

X

On level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change. Flat tyre

267Breakdown assistance Z