fuel MERCEDES-BENZ SPRINTER 2006 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 683 of 2305

ENGINE CONTROL MODULE C2 (OBD)CAV CIRCUIT FUNCTION

1 16BK/RD FUSED ENGINE CONTROL RELAY OUTPUT

2 14BR GROUND

3 14BK/BL FUSED ENGINE CONTROL RELAY OUTPUT

4 14BR GROUND

5 14BK/BL FUSED ENGINE CONTROL RELAY OUTPUT

6 14BR GROUND

7 18RD S/C SWITCH 12 VOLT SUPPLY

8 18BR/WT HIGH IDLE ON SIGNAL

10 18WT/RD BOOST PRESSURE SENSOR 5 VOLT SUPPLY

11 18WT/DG BOOST PRESSURE SENSOR SIGNAL

12 18BR/WT SENSOR GROUND

13 18GY/DG ACCEL PEDAL POSITION SENSOR SIGNAL NO. 2

14 18BR/GY ACCEL PEDAL POSITION SENSOR GROUND NO. 2

17 18BR/DG KICKDOWN SWITCH SIGNAL

18 20DG/YL ENGINE RPM

19 18BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

24 18BL/RD ACCEL PEDAL POSITION SENSOR 5 VOLT SUPPLY

25 18BL/DG ACCEL PEDAL POSITION SENSOR SIGNAL NO. 1

26 18BR/BL ACCEL PEDAL POSITION SENSOR GROUND NO. 1

28 18BR/DG INTAKE AIR TEMPERATURE SENSOR GROUND

31 20BL/YL K-ECM

32 20DG ENHANCED ACCIDENT REPORT DRIVER

36 18VT IGNITION SWITCH OUTPUT (START)

37 18DG ACCEL/SET SIGNAL

38 18BK VERIFICATION SIGNAL

42 18DG/WT INTAKE AIR TEMPERATURE SENSOR SIGNAL

43 18BK/RD GLOW PLUG MODULE CONTROL

44 18YL/BL ENGINE CONTROL RELAY CONTROL

50 18YL DECEL/SET SIGNAL

51 18GY OFF SIGNAL

52 18BL RESUME SIGNAL

53 20DG/WT CAN C BUS (+)

54 20DG CAN C BUS (-)

55 18BR/RD FUEL PUMP RELAY CONTROL

58 18VT/DG STARTER MOTOR RELAY CONTROL

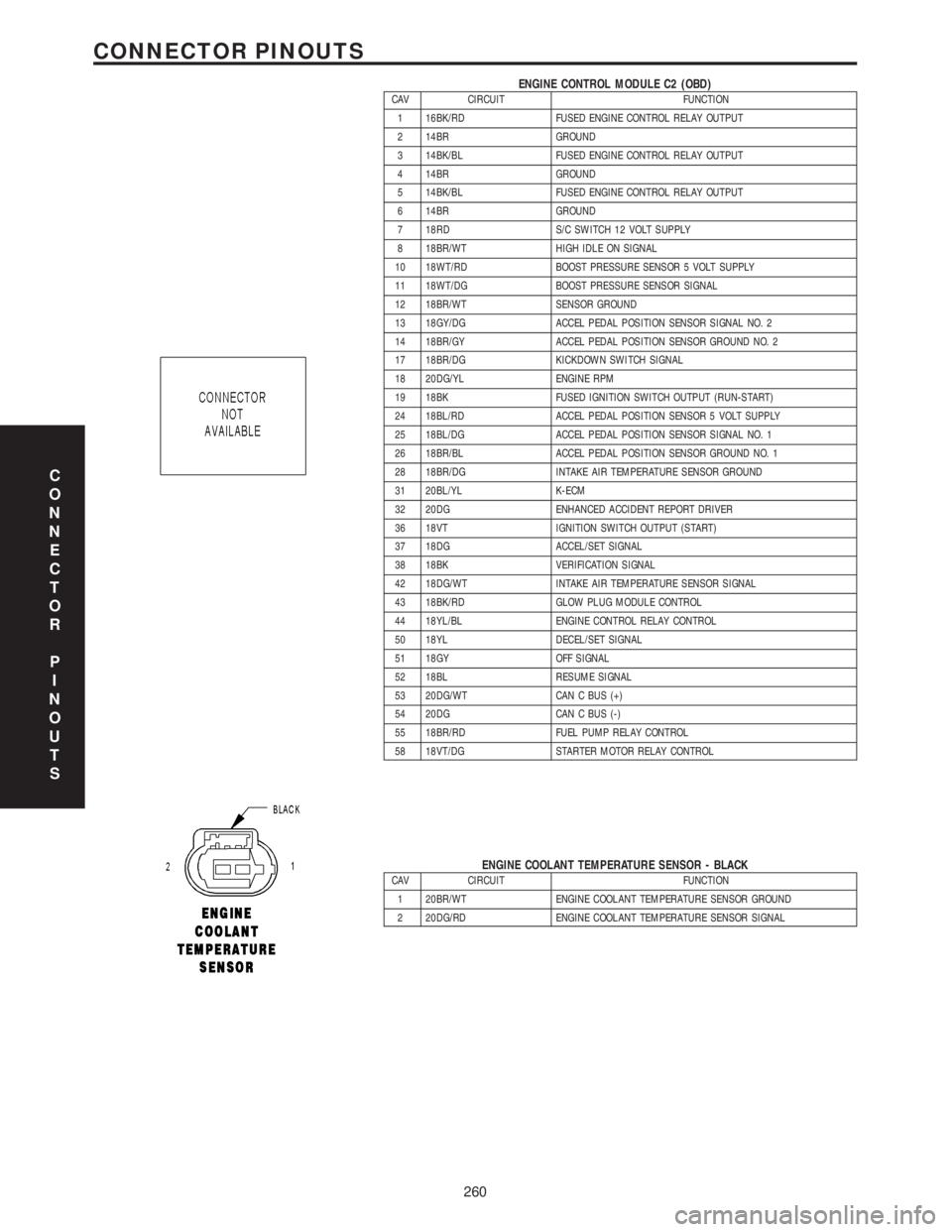

ENGINE COOLANT TEMPERATURE SENSOR - BLACKCAV CIRCUIT FUNCTION

1 20BR/WT ENGINE COOLANT TEMPERATURE SENSOR GROUND

2 20DG/RD ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

260

CONNECTOR PINOUTS

Page 684 of 2305

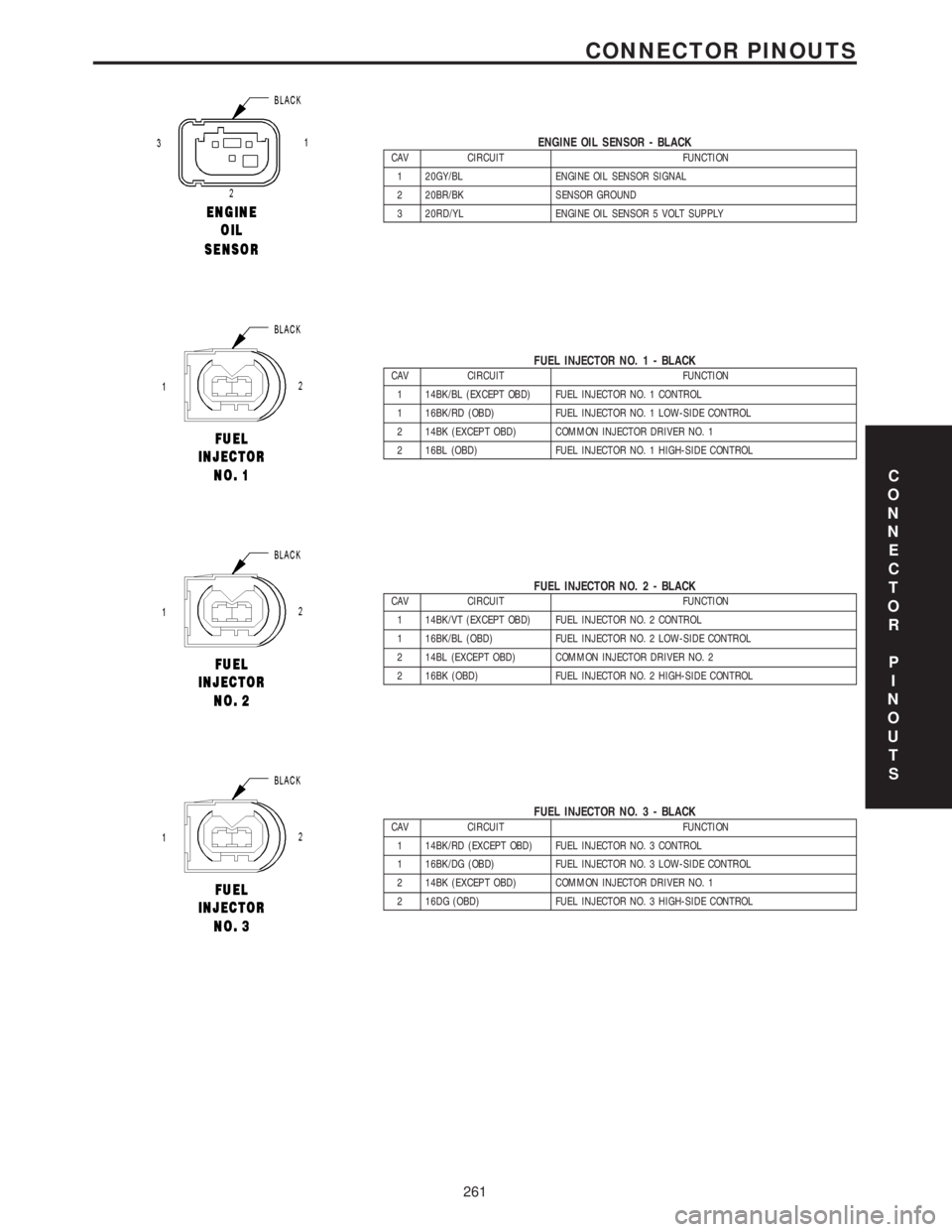

ENGINE OIL SENSOR - BLACKCAV CIRCUIT FUNCTION

1 20GY/BL ENGINE OIL SENSOR SIGNAL

2 20BR/BK SENSOR GROUND

3 20RD/YL ENGINE OIL SENSOR 5 VOLT SUPPLY

FUEL INJECTOR NO. 1 - BLACKCAV CIRCUIT FUNCTION

1 14BK/BL (EXCEPT OBD) FUEL INJECTOR NO. 1 CONTROL

1 16BK/RD (OBD) FUEL INJECTOR NO. 1 LOW-SIDE CONTROL

2 14BK (EXCEPT OBD) COMMON INJECTOR DRIVER NO. 1

2 16BL (OBD) FUEL INJECTOR NO. 1 HIGH-SIDE CONTROL

FUEL INJECTOR NO. 2 - BLACKCAV CIRCUIT FUNCTION

1 14BK/VT (EXCEPT OBD) FUEL INJECTOR NO. 2 CONTROL

1 16BK/BL (OBD) FUEL INJECTOR NO. 2 LOW-SIDE CONTROL

2 14BL (EXCEPT OBD) COMMON INJECTOR DRIVER NO. 2

2 16BK (OBD) FUEL INJECTOR NO. 2 HIGH-SIDE CONTROL

FUEL INJECTOR NO. 3 - BLACKCAV CIRCUIT FUNCTION

1 14BK/RD (EXCEPT OBD) FUEL INJECTOR NO. 3 CONTROL

1 16BK/DG (OBD) FUEL INJECTOR NO. 3 LOW-SIDE CONTROL

2 14BK (EXCEPT OBD) COMMON INJECTOR DRIVER NO. 1

2 16DG (OBD) FUEL INJECTOR NO. 3 HIGH-SIDE CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

261

CONNECTOR PINOUTS

Page 685 of 2305

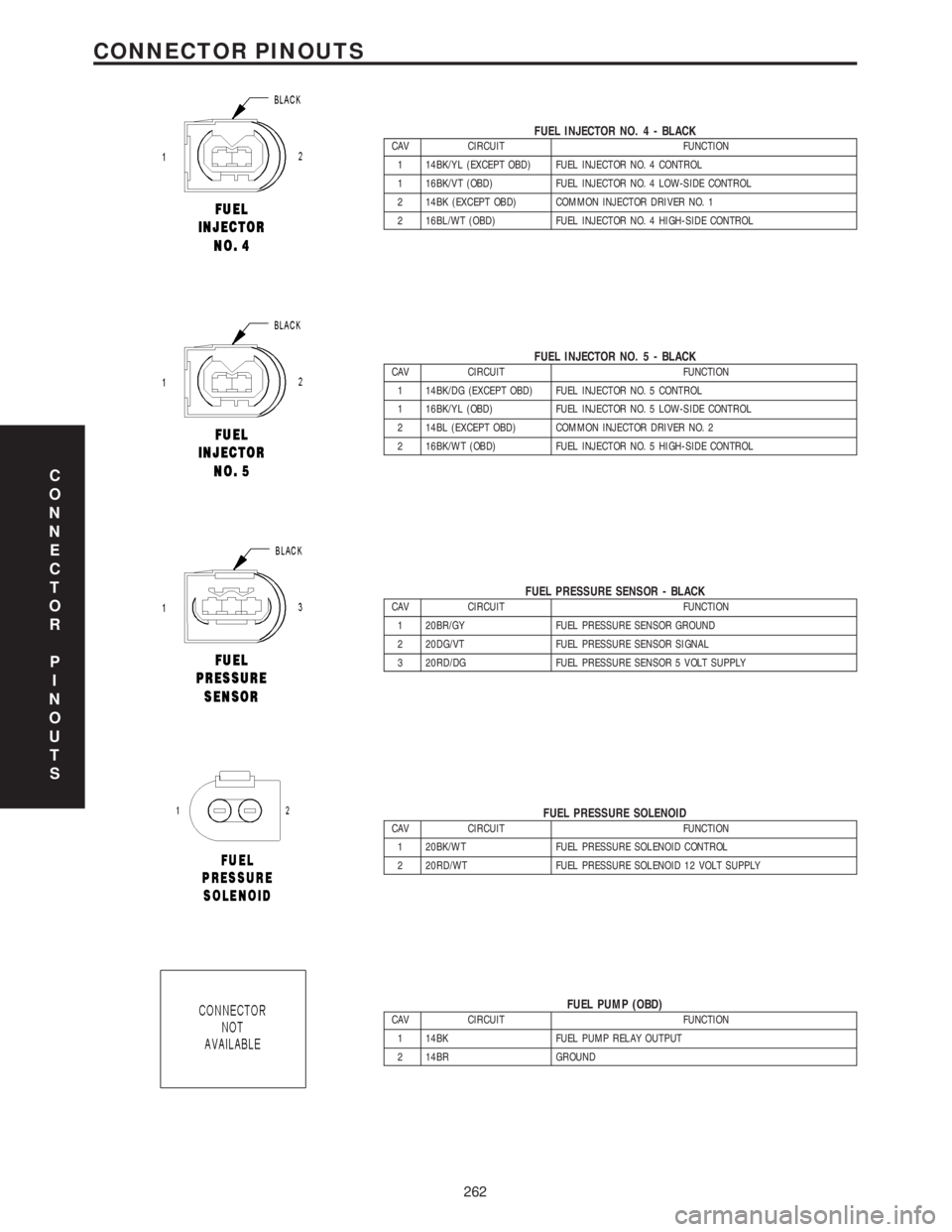

FUEL INJECTOR NO. 4 - BLACKCAV CIRCUIT FUNCTION

1 14BK/YL (EXCEPT OBD) FUEL INJECTOR NO. 4 CONTROL

1 16BK/VT (OBD) FUEL INJECTOR NO. 4 LOW-SIDE CONTROL

2 14BK (EXCEPT OBD) COMMON INJECTOR DRIVER NO. 1

2 16BL/WT (OBD) FUEL INJECTOR NO. 4 HIGH-SIDE CONTROL

FUEL INJECTOR NO. 5 - BLACKCAV CIRCUIT FUNCTION

1 14BK/DG (EXCEPT OBD) FUEL INJECTOR NO. 5 CONTROL

1 16BK/YL (OBD) FUEL INJECTOR NO. 5 LOW-SIDE CONTROL

2 14BL (EXCEPT OBD) COMMON INJECTOR DRIVER NO. 2

2 16BK/WT (OBD) FUEL INJECTOR NO. 5 HIGH-SIDE CONTROL

FUEL PRESSURE SENSOR - BLACKCAV CIRCUIT FUNCTION

1 20BR/GY FUEL PRESSURE SENSOR GROUND

2 20DG/VT FUEL PRESSURE SENSOR SIGNAL

3 20RD/DG FUEL PRESSURE SENSOR 5 VOLT SUPPLY

FUEL PRESSURE SOLENOIDCAV CIRCUIT FUNCTION

1 20BK/WT FUEL PRESSURE SOLENOID CONTROL

2 20RD/WT FUEL PRESSURE SOLENOID 12 VOLT SUPPLY

FUEL PUMP (OBD)CAV CIRCUIT FUNCTION

1 14BK FUEL PUMP RELAY OUTPUT

2 14BR GROUND

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

262

CONNECTOR PINOUTS

Page 686 of 2305

FUEL PUMP RELAY (OBD)CAV CIRCUIT FUNCTION

30 14RD/BK FUSED B(+)

85 18BR/RD FUEL PUMP RELAY CONTROL

86 18BK/RD FUSED ENGINE CONTROL RELAY OUTPUT

87 14BK FUEL PUMP RELAY OUTPUT

87A - -

FUEL QUANTITY CONTROL VALVE (OBD)CAV CIRCUIT FUNCTION

1 20BK/WT FUEL QUANTITY SOLENOID CONTROL

2 18RD/BK FUEL QUANTITY SOLENOID 12 VOLT SUPPLY

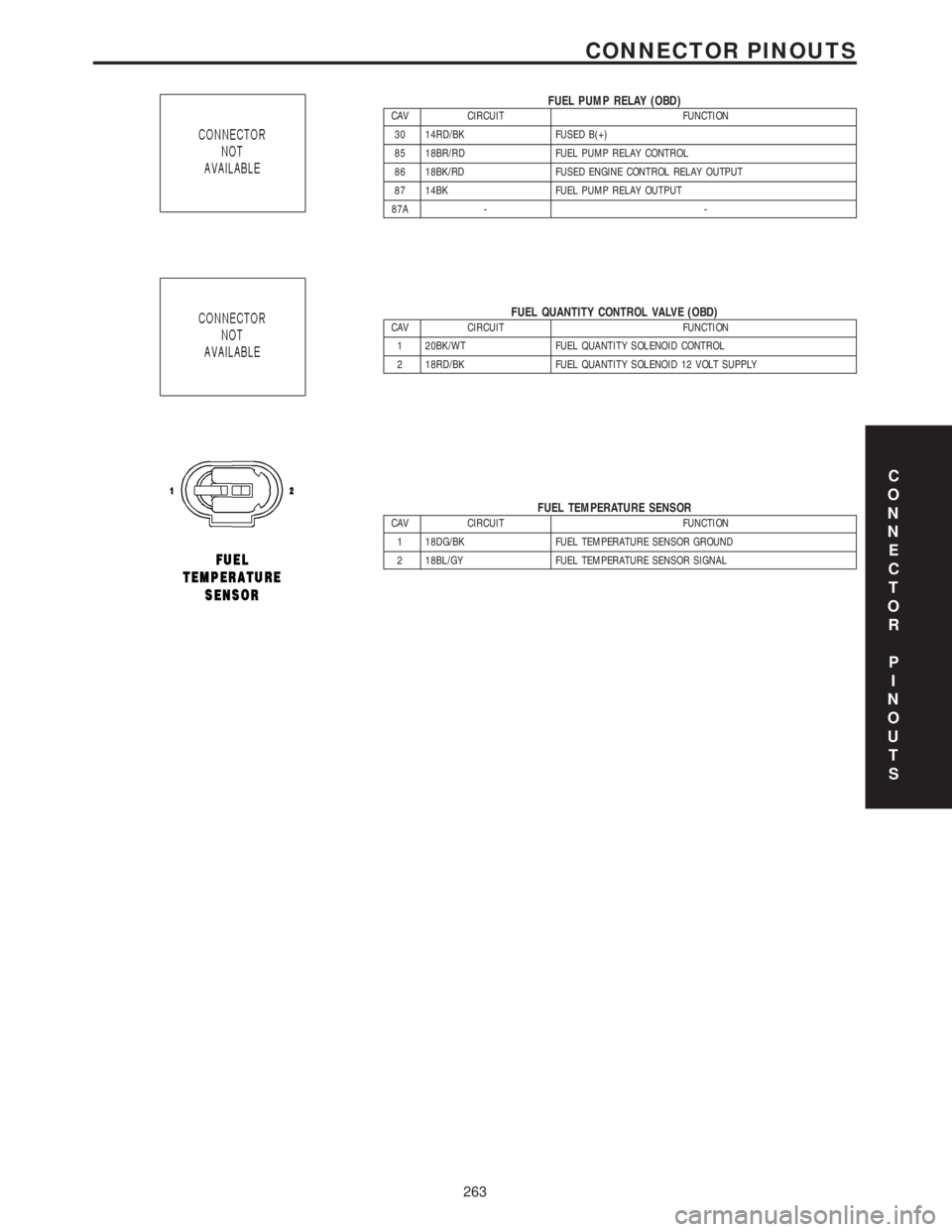

FUEL TEMPERATURE SENSORCAV CIRCUIT FUNCTION

1 18DG/BK FUEL TEMPERATURE SENSOR GROUND

2 18BL/GY FUEL TEMPERATURE SENSOR SIGNAL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

263

CONNECTOR PINOUTS

Page 696 of 2305

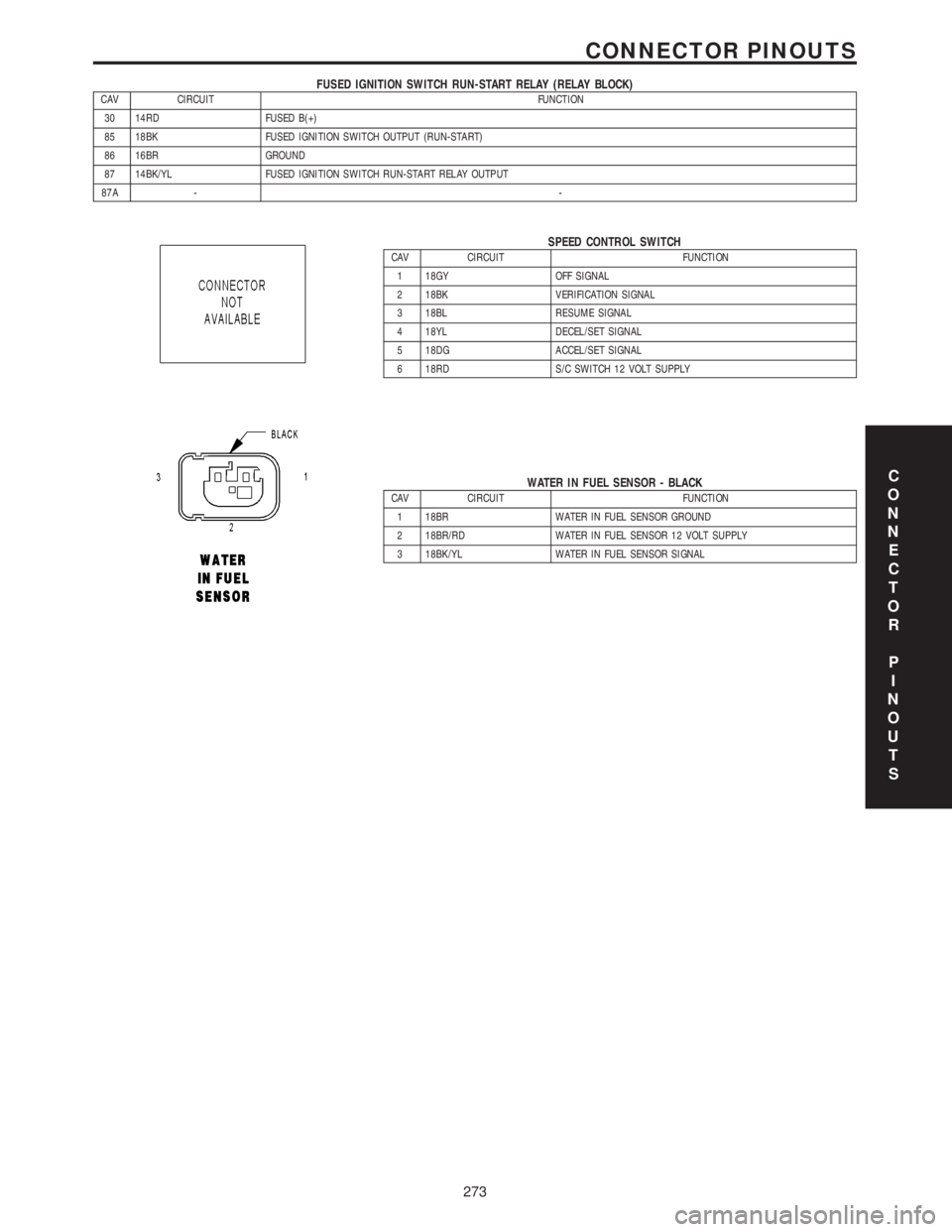

FUSED IGNITION SWITCH RUN-START RELAY (RELAY BLOCK)CAV CIRCUIT FUNCTION

30 14RD FUSED B(+)

85 18BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

86 16BR GROUND

87 14BK/YL FUSED IGNITION SWITCH RUN-START RELAY OUTPUT

87A --

SPEED CONTROL SWITCHCAV CIRCUIT FUNCTION

1 18GY OFF SIGNAL

2 18BK VERIFICATION SIGNAL

3 18BL RESUME SIGNAL

4 18YL DECEL/SET SIGNAL

5 18DG ACCEL/SET SIGNAL

6 18RD S/C SWITCH 12 VOLT SUPPLY

WATER IN FUEL SENSOR - BLACKCAV CIRCUIT FUNCTION

1 18BR WATER IN FUEL SENSOR GROUND

2 18BR/RD WATER IN FUEL SENSOR 12 VOLT SUPPLY

3 18BK/YL WATER IN FUEL SENSOR SIGNAL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

273

CONNECTOR PINOUTS

Page 704 of 2305

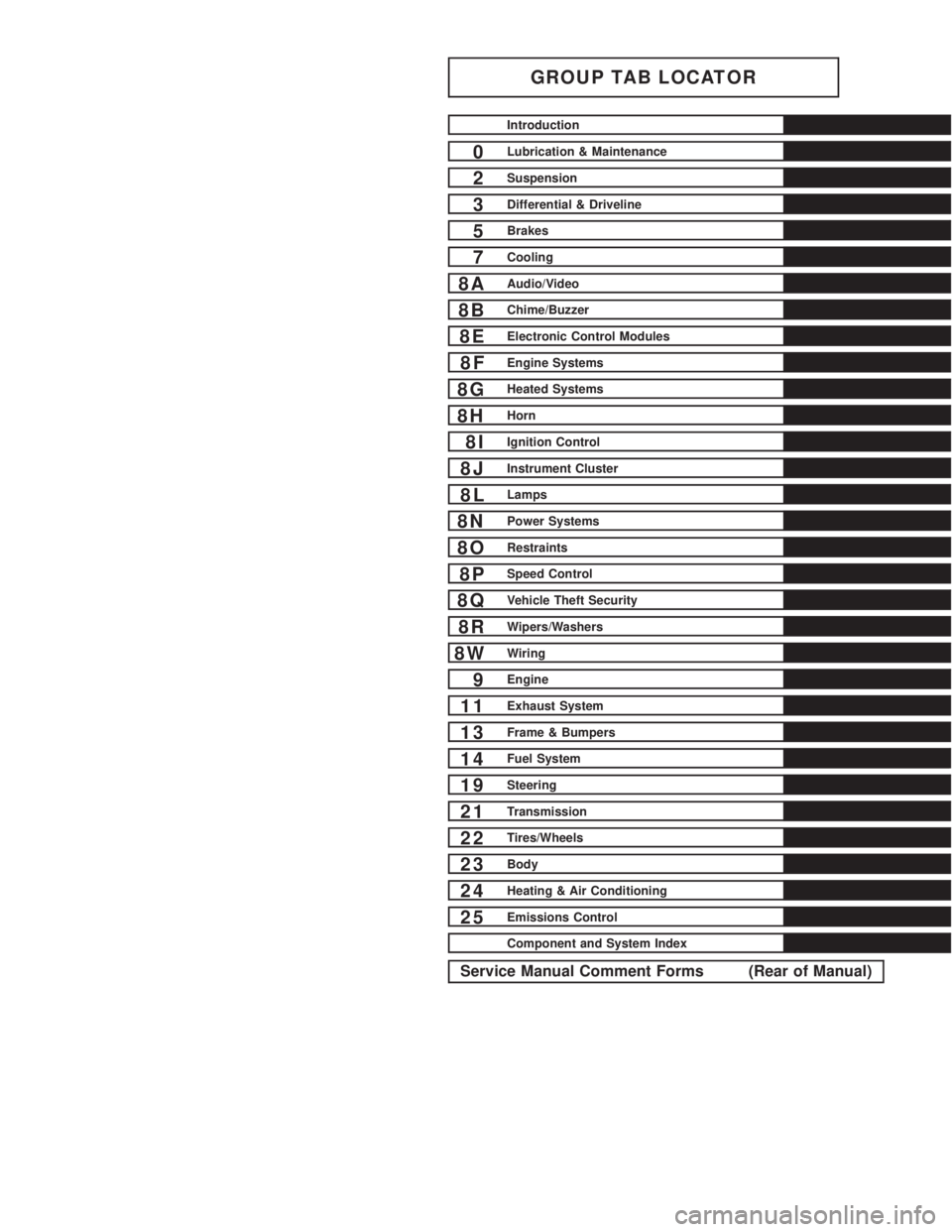

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 708 of 2305

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

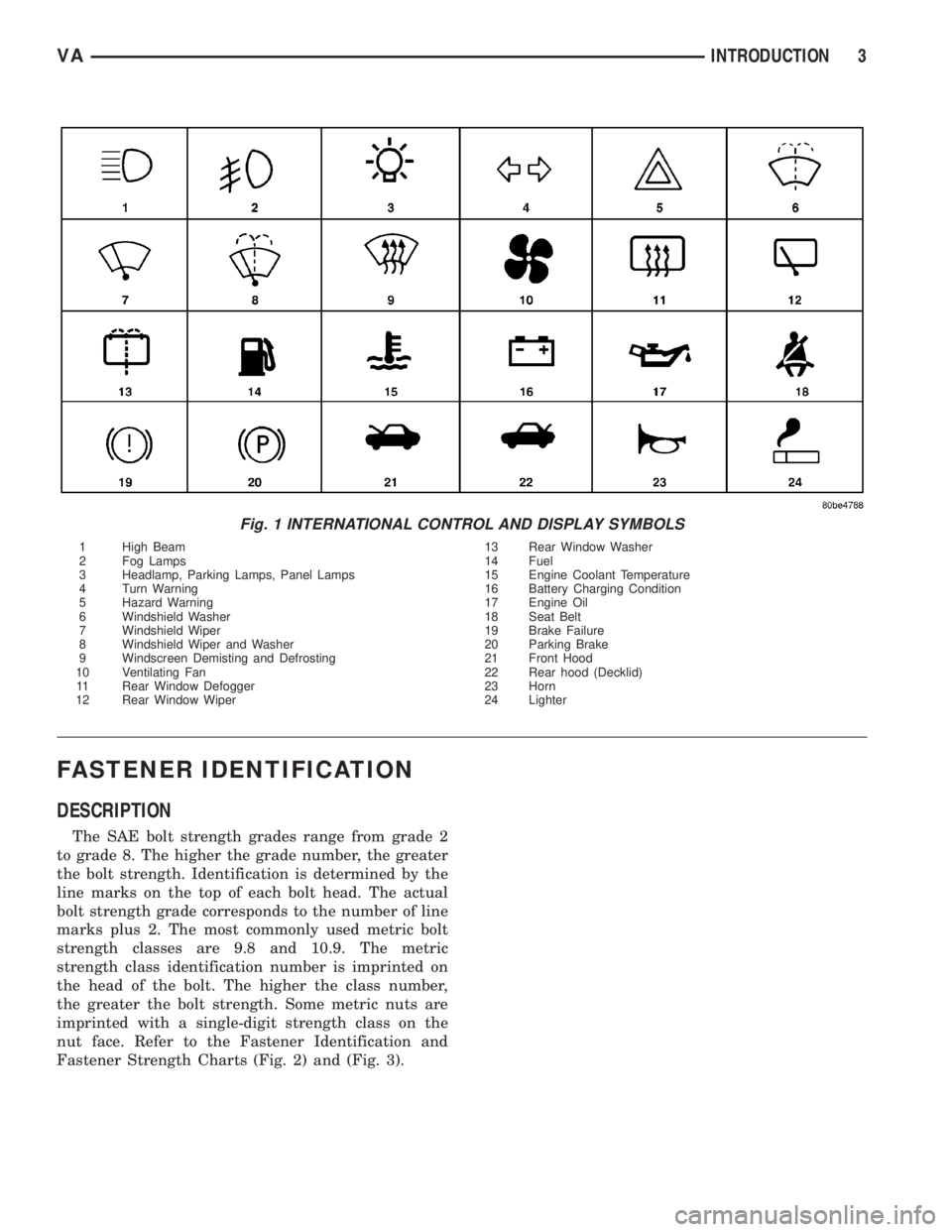

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

VAINTRODUCTION 3

Page 716 of 2305

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

FLUID TYPES

DESCRIPTION

PARTS AND LUBRICANT

RECOMMENDATIONS...................1

AUTOMATIC TRANSMISSION FLUID - NAG1 . 1

AXLE FLUID..........................2

BRAKE FLUID.........................2

HOAT COOLANT.......................2

ENGINE OIL - DIESEL ENGINES...........3

FUEL REQUIREMENTS - DIESEL ENGINE . . . 4

POWER STEERING FLUID...............5

OPERATION - AUTOMATIC TRANSMISSION

FLUID...............................5

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES.......5FLUID FILL/CHECK LOCATIONS

INSPECTION - FLUID FILL/CHECK

LOCATIONS..........................5

HOISTING

STANDARD PROCEDURE - HOISTING........5

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . . 6

TOWING

STANDARD PROCEDURE - TOWING.........7

MAINTENANCE SCHEDULES

DESCRIPTION..........................8

INTERNATIONAL SYMBOLS

DESCRIPTION..........................9

FLUID TYPES

DESCRIPTION

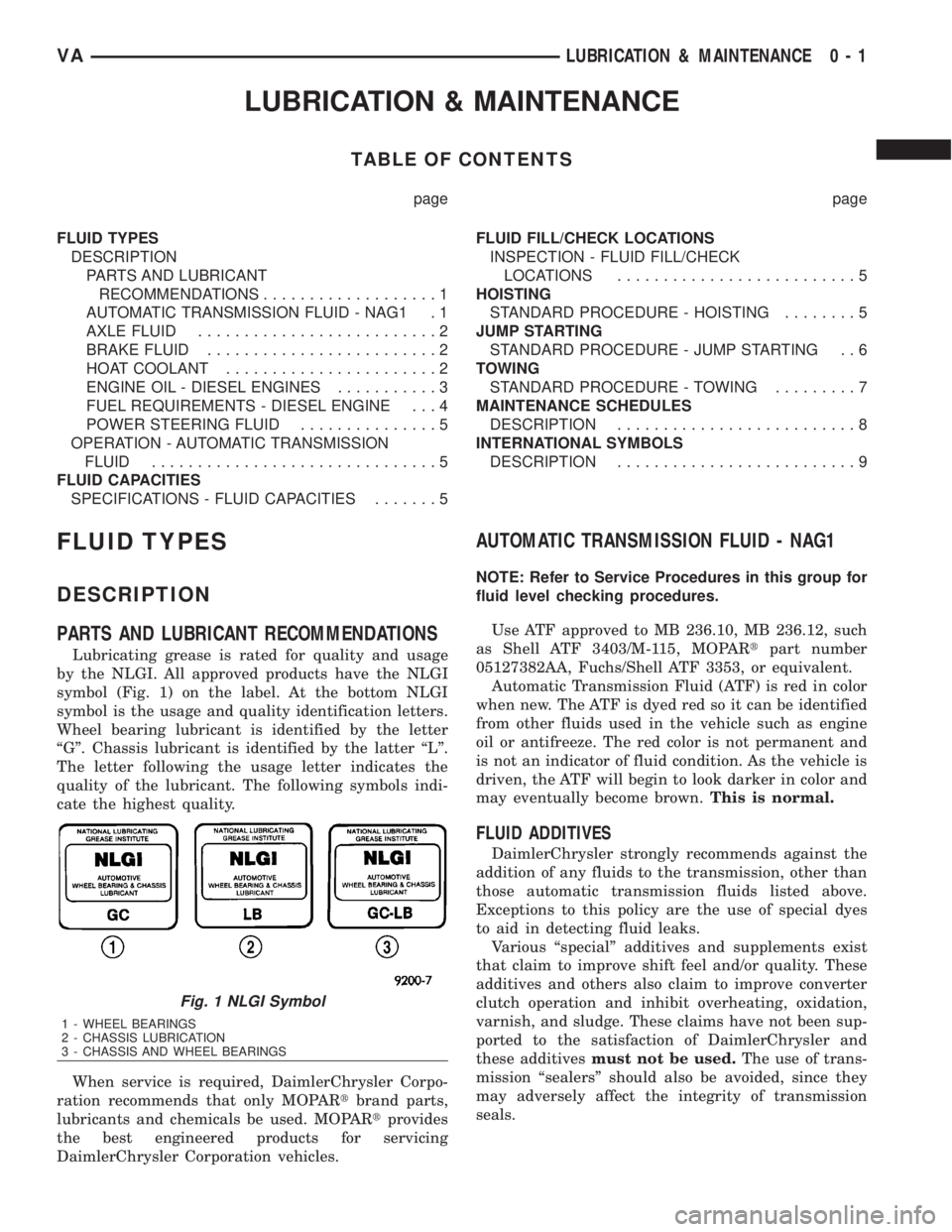

PARTS AND LUBRICANT RECOMMENDATIONS

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 1) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

When service is required, DaimlerChrysler Corpo-

ration recommends that only MOPARtbrand parts,

lubricants and chemicals be used. MOPARtprovides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

AUTOMATIC TRANSMISSION FLUID - NAG1

NOTE: Refer to Service Procedures in this group for

fluid level checking procedures.

Use ATF approved to MB 236.10, MB 236.12, such

as Shell ATF 3403/M-115, MOPARtpart number

05127382AA, Fuchs/Shell ATF 3353, or equivalent.

Automatic Transmission Fluid (ATF) is red in color

when new. The ATF is dyed red so it can be identified

from other fluids used in the vehicle such as engine

oil or antifreeze. The red color is not permanent and

is not an indicator of fluid condition. As the vehicle is

driven, the ATF will begin to look darker in color and

may eventually become brown.This is normal.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

Fig. 1 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

VALUBRICATION & MAINTENANCE 0 - 1

Page 719 of 2305

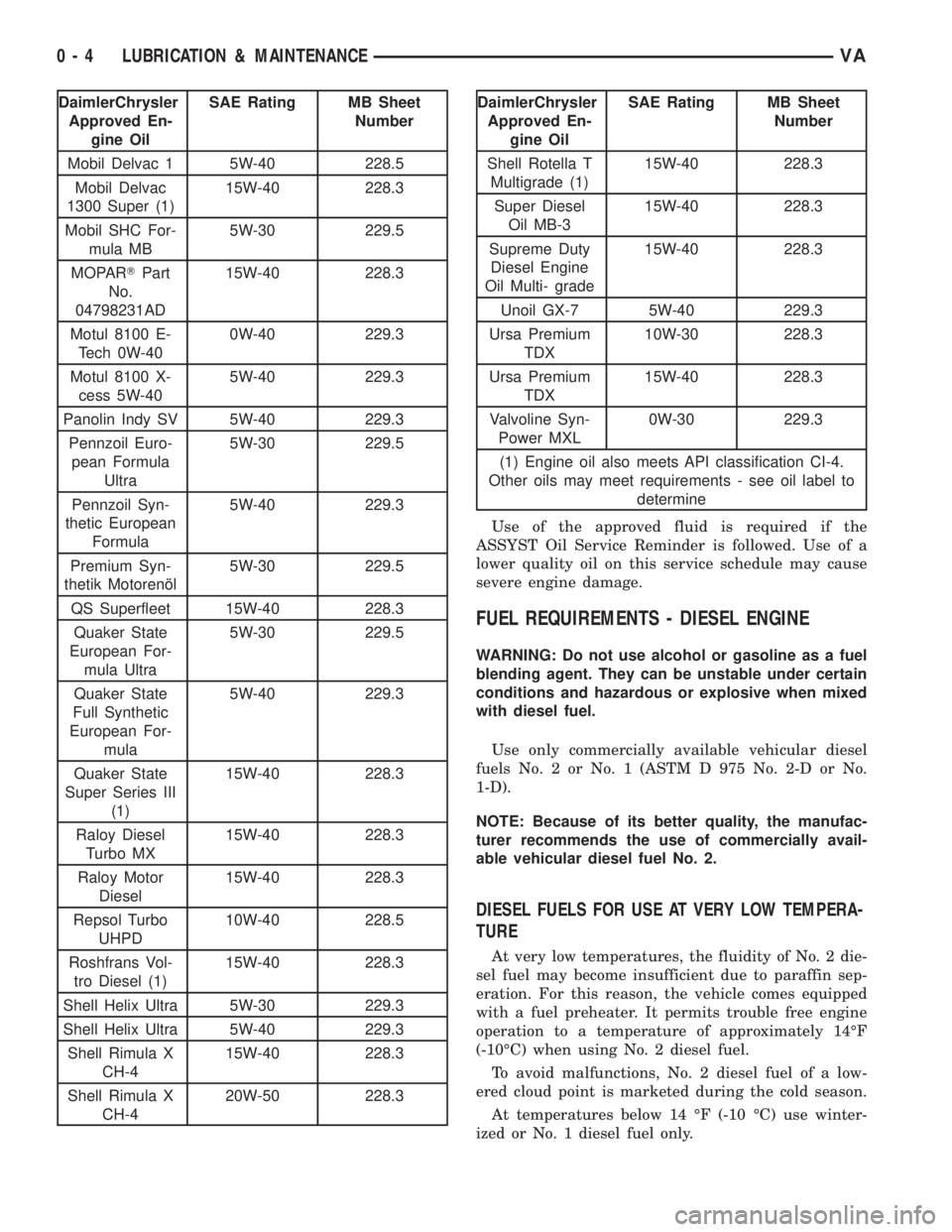

DaimlerChrysler

Approved En-

gine OilSAE Rating MB Sheet

Number

Mobil Delvac 1 5W-40 228.5

Mobil Delvac

1300 Super (1)15W-40 228.3

Mobil SHC For-

mula MB5W-30 229.5

MOPARTPart

No.

04798231AD15W-40 228.3

Motul 8100 E-

Tech 0W-400W-40 229.3

Motul 8100 X-

cess 5W-405W-40 229.3

Panolin Indy SV 5W-40 229.3

Pennzoil Euro-

pean Formula

Ultra5W-30 229.5

Pennzoil Syn-

thetic European

Formula5W-40 229.3

Premium Syn-

thetik Motorenæl5W-30 229.5

QS Superfleet 15W-40 228.3

Quaker State

European For-

mula Ultra5W-30 229.5

Quaker State

Full Synthetic

European For-

mula5W-40 229.3

Quaker State

Super Series III

(1)15W-40 228.3

Raloy Diesel

Turbo MX15W-40 228.3

Raloy Motor

Diesel15W-40 228.3

Repsol Turbo

UHPD10W-40 228.5

Roshfrans Vol-

tro Diesel (1)15W-40 228.3

Shell Helix Ultra 5W-30 229.3

Shell Helix Ultra 5W-40 229.3

Shell Rimula X

CH-415W-40 228.3

Shell Rimula X

CH-420W-50 228.3DaimlerChrysler

Approved En-

gine OilSAE Rating MB Sheet

Number

Shell Rotella T

Multigrade (1)15W-40 228.3

Super Diesel

Oil MB-315W-40 228.3

Supreme Duty

Diesel Engine

Oil Multi- grade15W-40 228.3

Unoil GX-7 5W-40 229.3

Ursa Premium

TDX10W-30 228.3

Ursa Premium

TDX15W-40 228.3

Valvoline Syn-

Power MXL0W-30 229.3

(1) Engine oil also meets API classification CI-4.

Other oils may meet requirements - see oil label to

determine

Use of the approved fluid is required if the

ASSYST Oil Service Reminder is followed. Use of a

lower quality oil on this service schedule may cause

severe engine damage.

FUEL REQUIREMENTS - DIESEL ENGINE

WARNING: Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed

with diesel fuel.

Use only commercially available vehicular diesel

fuels No. 2 or No. 1 (ASTM D 975 No. 2-D or No.

1-D).

NOTE: Because of its better quality, the manufac-

turer recommends the use of commercially avail-

able vehicular diesel fuel No. 2.

DIESEL FUELS FOR USE AT VERY LOW TEMPERA-

TURE

At very low temperatures, the fluidity of No. 2 die-

sel fuel may become insufficient due to paraffin sep-

eration. For this reason, the vehicle comes equipped

with a fuel preheater. It permits trouble free engine

operation to a temperature of approximately 14ÉF

(-10ÉC) when using No. 2 diesel fuel.

To avoid malfunctions, No. 2 diesel fuel of a low-

ered cloud point is marketed during the cold season.

At temperatures below 14 ÉF (-10 ÉC) use winter-

ized or No. 1 diesel fuel only.

0 - 4 LUBRICATION & MAINTENANCEVA

Page 720 of 2305

Do not blend other specific fuel additives with die-

sel fuel. They only result in unnecessary cost, and

may be harmful to the engine operation.

POWER STEERING FLUID

No fluid service required. Filled with Power Steer-

ing Fluid approved to MB 236.3, such as Mobil

ATF-D (Exxon Mobil Corporation) or equivalent.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

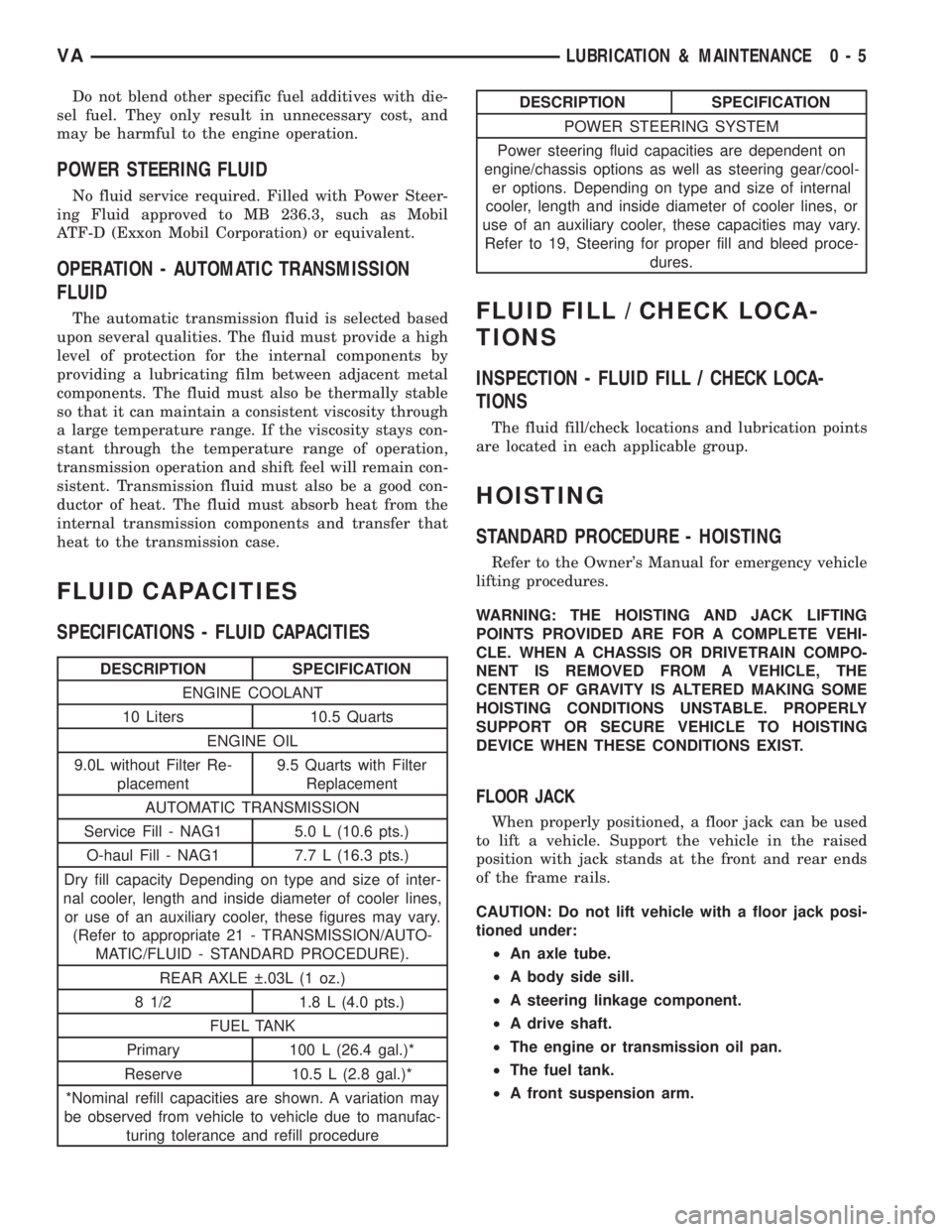

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

ENGINE COOLANT

10 Liters 10.5 Quarts

ENGINE OIL

9.0L without Filter Re-

placement9.5 Quarts with Filter

Replacement

AUTOMATIC TRANSMISSION

Service Fill - NAG1 5.0 L (10.6 pts.)

O-haul Fill - NAG1 7.7 L (16.3 pts.)

Dry fill capacity Depending on type and size of inter-

nal cooler, length and inside diameter of cooler lines,

or use of an auxiliary cooler, these figures may vary.

(Refer to appropriate 21 - TRANSMISSION/AUTO-

MATIC/FLUID - STANDARD PROCEDURE).

REAR AXLE .03L (1 oz.)

8 1/2 1.8 L (4.0 pts.)

FUEL TANK

Primary 100 L (26.4 gal.)*

Reserve 10.5 L (2.8 gal.)*

*Nominal refill capacities are shown. A variation may

be observed from vehicle to vehicle due to manufac-

turing tolerance and refill procedure

DESCRIPTION SPECIFICATION

POWER STEERING SYSTEM

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cool-

er options. Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these capacities may vary.

Refer to 19, Steering for proper fill and bleed proce-

dures.

FLUID FILL / CHECK LOCA-

TIONS

INSPECTION - FLUID FILL / CHECK LOCA-

TIONS

The fluid fill/check locations and lubrication points

are located in each applicable group.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a vehicle. Support the vehicle in the raised

position with jack stands at the front and rear ends

of the frame rails.

CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

²An axle tube.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

VALUBRICATION & MAINTENANCE 0 - 5