fuel MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 489 of 2305

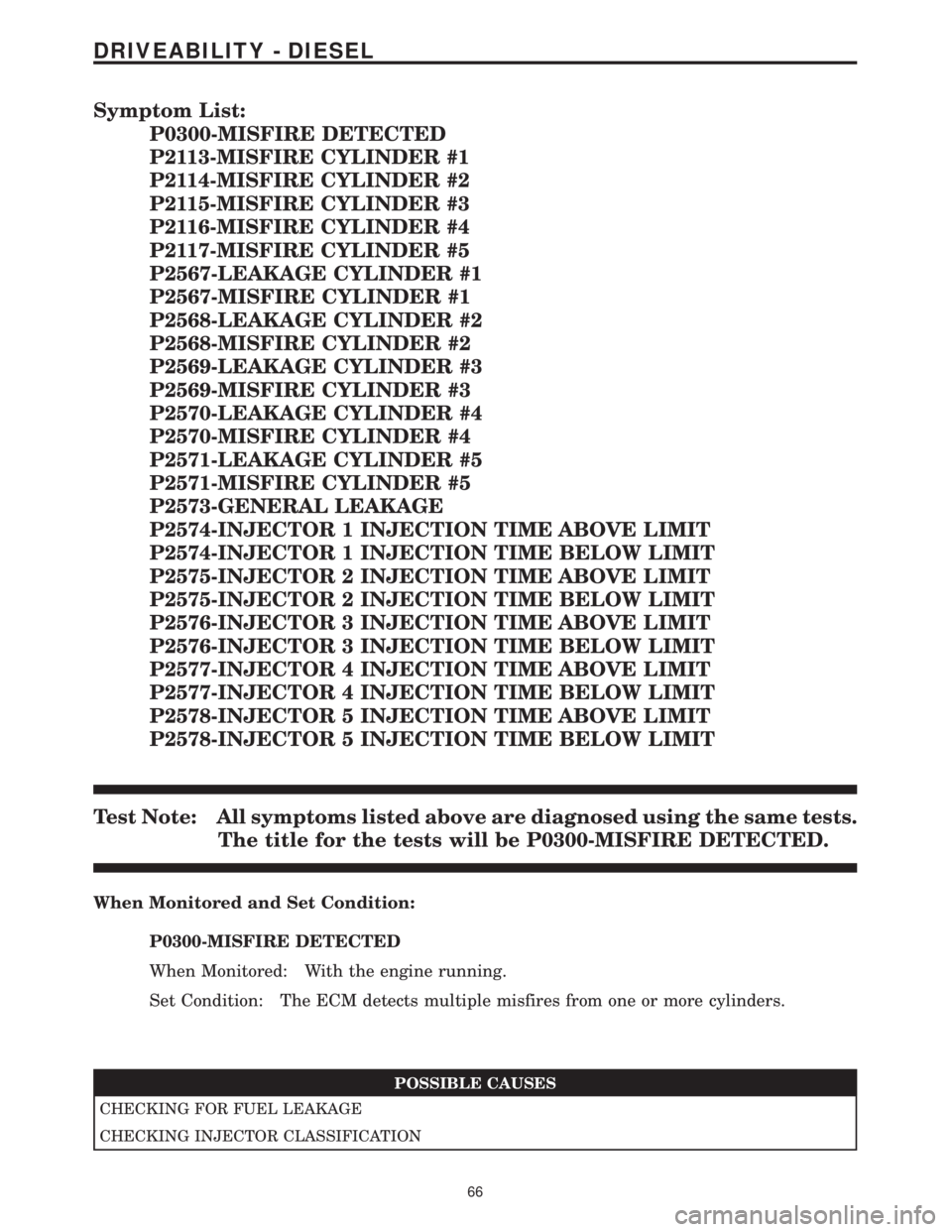

Symptom List:

P0300-MISFIRE DETECTED

P2113-MISFIRE CYLINDER #1

P2114-MISFIRE CYLINDER #2

P2115-MISFIRE CYLINDER #3

P2116-MISFIRE CYLINDER #4

P2117-MISFIRE CYLINDER #5

P2567-LEAKAGE CYLINDER #1

P2567-MISFIRE CYLINDER #1

P2568-LEAKAGE CYLINDER #2

P2568-MISFIRE CYLINDER #2

P2569-LEAKAGE CYLINDER #3

P2569-MISFIRE CYLINDER #3

P2570-LEAKAGE CYLINDER #4

P2570-MISFIRE CYLINDER #4

P2571-LEAKAGE CYLINDER #5

P2571-MISFIRE CYLINDER #5

P2573-GENERAL LEAKAGE

P2574-INJECTOR 1 INJECTION TIME ABOVE LIMIT

P2574-INJECTOR 1 INJECTION TIME BELOW LIMIT

P2575-INJECTOR 2 INJECTION TIME ABOVE LIMIT

P2575-INJECTOR 2 INJECTION TIME BELOW LIMIT

P2576-INJECTOR 3 INJECTION TIME ABOVE LIMIT

P2576-INJECTOR 3 INJECTION TIME BELOW LIMIT

P2577-INJECTOR 4 INJECTION TIME ABOVE LIMIT

P2577-INJECTOR 4 INJECTION TIME BELOW LIMIT

P2578-INJECTOR 5 INJECTION TIME ABOVE LIMIT

P2578-INJECTOR 5 INJECTION TIME BELOW LIMIT

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0300-MISFIRE DETECTED.

When Monitored and Set Condition:

P0300-MISFIRE DETECTED

When Monitored: With the engine running.

Set Condition: The ECM detects multiple misfires from one or more cylinders.

POSSIBLE CAUSES

CHECKING FOR FUEL LEAKAGE

CHECKING INJECTOR CLASSIFICATION

66

DRIVEABILITY - DIESEL

Page 490 of 2305

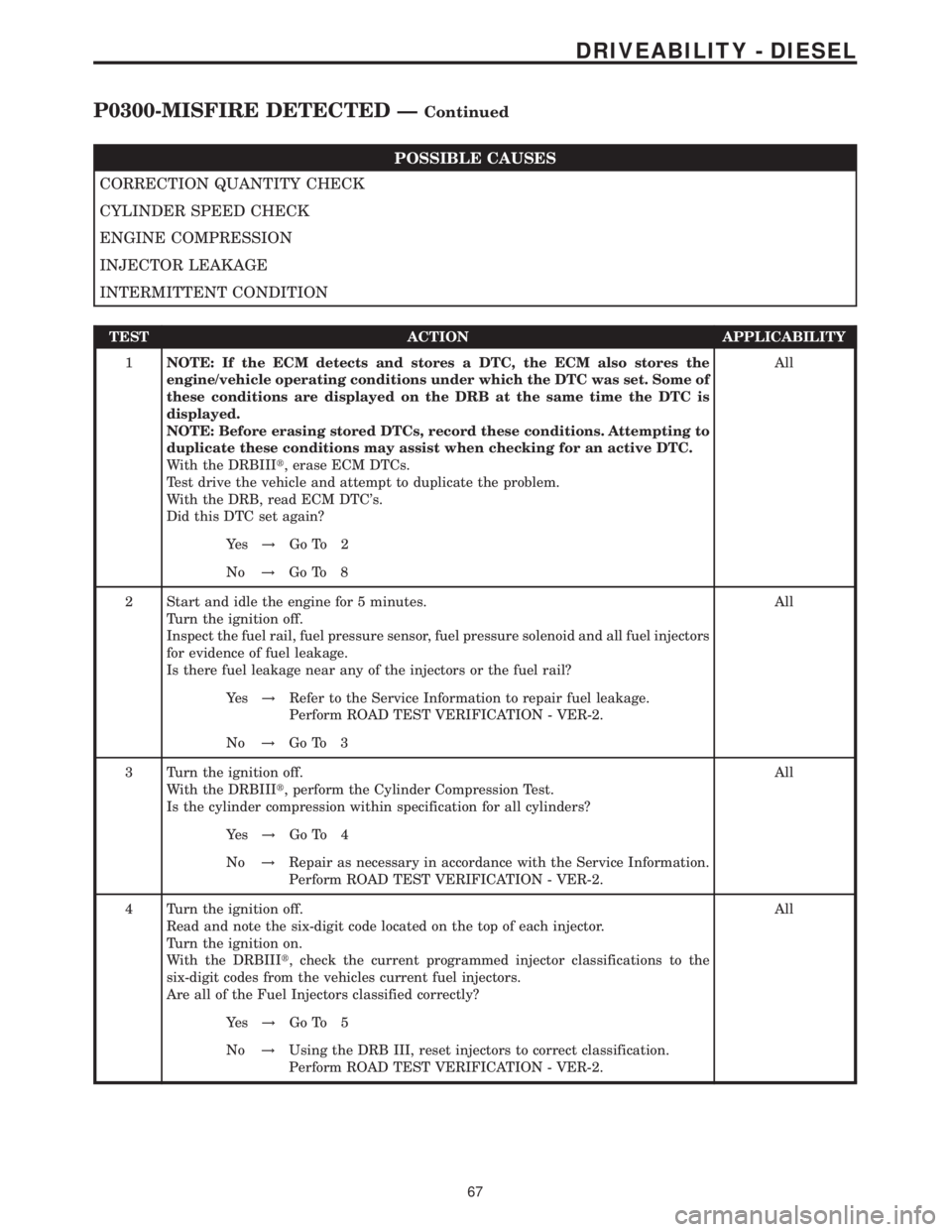

POSSIBLE CAUSES

CORRECTION QUANTITY CHECK

CYLINDER SPEED CHECK

ENGINE COMPRESSION

INJECTOR LEAKAGE

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1NOTE: If the ECM detects and stores a DTC, the ECM also stores the

engine/vehicle operating conditions under which the DTC was set. Some of

these conditions are displayed on the DRB at the same time the DTC is

displayed.

NOTE: Before erasing stored DTCs, record these conditions. Attempting to

duplicate these conditions may assist when checking for an active DTC.

With the DRBIIIt, erase ECM DTCs.

Test drive the vehicle and attempt to duplicate the problem.

With the DRB, read ECM DTC's.

Did this DTC set again?All

Ye s!Go To 2

No!Go To 8

2 Start and idle the engine for 5 minutes.

Turn the ignition off.

Inspect the fuel rail, fuel pressure sensor, fuel pressure solenoid and all fuel injectors

for evidence of fuel leakage.

Is there fuel leakage near any of the injectors or the fuel rail?All

Ye s!Refer to the Service Information to repair fuel leakage.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 3

3 Turn the ignition off.

With the DRBIIIt, perform the Cylinder Compression Test.

Is the cylinder compression within specification for all cylinders?All

Ye s!Go To 4

No!Repair as necessary in accordance with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Read and note the six-digit code located on the top of each injector.

Turn the ignition on.

With the DRBIIIt, check the current programmed injector classifications to the

six-digit codes from the vehicles current fuel injectors.

Are all of the Fuel Injectors classified correctly?All

Ye s!Go To 5

No!Using the DRB III, reset injectors to correct classification.

Perform ROAD TEST VERIFICATION - VER-2.

67

DRIVEABILITY - DIESEL

P0300-MISFIRE DETECTED ÐContinued

Page 491 of 2305

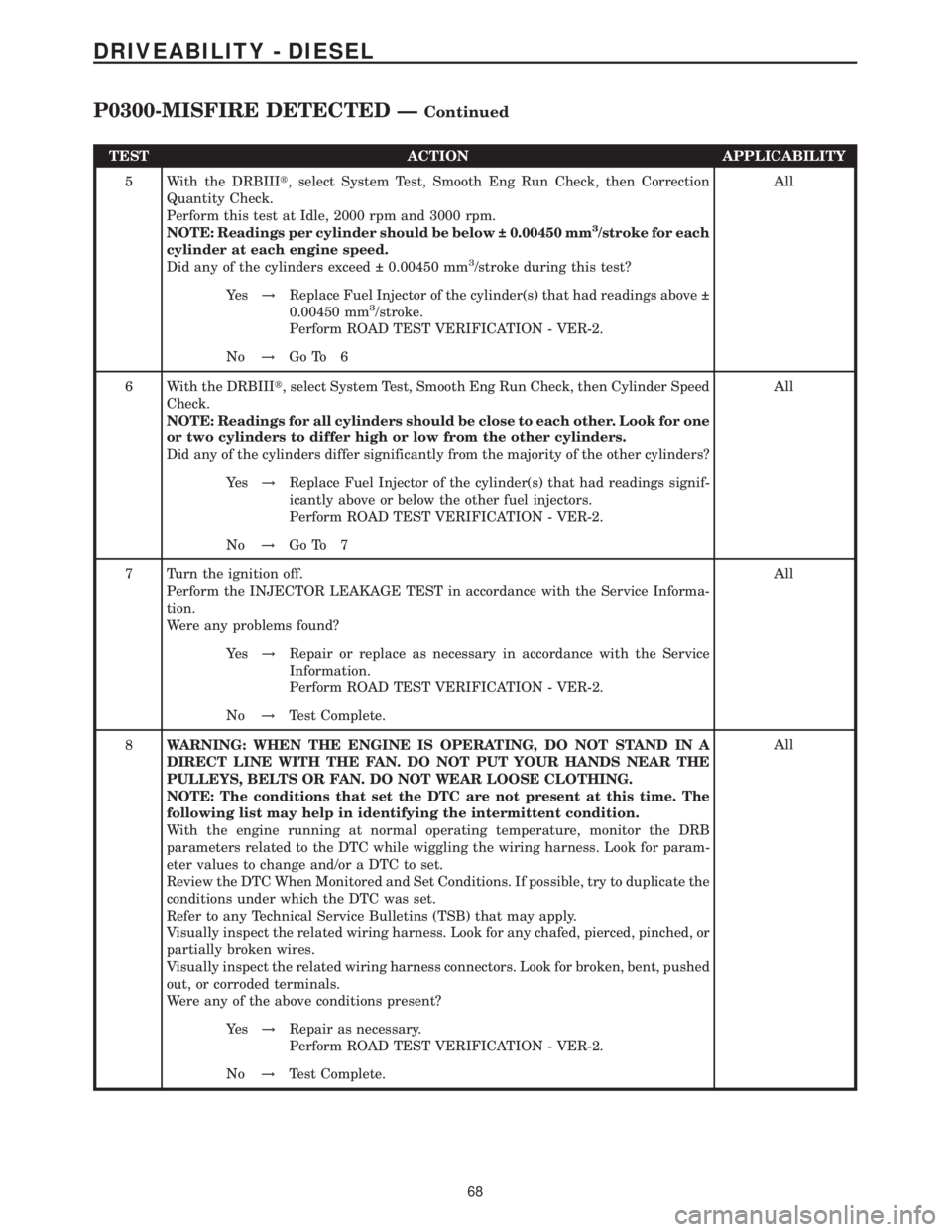

TEST ACTION APPLICABILITY

5 With the DRBIIIt, select System Test, Smooth Eng Run Check, then Correction

Quantity Check.

Perform this test at Idle, 2000 rpm and 3000 rpm.

NOTE: Readings per cylinder should be below 0.00450 mm

3/stroke for each

cylinder at each engine speed.

Did any of the cylinders exceed 0.00450 mm

3/stroke during this test?All

Ye s!Replace Fuel Injector of the cylinder(s) that had readings above

0.00450 mm

3/stroke.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 6

6 With the DRBIIIt, select System Test, Smooth Eng Run Check, then Cylinder Speed

Check.

NOTE: Readings for all cylinders should be close to each other. Look for one

or two cylinders to differ high or low from the other cylinders.

Did any of the cylinders differ significantly from the majority of the other cylinders?All

Ye s!Replace Fuel Injector of the cylinder(s) that had readings signif-

icantly above or below the other fuel injectors.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 7

7 Turn the ignition off.

Perform the INJECTOR LEAKAGE TEST in accordance with the Service Informa-

tion.

Were any problems found?All

Ye s!Repair or replace as necessary in accordance with the Service

Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Test Complete.

8WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s!Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No!Test Complete.

68

DRIVEABILITY - DIESEL

P0300-MISFIRE DETECTED ÐContinued

Page 529 of 2305

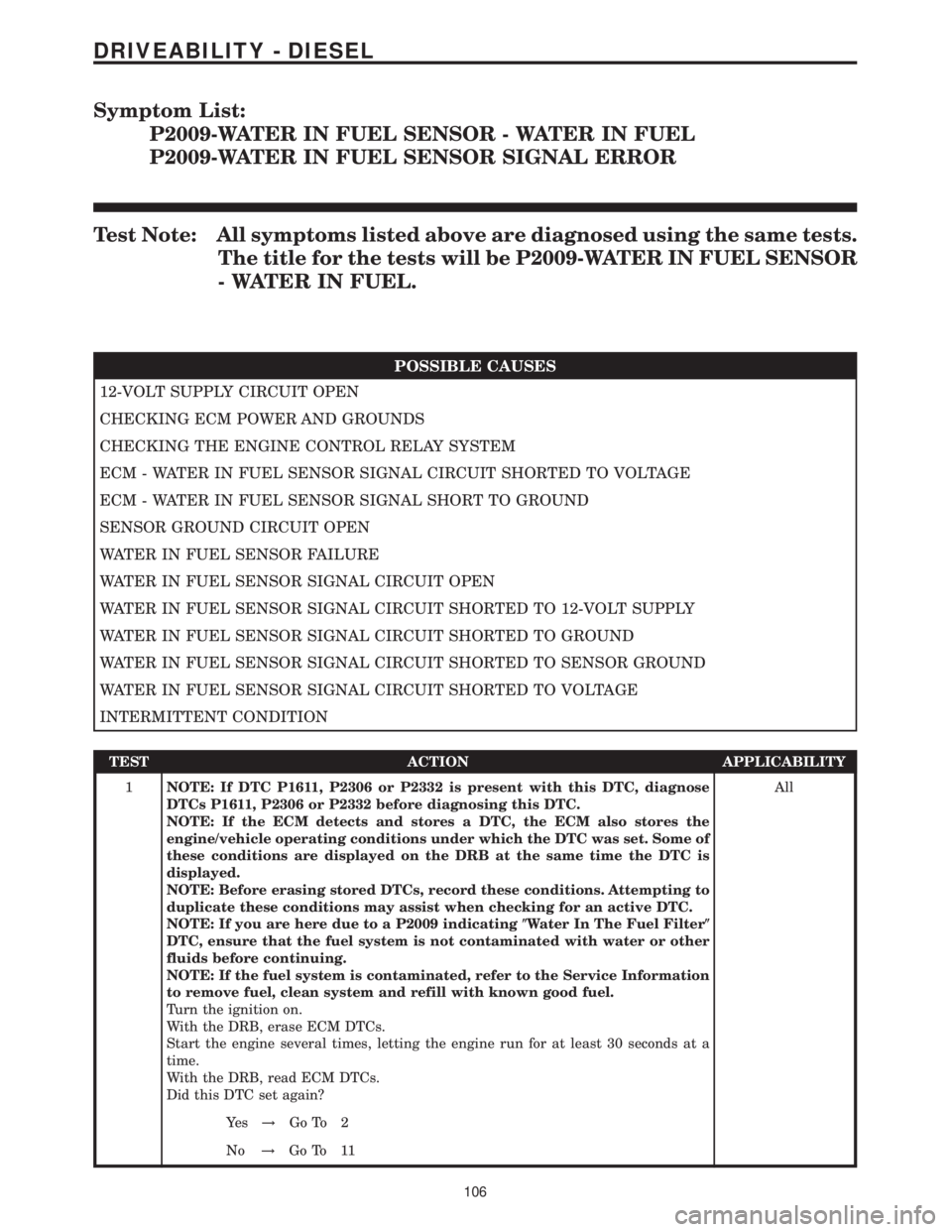

Symptom List:

P2009-WATER IN FUEL SENSOR - WATER IN FUEL

P2009-WATER IN FUEL SENSOR SIGNAL ERROR

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P2009-WATER IN FUEL SENSOR

- WATER IN FUEL.

POSSIBLE CAUSES

12-VOLT SUPPLY CIRCUIT OPEN

CHECKING ECM POWER AND GROUNDS

CHECKING THE ENGINE CONTROL RELAY SYSTEM

ECM - WATER IN FUEL SENSOR SIGNAL CIRCUIT SHORTED TO VOLTAGE

ECM - WATER IN FUEL SENSOR SIGNAL SHORT TO GROUND

SENSOR GROUND CIRCUIT OPEN

WATER IN FUEL SENSOR FAILURE

WATER IN FUEL SENSOR SIGNAL CIRCUIT OPEN

WATER IN FUEL SENSOR SIGNAL CIRCUIT SHORTED TO 12-VOLT SUPPLY

WATER IN FUEL SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

WATER IN FUEL SENSOR SIGNAL CIRCUIT SHORTED TO SENSOR GROUND

WATER IN FUEL SENSOR SIGNAL CIRCUIT SHORTED TO VOLTAGE

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1NOTE: If DTC P1611, P2306 or P2332 is present with this DTC, diagnose

DTCs P1611, P2306 or P2332 before diagnosing this DTC.

NOTE: If the ECM detects and stores a DTC, the ECM also stores the

engine/vehicle operating conditions under which the DTC was set. Some of

these conditions are displayed on the DRB at the same time the DTC is

displayed.

NOTE: Before erasing stored DTCs, record these conditions. Attempting to

duplicate these conditions may assist when checking for an active DTC.

NOTE: If you are here due to a P2009 indicating(Water In The Fuel Filter(

DTC, ensure that the fuel system is not contaminated with water or other

fluids before continuing.

NOTE: If the fuel system is contaminated, refer to the Service Information

to remove fuel, clean system and refill with known good fuel.

Turn the ignition on.

With the DRB, erase ECM DTCs.

Start the engine several times, letting the engine run for at least 30 seconds at a

time.

With the DRB, read ECM DTCs.

Did this DTC set again?All

Ye s!Go To 2

No!Go To 11

106

DRIVEABILITY - DIESEL

Page 530 of 2305

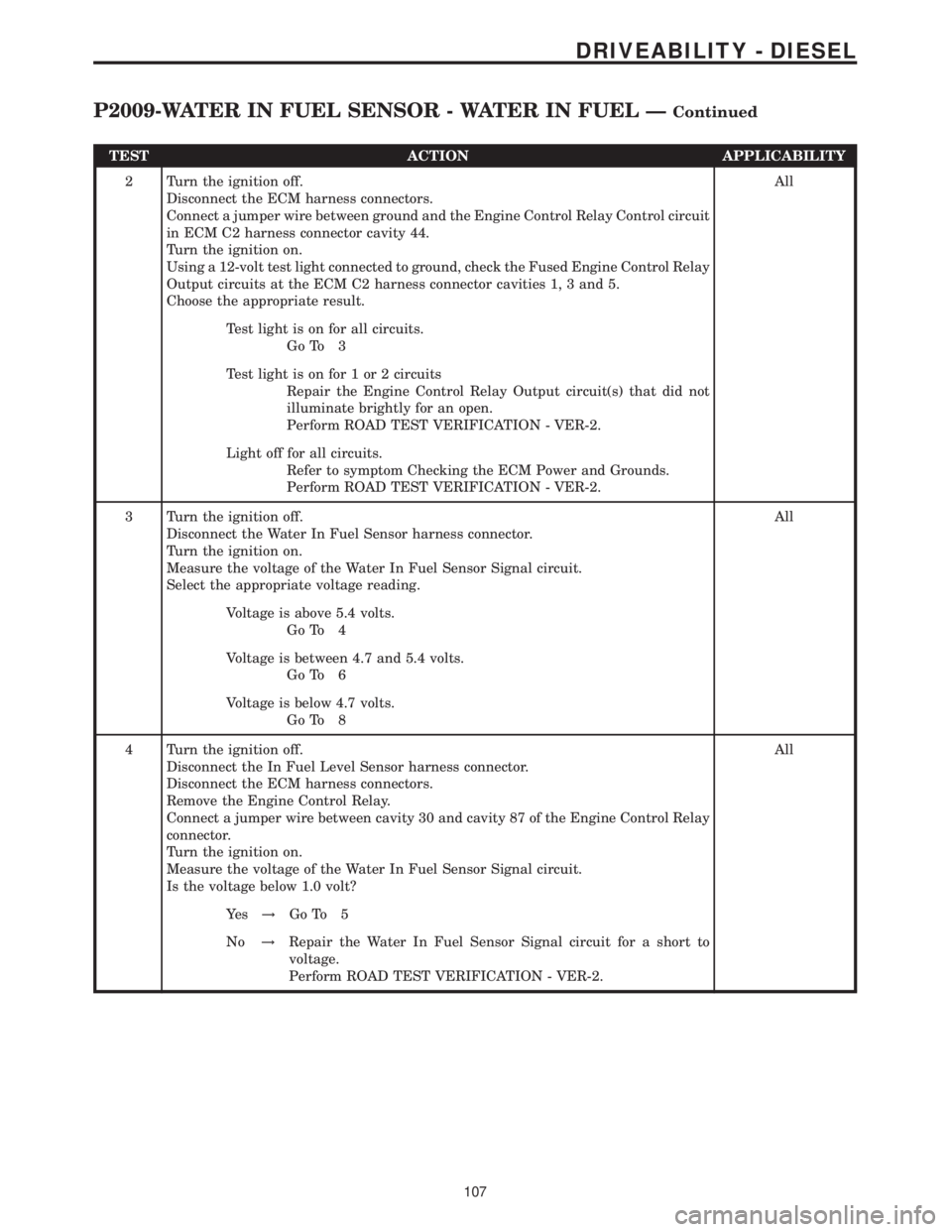

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Connect a jumper wire between ground and the Engine Control Relay Control circuit

in ECM C2 harness connector cavity 44.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Engine Control Relay

Output circuits at the ECM C2 harness connector cavities 1, 3 and 5.

Choose the appropriate result.All

Test light is on for all circuits.

Go To 3

Test light is on for 1 or 2 circuits

Repair the Engine Control Relay Output circuit(s) that did not

illuminate brightly for an open.

Perform ROAD TEST VERIFICATION - VER-2.

Light off for all circuits.

Refer to symptom Checking the ECM Power and Grounds.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the Water In Fuel Sensor harness connector.

Turn the ignition on.

Measure the voltage of the Water In Fuel Sensor Signal circuit.

Select the appropriate voltage reading.All

Voltage is above 5.4 volts.

Go To 4

Voltage is between 4.7 and 5.4 volts.

Go To 6

Voltage is below 4.7 volts.

Go To 8

4 Turn the ignition off.

Disconnect the In Fuel Level Sensor harness connector.

Disconnect the ECM harness connectors.

Remove the Engine Control Relay.

Connect a jumper wire between cavity 30 and cavity 87 of the Engine Control Relay

connector.

Turn the ignition on.

Measure the voltage of the Water In Fuel Sensor Signal circuit.

Is the voltage below 1.0 volt?All

Ye s!Go To 5

No!Repair the Water In Fuel Sensor Signal circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

107

DRIVEABILITY - DIESEL

P2009-WATER IN FUEL SENSOR - WATER IN FUEL ÐContinued

Page 531 of 2305

TEST ACTION APPLICABILITY

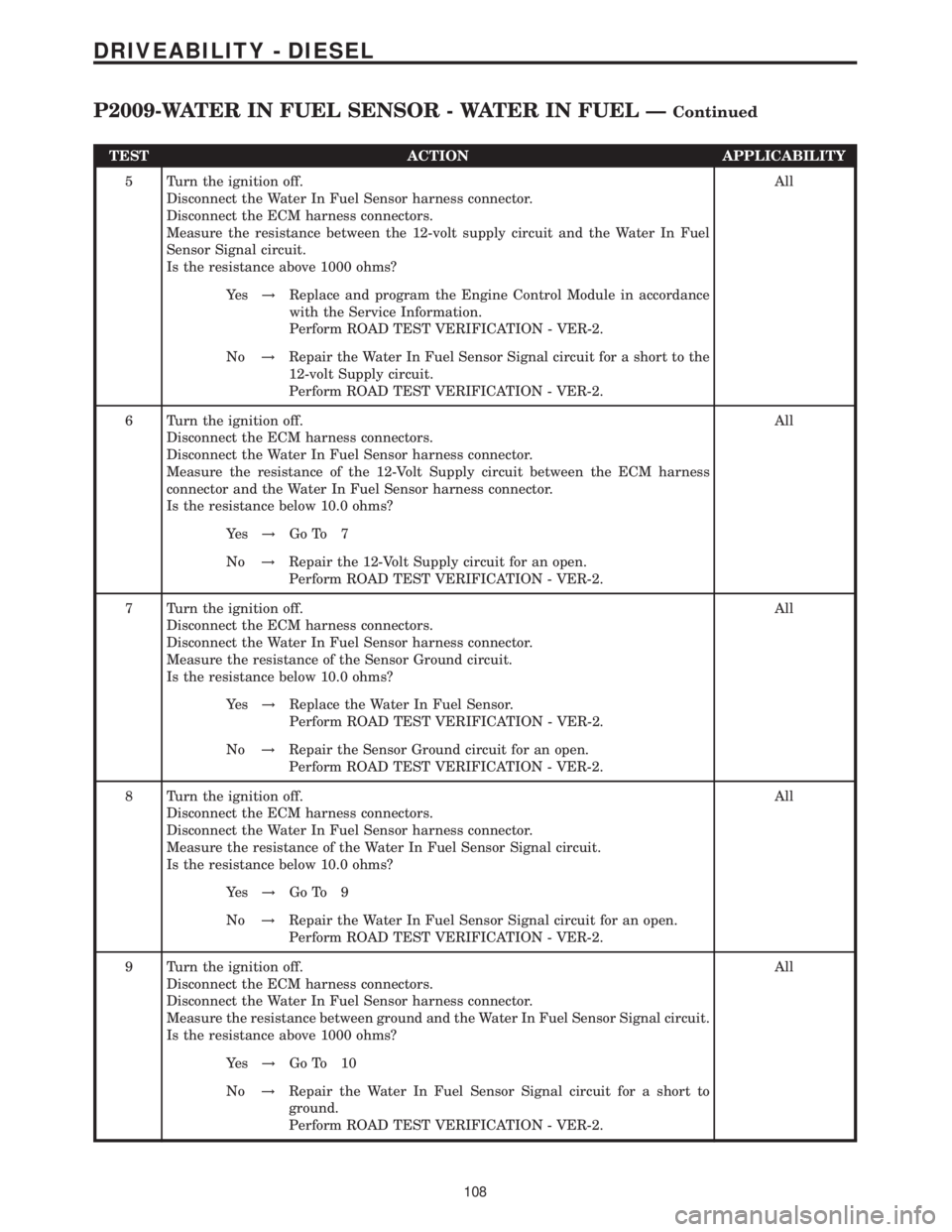

5 Turn the ignition off.

Disconnect the Water In Fuel Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between the 12-volt supply circuit and the Water In Fuel

Sensor Signal circuit.

Is the resistance above 1000 ohms?All

Ye s!Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Water In Fuel Sensor Signal circuit for a short to the

12-volt Supply circuit.

Perform ROAD TEST VERIFICATION - VER-2.

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Water In Fuel Sensor harness connector.

Measure the resistance of the 12-Volt Supply circuit between the ECM harness

connector and the Water In Fuel Sensor harness connector.

Is the resistance below 10.0 ohms?All

Ye s!Go To 7

No!Repair the 12-Volt Supply circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

7 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Water In Fuel Sensor harness connector.

Measure the resistance of the Sensor Ground circuit.

Is the resistance below 10.0 ohms?All

Ye s!Replace the Water In Fuel Sensor.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Sensor Ground circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

8 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Water In Fuel Sensor harness connector.

Measure the resistance of the Water In Fuel Sensor Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s!Go To 9

No!Repair the Water In Fuel Sensor Signal circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

9 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Water In Fuel Sensor harness connector.

Measure the resistance between ground and the Water In Fuel Sensor Signal circuit.

Is the resistance above 1000 ohms?All

Ye s!Go To 10

No!Repair the Water In Fuel Sensor Signal circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

108

DRIVEABILITY - DIESEL

P2009-WATER IN FUEL SENSOR - WATER IN FUEL ÐContinued

Page 532 of 2305

TEST ACTION APPLICABILITY

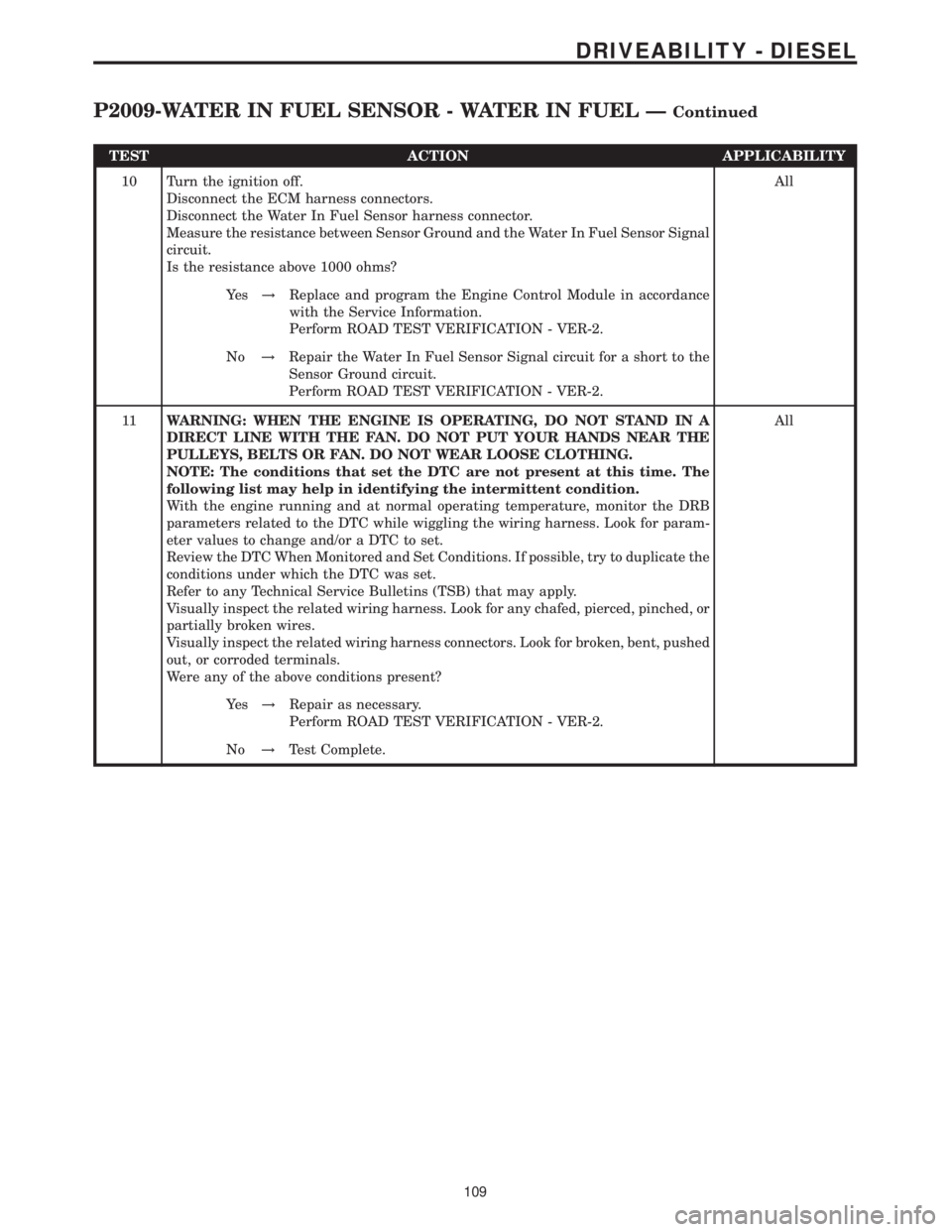

10 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Water In Fuel Sensor harness connector.

Measure the resistance between Sensor Ground and the Water In Fuel Sensor Signal

circuit.

Is the resistance above 1000 ohms?All

Ye s!Replace and program the Engine Control Module in accordance

with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Repair the Water In Fuel Sensor Signal circuit for a short to the

Sensor Ground circuit.

Perform ROAD TEST VERIFICATION - VER-2.

11WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running and at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DTC When Monitored and Set Conditions. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s!Repair as necessary.

Perform ROAD TEST VERIFICATION - VER-2.

No!Test Complete.

109

DRIVEABILITY - DIESEL

P2009-WATER IN FUEL SENSOR - WATER IN FUEL ÐContinued

Page 540 of 2305

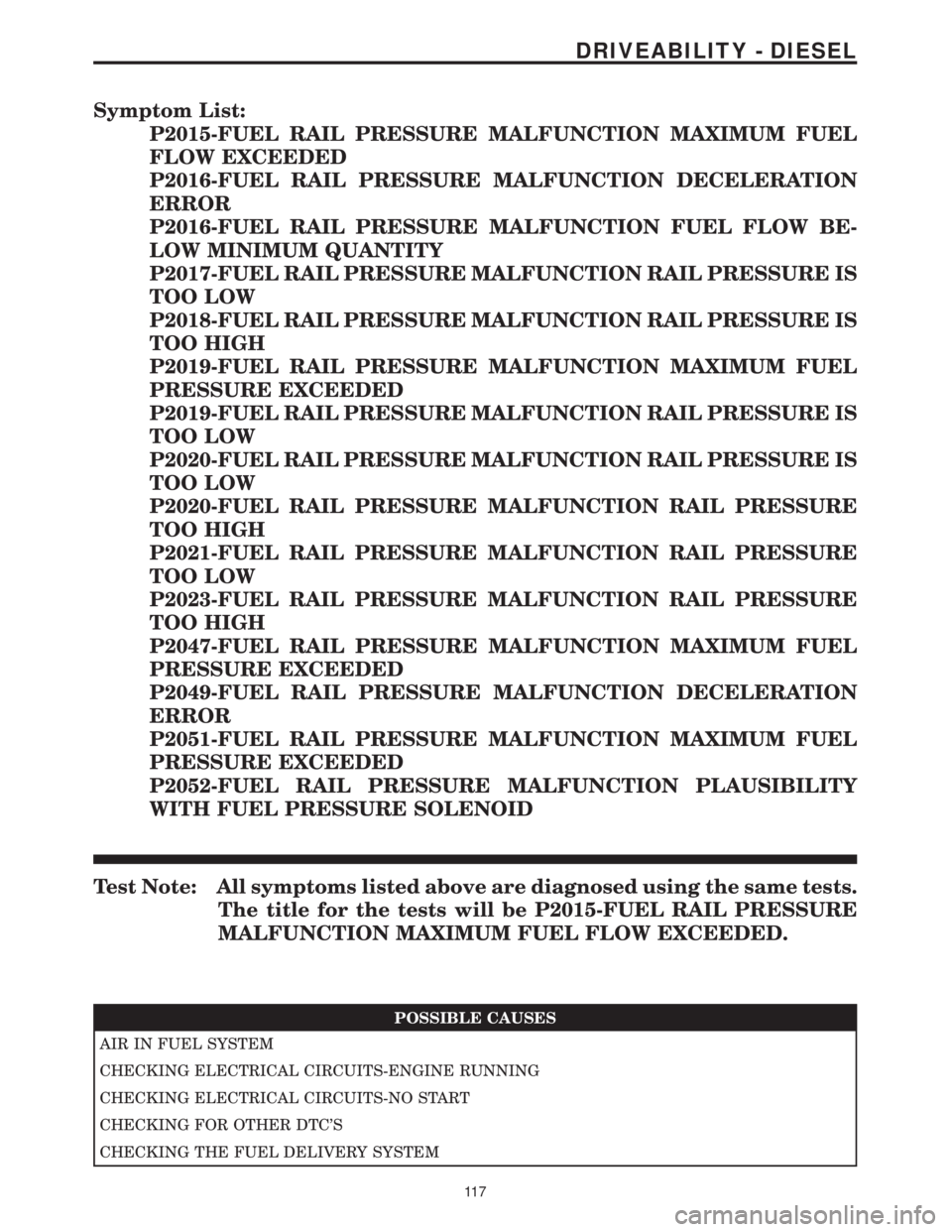

Symptom List:

P2015-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL

FLOW EXCEEDED

P2016-FUEL RAIL PRESSURE MALFUNCTION DECELERATION

ERROR

P2016-FUEL RAIL PRESSURE MALFUNCTION FUEL FLOW BE-

LOW MINIMUM QUANTITY

P2017-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE IS

TOO LOW

P2018-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE IS

TOO HIGH

P2019-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL

PRESSURE EXCEEDED

P2019-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE IS

TOO LOW

P2020-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE IS

TOO LOW

P2020-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE

TOO HIGH

P2021-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE

TOO LOW

P2023-FUEL RAIL PRESSURE MALFUNCTION RAIL PRESSURE

TOO HIGH

P2047-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL

PRESSURE EXCEEDED

P2049-FUEL RAIL PRESSURE MALFUNCTION DECELERATION

ERROR

P2051-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL

PRESSURE EXCEEDED

P2052-FUEL RAIL PRESSURE MALFUNCTION PLAUSIBILITY

WITH FUEL PRESSURE SOLENOID

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P2015-FUEL RAIL PRESSURE

MALFUNCTION MAXIMUM FUEL FLOW EXCEEDED.

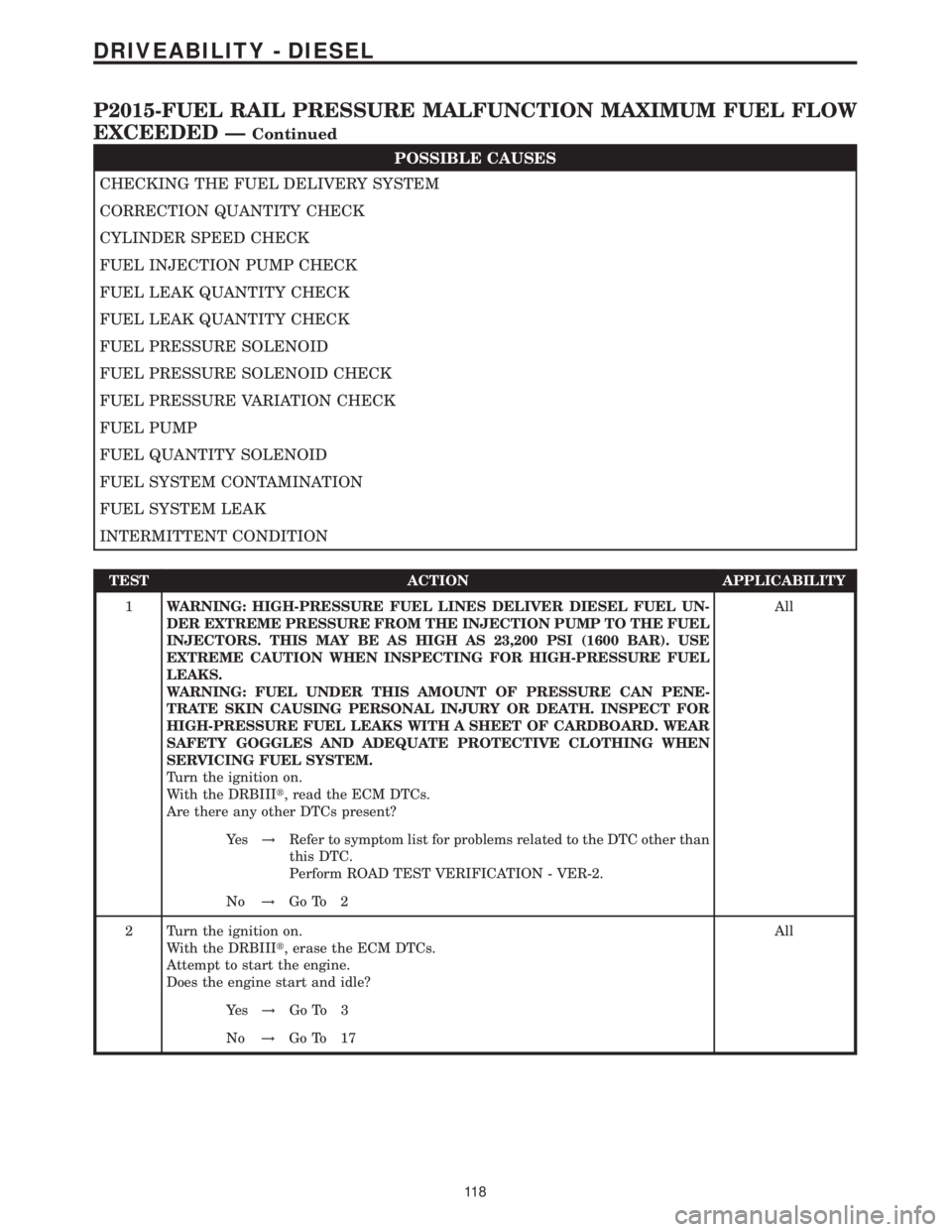

POSSIBLE CAUSES

AIR IN FUEL SYSTEM

CHECKING ELECTRICAL CIRCUITS-ENGINE RUNNING

CHECKING ELECTRICAL CIRCUITS-NO START

CHECKING FOR OTHER DTC'S

CHECKING THE FUEL DELIVERY SYSTEM

11 7

DRIVEABILITY - DIESEL

Page 541 of 2305

POSSIBLE CAUSES

CHECKING THE FUEL DELIVERY SYSTEM

CORRECTION QUANTITY CHECK

CYLINDER SPEED CHECK

FUEL INJECTION PUMP CHECK

FUEL LEAK QUANTITY CHECK

FUEL LEAK QUANTITY CHECK

FUEL PRESSURE SOLENOID

FUEL PRESSURE SOLENOID CHECK

FUEL PRESSURE VARIATION CHECK

FUEL PUMP

FUEL QUANTITY SOLENOID

FUEL SYSTEM CONTAMINATION

FUEL SYSTEM LEAK

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1WARNING: HIGH-PRESSURE FUEL LINES DELIVER DIESEL FUEL UN-

DER EXTREME PRESSURE FROM THE INJECTION PUMP TO THE FUEL

INJECTORS. THIS MAY BE AS HIGH AS 23,200 PSI (1600 BAR). USE

EXTREME CAUTION WHEN INSPECTING FOR HIGH-PRESSURE FUEL

LEAKS.

WARNING: FUEL UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE SKIN CAUSING PERSONAL INJURY OR DEATH. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF CARDBOARD. WEAR

SAFETY GOGGLES AND ADEQUATE PROTECTIVE CLOTHING WHEN

SERVICING FUEL SYSTEM.

Turn the ignition on.

With the DRBIIIt, read the ECM DTCs.

Are there any other DTCs present?All

Ye s!Refer to symptom list for problems related to the DTC other than

this DTC.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 2

2 Turn the ignition on.

With the DRBIIIt, erase the ECM DTCs.

Attempt to start the engine.

Does the engine start and idle?All

Ye s!Go To 3

No!Go To 17

11 8

DRIVEABILITY - DIESEL

P2015-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL FLOW

EXCEEDED Ð

Continued

Page 542 of 2305

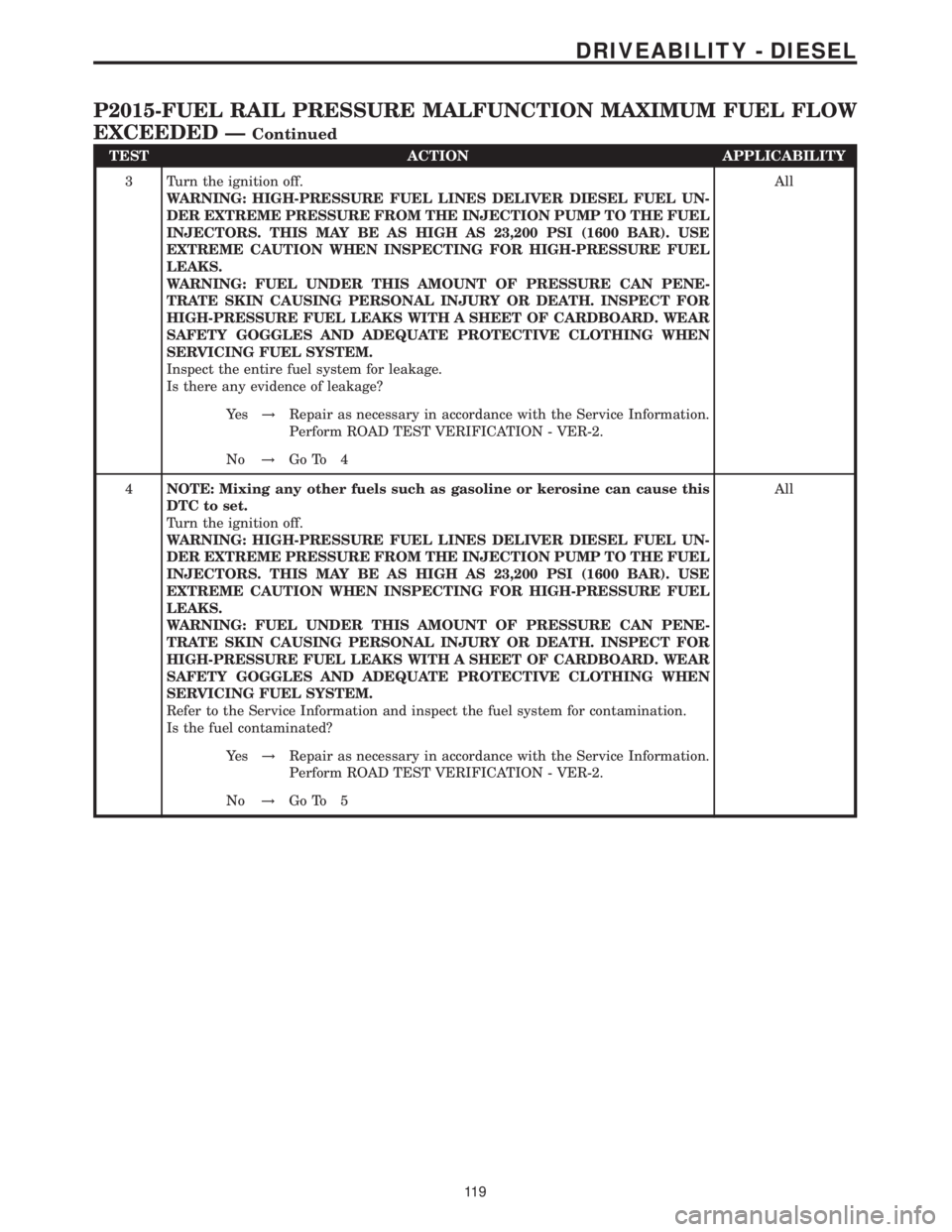

TEST ACTION APPLICABILITY

3 Turn the ignition off.

WARNING: HIGH-PRESSURE FUEL LINES DELIVER DIESEL FUEL UN-

DER EXTREME PRESSURE FROM THE INJECTION PUMP TO THE FUEL

INJECTORS. THIS MAY BE AS HIGH AS 23,200 PSI (1600 BAR). USE

EXTREME CAUTION WHEN INSPECTING FOR HIGH-PRESSURE FUEL

LEAKS.

WARNING: FUEL UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE SKIN CAUSING PERSONAL INJURY OR DEATH. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF CARDBOARD. WEAR

SAFETY GOGGLES AND ADEQUATE PROTECTIVE CLOTHING WHEN

SERVICING FUEL SYSTEM.

Inspect the entire fuel system for leakage.

Is there any evidence of leakage?All

Ye s!Repair as necessary in accordance with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 4

4NOTE: Mixing any other fuels such as gasoline or kerosine can cause this

DTC to set.

Turn the ignition off.

WARNING: HIGH-PRESSURE FUEL LINES DELIVER DIESEL FUEL UN-

DER EXTREME PRESSURE FROM THE INJECTION PUMP TO THE FUEL

INJECTORS. THIS MAY BE AS HIGH AS 23,200 PSI (1600 BAR). USE

EXTREME CAUTION WHEN INSPECTING FOR HIGH-PRESSURE FUEL

LEAKS.

WARNING: FUEL UNDER THIS AMOUNT OF PRESSURE CAN PENE-

TRATE SKIN CAUSING PERSONAL INJURY OR DEATH. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF CARDBOARD. WEAR

SAFETY GOGGLES AND ADEQUATE PROTECTIVE CLOTHING WHEN

SERVICING FUEL SYSTEM.

Refer to the Service Information and inspect the fuel system for contamination.

Is the fuel contaminated?All

Ye s!Repair as necessary in accordance with the Service Information.

Perform ROAD TEST VERIFICATION - VER-2.

No!Go To 5

11 9

DRIVEABILITY - DIESEL

P2015-FUEL RAIL PRESSURE MALFUNCTION MAXIMUM FUEL FLOW

EXCEEDED Ð

Continued