door lock MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1981 of 2305

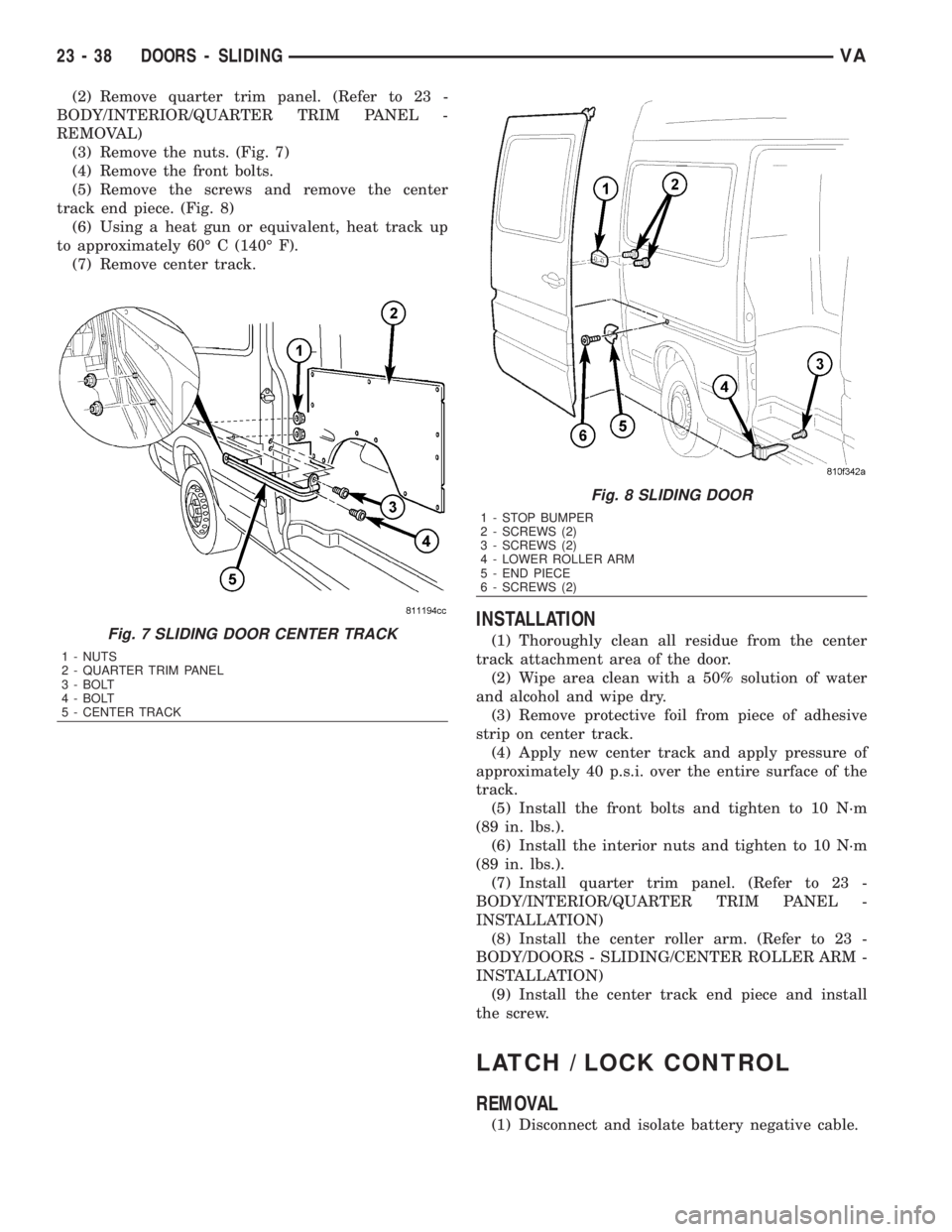

(2) Remove quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(3) Remove the nuts. (Fig. 7)

(4) Remove the front bolts.

(5) Remove the screws and remove the center

track end piece. (Fig. 8)

(6) Using a heat gun or equivalent, heat track up

to approximately 60É C (140É F).

(7) Remove center track.

INSTALLATION

(1) Thoroughly clean all residue from the center

track attachment area of the door.

(2) Wipe area clean with a 50% solution of water

and alcohol and wipe dry.

(3) Remove protective foil from piece of adhesive

strip on center track.

(4) Apply new center track and apply pressure of

approximately 40 p.s.i. over the entire surface of the

track.

(5) Install the front bolts and tighten to 10 N´m

(89 in. lbs.).

(6) Install the interior nuts and tighten to 10 N´m

(89 in. lbs.).

(7) Install quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION)

(8) Install the center roller arm. (Refer to 23 -

BODY/DOORS - SLIDING/CENTER ROLLER ARM -

INSTALLATION)

(9) Install the center track end piece and install

the screw.

LATCH / LOCK CONTROL

REMOVAL

(1) Disconnect and isolate battery negative cable.

Fig. 7 SLIDING DOOR CENTER TRACK

1 - NUTS

2 - QUARTER TRIM PANEL

3 - BOLT

4 - BOLT

5 - CENTER TRACK

Fig. 8 SLIDING DOOR

1 - STOP BUMPER

2 - SCREWS (2)

3 - SCREWS (2)

4 - LOWER ROLLER ARM

5 - END PIECE

6 - SCREWS (2)

23 - 38 DOORS - SLIDINGVA

Page 1982 of 2305

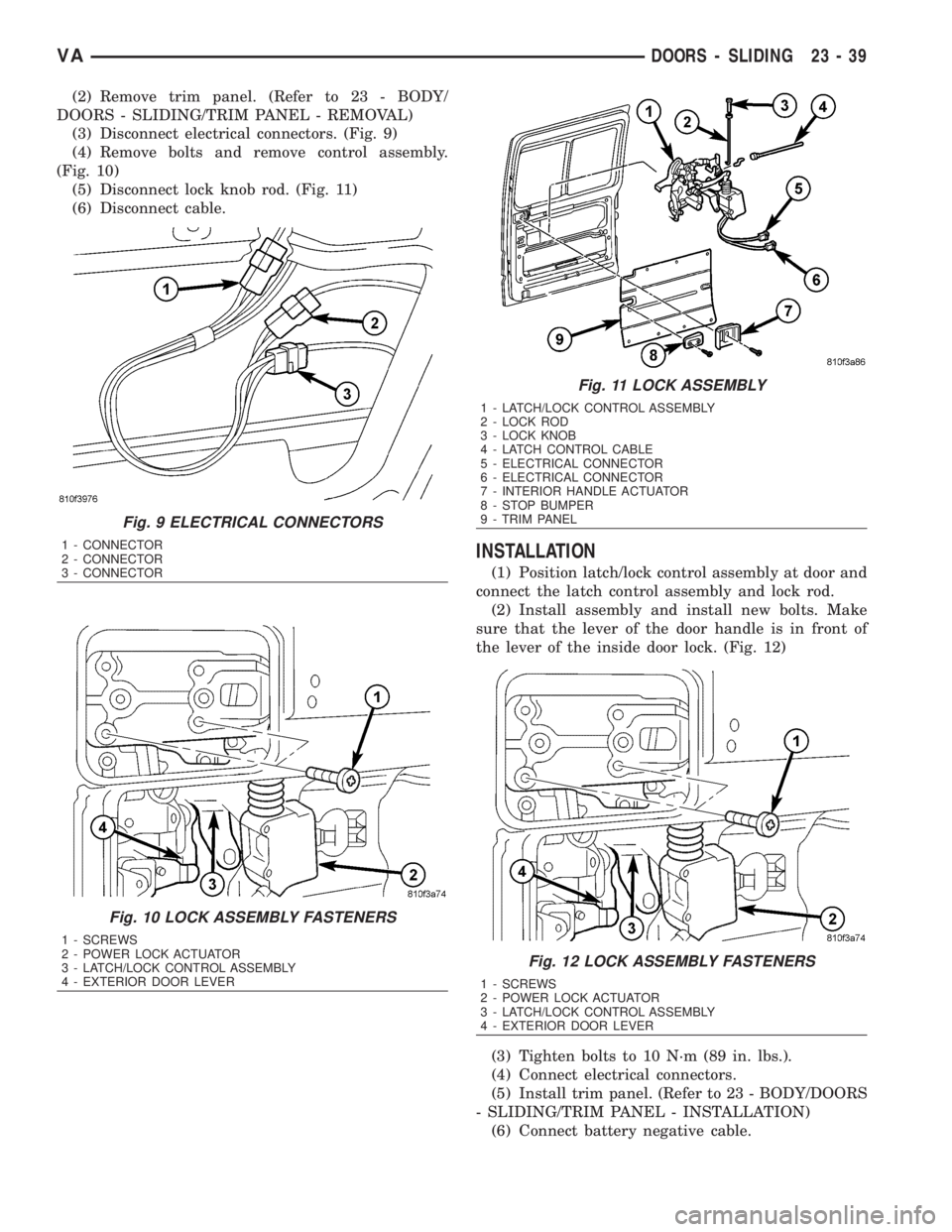

(2) Remove trim panel. (Refer to 23 - BODY/

DOORS - SLIDING/TRIM PANEL - REMOVAL)

(3) Disconnect electrical connectors. (Fig. 9)

(4) Remove bolts and remove control assembly.

(Fig. 10)

(5) Disconnect lock knob rod. (Fig. 11)

(6) Disconnect cable.

INSTALLATION

(1) Position latch/lock control assembly at door and

connect the latch control assembly and lock rod.

(2) Install assembly and install new bolts. Make

sure that the lever of the door handle is in front of

the lever of the inside door lock. (Fig. 12)

(3) Tighten bolts to 10 N´m (89 in. lbs.).

(4) Connect electrical connectors.

(5) Install trim panel. (Refer to 23 - BODY/DOORS

- SLIDING/TRIM PANEL - INSTALLATION)

(6) Connect battery negative cable.

Fig. 9 ELECTRICAL CONNECTORS

1 - CONNECTOR

2 - CONNECTOR

3 - CONNECTOR

Fig. 10 LOCK ASSEMBLY FASTENERS

1 - SCREWS

2 - POWER LOCK ACTUATOR

3 - LATCH/LOCK CONTROL ASSEMBLY

4 - EXTERIOR DOOR LEVER

Fig. 11 LOCK ASSEMBLY

1 - LATCH/LOCK CONTROL ASSEMBLY

2 - LOCK ROD

3 - LOCK KNOB

4 - LATCH CONTROL CABLE

5 - ELECTRICAL CONNECTOR

6 - ELECTRICAL CONNECTOR

7 - INTERIOR HANDLE ACTUATOR

8 - STOP BUMPER

9 - TRIM PANEL

Fig. 12 LOCK ASSEMBLY FASTENERS

1 - SCREWS

2 - POWER LOCK ACTUATOR

3 - LATCH/LOCK CONTROL ASSEMBLY

4 - EXTERIOR DOOR LEVER

VADOORS - SLIDING 23 - 39

Page 1985 of 2305

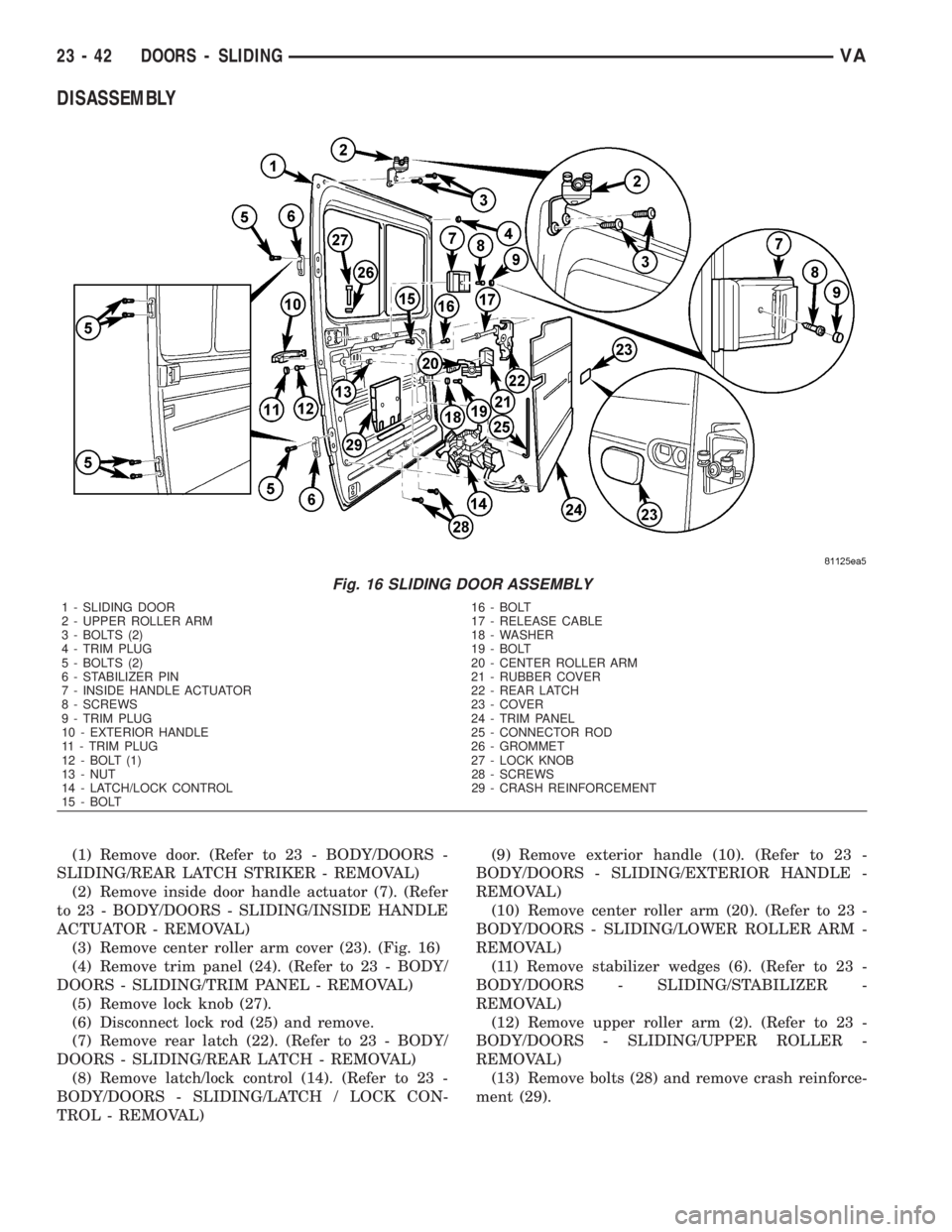

DISASSEMBLY

(1) Remove door. (Refer to 23 - BODY/DOORS -

SLIDING/REAR LATCH STRIKER - REMOVAL)

(2) Remove inside door handle actuator (7). (Refer

to 23 - BODY/DOORS - SLIDING/INSIDE HANDLE

ACTUATOR - REMOVAL)

(3) Remove center roller arm cover (23). (Fig. 16)

(4) Remove trim panel (24). (Refer to 23 - BODY/

DOORS - SLIDING/TRIM PANEL - REMOVAL)

(5) Remove lock knob (27).

(6) Disconnect lock rod (25) and remove.

(7) Remove rear latch (22). (Refer to 23 - BODY/

DOORS - SLIDING/REAR LATCH - REMOVAL)

(8) Remove latch/lock control (14). (Refer to 23 -

BODY/DOORS - SLIDING/LATCH / LOCK CON-

TROL - REMOVAL)(9) Remove exterior handle (10). (Refer to 23 -

BODY/DOORS - SLIDING/EXTERIOR HANDLE -

REMOVAL)

(10) Remove center roller arm (20). (Refer to 23 -

BODY/DOORS - SLIDING/LOWER ROLLER ARM -

REMOVAL)

(11) Remove stabilizer wedges (6). (Refer to 23 -

BODY/DOORS - SLIDING/STABILIZER -

REMOVAL)

(12) Remove upper roller arm (2). (Refer to 23 -

BODY/DOORS - SLIDING/UPPER ROLLER -

REMOVAL)

(13) Remove bolts (28) and remove crash reinforce-

ment (29).

Fig. 16 SLIDING DOOR ASSEMBLY

1 - SLIDING DOOR 16 - BOLT

2 - UPPER ROLLER ARM 17 - RELEASE CABLE

3 - BOLTS (2) 18 - WASHER

4 - TRIM PLUG 19 - BOLT

5 - BOLTS (2) 20 - CENTER ROLLER ARM

6 - STABILIZER PIN 21 - RUBBER COVER

7 - INSIDE HANDLE ACTUATOR 22 - REAR LATCH

8 - SCREWS 23 - COVER

9 - TRIM PLUG 24 - TRIM PANEL

10 - EXTERIOR HANDLE 25 - CONNECTOR ROD

11 - TRIM PLUG 26 - GROMMET

12 - BOLT (1) 27 - LOCK KNOB

13 - NUT 28 - SCREWS

14 - LATCH/LOCK CONTROL 29 - CRASH REINFORCEMENT

15 - BOLT

23 - 42 DOORS - SLIDINGVA

Page 1986 of 2305

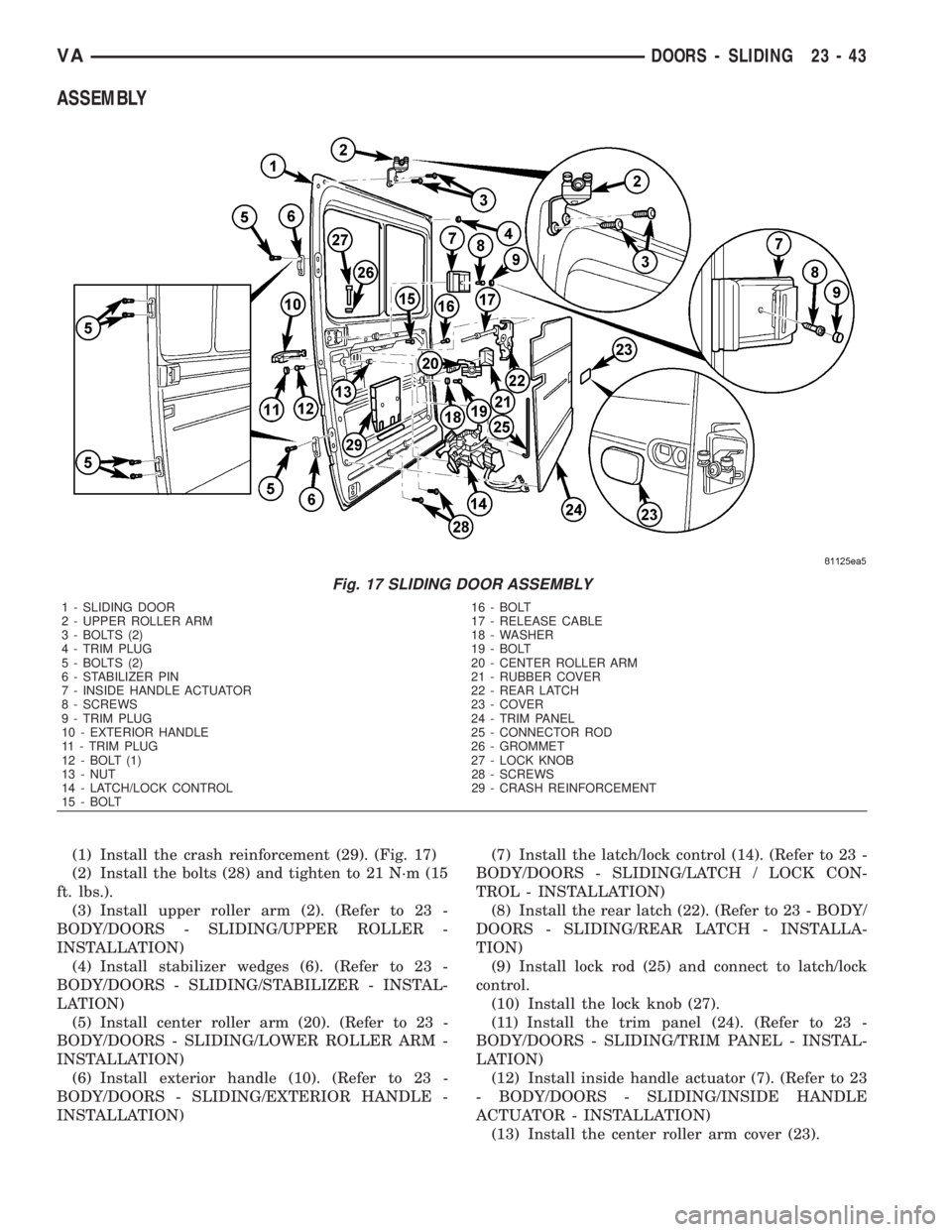

ASSEMBLY

(1) Install the crash reinforcement (29). (Fig. 17)

(2) Install the bolts (28) and tighten to 21 N´m (15

ft. lbs.).

(3) Install upper roller arm (2). (Refer to 23 -

BODY/DOORS - SLIDING/UPPER ROLLER -

INSTALLATION)

(4) Install stabilizer wedges (6). (Refer to 23 -

BODY/DOORS - SLIDING/STABILIZER - INSTAL-

LATION)

(5) Install center roller arm (20). (Refer to 23 -

BODY/DOORS - SLIDING/LOWER ROLLER ARM -

INSTALLATION)

(6) Install exterior handle (10). (Refer to 23 -

BODY/DOORS - SLIDING/EXTERIOR HANDLE -

INSTALLATION)(7) Install the latch/lock control (14). (Refer to 23 -

BODY/DOORS - SLIDING/LATCH / LOCK CON-

TROL - INSTALLATION)

(8) Install the rear latch (22). (Refer to 23 - BODY/

DOORS - SLIDING/REAR LATCH - INSTALLA-

TION)

(9) Install lock rod (25) and connect to latch/lock

control.

(10) Install the lock knob (27).

(11) Install the trim panel (24). (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION)

(12) Install inside handle actuator (7). (Refer to 23

- BODY/DOORS - SLIDING/INSIDE HANDLE

ACTUATOR - INSTALLATION)

(13) Install the center roller arm cover (23).

Fig. 17 SLIDING DOOR ASSEMBLY

1 - SLIDING DOOR 16 - BOLT

2 - UPPER ROLLER ARM 17 - RELEASE CABLE

3 - BOLTS (2) 18 - WASHER

4 - TRIM PLUG 19 - BOLT

5 - BOLTS (2) 20 - CENTER ROLLER ARM

6 - STABILIZER PIN 21 - RUBBER COVER

7 - INSIDE HANDLE ACTUATOR 22 - REAR LATCH

8 - SCREWS 23 - COVER

9 - TRIM PLUG 24 - TRIM PANEL

10 - EXTERIOR HANDLE 25 - CONNECTOR ROD

11 - TRIM PLUG 26 - GROMMET

12 - BOLT (1) 27 - LOCK KNOB

13 - NUT 28 - SCREWS

14 - LATCH/LOCK CONTROL 29 - CRASH REINFORCEMENT

15 - BOLT

VADOORS - SLIDING 23 - 43

Page 1989 of 2305

(3) Install wedge and install screws.

(4) Close sliding door to adjust closing wedge.

(5) Open door and tighten screws to 10 N´m (89 in.

lbs.).

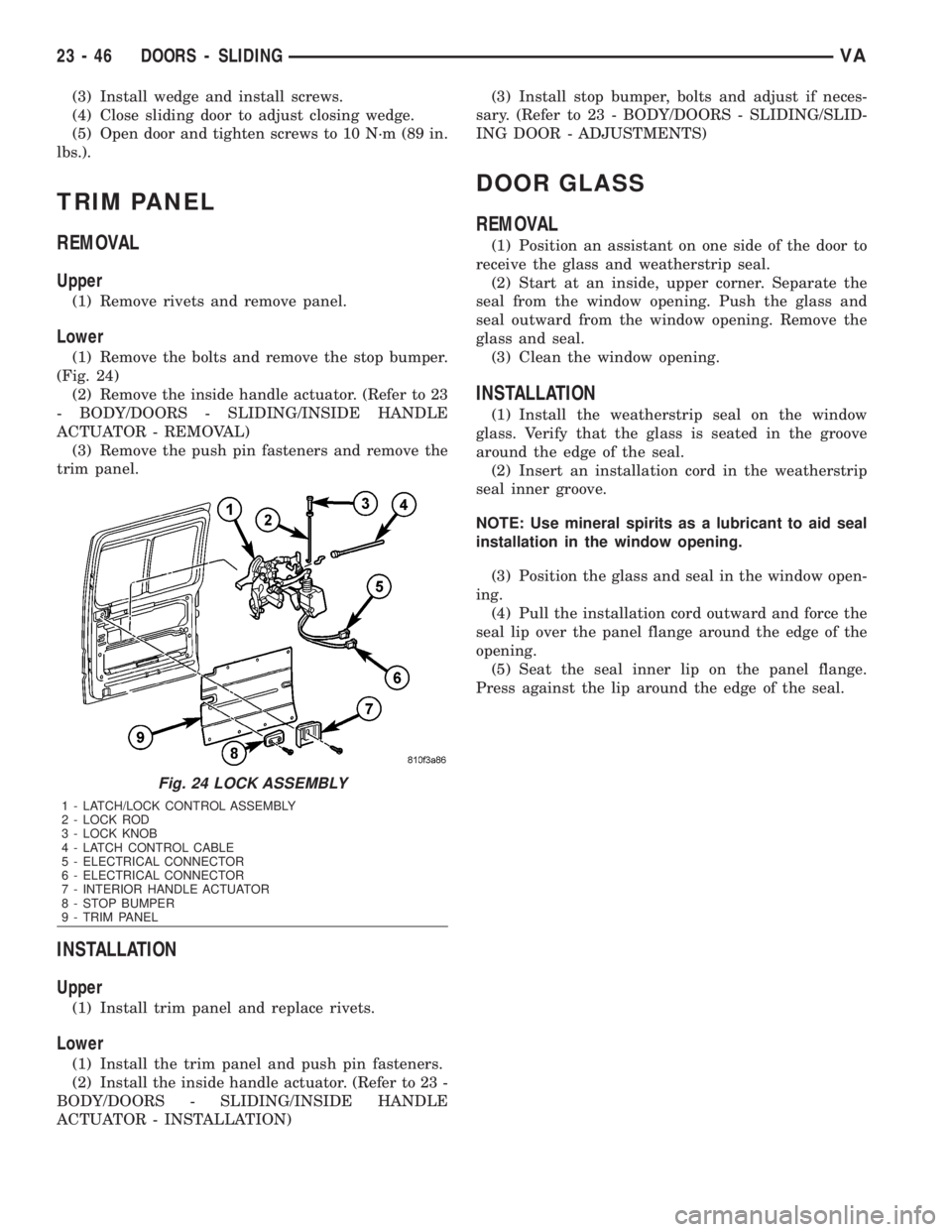

TRIM PANEL

REMOVAL

Upper

(1) Remove rivets and remove panel.

Lower

(1) Remove the bolts and remove the stop bumper.

(Fig. 24)

(2) Remove the inside handle actuator. (Refer to 23

- BODY/DOORS - SLIDING/INSIDE HANDLE

ACTUATOR - REMOVAL)

(3) Remove the push pin fasteners and remove the

trim panel.

INSTALLATION

Upper

(1) Install trim panel and replace rivets.

Lower

(1) Install the trim panel and push pin fasteners.

(2) Install the inside handle actuator. (Refer to 23 -

BODY/DOORS - SLIDING/INSIDE HANDLE

ACTUATOR - INSTALLATION)(3) Install stop bumper, bolts and adjust if neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

DOOR GLASS

REMOVAL

(1) Position an assistant on one side of the door to

receive the glass and weatherstrip seal.

(2) Start at an inside, upper corner. Separate the

seal from the window opening. Push the glass and

seal outward from the window opening. Remove the

glass and seal.

(3) Clean the window opening.

INSTALLATION

(1) Install the weatherstrip seal on the window

glass. Verify that the glass is seated in the groove

around the edge of the seal.

(2) Insert an installation cord in the weatherstrip

seal inner groove.

NOTE: Use mineral spirits as a lubricant to aid seal

installation in the window opening.

(3) Position the glass and seal in the window open-

ing.

(4) Pull the installation cord outward and force the

seal lip over the panel flange around the edge of the

opening.

(5) Seat the seal inner lip on the panel flange.

Press against the lip around the edge of the seal.

Fig. 24 LOCK ASSEMBLY

1 - LATCH/LOCK CONTROL ASSEMBLY

2 - LOCK ROD

3 - LOCK KNOB

4 - LATCH CONTROL CABLE

5 - ELECTRICAL CONNECTOR

6 - ELECTRICAL CONNECTOR

7 - INTERIOR HANDLE ACTUATOR

8 - STOP BUMPER

9 - TRIM PANEL

23 - 46 DOORS - SLIDINGVA

Page 2002 of 2305

INSTRUMENT PANEL ASSEM-

BLY

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

²WHEN REMOVING A DEPLOYED AIRBAG, RUB-

BER GLOVES, EYE PROTECTION, AND A LONG-

SLEEVED SHIRT SHOULD BE WORN. THERE MAY

BE DEPOSITS ON THE AIRBAG UNIT AND OTHER

INTERIOR SURFACES. IN LARGE DOSES, THESE

DEPOSITS MAY CAUSE IRRITATION TO THE SKIN

AND EYES.

²USE EXTREME CARE TO PREVENT ANY FOR-

EIGN MATERIAL FROM ENTERING THE PASSEN-

GER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

²THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAGS ARE SERVICED WITH DOORS IN THE

ORIGINAL COLORS. PAINT MAY CHANGE THE WAY

IN WHICH THE MATERIAL OF THE AIRBAG DOOR

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove radio. (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - REMOVAL)

(3) Remove glove compartment. (Refer to 23 -

BODY/INSTRUMENT PANEL/GLOVE BOX -

REMOVAL)

(4) Remove cup holder. (Refer to 23 - BODY/IN-

STRUMENT PANEL/CUP HOLDER - REMOVAL)

(5) Remove instrument cluster. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - REMOVAL)(6) Remove passenger airbag. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

REMOVAL)

(7) Remove right and left speakers. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(8) Remove center bezel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL CEN-

TER BEZEL - REMOVAL)

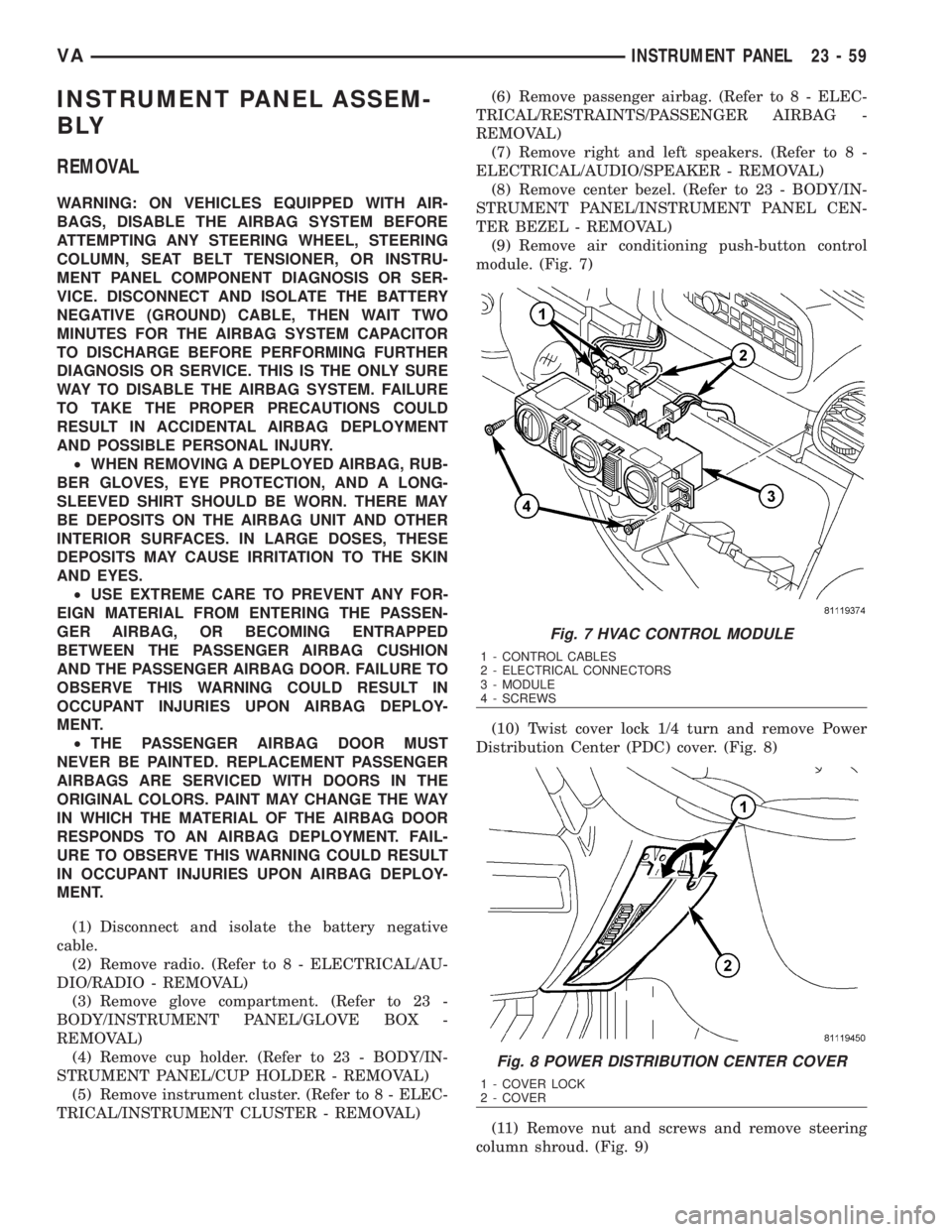

(9) Remove air conditioning push-button control

module. (Fig. 7)

(10) Twist cover lock 1/4 turn and remove Power

Distribution Center (PDC) cover. (Fig. 8)

(11) Remove nut and screws and remove steering

column shroud. (Fig. 9)

Fig. 7 HVAC CONTROL MODULE

1 - CONTROL CABLES

2 - ELECTRICAL CONNECTORS

3 - MODULE

4 - SCREWS

Fig. 8 POWER DISTRIBUTION CENTER COVER

1 - COVER LOCK

2 - COVER

VAINSTRUMENT PANEL 23 - 59

Page 2006 of 2305

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

²WHEN REMOVING A DEPLOYED AIRBAG, RUB-

BER GLOVES, EYE PROTECTION, AND A LONG-

SLEEVED SHIRT SHOULD BE WORN. THERE MAY

BE DEPOSITS ON THE AIRBAG UNIT AND OTHER

INTERIOR SURFACES. IN LARGE DOSES, THESE

DEPOSITS MAY CAUSE IRRITATION TO THE SKIN

AND EYES.

²USE EXTREME CARE TO PREVENT ANY FOR-

EIGN MATERIAL FROM ENTERING THE PASSEN-

GER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

²THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAGS ARE SERVICED WITH DOORS IN THE

ORIGINAL COLORS. PAINT MAY CHANGE THE WAY

IN WHICH THE MATERIAL OF THE AIRBAG DOOR

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

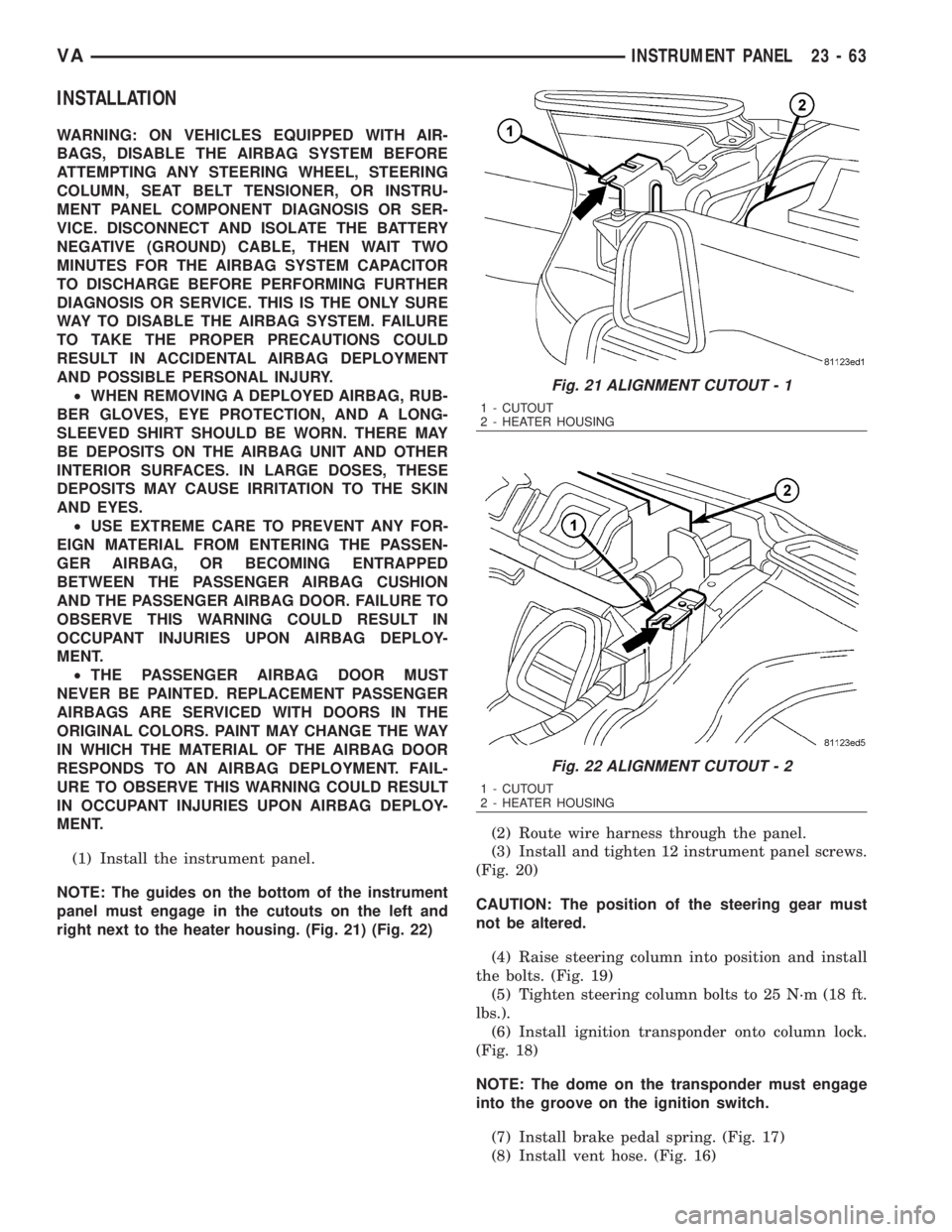

(1) Install the instrument panel.

NOTE: The guides on the bottom of the instrument

panel must engage in the cutouts on the left and

right next to the heater housing. (Fig. 21) (Fig. 22)(2) Route wire harness through the panel.

(3) Install and tighten 12 instrument panel screws.

(Fig. 20)

CAUTION: The position of the steering gear must

not be altered.

(4) Raise steering column into position and install

the bolts. (Fig. 19)

(5) Tighten steering column bolts to 25 N´m (18 ft.

lbs.).

(6) Install ignition transponder onto column lock.

(Fig. 18)

NOTE: The dome on the transponder must engage

into the groove on the ignition switch.

(7) Install brake pedal spring. (Fig. 17)

(8) Install vent hose. (Fig. 16)

Fig. 21 ALIGNMENT CUTOUT - 1

1 - CUTOUT

2 - HEATER HOUSING

Fig. 22 ALIGNMENT CUTOUT - 2

1 - CUTOUT

2 - HEATER HOUSING

VAINSTRUMENT PANEL 23 - 63

Page 2038 of 2305

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

A/C PERFORMANCE....................3

HEATER PERFORMANCE TEST...........5

ATC FUNCTION TEST...................6

SPECIFICATIONS

HEATING-A/C SYSTEM..................6CONTROLS-FRONT........................8

CONTROLS - REAR......................24

DISTRIBUTION - FRONT...................45

DISTRIBUTION - REAR....................52

PLUMBING.............................60

CABIN HEATER.........................104

HEATING & AIR CONDITION-

ING

DESCRIPTION

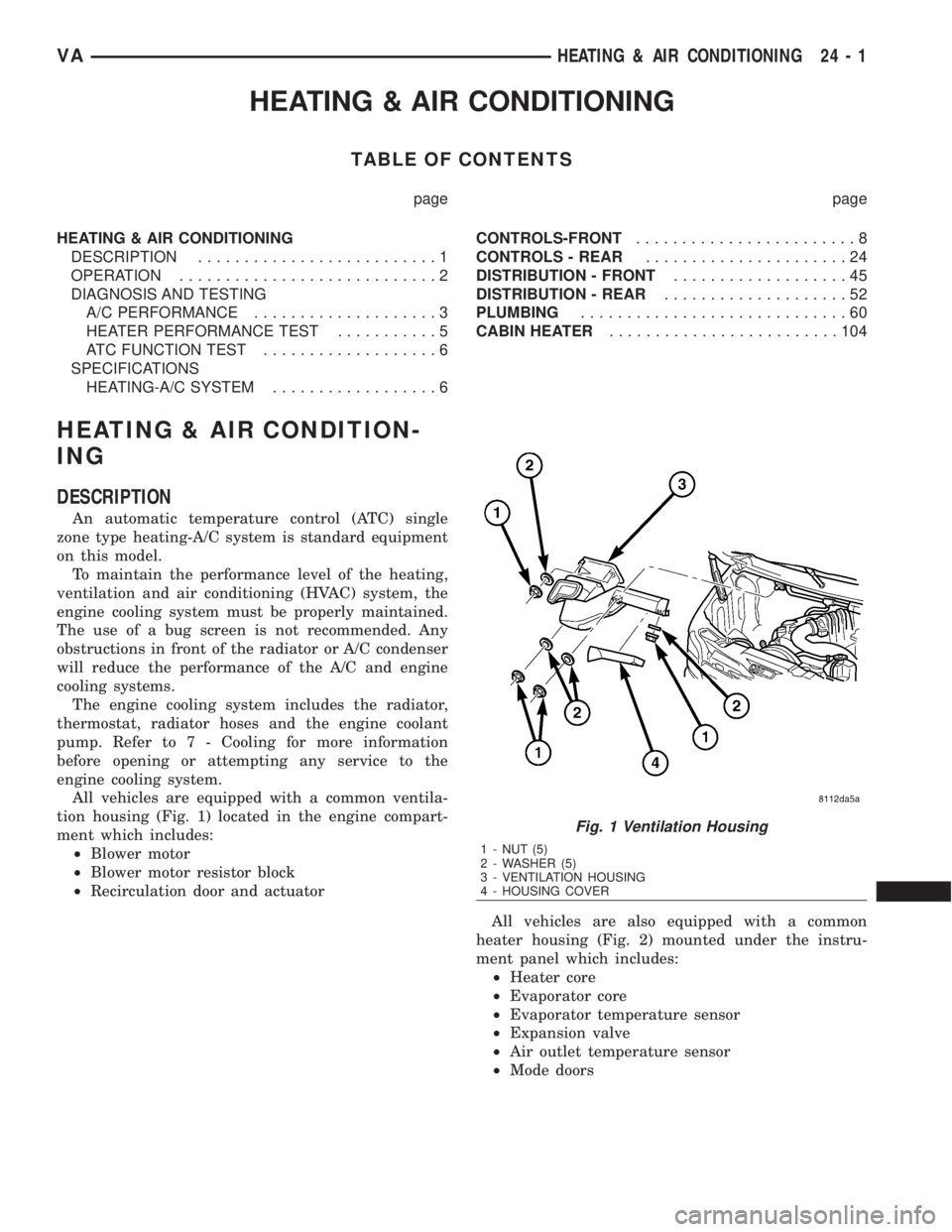

An automatic temperature control (ATC) single

zone type heating-A/C system is standard equipment

on this model.

To maintain the performance level of the heating,

ventilation and air conditioning (HVAC) system, the

engine cooling system must be properly maintained.

The use of a bug screen is not recommended. Any

obstructions in front of the radiator or A/C condenser

will reduce the performance of the A/C and engine

cooling systems.

The engine cooling system includes the radiator,

thermostat, radiator hoses and the engine coolant

pump. Refer to 7 - Cooling for more information

before opening or attempting any service to the

engine cooling system.

All vehicles are equipped with a common ventila-

tion housing (Fig. 1) located in the engine compart-

ment which includes:

²Blower motor

²Blower motor resistor block

²Recirculation door and actuator

All vehicles are also equipped with a common

heater housing (Fig. 2) mounted under the instru-

ment panel which includes:

²Heater core

²Evaporator core

²Evaporator temperature sensor

²Expansion valve

²Air outlet temperature sensor

²Mode doors

Fig. 1 Ventilation Housing

1 - NUT (5)

2 - WASHER (5)

3 - VENTILATION HOUSING

4 - HOUSING COVER

VAHEATING & AIR CONDITIONING 24 - 1

Page 2041 of 2305

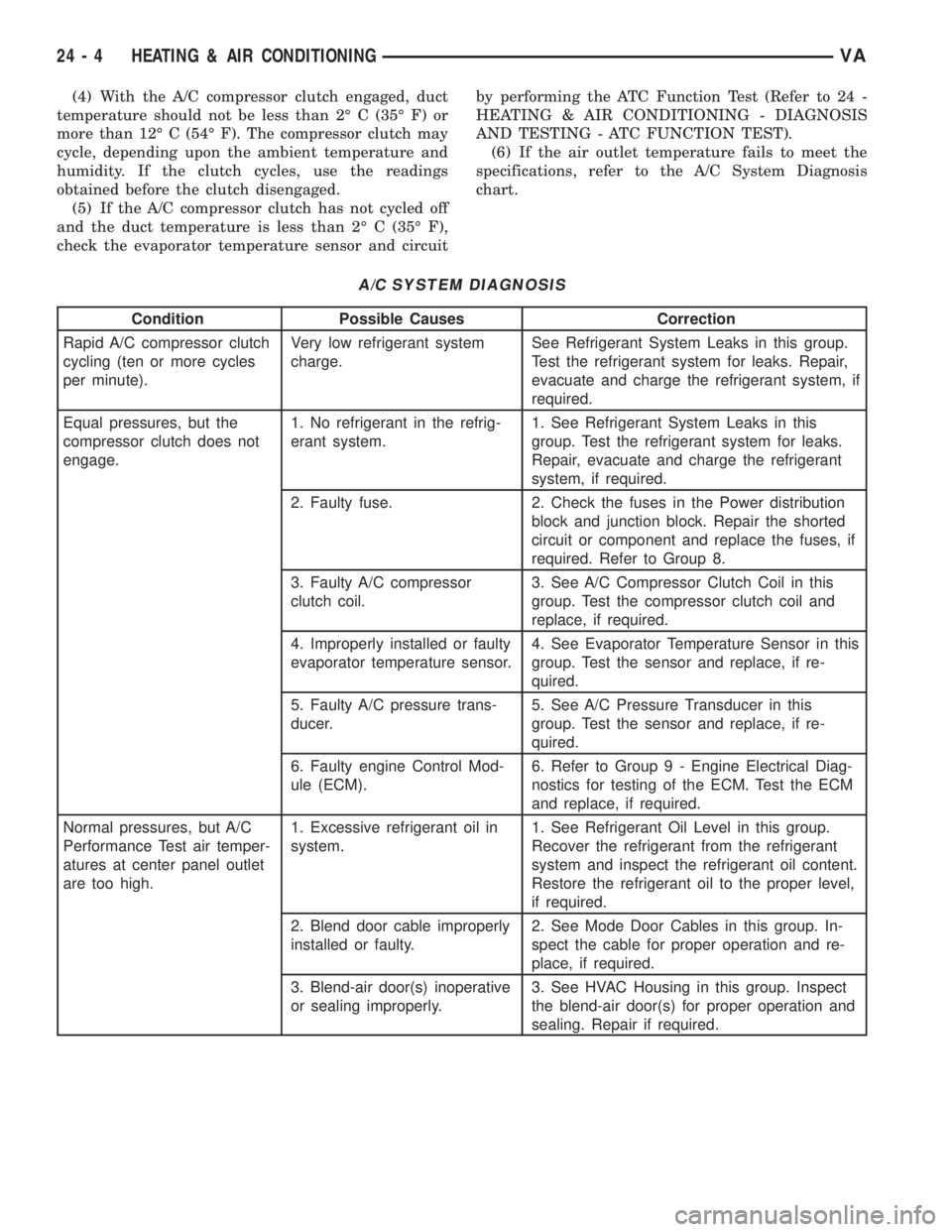

(4) With the A/C compressor clutch engaged, duct

temperature should not be less than 2É C (35É F) or

more than 12É C (54É F). The compressor clutch may

cycle, depending upon the ambient temperature and

humidity. If the clutch cycles, use the readings

obtained before the clutch disengaged.

(5) If the A/C compressor clutch has not cycled off

and the duct temperature is less than 2É C (35É F),

check the evaporator temperature sensor and circuitby performing the ATC Function Test (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - ATC FUNCTION TEST).

(6) If the air outlet temperature fails to meet the

specifications, refer to the A/C System Diagnosis

chart.

A/C SYSTEM DIAGNOSIS

Condition Possible Causes Correction

Rapid A/C compressor clutch

cycling (ten or more cycles

per minute).Very low refrigerant system

charge.See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the refrig-

erant system.1. See Refrigerant System Leaks in this

group. Test the refrigerant system for leaks.

Repair, evacuate and charge the refrigerant

system, if required.

2. Faulty fuse. 2. Check the fuses in the Power distribution

block and junction block. Repair the shorted

circuit or component and replace the fuses, if

required. Refer to Group 8.

3. Faulty A/C compressor

clutch coil.3. See A/C Compressor Clutch Coil in this

group. Test the compressor clutch coil and

replace, if required.

4. Improperly installed or faulty

evaporator temperature sensor.4. See Evaporator Temperature Sensor in this

group. Test the sensor and replace, if re-

quired.

5. Faulty A/C pressure trans-

ducer.5. See A/C Pressure Transducer in this

group. Test the sensor and replace, if re-

quired.

6. Faulty engine Control Mod-

ule (ECM).6. Refer to Group 9 - Engine Electrical Diag-

nostics for testing of the ECM. Test the ECM

and replace, if required.

Normal pressures, but A/C

Performance Test air temper-

atures at center panel outlet

are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil Level in this group.

Recover the refrigerant from the refrigerant

system and inspect the refrigerant oil content.

Restore the refrigerant oil to the proper level,

if required.

2. Blend door cable improperly

installed or faulty.2. See Mode Door Cables in this group. In-

spect the cable for proper operation and re-

place, if required.

3. Blend-air door(s) inoperative

or sealing improperly.3. See HVAC Housing in this group. Inspect

the blend-air door(s) for proper operation and

sealing. Repair if required.

24 - 4 HEATING & AIR CONDITIONINGVA

Page 2059 of 2305

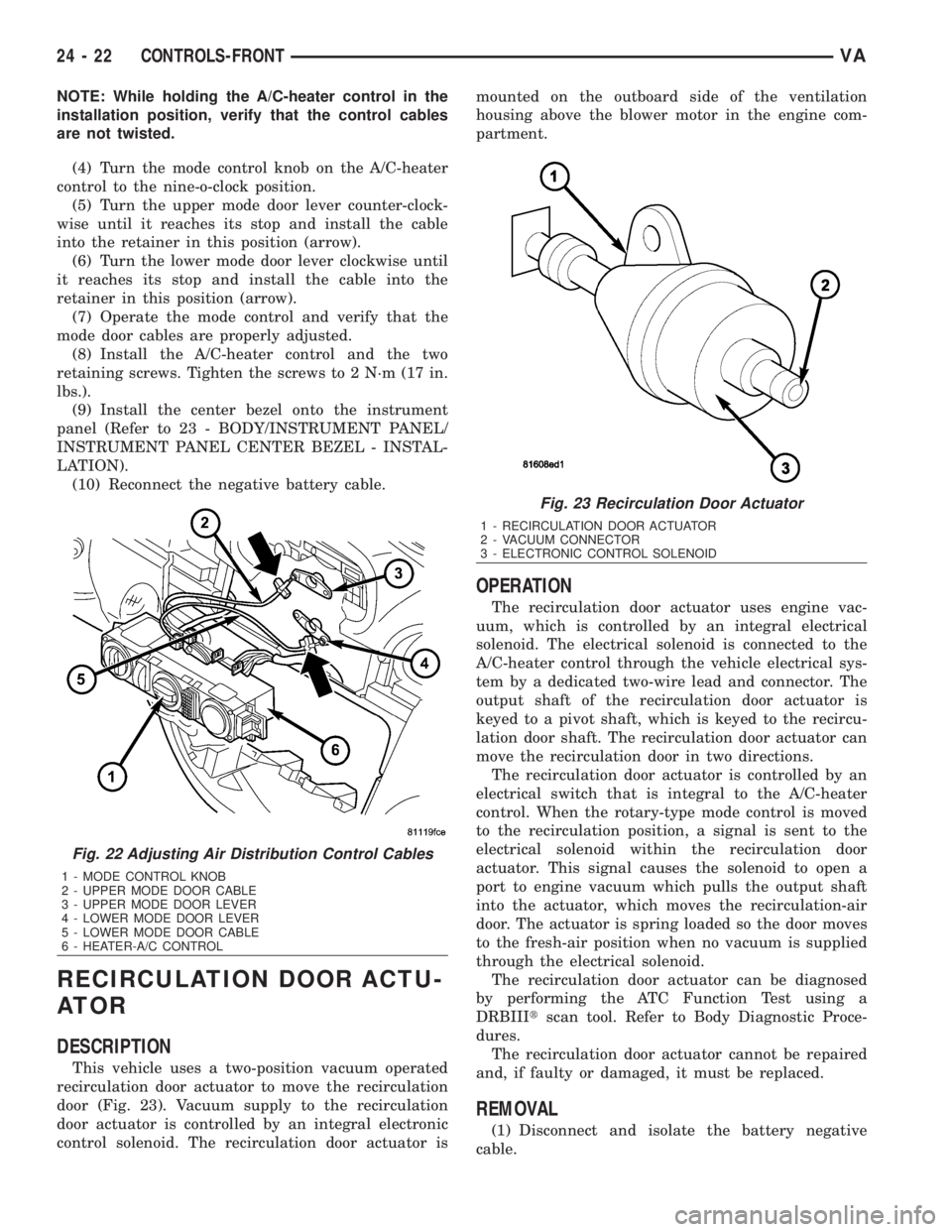

NOTE: While holding the A/C-heater control in the

installation position, verify that the control cables

are not twisted.

(4) Turn the mode control knob on the A/C-heater

control to the nine-o-clock position.

(5) Turn the upper mode door lever counter-clock-

wise until it reaches its stop and install the cable

into the retainer in this position (arrow).

(6) Turn the lower mode door lever clockwise until

it reaches its stop and install the cable into the

retainer in this position (arrow).

(7) Operate the mode control and verify that the

mode door cables are properly adjusted.

(8) Install the A/C-heater control and the two

retaining screws. Tighten the screws to 2 N´m (17 in.

lbs.).

(9) Install the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(10) Reconnect the negative battery cable.

RECIRCULATION DOOR ACTU-

ATOR

DESCRIPTION

This vehicle uses a two-position vacuum operated

recirculation door actuator to move the recirculation

door (Fig. 23). Vacuum supply to the recirculation

door actuator is controlled by an integral electronic

control solenoid. The recirculation door actuator ismounted on the outboard side of the ventilation

housing above the blower motor in the engine com-

partment.

OPERATION

The recirculation door actuator uses engine vac-

uum, which is controlled by an integral electrical

solenoid. The electrical solenoid is connected to the

A/C-heater control through the vehicle electrical sys-

tem by a dedicated two-wire lead and connector. The

output shaft of the recirculation door actuator is

keyed to a pivot shaft, which is keyed to the recircu-

lation door shaft. The recirculation door actuator can

move the recirculation door in two directions.

The recirculation door actuator is controlled by an

electrical switch that is integral to the A/C-heater

control. When the rotary-type mode control is moved

to the recirculation position, a signal is sent to the

electrical solenoid within the recirculation door

actuator. This signal causes the solenoid to open a

port to engine vacuum which pulls the output shaft

into the actuator, which moves the recirculation-air

door. The actuator is spring loaded so the door moves

to the fresh-air position when no vacuum is supplied

through the electrical solenoid.

The recirculation door actuator can be diagnosed

by performing the ATC Function Test using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

The recirculation door actuator cannot be repaired

and, if faulty or damaged, it must be replaced.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 22 Adjusting Air Distribution Control Cables

1 - MODE CONTROL KNOB

2 - UPPER MODE DOOR CABLE

3 - UPPER MODE DOOR LEVER

4 - LOWER MODE DOOR LEVER

5 - LOWER MODE DOOR CABLE

6 - HEATER-A/C CONTROL

Fig. 23 Recirculation Door Actuator

1 - RECIRCULATION DOOR ACTUATOR

2 - VACUUM CONNECTOR

3 - ELECTRONIC CONTROL SOLENOID

24 - 22 CONTROLS-FRONTVA