door lock MERCEDES-BENZ SPRINTER 2006 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1511 of 2305

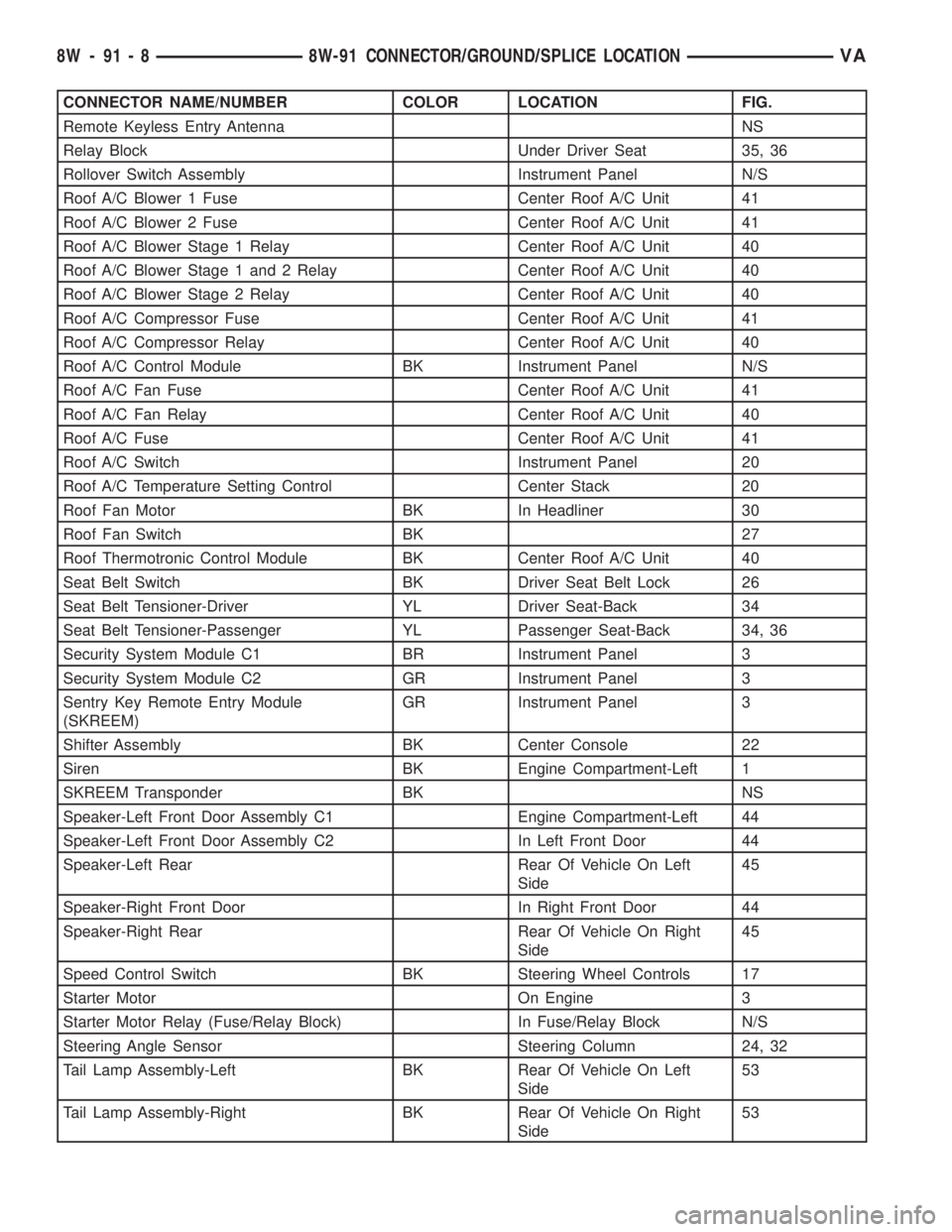

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Remote Keyless Entry Antenna NS

Relay Block Under Driver Seat 35, 36

Rollover Switch Assembly Instrument Panel N/S

Roof A/C Blower 1 Fuse Center Roof A/C Unit 41

Roof A/C Blower 2 Fuse Center Roof A/C Unit 41

Roof A/C Blower Stage 1 Relay Center Roof A/C Unit 40

Roof A/C Blower Stage 1 and 2 Relay Center Roof A/C Unit 40

Roof A/C Blower Stage 2 Relay Center Roof A/C Unit 40

Roof A/C Compressor Fuse Center Roof A/C Unit 41

Roof A/C Compressor Relay Center Roof A/C Unit 40

Roof A/C Control Module BK Instrument Panel N/S

Roof A/C Fan Fuse Center Roof A/C Unit 41

Roof A/C Fan Relay Center Roof A/C Unit 40

Roof A/C Fuse Center Roof A/C Unit 41

Roof A/C Switch Instrument Panel 20

Roof A/C Temperature Setting Control Center Stack 20

Roof Fan Motor BK In Headliner 30

Roof Fan Switch BK 27

Roof Thermotronic Control Module BK Center Roof A/C Unit 40

Seat Belt Switch BK Driver Seat Belt Lock 26

Seat Belt Tensioner-Driver YL Driver Seat-Back 34

Seat Belt Tensioner-Passenger YL Passenger Seat-Back 34, 36

Security System Module C1 BR Instrument Panel 3

Security System Module C2 GR Instrument Panel 3

Sentry Key Remote Entry Module

(SKREEM)GR Instrument Panel 3

Shifter Assembly BK Center Console 22

Siren BK Engine Compartment-Left 1

SKREEM Transponder BK NS

Speaker-Left Front Door Assembly C1 Engine Compartment-Left 44

Speaker-Left Front Door Assembly C2 In Left Front Door 44

Speaker-Left Rear Rear Of Vehicle On Left

Side45

Speaker-Right Front Door In Right Front Door 44

Speaker-Right Rear Rear Of Vehicle On Right

Side45

Speed Control Switch BK Steering Wheel Controls 17

Starter Motor On Engine 3

Starter Motor Relay (Fuse/Relay Block) In Fuse/Relay Block N/S

Steering Angle Sensor Steering Column 24, 32

Tail Lamp Assembly-Left BK Rear Of Vehicle On Left

Side53

Tail Lamp Assembly-Right BK Rear Of Vehicle On Right

Side53

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONVA

Page 1559 of 2305

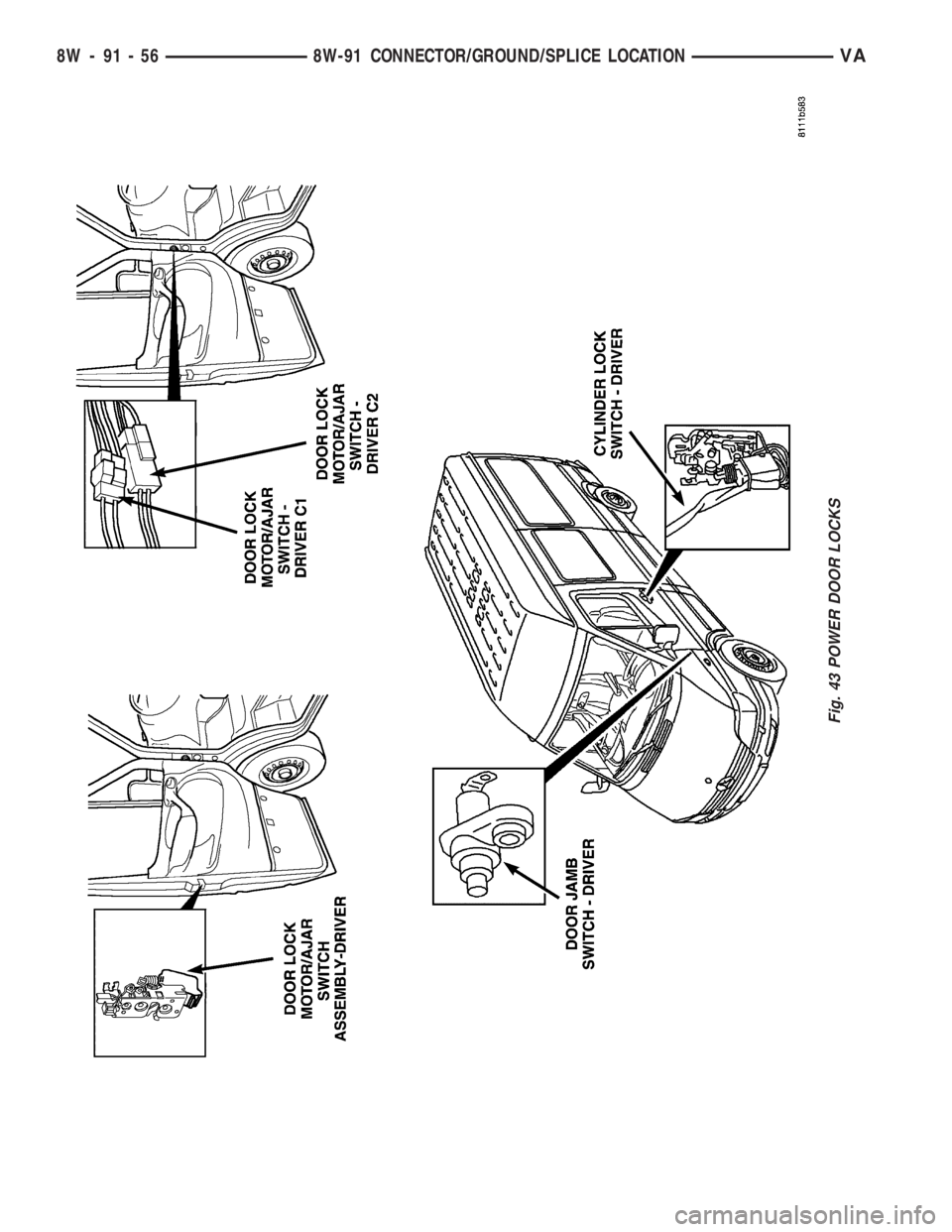

Fig. 43 POWER DOOR LOCKS

8W - 91 - 56 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONVA

Page 1562 of 2305

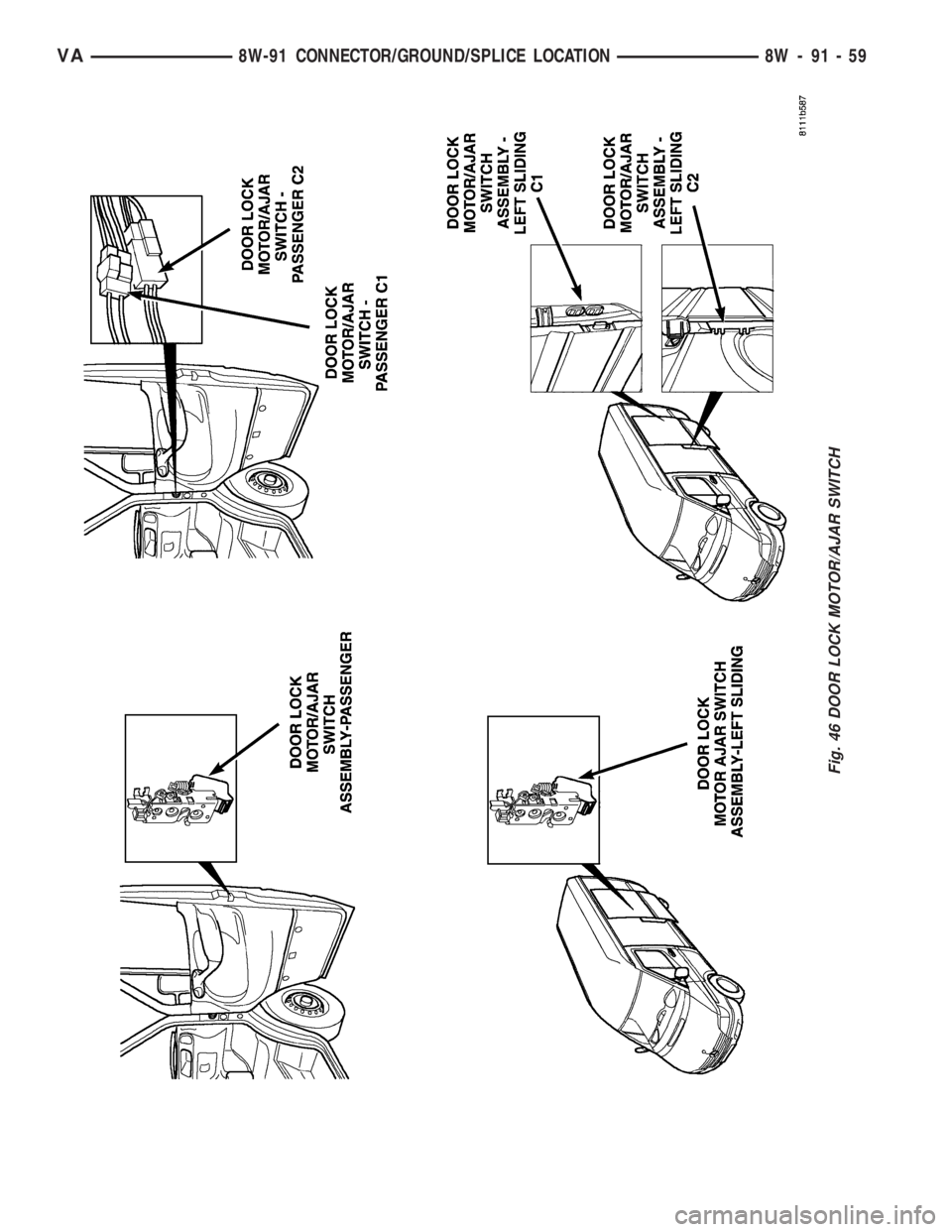

Fig. 46 DOOR LOCK MOTOR/AJAR SWITCH

VA8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 59

Page 1944 of 2305

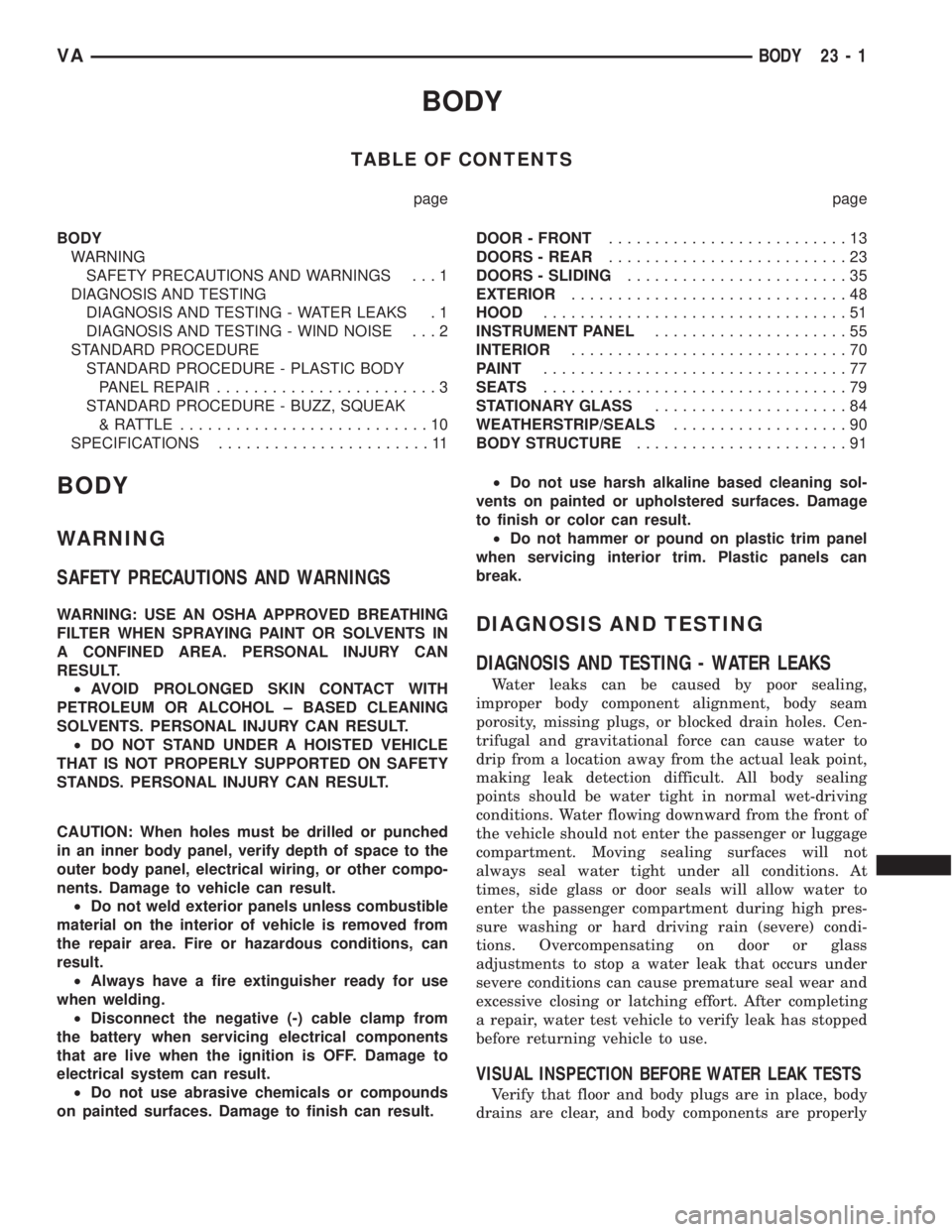

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 1

DIAGNOSIS AND TESTING - WIND NOISE . . . 2

STANDARD PROCEDURE

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - BUZZ, SQUEAK

& RATTLE...........................10

SPECIFICATIONS.......................11DOOR - FRONT..........................13

DOORS - REAR..........................23

DOORS - SLIDING........................35

EXTERIOR..............................48

HOOD.................................51

INSTRUMENT PANEL.....................55

INTERIOR..............................70

PAINT.................................77

SEATS.................................79

STATIONARY GLASS.....................84

WEATHERSTRIP/SEALS...................90

BODY STRUCTURE.......................91

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL ± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.

²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

VABODY 23 - 1

Page 1947 of 2305

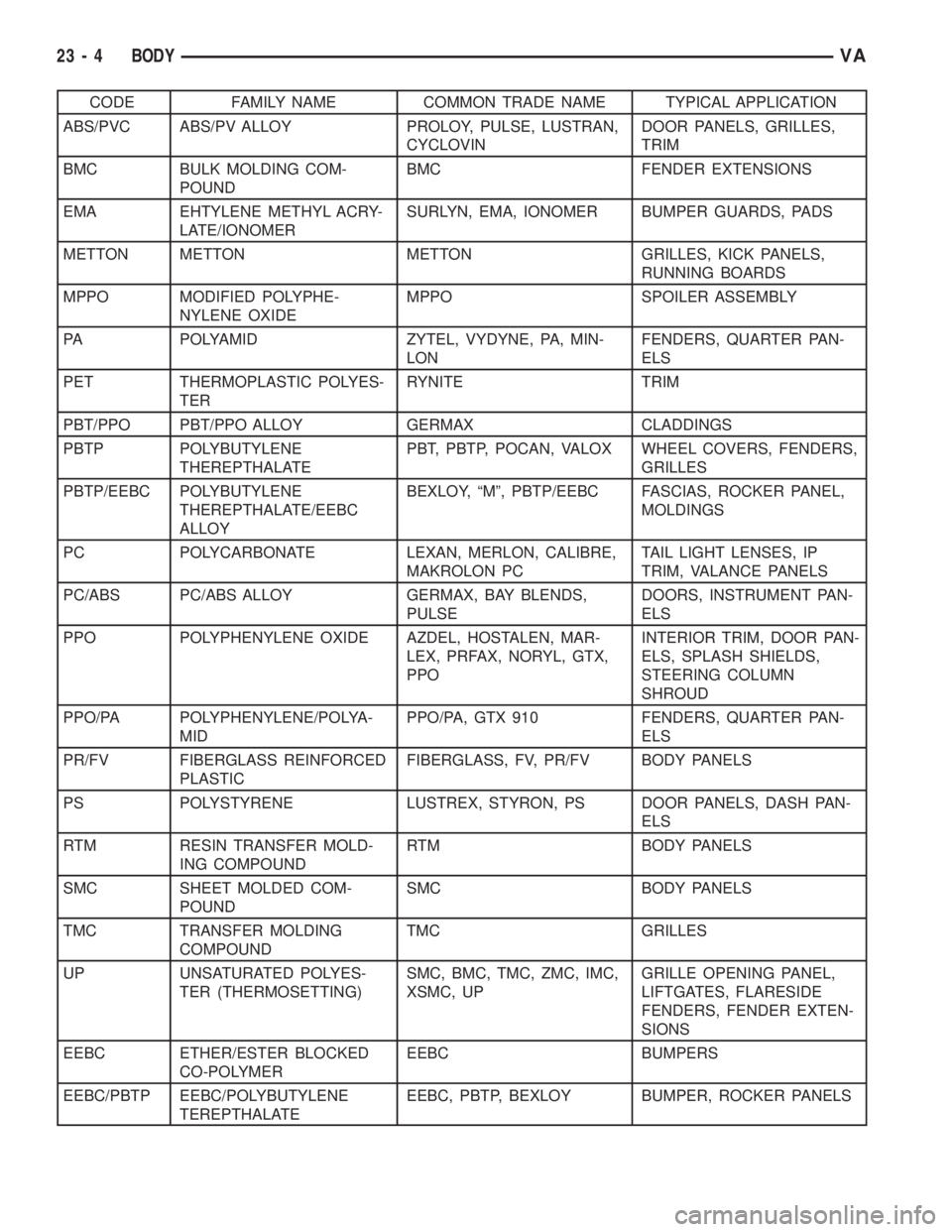

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

ABS/PVC ABS/PV ALLOY PROLOY, PULSE, LUSTRAN,

CYCLOVINDOOR PANELS, GRILLES,

TRIM

BMC BULK MOLDING COM-

POUNDBMC FENDER EXTENSIONS

EMA EHTYLENE METHYL ACRY-

LATE/IONOMERSURLYN, EMA, IONOMER BUMPER GUARDS, PADS

METTON METTON METTON GRILLES, KICK PANELS,

RUNNING BOARDS

MPPO MODIFIED POLYPHE-

NYLENE OXIDEMPPO SPOILER ASSEMBLY

PA POLYAMID ZYTEL, VYDYNE, PA, MIN-

LONFENDERS, QUARTER PAN-

ELS

PET THERMOPLASTIC POLYES-

TERRYNITE TRIM

PBT/PPO PBT/PPO ALLOY GERMAX CLADDINGS

PBTP POLYBUTYLENE

THEREPTHALATEPBT, PBTP, POCAN, VALOX WHEEL COVERS, FENDERS,

GRILLES

PBTP/EEBC POLYBUTYLENE

THEREPTHALATE/EEBC

ALLOYBEXLOY, ªMº, PBTP/EEBC FASCIAS, ROCKER PANEL,

MOLDINGS

PC POLYCARBONATE LEXAN, MERLON, CALIBRE,

MAKROLON PCTAIL LIGHT LENSES, IP

TRIM, VALANCE PANELS

PC/ABS PC/ABS ALLOY GERMAX, BAY BLENDS,

PULSEDOORS, INSTRUMENT PAN-

ELS

PPO POLYPHENYLENE OXIDE AZDEL, HOSTALEN, MAR-

LEX, PRFAX, NORYL, GTX,

PPOINTERIOR TRIM, DOOR PAN-

ELS, SPLASH SHIELDS,

STEERING COLUMN

SHROUD

PPO/PA POLYPHENYLENE/POLYA-

MIDPPO/PA, GTX 910 FENDERS, QUARTER PAN-

ELS

PR/FV FIBERGLASS REINFORCED

PLASTICFIBERGLASS, FV, PR/FV BODY PANELS

PS POLYSTYRENE LUSTREX, STYRON, PS DOOR PANELS, DASH PAN-

ELS

RTM RESIN TRANSFER MOLD-

ING COMPOUNDRTM BODY PANELS

SMC SHEET MOLDED COM-

POUNDSMC BODY PANELS

TMC TRANSFER MOLDING

COMPOUNDTMC GRILLES

UP UNSATURATED POLYES-

TER (THERMOSETTING)SMC, BMC, TMC, ZMC, IMC,

XSMC, UPGRILLE OPENING PANEL,

LIFTGATES, FLARESIDE

FENDERS, FENDER EXTEN-

SIONS

EEBC ETHER/ESTER BLOCKED

CO-POLYMEREEBC BUMPERS

EEBC/PBTP EEBC/POLYBUTYLENE

TEREPTHALATEEEBC, PBTP, BEXLOY BUMPER, ROCKER PANELS

23 - 4 BODYVA

Page 1955 of 2305

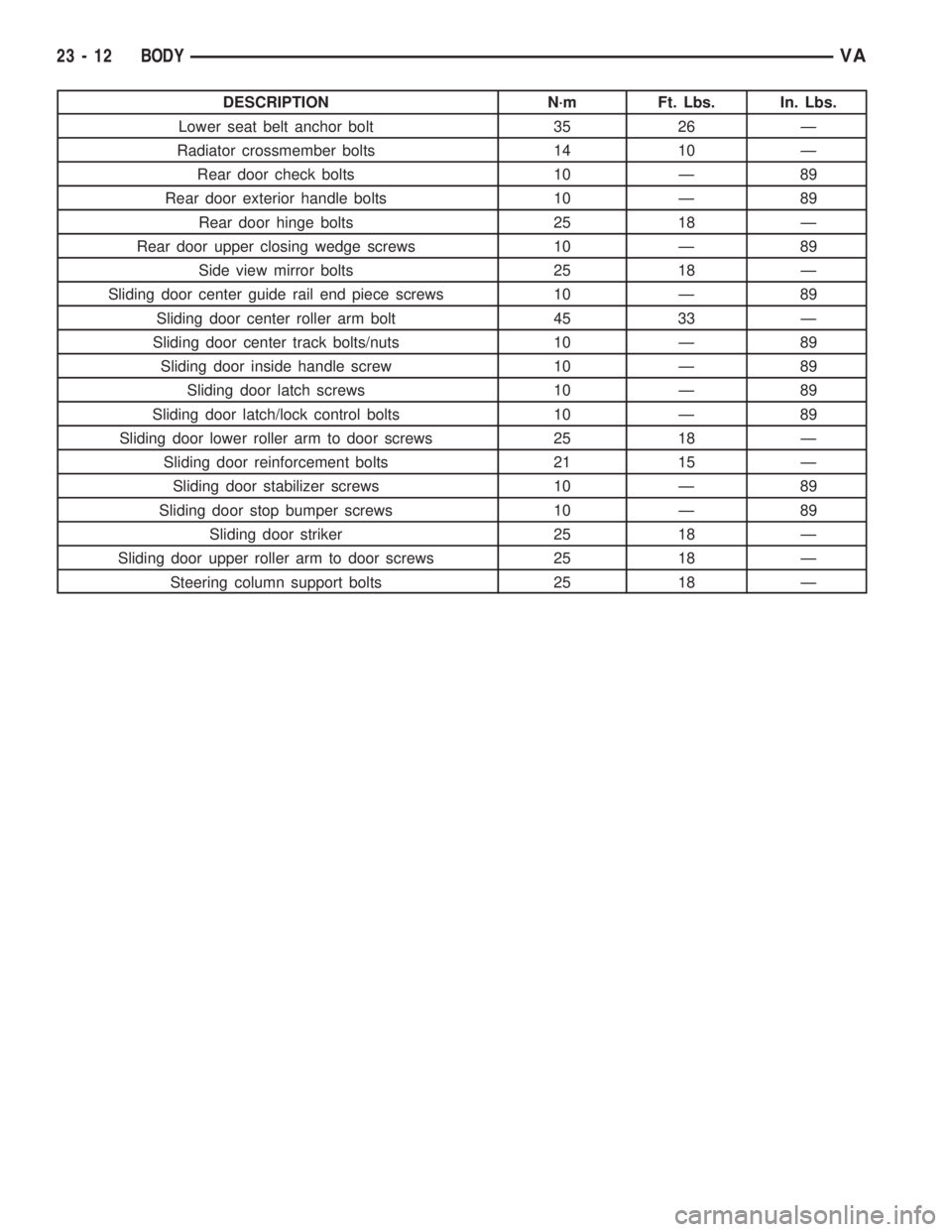

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lower seat belt anchor bolt 35 26 Ð

Radiator crossmember bolts 14 10 Ð

Rear door check bolts 10 Ð 89

Rear door exterior handle bolts 10 Ð 89

Rear door hinge bolts 25 18 Ð

Rear door upper closing wedge screws 10 Ð 89

Side view mirror bolts 25 18 Ð

Sliding door center guide rail end piece screws 10 Ð 89

Sliding door center roller arm bolt 45 33 Ð

Sliding door center track bolts/nuts 10 Ð 89

Sliding door inside handle screw 10 Ð 89

Sliding door latch screws 10 Ð 89

Sliding door latch/lock control bolts 10 Ð 89

Sliding door lower roller arm to door screws 25 18 Ð

Sliding door reinforcement bolts 21 15 Ð

Sliding door stabilizer screws 10 Ð 89

Sliding door stop bumper screws 10 Ð 89

Sliding door striker 25 18 Ð

Sliding door upper roller arm to door screws 25 18 Ð

Steering column support bolts 25 18 Ð

23 - 12 BODYVA

Page 1956 of 2305

DOOR - FRONT

TABLE OF CONTENTS

page page

CHECK

REMOVAL.............................13

INSTALLATION.........................13

DOOR

REMOVAL.............................14

INSTALLATION.........................14

ADJUSTMENTS

ADJUSTMENT........................15

DOOR GLASS

REMOVAL.............................15

INSTALLATION.........................15

EXTERIOR HANDLE

REMOVAL.............................16

INSTALLATION.........................16

HINGE

REMOVAL.............................17

INSTALLATION.........................17

LATCH

REMOVAL.............................18INSTALLATION.........................18

LATCH STRIKER

REMOVAL.............................18

INSTALLATION.........................18

LOCK CYLINDER

REMOVAL.............................18

INSTALLATION.........................18

TRIM PANEL

REMOVAL.............................18

INSTALLATION.........................20

WINDOW REGULATOR - POWER

REMOVAL.............................20

INSTALLATION.........................21

WINDOW REGULATOR - MANUAL

REMOVAL.............................21

INSTALLATION.........................22

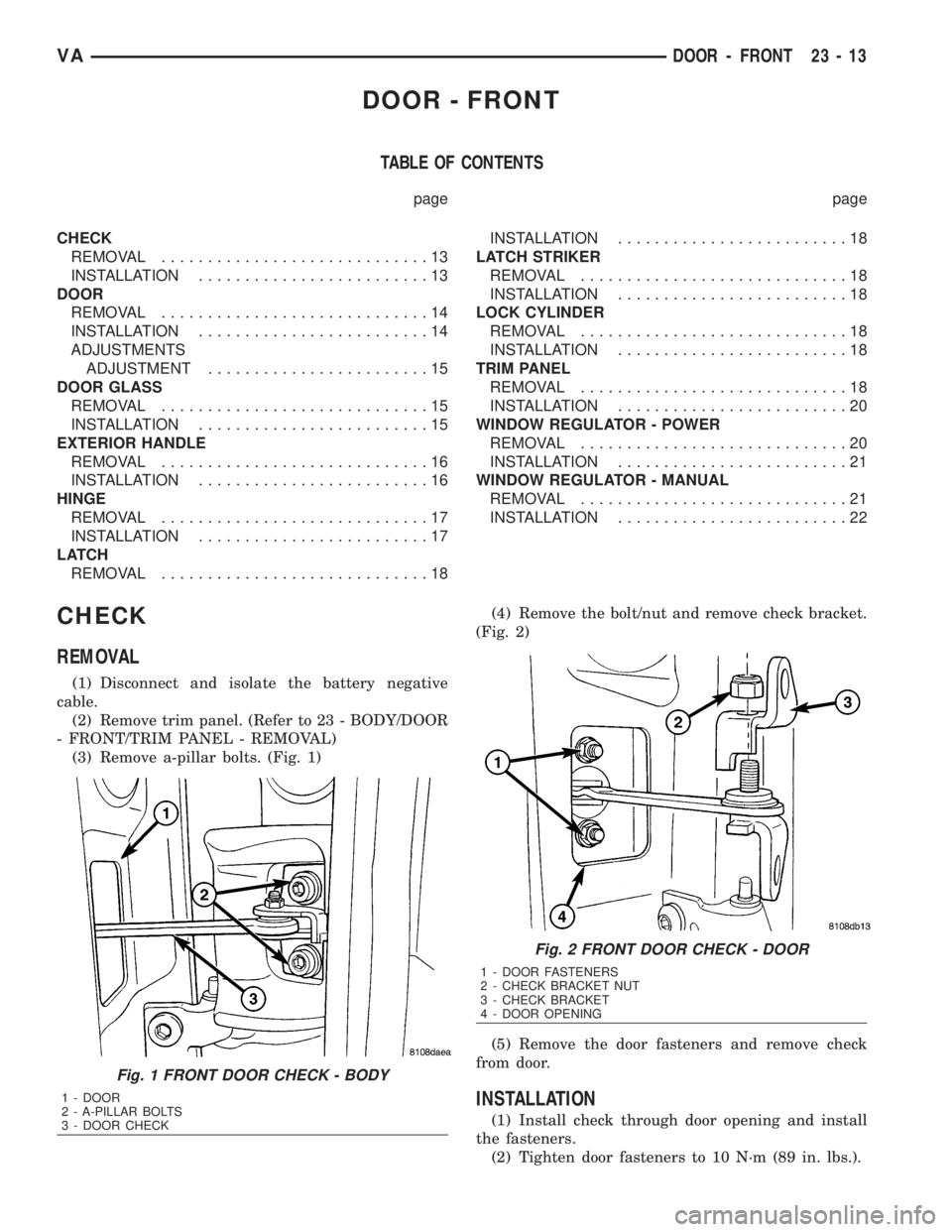

CHECK

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove trim panel. (Refer to 23 - BODY/DOOR

- FRONT/TRIM PANEL - REMOVAL)

(3) Remove a-pillar bolts. (Fig. 1)(4) Remove the bolt/nut and remove check bracket.

(Fig. 2)

(5) Remove the door fasteners and remove check

from door.

INSTALLATION

(1) Install check through door opening and install

the fasteners.

(2) Tighten door fasteners to 10 N´m (89 in. lbs.).

Fig. 1 FRONT DOOR CHECK - BODY

1 - DOOR

2 - A-PILLAR BOLTS

3 - DOOR CHECK

Fig. 2 FRONT DOOR CHECK - DOOR

1 - DOOR FASTENERS

2 - CHECK BRACKET NUT

3 - CHECK BRACKET

4 - DOOR OPENING

VADOOR - FRONT 23 - 13

Page 1959 of 2305

(4) Tighten the reinforcement bolts to 21 N´m (18

ft. lbs.).

(5) Install the regulator. (Refer to 23 - BODY/

DOOR - FRONT/WINDOW REGULATOR - POWER

or MANUAL - INSTALLATION)

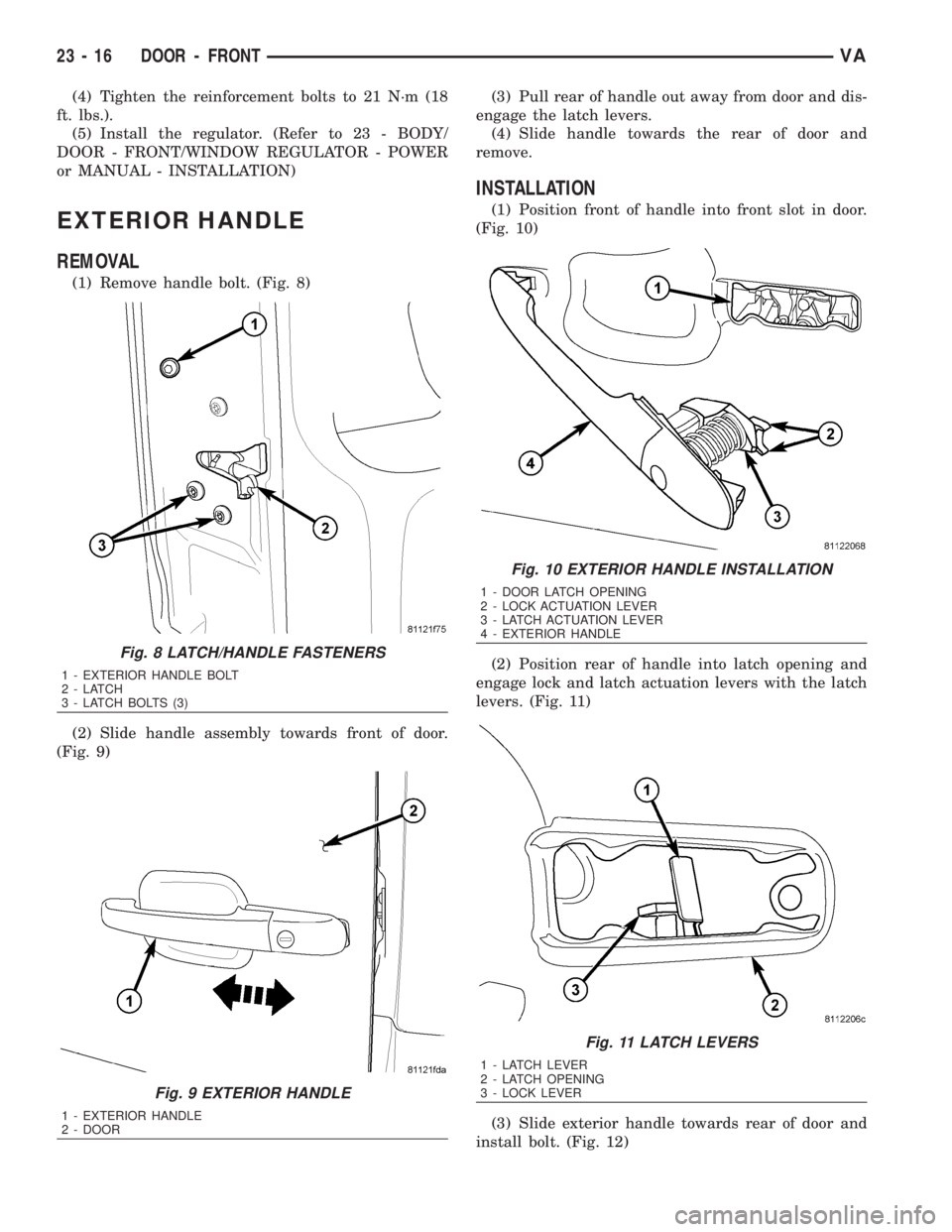

EXTERIOR HANDLE

REMOVAL

(1) Remove handle bolt. (Fig. 8)

(2) Slide handle assembly towards front of door.

(Fig. 9)(3) Pull rear of handle out away from door and dis-

engage the latch levers.

(4) Slide handle towards the rear of door and

remove.

INSTALLATION

(1) Position front of handle into front slot in door.

(Fig. 10)

(2) Position rear of handle into latch opening and

engage lock and latch actuation levers with the latch

levers. (Fig. 11)

(3) Slide exterior handle towards rear of door and

install bolt. (Fig. 12)

Fig. 8 LATCH/HANDLE FASTENERS

1 - EXTERIOR HANDLE BOLT

2-LATCH

3 - LATCH BOLTS (3)

Fig. 9 EXTERIOR HANDLE

1 - EXTERIOR HANDLE

2 - DOOR

Fig. 10 EXTERIOR HANDLE INSTALLATION

1 - DOOR LATCH OPENING

2 - LOCK ACTUATION LEVER

3 - LATCH ACTUATION LEVER

4 - EXTERIOR HANDLE

Fig. 11 LATCH LEVERS

1 - LATCH LEVER

2 - LATCH OPENING

3 - LOCK LEVER

23 - 16 DOOR - FRONTVA

Page 1961 of 2305

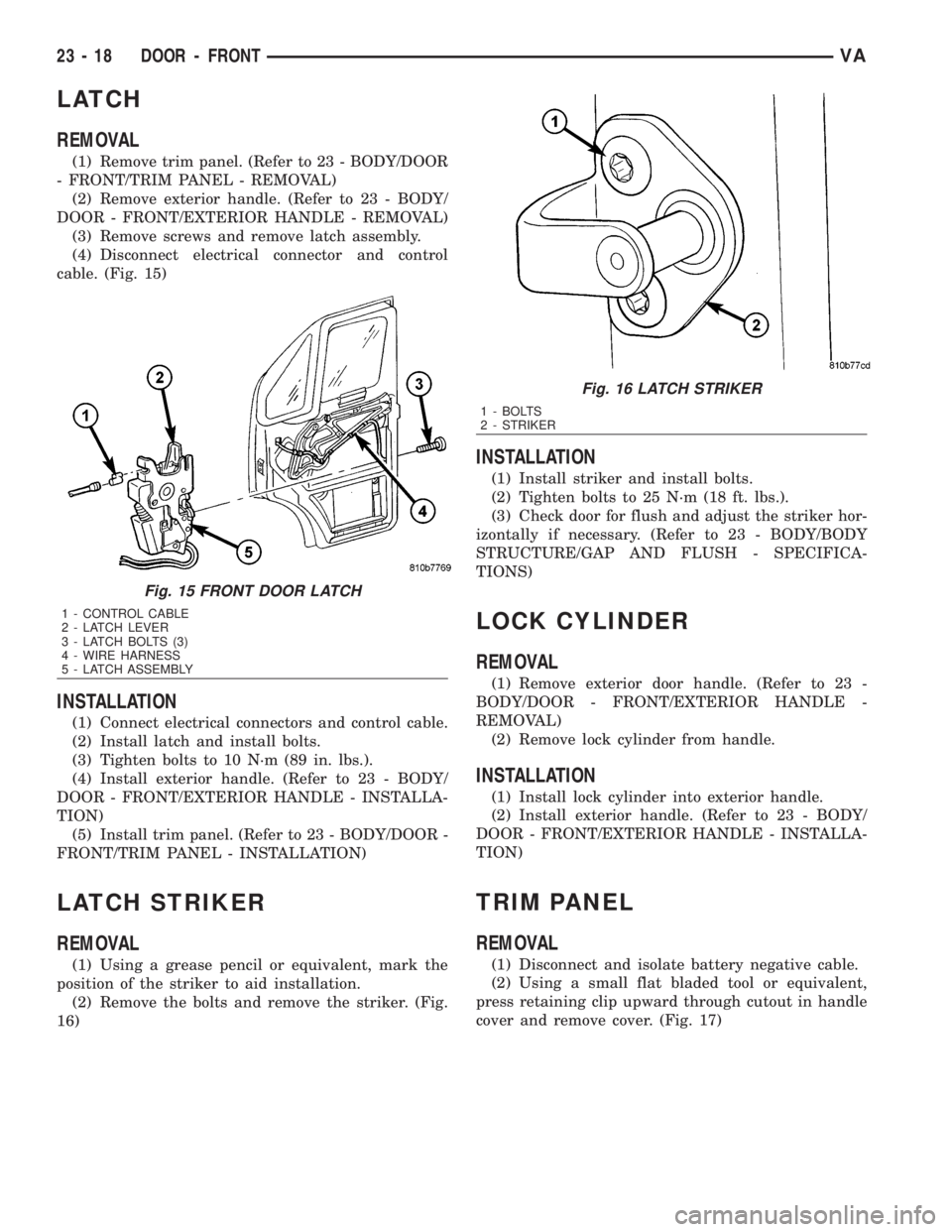

LATCH

REMOVAL

(1) Remove trim panel. (Refer to 23 - BODY/DOOR

- FRONT/TRIM PANEL - REMOVAL)

(2) Remove exterior handle. (Refer to 23 - BODY/

DOOR - FRONT/EXTERIOR HANDLE - REMOVAL)

(3) Remove screws and remove latch assembly.

(4) Disconnect electrical connector and control

cable. (Fig. 15)

INSTALLATION

(1) Connect electrical connectors and control cable.

(2) Install latch and install bolts.

(3) Tighten bolts to 10 N´m (89 in. lbs.).

(4) Install exterior handle. (Refer to 23 - BODY/

DOOR - FRONT/EXTERIOR HANDLE - INSTALLA-

TION)

(5) Install trim panel. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION)

LATCH STRIKER

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the striker to aid installation.

(2) Remove the bolts and remove the striker. (Fig.

16)

INSTALLATION

(1) Install striker and install bolts.

(2) Tighten bolts to 25 N´m (18 ft. lbs.).

(3) Check door for flush and adjust the striker hor-

izontally if necessary. (Refer to 23 - BODY/BODY

STRUCTURE/GAP AND FLUSH - SPECIFICA-

TIONS)

LOCK CYLINDER

REMOVAL

(1) Remove exterior door handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

REMOVAL)

(2) Remove lock cylinder from handle.

INSTALLATION

(1) Install lock cylinder into exterior handle.

(2) Install exterior handle. (Refer to 23 - BODY/

DOOR - FRONT/EXTERIOR HANDLE - INSTALLA-

TION)

TRIM PANEL

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Using a small flat bladed tool or equivalent,

press retaining clip upward through cutout in handle

cover and remove cover. (Fig. 17)

Fig. 15 FRONT DOOR LATCH

1 - CONTROL CABLE

2 - LATCH LEVER

3 - LATCH BOLTS (3)

4 - WIRE HARNESS

5 - LATCH ASSEMBLY

Fig. 16 LATCH STRIKER

1 - BOLTS

2 - STRIKER

23 - 18 DOOR - FRONTVA

Page 1963 of 2305

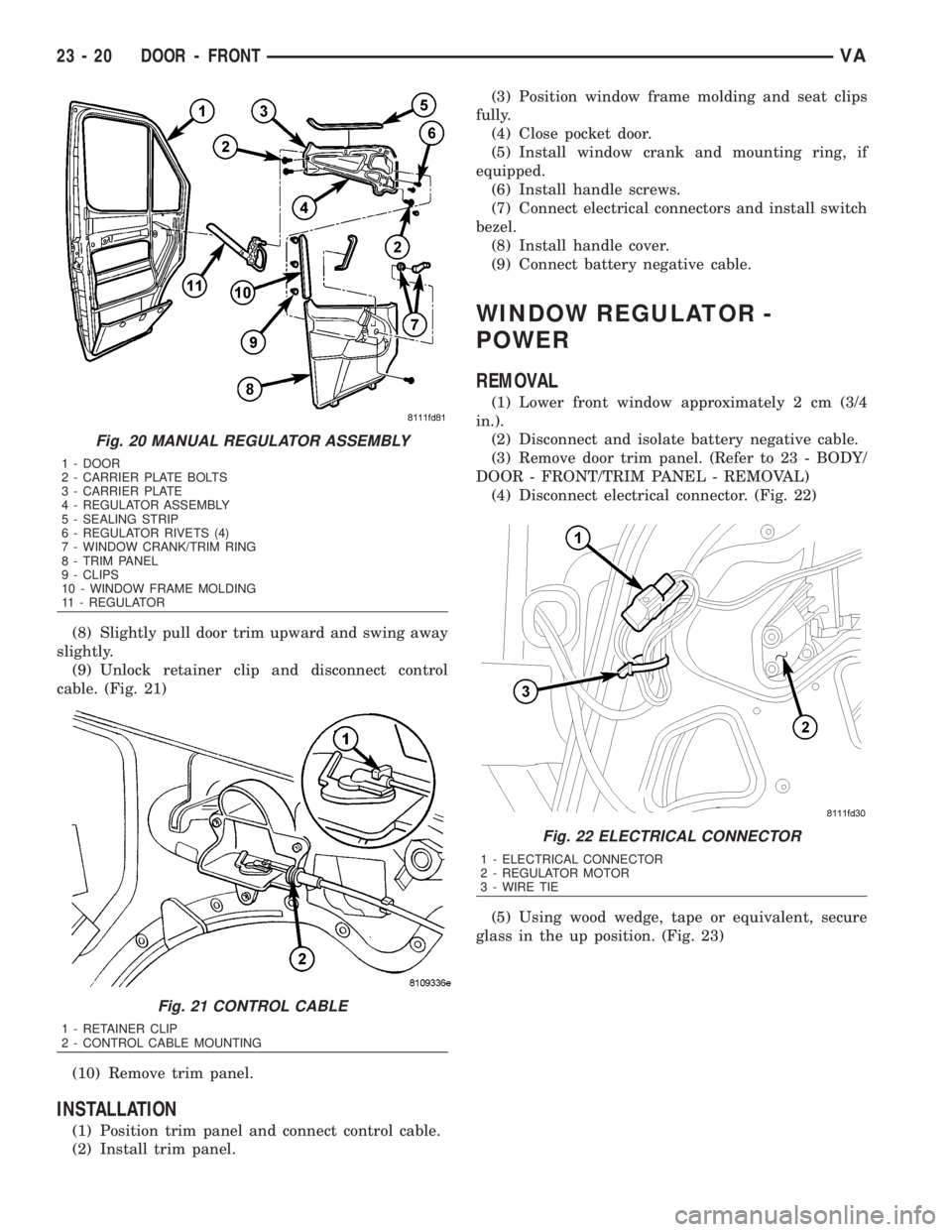

(8) Slightly pull door trim upward and swing away

slightly.

(9) Unlock retainer clip and disconnect control

cable. (Fig. 21)

(10) Remove trim panel.

INSTALLATION

(1) Position trim panel and connect control cable.

(2) Install trim panel.(3) Position window frame molding and seat clips

fully.

(4) Close pocket door.

(5) Install window crank and mounting ring, if

equipped.

(6) Install handle screws.

(7) Connect electrical connectors and install switch

bezel.

(8) Install handle cover.

(9) Connect battery negative cable.

WINDOW REGULATOR -

POWER

REMOVAL

(1) Lower front window approximately 2 cm (3/4

in.).

(2) Disconnect and isolate battery negative cable.

(3) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(4) Disconnect electrical connector. (Fig. 22)

(5) Using wood wedge, tape or equivalent, secure

glass in the up position. (Fig. 23)

Fig. 20 MANUAL REGULATOR ASSEMBLY

1 - DOOR

2 - CARRIER PLATE BOLTS

3 - CARRIER PLATE

4 - REGULATOR ASSEMBLY

5 - SEALING STRIP

6 - REGULATOR RIVETS (4)

7 - WINDOW CRANK/TRIM RING

8 - TRIM PANEL

9 - CLIPS

10 - WINDOW FRAME MOLDING

11 - REGULATOR

Fig. 21 CONTROL CABLE

1 - RETAINER CLIP

2 - CONTROL CABLE MOUNTING

Fig. 22 ELECTRICAL CONNECTOR

1 - ELECTRICAL CONNECTOR

2 - REGULATOR MOTOR

3 - WIRE TIE

23 - 20 DOOR - FRONTVA