fuse MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 905 of 2305

²The coil ground terminal (86) is hardwired to

ground point G202.

²The coil battery terminal (85) receives a battery

current input from the rear window defogger module

when the rear window defogger switch is energized.

²The normally open terminal (87) provides a bat-

tery current output to the rear window defogger grid

lines through the relay output circuit only when the

rear window defogger relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear window

defogger relay coil is de-energized.

The left and right EBL relays cannot be repaired

and, if faulty or damaged, they must be replaced.

Refer to the appropriate wiring information for diag-

nosis and testing of the EBL relays and for complete

rear window defogger system wiring diagrams.

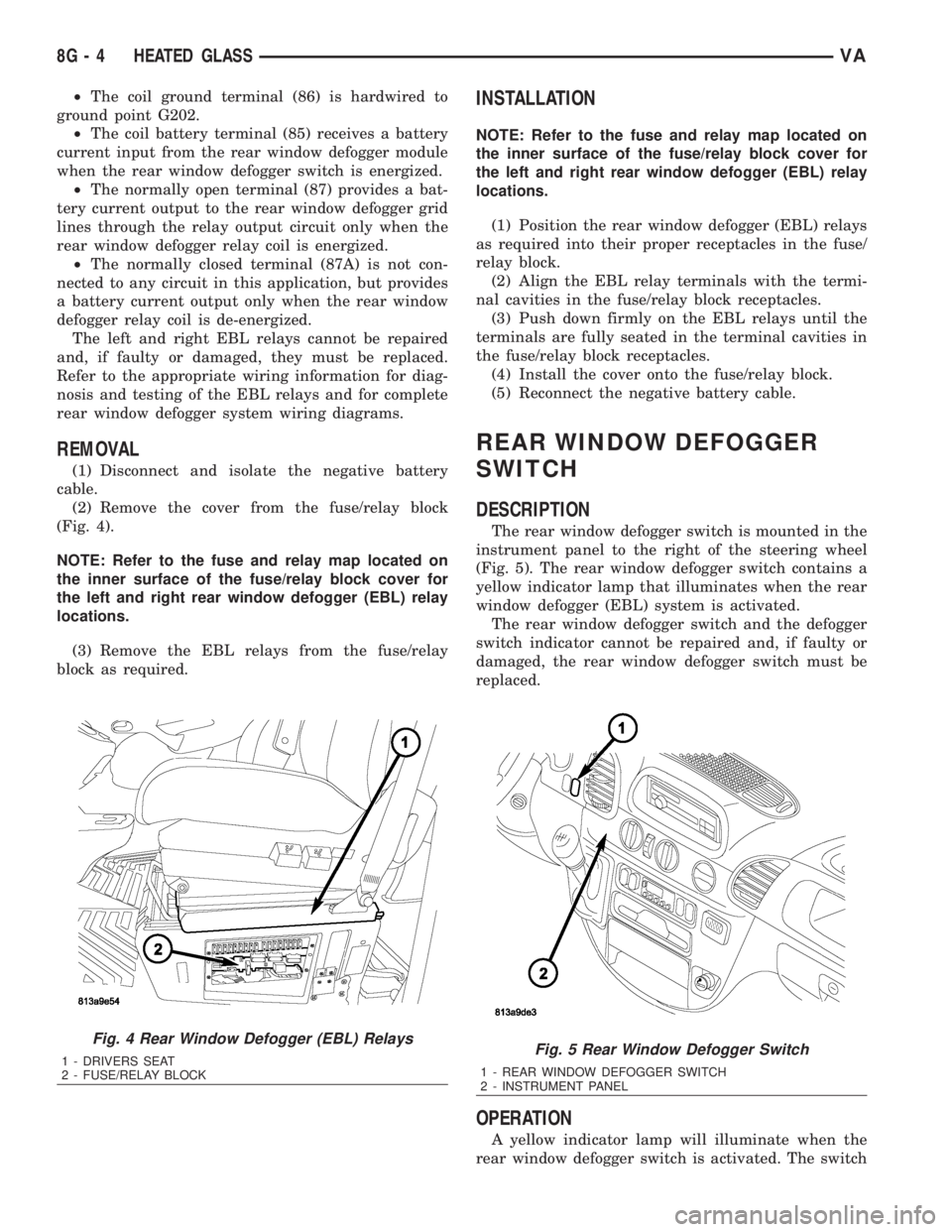

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the fuse/relay block

(Fig. 4).

NOTE: Refer to the fuse and relay map located on

the inner surface of the fuse/relay block cover for

the left and right rear window defogger (EBL) relay

locations.

(3) Remove the EBL relays from the fuse/relay

block as required.

INSTALLATION

NOTE: Refer to the fuse and relay map located on

the inner surface of the fuse/relay block cover for

the left and right rear window defogger (EBL) relay

locations.

(1) Position the rear window defogger (EBL) relays

as required into their proper receptacles in the fuse/

relay block.

(2) Align the EBL relay terminals with the termi-

nal cavities in the fuse/relay block receptacles.

(3) Push down firmly on the EBL relays until the

terminals are fully seated in the terminal cavities in

the fuse/relay block receptacles.

(4) Install the cover onto the fuse/relay block.

(5) Reconnect the negative battery cable.

REAR WINDOW DEFOGGER

SWITCH

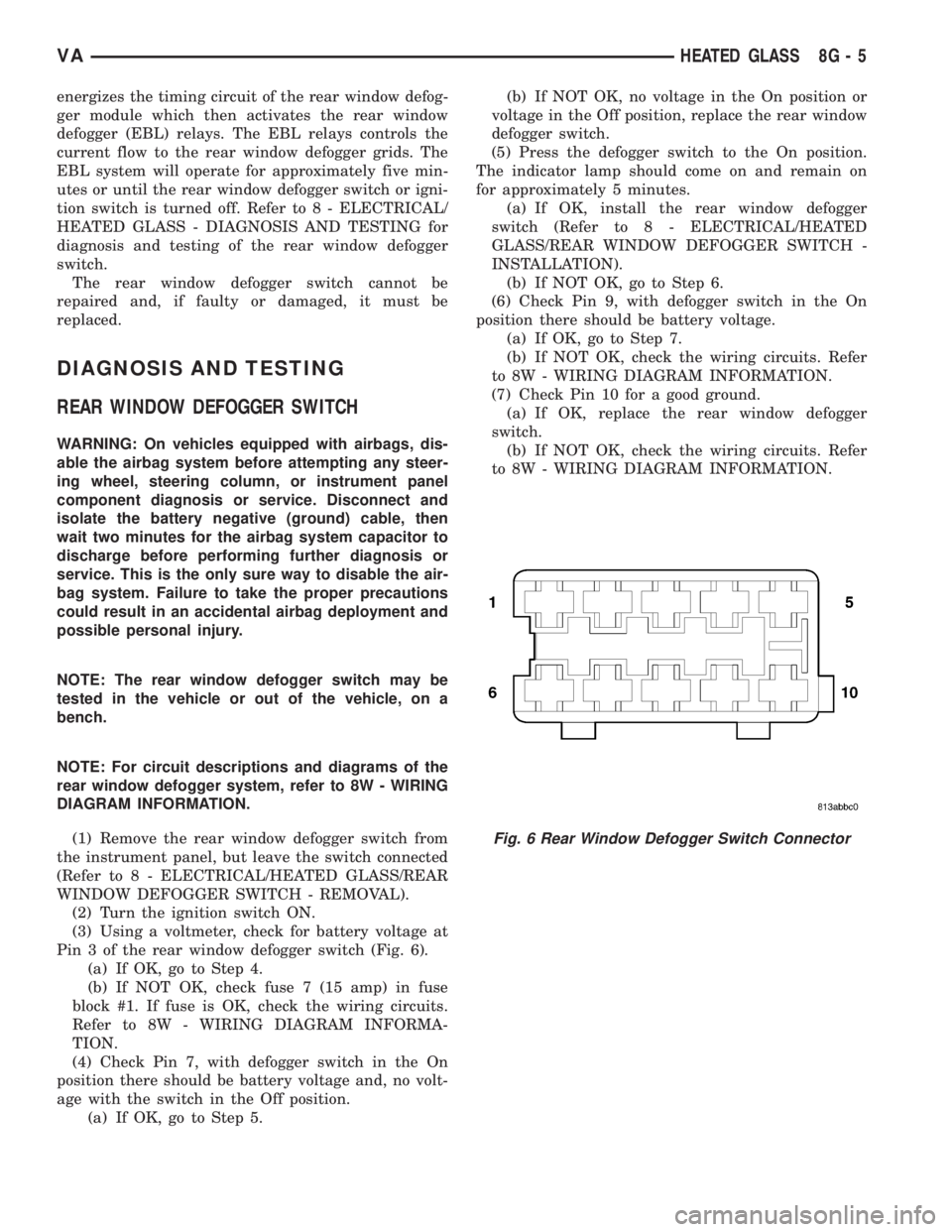

DESCRIPTION

The rear window defogger switch is mounted in the

instrument panel to the right of the steering wheel

(Fig. 5). The rear window defogger switch contains a

yellow indicator lamp that illuminates when the rear

window defogger (EBL) system is activated.

The rear window defogger switch and the defogger

switch indicator cannot be repaired and, if faulty or

damaged, the rear window defogger switch must be

replaced.

OPERATION

A yellow indicator lamp will illuminate when the

rear window defogger switch is activated. The switch

Fig. 4 Rear Window Defogger (EBL) Relays

1 - DRIVERS SEAT

2 - FUSE/RELAY BLOCKFig. 5 Rear Window Defogger Switch

1 - REAR WINDOW DEFOGGER SWITCH

2 - INSTRUMENT PANEL

8G - 4 HEATED GLASSVA

Page 906 of 2305

energizes the timing circuit of the rear window defog-

ger module which then activates the rear window

defogger (EBL) relays. The EBL relays controls the

current flow to the rear window defogger grids. The

EBL system will operate for approximately five min-

utes or until the rear window defogger switch or igni-

tion switch is turned off. Refer to 8 - ELECTRICAL/

HEATED GLASS - DIAGNOSIS AND TESTING for

diagnosis and testing of the rear window defogger

switch.

The rear window defogger switch cannot be

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING

REAR WINDOW DEFOGGER SWITCH

WARNING: On vehicles equipped with airbags, dis-

able the airbag system before attempting any steer-

ing wheel, steering column, or instrument panel

component diagnosis or service. Disconnect and

isolate the battery negative (ground) cable, then

wait two minutes for the airbag system capacitor to

discharge before performing further diagnosis or

service. This is the only sure way to disable the air-

bag system. Failure to take the proper precautions

could result in an accidental airbag deployment and

possible personal injury.

NOTE: The rear window defogger switch may be

tested in the vehicle or out of the vehicle, on a

bench.

NOTE: For circuit descriptions and diagrams of the

rear window defogger system, refer to 8W - WIRING

DIAGRAM INFORMATION.

(1) Remove the rear window defogger switch from

the instrument panel, but leave the switch connected

(Refer to 8 - ELECTRICAL/HEATED GLASS/REAR

WINDOW DEFOGGER SWITCH - REMOVAL).

(2) Turn the ignition switch ON.

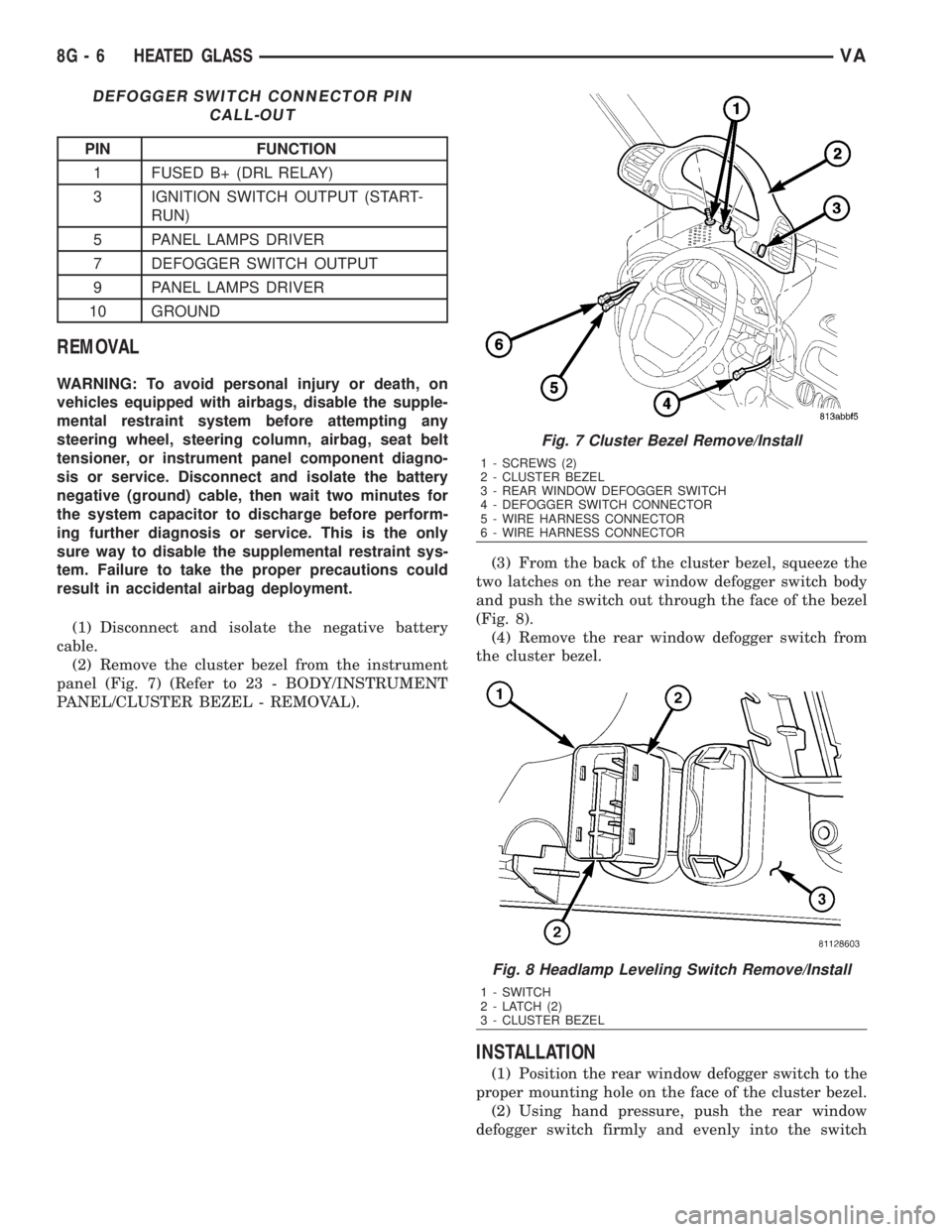

(3) Using a voltmeter, check for battery voltage at

Pin 3 of the rear window defogger switch (Fig. 6).

(a) If OK, go to Step 4.

(b) If NOT OK, check fuse 7 (15 amp) in fuse

block #1. If fuse is OK, check the wiring circuits.

Refer to 8W - WIRING DIAGRAM INFORMA-

TION.

(4) Check Pin 7, with defogger switch in the On

position there should be battery voltage and, no volt-

age with the switch in the Off position.

(a) If OK, go to Step 5.(b) If NOT OK, no voltage in the On position or

voltage in the Off position, replace the rear window

defogger switch.

(5) Press the defogger switch to the On position.

The indicator lamp should come on and remain on

for approximately 5 minutes.

(a) If OK, install the rear window defogger

switch (Refer to 8 - ELECTRICAL/HEATED

GLASS/REAR WINDOW DEFOGGER SWITCH -

INSTALLATION).

(b) If NOT OK, go to Step 6.

(6) Check Pin 9, with defogger switch in the On

position there should be battery voltage.

(a) If OK, go to Step 7.

(b) If NOT OK, check the wiring circuits. Refer

to 8W - WIRING DIAGRAM INFORMATION.

(7) Check Pin 10 for a good ground.

(a) If OK, replace the rear window defogger

switch.

(b) If NOT OK, check the wiring circuits. Refer

to 8W - WIRING DIAGRAM INFORMATION.

Fig. 6 Rear Window Defogger Switch Connector

VAHEATED GLASS 8G - 5

Page 907 of 2305

DEFOGGER SWITCH CONNECTOR PIN

CALL-OUT

PIN FUNCTION

1 FUSED B+ (DRL RELAY)

3 IGNITION SWITCH OUTPUT (START-

RUN)

5 PANEL LAMPS DRIVER

7 DEFOGGER SWITCH OUTPUT

9 PANEL LAMPS DRIVER

10 GROUND

REMOVAL

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

(1) Disconnect and isolate the negative battery

cable.

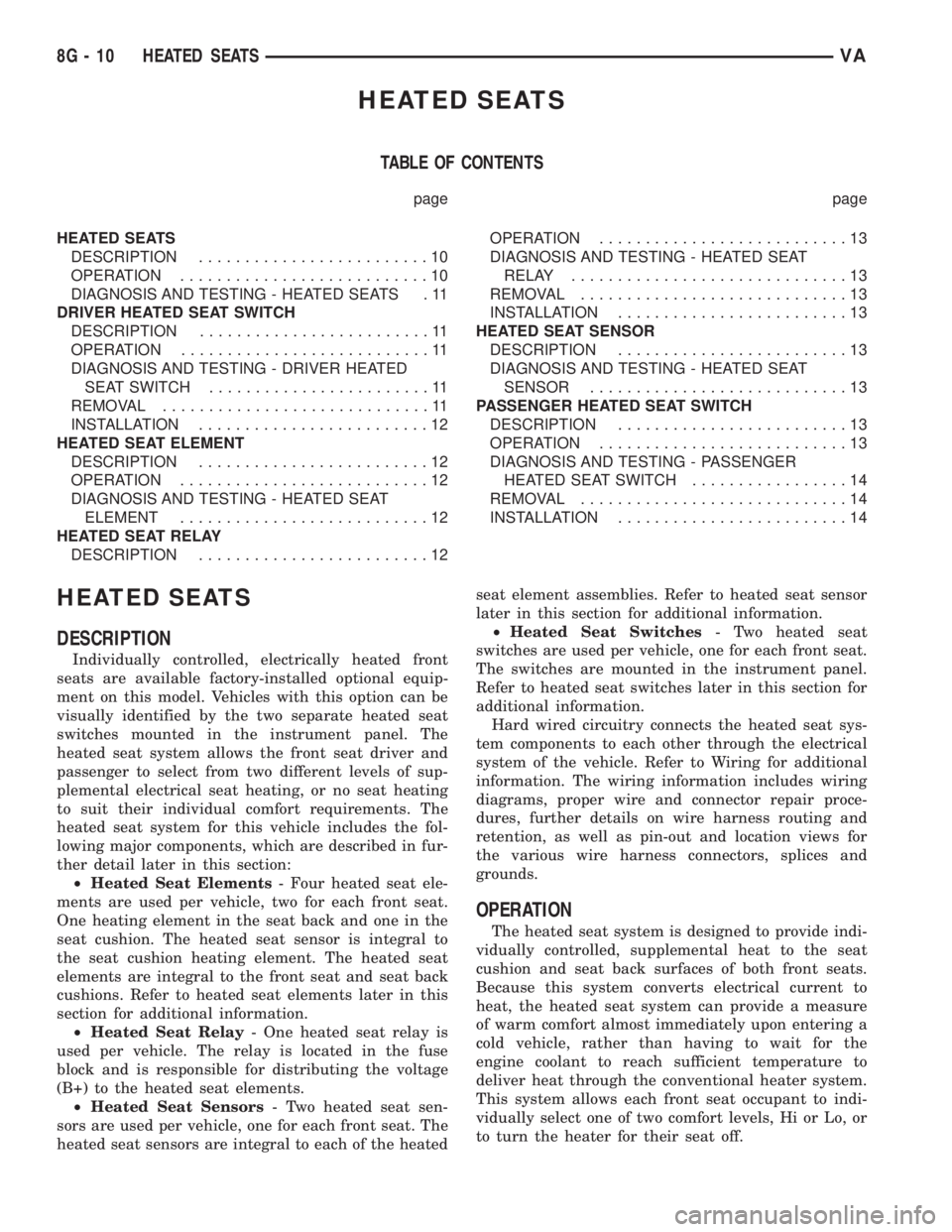

(2) Remove the cluster bezel from the instrument

panel (Fig. 7) (Refer to 23 - BODY/INSTRUMENT

PANEL/CLUSTER BEZEL - REMOVAL).(3) From the back of the cluster bezel, squeeze the

two latches on the rear window defogger switch body

and push the switch out through the face of the bezel

(Fig. 8).

(4) Remove the rear window defogger switch from

the cluster bezel.

INSTALLATION

(1) Position the rear window defogger switch to the

proper mounting hole on the face of the cluster bezel.

(2) Using hand pressure, push the rear window

defogger switch firmly and evenly into the switch

Fig. 7 Cluster Bezel Remove/Install

1 - SCREWS (2)

2 - CLUSTER BEZEL

3 - REAR WINDOW DEFOGGER SWITCH

4 - DEFOGGER SWITCH CONNECTOR

5 - WIRE HARNESS CONNECTOR

6 - WIRE HARNESS CONNECTOR

Fig. 8 Headlamp Leveling Switch Remove/Install

1 - SWITCH

2 - LATCH (2)

3 - CLUSTER BEZEL

8G - 6 HEATED GLASSVA

Page 911 of 2305

HEATED SEATS

TABLE OF CONTENTS

page page

HEATED SEATS

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - HEATED SEATS . 11

DRIVER HEATED SEAT SWITCH

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH........................11

REMOVAL.............................11

INSTALLATION.........................12

HEATED SEAT ELEMENT

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT...........................12

HEATED SEAT RELAY

DESCRIPTION.........................12OPERATION...........................13

DIAGNOSIS AND TESTING - HEATED SEAT

RELAY..............................13

REMOVAL.............................13

INSTALLATION.........................13

HEATED SEAT SENSOR

DESCRIPTION.........................13

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR............................13

PASSENGER HEATED SEAT SWITCH

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH.................14

REMOVAL.............................14

INSTALLATION.........................14

HEATED SEATS

DESCRIPTION

Individually controlled, electrically heated front

seats are available factory-installed optional equip-

ment on this model. Vehicles with this option can be

visually identified by the two separate heated seat

switches mounted in the instrument panel. The

heated seat system allows the front seat driver and

passenger to select from two different levels of sup-

plemental electrical seat heating, or no seat heating

to suit their individual comfort requirements. The

heated seat system for this vehicle includes the fol-

lowing major components, which are described in fur-

ther detail later in this section:

²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle, two for each front seat.

One heating element in the seat back and one in the

seat cushion. The heated seat sensor is integral to

the seat cushion heating element. The heated seat

elements are integral to the front seat and seat back

cushions. Refer to heated seat elements later in this

section for additional information.

²Heated Seat Relay- One heated seat relay is

used per vehicle. The relay is located in the fuse

block and is responsible for distributing the voltage

(B+) to the heated seat elements.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle, one for each front seat. The

heated seat sensors are integral to each of the heatedseat element assemblies. Refer to heated seat sensor

later in this section for additional information.

²Heated Seat Switches- Two heated seat

switches are used per vehicle, one for each front seat.

The switches are mounted in the instrument panel.

Refer to heated seat switches later in this section for

additional information.

Hard wired circuitry connects the heated seat sys-

tem components to each other through the electrical

system of the vehicle. Refer to Wiring for additional

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, further details on wire harness routing and

retention, as well as pin-out and location views for

the various wire harness connectors, splices and

grounds.

OPERATION

The heated seat system is designed to provide indi-

vidually controlled, supplemental heat to the seat

cushion and seat back surfaces of both front seats.

Because this system converts electrical current to

heat, the heated seat system can provide a measure

of warm comfort almost immediately upon entering a

cold vehicle, rather than having to wait for the

engine coolant to reach sufficient temperature to

deliver heat through the conventional heater system.

This system allows each front seat occupant to indi-

vidually select one of two comfort levels, Hi or Lo, or

to turn the heater for their seat off.

8G - 10 HEATED SEATSVA

Page 912 of 2305

The heated seat system components operate on

battery current received through a fuse in the Fuse

Block on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the On or Accessory positions.

The heated seat system will be turned Off automati-

cally whenever the ignition switch is turned to any

position except On or Accessory. Also, the heated seat

system will not operate when the surface tempera-

ture of the seat cushion cover at either heated seat

sensor is above the designed temperature set points

of the system.DIAGNOSIS AND TESTING - HEATED SEATS

Refer toWiringfor the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

HEATED SEAT SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO HEATED SEAT SWITCH

ILLUMINATION WITH IGNI-

TION ON1. Faulty fuse. 1. Check heated seat fuse in Fuse Block. Re-

place fuse, if required.

2. Wiring faulty. 2. Check fused ignition switch output (run-acc)

circuit from heated seat switch connector to igni-

tion switch. Repair, if required.

3. Ground faulty. 3. Check for ground at heated seat switch con-

nector. Repair, if required.

4. Faulty switch. 4. Refer to Heated Seat Switch for the proper

switch diagnosis and testing procedures.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are located on the instru-

ment panel, in the accessory switch bezel. The two,

momentary rocker type switches provide a signal to

the Heated Seat Relay through separate hard wired

circuits. Each switch contains two light emitting

diodes (LED), one for each High and Low setting to

let the occupant know that the seat heater system is

on.

The heated seat switches and their LED's cannot

be repaired. If either switch is faulty or damaged the

entire switch must be replaced.

OPERATION

There are three modes that can be selected with

each of the heated seat switches: Off, Low, and High.

When the top of the switch rocker is depressed, the

low mode is selected and the low mode LED indicator

illuminates. Depressing the top of the switch rocker a

second time will turn the heated seat to Off. This

same process is repeated for High heat setting. The

heated seats will automatically return to the Off

mode anytime the vehicle ignition switch is turned

Off.Both switches provide separate hard wire inputs to

the Heated Seat Relay to indicate the selected mode.

The Heated Seat Relay responds to the heated seat

switch messages by controlling the output to the seat

heater elements of the selected seat.

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For circuit description and diagrams, refer toWir-

ing.

(1) Inspect the Heated Seat Switches for apparent

damage or sticking/binding and replace if required.

Refer to Heated Seat Switch Removal and Installa-

tion in this section.

(2) Replace the heated seat switch with a known

good unit and retest the heated seat system.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the gear selector bezel trim. Refer to

the Body section for the procedure.

(3) Remove the storage bin. Refer to the Body sec-

tion for the procedure.

(4) Remove the switch bezel retaining screw and

remove the switch bezel from the instrument panel.

Refer to the Body section for the procedure.

(5) Disconnect electrical connections.

VAHEATED SEATS 8G - 11

Page 913 of 2305

(6) Working from the underside of the switch, gen-

tly rock the switch back and forth out of its mounting

location in the switch bezel.

INSTALLATION

(1) Install the heated seat switch in its mounting

location in the switch bezel.

(2) Connect electrical connections.

(3) Position the switch bezel and install the retain-

ing screw. Refer to the Body section for the proce-

dure.

(4) Install the storage bin. Refer to the Body sec-

tion for the procedure.

(5) Install the gear selector bezel trim. Refer to the

Body section for the procedure.

(6) Connect the negative battery cable.

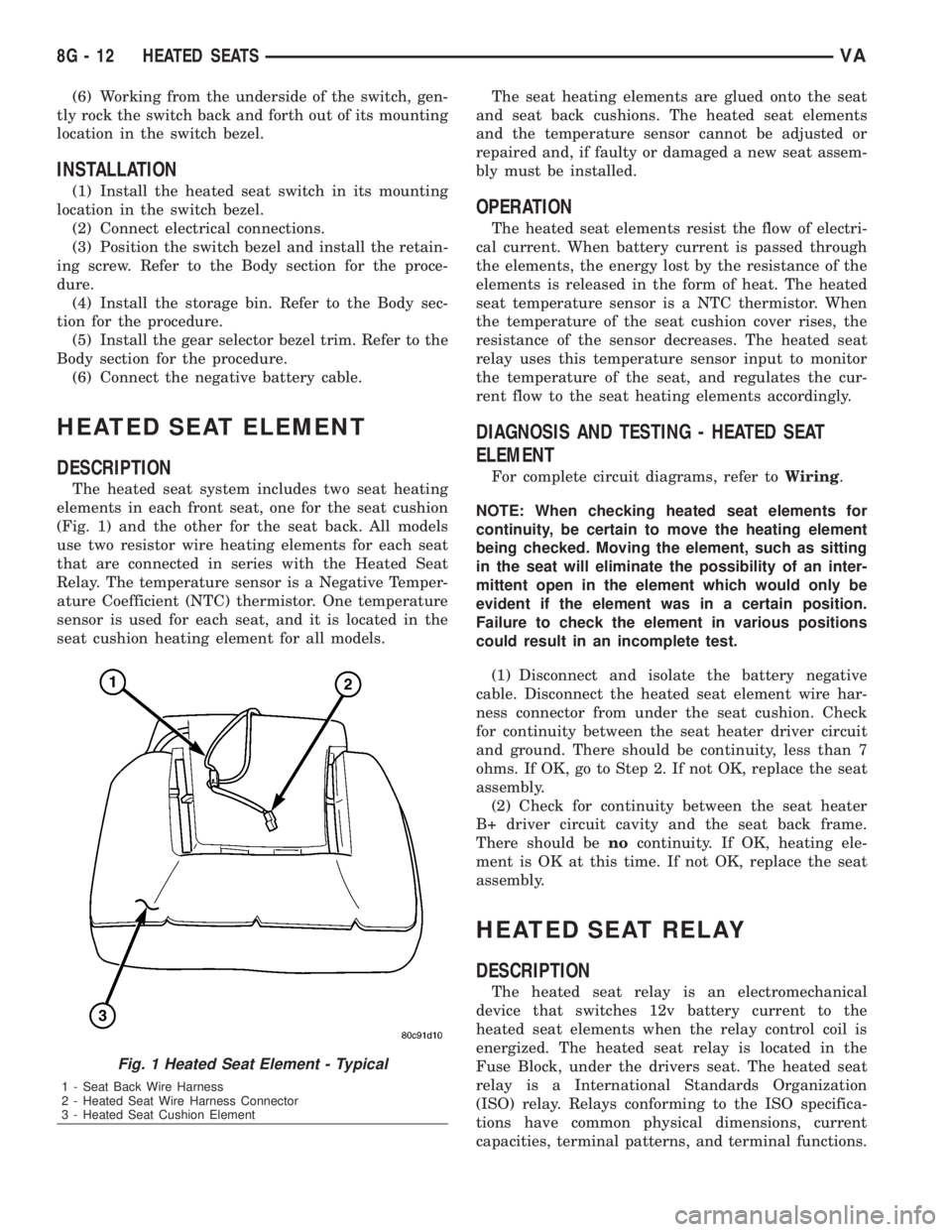

HEATED SEAT ELEMENT

DESCRIPTION

The heated seat system includes two seat heating

elements in each front seat, one for the seat cushion

(Fig. 1) and the other for the seat back. All models

use two resistor wire heating elements for each seat

that are connected in series with the Heated Seat

Relay. The temperature sensor is a Negative Temper-

ature Coefficient (NTC) thermistor. One temperature

sensor is used for each seat, and it is located in the

seat cushion heating element for all models.The seat heating elements are glued onto the seat

and seat back cushions. The heated seat elements

and the temperature sensor cannot be adjusted or

repaired and, if faulty or damaged a new seat assem-

bly must be installed.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the energy lost by the resistance of the

elements is released in the form of heat. The heated

seat temperature sensor is a NTC thermistor. When

the temperature of the seat cushion cover rises, the

resistance of the sensor decreases. The heated seat

relay uses this temperature sensor input to monitor

the temperature of the seat, and regulates the cur-

rent flow to the seat heating elements accordingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT

For complete circuit diagrams, refer toWiring.

NOTE: When checking heated seat elements for

continuity, be certain to move the heating element

being checked. Moving the element, such as sitting

in the seat will eliminate the possibility of an inter-

mittent open in the element which would only be

evident if the element was in a certain position.

Failure to check the element in various positions

could result in an incomplete test.

(1) Disconnect and isolate the battery negative

cable. Disconnect the heated seat element wire har-

ness connector from under the seat cushion. Check

for continuity between the seat heater driver circuit

and ground. There should be continuity, less than 7

ohms. If OK, go to Step 2. If not OK, replace the seat

assembly.

(2) Check for continuity between the seat heater

B+ driver circuit cavity and the seat back frame.

There should benocontinuity. If OK, heating ele-

ment is OK at this time. If not OK, replace the seat

assembly.

HEATED SEAT RELAY

DESCRIPTION

The heated seat relay is an electromechanical

device that switches 12v battery current to the

heated seat elements when the relay control coil is

energized. The heated seat relay is located in the

Fuse Block, under the drivers seat. The heated seat

relay is a International Standards Organization

(ISO) relay. Relays conforming to the ISO specifica-

tions have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

Fig. 1 Heated Seat Element - Typical

1 - Seat Back Wire Harness

2 - Heated Seat Wire Harness Connector

3 - Heated Seat Cushion Element

8G - 12 HEATED SEATSVA

Page 914 of 2305

The heated seat relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact. When the electromagnetic coil is de-ener-

gized, spring pressure returns the movable contact to

the normally closed position. The resistor or diode is

connected in parallel with the electromagnetic coil in

the relay, and helps to dissipate voltage spikes that

are produced when the coil is de-energized.

DIAGNOSIS AND TESTING - HEATED SEAT

RELAY

The heated seat relay is located in the Fuse Block,

under the drivers seat. Refer toWiringfor the loca-

tion of complete heated seat system wiring diagrams.

(1) Remove the heated seat relay from the fuse

block.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, check the relay supply circuits. If not

OK, replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) The heated seat relay is located in the fuse

block, under the drivers seat. Refer to wiring for

detailed location.

(3) Grasp the heated seat relay firmly and pull it

straight out from the fuse block. A slight rocking

motion will aid in removal.

INSTALLATION

(1) Grasp the heated seat relay firmly and push it

straight in the fuse block.

(2) Reconnect the battery negative cable.

HEATED SEAT SENSOR

DESCRIPTION

The heated seat temperature sensor is a Negative

Temperature Coefficient (NTC) thermistor. One tem-

perature sensor is used for each seat. The sensor is

located in the seat cushion heating element for all

models.

The heated seat sensor cannot be adjusted or

repaired and if it is found to be faulty, the complete

heated seat element must be replaced.

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR

For complete circuit diagrams, refer toWiring.

NOTE: Any resistance values (ohmsV) given in the

following text are supplied using the automatic

range generated by a FLUKETautomotive meter. If

another type of measuring device is used the val-

ues generated may not be the same as the results

shown here, or may have to be converted to the

range used here.

(1) Backprobe the heated seat relay wire harness

connector, do not disconnect. Using an voltmeter,

check the voltage of the seat temperature sensor

input cavity of the heated seat relay wire harness

connector. The seat sensor input voltage should be

between 1.7 volts and 3.0 volts with the system ON.

If OK, sensor is OK at this time. If not OK, replace

the faulty seat cushion heating element and sensor

assembly.

PASSENGER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are located on the instru-

ment panel, in the accessory switch bezel. The two,

momentary rocker type switches provide a signal to

the Heated Seat Relay through separate hard wired

circuits. Each switch contains two light emitting

diodes (LED), one for each High and Low setting to

let the occupant know that the seat heater system is

on.

The heated seat switches and their LED's cannot

be repaired. If either switch is faulty or damaged the

entire switch must be replaced.

OPERATION

There are three modes that can be selected with

each of the heated seat switches: Off, Low, and High.

When the top of the switch rocker is depressed, the

low mode is selected and the low mode LED indicator

illuminates. Depressing the top of the switch rocker a

VAHEATED SEATS 8G - 13

Page 924 of 2305

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator,

the multi-fuction indicator LCD unit, an electronic

tone generator, the electronic circuit board, the cir-

cuit board hardware, the cluster overlay, the cluster

housing, the cluster hood, the cluster lens, or the

cluster rear cover are damaged or faulty, the entire

EMIC module must be replaced.

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

is designed to allow the vehicle operator to monitor

the conditions of many of the vehicle components and

operating systems. The gauges, meters and indicators

in the EMIC provide valuable information about the

powertrain, fuel and emissions systems, cooling sys-

tem, lighting systems, safety systems and many

other convenience items. The EMIC is installed in

the instrument panel so that all of these monitors

can be easily viewed by the vehicle operator when

driving, while still allowing relative ease of access for

service. The microprocessor-based EMIC hardware

and software uses various inputs to control the

gauges and indicators visible on the face of the clus-

ter. Some of these inputs are hard wired, but many

are in the form of electronic messages that are trans-

mitted by other electronic modules over the Control-

ler Area Network (CAN) data bus network. (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist such as high coolant tem-

perature, the algorithm can drive the gauge pointer

to an extreme position and the microprocessor can

sound a chime through the on-board audible tone

generator to provide distinct visual and audible indi-

cations of a problem to the vehicle operator. The

instrument cluster circuitry also provides audible

turn signal and hazard warning support by emulat-

ing the ªtickingº sound associated with a conven-

tional electro-mechanical flasher using a contactless

relay. The relay will also provide an indication of a

turn signal failure by sounding at double the usual

frequency. Each audible warning is provided to the

vehicle operator to supplement a visual indication.

The EMIC circuitry operates on battery current

received through a non-switched fused B(+) circuit,

and on a fused ignition switch output circuit. TheEMIC circuitry is grounded through a ground circuit

and take out of the frame wire harness with an eye-

let terminal connector that is secured to a stud by a

nut at a ground location on the dash panel just for-

ward of the instrument cluster. Separate switched

ground inputs from the key-in ignition switch and

the front door jamb switches provide wake-up signals

to the EMIC circuitry. This arrangement allows the

EMIC to provide some features regardless of the igni-

tion switch position, while other features will operate

only with the ignition switch in the On position.

Proper diagnosis and testing of the EMIC, the

CAN data bus, the data bus electronic message

inputs to and outputs from the EMIC, as well as the

retrieval or erasure of a Diagnostic Trouble Code

(DTC) requires the use of a diagnostic scan tool.

Refer to the appropriate diagnostic information. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of the

EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry only when the instrument cluster

detects the ignition switch is in the On position. With

the ignition switch in the Off position, battery cur-

rent is not supplied to any gauges and the EMIC cir-

cuitry is programmed to move all of the gauge

needles back to the low end of their respective scales.

Therefore, the gauges do not accurately indicate any

vehicle condition unless the ignition switch is in the

On position.

All of the EMIC gauges are air core magnetic

units. Two fixed electromagnetic coils are located

within each gauge. These coils are wrapped at right

angles to each other around a movable permanent

magnet. The movable magnet is suspended within

the coils on one end of a pivot shaft, while the gauge

needle is attached to the other end of the shaft. One

of the coils has a fixed current flowing through it to

maintain a constant magnetic field strength. Current

flow through the second coil changes, which causes

changes in its magnetic field strength. The current

flowing through the second coil is changed by the

EMIC circuitry in response to messages received over

the CAN data bus. The gauge needle moves as the

movable permanent magnet aligns itself to the

changing magnetic fields created around it by the

electromagnets.

Proper diagnosis and testing of the gauges, the

CAN data bus and the electronic data bus message

inputs to the EMIC that control each gauge require

the use of a diagnostic scan tool. Refer to the appro-

priate diagnostic information. Specific operation

details for each gauge may be found elsewhere in

this service information.

VAINSTRUMENT CLUSTER 8J - 5

Page 925 of 2305

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC elec-

tronic circuit board. The ambient temperature indica-

tor (optional), brake indicator, brake wear indicator,

charging indicator, coolant low indicator, high beam

indicator, low fuel indicator, park brake indicator,

seatbelt indicator, turn signal indicators, and washer

fluid indicator operate based upon hard wired inputs

to the EMIC. The airbag (SRS) indicator is normally

controlled by a hard wired input from the Airbag

Control Module (ACM); however, if the EMIC sees an

abnormal or no input from the ACM, it will automat-

ically turn the airbag indicator On until the hard

wired input from the ACM has been restored. The

Malfunction Indicator Lamp (MIL) is normally con-

trolled by CAN data bus messages from the Engine

Control Module (ECM); however, if the EMIC loses

CAN data bus communication, the EMIC circuitry

will automatically turn the MIL on until CAN data

bus communication is restored. The EMIC uses CAN

data bus messages from the ECM, the ACM, and the

Controller Antilock Brake to control all of the

remaining indicators.

The various EMIC indicators are controlled by dif-

ferent strategies; some receive battery feed from the

EMIC circuitry and have a switched ground, while

others are grounded through the EMIC circuitry and

have a switched battery feed. However, all indicators

are completely controlled by the EMIC microproces-

sor based upon various hard wired and electronic

message inputs. Except for the indications provided

by the multi-function indicator Liquid Crystal Dis-

play (LCD) unit, all indicators are illuminated at a

fixed intensity, which is not affected by the selected

illumination intensity of the EMIC general illumina-

tion lamps.

The hard wired indicator inputs may be diagnosed

using conventional diagnostic methods. However,

proper testing of the EMIC circuitry and the CAN

bus message controlled indicators requires the use of

a diagnostic scan tool. Refer to the appropriate diag-

nostic information. Specific details of the operation

for each indicator may be found elsewhere in this

service information.

CLUSTER ILLUMINATION

The EMIC has several general illumination lamps

that are illuminated when the exterior lighting is

turned on with the multi-function switch. The illumi-

nation intensity of these lamps is adjusted by a dim-

ming level input received from the multi-function

indicator ª+º (plus) and ª±º (minus) switch push but-

tons that extend through the lower edge of the clus-

ter lens below the right end of the multi-function

indicator. When the exterior lighting is turned Off,

the display is illuminated at maximum brightness.

When the exterior lighting is turned On and thetransmission gear selector is in the Park position,

depressing the plus switch push button brightens the

display lighting, and depressing the minus switch

push button dims the display lighting. The EMIC

also provides a Pulse-Width Modulated (PWM) panel

lamps dimmer output that can be used to synchro-

nize the illumination lighting levels of external illu-

mination lamps (up to about 23 to 30 watts) with

that of the EMIC.

The hard wired multi-function switch input and

the EMIC panel lamps dimmer output may be diag-

nosed using conventional diagnostic methods. How-

ever, proper testing of the PWM control of the EMIC

and the electronic dimming level inputs from the

multi-function indicator push buttons requires the

use of a diagnostic scan tool. Refer to the appropriate

diagnostic information.

INPUT AND OUTPUT CIRCUITS

HARD WIRED INPUTS

The hard wired inputs to the EMIC include the fol-

lowing:

NOTE: Final approved circuit names were not yet

available at the time this information was compiled.

²Airbag Indicator Driver

²Ambient Temperature Sensor Signal

(Optional)

²Brake Wear Indicator Sense

²Charging Indicator Driver

²Coolant Level Switch Sense

²Front Door Jamb Switch Sense

²Fuel Level Sensor Signal

²Fused B(+)

²Fused Ignition Switch Output

²High Beam Indicator Driver

²Key-In Ignition Switch Sense

²Left Turn Signal

²Park Brake Switch Sense

²Right Turn Signal

²Seat Belt Switch Sense

²Washer Fluid Switch Sense (Optional)

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS

The hard wired outputs of the EMIC include the

following:

²Engine Running Relay Control

²Panel Lamps Driver

Refer to the appropriate wiring information for

additional details.

8J - 6 INSTRUMENT CLUSTERVA

Page 926 of 2305

GROUNDS

The EMIC receives and supplies a ground path to

several switches and sensors through the following

hard wired circuits:

²Ambient Temperature Sensor Return

(Optional)

²Fuel Level Sensor Return

²Ground

Refer to the appropriate wiring information for

additional details.

COMMUNICATION

The EMIC has provisions for the following commu-

nication circuits:

²CAN Data Bus - High

²CAN Data Bus - Low

²Diagnostic Serial Communication Interface

(SCI) Data Bus Line

Refer to the appropriate wiring information for

additional details.

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER

The hard wired inputs to and outputs from the

instrument cluster may be diagnosed and tested

using conventional diagnostic tools and procedures.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

If the instrument cluster is completely inoperative,

be certain to check the fused B(+) circuit fuses and

wiring for the instrument cluster. If the cluster gen-

eral illumination is inoperative, be certain to check

the instrument lighting fuse and the input circuit to

the instrument cluster from the exterior lighting cir-

cuitry of the multi-function switch on the steering

column.

Conventional diagnostic methods may not prove

conclusive in the diagnosis of the instrument cluster.

In order to obtain conclusive testing of the instru-

ment cluster, the Controller Area Network (CAN)

data bus network and all of the electronic modules

that provide inputs to or receive outputs from the

instrument cluster must also be checked. The most

reliable, efficient, and accurate means to diagnose

the instrument cluster, the CAN data bus network,

and the electronic modules that provide inputs to or

receive outputs from the instrument cluster requires

the use of a diagnostic scan tool and the appropriate

diagnostic information. The diagnostic scan tool can

provide confirmation that the CAN data bus network

is functional, that all of the modules are sending and

receiving the proper electronic messages over the

CAN data bus, and that the instrument cluster isreceiving the proper hard wired inputs and respond-

ing with the proper hard wired outputs needed to

perform its many functions.

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

STANDARD PROCEDURE

CLUSTER PROGRAMMING

NOTE: After replacing the Instrument Cluster (IC)

according to the service procedures, determine the

optional equipment on the vehicle by accessing the

sales code information using the Vehicle Identifica-

tion Number (VIN) on DealerCONNECT.

(1) Using the DRBIIIt, selectMISCELLANEOUS

FUNCTIONSin the Instrument Cluster (IC) section.

(2) SelectMODULE SERVICE REPLACE-

MENT.

(3) Following the prompts on the DRBIIIt, enter

the correct parameters that are applicable to the

vehicle. Use the sales code information and visual

inspection to obtain the correct parameters.

CAUTION: Do not lock down the instrument cluster

until the following steps are followed or the instru-

ment cluster may be irreversibly damaged.

(4) After entering the proper parameters into the

IC, turn the ignition switch to the OFF position for

30 seconds, then turn the ignition switch ON.

(5) Test drive the vehicle for at least 10 minutes

before proceeding.

(6) Check ALL modules for any parameterization

DTCs. If any parameterization DTCs are present, one

or more parameters entered into the IC are incorrect.

Verify all parameters entered using the sales code

information and visual inspection of the vehicle.

(7) If the parameters entered are verified as cor-

rect and parameterization DTCs are still present,

refer to the appropriate diagnostic information.

(8) If no parameterization DTCs are present, lock

down the IC.

VAINSTRUMENT CLUSTER 8J - 7