engine coolant MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 155 of 2305

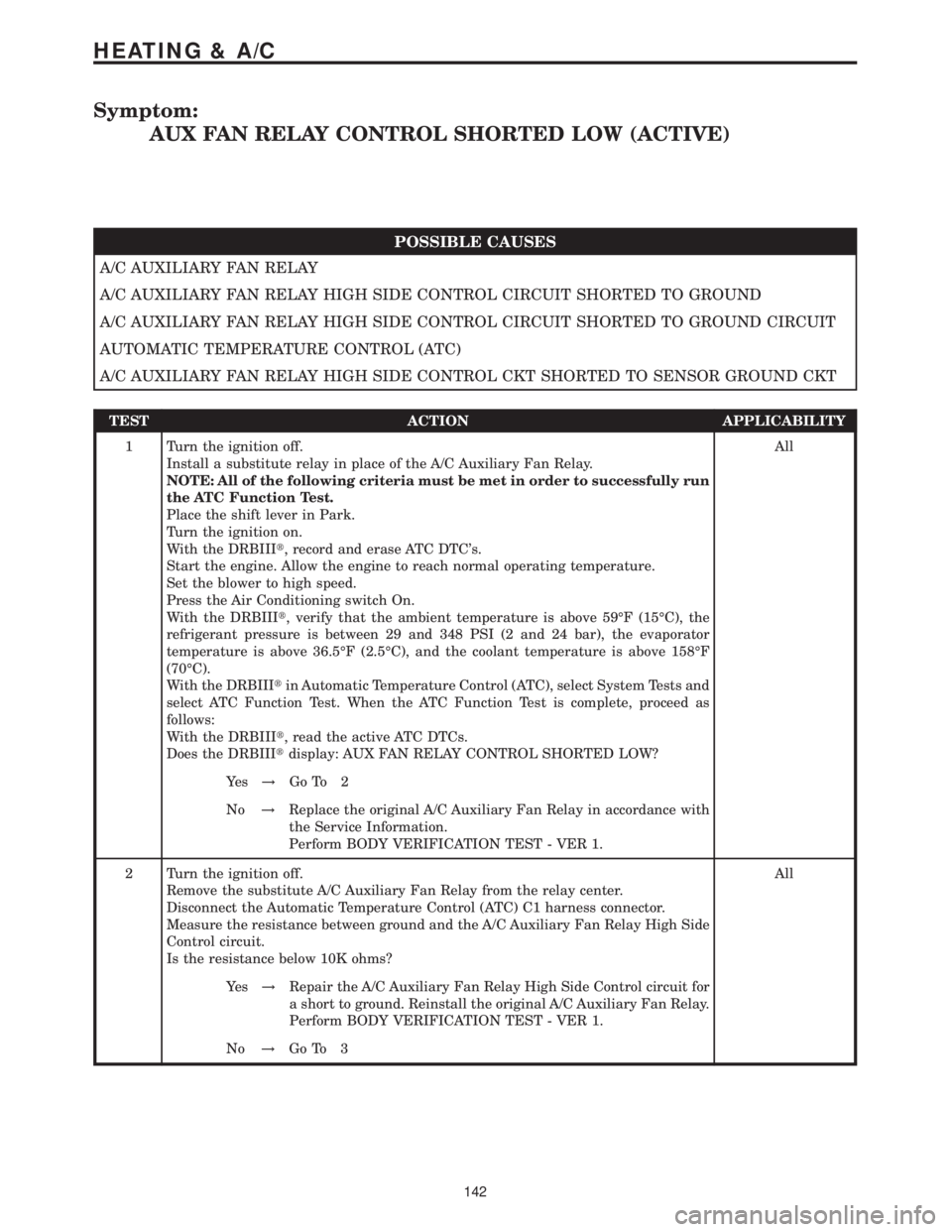

Symptom:

AUX FAN RELAY CONTROL SHORTED LOW (ACTIVE)

POSSIBLE CAUSES

A/C AUXILIARY FAN RELAY

A/C AUXILIARY FAN RELAY HIGH SIDE CONTROL CIRCUIT SHORTED TO GROUND

A/C AUXILIARY FAN RELAY HIGH SIDE CONTROL CIRCUIT SHORTED TO GROUND CIRCUIT

AUTOMATIC TEMPERATURE CONTROL (ATC)

A/C AUXILIARY FAN RELAY HIGH SIDE CONTROL CKT SHORTED TO SENSOR GROUND CKT

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Install a substitute relay in place of the A/C Auxiliary Fan Relay.

NOTE: All of the following criteria must be met in order to successfully run

the ATC Function Test.

Place the shift lever in Park.

Turn the ignition on.

With the DRBIIIt, record and erase ATC DTC's.

Start the engine. Allow the engine to reach normal operating temperature.

Set the blower to high speed.

Press the Air Conditioning switch On.

With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the

refrigerant pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator

temperature is above 36.5ÉF (2.5ÉC), and the coolant temperature is above 158ÉF

(70ÉC).

With the DRBIIItin Automatic Temperature Control (ATC), select System Tests and

select ATC Function Test. When the ATC Function Test is complete, proceed as

follows:

With the DRBIIIt, read the active ATC DTCs.

Does the DRBIIItdisplay: AUX FAN RELAY CONTROL SHORTED LOW?All

Ye s!Go To 2

No!Replace the original A/C Auxiliary Fan Relay in accordance with

the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Remove the substitute A/C Auxiliary Fan Relay from the relay center.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Measure the resistance between ground and the A/C Auxiliary Fan Relay High Side

Control circuit.

Is the resistance below 10K ohms?All

Ye s!Repair the A/C Auxiliary Fan Relay High Side Control circuit for

a short to ground. Reinstall the original A/C Auxiliary Fan Relay.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

142

HEATING & A/C

Page 159 of 2305

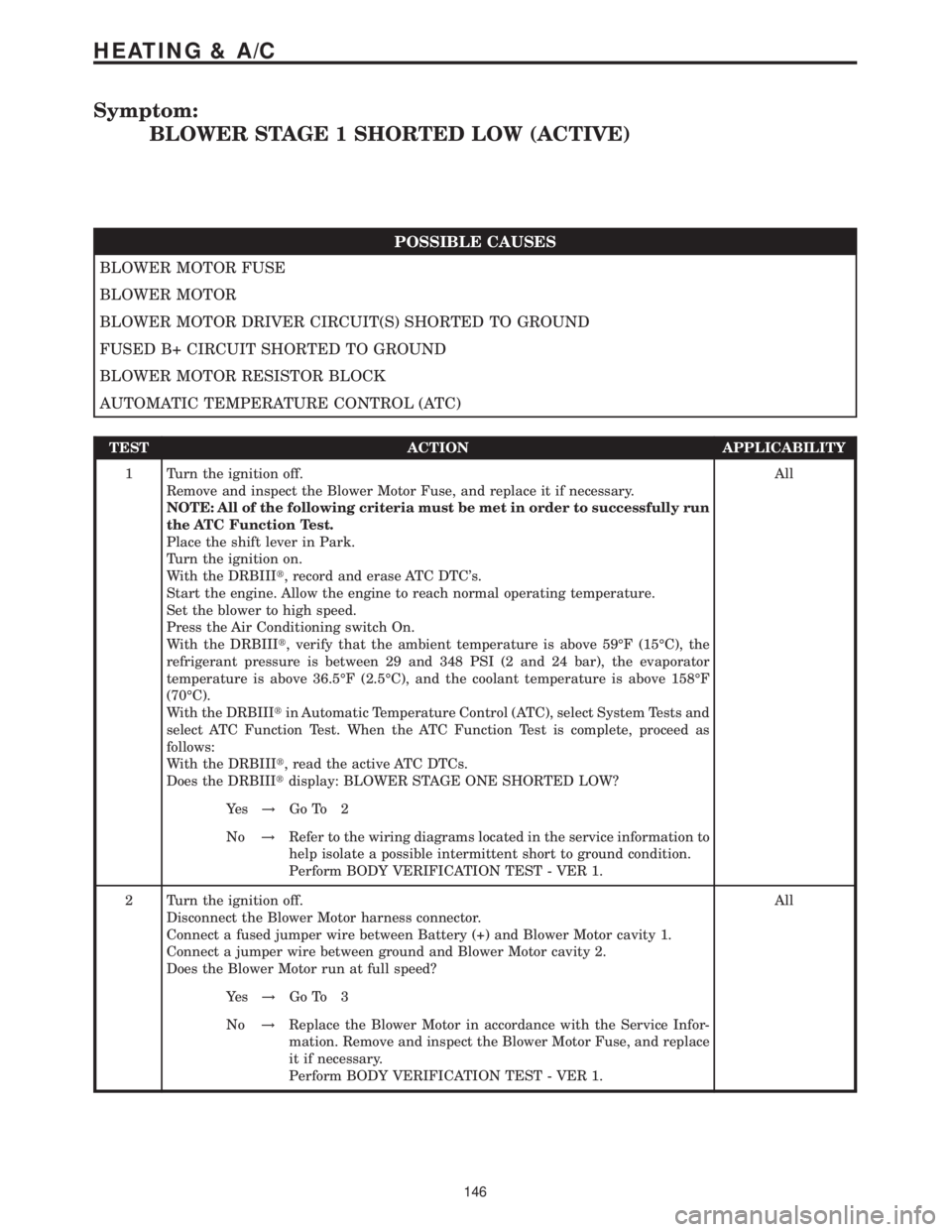

Symptom:

BLOWER STAGE 1 SHORTED LOW (ACTIVE)

POSSIBLE CAUSES

BLOWER MOTOR FUSE

BLOWER MOTOR

BLOWER MOTOR DRIVER CIRCUIT(S) SHORTED TO GROUND

FUSED B+ CIRCUIT SHORTED TO GROUND

BLOWER MOTOR RESISTOR BLOCK

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Remove and inspect the Blower Motor Fuse, and replace it if necessary.

NOTE: All of the following criteria must be met in order to successfully run

the ATC Function Test.

Place the shift lever in Park.

Turn the ignition on.

With the DRBIIIt, record and erase ATC DTC's.

Start the engine. Allow the engine to reach normal operating temperature.

Set the blower to high speed.

Press the Air Conditioning switch On.

With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the

refrigerant pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator

temperature is above 36.5ÉF (2.5ÉC), and the coolant temperature is above 158ÉF

(70ÉC).

With the DRBIIItin Automatic Temperature Control (ATC), select System Tests and

select ATC Function Test. When the ATC Function Test is complete, proceed as

follows:

With the DRBIIIt, read the active ATC DTCs.

Does the DRBIIItdisplay: BLOWER STAGE ONE SHORTED LOW?All

Ye s!Go To 2

No!Refer to the wiring diagrams located in the service information to

help isolate a possible intermittent short to ground condition.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Disconnect the Blower Motor harness connector.

Connect a fused jumper wire between Battery (+) and Blower Motor cavity 1.

Connect a jumper wire between ground and Blower Motor cavity 2.

Does the Blower Motor run at full speed?All

Ye s!Go To 3

No!Replace the Blower Motor in accordance with the Service Infor-

mation. Remove and inspect the Blower Motor Fuse, and replace

it if necessary.

Perform BODY VERIFICATION TEST - VER 1.

146

HEATING & A/C

Page 163 of 2305

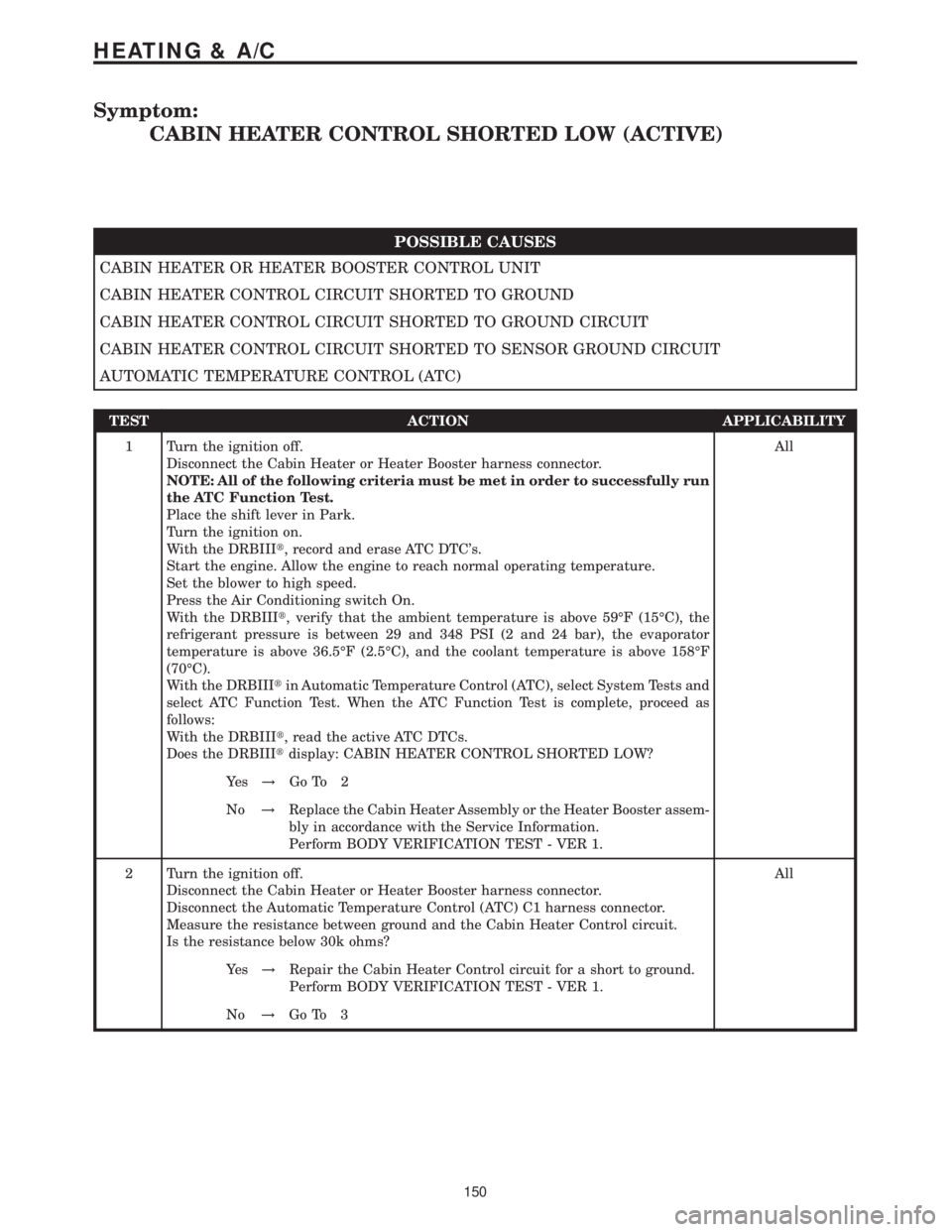

Symptom:

CABIN HEATER CONTROL SHORTED LOW (ACTIVE)

POSSIBLE CAUSES

CABIN HEATER OR HEATER BOOSTER CONTROL UNIT

CABIN HEATER CONTROL CIRCUIT SHORTED TO GROUND

CABIN HEATER CONTROL CIRCUIT SHORTED TO GROUND CIRCUIT

CABIN HEATER CONTROL CIRCUIT SHORTED TO SENSOR GROUND CIRCUIT

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Cabin Heater or Heater Booster harness connector.

NOTE: All of the following criteria must be met in order to successfully run

the ATC Function Test.

Place the shift lever in Park.

Turn the ignition on.

With the DRBIIIt, record and erase ATC DTC's.

Start the engine. Allow the engine to reach normal operating temperature.

Set the blower to high speed.

Press the Air Conditioning switch On.

With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the

refrigerant pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator

temperature is above 36.5ÉF (2.5ÉC), and the coolant temperature is above 158ÉF

(70ÉC).

With the DRBIIItin Automatic Temperature Control (ATC), select System Tests and

select ATC Function Test. When the ATC Function Test is complete, proceed as

follows:

With the DRBIIIt, read the active ATC DTCs.

Does the DRBIIItdisplay: CABIN HEATER CONTROL SHORTED LOW?All

Ye s!Go To 2

No!Replace the Cabin Heater Assembly or the Heater Booster assem-

bly in accordance with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Disconnect the Cabin Heater or Heater Booster harness connector.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Measure the resistance between ground and the Cabin Heater Control circuit.

Is the resistance below 30k ohms?All

Ye s!Repair the Cabin Heater Control circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

150

HEATING & A/C

Page 186 of 2305

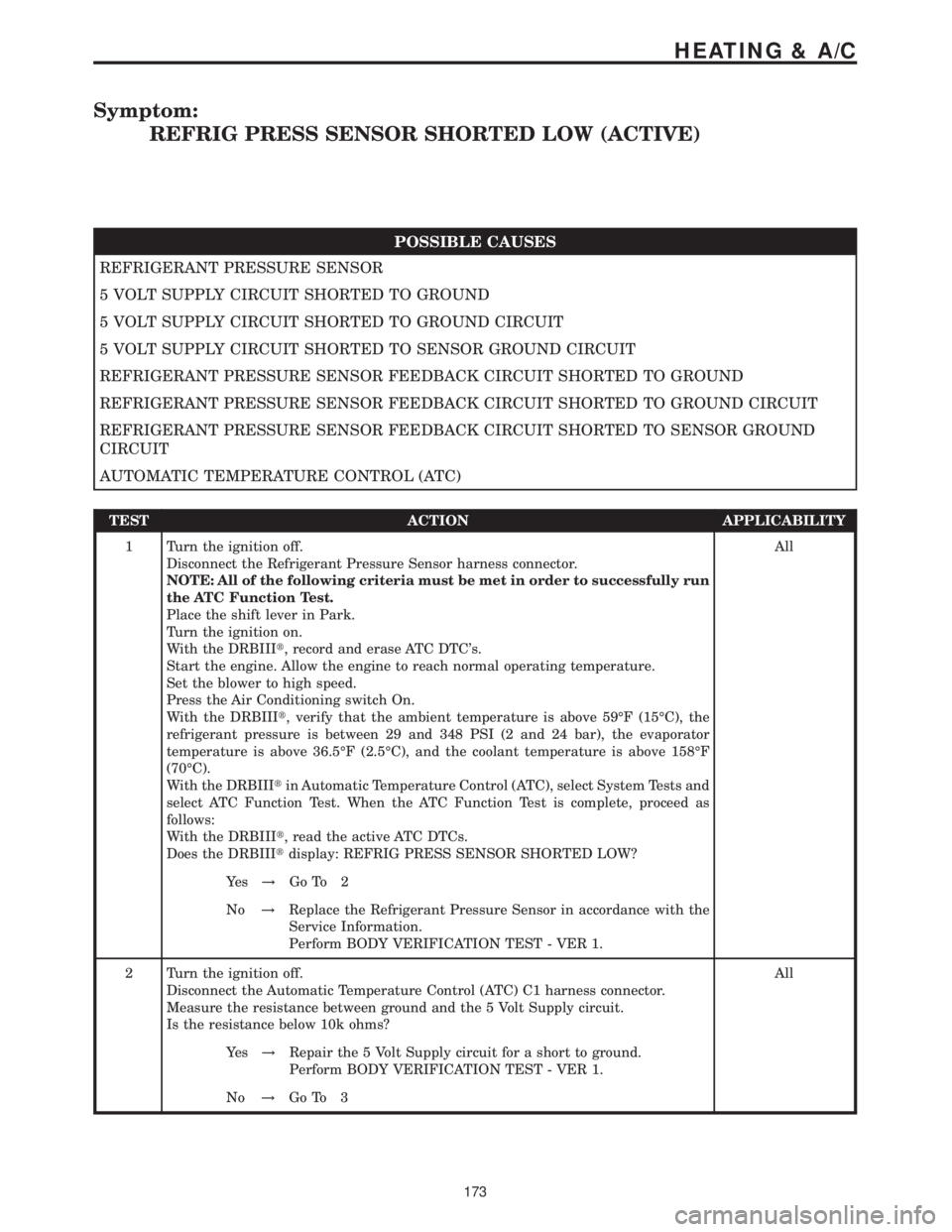

Symptom:

REFRIG PRESS SENSOR SHORTED LOW (ACTIVE)

POSSIBLE CAUSES

REFRIGERANT PRESSURE SENSOR

5 VOLT SUPPLY CIRCUIT SHORTED TO GROUND

5 VOLT SUPPLY CIRCUIT SHORTED TO GROUND CIRCUIT

5 VOLT SUPPLY CIRCUIT SHORTED TO SENSOR GROUND CIRCUIT

REFRIGERANT PRESSURE SENSOR FEEDBACK CIRCUIT SHORTED TO GROUND

REFRIGERANT PRESSURE SENSOR FEEDBACK CIRCUIT SHORTED TO GROUND CIRCUIT

REFRIGERANT PRESSURE SENSOR FEEDBACK CIRCUIT SHORTED TO SENSOR GROUND

CIRCUIT

AUTOMATIC TEMPERATURE CONTROL (ATC)

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the Refrigerant Pressure Sensor harness connector.

NOTE: All of the following criteria must be met in order to successfully run

the ATC Function Test.

Place the shift lever in Park.

Turn the ignition on.

With the DRBIIIt, record and erase ATC DTC's.

Start the engine. Allow the engine to reach normal operating temperature.

Set the blower to high speed.

Press the Air Conditioning switch On.

With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the

refrigerant pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator

temperature is above 36.5ÉF (2.5ÉC), and the coolant temperature is above 158ÉF

(70ÉC).

With the DRBIIItin Automatic Temperature Control (ATC), select System Tests and

select ATC Function Test. When the ATC Function Test is complete, proceed as

follows:

With the DRBIIIt, read the active ATC DTCs.

Does the DRBIIItdisplay: REFRIG PRESS SENSOR SHORTED LOW?All

Ye s!Go To 2

No!Replace the Refrigerant Pressure Sensor in accordance with the

Service Information.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Disconnect the Automatic Temperature Control (ATC) C1 harness connector.

Measure the resistance between ground and the 5 Volt Supply circuit.

Is the resistance below 10k ohms?All

Ye s!Repair the 5 Volt Supply circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No!Go To 3

173

HEATING & A/C

Page 258 of 2305

BODY VERIFICATION TEST - VER 1 APPLICABILITY

1. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

2. Ensure that all accessories are turned off and the battery is fully charged.

3. NOTE: Refer to the service information for proper programming procedures if the

ABM; ACM; ATC; CTM; ECM; IC; SKREEM; SLA; or SSM was replaced.

4. If the SKREEM was replaced, program all RKE transmitters used with this vehicle.

5. NOTE: Perform the next 8 steps of this procedure if either diagnosing the

Automatic Temperature Control (ATC) system or if repairs were made to the ATC

system. All of the following criteria must be met in order to successfully run the ATC

Function Test.

6. With DRBIIIt, record and erase ATC DTCs.

7. Place the shift lever in Park.

8. Start the engine. Allow the engine to reach normal operating temperature.

9. Set the blower to high speed.

10. Press the Air Conditioning switch On.

11. With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the refrigerant

pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator temperature is above 36.5ÉF

(2.5ÉC), and the coolant temperature is above 158ÉF (70ÉC).

12. With the DRBIIItin ATC, select System Tests and select ATC Function Test. When the ATC

Function Test is complete, proceed to the next step of this procedure.

13. With the DRBIIIt, read active ATC DTCs. If any DTC is active or if the original condition

is still present, proceed to the conclusion question and answer Yes.

14. With the DRBIIIt, record and erase all DTCs from ALL modules. Start and run the engine

for 2 minutes. Operate all functions of the system that caused the original concern.

15. Turn the ignition off and wait 5 seconds. Turn the ignition on and using the DRBIIIt, read

DTCs from ALL modules.

Are any DTC's present or is the original condition still present?All

Ye s!Repair is not complete, refer to the appropriate symptom.

No!Repair is complete.

245

VERIFICATION TESTS

Verification Tests ÐContinued

Page 259 of 2305

HEATER VERIFICATION TEST - VER 1 APPLICABILITY

1. WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA THAT DOES

NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS VENT THE HEATER's

EXHAUST WHEN OPERATING THE HEATER. FAILURE TO FOLLOW THESE IN-

STRUCTIONS CAN RESULT IN PERSONAL INJURY OR DEATH.

2. WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PERFORMING A

COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY OR DEATH.

3. NOTE: The heater's control unit will store up to five DTCs in its memory.

4. NOTE: If the heater's control unit detects a new fault in the system, one that is not

already stored in its memory, it will clear the oldest of the five stored DTCs, and it

will store the new fault's DTC.

5. NOTE: If the heater's control unit detects a reoccurrence of a stored fault, it will

overwrite that fault's DTC with the most recent occurrence.

6. Verify that the vehicle's battery is fully charged.

7. Verify that there is more than 1/8 of a tank of fuel in the vehicle's fuel tank. Add fuel, if

necessary.

8. Verify that all heater's coolant hoses and fuel lines are securely fastened to their respective

components.

9. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

10. If a heater installation/cooling system service was performed, purge the coolant circuit of air

in accordance with the Service Information.

11. Turn the ignition on.

12. Verify that the Cabin Heater or Heater Booster is switched off.

13. Ensure that all accessories are turned off.

14. Set the blend control to the max heat position and the mode control to the floor position.

15. If a fuel system service requiring fuel to drain out of the heater's fuel line was performed,

prime the heater's Dosing Pump in accordance with the Service Information.

16. With the DRBIIIt, record and erase all DTCs from the Cabin Heater Module or Heater

Booster Module. Turn the ignition off, wait 5 seconds, then turn start the engine.

17. Allow the engine to idle.

18. NOTE: Do not disconnect the vehicle's battery or the heater's main power supply

while the heater is in operation or in run-down mode. Failure to follow these

instructions can result in excess emissions from the heater during heater operation.

19. Switch the Cabin Heater or Heater Booster on. Allow the heater to run through at least one

cycle of operation (approximately 10 minutes), and then turn the heater off.

20. With the DRBIIIt, read the Cabin Heater or Heater Booster Module's DTC.

21. Turn the engine off.

Are any DTC's present or is the original condition still present?All

Ye s!Repair is not complete, refer to the appropriate symptom.

No!Repair is complete.

246

VERIFICATION TESTS

Verification Tests ÐContinued

Page 292 of 2305

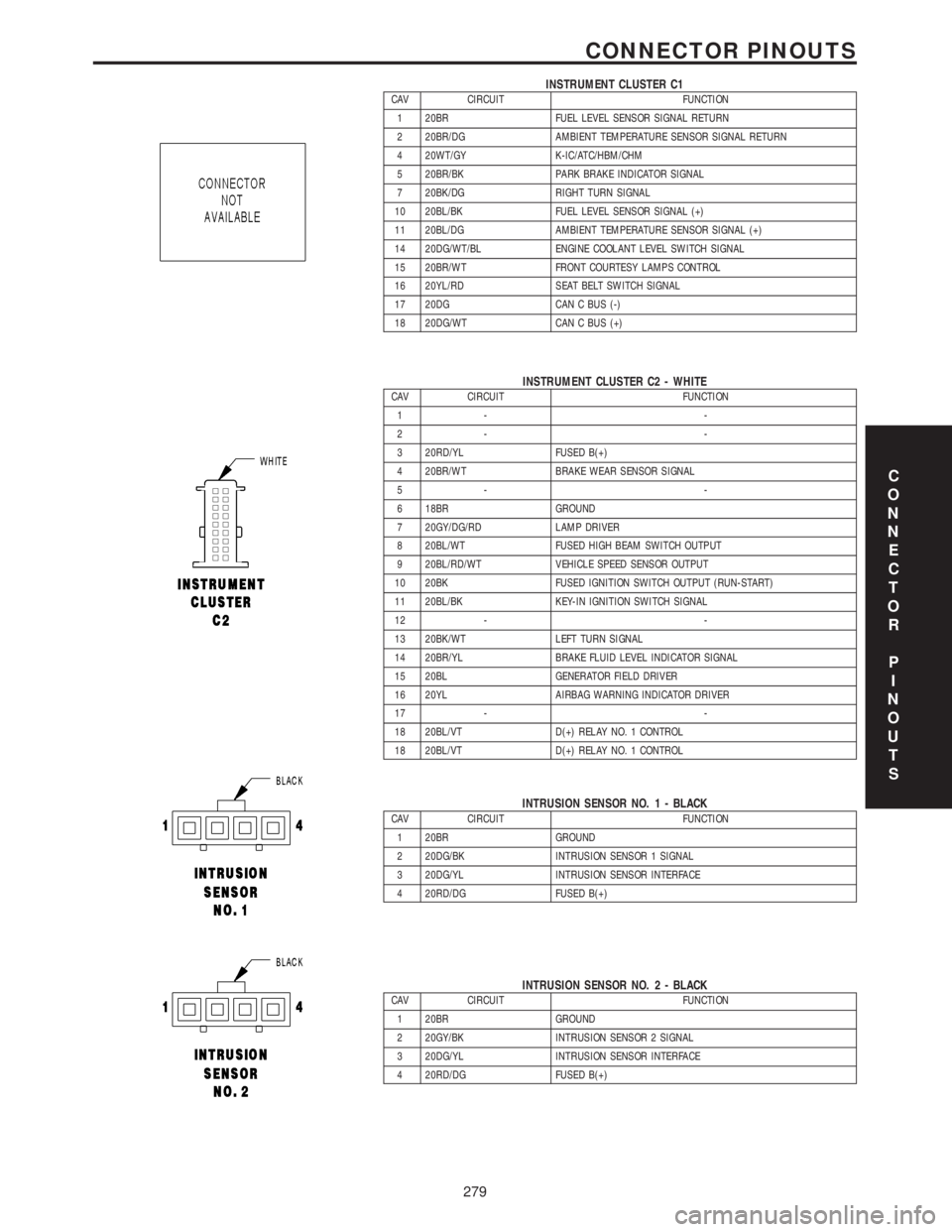

INSTRUMENT CLUSTER C1CAV CIRCUIT FUNCTION

1 20BR FUEL LEVEL SENSOR SIGNAL RETURN

2 20BR/DG AMBIENT TEMPERATURE SENSOR SIGNAL RETURN

4 20WT/GY K-IC/ATC/HBM/CHM

5 20BR/BK PARK BRAKE INDICATOR SIGNAL

7 20BK/DG RIGHT TURN SIGNAL

10 20BL/BK FUEL LEVEL SENSOR SIGNAL (+)

11 20BL/DG AMBIENT TEMPERATURE SENSOR SIGNAL (+)

14 20DG/WT/BL ENGINE COOLANT LEVEL SWITCH SIGNAL

15 20BR/WT FRONT COURTESY LAMPS CONTROL

16 20YL/RD SEAT BELT SWITCH SIGNAL

17 20DG CAN C BUS (-)

18 20DG/WT CAN C BUS (+)

INSTRUMENT CLUSTER C2 - WHITECAV CIRCUIT FUNCTION

1- -

2- -

3 20RD/YL FUSED B(+)

4 20BR/WT BRAKE WEAR SENSOR SIGNAL

5- -

6 18BR GROUND

7 20GY/DG/RD LAMP DRIVER

8 20BL/WT FUSED HIGH BEAM SWITCH OUTPUT

9 20BL/RD/WT VEHICLE SPEED SENSOR OUTPUT

10 20BK FUSED IGNITION SWITCH OUTPUT (RUN-START)

11 20BL/BK KEY-IN IGNITION SWITCH SIGNAL

12 - -

13 20BK/WT LEFT TURN SIGNAL

14 20BR/YL BRAKE FLUID LEVEL INDICATOR SIGNAL

15 20BL GENERATOR FIELD DRIVER

16 20YL AIRBAG WARNING INDICATOR DRIVER

17 - -

18 20BL/VT D(+) RELAY NO. 1 CONTROL

18 20BL/VT D(+) RELAY NO. 1 CONTROL

INTRUSION SENSOR NO. 1 - BLACKCAV CIRCUIT FUNCTION

1 20BR GROUND

2 20DG/BK INTRUSION SENSOR 1 SIGNAL

3 20DG/YL INTRUSION SENSOR INTERFACE

4 20RD/DG FUSED B(+)

INTRUSION SENSOR NO. 2 - BLACKCAV CIRCUIT FUNCTION

1 20BR GROUND

2 20GY/BK INTRUSION SENSOR 2 SIGNAL

3 20DG/YL INTRUSION SENSOR INTERFACE

4 20RD/DG FUSED B(+)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

279

CONNECTOR PINOUTS

Page 401 of 2305

BODY VERIFICATION TEST - VER 1 APPLICABILITY

1. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

2. Ensure that all accessories are turned off and the battery is fully charged.

3. NOTE: Refer to the service information for proper programming procedures if the

ABM; ACM; ATC; CTM; ECM; IC; SKREEM; SLA; or SSM was replaced.

4. If the SKREEM was replaced, program all RKE transmitters used with this vehicle.

5. NOTE: Perform the next 8 steps of this procedure if either diagnosing the

Automatic Temperature Control (ATC) system or if repairs were made to the ATC

system. All of the following criteria must be met in order to successfully run the ATC

Function Test.

6. With DRBIIIt, record and erase ATC DTCs.

7. Place the shift lever in Park.

8. Start the engine. Allow the engine to reach normal operating temperature.

9. Set the blower to high speed.

10. Press the Air Conditioning switch On.

11. With the DRBIIIt, verify that the ambient temperature is above 59ÉF (15ÉC), the refrigerant

pressure is between 29 and 348 PSI (2 and 24 bar), the evaporator temperature is above 36.5ÉF

(2.5ÉC), and the coolant temperature is above 158ÉF (70ÉC).

12. With the DRBIIItin ATC, select System Tests and select ATC Function Test. When the ATC

Function Test is complete, proceed to the next step of this procedure.

13. With the DRBIIIt, read active ATC DTCs. If any DTC is active or if the original condition

is still present, proceed to the conclusion question and answer Yes.

14. With the DRBIIIt, record and erase all DTCs from ALL modules. Start and run the engine

for 2 minutes. Operate all functions of the system that caused the original concern.

15. Turn the ignition off and wait 5 seconds. Turn the ignition on and using the DRBIIIt, read

DTCs from ALL modules.

Are any DTC's present or is the original condition still present?All

Ye s!Repair is not complete, refer to the appropriate symptom.

No!Repair is complete.

80

VERIFICATION TESTS

Verification Tests ÐContinued

Page 414 of 2305

TABLE OF CONTENTS - Continued

P0100-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW...............19

P2011-MASS AIR FLOW SENSOR PLAUSIBILITY AIR MASS TOO HIGH.........19

P2011-MASS AIR FLOW SENSOR PLAUSIBILITY AIR MASS TOO LOW..........19

P2024-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO HIGH...............19

P2024-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW...............19

P2065-MASS AIR FLOW SENSOR SUPPLY VOLTAGE TOO HIGH...............19

P2065-MASS AIR FLOW SENSOR SUPPLY VOLTAGE TOO LOW...............19

P2067-MASS AIR FLOW SENSOR SIGNAL CIRCUIT OPEN OR SHORTED.......19

P2067-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO HIGH...............19

P2067-MASS AIR FLOW SENSOR SIGNAL VOLTAGE TOO LOW...............19

P2068-MASS AIR FLOW SENSOR PLAUSIBILITY SIGNAL RATIO ERROR........19

P2633-MAF SENSOR SIGNAL PLAUSIBILITY................................19

P0105-INTAKE PRESSURE SENSOR CAN MESSAGE ERROR.................25

P0105-INTAKE PRESSURE SENSOR PLAUSIBILITY..........................25

P0105-INTAKE PRESSURE SENSOR SIGNAL VOLTAGE TOO HIGH.............28

P0105-INTAKE PRESSURE SENSOR SIGNAL VOLTAGE TOO LOW.............31

P0110-INTAKE AIR TEMP SENSOR SIGNAL VOLTAGE TOO HIGH..............34

P2063-INTAKE AIR TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO HIGH......34

P0110-INTAKE AIR TEMP SENSOR SIGNAL VOLTAGE TOO LOW...............37

P2063-INTAKE AIR TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO LOW......37

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY.............40

P2012-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY.............40

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT PLAUSIBILITY WITH ENGINE

OIL SENSOR...........................................................42

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO

HIGH.................................................................44

P2054-ENGINE COOLANT TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO

HIGH.................................................................44

P2054-ENGINE COOLANT TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO

LOW..................................................................44

P0115-ENGINE COOLANT TEMP SENSOR CIRCUIT SIGNAL VOLTAGE TOO

LOW..................................................................47

P0180-FUEL TEMPERATURE SENSOR CIRCUIT - SIGNAL VOLTAGE TOO HIGH. .49

P0180-FUEL TEMPERATURE SENSOR CIRCUIT - SIGNAL VOLTAGE TOO LOW . .51

P2625-FUEL TEMPERATURE SENSOR PLAUSIBILITY........................51

P0190-FUEL PRESS SENSOR CIRCUIT MALF SIGNAL VOLTAGE TOO HIGH.....53

P2008-FUEL PRESSURE SENSOR CIRCUIT SIGNAL VOLTAGE TOO HIGH......53

P0190-FUEL PRESS SENSOR CIRCUIT MALF SIGNAL VOLTAGE TOO LOW.....57

P2008-FUEL PRESSURE SENSOR CIRCUIT SIGNAL VOLTAGE TOO LOW.......57

P0201-CYLINDER 1-INJECTOR CIRCUIT EXCESSIVE CURRENT...............60

P0201-CYLINDER 1-INJECTOR CIRCUIT OPEN OR SHORTED TO GROUND.....60

P0201-CYLINDER 1-INJECTOR CIRCUIT SHORTED TO GROUND..............60

P0201-CYLINDER 1-INJECTOR CIRCUIT SHORTED TO VOLTAGE..............60

P0202-CYLINDER 2-INJECTOR CIRCUIT EXCESSIVE CURRENT...............60

P0202-CYLINDER 2-INJECTOR CIRCUIT OPEN OR SHORTED TO GROUND.....60

P0202-CYLINDER 2-INJECTOR CIRCUIT SHORTED TO GROUND..............60

P0202-CYLINDER 2-INJECTOR CIRCUIT SHORTED TO VOLTAGE..............60

P0203-CYLINDER 3-INJECTOR CIRCUIT EXCESSIVE CURRENT...............60

P0203-CYLINDER 3-INJECTOR CIRCUIT OPEN OR SHORTED TO GROUND.....60

P0203-CYLINDER 3-INJECTOR CIRCUIT SHORTED TO GROUND..............60

P0203-CYLINDER 3-INJECTOR CIRCUIT SHORTED TO VOLTAGE..............60

P0204-CYLINDER 4-INJECTOR CIRCUIT EXCESSIVE CURRENT...............60

P0204-CYLINDER 4-INJECTOR CIRCUIT OPEN OR SHORTED TO GROUND.....60

iii

Page 421 of 2305

TABLE OF CONTENTS - Continued

*CHECKING THE FUEL PRESSURE SOLENOID CIRCUITS...................233

*CHECKING THE FUEL QUANTITY SOLENOID CIRCUITS....................234

*CHECKING THE POWER AND GROUNDS................................235

*ENGINE CRANKS BUT WILL NOT START.................................239

*ENGINE WILL NOT CRANK.............................................242

VERIFICATION TESTS

VERIFICATION TESTS..................................................246

8.0 COMPONENT LOCATIONS..............................................249

8.1CONTROL MODULES.............................................249

8.2CONTROLS AND SOLENOIDS......................................249

8.3DATA LINK CONNECTOR..........................................250

8.4SENSORS.......................................................251

8.5SWITCHES......................................................253

9.0 CONNECTOR PINOUTS................................................255

ACCELERATOR PEDAL POSITION SENSOR (OBD).........................255

AIRBAG CONTROL MODULE - YELLOW...................................255

BOOST PRESSURE SENSOR (OBD)......................................255

BOOST PRESSURE SERVOMOTOR (OBD)................................256

CAMSHAFT POSITION SENSOR - BLACK.................................256

CONTROLLER ANTILOCK BRAKE........................................257

CRANKCASE HEATER - BLACK..........................................257

CRANKSHAFT POSITION SENSOR - BLACK...............................258

DATA LINK CONNECTOR - BLACK........................................258

EGR VALVE - BLACK...................................................258

ENGINE CONTROL MODULE C1 (OBD)...................................259

ENGINE CONTROL MODULE C2 (OBD)...................................260

ENGINE COOLANT TEMPERATURE SENSOR - BLACK......................260

ENGINE OIL SENSOR - BLACK..........................................261

FUEL INJECTOR NO. 1 - BLACK.........................................261

FUEL INJECTOR NO. 2 - BLACK.........................................261

FUEL INJECTOR NO. 3 - BLACK.........................................261

FUEL INJECTOR NO. 4 - BLACK.........................................262

FUEL INJECTOR NO. 5 - BLACK.........................................262

FUEL PRESSURE SENSOR - BLACK.....................................262

FUEL PRESSURE SOLENOID............................................262

FUEL PUMP (OBD).....................................................262

FUEL PUMP RELAY (OBD)..............................................263

FUEL QUANTITY CONTROL VALVE (OBD).................................263

FUEL TEMPERATURE SENSOR..........................................263

ENGINE CONTROL RELAY (FUSE BLOCK NO. 1)...........................265

FUSES (FUSE BLOCK NO. 1)............................................265

FUSES (FUSE BLOCK NO. 2)............................................267

FUSES (FUSE/RELAY BLOCK)...........................................269

STARTER MOTOR RELAY (FUSE/RELAY BLOCK)...........................269

GLOW PLUG CONTROL MODULE C1 - BLACK.............................270

GLOW PLUG CONTROL MODULE C2 - BLACK.............................270

INTAKE AIR PRESSURE SENSOR (OBD)..................................270

INTAKE AIR TEMPERATURE SENSOR - BLACK............................270

x