set clock MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 940 of 2305

next required engine oil maintenance is anticipated.

ASSYST also provides several audible indications

using the electronic tone generator on the instrument

cluster circuit board to supplement these visual dis-

plays.

The indications of the ASSYST engine oil mainte-

nance indicator are not visible when the LCD is not

illuminated. When illuminated, the ASSYST indica-

tions appear as dark characters and icons silhouetted

against an amber field. When the exterior lighting is

turned Off, the display is illuminated at maximum

brightness. When the exterior lighting is turned On,

the display illumination level can be adjusted in con-

cert with the cluster general illumination lighting

using the ª+º (plus) and ª2º (minus) multi-function

indicator push buttons. The ASSYST engine oil main-

tenance indicator is serviced as a unit with the

instrument cluster.

OPERATION

The ASSYST engine oil maintenance indicator

microprocessor uses numerous criteria besides time

and mileage to evaluate vehicle maintenance require-

ments. Time data is taken from the electronic digital

clock integral to the instrument cluster. Vehicle dis-

tance data is obtained from the Controller Antilock

Brake (CAB) over the Controller Area Network

(CAN) data bus. Coolant temperature, engine oil

temperature, engine oil level, engine oil quality,

engine speed, and engine load data are obtained from

the Engine Control Module (ECM) over the CAN

data bus. Using all of the available data and internal

programming, the ASSYST microprocessor then cal-

culates the estimated time and distance to the next

required engine oil maintenance interval. The

ASSYST uses the multi-function indicator LCD to

display that data and, when necessary, issues audible

alerts to the vehicle operator through the electronic

tone generator on the cluster circuit board.

See the owner's manual in the vehicle glove box for

more information on the features, use, operation and

resetting procedures for the ASSYST maintenance

computer. Proper diagnosis and testing of the

ASSYST engine oil maintenance computer, the CAN

data bus and the electronic data bus message inputs

to the EMIC that are used by the ASSYST computer

for its calculations requires the use of a diagnostic

scan tool. Refer to the appropriate diagnostic infor-

mation.

MALFUNCTION INDICATOR

LAMP (MIL)

DESCRIPTION

A Malfunction Indicator Lamp (MIL) is standard

equipment on all instrument clusters. The MIL islocated near the lower edge of the instrument cluster,

to the right of the multi-function indicator display.

The MIL consists of the International Control and

Display Symbol icon for ªEngineº imprinted within a

rectangular cutout in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. An amber Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by the LED, which is sol-

dered onto the instrument cluster electronic circuit

board. The MIL is serviced as a unit with the instru-

ment cluster.

OPERATION

The Malfunction Indicator Lamp (MIL) gives an

indication to the vehicle operator when the Engine

Control Module (ECM) has recorded a Diagnostic

Trouble Code (DTC) for an On-Board Diagnostics II

(OBDII) emissions-related circuit or component mal-

function. The MIL is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the ECM over the Controller Area

Network (CAN) data bus. The MIL Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster detects that the ignition switch is in the On

position. Therefore, the LED will always be off when

the ignition switch is in any position except On. The

LED only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the MIL for the fol-

lowing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the MIL is illuminated as a

bulb test. The indicator will remain illuminated until

the engine is started, or until the ignition switch is

turned to the Off position, whichever occurs first.

²MIL Lamp-On Message- Each time the clus-

ter receives a MIL lamp-on message from the ECM,

the indicator will be illuminated. The indicator will

remain illuminated until the detected fault is

repaired, or until the ignition switch is turned to the

Off position, whichever occurs first. For more infor-

mation on the ECM and the DTC set and reset

parameters, (Refer to 25 - EMISSIONS CONTROL -

OPERATION).

²Communication Error- If the cluster receives

no lamp-on or lamp-off message from the ECM, the

MIL is illuminated by the instrument cluster. The

indicator remains controlled and illuminated by the

cluster until a valid lamp-on or lamp-off message is

received from the ECM.

VAINSTRUMENT CLUSTER 8J - 21

Page 941 of 2305

The ECM continually monitors the fuel and emis-

sions system circuits and sensors to decide whether

the system is in good operating condition. The ECM

then sends the proper lamp-on or lamp-off messages

to the instrument cluster. If the instrument cluster

turns on the MIL after the bulb test, it may indicate

that a malfunction has occurred and that the fuel

and emissions systems may require service. For

proper diagnosis of the fuel and emissions systems,

the ECM, the CAN data bus, or the electronic mes-

sage inputs to the instrument cluster that control the

MIL, a diagnostic scan tool is required. Refer to the

appropriate diagnostic information.

MULTI - FUNCTION INDICA-

TOR

DESCRIPTION

A multi-function indicator is standard equipment

on all instrument clusters. The multi-function indica-

tor is located near the lower edge of the instrument

cluster, directly below the speedometer. The multi-

function indicator consists of a Liquid Crystal Dis-

play (LCD) unit and four push button-controlled

switches that are soldered onto the instrument clus-

ter electronic circuit board. The LCD is visible

through a large rectangular cutout in the instrument

cluster overlay, while the four switch push buttons

extend through a black plastic switch bezel located

on the cluster lens directly below the LCD. The four

multi-function indicator push buttons allow the vehi-

cle operator to configure and adjust several of the

display features. The buttons are labeled from left to

right: ªmiº (miles) or ªkmº (kilometers), an icon

depicting an analog clock face (clock), ª2º (minus),

and ª+º (plus).

The multi-function indicator LCD displays both

alpha-numeric characters and numerous icons to pro-

vide information to the vehicle operator. The indica-

tions of the multi-function indicator are not visible

when the LCD is not illuminated. When illuminated

the indications appear as dark characters and icons

silhouetted against an amber field. When the exterior

lighting is turned Off, the display is illuminated at

maximum brightness. When the exterior lighting is

turned On the display illumination level can be

adjusted in concert with the cluster general illumina-

tion lighting using the ª+º (plus) and ª2º (minus)

multi-function indicator push buttons. The multi-

function indicator LCD unit and push button

switches are serviced as a unit with the instrument

cluster.

OPERATION

The multi-function indicator has several display

capabilities including odometer, trip odometer, clock,engine oil level data, gear selector indicator

(PRNDL), certain diagnostic information and, on

vehicles so equipped, an optional Active Service SYS-

Tem (ASSYST) engine oil maintenance indicator and

an optional outside ambient temperature indicator.

The multi-function indicator is completely controlled

by the instrument cluster logic circuit, and that logic

will allow this indication to be viewed whenever the

multi-function indicator Liquid Crystal Display

(LCD) is activated. Therefore, the indicator remains

functional regardless of the ignition switch position.

With the ignition switch in the Off or Accessory posi-

tions and the key removed from the ignition lock cyl-

inder, the display is activated when the park lamps

are turned On or, for about thirty seconds after any

one of the multi-function indicator switch push but-

tons is depressed. Otherwise, the display unit is

active for about thirty seconds after the key is

inserted into the ignition lock cylinder, and inactive

about thirty seconds after the key is removed from

the ignition lock cylinder.

The multi-function indicator ªmiº (miles) or

ªkmº(kilometers) switch push button is used to con-

trol the odometer/trip odometer display modes. The

multi-function indicator clock switch push button is

used to control the clock/outside temperature display

modes. The multi-function indicator ª+º (plus) and

ª2º (minus) switch push buttons are used to adjust

the cluster general illumination dimming level, the

clock, and other cluster settings. See the owner's

manual in the vehicle glove box for more information

on the features, use, operation and setting proce-

dures for the various standard and optional multi-

function indicator displays.

Proper testing of the multi-function indicator LCD

unit, the CAN data bus and the electronic data bus

message inputs to the instrument cluster that control

some of the multi-function indicator functions

requires the use of a diagnostic scan tool. Refer to

the appropriate diagnostic information. Additional

details for the odometer/trip odometer, the clock, the

gear selector indicator, the ambient temperature indi-

cator and the ASSYST warning and reminder func-

tions of the multi-function indicator may be found

elsewhere in this service information.

ODOMETER

DESCRIPTION

An odometer and trip odometer are standard

equipment in all instrument clusters. The odometer

and trip odometer values are displayed on the left

side of the multi-function indicator Liquid Crystal

Display (LCD). The LCD is soldered onto the cluster

electronic circuit board and is visible through a win-

dow with a clear lens located near the lower edge of

8J - 22 INSTRUMENT CLUSTERVA

Page 1637 of 2305

(6) Remove pressed - out oil pump chain pin from

chain seperation tool.

CAUTION: IT IS ESSENTIAL that the installation pro-

cedure for the oil pump chain is followed exactly.

Failure to do so will result in severe engine dam-

age.

INSTALLATION

INSTALLATION

NOTE: If the oil pump is dry, fill it with clean engine

oil before installation. Clean the oil pick±up tube

and strainer.

(1) Clean all sealing surfaces.

(2) Position the oil pump onto the drive chain and

reset tensioner.

(3) Install oil pump retaining bolts and tighten to

18 N´m (160 lbs. in.).

(4) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(5) Refill the crankcase to the appropriate level

with the proper engine oil (Refer to LUBRICATION

& MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(6) Start the vehicle and inspect for leaks.

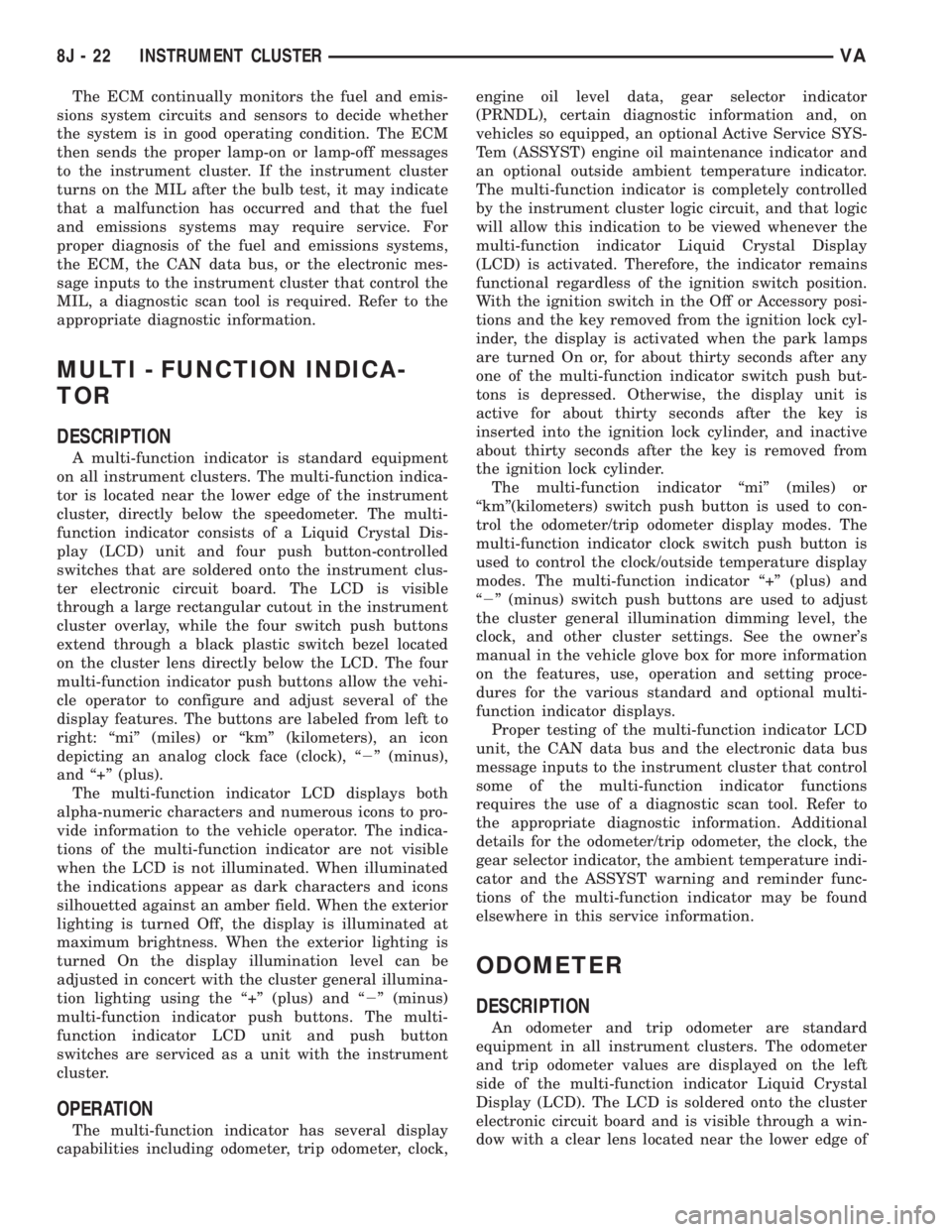

INSTALLATION - OIL PUMP CHAIN

CAUTION: IT IS ESSENTIAL that the installation pro-

cedure is followed exactly. Failure to do so will

result in severe engine damage.

(1) Connect old oil pump chain and new chain with

temporary link, outer plate and locking element (Fig.

61).(2) Slowly rotate crankshaft in a clockwise direc-

tion until it is possible to connect the ends of the new

and old oil pump chains.

(3) Remove assembly locking element, outer plate

and assembly link (Fig. 62).

Fig. 61 INSTALLING OIL PUMP CHAIN TEMPORARY

LINK

1 - VIBRATION DAMPER/CRANKSHAFT PULLEY

2 - OLD OIL PUMP CHAIN

3 - NEW OIL PUMP CHAIN

4 - TEMPORARY LINK

9 - 62 ENGINEVA

Page 1878 of 2305

(14) Remove the transmission oil filter (1) and

o-ring from the electrohydraulic control unit.

(15) Clean the inside of the oil pan (3) of any

debris. Inspect the oil pan gasket (2) and replace if

necessary.

(16) Install a new oil filter (1) and o-ring into the

electrohydraulic control unit.

(17) Install the oil pan (3) and gasket (2) onto the

transmission.

(18) Install the oil pan bolts (5) and retainers (4).

Torque the bolts to 8 N´m (70 in.lbs.).

(19) Lower the vehicle and add 7.0 L (7.4 qts.) of

transmission fluid to the transmission.

(20) Check the oil level (Refer to 21 - TRANSMIS-

SION/AUTOMATIC - NAG1/FLUID AND FILTER -

STANDARD PROCEDURE - CHECK OIL LEVEL).

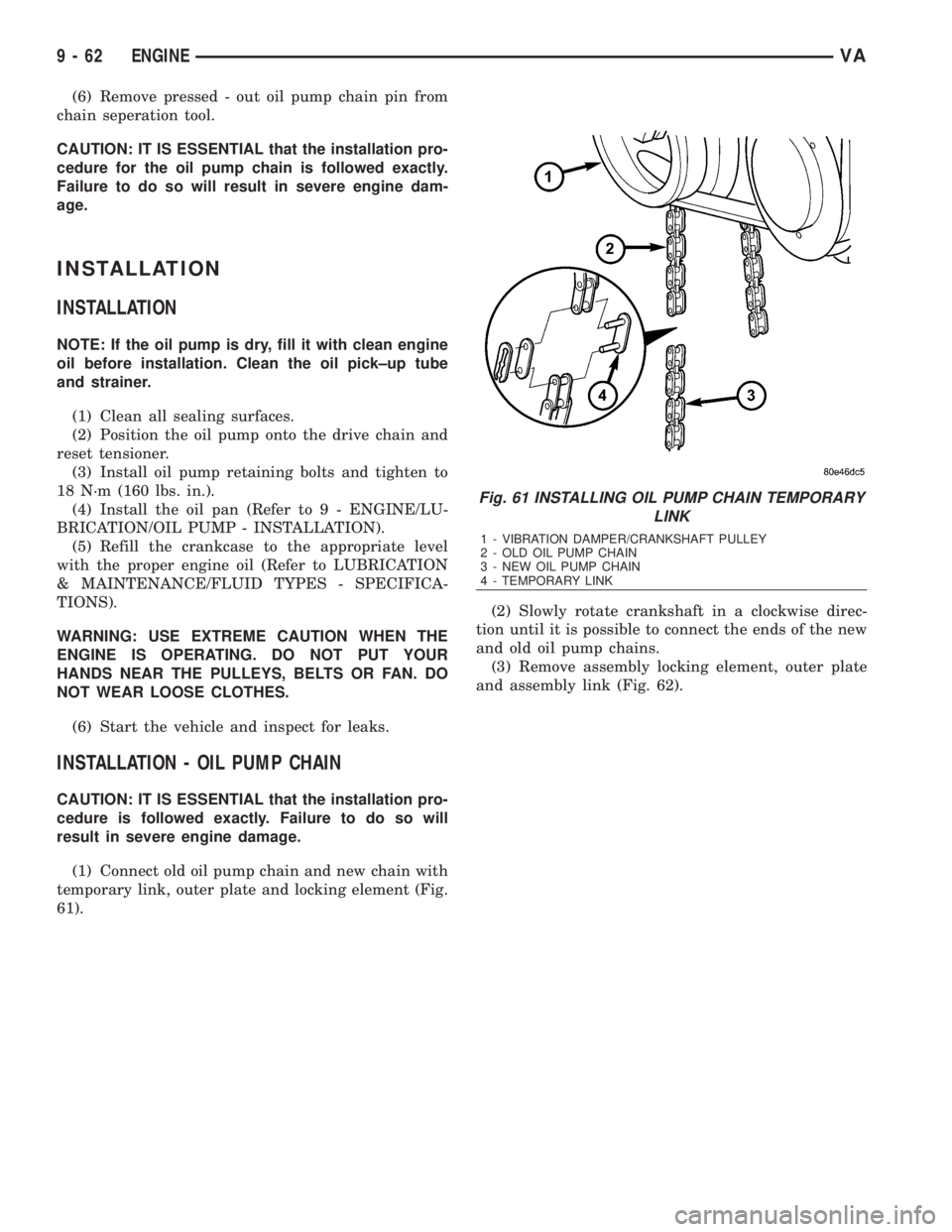

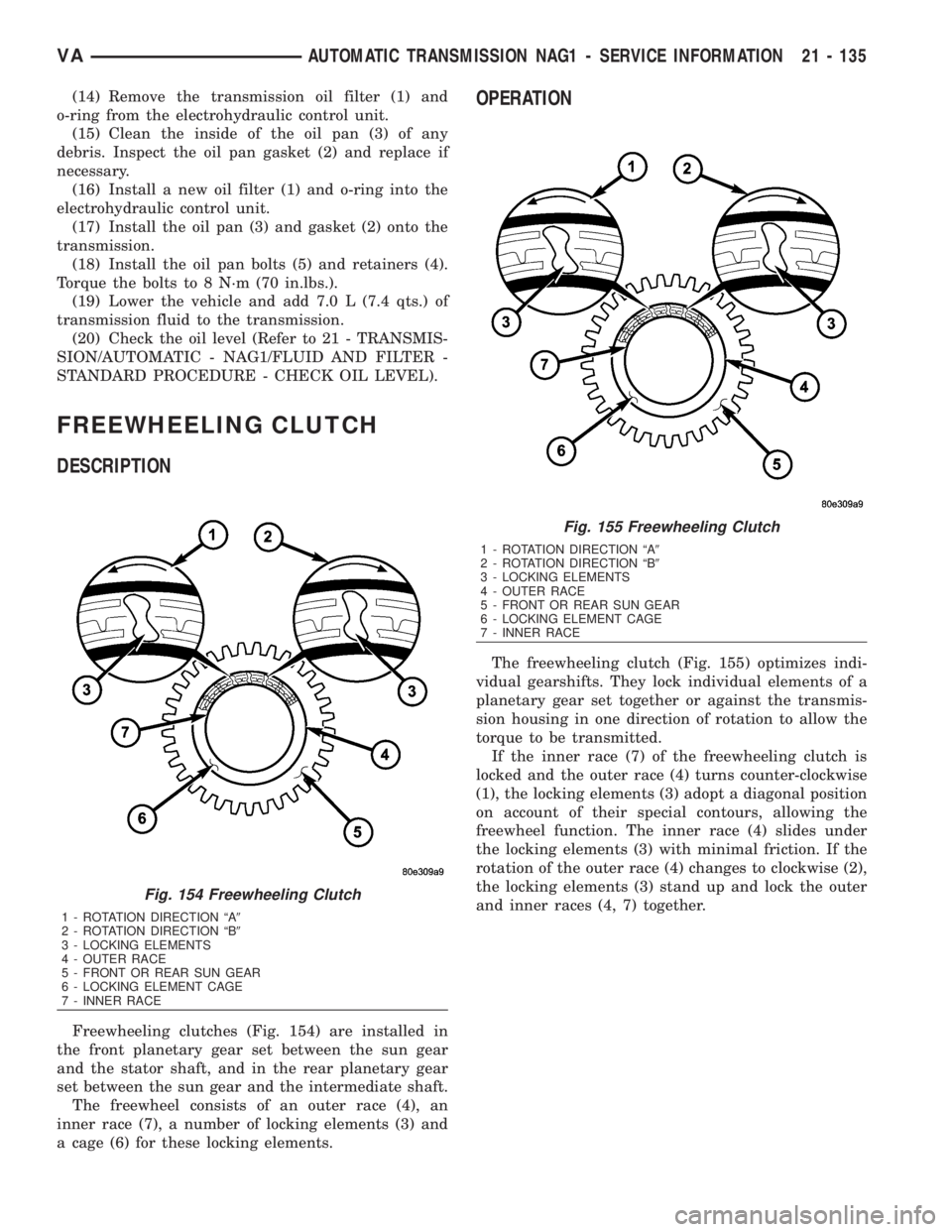

FREEWHEELING CLUTCH

DESCRIPTION

Freewheeling clutches (Fig. 154) are installed in

the front planetary gear set between the sun gear

and the stator shaft, and in the rear planetary gear

set between the sun gear and the intermediate shaft.

The freewheel consists of an outer race (4), an

inner race (7), a number of locking elements (3) and

a cage (6) for these locking elements.

OPERATION

The freewheeling clutch (Fig. 155) optimizes indi-

vidual gearshifts. They lock individual elements of a

planetary gear set together or against the transmis-

sion housing in one direction of rotation to allow the

torque to be transmitted.

If the inner race (7) of the freewheeling clutch is

locked and the outer race (4) turns counter-clockwise

(1), the locking elements (3) adopt a diagonal position

on account of their special contours, allowing the

freewheel function. The inner race (4) slides under

the locking elements (3) with minimal friction. If the

rotation of the outer race (4) changes to clockwise (2),

the locking elements (3) stand up and lock the outer

and inner races (4, 7) together.

Fig. 154 Freewheeling Clutch

1 - ROTATION DIRECTION ªA9

2 - ROTATION DIRECTION ªB9

3 - LOCKING ELEMENTS

4 - OUTER RACE

5 - FRONT OR REAR SUN GEAR

6 - LOCKING ELEMENT CAGE

7 - INNER RACE

Fig. 155 Freewheeling Clutch

1 - ROTATION DIRECTION ªA9

2 - ROTATION DIRECTION ªB9

3 - LOCKING ELEMENTS

4 - OUTER RACE

5 - FRONT OR REAR SUN GEAR

6 - LOCKING ELEMENT CAGE

7 - INNER RACE

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 135

Page 1924 of 2305

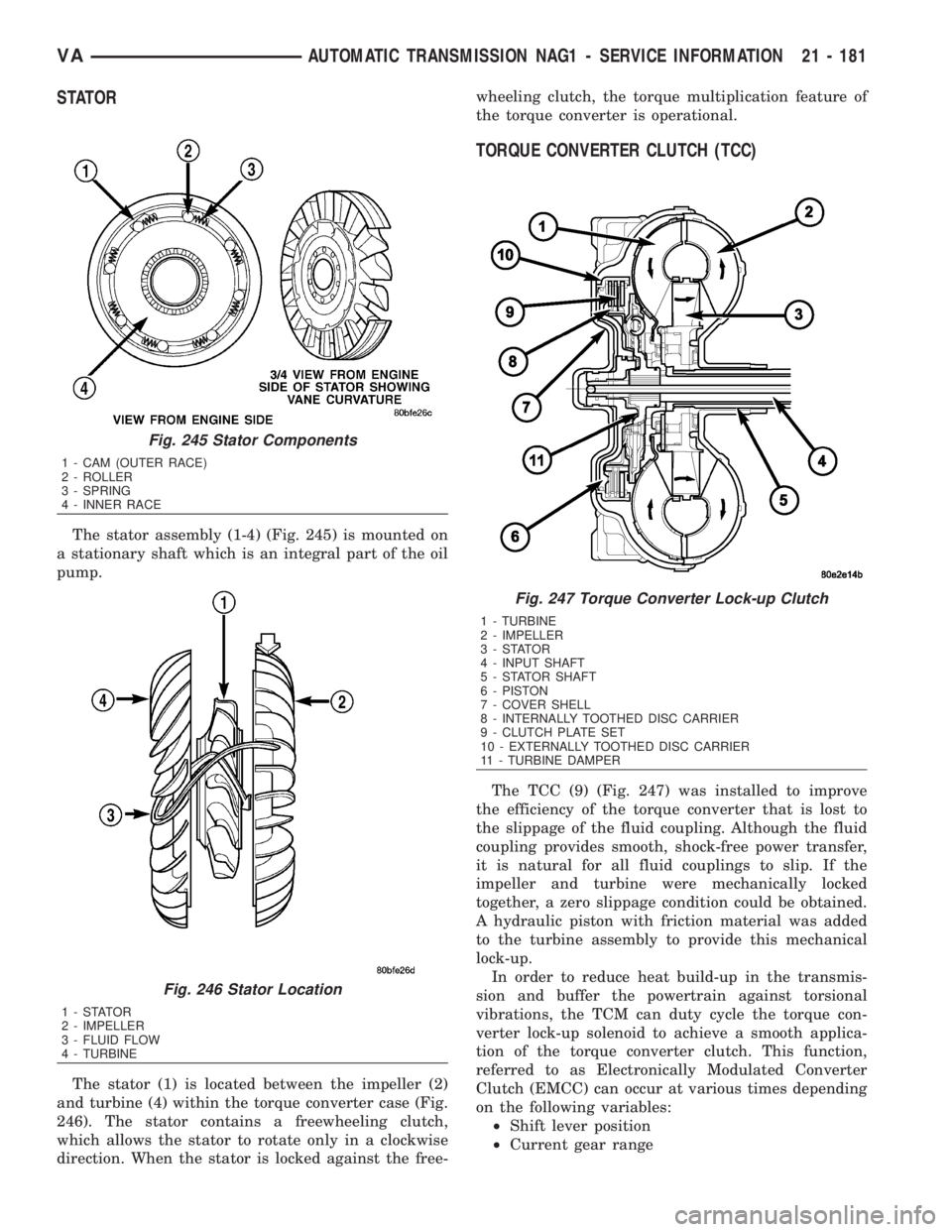

STATOR

The stator assembly (1-4) (Fig. 245) is mounted on

a stationary shaft which is an integral part of the oil

pump.

The stator (1) is located between the impeller (2)

and turbine (4) within the torque converter case (Fig.

246). The stator contains a freewheeling clutch,

which allows the stator to rotate only in a clockwise

direction. When the stator is locked against the free-wheeling clutch, the torque multiplication feature of

the torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (9) (Fig. 247) was installed to improve

the efficiency of the torque converter that is lost to

the slippage of the fluid coupling. Although the fluid

coupling provides smooth, shock-free power transfer,

it is natural for all fluid couplings to slip. If the

impeller and turbine were mechanically locked

together, a zero slippage condition could be obtained.

A hydraulic piston with friction material was added

to the turbine assembly to provide this mechanical

lock-up.

In order to reduce heat build-up in the transmis-

sion and buffer the powertrain against torsional

vibrations, the TCM can duty cycle the torque con-

verter lock-up solenoid to achieve a smooth applica-

tion of the torque converter clutch. This function,

referred to as Electronically Modulated Converter

Clutch (EMCC) can occur at various times depending

on the following variables:

²Shift lever position

²Current gear range

Fig. 245 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 246 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 247 Torque Converter Lock-up Clutch

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

6 - PISTON

7 - COVER SHELL

8 - INTERNALLY TOOTHED DISC CARRIER

9 - CLUTCH PLATE SET

10 - EXTERNALLY TOOTHED DISC CARRIER

11 - TURBINE DAMPER

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 181

Page 2100 of 2305

SYSTEM EMPTY

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approximately 28 in Hg.)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM EVACUATE). Determine if the

system holds a vacuum for 15 minutes. If vacuum is

held, a leak is probably not present. If system will

not maintain vacuum level, proceed to Step 2.

(2) Prepare and dispense 0.284 kilograms (10

ounces) of R-134a refrigerant into the evacuated

refrigerant system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE) and

proceed to Step 1 of the System Low procedure.

SYSTEM LOW

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Operate the heating-A/C system with the

engine at idle under the following conditions for at

least five minutes.

²Doors or windows open

²Transmission in Park

²A/C-heater controls set to outside air, full cool,

panel mode, high blower and with A/C compressor

engaged

CAUTION: A leak detector only designed for R-12

refrigerant will not detect leaks in a R-134a refriger-

ant system.

(3) Shut the vehicle Off and wait 2-7 minutes.

Then use an electronic leak detector that is designed

to detect R-134a refrigerant and search for leaks. Fit-

tings, lines or components that appear to be oily usu-

ally indicate a refrigerant leak. To inspect the A/C

evaporator for leaks, insert the leak detector probe

into the drain tube opening or an air outlet. A dye for

R-134a is available to aid in leak detection. Use only

DaimlerChrysler approved refrigerant dye.

STANDARD PROCEDURE

REFRIGERANT SYSTEM SERVICE EQUIPMENT

WARNING: Eye protection must be worn when ser-

vicing an A/C refrigerant system. Turn off (rotate

clockwise) all valves on the equipment being used,

before connecting to or disconnecting from the

refrigerant system. Failure to observe these warn-

ings may result in possible personal injury.

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Referto 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-

tions could result in possible personal injury or

death.

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

equipment manufacturer for proper care and use of

this equipment.

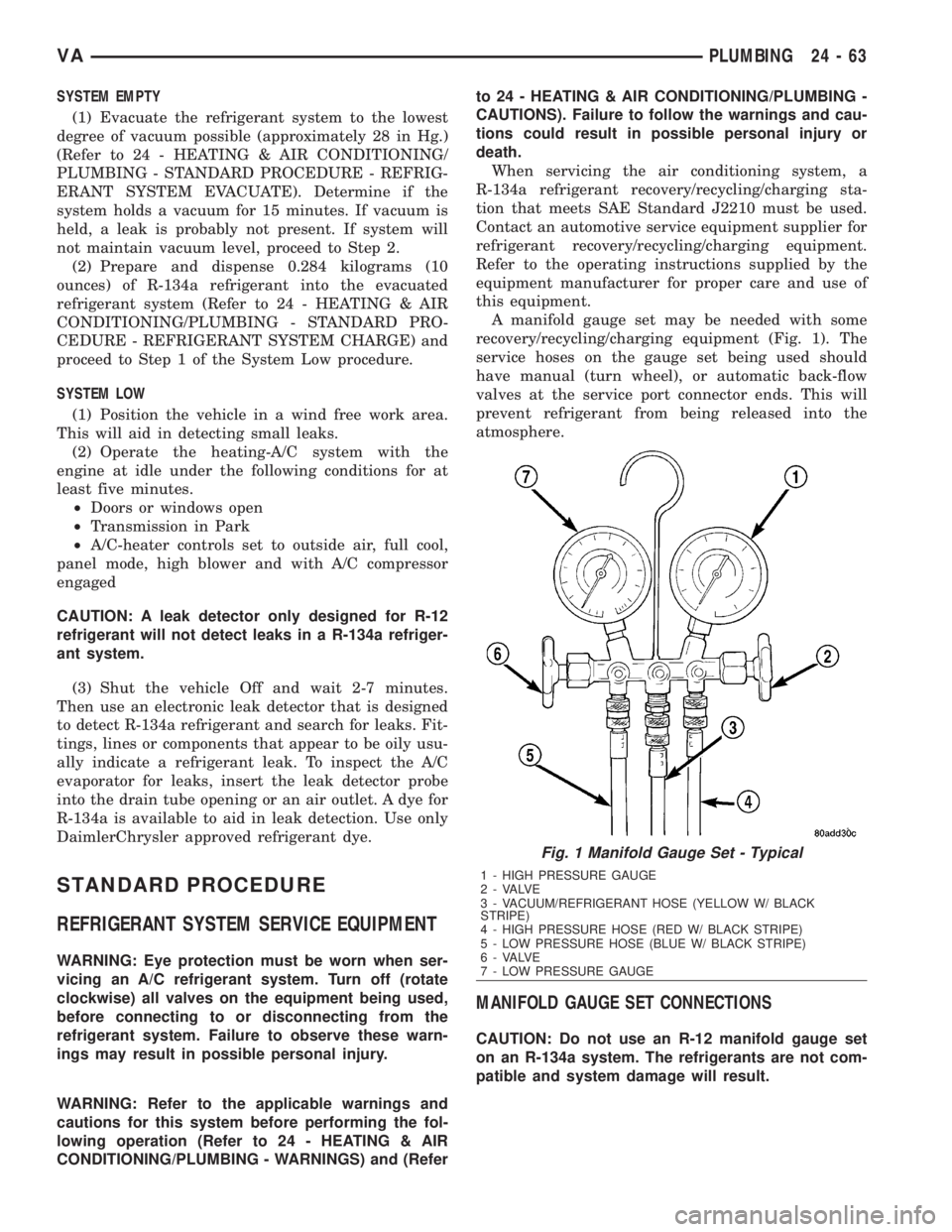

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 1). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

Fig. 1 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/ BLACK

STRIPE)

4 - HIGH PRESSURE HOSE (RED W/ BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/ BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

VAPLUMBING 24 - 63