wheel alignment MERCEDES-BENZ SPRINTER 2006 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 726 of 2305

SUSPENSION

TABLE OF CONTENTS

page page

FRONT.................................1

REAR..................................11WHEEL ALIGNMENT......................17

FRONT

TABLE OF CONTENTS

page page

FRONT

SPECIFICATIONS - TORQUE CHART.........1

SPECIAL TOOLS

FRONT SUSPENSION...................2

BUSHINGS

REMOVAL.............................3

INSTALLATION..........................3

HUB / BEARING

DIAGNOSIS AND TESTING -...............4

REMOVAL.............................4

INSTALLATION..........................5

KNUCKLE

REMOVAL.............................5

INSTALLATION..........................6

LOWER BALL JOINT

REMOVAL.............................6

INSTALLATION..........................6

LOWER CONTROL ARM

REMOVAL.............................6

INSTALLATION..........................7SPRING

REMOVAL.............................7

INSTALLATION..........................8

SPRING CLAMP PLATES

REMOVAL.............................8

INSTALLATION..........................9

SPRING STOP PLATES

REMOVAL.............................9

INSTALLATION..........................9

STABILIZER BAR

DESCRIPTION..........................9

OPERATION............................9

REMOVAL.............................9

INSTALLATION..........................9

STABILIZER LINK

REMOVAL.............................10

INSTALLATION.........................10

STRUT

REMOVAL.............................10

INSTALLATION.........................10

FRONT

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lower Ball Joint To Steer-

ing Knuckle280 206 Ð

Strut To Steering Knuckle 185 136 Ð

Strut To Body 100 74 Ð

Bottom Spring Clamp

Plate To Front Axle

M12 X 1.5 Bolt130 96 Ð

VASUSPENSION 2 - 1

Page 731 of 2305

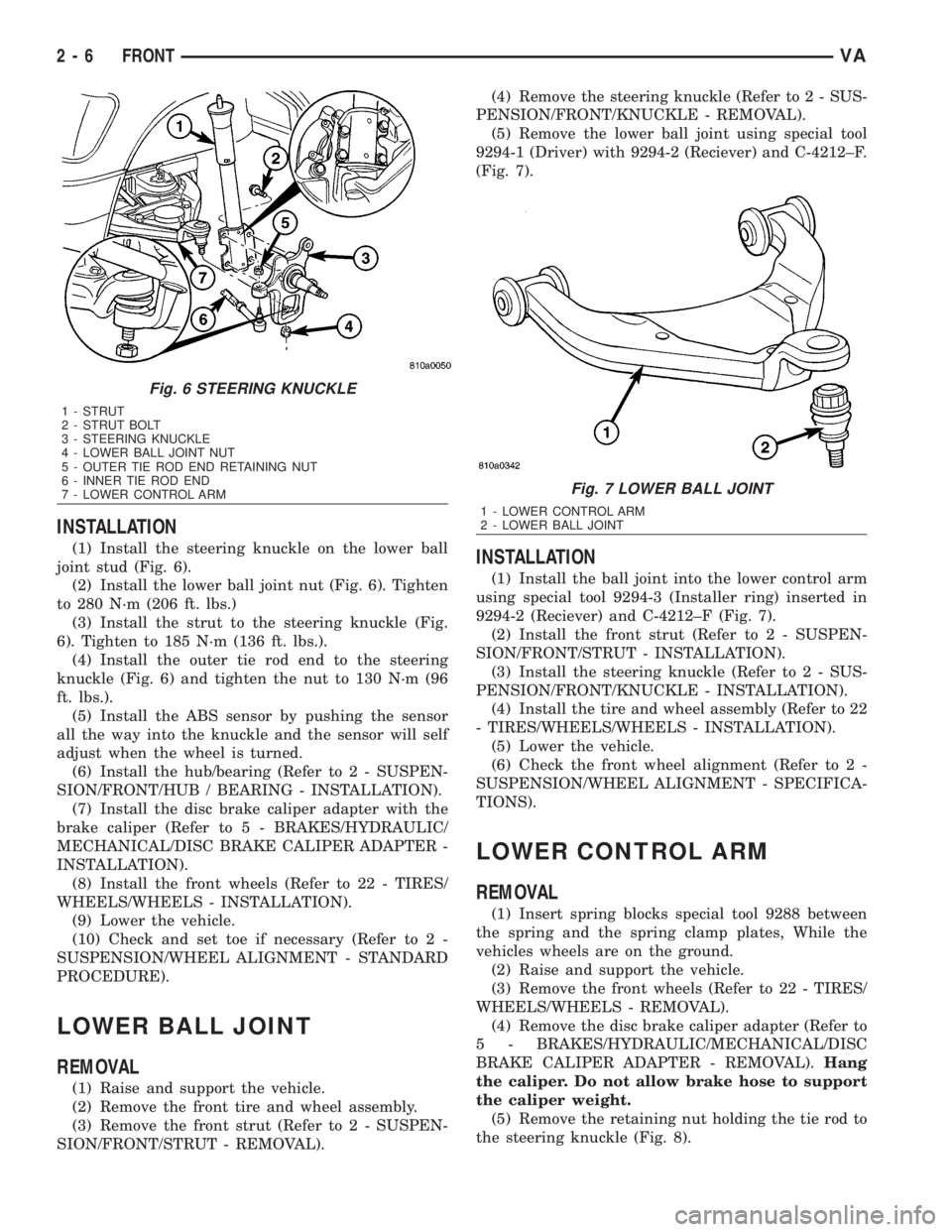

INSTALLATION

(1) Install the steering knuckle on the lower ball

joint stud (Fig. 6).

(2) Install the lower ball joint nut (Fig. 6). Tighten

to 280 N´m (206 ft. lbs.)

(3) Install the strut to the steering knuckle (Fig.

6). Tighten to 185 N´m (136 ft. lbs.).

(4) Install the outer tie rod end to the steering

knuckle (Fig. 6) and tighten the nut to 130 N´m (96

ft. lbs.).

(5) Install the ABS sensor by pushing the sensor

all the way into the knuckle and the sensor will self

adjust when the wheel is turned.

(6) Install the hub/bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - INSTALLATION).

(7) Install the disc brake caliper adapter with the

brake caliper (Refer to 5 - BRAKES/HYDRAULIC/

MECHANICAL/DISC BRAKE CALIPER ADAPTER -

INSTALLATION).

(8) Install the front wheels (Refer to 22 - TIRES/

WHEELS/WHEELS - INSTALLATION).

(9) Lower the vehicle.

(10) Check and set toe if necessary (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

LOWER BALL JOINT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front tire and wheel assembly.

(3) Remove the front strut (Refer to 2 - SUSPEN-

SION/FRONT/STRUT - REMOVAL).(4) Remove the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - REMOVAL).

(5) Remove the lower ball joint using special tool

9294-1 (Driver) with 9294-2 (Reciever) and C-4212±F.

(Fig. 7).

INSTALLATION

(1) Install the ball joint into the lower control arm

using special tool 9294-3 (Installer ring) inserted in

9294-2 (Reciever) and C-4212±F (Fig. 7).

(2) Install the front strut (Refer to 2 - SUSPEN-

SION/FRONT/STRUT - INSTALLATION).

(3) Install the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - INSTALLATION).

(4) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - INSTALLATION).

(5) Lower the vehicle.

(6) Check the front wheel alignment (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - SPECIFICA-

TIONS).

LOWER CONTROL ARM

REMOVAL

(1) Insert spring blocks special tool 9288 between

the spring and the spring clamp plates, While the

vehicles wheels are on the ground.

(2) Raise and support the vehicle.

(3) Remove the front wheels (Refer to 22 - TIRES/

WHEELS/WHEELS - REMOVAL).

(4) Remove the disc brake caliper adapter (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).Hang

the caliper. Do not allow brake hose to support

the caliper weight.

(5) Remove the retaining nut holding the tie rod to

the steering knuckle (Fig. 8).

Fig. 6 STEERING KNUCKLE

1 - STRUT

2 - STRUT BOLT

3 - STEERING KNUCKLE

4 - LOWER BALL JOINT NUT

5 - OUTER TIE ROD END RETAINING NUT

6 - INNER TIE ROD END

7 - LOWER CONTROL ARM

Fig. 7 LOWER BALL JOINT

1 - LOWER CONTROL ARM

2 - LOWER BALL JOINT

2 - 6 FRONTVA

Page 734 of 2305

(5) Remove the spring clamp plate and rubber

block.

(6) Remove the shear bushings from the front and

rear bolts.

INSTALLATION

(1) Install a jack under the lower ball joint and

lower the weight of the vehicle enough to allow a

wrench between the lower control arm and the

bracket tighten the nut.

(2) Fit one spring clamp plate together with the

lower spring rubber block.

(3) Install the bolt with the shear bushing on the

rear mounting,Do not tighten yet.

(4) Install the four retaining bolts for the spring

clamp plate. Tighten to 65 N´m (48 ft.lbs.).

(5) Align the holes for the front clamp plate joint

using a suitable drift (shear bushing not installed).

(6) Remove the alignment drift.

(7) Insert the shear bushing and retaining bolt

into the hole and tighten to 130 N´m (96 ft.lbs.).

(8) Remove the jack and lower the vehicle.

SPRING STOP PLATES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the lower end of the stabilizer link

from the stop plate.

(4) Remove the three bolts retaining the spring

stop plate from the lower control arm.

INSTALLATION

(1) Install the spring stop plate to the lower con-

trol arm. Tighten the bolts to 60 N´m (44 ft. lbs.).

(2) Install the stabilizer link to the spring stop

plate.

(3) Install the tire and wheel assembly.

(4) Lower the vehicle.

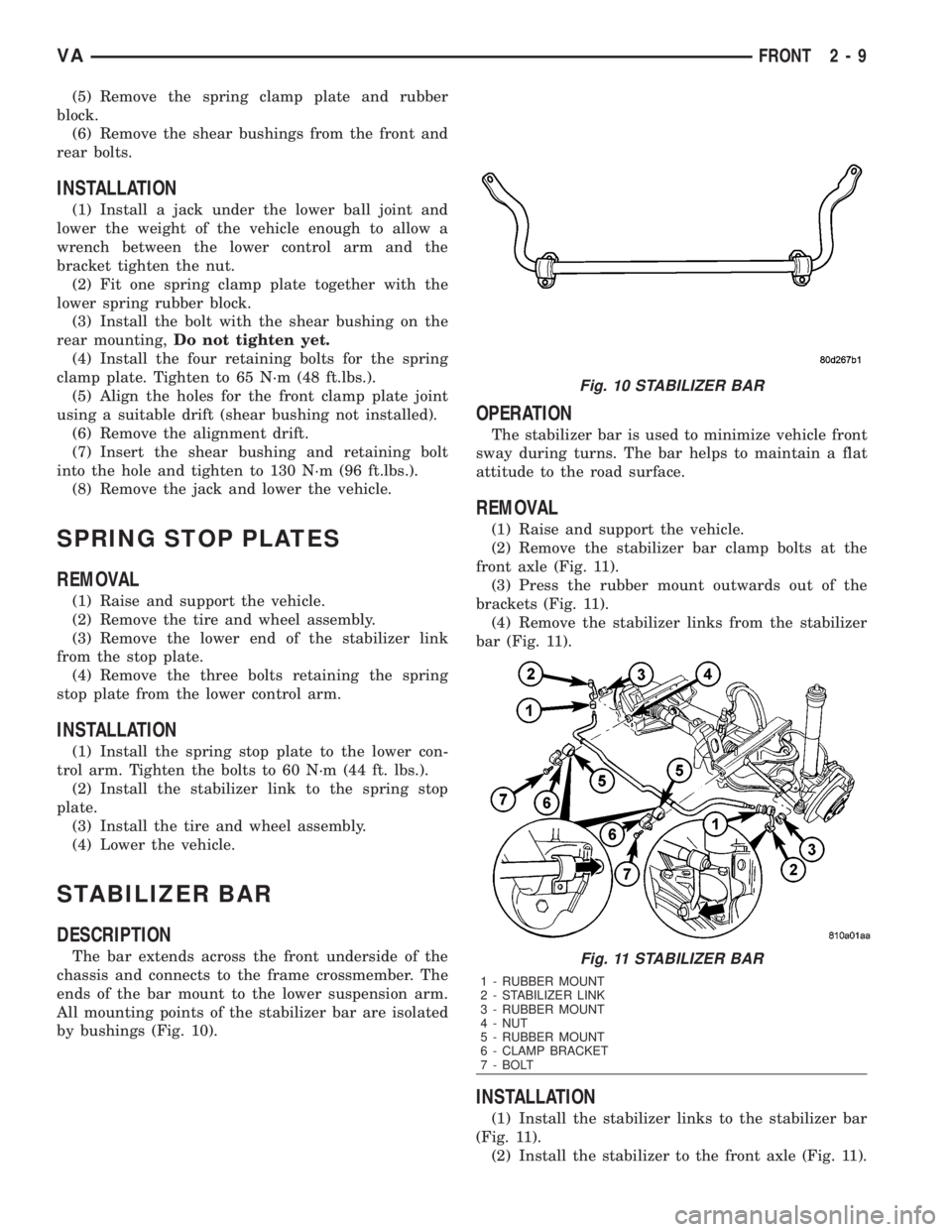

STABILIZER BAR

DESCRIPTION

The bar extends across the front underside of the

chassis and connects to the frame crossmember. The

ends of the bar mount to the lower suspension arm.

All mounting points of the stabilizer bar are isolated

by bushings (Fig. 10).

OPERATION

The stabilizer bar is used to minimize vehicle front

sway during turns. The bar helps to maintain a flat

attitude to the road surface.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the stabilizer bar clamp bolts at the

front axle (Fig. 11).

(3) Press the rubber mount outwards out of the

brackets (Fig. 11).

(4) Remove the stabilizer links from the stabilizer

bar (Fig. 11).

INSTALLATION

(1) Install the stabilizer links to the stabilizer bar

(Fig. 11).

(2) Install the stabilizer to the front axle (Fig. 11).

Fig. 10 STABILIZER BAR

Fig. 11 STABILIZER BAR

1 - RUBBER MOUNT

2 - STABILIZER LINK

3 - RUBBER MOUNT

4 - NUT

5 - RUBBER MOUNT

6 - CLAMP BRACKET

7 - BOLT

VAFRONT 2 - 9

Page 742 of 2305

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION........................17

DIAGNOSIS AND TESTING - PRE-ALIGNMENT

INSPECTION.........................17STANDARD PROCEDURE - TOE

ADJUSTMENT........................18

SPECIFICATIONS.....................19

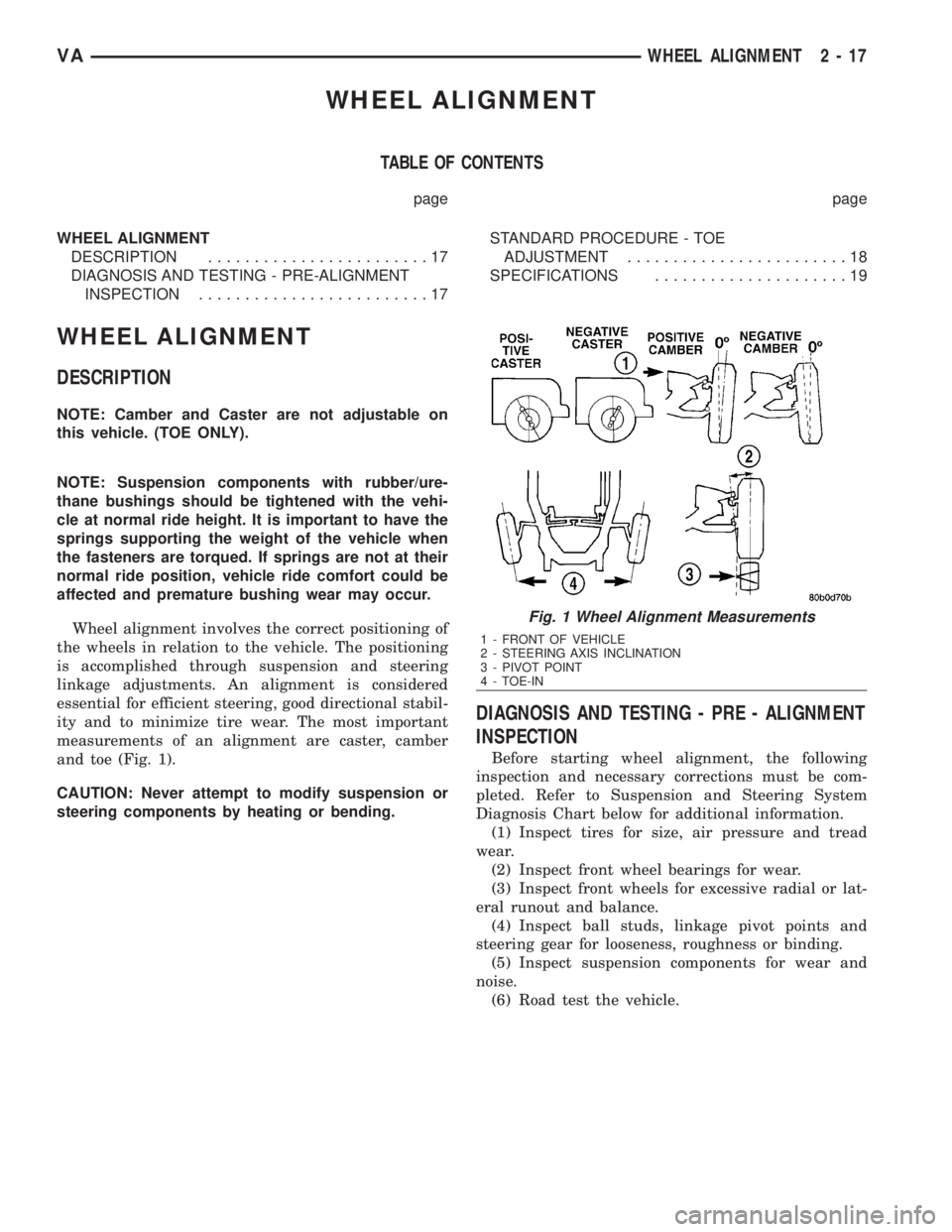

WHEEL ALIGNMENT

DESCRIPTION

NOTE: Camber and Caster are not adjustable on

this vehicle. (TOE ONLY).

NOTE: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. If springs are not at their

normal ride position, vehicle ride comfort could be

affected and premature bushing wear may occur.

Wheel alignment involves the correct positioning of

the wheels in relation to the vehicle. The positioning

is accomplished through suspension and steering

linkage adjustments. An alignment is considered

essential for efficient steering, good directional stabil-

ity and to minimize tire wear. The most important

measurements of an alignment are caster, camber

and toe (Fig. 1).

CAUTION: Never attempt to modify suspension or

steering components by heating or bending.

DIAGNOSIS AND TESTING - PRE - ALIGNMENT

INSPECTION

Before starting wheel alignment, the following

inspection and necessary corrections must be com-

pleted. Refer to Suspension and Steering System

Diagnosis Chart below for additional information.

(1) Inspect tires for size, air pressure and tread

wear.

(2) Inspect front wheel bearings for wear.

(3) Inspect front wheels for excessive radial or lat-

eral runout and balance.

(4) Inspect ball studs, linkage pivot points and

steering gear for looseness, roughness or binding.

(5) Inspect suspension components for wear and

noise.

(6) Road test the vehicle.

Fig. 1 Wheel Alignment Measurements

1 - FRONT OF VEHICLE

2 - STEERING AXIS INCLINATION

3 - PIVOT POINT

4 - TOE-IN

VAWHEEL ALIGNMENT 2 - 17

Page 743 of 2305

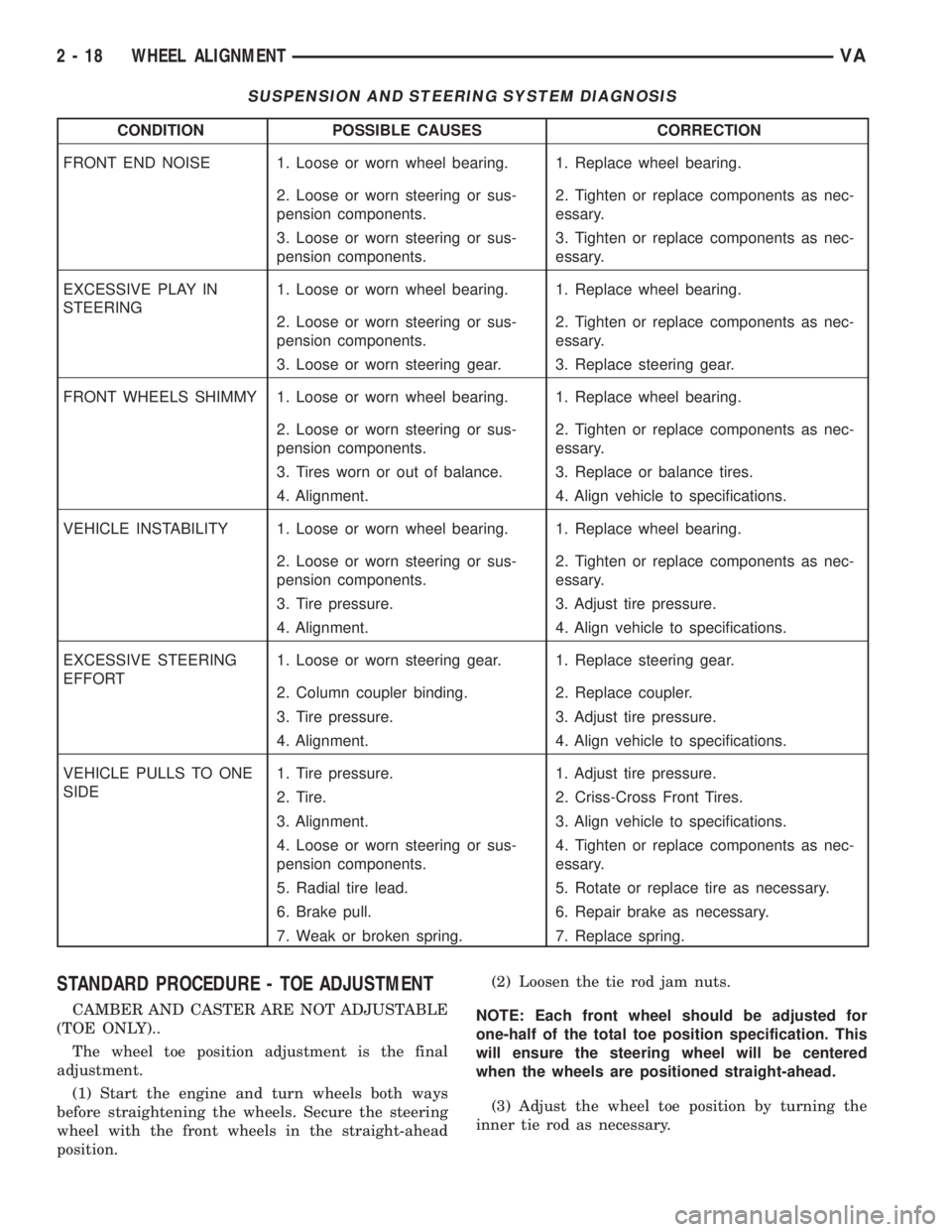

SUSPENSION AND STEERING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Loose or worn steering or sus-

pension components.3. Tighten or replace components as nec-

essary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Loose or worn steering gear. 3. Replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE INSTABILITY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Replace steering gear.

2. Column coupler binding. 2. Replace coupler.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE PULLS TO ONE

SIDE1. Tire pressure. 1. Adjust tire pressure.

2. Tire. 2. Criss-Cross Front Tires.

3. Alignment. 3. Align vehicle to specifications.

4. Loose or worn steering or sus-

pension components.4. Tighten or replace components as nec-

essary.

5. Radial tire lead. 5. Rotate or replace tire as necessary.

6. Brake pull. 6. Repair brake as necessary.

7. Weak or broken spring. 7. Replace spring.

STANDARD PROCEDURE - TOE ADJUSTMENT

CAMBER AND CASTER ARE NOT ADJUSTABLE

(TOE ONLY)..

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary.

2 - 18 WHEEL ALIGNMENTVA

Page 744 of 2305

(4) Tighten the tie rod jam nut to 50 N´m (37 ft.

lbs.).

(5) Verify the specifications

(6) Turn off engine.

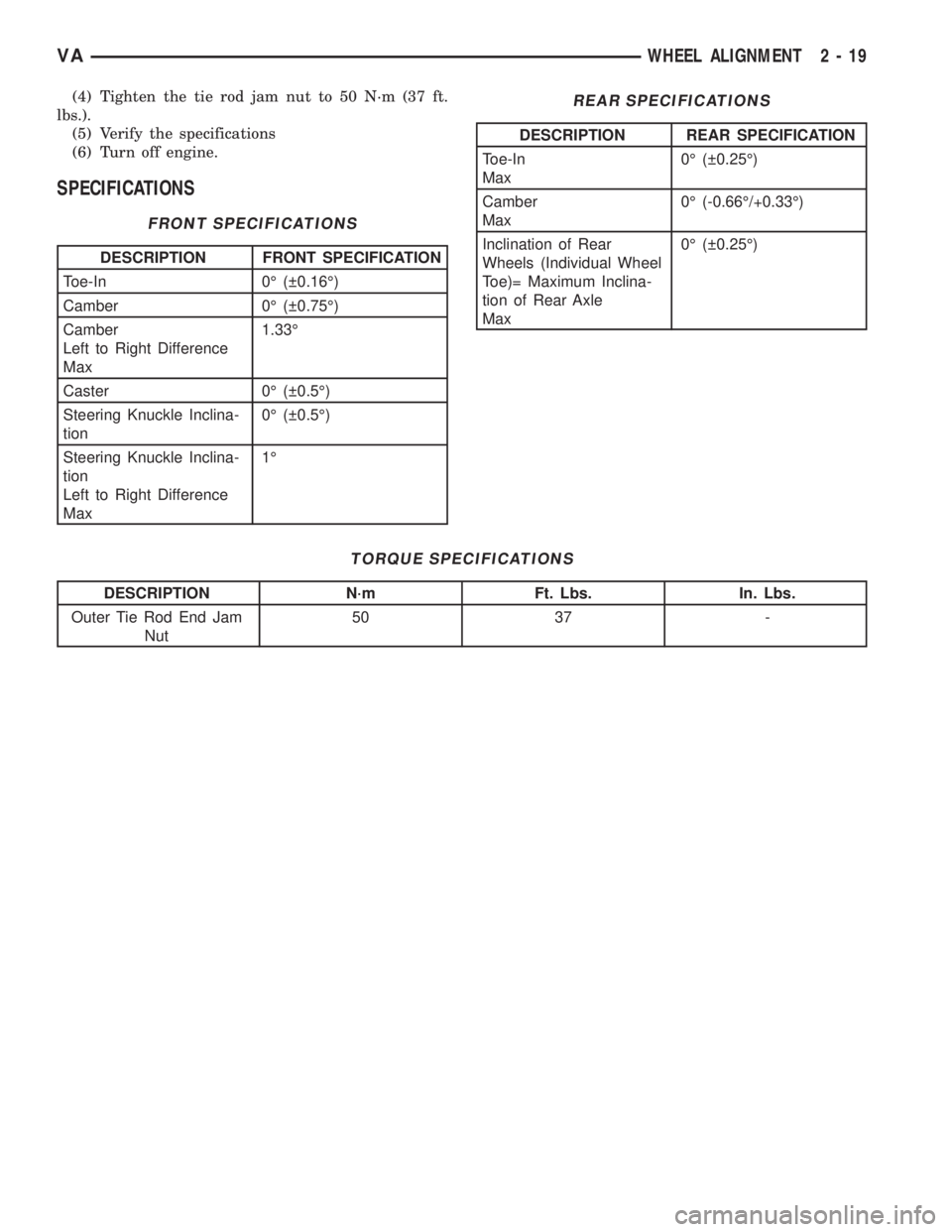

SPECIFICATIONS

FRONT SPECIFICATIONS

DESCRIPTION FRONT SPECIFICATION

Toe-In 0É ( 0.16É)

Camber 0É ( 0.75É)

Camber

Left to Right Difference

Max1.33É

Caster 0É ( 0.5É)

Steering Knuckle Inclina-

tion0É ( 0.5É)

Steering Knuckle Inclina-

tion

Left to Right Difference

Max1É

REAR SPECIFICATIONS

DESCRIPTION REAR SPECIFICATION

Toe-In

Max0É ( 0.25É)

Camber

Max0É (-0.66É/+0.33É)

Inclination of Rear

Wheels (Individual Wheel

Toe)= Maximum Inclina-

tion of Rear Axle

Max0É ( 0.25É)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Outer Tie Rod End Jam

Nut50 37 -

VAWHEEL ALIGNMENT 2 - 19

Page 747 of 2305

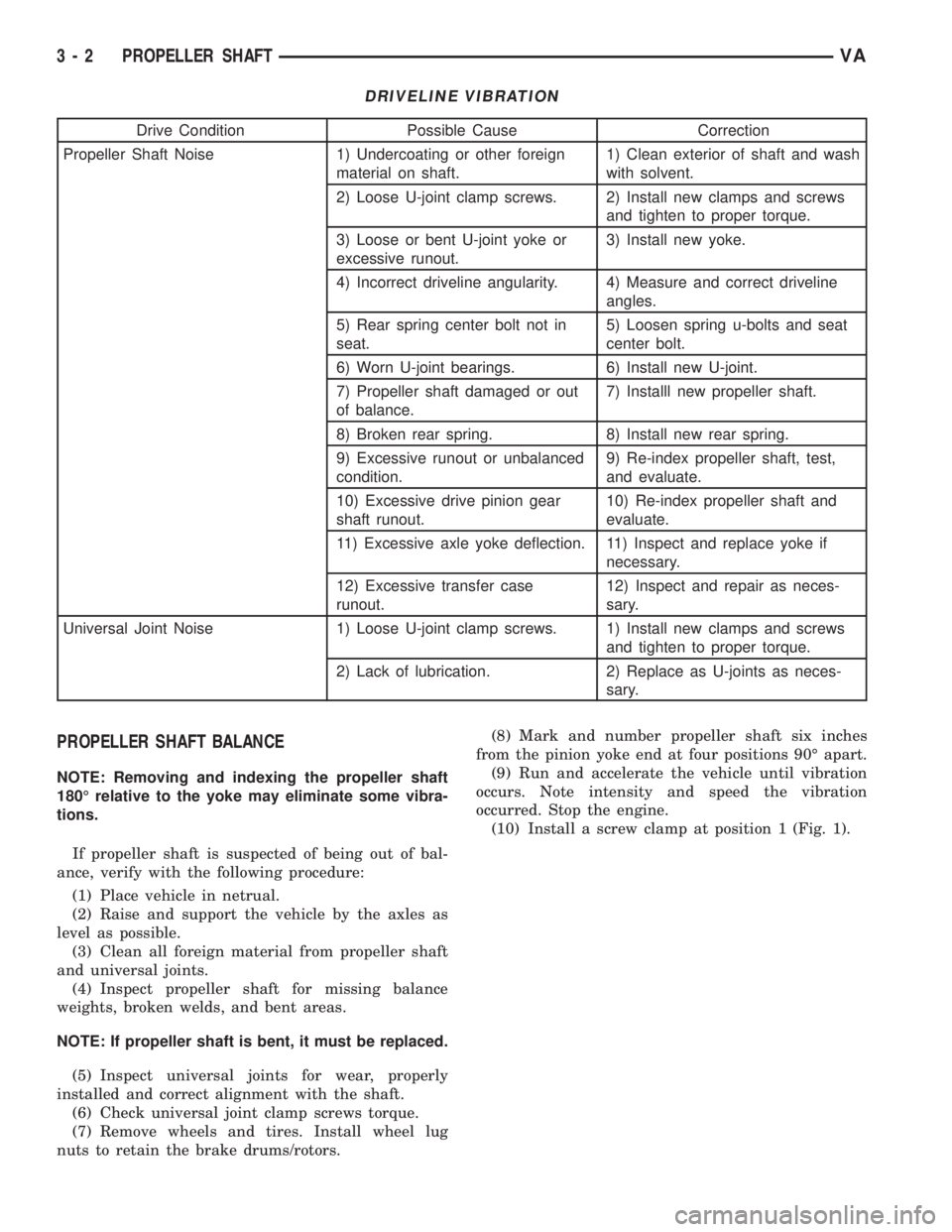

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign

material on shaft.1) Clean exterior of shaft and wash

with solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws

and tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline

angles.

5) Rear spring center bolt not in

seat.5) Loosen spring u-bolts and seat

center bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out

of balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test,

and evaluate.

10) Excessive drive pinion gear

shaft runout.10) Re-index propeller shaft and

evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if

necessary.

12) Excessive transfer case

runout.12) Inspect and repair as neces-

sary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws

and tighten to proper torque.

2) Lack of lubrication. 2) Replace as U-joints as neces-

sary.

PROPELLER SHAFT BALANCE

NOTE: Removing and indexing the propeller shaft

180É relative to the yoke may eliminate some vibra-

tions.

If propeller shaft is suspected of being out of bal-

ance, verify with the following procedure:

(1) Place vehicle in netrual.

(2) Raise and support the vehicle by the axles as

level as possible.

(3) Clean all foreign material from propeller shaft

and universal joints.

(4) Inspect propeller shaft for missing balance

weights, broken welds, and bent areas.

NOTE: If propeller shaft is bent, it must be replaced.

(5) Inspect universal joints for wear, properly

installed and correct alignment with the shaft.

(6) Check universal joint clamp screws torque.

(7) Remove wheels and tires. Install wheel lug

nuts to retain the brake drums/rotors.(8) Mark and number propeller shaft six inches

from the pinion yoke end at four positions 90É apart.

(9) Run and accelerate the vehicle until vibration

occurs. Note intensity and speed the vibration

occurred. Stop the engine.

(10) Install a screw clamp at position 1 (Fig. 1).

3 - 2 PROPELLER SHAFTVA

Page 752 of 2305

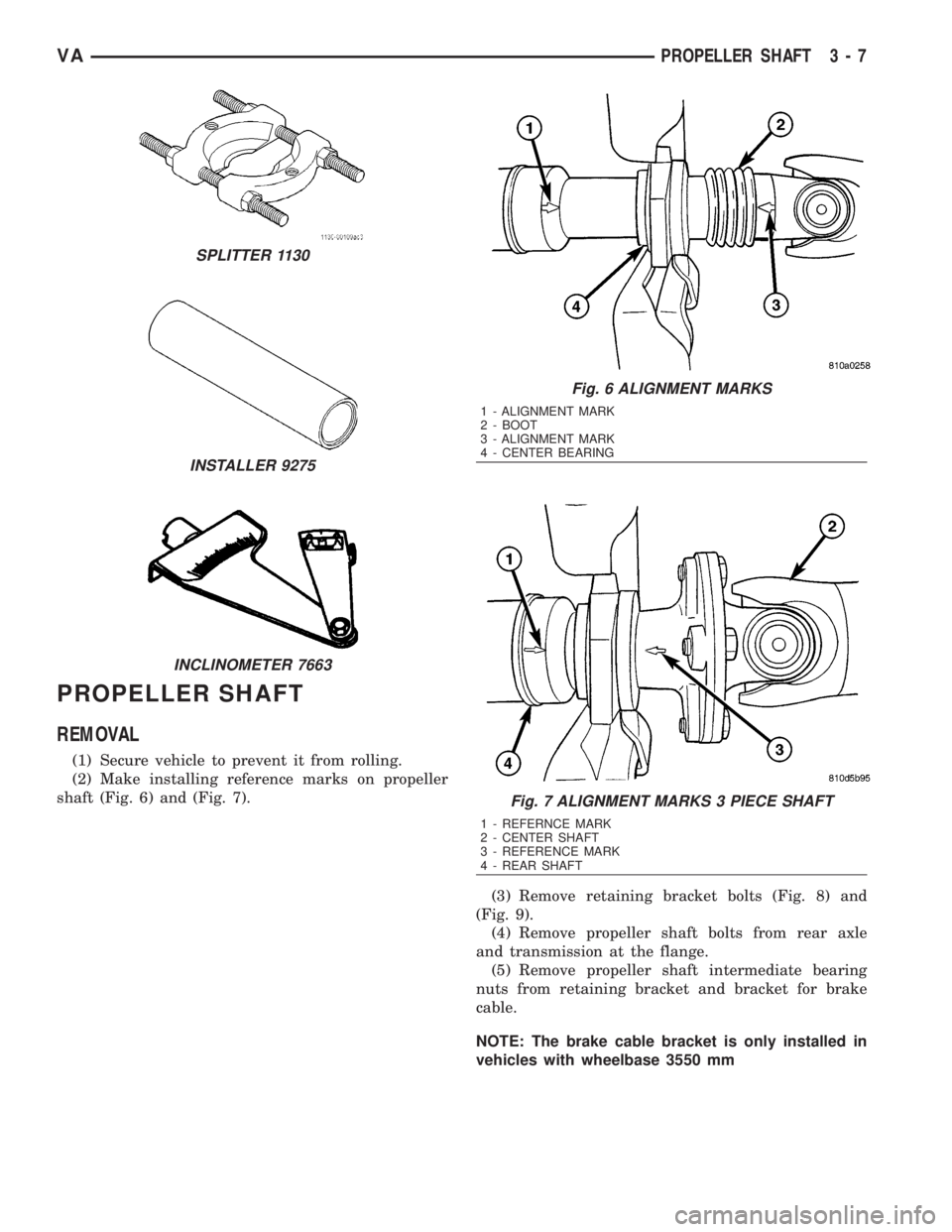

PROPELLER SHAFT

REMOVAL

(1) Secure vehicle to prevent it from rolling.

(2) Make installing reference marks on propeller

shaft (Fig. 6) and (Fig. 7).

(3) Remove retaining bracket bolts (Fig. 8) and

(Fig. 9).

(4) Remove propeller shaft bolts from rear axle

and transmission at the flange.

(5) Remove propeller shaft intermediate bearing

nuts from retaining bracket and bracket for brake

cable.

NOTE: The brake cable bracket is only installed in

vehicles with wheelbase 3550 mm

SPLITTER 1130

INSTALLER 9275

INCLINOMETER 7663

Fig. 6 ALIGNMENT MARKS

1 - ALIGNMENT MARK

2 - BOOT

3 - ALIGNMENT MARK

4 - CENTER BEARING

Fig. 7 ALIGNMENT MARKS 3 PIECE SHAFT

1 - REFERNCE MARK

2 - CENTER SHAFT

3 - REFERENCE MARK

4 - REAR SHAFT

VAPROPELLER SHAFT 3 - 7

Page 754 of 2305

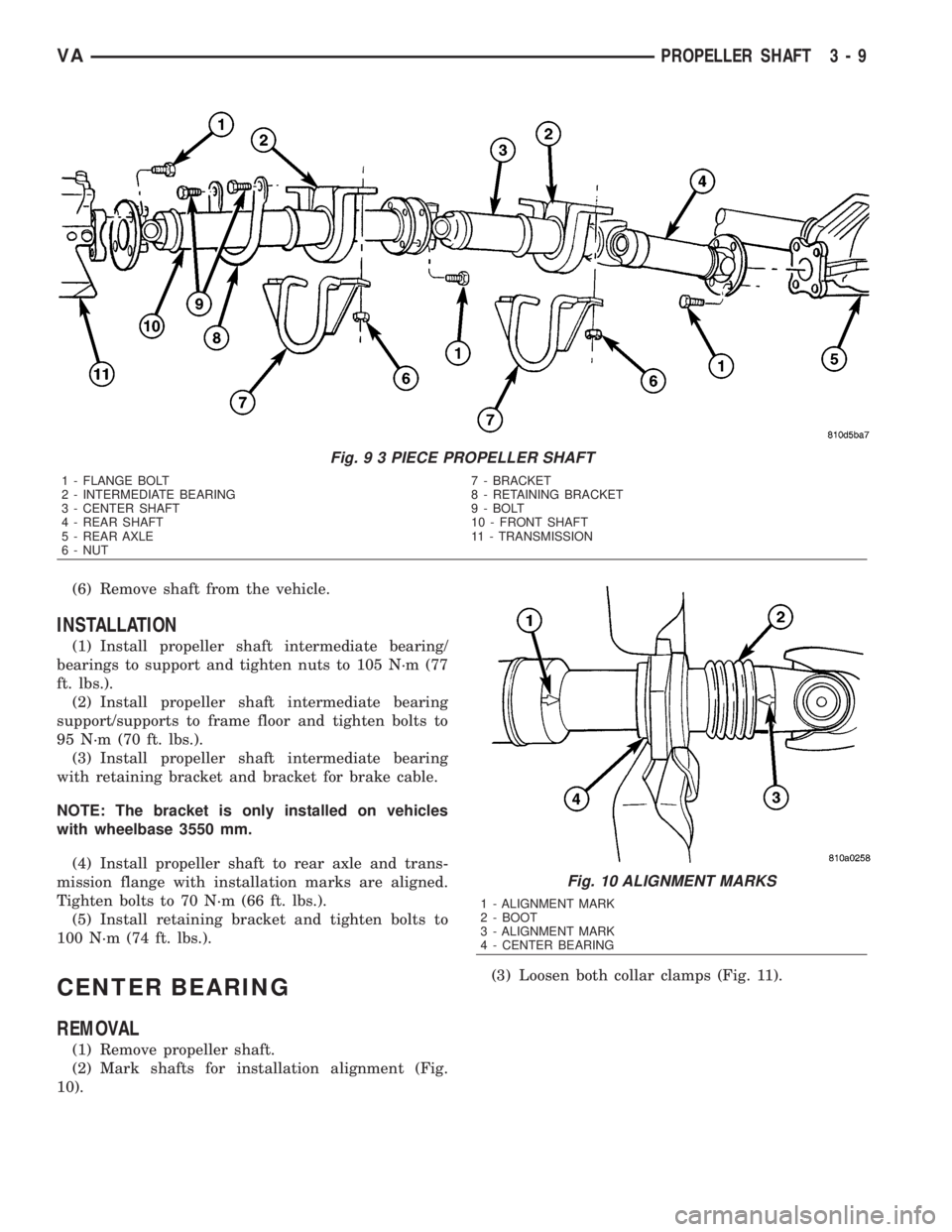

(6) Remove shaft from the vehicle.

INSTALLATION

(1) Install propeller shaft intermediate bearing/

bearings to support and tighten nuts to 105 N´m (77

ft. lbs.).

(2) Install propeller shaft intermediate bearing

support/supports to frame floor and tighten bolts to

95 N´m (70 ft. lbs.).

(3) Install propeller shaft intermediate bearing

with retaining bracket and bracket for brake cable.

NOTE: The bracket is only installed on vehicles

with wheelbase 3550 mm.

(4) Install propeller shaft to rear axle and trans-

mission flange with installation marks are aligned.

Tighten bolts to 70 N´m (66 ft. lbs.).

(5) Install retaining bracket and tighten bolts to

100 N´m (74 ft. lbs.).

CENTER BEARING

REMOVAL

(1) Remove propeller shaft.

(2) Mark shafts for installation alignment (Fig.

10).(3) Loosen both collar clamps (Fig. 11).

Fig. 9 3 PIECE PROPELLER SHAFT

1 - FLANGE BOLT 7 - BRACKET

2 - INTERMEDIATE BEARING 8 - RETAINING BRACKET

3 - CENTER SHAFT 9 - BOLT

4 - REAR SHAFT 10 - FRONT SHAFT

5 - REAR AXLE 11 - TRANSMISSION

6 - NUT

Fig. 10 ALIGNMENT MARKS

1 - ALIGNMENT MARK

2 - BOOT

3 - ALIGNMENT MARK

4 - CENTER BEARING

VAPROPELLER SHAFT 3 - 9

Page 962 of 2305

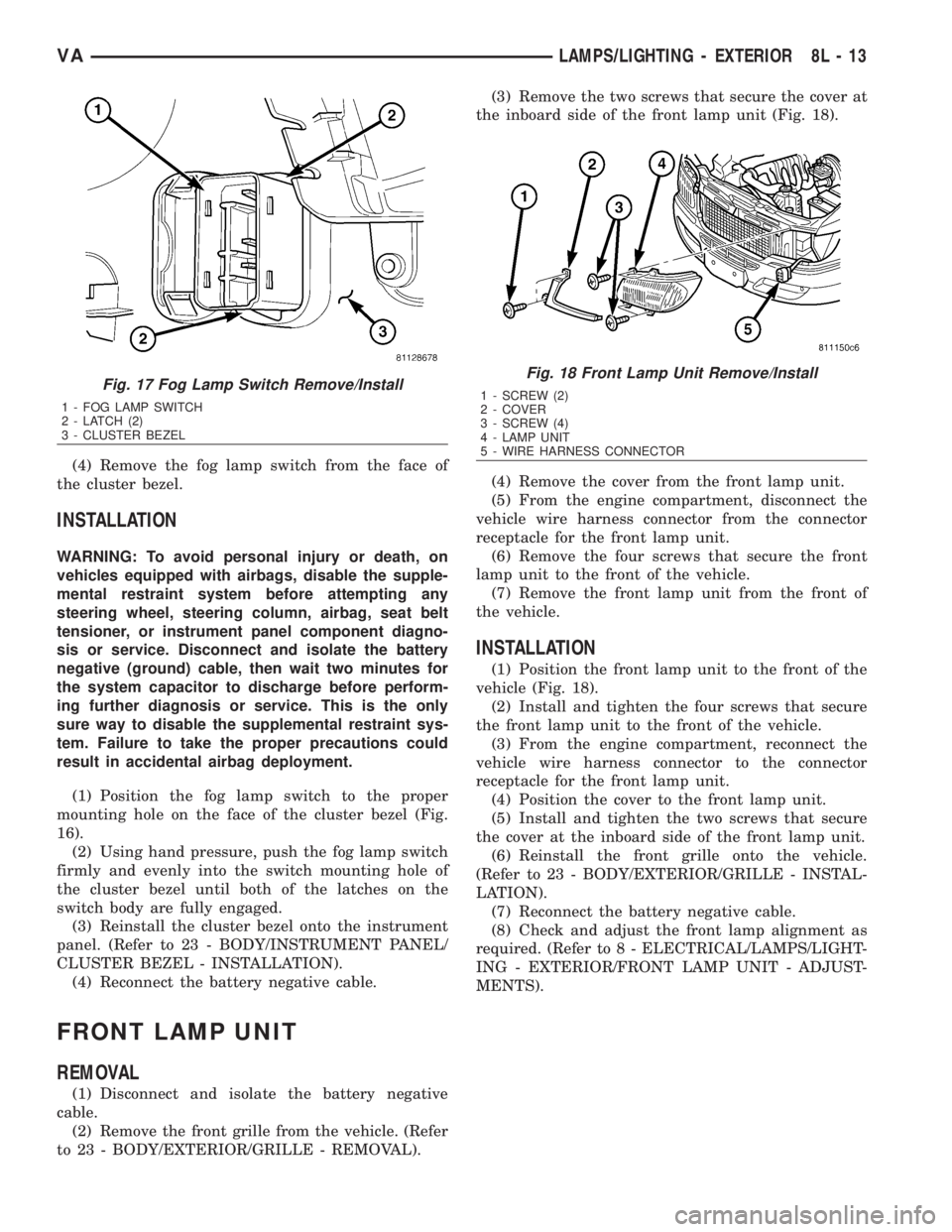

(4) Remove the fog lamp switch from the face of

the cluster bezel.

INSTALLATION

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

(1) Position the fog lamp switch to the proper

mounting hole on the face of the cluster bezel (Fig.

16).

(2) Using hand pressure, push the fog lamp switch

firmly and evenly into the switch mounting hole of

the cluster bezel until both of the latches on the

switch body are fully engaged.

(3) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(4) Reconnect the battery negative cable.

FRONT LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front grille from the vehicle. (Refer

to 23 - BODY/EXTERIOR/GRILLE - REMOVAL).(3) Remove the two screws that secure the cover at

the inboard side of the front lamp unit (Fig. 18).

(4) Remove the cover from the front lamp unit.

(5) From the engine compartment, disconnect the

vehicle wire harness connector from the connector

receptacle for the front lamp unit.

(6) Remove the four screws that secure the front

lamp unit to the front of the vehicle.

(7) Remove the front lamp unit from the front of

the vehicle.

INSTALLATION

(1) Position the front lamp unit to the front of the

vehicle (Fig. 18).

(2) Install and tighten the four screws that secure

the front lamp unit to the front of the vehicle.

(3) From the engine compartment, reconnect the

vehicle wire harness connector to the connector

receptacle for the front lamp unit.

(4) Position the cover to the front lamp unit.

(5) Install and tighten the two screws that secure

the cover at the inboard side of the front lamp unit.

(6) Reinstall the front grille onto the vehicle.

(Refer to 23 - BODY/EXTERIOR/GRILLE - INSTAL-

LATION).

(7) Reconnect the battery negative cable.

(8) Check and adjust the front lamp alignment as

required. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/FRONT LAMP UNIT - ADJUST-

MENTS).

Fig. 17 Fog Lamp Switch Remove/Install

1 - FOG LAMP SWITCH

2 - LATCH (2)

3 - CLUSTER BEZEL

Fig. 18 Front Lamp Unit Remove/Install

1 - SCREW (2)

2 - COVER

3 - SCREW (4)

4 - LAMP UNIT

5 - WIRE HARNESS CONNECTOR

VALAMPS/LIGHTING - EXTERIOR 8L - 13