drain bolt MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 763 of 2305

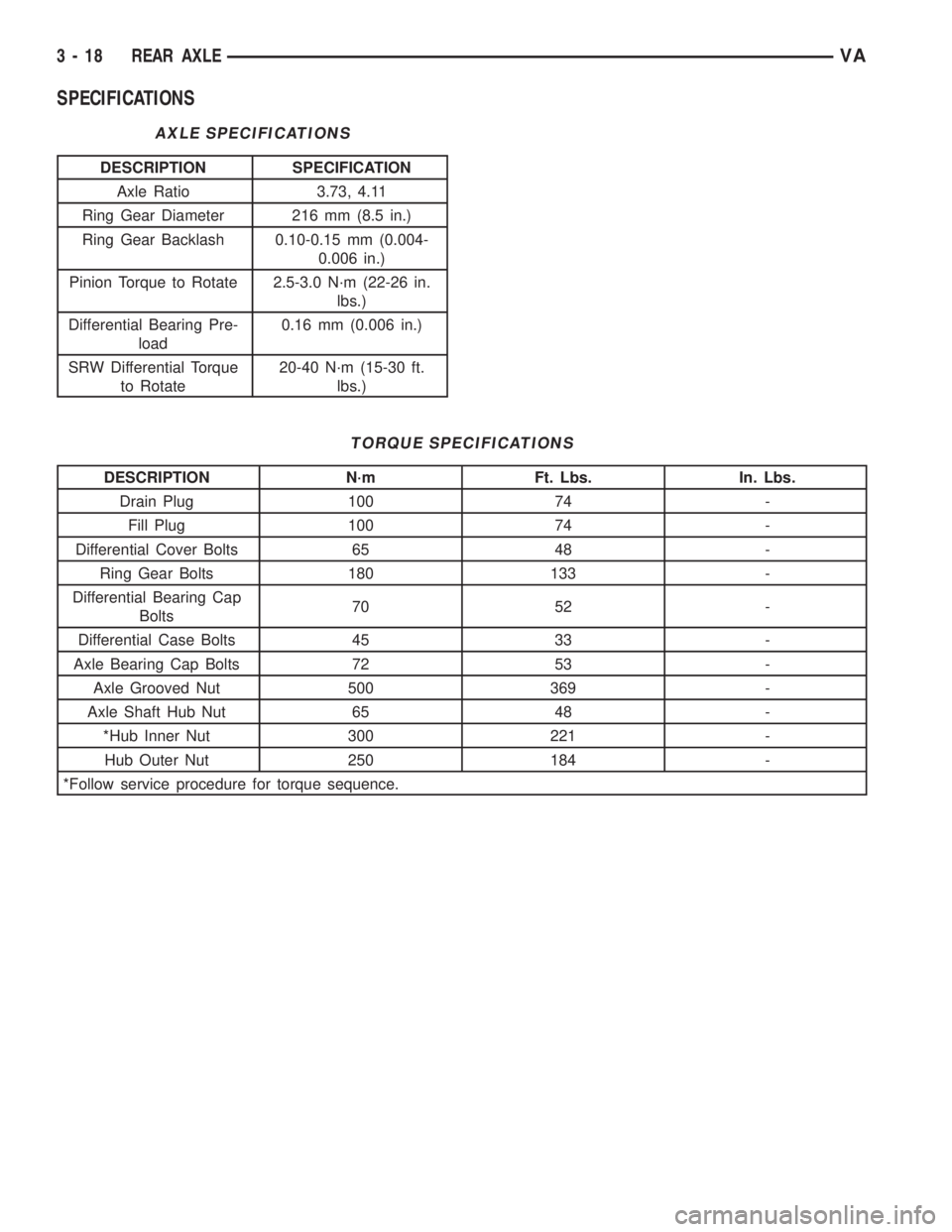

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.73, 4.11

Ring Gear Diameter 216 mm (8.5 in.)

Ring Gear Backlash 0.10-0.15 mm (0.004-

0.006 in.)

Pinion Torque to Rotate 2.5-3.0 N´m (22-26 in.

lbs.)

Differential Bearing Pre-

load0.16 mm (0.006 in.)

SRW Differential Torque

to Rotate20-40 N´m (15-30 ft.

lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Drain Plug 100 74 -

Fill Plug 100 74 -

Differential Cover Bolts 65 48 -

Ring Gear Bolts 180 133 -

Differential Bearing Cap

Bolts70 52 -

Differential Case Bolts 45 33 -

Axle Bearing Cap Bolts 72 53 -

Axle Grooved Nut 500 369 -

Axle Shaft Hub Nut 65 48 -

*Hub Inner Nut 300 221 -

Hub Outer Nut 250 184 -

*Follow service procedure for torque sequence.

3 - 18 REAR AXLEVA

Page 776 of 2305

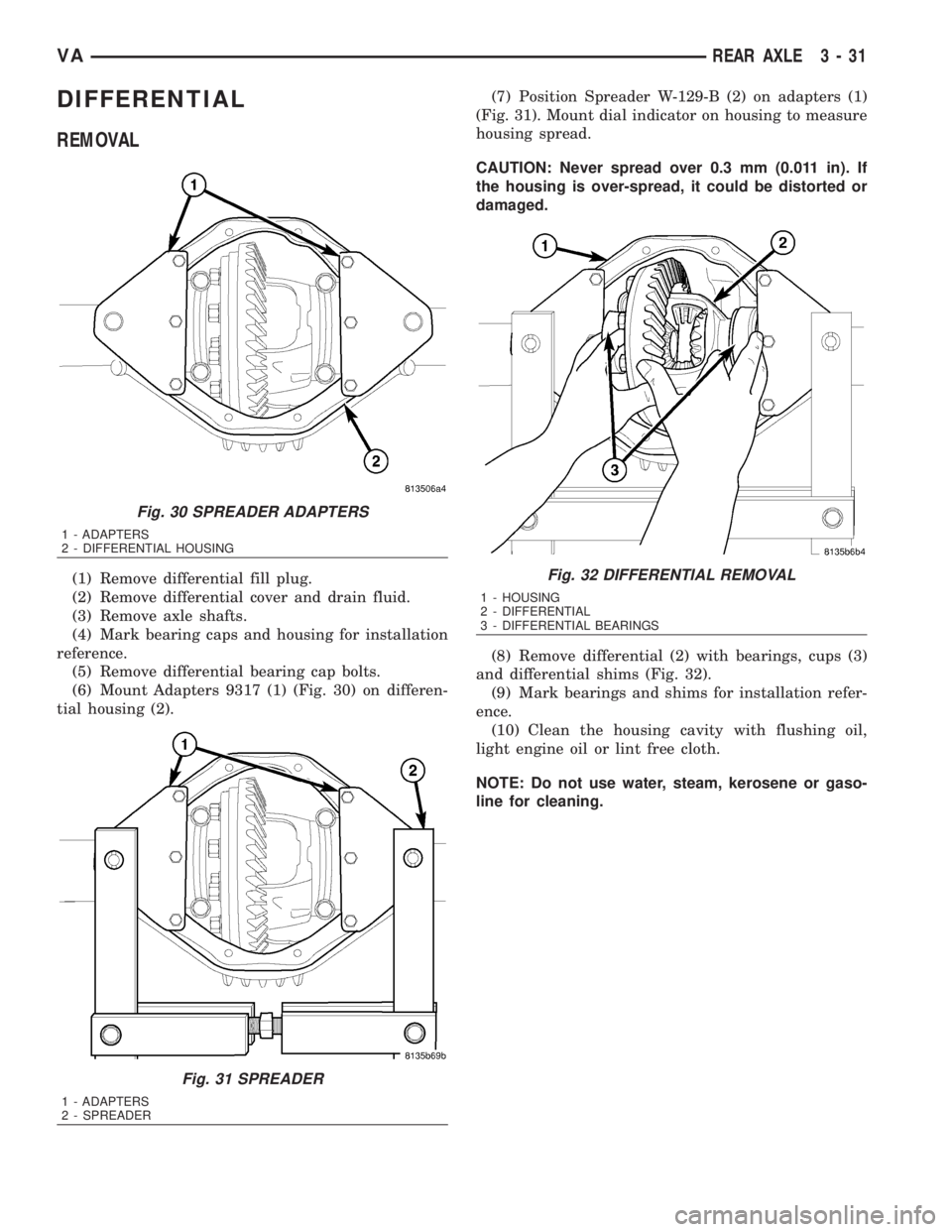

DIFFERENTIAL

REMOVAL

(1) Remove differential fill plug.

(2) Remove differential cover and drain fluid.

(3) Remove axle shafts.

(4) Mark bearing caps and housing for installation

reference.

(5) Remove differential bearing cap bolts.

(6) Mount Adapters 9317 (1) (Fig. 30) on differen-

tial housing (2).(7) Position Spreader W-129-B (2) on adapters (1)

(Fig. 31). Mount dial indicator on housing to measure

housing spread.

CAUTION: Never spread over 0.3 mm (0.011 in). If

the housing is over-spread, it could be distorted or

damaged.

(8) Remove differential (2) with bearings, cups (3)

and differential shims (Fig. 32).

(9) Mark bearings and shims for installation refer-

ence.

(10) Clean the housing cavity with flushing oil,

light engine oil or lint free cloth.

NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

Fig. 30 SPREADER ADAPTERS

1 - ADAPTERS

2 - DIFFERENTIAL HOUSING

Fig. 31 SPREADER

1 - ADAPTERS

2 - SPREADER

Fig. 32 DIFFERENTIAL REMOVAL

1 - HOUSING

2 - DIFFERENTIAL

3 - DIFFERENTIAL BEARINGS

VAREAR AXLE 3 - 31

Page 786 of 2305

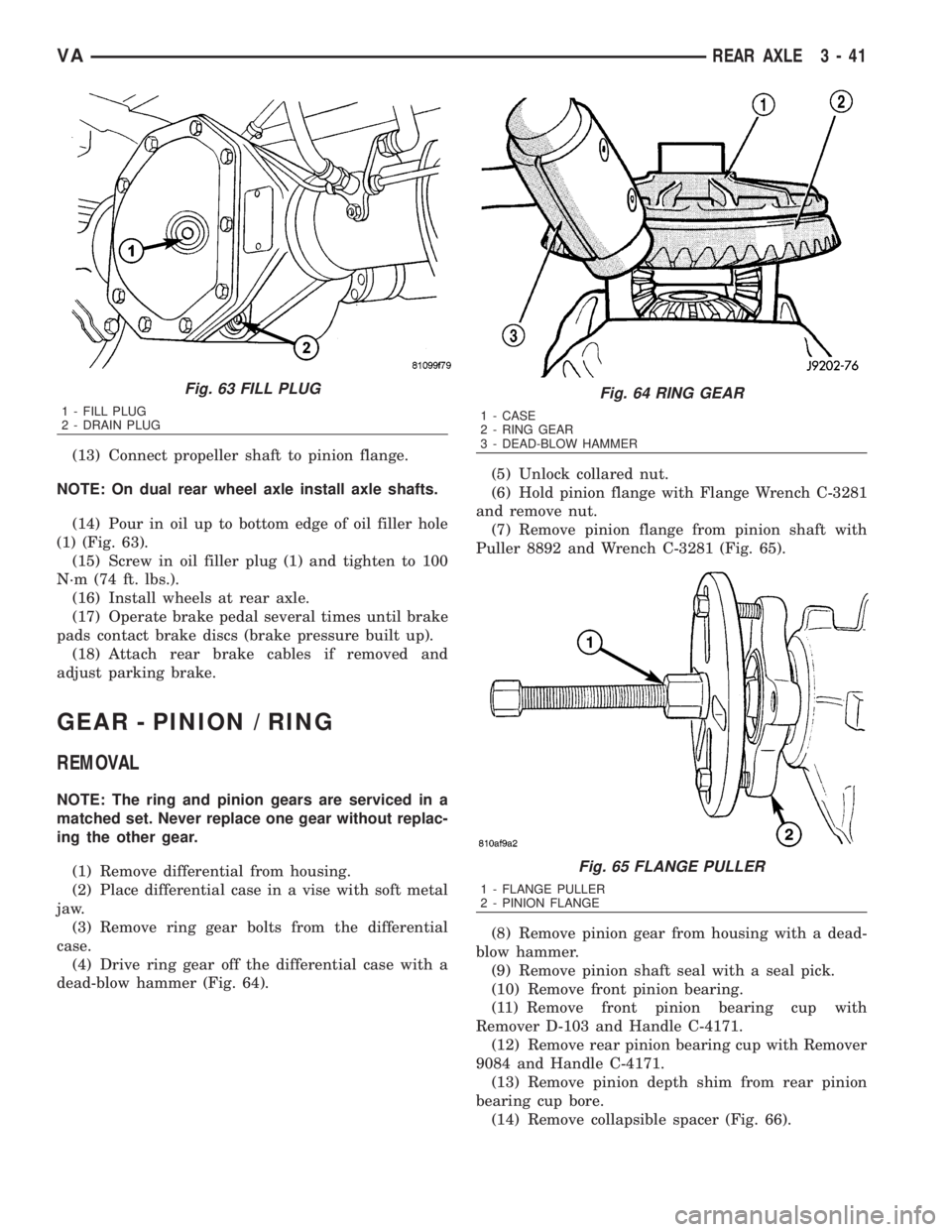

(13) Connect propeller shaft to pinion flange.

NOTE: On dual rear wheel axle install axle shafts.

(14) Pour in oil up to bottom edge of oil filler hole

(1) (Fig. 63).

(15) Screw in oil filler plug (1) and tighten to 100

N´m (74 ft. lbs.).

(16) Install wheels at rear axle.

(17) Operate brake pedal several times until brake

pads contact brake discs (brake pressure built up).

(18) Attach rear brake cables if removed and

adjust parking brake.

GEAR - PINION / RING

REMOVAL

NOTE: The ring and pinion gears are serviced in a

matched set. Never replace one gear without replac-

ing the other gear.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft metal

jaw.

(3) Remove ring gear bolts from the differential

case.

(4) Drive ring gear off the differential case with a

dead-blow hammer (Fig. 64).(5) Unlock collared nut.

(6) Hold pinion flange with Flange Wrench C-3281

and remove nut.

(7) Remove pinion flange from pinion shaft with

Puller 8892 and Wrench C-3281 (Fig. 65).

(8) Remove pinion gear from housing with a dead-

blow hammer.

(9) Remove pinion shaft seal with a seal pick.

(10) Remove front pinion bearing.

(11) Remove front pinion bearing cup with

Remover D-103 and Handle C-4171.

(12) Remove rear pinion bearing cup with Remover

9084 and Handle C-4171.

(13) Remove pinion depth shim from rear pinion

bearing cup bore.

(14) Remove collapsible spacer (Fig. 66).

Fig. 63 FILL PLUG

1 - FILL PLUG

2 - DRAIN PLUG

Fig. 64 RING GEAR

1 - CASE

2 - RING GEAR

3 - DEAD-BLOW HAMMER

Fig. 65 FLANGE PULLER

1 - FLANGE PULLER

2 - PINION FLANGE

VAREAR AXLE 3 - 41

Page 843 of 2305

(3) Refill coolant system to proper level with

proper mixture of coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(4) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(5) Connect negative battery cable.

WARNING: Use extreme caution when engine is

operating. Do not stand in a direct line with fan. do

not put your hands near pulleys, belts or fan. Do

not wear loose clothes.

(6) Start engine and inspect for leaks.

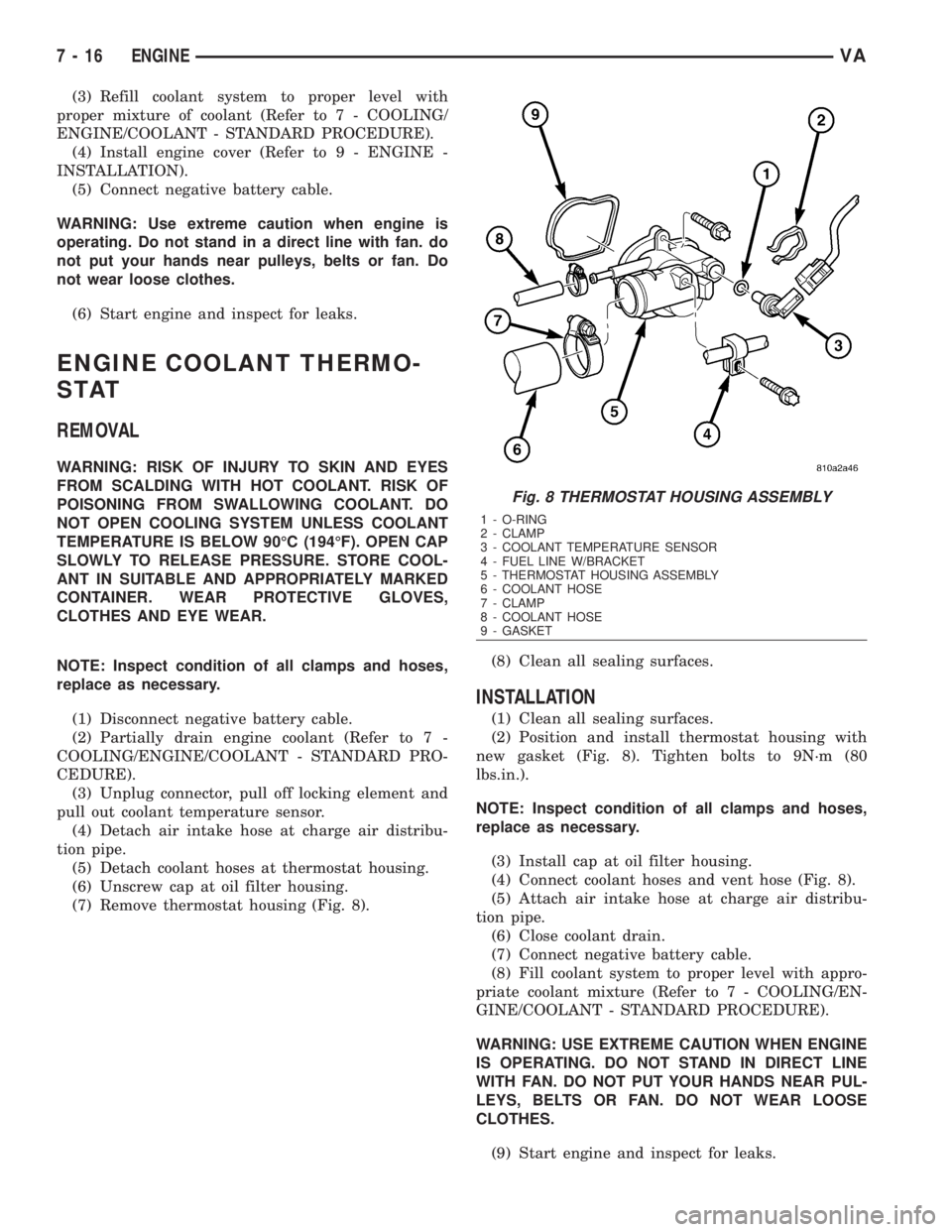

ENGINE COOLANT THERMO-

STAT

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

NOTE: Inspect condition of all clamps and hoses,

replace as necessary.

(1) Disconnect negative battery cable.

(2) Partially drain engine coolant (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(3) Unplug connector, pull off locking element and

pull out coolant temperature sensor.

(4) Detach air intake hose at charge air distribu-

tion pipe.

(5) Detach coolant hoses at thermostat housing.

(6) Unscrew cap at oil filter housing.

(7) Remove thermostat housing (Fig. 8).(8) Clean all sealing surfaces.

INSTALLATION

(1) Clean all sealing surfaces.

(2) Position and install thermostat housing with

new gasket (Fig. 8). Tighten bolts to 9N´m (80

lbs.in.).

NOTE: Inspect condition of all clamps and hoses,

replace as necessary.

(3) Install cap at oil filter housing.

(4) Connect coolant hoses and vent hose (Fig. 8).

(5) Attach air intake hose at charge air distribu-

tion pipe.

(6) Close coolant drain.

(7) Connect negative battery cable.

(8) Fill coolant system to proper level with appro-

priate coolant mixture (Refer to 7 - COOLING/EN-

GINE/COOLANT - STANDARD PROCEDURE).

WARNING: USE EXTREME CAUTION WHEN ENGINE

IS OPERATING. DO NOT STAND IN DIRECT LINE

WITH FAN. DO NOT PUT YOUR HANDS NEAR PUL-

LEYS, BELTS OR FAN. DO NOT WEAR LOOSE

CLOTHES.

(9) Start engine and inspect for leaks.

Fig. 8 THERMOSTAT HOUSING ASSEMBLY

1 - O-RING

2 - CLAMP

3 - COOLANT TEMPERATURE SENSOR

4 - FUEL LINE W/BRACKET

5 - THERMOSTAT HOUSING ASSEMBLY

6 - COOLANT HOSE

7 - CLAMP

8 - COOLANT HOSE

9 - GASKET

7 - 16 ENGINEVA

Page 844 of 2305

FAN DRIVE VISCOUS CLUTCH

REMOVAL

(1) For fan drive viscous clutch removal refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

INSTALLATION

(1) For fan drive viscous clutch installation refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

RADIATOR

REMOVAL

WARNING: RISK OF INJURY TO SKIN AND EYES

FROM SCALDING WITH HOT COOLANT. RISK OF

POISONING FROM SWALLOWING COOLANT. DO

NOT OPEN COOLING SYSTEM UNLESS COOLANT

TEMPERATURE IS BELOW 90ÉC (194ÉF). OPEN CAP

SLOWLY TO RELEASE PRESSURE. STORE COOL-

ANT IN SUITABLE AND APPROPRIATELY MARKED

CONTAINER. WEAR PROTECTIVE GLOVES,

CLOTHES AND EYE WEAR.

NOTE: Capture all residual fluid spillage and store

in suitably marked containers. Inspect condition of

all clamps and hoses, replace as necessary.

(1) Drain coolant from radiator only (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(2) Remove headlamps.

(3) Remove front cross member together with front

grille.

(4) Remove front bumper.

(5) Remove bolts holding air charge hose to sheet

metal and intercooler.

(6) Detach air intake pipe at the body (Fig. 9).

(7) Detach both coolant hoses at the coolant reser-

voir (Fig. 9).

VAENGINE 7 - 17

Page 849 of 2305

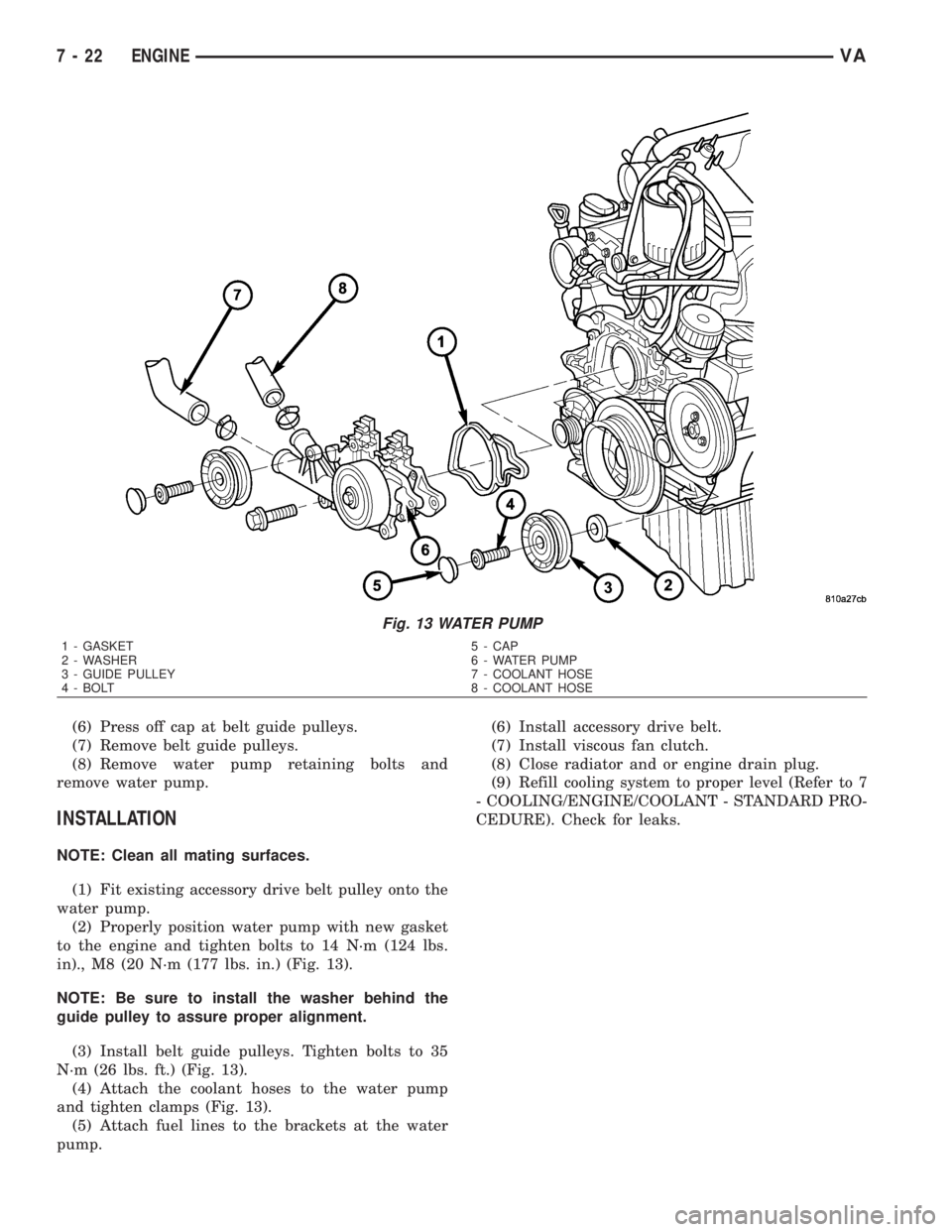

(6) Press off cap at belt guide pulleys.

(7) Remove belt guide pulleys.

(8) Remove water pump retaining bolts and

remove water pump.

INSTALLATION

NOTE: Clean all mating surfaces.

(1) Fit existing accessory drive belt pulley onto the

water pump.

(2) Properly position water pump with new gasket

to the engine and tighten bolts to 14 N´m (124 lbs.

in)., M8 (20 N´m (177 lbs. in.) (Fig. 13).

NOTE: Be sure to install the washer behind the

guide pulley to assure proper alignment.

(3) Install belt guide pulleys. Tighten bolts to 35

N´m (26 lbs. ft.) (Fig. 13).

(4) Attach the coolant hoses to the water pump

and tighten clamps (Fig. 13).

(5) Attach fuel lines to the brackets at the water

pump.(6) Install accessory drive belt.

(7) Install viscous fan clutch.

(8) Close radiator and or engine drain plug.

(9) Refill cooling system to proper level (Refer to 7

- COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE). Check for leaks.

Fig. 13 WATER PUMP

1 - GASKET 5 - CAP

2 - WASHER 6 - WATER PUMP

3 - GUIDE PULLEY 7 - COOLANT HOSE

4 - BOLT 8 - COOLANT HOSE

7 - 22 ENGINEVA

Page 881 of 2305

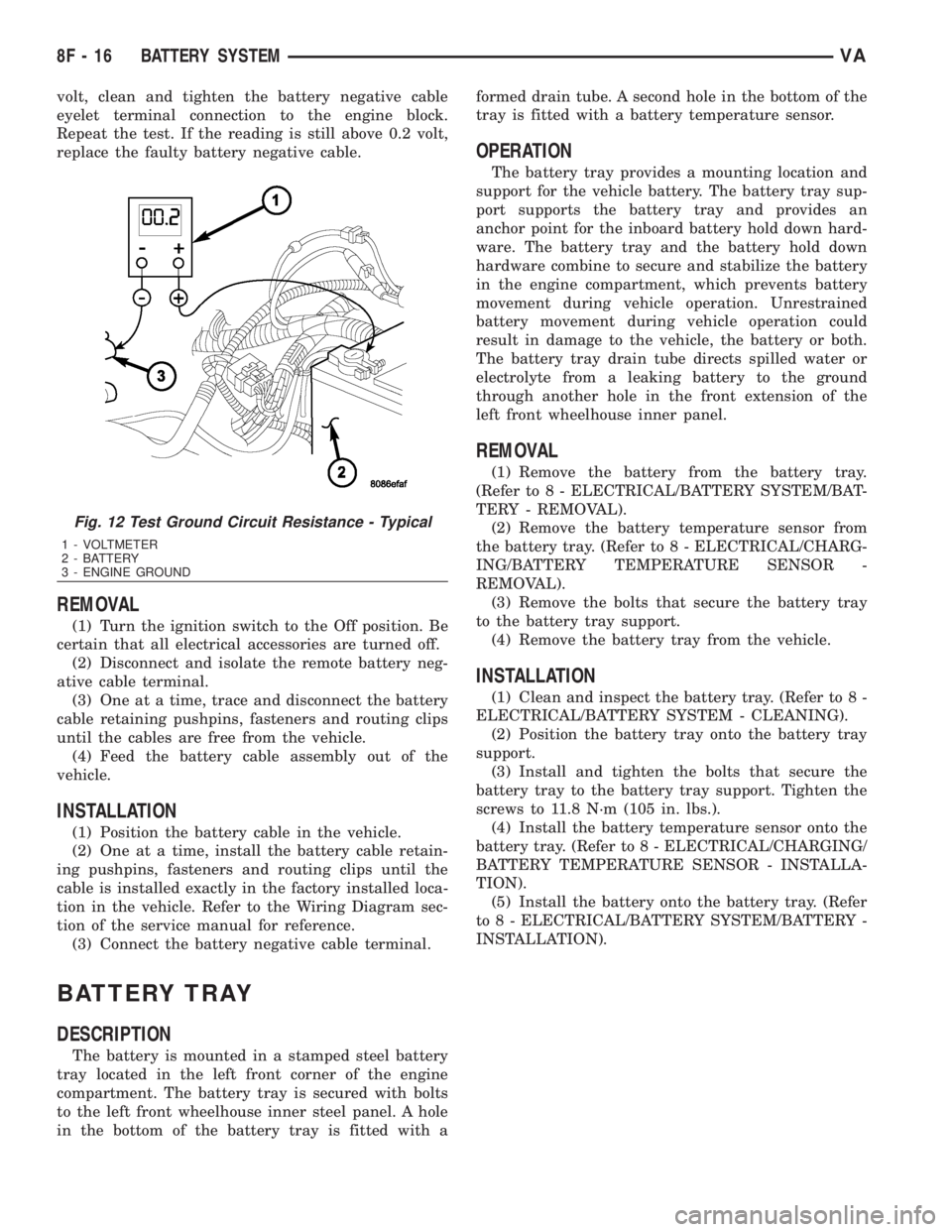

volt, clean and tighten the battery negative cable

eyelet terminal connection to the engine block.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery negative cable.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Disconnect and isolate the remote battery neg-

ative cable terminal.

(3) One at a time, trace and disconnect the battery

cable retaining pushpins, fasteners and routing clips

until the cables are free from the vehicle.

(4) Feed the battery cable assembly out of the

vehicle.

INSTALLATION

(1) Position the battery cable in the vehicle.

(2) One at a time, install the battery cable retain-

ing pushpins, fasteners and routing clips until the

cable is installed exactly in the factory installed loca-

tion in the vehicle. Refer to the Wiring Diagram sec-

tion of the service manual for reference.

(3) Connect the battery negative cable terminal.

BATTERY TRAY

DESCRIPTION

The battery is mounted in a stamped steel battery

tray located in the left front corner of the engine

compartment. The battery tray is secured with bolts

to the left front wheelhouse inner steel panel. A hole

in the bottom of the battery tray is fitted with aformed drain tube. A second hole in the bottom of the

tray is fitted with a battery temperature sensor.

OPERATION

The battery tray provides a mounting location and

support for the vehicle battery. The battery tray sup-

port supports the battery tray and provides an

anchor point for the inboard battery hold down hard-

ware. The battery tray and the battery hold down

hardware combine to secure and stabilize the battery

in the engine compartment, which prevents battery

movement during vehicle operation. Unrestrained

battery movement during vehicle operation could

result in damage to the vehicle, the battery or both.

The battery tray drain tube directs spilled water or

electrolyte from a leaking battery to the ground

through another hole in the front extension of the

left front wheelhouse inner panel.

REMOVAL

(1) Remove the battery from the battery tray.

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - REMOVAL).

(2) Remove the battery temperature sensor from

the battery tray. (Refer to 8 - ELECTRICAL/CHARG-

ING/BATTERY TEMPERATURE SENSOR -

REMOVAL).

(3) Remove the bolts that secure the battery tray

to the battery tray support.

(4) Remove the battery tray from the vehicle.

INSTALLATION

(1) Clean and inspect the battery tray. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM - CLEANING).

(2) Position the battery tray onto the battery tray

support.

(3) Install and tighten the bolts that secure the

battery tray to the battery tray support. Tighten the

screws to 11.8 N´m (105 in. lbs.).

(4) Install the battery temperature sensor onto the

battery tray. (Refer to 8 - ELECTRICAL/CHARGING/

BATTERY TEMPERATURE SENSOR - INSTALLA-

TION).

(5) Install the battery onto the battery tray. (Refer

to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY -

INSTALLATION).

Fig. 12 Test Ground Circuit Resistance - Typical

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

8F - 16 BATTERY SYSTEMVA

Page 1583 of 2305

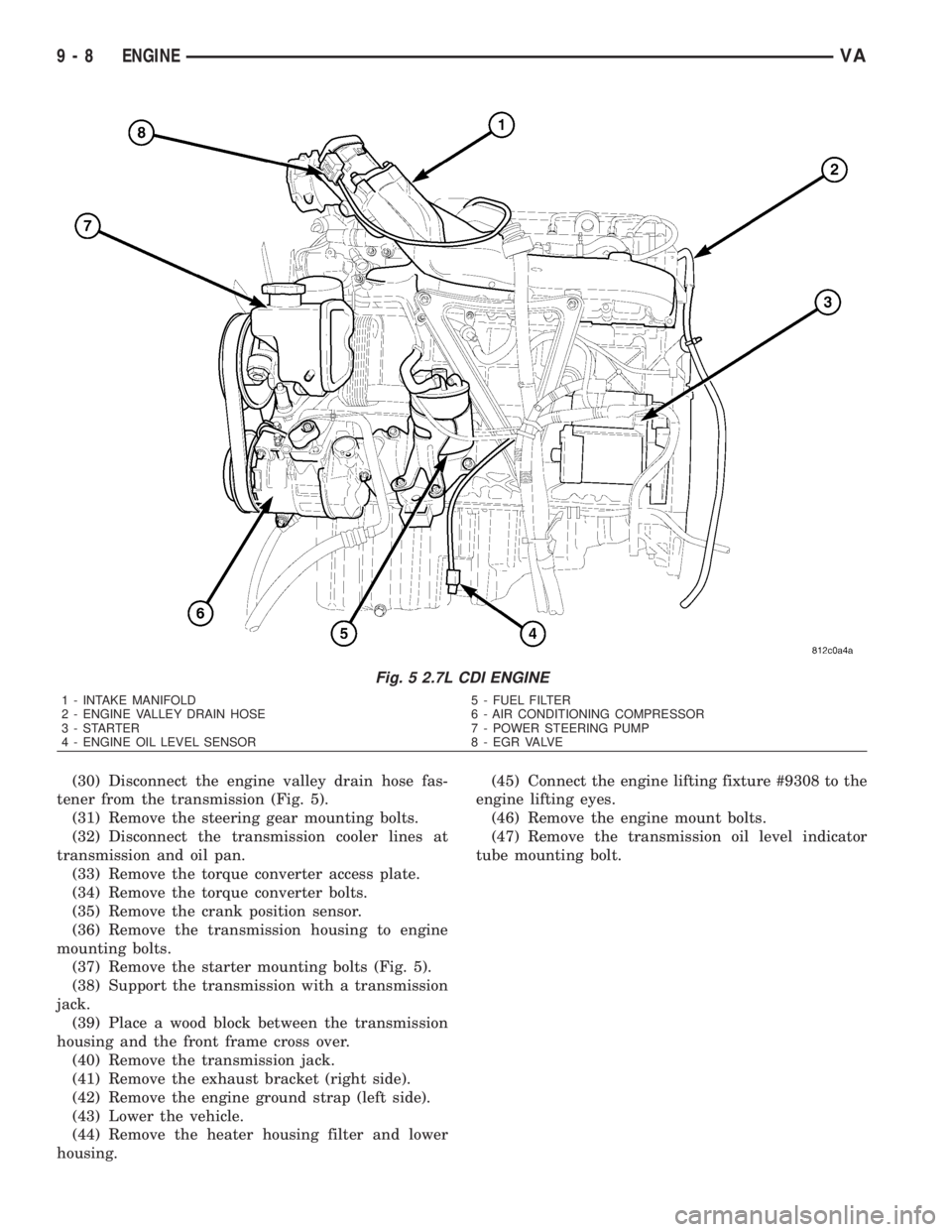

(30) Disconnect the engine valley drain hose fas-

tener from the transmission (Fig. 5).

(31) Remove the steering gear mounting bolts.

(32) Disconnect the transmission cooler lines at

transmission and oil pan.

(33) Remove the torque converter access plate.

(34) Remove the torque converter bolts.

(35) Remove the crank position sensor.

(36) Remove the transmission housing to engine

mounting bolts.

(37) Remove the starter mounting bolts (Fig. 5).

(38) Support the transmission with a transmission

jack.

(39) Place a wood block between the transmission

housing and the front frame cross over.

(40) Remove the transmission jack.

(41) Remove the exhaust bracket (right side).

(42) Remove the engine ground strap (left side).

(43) Lower the vehicle.

(44) Remove the heater housing filter and lower

housing.(45) Connect the engine lifting fixture #9308 to the

engine lifting eyes.

(46) Remove the engine mount bolts.

(47) Remove the transmission oil level indicator

tube mounting bolt.

Fig. 5 2.7L CDI ENGINE

1 - INTAKE MANIFOLD 5 - FUEL FILTER

2 - ENGINE VALLEY DRAIN HOSE 6 - AIR CONDITIONING COMPRESSOR

3 - STARTER 7 - POWER STEERING PUMP

4 - ENGINE OIL LEVEL SENSOR 8 - EGR VALVE

9 - 8 ENGINEVA

Page 1586 of 2305

(39) Fill cooling system to proper level with the

appropriate coolant.

(40) Evacuate and recharge air conditioning.

(41) Check and refill all ancillary system fluid lev-

els.(42) Start engine and inspect for leaks (Refer to 14

- FUEL SYSTEM - WARNING).

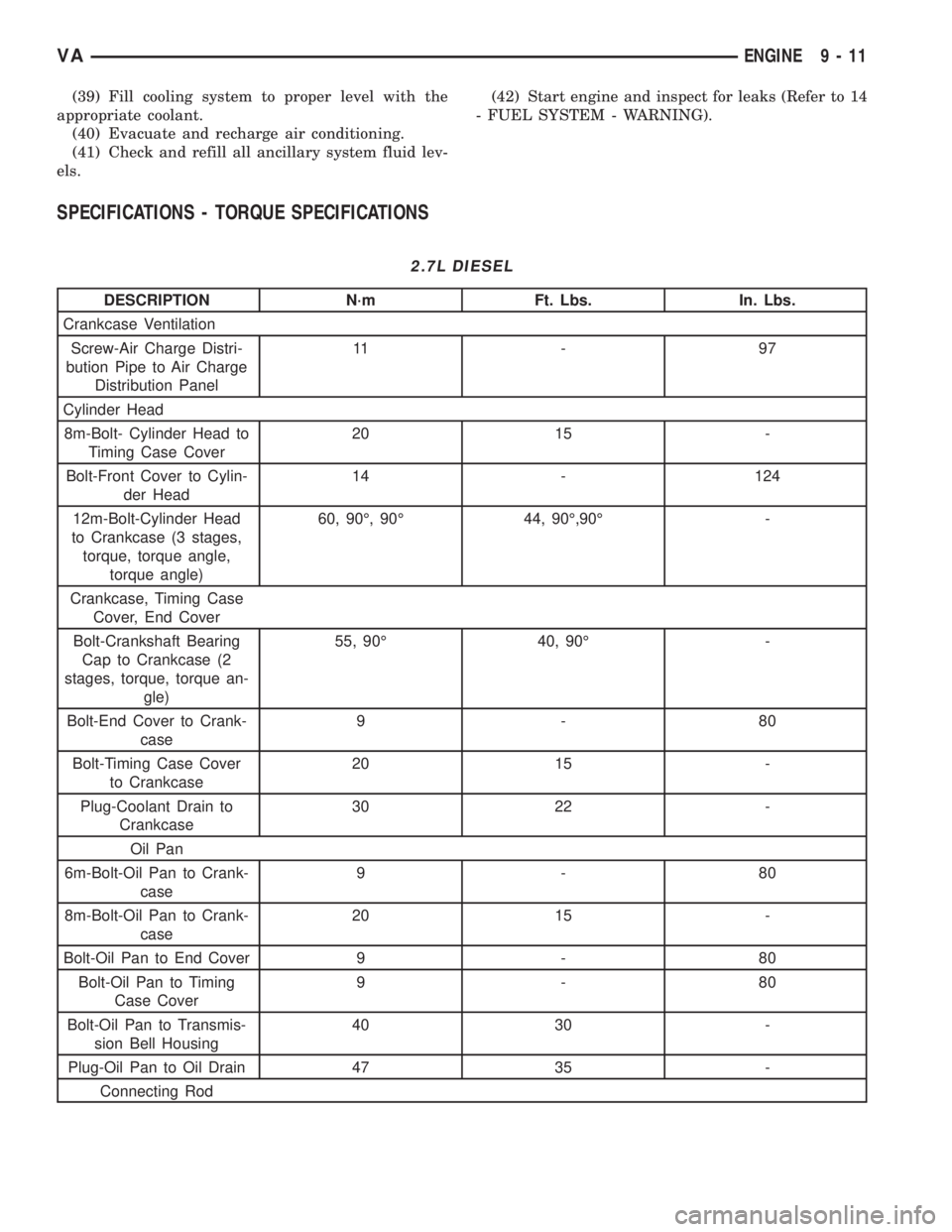

SPECIFICATIONS - TORQUE SPECIFICATIONS

2.7L DIESEL

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Crankcase Ventilation

Screw-Air Charge Distri-

bution Pipe to Air Charge

Distribution Panel11 - 9 7

Cylinder Head

8m-Bolt- Cylinder Head to

Timing Case Cover20 15 -

Bolt-Front Cover to Cylin-

der Head14 - 124

12m-Bolt-Cylinder Head

to Crankcase (3 stages,

torque, torque angle,

torque angle)60, 90É, 90É 44, 90É,90É -

Crankcase, Timing Case

Cover, End Cover

Bolt-Crankshaft Bearing

Cap to Crankcase (2

stages, torque, torque an-

gle)55, 90É 40, 90É -

Bolt-End Cover to Crank-

case9-80

Bolt-Timing Case Cover

to Crankcase20 15 -

Plug-Coolant Drain to

Crankcase30 22 -

Oil Pan

6m-Bolt-Oil Pan to Crank-

case9-80

8m-Bolt-Oil Pan to Crank-

case20 15 -

Bolt-Oil Pan to End Cover 9 - 80

Bolt-Oil Pan to Timing

Case Cover9-80

Bolt-Oil Pan to Transmis-

sion Bell Housing40 30 -

Plug-Oil Pan to Oil Drain 47 35 -

Connecting Rod

VAENGINE 9 - 11

Page 1589 of 2305

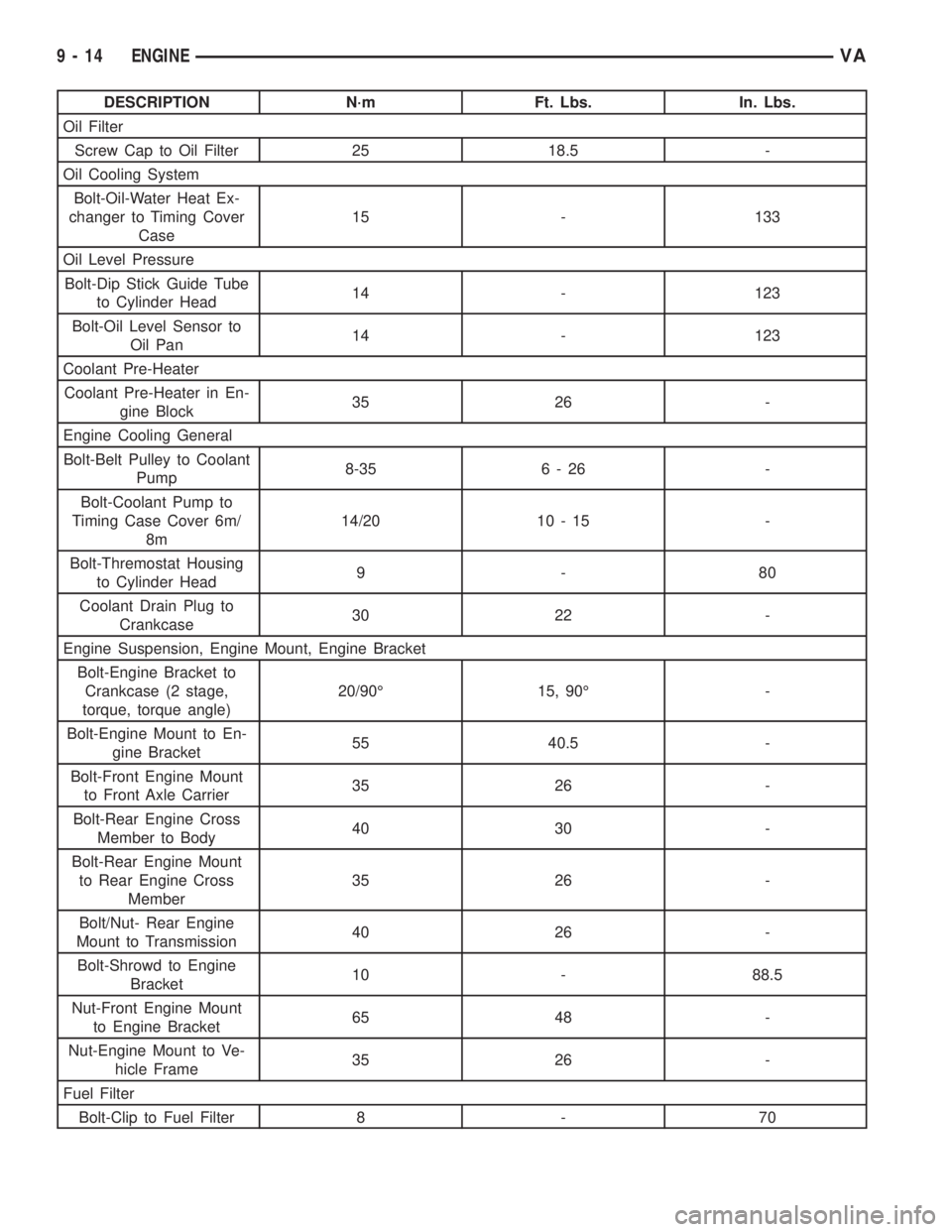

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Oil Filter

Screw Cap to Oil Filter 25 18.5 -

Oil Cooling System

Bolt-Oil-Water Heat Ex-

changer to Timing Cover

Case15 - 133

Oil Level Pressure

Bolt-Dip Stick Guide Tube

to Cylinder Head14 - 123

Bolt-Oil Level Sensor to

Oil Pan14 - 123

Coolant Pre-Heater

Coolant Pre-Heater in En-

gine Block35 26 -

Engine Cooling General

Bolt-Belt Pulley to Coolant

Pump8-35 6 - 26 -

Bolt-Coolant Pump to

Timing Case Cover 6m/

8m14/20 10 - 15 -

Bolt-Thremostat Housing

to Cylinder Head9-80

Coolant Drain Plug to

Crankcase30 22 -

Engine Suspension, Engine Mount, Engine Bracket

Bolt-Engine Bracket to

Crankcase (2 stage,

torque, torque angle)20/90É 15, 90É -

Bolt-Engine Mount to En-

gine Bracket55 40.5 -

Bolt-Front Engine Mount

to Front Axle Carrier35 26 -

Bolt-Rear Engine Cross

Member to Body40 30 -

Bolt-Rear Engine Mount

to Rear Engine Cross

Member35 26 -

Bolt/Nut- Rear Engine

Mount to Transmission40 26 -

Bolt-Shrowd to Engine

Bracket10 - 88.5

Nut-Front Engine Mount

to Engine Bracket65 48 -

Nut-Engine Mount to Ve-

hicle Frame35 26 -

Fuel Filter

Bolt-Clip to Fuel Filter 8 - 70

9 - 14 ENGINEVA