mirror MERCEDES-BENZ SPRINTER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1805 of 2305

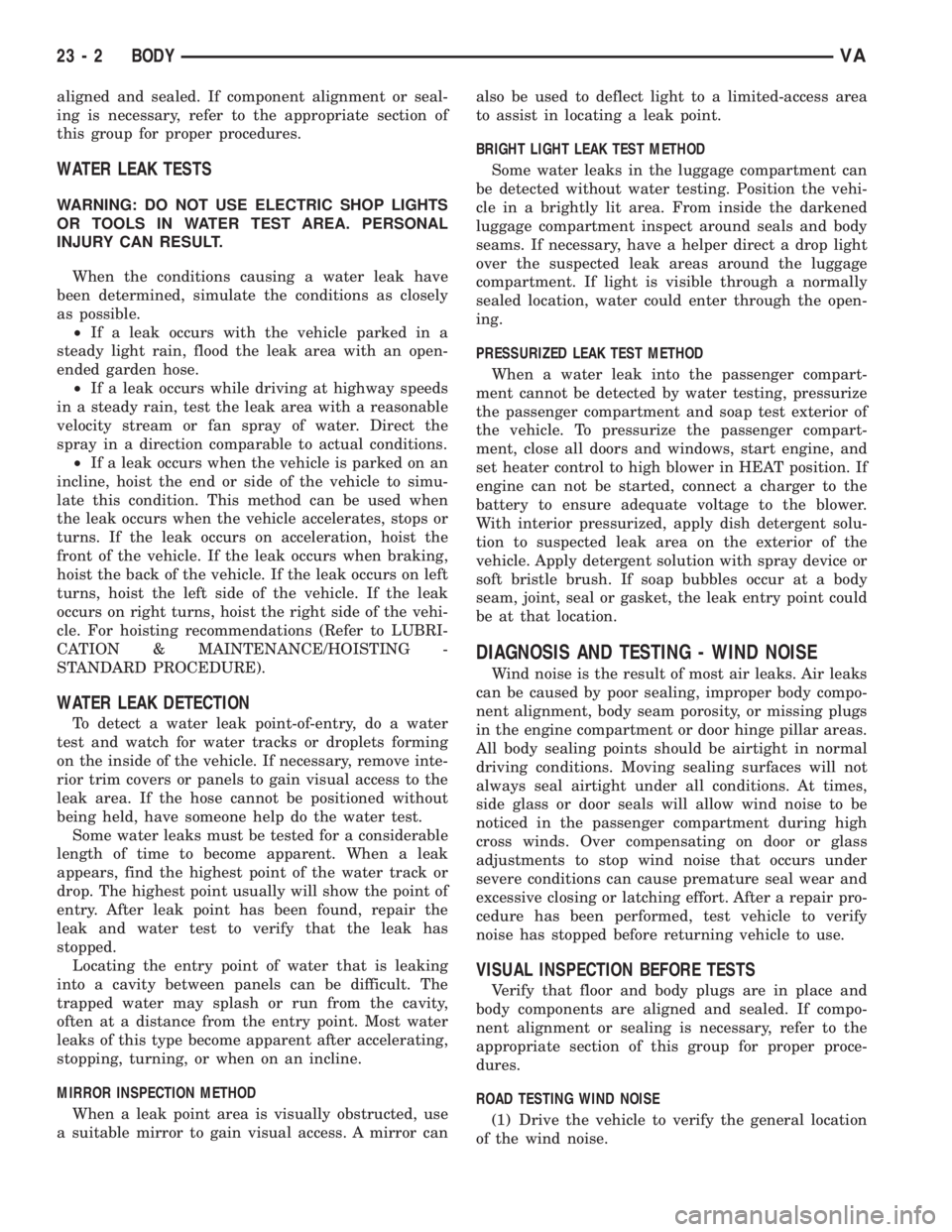

(14) Install the transmission electrical connector

(2) (Fig. 71) from transmission and hang to the side.

Turn sealing ring (3) clockwise and connect plug con-

nection (2).

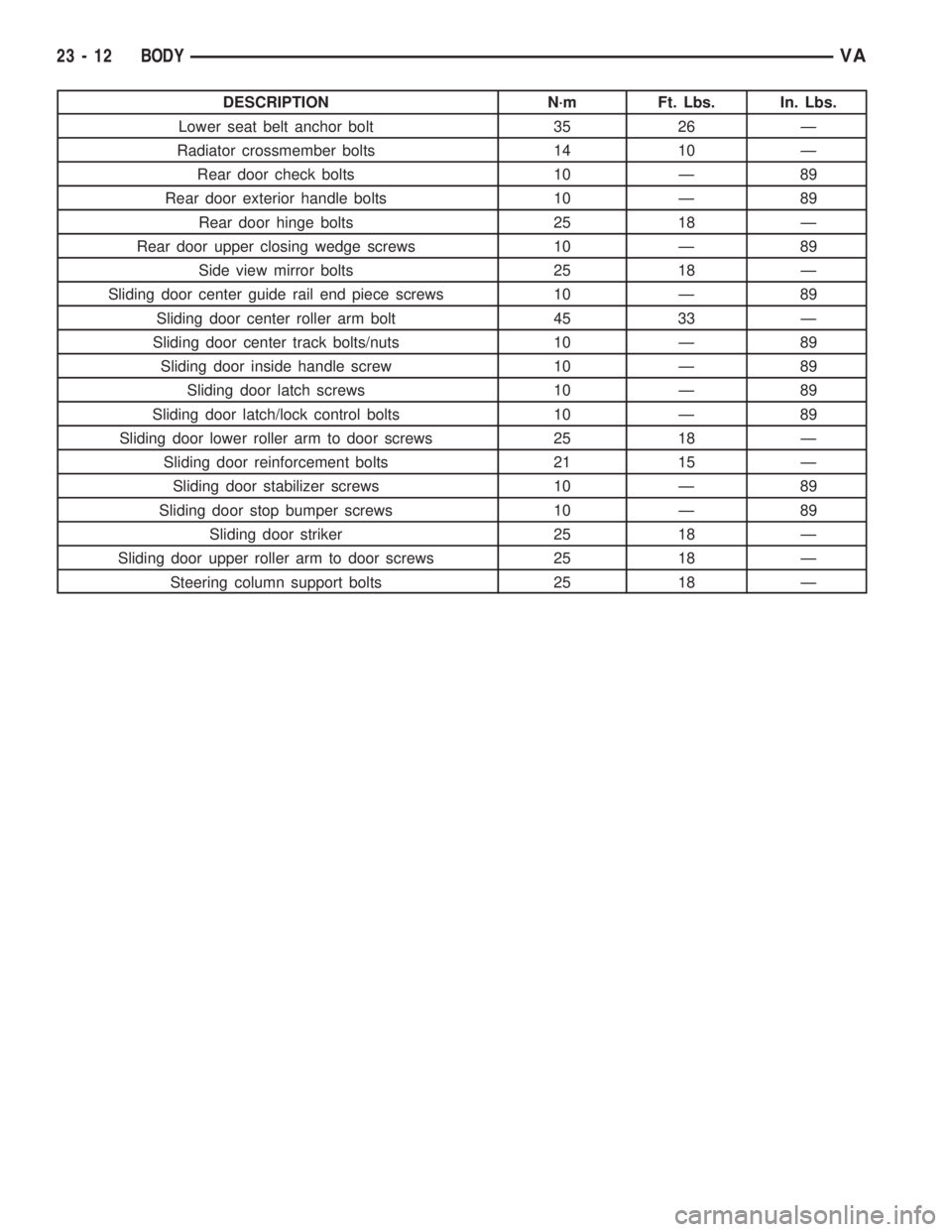

(15) Install the shift cable (Fig. 72) to the trans-

mission.

(a) Push shift cable onto the transmission shift

lever ball socket.

(b) Latch ball socket latch of cable.

(c) Clip shift cable retainer into retainer

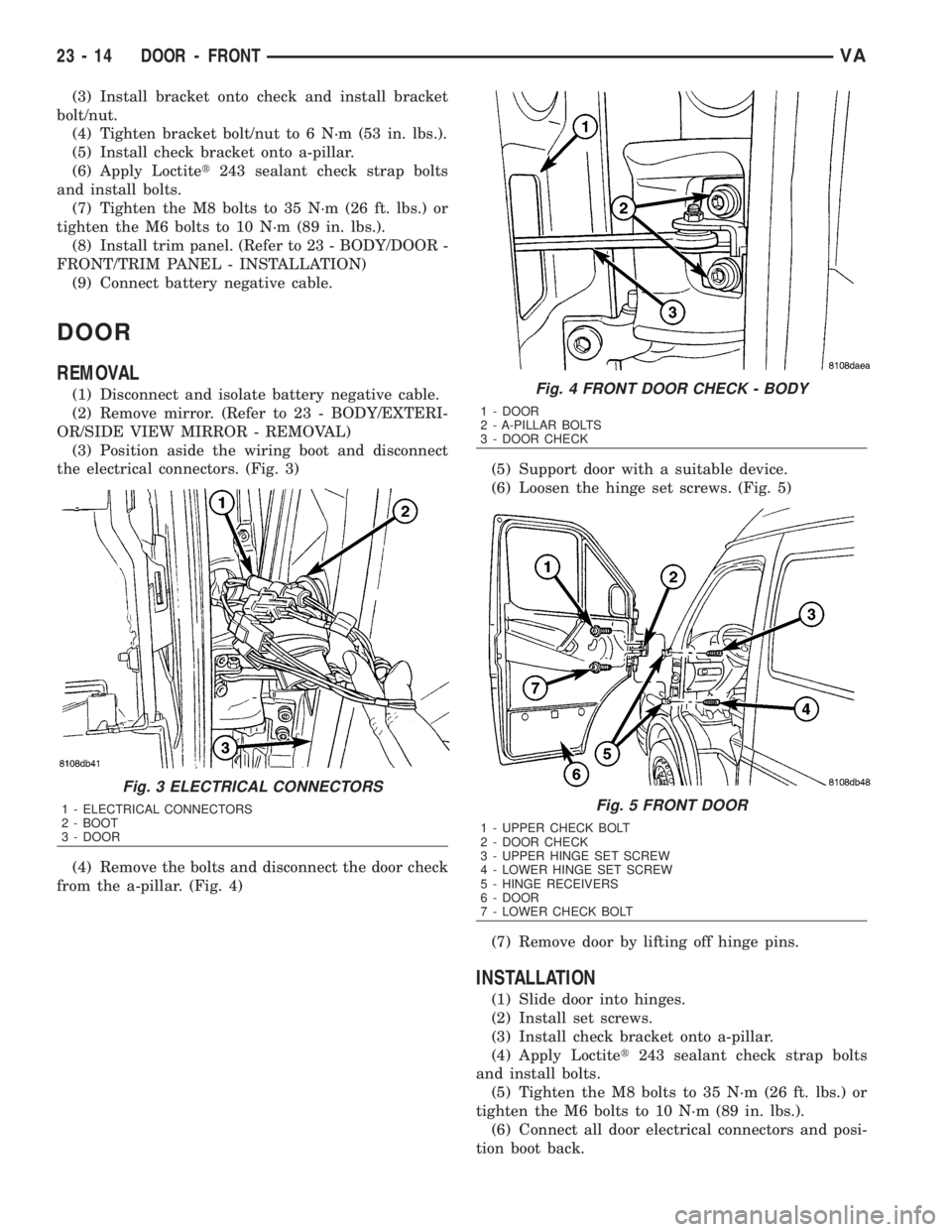

bracket.(16) Install the cooler lines to the transmission.

(a) Install the brackets for the oil cooler feed and

return lines (1) (Fig. 73) onto the engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Attach the bracket for the cable retainer (4)

(Fig. 74) to the threaded shank of a engine oil pan

bolt (5).

(c) Install the bolts to hold the oil cooler lines (6)

to the left (Fig. 75) and right sides of transmission.

Torque the bolts to 34 N´m (25 ft.lbs.).

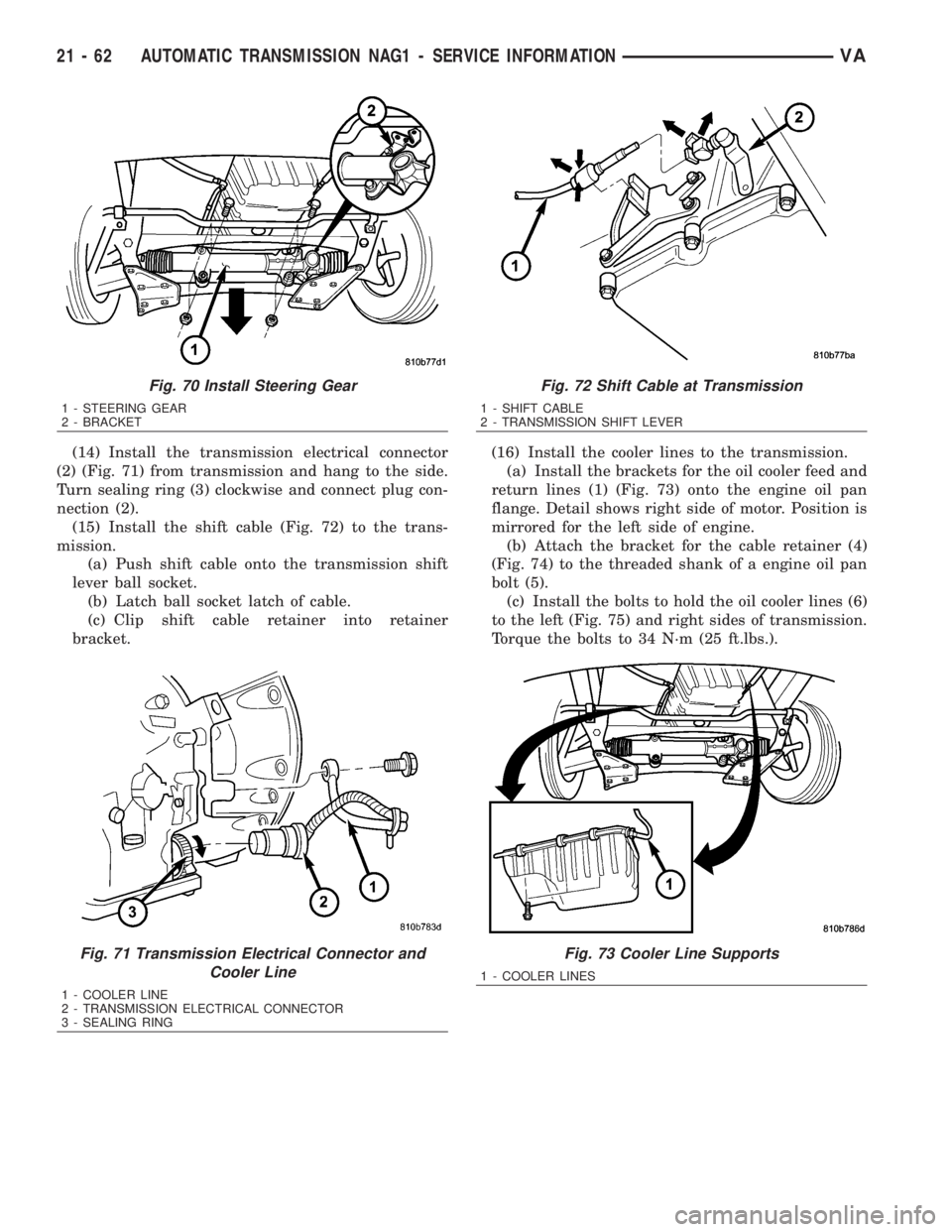

Fig. 70 Install Steering Gear

1 - STEERING GEAR

2 - BRACKET

Fig. 71 Transmission Electrical Connector and

Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

Fig. 72 Shift Cable at Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 73 Cooler Line Supports

1 - COOLER LINES

21 - 62 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1945 of 2305

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror canalso be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

23 - 2 BODYVA

Page 1955 of 2305

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lower seat belt anchor bolt 35 26 Ð

Radiator crossmember bolts 14 10 Ð

Rear door check bolts 10 Ð 89

Rear door exterior handle bolts 10 Ð 89

Rear door hinge bolts 25 18 Ð

Rear door upper closing wedge screws 10 Ð 89

Side view mirror bolts 25 18 Ð

Sliding door center guide rail end piece screws 10 Ð 89

Sliding door center roller arm bolt 45 33 Ð

Sliding door center track bolts/nuts 10 Ð 89

Sliding door inside handle screw 10 Ð 89

Sliding door latch screws 10 Ð 89

Sliding door latch/lock control bolts 10 Ð 89

Sliding door lower roller arm to door screws 25 18 Ð

Sliding door reinforcement bolts 21 15 Ð

Sliding door stabilizer screws 10 Ð 89

Sliding door stop bumper screws 10 Ð 89

Sliding door striker 25 18 Ð

Sliding door upper roller arm to door screws 25 18 Ð

Steering column support bolts 25 18 Ð

23 - 12 BODYVA

Page 1957 of 2305

(3) Install bracket onto check and install bracket

bolt/nut.

(4) Tighten bracket bolt/nut to 6 N´m (53 in. lbs.).

(5) Install check bracket onto a-pillar.

(6) Apply Loctitet243 sealant check strap bolts

and install bolts.

(7) Tighten the M8 bolts to 35 N´m (26 ft. lbs.) or

tighten the M6 bolts to 10 N´m (89 in. lbs.).

(8) Install trim panel. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION)

(9) Connect battery negative cable.

DOOR

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - REMOVAL)

(3) Position aside the wiring boot and disconnect

the electrical connectors. (Fig. 3)

(4) Remove the bolts and disconnect the door check

from the a-pillar. (Fig. 4)(5) Support door with a suitable device.

(6) Loosen the hinge set screws. (Fig. 5)

(7) Remove door by lifting off hinge pins.

INSTALLATION

(1) Slide door into hinges.

(2) Install set screws.

(3) Install check bracket onto a-pillar.

(4) Apply Loctitet243 sealant check strap bolts

and install bolts.

(5) Tighten the M8 bolts to 35 N´m (26 ft. lbs.) or

tighten the M6 bolts to 10 N´m (89 in. lbs.).

(6) Connect all door electrical connectors and posi-

tion boot back.

Fig. 3 ELECTRICAL CONNECTORS

1 - ELECTRICAL CONNECTORS

2 - BOOT

3 - DOOR

Fig. 4 FRONT DOOR CHECK - BODY

1 - DOOR

2 - A-PILLAR BOLTS

3 - DOOR CHECK

Fig. 5 FRONT DOOR

1 - UPPER CHECK BOLT

2 - DOOR CHECK

3 - UPPER HINGE SET SCREW

4 - LOWER HINGE SET SCREW

5 - HINGE RECEIVERS

6 - DOOR

7 - LOWER CHECK BOLT

23 - 14 DOOR - FRONTVA

Page 1958 of 2305

(7) Install mirror. (Refer to 23 - BODY/EXTERI-

OR/SIDE VIEW MIRROR - INSTALLATION)

(8) Adjust door if required. (Refer to 23 - BODY/

DOOR - FRONT/DOOR - ADJUSTMENTS)

(9) Connect battery negative cable.

ADJUSTMENTS

ADJUSTMENT

NOTE: Door adjustment measurements should be

taken from stationary or welded body panels like

the roof, rocker or quarter panels.

²During adjustment procedures, it is recom-

mended that all the hinge fasteners be loosened

except for the upper most fasteners. Adjustments

can be made using the upper bolts to hold the door

with final torque of the fasteners occurring after

correct door positioning is achieved.

²A suitable body sealant should be used when

removing or moving the hinges.

(1) Check door alignment. (Refer to 23 - BODY/

BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS)

(2) If adjustment is required, remove latch striker.

(Refer to 23 - BODY/DOOR - FRONT/LATCH

STRIKER - REMOVAL)

(3) Remove side view mirror. (Refer to 23 - BODY/

EXTERIOR/SIDE VIEW MIRROR - REMOVAL)

(4) Loosen hinge bolts and adjust door gap and

align ridge pattern as necessary.

(5) Tighten hinge bolts to 25 N´m (18 ft. lbs.).

(6) Install latch striker and adjust flush measure-

ment as necessary. (Refer to 23 - BODY/DOOR -

FRONT/LATCH STRIKER - INSTALLATION)

(7) Install side view mirror. (Refer to 23 - BODY/

EXTERIOR/SIDE VIEW MIRROR - INSTALLA-

TION)

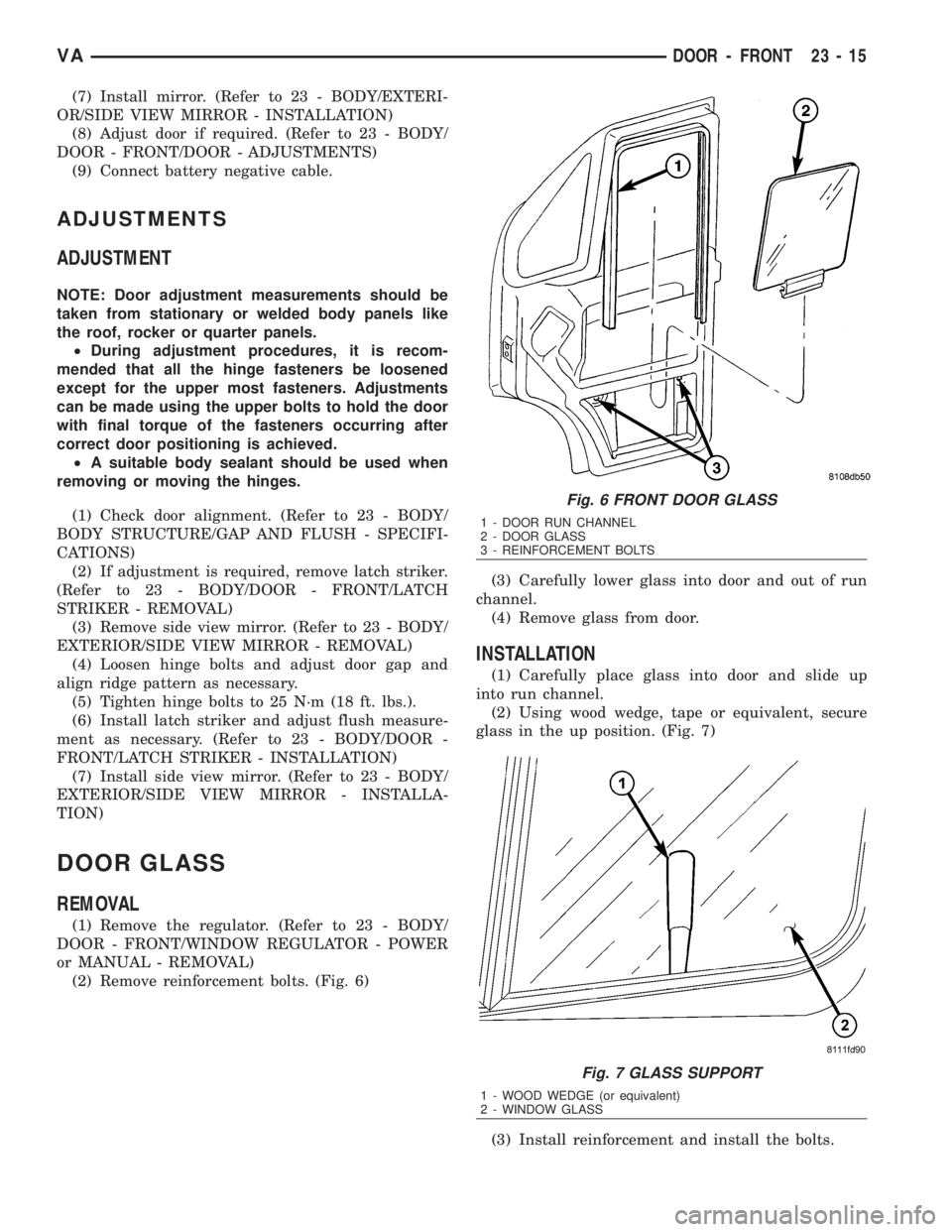

DOOR GLASS

REMOVAL

(1) Remove the regulator. (Refer to 23 - BODY/

DOOR - FRONT/WINDOW REGULATOR - POWER

or MANUAL - REMOVAL)

(2) Remove reinforcement bolts. (Fig. 6)(3) Carefully lower glass into door and out of run

channel.

(4) Remove glass from door.

INSTALLATION

(1) Carefully place glass into door and slide up

into run channel.

(2) Using wood wedge, tape or equivalent, secure

glass in the up position. (Fig. 7)

(3) Install reinforcement and install the bolts.

Fig. 6 FRONT DOOR GLASS

1 - DOOR RUN CHANNEL

2 - DOOR GLASS

3 - REINFORCEMENT BOLTS

Fig. 7 GLASS SUPPORT

1 - WOOD WEDGE (or equivalent)

2 - WINDOW GLASS

VADOOR - FRONT 23 - 15

Page 1960 of 2305

(4) Tighten bolt to 10 N´m (89 in. lbs.).

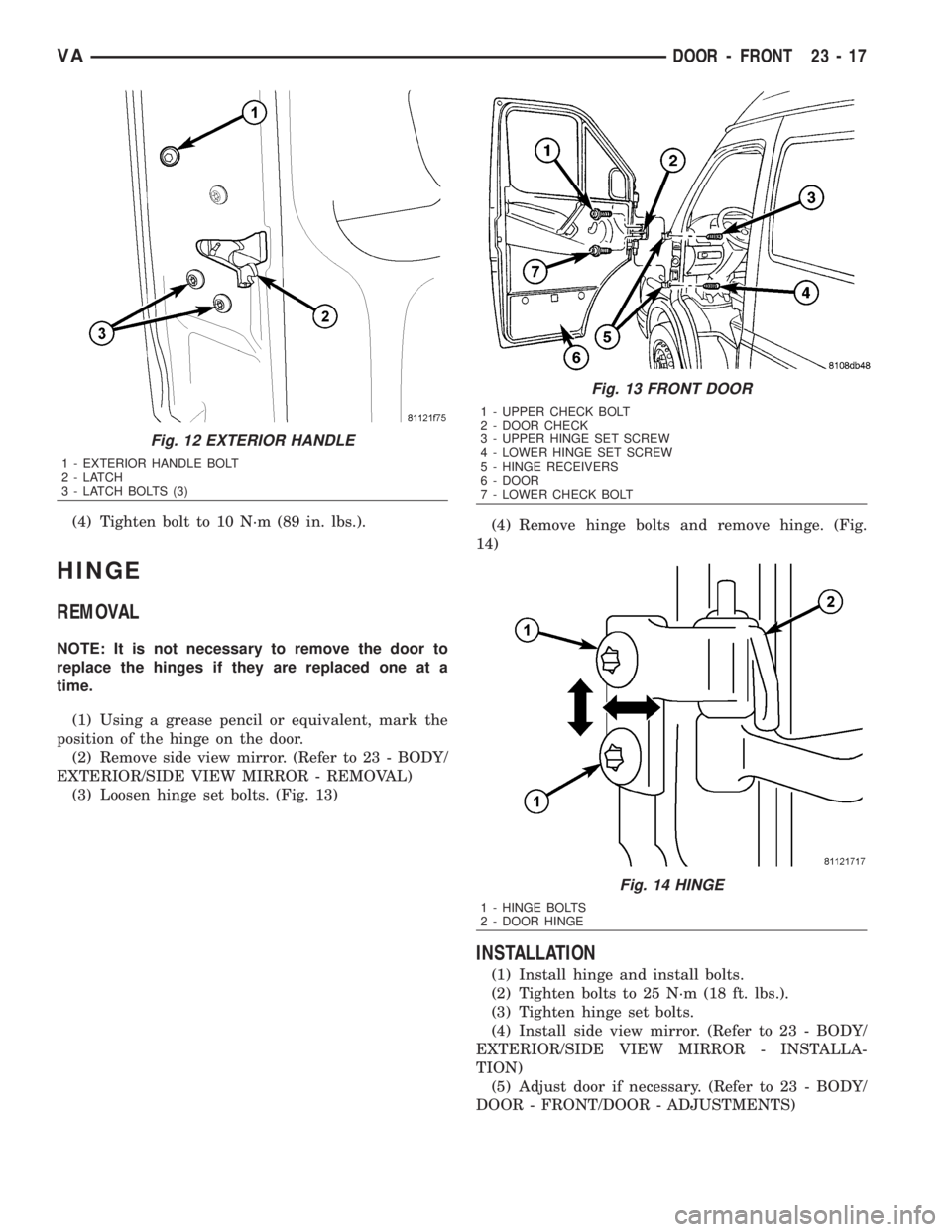

HINGE

REMOVAL

NOTE: It is not necessary to remove the door to

replace the hinges if they are replaced one at a

time.

(1) Using a grease pencil or equivalent, mark the

position of the hinge on the door.

(2) Remove side view mirror. (Refer to 23 - BODY/

EXTERIOR/SIDE VIEW MIRROR - REMOVAL)

(3) Loosen hinge set bolts. (Fig. 13)(4) Remove hinge bolts and remove hinge. (Fig.

14)

INSTALLATION

(1) Install hinge and install bolts.

(2) Tighten bolts to 25 N´m (18 ft. lbs.).

(3) Tighten hinge set bolts.

(4) Install side view mirror. (Refer to 23 - BODY/

EXTERIOR/SIDE VIEW MIRROR - INSTALLA-

TION)

(5) Adjust door if necessary. (Refer to 23 - BODY/

DOOR - FRONT/DOOR - ADJUSTMENTS)

Fig. 12 EXTERIOR HANDLE

1 - EXTERIOR HANDLE BOLT

2-LATCH

3 - LATCH BOLTS (3)

Fig. 13 FRONT DOOR

1 - UPPER CHECK BOLT

2 - DOOR CHECK

3 - UPPER HINGE SET SCREW

4 - LOWER HINGE SET SCREW

5 - HINGE RECEIVERS

6 - DOOR

7 - LOWER CHECK BOLT

Fig. 14 HINGE

1 - HINGE BOLTS

2 - DOOR HINGE

VADOOR - FRONT 23 - 17

Page 1991 of 2305

EXTERIOR

TABLE OF CONTENTS

page page

FUEL FILL DOOR

REMOVAL.............................48

INSTALLATION.........................48

GRILLE

REMOVAL.............................48

INSTALLATION.........................48

LICENSE PLATE BRACKET

REMOVAL.............................48

INSTALLATION.........................48RADIATOR CROSSMEMBER

REMOVAL.............................49

INSTALLATION.........................49

SIDE VIEW MIRROR

REMOVAL.............................49

INSTALLATION.........................50

SIDE VIEW MIRROR - GLASS

REMOVAL.............................50

INSTALLATION.........................50

FUEL FILL DOOR

REMOVAL

(1) Open passenger compartment door.

(2) Open fuel fill door.

(3) Using a trim stick C-4755 or equivalent, dis-

connect the filler cap tether.

(4) Remove two bolts and remove filler door.

INSTALLATION

(1) Install the door and bolts.

(2) Connect filler cap tether.

(3) Close doors.

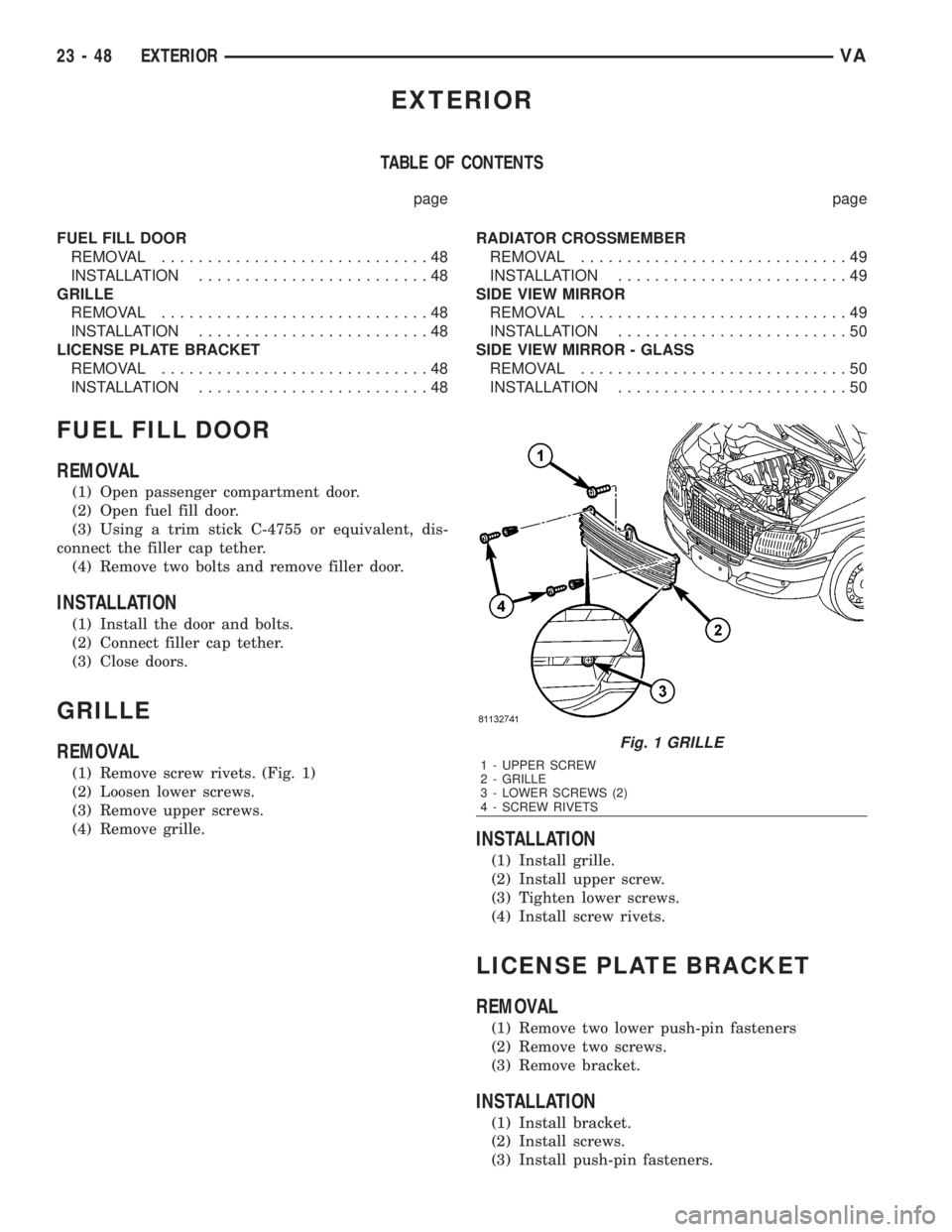

GRILLE

REMOVAL

(1) Remove screw rivets. (Fig. 1)

(2) Loosen lower screws.

(3) Remove upper screws.

(4) Remove grille.

INSTALLATION

(1) Install grille.

(2) Install upper screw.

(3) Tighten lower screws.

(4) Install screw rivets.

LICENSE PLATE BRACKET

REMOVAL

(1) Remove two lower push-pin fasteners

(2) Remove two screws.

(3) Remove bracket.

INSTALLATION

(1) Install bracket.

(2) Install screws.

(3) Install push-pin fasteners.

Fig. 1 GRILLE

1 - UPPER SCREW

2 - GRILLE

3 - LOWER SCREWS (2)

4 - SCREW RIVETS

23 - 48 EXTERIORVA

Page 1992 of 2305

RADIATOR CROSSMEMBER

REMOVAL

(1) Remove grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - REMOVAL)

(2) Remove headlamps. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/FRONT

LAMP UNIT - REMOVAL)

(3) Remove heat shield. (Fig. 2)

(4) Remove retaining clamps and rubber mounts.

(5) Remove bolts.

(6) Remove crossmember and disconnect hood

cable.

INSTALLATION

(1) Connect hood release cable and install cross-

member.

(2) Install crossmember bolts and tighten to 14

N´m (10 ft. lbs.).

(3) Install rubber mounts and retaining clamps.

(4) Install heat shield.

(5) Install headlamps. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/FRONT LAMP

UNIT - INSTALLATION)

(6) Install grille. (Refer to 23 - BODY/EXTERIOR/

GRILLE - INSTALLATION)

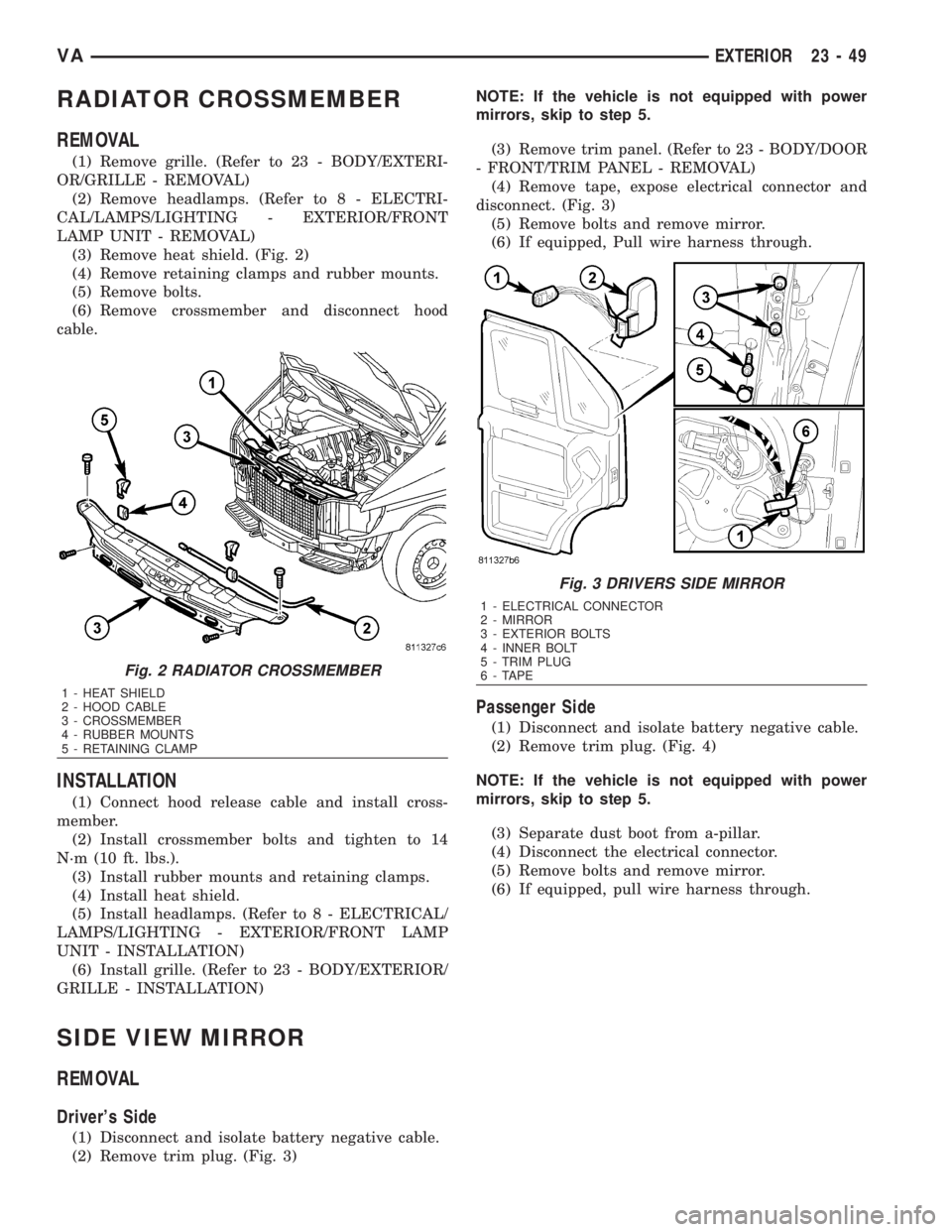

SIDE VIEW MIRROR

REMOVAL

Driver's Side

(1) Disconnect and isolate battery negative cable.

(2) Remove trim plug. (Fig. 3)NOTE: If the vehicle is not equipped with power

mirrors, skip to step 5.

(3) Remove trim panel. (Refer to 23 - BODY/DOOR

- FRONT/TRIM PANEL - REMOVAL)

(4) Remove tape, expose electrical connector and

disconnect. (Fig. 3)

(5) Remove bolts and remove mirror.

(6) If equipped, Pull wire harness through.

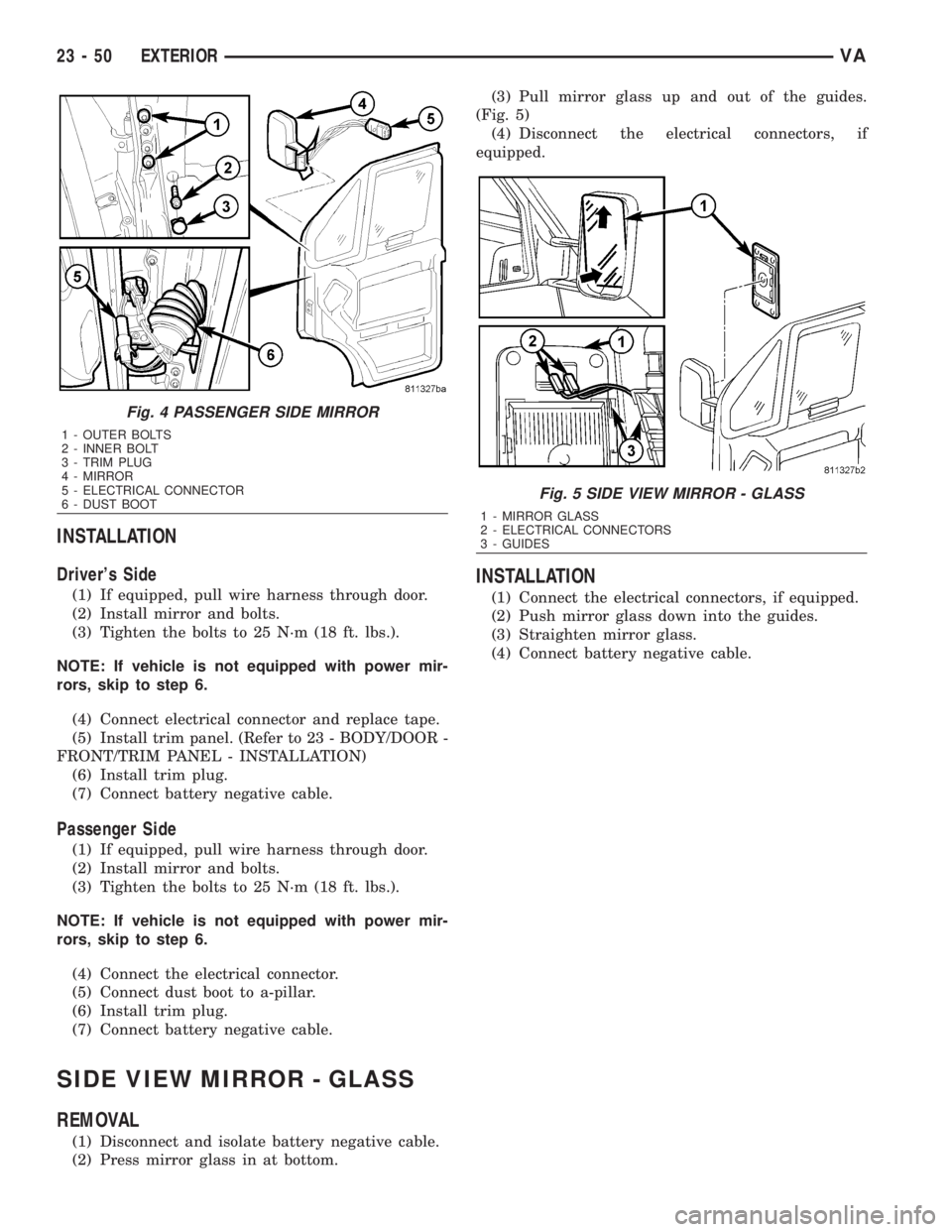

Passenger Side

(1) Disconnect and isolate battery negative cable.

(2) Remove trim plug. (Fig. 4)

NOTE: If the vehicle is not equipped with power

mirrors, skip to step 5.

(3) Separate dust boot from a-pillar.

(4) Disconnect the electrical connector.

(5) Remove bolts and remove mirror.

(6) If equipped, pull wire harness through.

Fig. 2 RADIATOR CROSSMEMBER

1 - HEAT SHIELD

2 - HOOD CABLE

3 - CROSSMEMBER

4 - RUBBER MOUNTS

5 - RETAINING CLAMP

Fig. 3 DRIVERS SIDE MIRROR

1 - ELECTRICAL CONNECTOR

2 - MIRROR

3 - EXTERIOR BOLTS

4 - INNER BOLT

5 - TRIM PLUG

6 - TAPE

VAEXTERIOR 23 - 49

Page 1993 of 2305

INSTALLATION

Driver's Side

(1) If equipped, pull wire harness through door.

(2) Install mirror and bolts.

(3) Tighten the bolts to 25 N´m (18 ft. lbs.).

NOTE: If vehicle is not equipped with power mir-

rors, skip to step 6.

(4) Connect electrical connector and replace tape.

(5) Install trim panel. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION)

(6) Install trim plug.

(7) Connect battery negative cable.

Passenger Side

(1) If equipped, pull wire harness through door.

(2) Install mirror and bolts.

(3) Tighten the bolts to 25 N´m (18 ft. lbs.).

NOTE: If vehicle is not equipped with power mir-

rors, skip to step 6.

(4) Connect the electrical connector.

(5) Connect dust boot to a-pillar.

(6) Install trim plug.

(7) Connect battery negative cable.

SIDE VIEW MIRROR - GLASS

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Press mirror glass in at bottom.(3) Pull mirror glass up and out of the guides.

(Fig. 5)

(4) Disconnect the electrical connectors, if

equipped.

INSTALLATION

(1) Connect the electrical connectors, if equipped.

(2) Push mirror glass down into the guides.

(3) Straighten mirror glass.

(4) Connect battery negative cable.

Fig. 4 PASSENGER SIDE MIRROR

1 - OUTER BOLTS

2 - INNER BOLT

3 - TRIM PLUG

4 - MIRROR

5 - ELECTRICAL CONNECTOR

6 - DUST BOOT

Fig. 5 SIDE VIEW MIRROR - GLASS

1 - MIRROR GLASS

2 - ELECTRICAL CONNECTORS

3 - GUIDES

23 - 50 EXTERIORVA

Page 2013 of 2305

INTERIOR

TABLE OF CONTENTS

page page

INTERIOR

CAUTION.............................70

A-PILLAR TRIM

REMOVAL.............................70

INSTALLATION.........................71

ASSIST HANDLE

REMOVAL.............................71

INSTALLATION.........................71

B-PILLAR TRIM

REMOVAL.............................71

INSTALLATION.........................72

BULKHEAD TRIM PANEL

REMOVAL.............................72

INSTALLATION.........................72

CARPETS AND FLOOR MATS

REMOVAL.............................72

INSTALLATION.........................73

COWL TRIM

REMOVAL.............................73

INSTALLATION.........................73

D-PILLAR TRIM

REMOVAL.............................73INSTALLATION.........................73

HEADLINER

REMOVAL.............................73

INSTALLATION.........................74

QUARTER TRIM PANEL

REMOVAL.............................74

INSTALLATION.........................75

REAR VIEW MIRROR

REMOVAL.............................75

INSTALLATION

INSTALLATION.......................75

INSTALLATION - REAR VIEW MIRROR

SUPPORT BRACKET...................75

STEPWELL SCUFF PADS

REMOVAL.............................75

INSTALLATION.........................76

SUN VISOR

REMOVAL.............................76

INSTALLATION.........................76

INTERIOR

CAUTION

CAUTION:: Do not attempt to remove interior trim

panels/moldings without first removing the neces-

sary adjacent panels. To avoid damaging the pan-

els, ensure that all the screws and clips are

removed before attempting to remove an interior

trim panel/molding. Trim panels are somewhat flex-

ible but can be damaged if handled improperly.

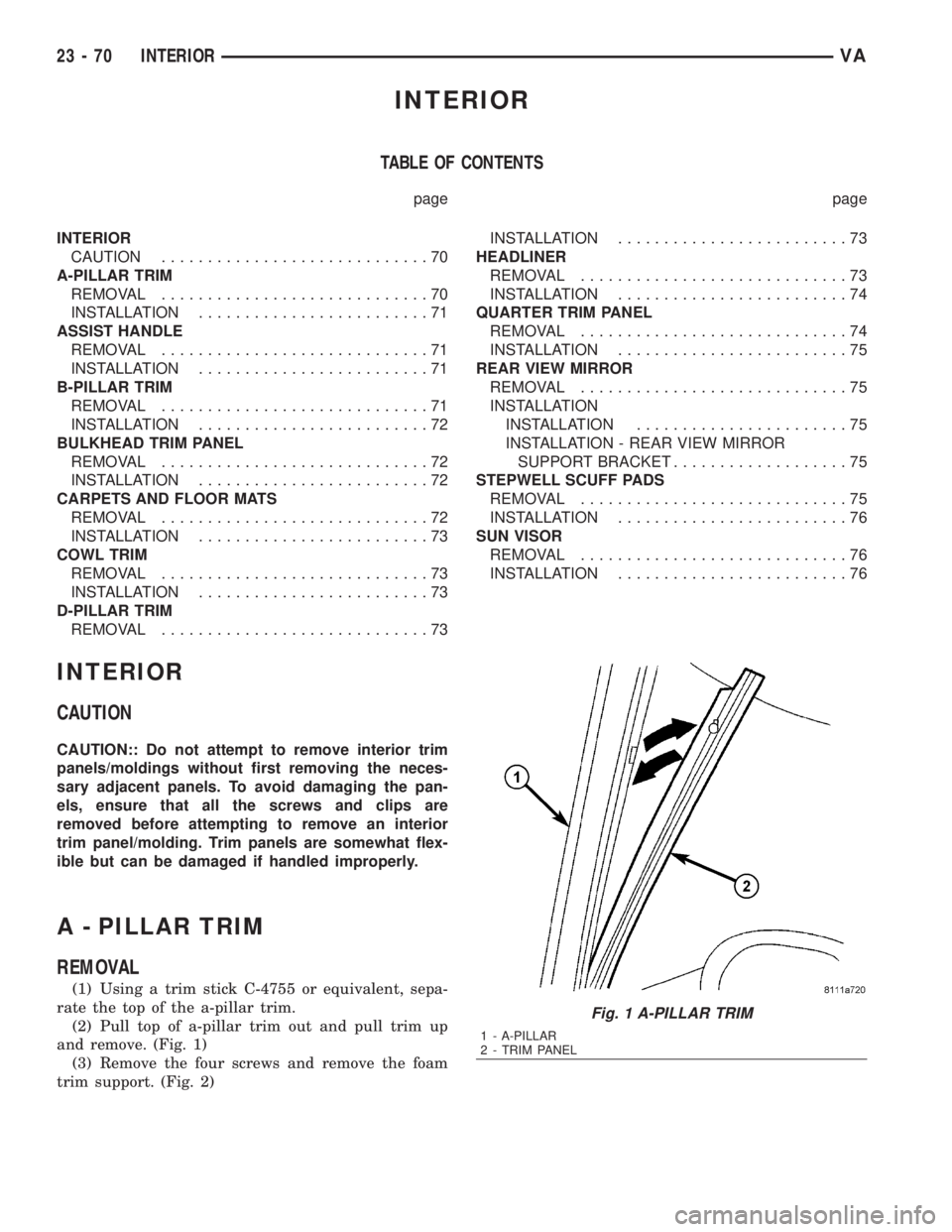

A - PILLAR TRIM

REMOVAL

(1) Using a trim stick C-4755 or equivalent, sepa-

rate the top of the a-pillar trim.

(2) Pull top of a-pillar trim out and pull trim up

and remove. (Fig. 1)

(3) Remove the four screws and remove the foam

trim support. (Fig. 2)

Fig. 1 A-PILLAR TRIM

1 - A-PILLAR

2 - TRIM PANEL

23 - 70 INTERIORVA