reset MERCEDES-BENZ SPRINTER 2006 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 723 of 2305

effect panels. If necessary, remove the wheels from

the lifted end of the vehicle and lower the vehicle

closer to the ground, to increase the ground clearance

at the opposite end of the vehicle. Install lug nuts on

wheel attaching studs to retain brake drums.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used provided all the wheels are lifted

off the ground using tow dollies.

MAINTENANCE SCHEDULES

DESCRIPTION

The use of special lubricant additives is not recom-

mended. The use of such additives may affect the

warranty rights. With regard to legal stipulations

concerning emissions control, please note that

engines have to be serviced and adjusted in accor-

dance with special instructions and using special

measuring equipment. Modifications to or interfer-

ence with the emissions control systems are not per-

missible.

MAINTENANCE - WITHOUT ASSYST MAINTE-

NANCE COMPUTER

Maintenance Intervals

²Oil service ±Normal Operationevery 10,000

miles or 16,000 km or 12 months.

²Maintenance service every 30,000 miles or

48,000 km.

Additional work must be carried out at yearly

intervals.

MAINTENANCE - WITH ASSYST MAINTENANCE

COMPUTER

ASSYST provides information on the best possible

timing for maintenance work.

When the next maintenance service is due, this

will be indicated in the multi-function display with

the wrench icon symbol displayed in km/miles or

days.

²One wrench icon showing indicates Oil Service

is necessary.

²Two wrench icons showing indicates Mainte-

nance Service is necessary ± displayed in km/miles or

days.

If the display shows the number of days, a clock

symbol will also appear in the multi-function display.You should have the maintenance performed

within the stated period/distance.

The service indicator will be reset after an oil ser-

vice and/or maintenance service has been performed.

REGULAR CHECK - UPS

To maintain the safe operation of the vehicle, it is

recommended that the following tasks be performed

on a regular basis (i.e. weekly or whenever the vehi-

cle is refueled). Check:

²Engine oil level

²Brake system - fluid level

²Battery - acid level

²Windshield washer system and headlamp clean-

ing system - fluid level

²Mechanical assemblies (e.g. engine, transmis-

sion, etc.) - check for leaks

²Condition of tires and tires pressures

²All exterior lights

SPECIAL MAINTENANCE REQUIREMENTS

If bodies built by manufacturers other than

DaimlerChrysler Corporation are fitted to the vehi-

cle, the maintenance requirements and lubrication

intervals specified by the body manufacturer must be

adhered to, in addition to all standard maintenance

requirements.

Coolant

Corrosion inhibitor/antifreeze concentration in the

coolant should be checked before the onset of winter

(once year in countries with high prevailing temper-

atures).

Replace the coolant every five years or 100,000

miles.

Dust Filter for Heating / Ventilation Replacement

The dust filter and the tailgate interior filter are to

be renewed during routine maintenance service. If

operating conditions are dusty, these filters should be

renewed more frequently.

ENGINE OIL CHANGE AND FILTER REPLACEMENT

At a minimum, change the engine oil and oil filter

once a year ± even if the vehicle mileage per year is

extremely low. For standard oil service schedules

refer to the chapter oil service and maintenance ser-

vice.

Once a Year

Select the viscosity of the engine oil (SAE classes)

according to the outside air temperature.

Only use engine oil approved by DaimlerChrysler

Corporation if following the ASSYST system guide-

lines.

0 - 8 LUBRICATION & MAINTENANCEVA

Page 724 of 2305

SCOPE OF WORK FOR MAINTENANCE SERVICE

Oil Service

²Engine: Oil change and filter replacement

Check fluid levels of the following system, refill as neces-

sary.

²If fluid is lost, trace and eliminate cause - as a

separate order.

²Power-assisted steering

Lubrication work:

²Trailer tow hitch (original equipment)

Maintenance

²ASSYST maintenance computer reset

Function check

²Signalling system, warning and indicator lamps

²Headlamps, exterior lighting

²Windshield wipers, windshield washer system

Check for leaks and damage

²Check for abrasion points and ensure that lines

are correctly routed!

²All lines and hoses, sensor cables

²Rubber boots on front axle drive shafts, rubber

boots on front axle suspension ball joints, shock

absorbers

²Check fluid levels for the following systems, cor-

rect as necessary

NOTE: Should there be a loss of fluid which cannot

be explained by regular use, trace and eliminate the

cause.

²Engine cooling system. Check corrosion inhibi-

tor/antifreeze, refill as necessary.

²Hydraulic brake system

²Battery

²Windshield washer system

Engine

²Fuel filter renewal - Every oil service

²Air cleaner with maintenance indicator:

²Check degree of contamination.

²Air cleaner filter element renewed as necessary.

Chassis and body

²Trailer coupling: Check operation, play and

retaining fixtures

²Secondary rubber springs: Visual check

²Tire pressures: Correct as necessary, including

spare tire

²Check thickness of brake pads

²Brake test

²Check condition of steering mechanism

²Heating/ventilation dust filter renewal

ADDITIONAL MAINTENANCE WORK

Automatic transmission once only at 80,000 miles / 128000

km

²Oil and filter change

During every second maintenance service

²Air cleaner without maintenance indicator:

²Air cleaner filter element renewal

²Check poly-V-belt for wear and signs of damage

During every fourth maintenance service

²Change rear axle fluid

ADDITIONAL MAINTENANCE WORK AFTER YEARS

Every 2 years

²Change brake fluid.

Every 3 years

²Air cleaner filter element renewal (note installa-

tion date)

Every 15 years or 100,000 miles

²Coolant renewal

²Note coolant composition

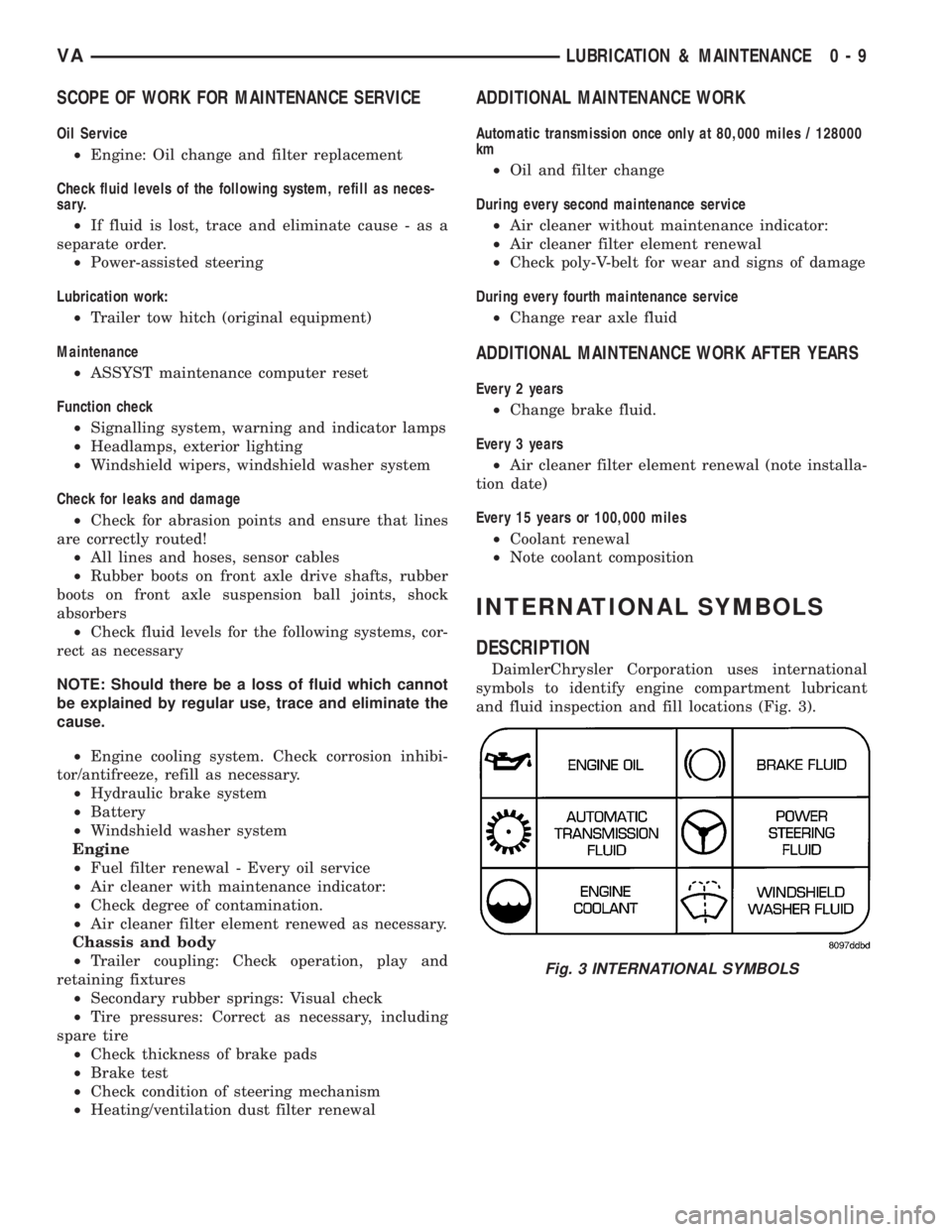

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid inspection and fill locations (Fig. 3).

Fig. 3 INTERNATIONAL SYMBOLS

VALUBRICATION & MAINTENANCE 0 - 9

Page 865 of 2305

predefined gear, there are several shift performance

concerns. For instance, if the transmission is slip-

ping, the controller tries to place the transmission

into 3rd gear and maintain 3rd gear for all forward

drive conditions.

STANDARD PROCEDURE - TCM ADAPTATION

The adaptation procedure requires the use of the

appropriate scan tool. This program allows the elec-

tronic transmission system to re-calibrate itself. This

will provide the proper baseline transmission opera-

tion. The adaptation procedure should be performed

if any of the following procedures are performed:

²Transmission Assembly Replacement

²Transmission Control Module Replacement

²Clutch Plate and/or Seal Replacement

²Electrohydraulic Unit Replacement or Recondi-

tion

(1) With the scan tool, reset the Transmission

adaptives. Resetting the adaptives will set the adap-

tives to factory settings.

NOTE: Perform the Coast Down Adaptations first.

The Transmission Temperature must be greater

than 60ÉC (140ÉF) and less than 70ÉC (158ÉF). Fail-

ure to stay within these temperature ranges will

void the procedure.

(2) Drive the vehicle until the transmission tem-

perature is in the specified range.

(3) Perform 4 to 5 coast downs from 5th to 4th

gear and then 4th to 3rd gear.

NOTE: For Upshift adaptation, the Transmission

temperature must be greater than 60ÉC (140ÉF) and

less than 100ÉC (212ÉF). Failure to stay within these

temperature ranges will void this procedure.

(4) From a stop, moderately accelerate the vehicle

and obtain all forward gear ranges while keeping the

Engine RPM below 1800 RPM. Repeat this procedure

4 to 5 times.

(5) Obtaining 5th gear may be difficult at 1800

RPM. Allow the transmission to shift into 5th gear at

a higher RPM then lower the RPM to 1800 and per-

form manual shifts between 4th and 5th gears using

the shift lever.

(6) The TCM will store the adaptives every 10

minutes. After completion of the adaptation proce-

dure make sure the vehicle stays running for at least

10 minutes.

(7) It is possible to manually store the adaptives

under the 10 minute time frame using the DRBIIIt

Store Adaptives procedure.

8E - 10 ELECTRONIC CONTROL MODULESVA

Page 930 of 2305

remains illuminated until the cluster receives a

lamp-off message from the ECM, or until the ignition

switch is turned to the Off position, whichever occurs

first.

The ECM continually monitors the constant engine

speed (ADR) switch and electronic messages from the

Controller Antilock Brake (CAB) concerning the sta-

tus of the four wheel speed sensors, the park brake

switch and the brake lamp switch to determine the

correct operating mode for the ADR feature. The

ECM then sends the proper lamp-on or lamp-off mes-

sages to the instrument cluster. See the owner's man-

ual in the vehicle glove box for more information on

the features, use, activation and deactivation of the

constant engine speed (ADR) feature. For proper

diagnosis of the ADR feature, the ECM, the CAB, the

CAN data bus, or the electronic message inputs to

the instrument cluster that control the ADR indica-

tor, a diagnostic scan tool is required. Refer to the

appropriate diagnostic information.

AIRBAG INDICATOR

DESCRIPTION

An airbag indicator is standard equipment on all

instrument clusters. The airbag indicator is located

near the left edge of the instrument cluster, next to

the tachometer. The airbag indicator consists of a

stencil-like cutout of the letters ªSRSº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

Light Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the ªSRSº text to

appear in red through the translucent outer layer of

the overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The air-

bag indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The airbag (SRS) indicator gives an indication to

the vehicle operator when the Airbag Control Module

(ACM) has recorded a Diagnostic Trouble Code (DTC)

for a Supplemental Restraint System (SRS) circuit or

component malfunction. Such a DTC may indicate

that the SRS is faulty or inoperative. The airbag

indicator is controlled by a transistor on the instru-

ment cluster circuit board based upon cluster pro-

gramming and a hard wired input received by the

cluster from the ACM. The airbag indicator Light

Emitting Diode (LED) is completely controlled by the

instrument cluster logic circuit, and that logic will

only allow this indicator to operate when the instru-

ment cluster detects that the ignition switch is in the

On position. Therefore, the LED will always be offwhen the ignition switch is in any position except

On. The LED only illuminates when it is provided a

path to ground by the instrument cluster transistor.

The instrument cluster will turn on the airbag indi-

cator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the airbag indicator is illu-

minated for about four seconds. The entire four sec-

ond bulb test is a function of the ACM.

²Airbag Lamp-On Input- Each time the cluster

receives a lamp-on input from the ACM, the airbag

indicator will be illuminated. The indicator can be

flashed on and off, or illuminated solid, as dictated

by the ACM input. For some DTC's, if the problem

does not recur, the ACM will send a lamp-off input

automatically. Other DTC's may require that a fault

be repaired and the ACM be reset before a lamp-off

input will be sent. For more information on the ACM

and the DTC set and reset parameters, refer to 8 -

ELECTRICAL/RESTRAINTS/AIRBAG CONTROL

MODULE - OPERATION). The indicator remains

illuminated until the cluster receives a lamp-off

input from the ACM, or until the ignition switch is

turned to the Off position, whichever occurs first.

²Airbag Indicator Malfunction- Following the

seatbelt reminder function, each time the cluster

detects a malfunction in the airbag (SRS) indicator or

the airbag indicator circuit, the cluster will flash the

seatbelt indicator on and off. The cluster will con-

tinue to flash the seatbelt indicator until the airbag

indicator circuit fault is resolved, or until the ignition

switch is turned to the Off position, whichever occurs

first.

The ACM continually monitors the SRS circuits

and sensors to decide whether the system is in good

operating condition. The ACM then provides the

proper lamp-on or lamp-off inputs to the instrument

cluster. If the ACM provides a lamp-on input after

the bulb test, it indicates that the ACM has detected

a system malfunction and/or that the airbags and

seat belt tensioners may not deploy when required,

or may deploy when not required. The ACM will

store a DTC for any malfunction it detects. The ACM

input circuit to the instrument cluster can be diag-

nosed using conventional diagnostic tools and meth-

ods. For proper diagnosis of the SRS, the ACM, or

the instrument cluster circuitry that controls the air-

bag indicator, a diagnostic scan tool is required. Refer

to the appropriate diagnostic information.

AMBIENT TEMPERATURE

INDICATOR

DESCRIPTION

An ambient temperature indicator is optional

equipment on all instrument clusters. In vehicles so

VAINSTRUMENT CLUSTER 8J - 11

Page 940 of 2305

next required engine oil maintenance is anticipated.

ASSYST also provides several audible indications

using the electronic tone generator on the instrument

cluster circuit board to supplement these visual dis-

plays.

The indications of the ASSYST engine oil mainte-

nance indicator are not visible when the LCD is not

illuminated. When illuminated, the ASSYST indica-

tions appear as dark characters and icons silhouetted

against an amber field. When the exterior lighting is

turned Off, the display is illuminated at maximum

brightness. When the exterior lighting is turned On,

the display illumination level can be adjusted in con-

cert with the cluster general illumination lighting

using the ª+º (plus) and ª2º (minus) multi-function

indicator push buttons. The ASSYST engine oil main-

tenance indicator is serviced as a unit with the

instrument cluster.

OPERATION

The ASSYST engine oil maintenance indicator

microprocessor uses numerous criteria besides time

and mileage to evaluate vehicle maintenance require-

ments. Time data is taken from the electronic digital

clock integral to the instrument cluster. Vehicle dis-

tance data is obtained from the Controller Antilock

Brake (CAB) over the Controller Area Network

(CAN) data bus. Coolant temperature, engine oil

temperature, engine oil level, engine oil quality,

engine speed, and engine load data are obtained from

the Engine Control Module (ECM) over the CAN

data bus. Using all of the available data and internal

programming, the ASSYST microprocessor then cal-

culates the estimated time and distance to the next

required engine oil maintenance interval. The

ASSYST uses the multi-function indicator LCD to

display that data and, when necessary, issues audible

alerts to the vehicle operator through the electronic

tone generator on the cluster circuit board.

See the owner's manual in the vehicle glove box for

more information on the features, use, operation and

resetting procedures for the ASSYST maintenance

computer. Proper diagnosis and testing of the

ASSYST engine oil maintenance computer, the CAN

data bus and the electronic data bus message inputs

to the EMIC that are used by the ASSYST computer

for its calculations requires the use of a diagnostic

scan tool. Refer to the appropriate diagnostic infor-

mation.

MALFUNCTION INDICATOR

LAMP (MIL)

DESCRIPTION

A Malfunction Indicator Lamp (MIL) is standard

equipment on all instrument clusters. The MIL islocated near the lower edge of the instrument cluster,

to the right of the multi-function indicator display.

The MIL consists of the International Control and

Display Symbol icon for ªEngineº imprinted within a

rectangular cutout in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. An amber Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by the LED, which is sol-

dered onto the instrument cluster electronic circuit

board. The MIL is serviced as a unit with the instru-

ment cluster.

OPERATION

The Malfunction Indicator Lamp (MIL) gives an

indication to the vehicle operator when the Engine

Control Module (ECM) has recorded a Diagnostic

Trouble Code (DTC) for an On-Board Diagnostics II

(OBDII) emissions-related circuit or component mal-

function. The MIL is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the ECM over the Controller Area

Network (CAN) data bus. The MIL Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster detects that the ignition switch is in the On

position. Therefore, the LED will always be off when

the ignition switch is in any position except On. The

LED only illuminates when it is provided a path to

ground by the instrument cluster transistor. The

instrument cluster will turn on the MIL for the fol-

lowing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the MIL is illuminated as a

bulb test. The indicator will remain illuminated until

the engine is started, or until the ignition switch is

turned to the Off position, whichever occurs first.

²MIL Lamp-On Message- Each time the clus-

ter receives a MIL lamp-on message from the ECM,

the indicator will be illuminated. The indicator will

remain illuminated until the detected fault is

repaired, or until the ignition switch is turned to the

Off position, whichever occurs first. For more infor-

mation on the ECM and the DTC set and reset

parameters, (Refer to 25 - EMISSIONS CONTROL -

OPERATION).

²Communication Error- If the cluster receives

no lamp-on or lamp-off message from the ECM, the

MIL is illuminated by the instrument cluster. The

indicator remains controlled and illuminated by the

cluster until a valid lamp-on or lamp-off message is

received from the ECM.

VAINSTRUMENT CLUSTER 8J - 21

Page 942 of 2305

the instrument cluster, directly below the speedome-

ter. However, the odometer and trip odometer infor-

mation are not displayed simultaneously. The ªmiº

(miles) or ªkmº (kilometers) switch on the instrument

cluster circuit board toggles the display between

odometer and trip odometer modes by depressing the

switch push button that extends through the lower

edge of the cluster lens, directly below the multi-

function indicator LCD.

The odometer and trip odometer information is

stored in the instrument cluster memory. This infor-

mation can be increased when the proper inputs are

provided to the instrument cluster, but the informa-

tion cannot be decreased. The odometer can display

values up to 999,999 kilometers (999,999 miles). The

odometer latches at these values, and will not roll

over to zero. The trip odometer can display values up

to 999.9 kilometers (999.9 miles) before it rolls over

to zero. The odometer display does not have a deci-

mal point and will not show values less than a full

unit (kilometer or mile), while the trip odometer dis-

play does have a decimal point and will show tenths

of a unit (kilometer or mile). The unit of measure

(kilometers or miles) for the odometer and trip odom-

eter display is imprinted on the cluster overlay below

the left end of the LCD. The unit of measure for the

instrument cluster odometer/trip odometer is selected

at the time that it is manufactured, and cannot be

changed.

The indications of the odometer/trip odometer are

not visible when the LCD is not illuminated. When

illuminated the indications appear as dark charac-

ters silhouetted against an amber field. When the

exterior lighting is turned Off, the display is illumi-

nated at maximum brightness. When the exterior

lighting is turned On the display illumination level

can be adjusted in concert with the cluster general

illumination lighting using the plus and minus multi-

function indicator push buttons. The odometer has a

ªRental Carº mode, which will activate the multi-

function indicator LCD and illuminate the odometer

information for about thirty seconds after one of the

multi-function indicator push buttons is momentarily

depressed, or after the key is inserted into the igni-

tion switch lock cylinder with the ignition switch in

the Off position.

The odometer/trip odometer and the miles/kilome-

ters switch, and the miles/kilometers switch push

button are serviced as a unit with the instrument

cluster.

OPERATION

The odometer and trip odometer give an indication

to the vehicle operator of the distance the vehicle has

traveled. This indicator is controlled by the instru-

ment cluster circuitry based upon cluster program-

ming and electronic messages received by the cluster

from the Controller Anti-lock Brake (CAB) over theController Area Network (CAN) data bus. The odom-

eter and trip odometer information is displayed by

the multi-function indicator Liquid Crystal Display

(LCD). The LCD will display the odometer informa-

tion whenever it is activated, and will display the

last previously selected odometer or trip odometer

information when the ignition switch is turned to the

On position. The instrument cluster circuitry controls

the LCD and provides the following features:

²Odometer/Trip Odometer Display Toggling-

Actuating the multi-function indicator ªmiº (miles) or

ªkmº (kilometers) switch push button momentarily

with the LCD illuminated will toggle the display

between the odometer and trip odometer information.

Each time the LCD is illuminated with the ignition

switch in the On or Start positions, the display will

automatically return to the last mode previously

selected (odometer or trip odometer).

²Trip Odometer Reset- When the multi-func-

tion indicator ªmiº (miles) or ªkmº (kilometers) switch

push button is pressed and held for longer than

about two seconds, the trip odometer will be reset to

000.0 kilometers (miles). The LCD must be display-

ing the trip odometer information in order for the

trip odometer information to be reset.

The CAB continually monitors the vehicle speed

pulse information received from the four wheel speed

sensors, then sends the proper distance messages to

the instrument cluster. For proper diagnosis of the

wheel speed sensors, the CAB, the CAN data bus, or

the electronic message inputs to the instrument clus-

ter that control the odometer/trip odometer, a diag-

nostic scan tool is required. Refer to the appropriate

diagnostic information.

PARK BRAKE INDICATOR

DESCRIPTION

A park brake indicator is standard equipment on

all instrument clusters. The park brake indicator is

located near the lower edge of the instrument cluster,

to the left of the multi-function indicator display. The

park brake indicator consists of stencil-like cutout of

the word ªPARKº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. A red Light Emitting

Diode (LED) behind the cutout in the opaque layer of

the overlay causes the ªPARKº text to appear in red

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by the

LED, which is soldered onto the instrument cluster

electronic circuit board. The park brake indicator is

serviced as a unit with the instrument cluster.

VAINSTRUMENT CLUSTER 8J - 23

Page 1075 of 2305

OPERATION

The wiper motor operation is controlled by the

vehicle operator through battery current inputs

received by the wiper motor from the wiper switch

circuitry of the multi-function switch on the top of

the steering column, and from the wiper relay on the

fuse block underneath the steering column. The

wiper motor speed is controlled by current flow to

either the low speed or the high speed set of brushes.

The automatic resetting circuit breaker protects the

motor from overloads.

The park switch consists of a contact disc and

three contacts. The contact disc is mechanically fas-

tened to and rotated with a gear in the wiper motor

transmission. Two input contacts alternately close

the wiper park switch sense output circuit contact to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

allows the intermittent wipe logic circuit to monitor

the position and the cycles of the wiper motor to pro-

vide the intermittent wipe and wipe-after-wash

modes, as well as allowing the motor to complete its

current wipe cycle after the wiper system has been

turned Off and park the wiper blades in the lowest

portion of the wipe pattern.

The wiper motor may be diagnosed using conven-

tional diagnostic tools and methods.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the vehicle wire harness connector

for the wiper motor from the motor pigtail wire con-

nector (Fig. 32).

8R - 32 WIPERS/WASHERSVA

Page 1570 of 2305

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

CIGAR LIGHTER OUTLET

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

REMOVAL.............................2

CIRCUIT BREAKER

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIRCUIT

BREAKER............................2

FUSE BLOCK #1

DESCRIPTION..........................2

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................3FUSE BLOCK #2

DESCRIPTION..........................3

OPERATION............................3

POWER DISTRIBUTION CENTER

DESCRIPTION..........................3

OPERATION............................3

POWER OUTLET

DESCRIPTION..........................3

OPERATION............................4

DIAGNOSIS AND TESTING - POWER OUTLET . 4

REMOVAL.............................4

INSTALLATION..........................4

RELAY

DESCRIPTION..........................4

OPERATION............................5

DIAGNOSIS AND TESTING - RELAY.........5

REMOVAL.............................5

INSTALLATION..........................5

POWER DISTRIBUTION

DESCRIPTION

This section describes the power distribution com-

ponents used on this model as well as the methods in

which battery voltage and charging system voltage is

distributed throughout the vehicle. The power distri-

bution system for this vehicle consists of the follow-

ing major components which are covered in further

detail later in this section:

²Fuseblock #1

²Fuseblock #2

²Power Distribution Center (PDC)

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Cartridge fuses

²Relays

Following are general descriptions and theory of

operation for the major components in the power dis-

tribution system. Refer to Wiring for the location of

complete circuit diagrams for the various power dis-

tribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the standard and optional factory-in-

stalled electrical and powertrain, chassis, safety,

security and convenience systems. At the same time,

the power distribution system was designed to pro-

vide easy access to these electrical distribution points

for the vehicle technician to use when conducting

diagnosis and repair of faulty circuits. The power dis-

tribution system can also prove useful for the addi-

tion of electrical circuits that may be required to

operate accessories that the vehicle owner may

choose to have installed in the aftermarket.

CIGAR LIGHTER OUTLET

DESCRIPTION

The cigar lighter outlet is installed in the instru-

ment panel, near the center of the instrument panel.

The cigar lighter outlet is secured by a snap fit

within the instrument panel.

The cigar lighter knob/heating element, and the

cigar lighter outlet are available for service. These

components cannot be repaired and, if faulty or dam-

aged, they must be replaced.

VA8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1571 of 2305

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or receptacle shell. The receptacle shell

is connected to ground, and an insulated contact in

the bottom of the shell is connected to battery cur-

rent. The cigar lighter receives battery voltage from a

fuse in the fuseblock only when the ignition switch is

in the Accessory or On positions.

The knob and heating element are encased within

a spring-loaded housing, which also features a sliding

protective heat shield. When the heating element is

inserted in the receptacle shell, the heating element

resistor coil is grounded through its housing to the

receptacle shell. If the cigar lighter knob is pushed

inward, the heat shield slides up toward the knob

exposing the heating element.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the receptacle shell. These clips engage and hold

the heating element against the insulated contact

long enough for the resistor coil to heat up and glow.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the receptacle shell, the protective

heat shield slides downward on the housing so that

the heating element is recessed and shielded around

its circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For cigar lighter outlet diagnosis and testing pro-

cedures (Refer to 8 - ELECTRICAL/POWER DISTRI-

BUTION/POWER OUTLET - DIAGNOSIS AND

TESTING)

REMOVAL

For cigar lighter outlet removal procedure (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/POWER

OUTLET - REMOVAL).

CIRCUIT BREAKER

DESCRIPTION

Automatic resetting circuit breakers are used to

protect the power window voltage supply circuits.

These circuit breakers can protect the systems from a

short circuit, or from an overload condition caused byan obstructed or stuck power window regulator or

switch.

The circuit breaker cannot be repaired and, if

faulty or damaged, it must be replaced.

OPERATION

The circuit breaker contains a bi-metal strip sand-

wiched between two contacts forming the connection

in the circuit. An overload condition causes the

bi-metal strip to heat and bend to the open position,

disconnecting current flow to the circuit. Then as the

system overload or short circuit is removed, the

bi-metal strip cools, re-establishing contact to allow

current flow to the circuit.

DIAGNOSIS AND TESTING - CIRCUIT BREAKER

For complete circuit descriptions and diagrams,

refer toWiring.

(1) Locate the correct circuit breaker in the fuse-

block. Pull out the circuit breaker slightly, but be cer-

tain that the circuit breaker terminals still contact

the terminals in the fuseblock cavities.

(2) Connect the negative lead of a 12-volt DC volt-

meter to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither ter-

minal has battery voltage, repair the open circuit

from the Power Distribution Center as required.

FUSE BLOCK #1

DESCRIPTION

An electrical fuse block is concealed under the

driver side steering column. The fuse block serves to

distribute electrical current to many of the electrical

systems in the vehicle. The fuse block contains blade-

type mini fuses, relays and micro processors that

enable automatic control of some of the power distri-

bution circuits throughout the vehicle.

The molded plastic fuse block housing has an inte-

gral mounting bracket that is secured with screws to

the steering column. A finger recess is molded into

the cover for easy removal. A fuse layout map is

molded onto the back side of the cover to ensure

proper fuse identification.

The fuse block cannot be repaired, if the fuse block

is faulty or damaged or if any internal circuit is

faulty or damaged, the entire fuse block must be

replaced.

8W - 97 - 2 8W-97 POWER DISTRIBUTIONVA

Page 1572 of 2305

OPERATION

All of the circuits entering and leaving the fuse

block do so through the instrument panel wire har-

ness. Internal connection of all of the fuse block cir-

cuits is accomplished by an intricate combination of

hard wiring and bus bars. Internal relays and micro

processors allow the vehicle electronics to control

some of the power distribution circuits throughout

the vehicle. Refer to the Wiring section for complete

circuit diagrams.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove fuse block cover by rotating locking

screw 90É.

(3) Remove the steering column cover. Refer to the

Body section for the procedure.

(4) Unscrew fuse block connections and disconnect

all electrical connectors from the fuse block.

(5) Remove the fuse block from the steering col-

umn.

INSTALLATION

(1) Position the fuse block in the steering column.

(2) Install fuse block connections and connect all

electrical connectors on the fuse block.

(3) Install the steering column cover. Refer to the

Body section for the procedure.

(4) Install fuse block cover by rotating locking

screw 90É.

(5) Connect the negative battery cable.

(6) Set time and radio stations.

FUSE BLOCK #2

DESCRIPTION

An electrical fuse block is concealed under the

driver side front seat. The fuse block serves to dis-

tribute electrical current to many of the electrical

systems in the vehicle. The fuse block houses blade-

type mini fuses, blade-type automatic resetting cir-

cuit breakers and International Standards

Organization relays. Additional provisions are avail-

able in the fuse block for additional fuses and ISO

relays.

The molded plastic fuse block housing has an inte-

gral mounting bracket that is secured with screws to

the seat base. The driver side seat base also has a

snap-fit fuse access panel that can be removed for

service of the fuses and the relays. A finger recess is

molded into one end for easy removal. A fuse layout

map is molded onto the back side of the panel to

ensure proper fuse identification.

The fuse block is integral to the body wire harness.

If any internal circuit or the fuse block housing isfaulty or damaged, the entire fuse block and body

wire harness unit must be replaced.

OPERATION

All of the circuits entering and leaving the fuse

block do so through the body wire harness. Internal

connection of all of the fuse block circuits is accom-

plished by an intricate combination of hard wiring

and bus bars.

POWER DISTRIBUTION CEN-

TER

DESCRIPTION

All of the electrical current distributed throughout

this vehicle is directed through the Power Distribu-

tion Center (PDC). The molded plastic PDC housing

is located in the left front corner of the engine com-

partment, on the battery positive cable. The PDC

housing has a molded plastic cover that slides over

the PDC housing. The PDC cover is easily opened or

removed for service access.

The PDC unit cannot be repaired and is only ser-

viced as a unit with the headlamp and dash wire

harness. If the internal circuits or the PDC housing

are faulty or damaged, the headlamp and dash wire

harness unit must be replaced.

OPERATION

All of the current from the battery and the gener-

ator output enters the PDC through the positive bat-

tery cable. The PDC cover is removed to access the

battery and generator output connection B(+) termi-

nal studs. Internal connection of all of the PDC cir-

cuits is accomplished by an intricate combination of

hard wiring and bus bars. Refer to Wiring Diagrams

for the location of complete PDC circuit diagrams.

POWER OUTLET

DESCRIPTION

The power outlet is installed in the instrument

panel accessory switch plate, which is located near

the center of the instrument panel. The power outlet

base is secured by a snap fit within the instrument

panel. A plastic protective cap snaps over the power

outlet base when the power outlet is not being used.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

The power outlet receptacle unit are available for

service. The power outlet receptacle cannot be

VA8W-97 POWER DISTRIBUTION 8W - 97 - 3