fuse MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 295 of 2305

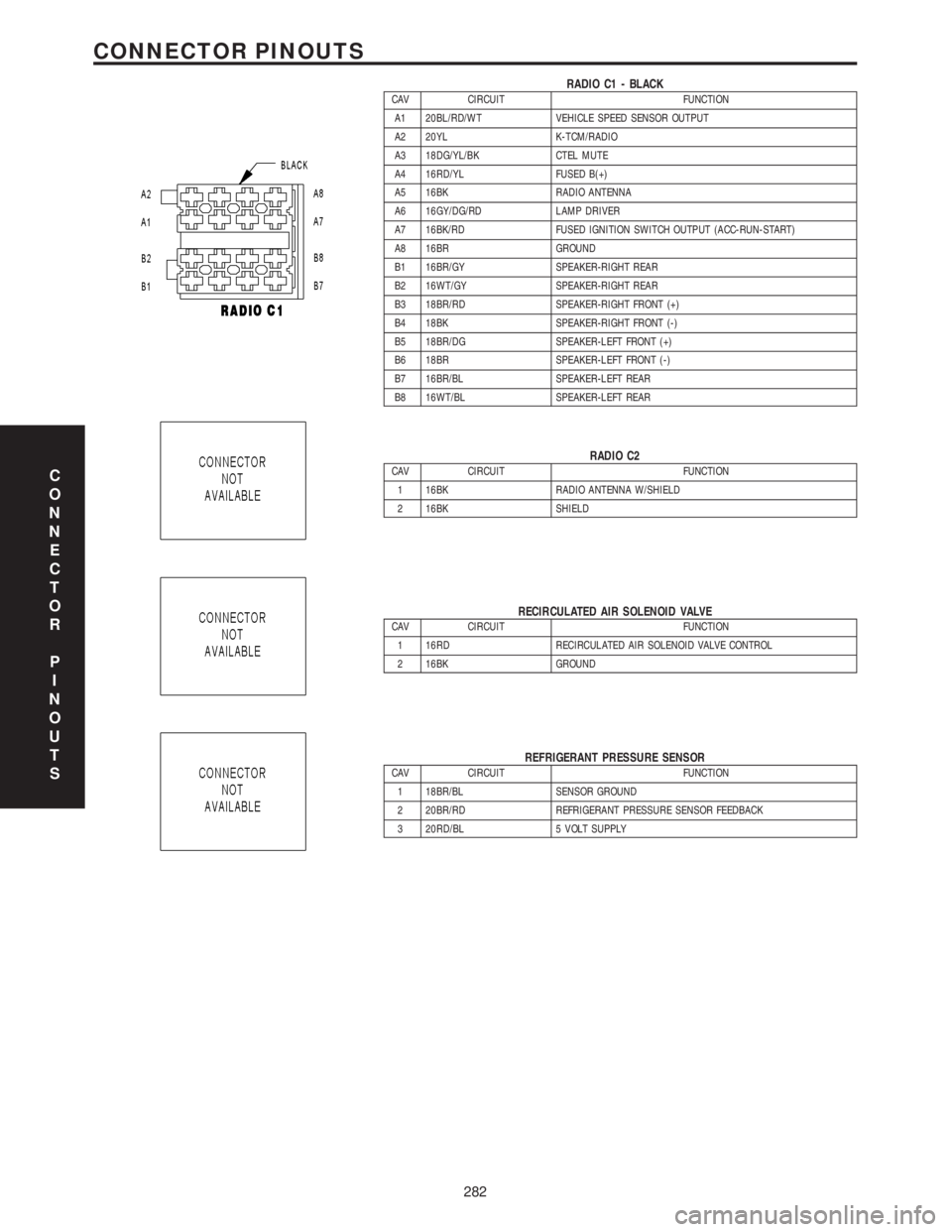

RADIO C1 - BLACKCAV CIRCUIT FUNCTION

A1 20BL/RD/WT VEHICLE SPEED SENSOR OUTPUT

A2 20YL K-TCM/RADIO

A3 18DG/YL/BK CTEL MUTE

A4 16RD/YL FUSED B(+)

A5 16BK RADIO ANTENNA

A6 16GY/DG/RD LAMP DRIVER

A7 16BK/RD FUSED IGNITION SWITCH OUTPUT (ACC-RUN-START)

A8 16BR GROUND

B1 16BR/GY SPEAKER-RIGHT REAR

B2 16WT/GY SPEAKER-RIGHT REAR

B3 18BR/RD SPEAKER-RIGHT FRONT (+)

B4 18BK SPEAKER-RIGHT FRONT (-)

B5 18BR/DG SPEAKER-LEFT FRONT (+)

B6 18BR SPEAKER-LEFT FRONT (-)

B7 16BR/BL SPEAKER-LEFT REAR

B8 16WT/BL SPEAKER-LEFT REAR

RADIO C2CAV CIRCUIT FUNCTION

1 16BK RADIO ANTENNA W/SHIELD

2 16BK SHIELD

RECIRCULATED AIR SOLENOID VALVECAV CIRCUIT FUNCTION

1 16RD RECIRCULATED AIR SOLENOID VALVE CONTROL

2 16BK GROUND

REFRIGERANT PRESSURE SENSORCAV CIRCUIT FUNCTION

1 18BR/BL SENSOR GROUND

2 20BR/RD REFRIGERANT PRESSURE SENSOR FEEDBACK

3 20RD/BL 5 VOLT SUPPLY

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

282

CONNECTOR PINOUTS

Page 297 of 2305

A/C AUXILIARY FAN RELAY (RELAY BLOCK)CAV CIRCUIT FUNCTION

30 14BL/YL FUSED B(+)

85 18BR GROUND

86 18BK/RD A/C AUXILIARY FAN RELAY CONTROL

87 14DG/BK A/C AUXILIARY FAN RELAY OUTPUT

87A --

CIRCULATION PUMP RELAY-CABIN HEATER MODULE (RELAY BLOCK)CAV CIRCUIT FUNCTION

30 18DG/BK CIRCULATION PUMP RELAY OUTPUT

85 16BR GROUND

86 16BL/YL CIRCULATION PUMP RELAY HIGH SIDE CONTROL

87 16RD/BL FUSED B(+)

87A 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

D+ RELAY NO. 2 (RELAY BLOCK)CAV CIRCUIT FUNCTION

30 14RD FUSED B(+)

85 16RD/BK FUSED D(+) RELAY NO. 1 OUTPUT

86 16BR GROUND

87 14BL/YL D(+) RELAY NO. 2 OUTPUT

87A --

FAN STAGE 1 RELAY (RELAY BLOCK)CAV CIRCUIT FUNCTION

30 14BK/VT FAN STAGE 1 RELAY OUTPUT

85 16BR GROUND

86 16BL/YL FAN STAGE 1 RELAY HIGH SIDE CONTROL

87 16RD/WT FUSED B(+)

87A --

OPTIONAL EQUIPMENT RELAY (RELAY BLOCK)CAV CIRCUIT FUNCTION

30 10RD FUSED B(+)

85 16BR GROUND

86 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

87 10BK OPTIONAL EQUIPMENT RELAY OUTPUT

87A --

REMOTE KEYLESS ENTRY ANTENNACAV CIRCUIT FUNCTION

1 20BR RKE ANTENNA

3 - GROUND

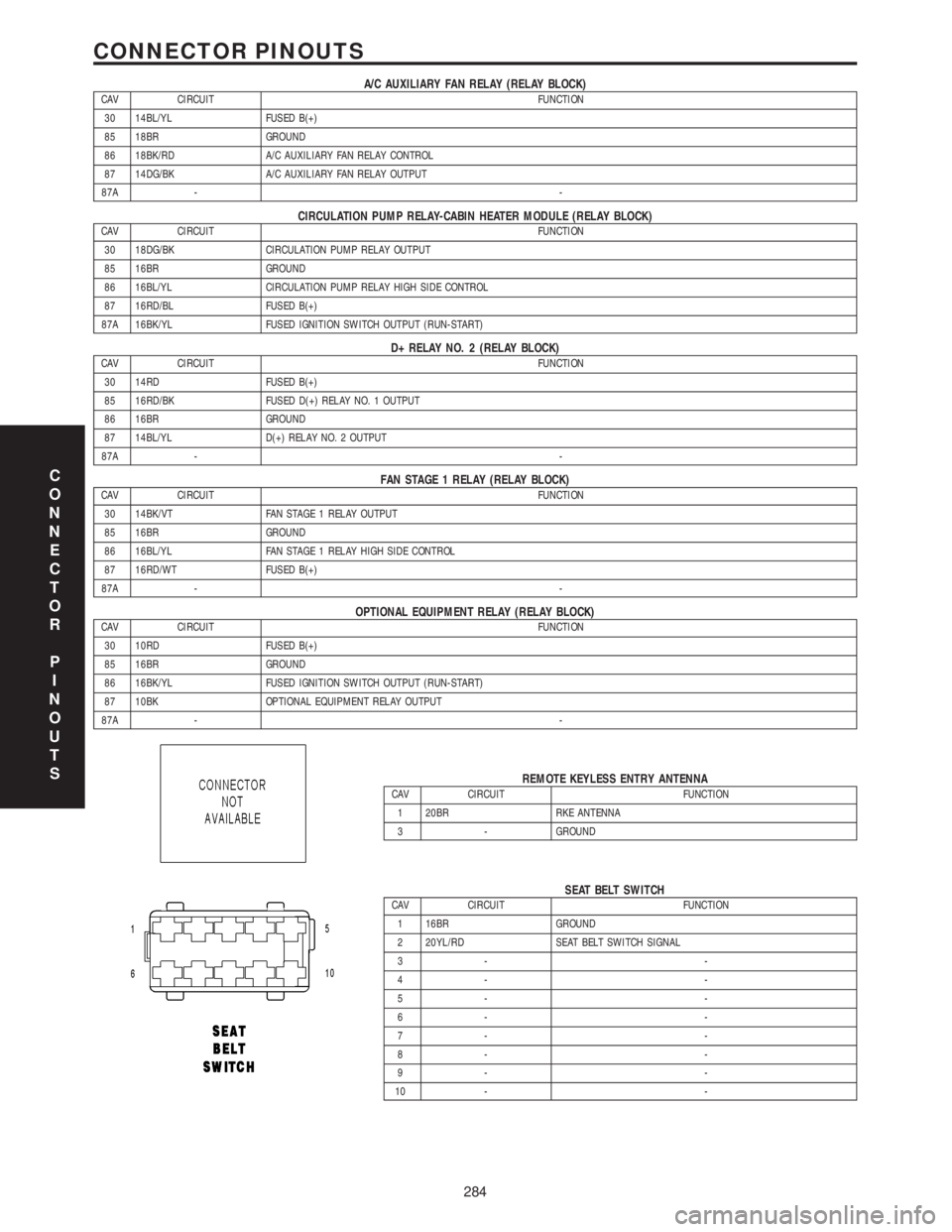

SEAT BELT SWITCHCAV CIRCUIT FUNCTION

1 16BR GROUND

2 20YL/RD SEAT BELT SWITCH SIGNAL

3- -

4- -

5- -

6- -

7- -

8- -

9- -

10 - -

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

284

CONNECTOR PINOUTS

Page 298 of 2305

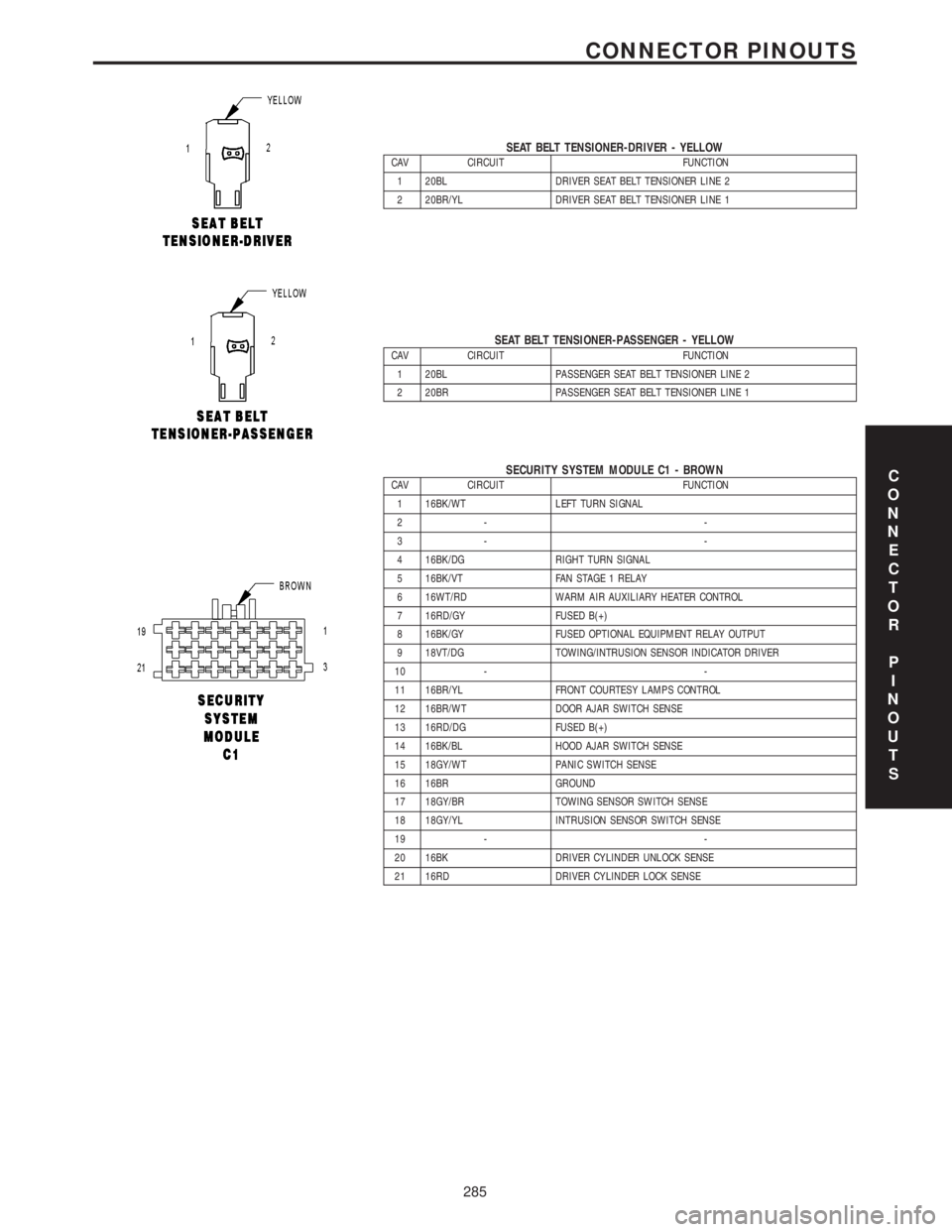

SEAT BELT TENSIONER-DRIVER - YELLOWCAV CIRCUIT FUNCTION

1 20BL DRIVER SEAT BELT TENSIONER LINE 2

2 20BR/YL DRIVER SEAT BELT TENSIONER LINE 1

SEAT BELT TENSIONER-PASSENGER - YELLOWCAV CIRCUIT FUNCTION

1 20BL PASSENGER SEAT BELT TENSIONER LINE 2

2 20BR PASSENGER SEAT BELT TENSIONER LINE 1

SECURITY SYSTEM MODULE C1 - BROWNCAV CIRCUIT FUNCTION

1 16BK/WT LEFT TURN SIGNAL

2- -

3- -

4 16BK/DG RIGHT TURN SIGNAL

5 16BK/VT FAN STAGE 1 RELAY

6 16WT/RD WARM AIR AUXILIARY HEATER CONTROL

7 16RD/GY FUSED B(+)

8 16BK/GY FUSED OPTIONAL EQUIPMENT RELAY OUTPUT

9 18VT/DG TOWING/INTRUSION SENSOR INDICATOR DRIVER

10 - -

11 16BR/YL FRONT COURTESY LAMPS CONTROL

12 16BR/WT DOOR AJAR SWITCH SENSE

13 16RD/DG FUSED B(+)

14 16BK/BL HOOD AJAR SWITCH SENSE

15 18GY/WT PANIC SWITCH SENSE

16 16BR GROUND

17 18GY/BR TOWING SENSOR SWITCH SENSE

18 18GY/YL INTRUSION SENSOR SWITCH SENSE

19 - -

20 16BK DRIVER CYLINDER UNLOCK SENSE

21 16RD DRIVER CYLINDER LOCK SENSEC

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

285

CONNECTOR PINOUTS

Page 299 of 2305

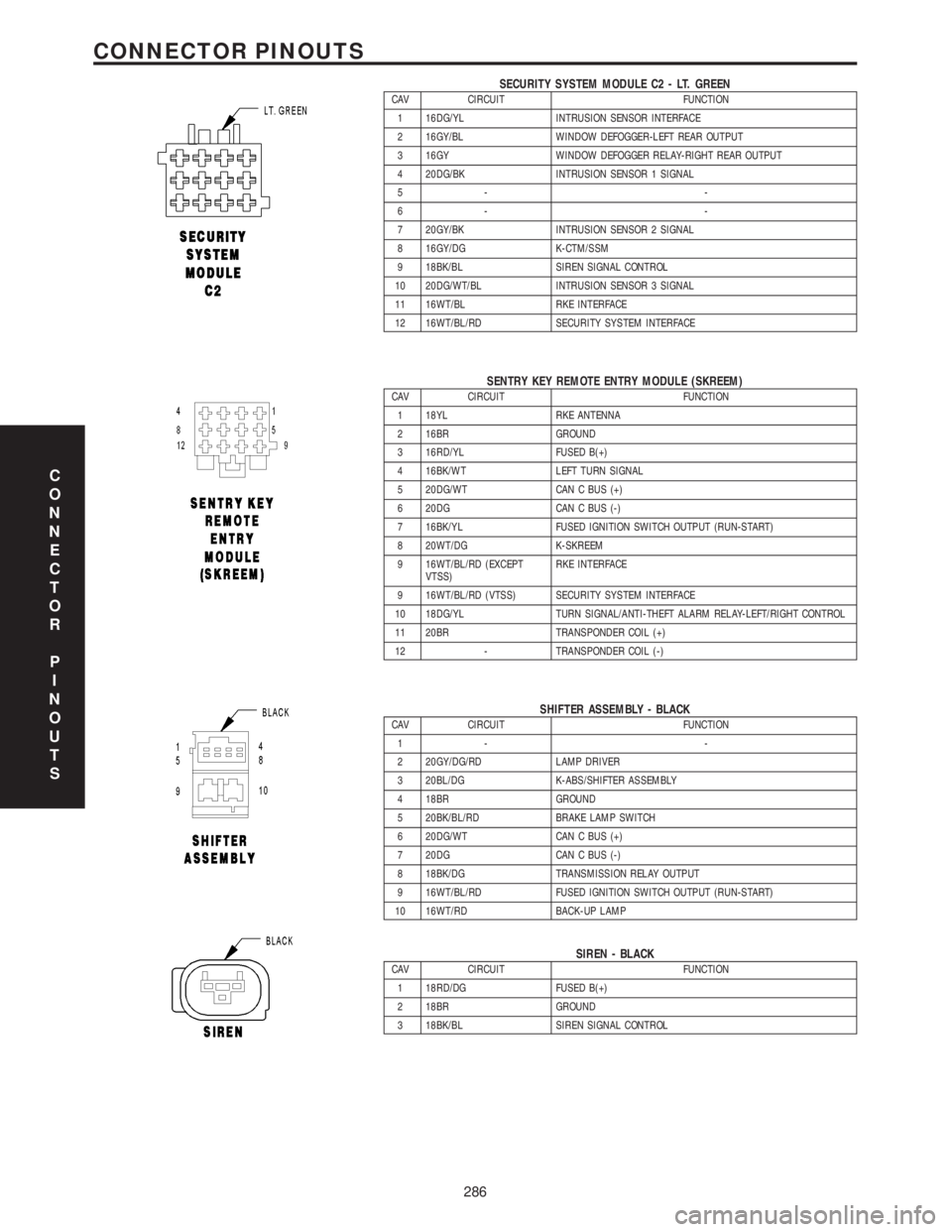

SECURITY SYSTEM MODULE C2 - LT. GREENCAV CIRCUIT FUNCTION

1 16DG/YL INTRUSION SENSOR INTERFACE

2 16GY/BL WINDOW DEFOGGER-LEFT REAR OUTPUT

3 16GY WINDOW DEFOGGER RELAY-RIGHT REAR OUTPUT

4 20DG/BK INTRUSION SENSOR 1 SIGNAL

5- -

6- -

7 20GY/BK INTRUSION SENSOR 2 SIGNAL

8 16GY/DG K-CTM/SSM

9 18BK/BL SIREN SIGNAL CONTROL

10 20DG/WT/BL INTRUSION SENSOR 3 SIGNAL

11 16WT/BL RKE INTERFACE

12 16WT/BL/RD SECURITY SYSTEM INTERFACE

SENTRY KEY REMOTE ENTRY MODULE (SKREEM)CAV CIRCUIT FUNCTION

1 18YL RKE ANTENNA

2 16BR GROUND

3 16RD/YL FUSED B(+)

4 16BK/WT LEFT TURN SIGNAL

5 20DG/WT CAN C BUS (+)

6 20DG CAN C BUS (-)

7 16BK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

8 20WT/DG K-SKREEM

9 16WT/BL/RD (EXCEPT

VTSS)RKE INTERFACE

9 16WT/BL/RD (VTSS) SECURITY SYSTEM INTERFACE

10 18DG/YL TURN SIGNAL/ANTI-THEFT ALARM RELAY-LEFT/RIGHT CONTROL

11 20BR TRANSPONDER COIL (+)

12 - TRANSPONDER COIL (-)

SHIFTER ASSEMBLY - BLACKCAV CIRCUIT FUNCTION

1- -

2 20GY/DG/RD LAMP DRIVER

3 20BL/DG K-ABS/SHIFTER ASSEMBLY

4 18BR GROUND

5 20BK/BL/RD BRAKE LAMP SWITCH

6 20DG/WT CAN C BUS (+)

7 20DG CAN C BUS (-)

8 18BK/DG TRANSMISSION RELAY OUTPUT

9 16WT/BL/RD FUSED IGNITION SWITCH OUTPUT (RUN-START)

10 16WT/RD BACK-UP LAMP

SIREN - BLACKCAV CIRCUIT FUNCTION

1 18RD/DG FUSED B(+)

2 18BR GROUND

3 18BK/BL SIREN SIGNAL CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

286

CONNECTOR PINOUTS

Page 300 of 2305

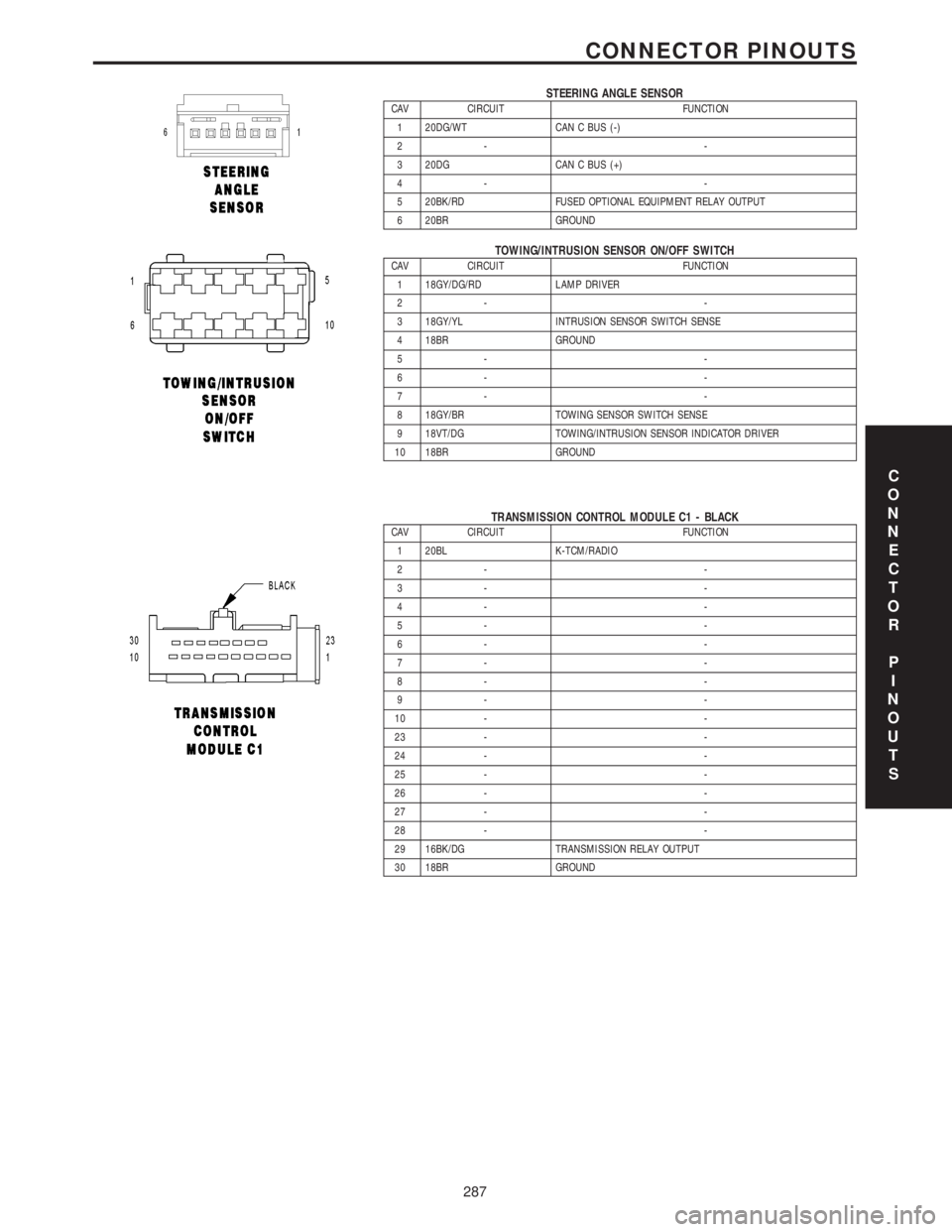

STEERING ANGLE SENSORCAV CIRCUIT FUNCTION

1 20DG/WT CAN C BUS (-)

2- -

3 20DG CAN C BUS (+)

4- -

5 20BK/RD FUSED OPTIONAL EQUIPMENT RELAY OUTPUT

6 20BR GROUND

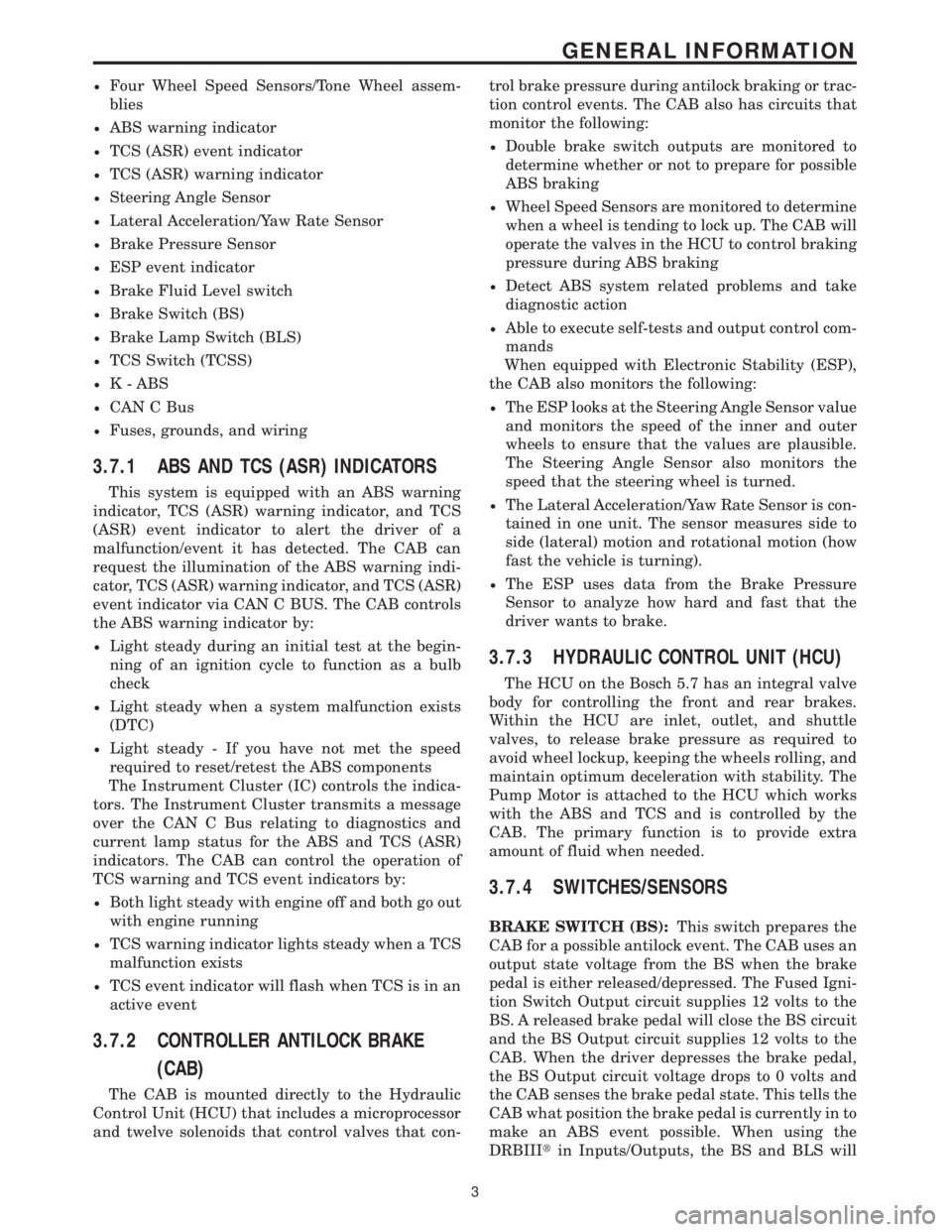

TOWING/INTRUSION SENSOR ON/OFF SWITCHCAV CIRCUIT FUNCTION

1 18GY/DG/RD LAMP DRIVER

2- -

3 18GY/YL INTRUSION SENSOR SWITCH SENSE

4 18BR GROUND

5- -

6- -

7- -

8 18GY/BR TOWING SENSOR SWITCH SENSE

9 18VT/DG TOWING/INTRUSION SENSOR INDICATOR DRIVER

10 18BR GROUND

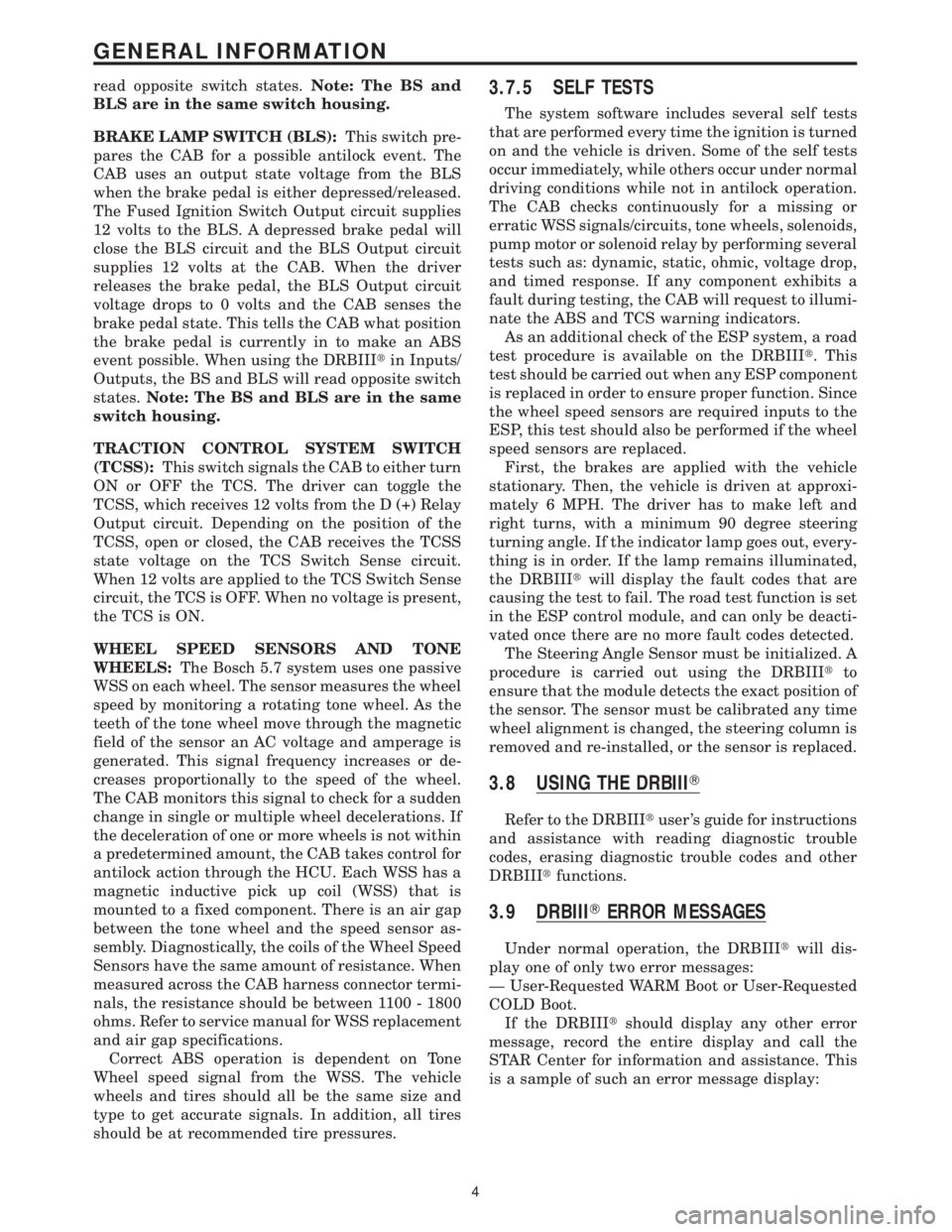

TRANSMISSION CONTROL MODULE C1 - BLACKCAV CIRCUIT FUNCTION

1 20BL K-TCM/RADIO

2- -

3- -

4- -

5- -

6- -

7- -

8- -

9- -

10 - -

23 - -

24 - -

25 - -

26 - -

27 - -

28 - -

29 16BK/DG TRANSMISSION RELAY OUTPUT

30 18BR GROUND

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

287

CONNECTOR PINOUTS

Page 324 of 2305

²Four Wheel Speed Sensors/Tone Wheel assem-

blies

²ABS warning indicator

²TCS (ASR) event indicator

²TCS (ASR) warning indicator

²Steering Angle Sensor

²Lateral Acceleration/Yaw Rate Sensor

²Brake Pressure Sensor

²ESP event indicator

²Brake Fluid Level switch

²Brake Switch (BS)

²Brake Lamp Switch (BLS)

²TCS Switch (TCSS)

²K - ABS

²CAN C Bus

²Fuses, grounds, and wiring

3.7.1 ABS AND TCS (ASR) INDICATORS

This system is equipped with an ABS warning

indicator, TCS (ASR) warning indicator, and TCS

(ASR) event indicator to alert the driver of a

malfunction/event it has detected. The CAB can

request the illumination of the ABS warning indi-

cator, TCS (ASR) warning indicator, and TCS (ASR)

event indicator via CAN C BUS. The CAB controls

the ABS warning indicator by:

²Light steady during an initial test at the begin-

ning of an ignition cycle to function as a bulb

check

²Light steady when a system malfunction exists

(DTC)

²Light steady - If you have not met the speed

required to reset/retest the ABS components

The Instrument Cluster (IC) controls the indica-

tors. The Instrument Cluster transmits a message

over the CAN C Bus relating to diagnostics and

current lamp status for the ABS and TCS (ASR)

indicators. The CAB can control the operation of

TCS warning and TCS event indicators by:

²Both light steady with engine off and both go out

with engine running

²TCS warning indicator lights steady when a TCS

malfunction exists

²TCS event indicator will flash when TCS is in an

active event

3.7.2 CONTROLLER ANTILOCK BRAKE

(CAB)

The CAB is mounted directly to the Hydraulic

Control Unit (HCU) that includes a microprocessor

and twelve solenoids that control valves that con-trol brake pressure during antilock braking or trac-

tion control events. The CAB also has circuits that

monitor the following:

²Double brake switch outputs are monitored to

determine whether or not to prepare for possible

ABS braking

²Wheel Speed Sensors are monitored to determine

when a wheel is tending to lock up. The CAB will

operate the valves in the HCU to control braking

pressure during ABS braking

²Detect ABS system related problems and take

diagnostic action

²Able to execute self-tests and output control com-

mands

When equipped with Electronic Stability (ESP),

the CAB also monitors the following:

²The ESP looks at the Steering Angle Sensor value

and monitors the speed of the inner and outer

wheels to ensure that the values are plausible.

The Steering Angle Sensor also monitors the

speed that the steering wheel is turned.

²The Lateral Acceleration/Yaw Rate Sensor is con-

tained in one unit. The sensor measures side to

side (lateral) motion and rotational motion (how

fast the vehicle is turning).

²The ESP uses data from the Brake Pressure

Sensor to analyze how hard and fast that the

driver wants to brake.

3.7.3 HYDRAULIC CONTROL UNIT (HCU)

The HCU on the Bosch 5.7 has an integral valve

body for controlling the front and rear brakes.

Within the HCU are inlet, outlet, and shuttle

valves, to release brake pressure as required to

avoid wheel lockup, keeping the wheels rolling, and

maintain optimum deceleration with stability. The

Pump Motor is attached to the HCU which works

with the ABS and TCS and is controlled by the

CAB. The primary function is to provide extra

amount of fluid when needed.

3.7.4 SWITCHES/SENSORS

BRAKE SWITCH (BS):This switch prepares the

CAB for a possible antilock event. The CAB uses an

output state voltage from the BS when the brake

pedal is either released/depressed. The Fused Igni-

tion Switch Output circuit supplies 12 volts to the

BS. A released brake pedal will close the BS circuit

and the BS Output circuit supplies 12 volts to the

CAB. When the driver depresses the brake pedal,

the BS Output circuit voltage drops to 0 volts and

the CAB senses the brake pedal state. This tells the

CAB what position the brake pedal is currently in to

make an ABS event possible. When using the

DRBIIItin Inputs/Outputs, the BS and BLS will

3

GENERAL INFORMATION

Page 325 of 2305

read opposite switch states.Note: The BS and

BLS are in the same switch housing.

BRAKE LAMP SWITCH (BLS):This switch pre-

pares the CAB for a possible antilock event. The

CAB uses an output state voltage from the BLS

when the brake pedal is either depressed/released.

The Fused Ignition Switch Output circuit supplies

12 volts to the BLS. A depressed brake pedal will

close the BLS circuit and the BLS Output circuit

supplies 12 volts at the CAB. When the driver

releases the brake pedal, the BLS Output circuit

voltage drops to 0 volts and the CAB senses the

brake pedal state. This tells the CAB what position

the brake pedal is currently in to make an ABS

event possible. When using the DRBIIItin Inputs/

Outputs, the BS and BLS will read opposite switch

states.Note: The BS and BLS are in the same

switch housing.

TRACTION CONTROL SYSTEM SWITCH

(TCSS):This switch signals the CAB to either turn

ON or OFF the TCS. The driver can toggle the

TCSS, which receives 12 volts from the D (+) Relay

Output circuit. Depending on the position of the

TCSS, open or closed, the CAB receives the TCSS

state voltage on the TCS Switch Sense circuit.

When 12 volts are applied to the TCS Switch Sense

circuit, the TCS is OFF. When no voltage is present,

the TCS is ON.

WHEEL SPEED SENSORS AND TONE

WHEELS:The Bosch 5.7 system uses one passive

WSS on each wheel. The sensor measures the wheel

speed by monitoring a rotating tone wheel. As the

teeth of the tone wheel move through the magnetic

field of the sensor an AC voltage and amperage is

generated. This signal frequency increases or de-

creases proportionally to the speed of the wheel.

The CAB monitors this signal to check for a sudden

change in single or multiple wheel decelerations. If

the deceleration of one or more wheels is not within

a predetermined amount, the CAB takes control for

antilock action through the HCU. Each WSS has a

magnetic inductive pick up coil (WSS) that is

mounted to a fixed component. There is an air gap

between the tone wheel and the speed sensor as-

sembly. Diagnostically, the coils of the Wheel Speed

Sensors have the same amount of resistance. When

measured across the CAB harness connector termi-

nals, the resistance should be between 1100 - 1800

ohms. Refer to service manual for WSS replacement

and air gap specifications.

Correct ABS operation is dependent on Tone

Wheel speed signal from the WSS. The vehicle

wheels and tires should all be the same size and

type to get accurate signals. In addition, all tires

should be at recommended tire pressures.3.7.5 SELF TESTS

The system software includes several self tests

that are performed every time the ignition is turned

on and the vehicle is driven. Some of the self tests

occur immediately, while others occur under normal

driving conditions while not in antilock operation.

The CAB checks continuously for a missing or

erratic WSS signals/circuits, tone wheels, solenoids,

pump motor or solenoid relay by performing several

tests such as: dynamic, static, ohmic, voltage drop,

and timed response. If any component exhibits a

fault during testing, the CAB will request to illumi-

nate the ABS and TCS warning indicators.

As an additional check of the ESP system, a road

test procedure is available on the DRBIIIt. This

test should be carried out when any ESP component

is replaced in order to ensure proper function. Since

the wheel speed sensors are required inputs to the

ESP, this test should also be performed if the wheel

speed sensors are replaced.

First, the brakes are applied with the vehicle

stationary. Then, the vehicle is driven at approxi-

mately 6 MPH. The driver has to make left and

right turns, with a minimum 90 degree steering

turning angle. If the indicator lamp goes out, every-

thing is in order. If the lamp remains illuminated,

the DRBIIItwill display the fault codes that are

causing the test to fail. The road test function is set

in the ESP control module, and can only be deacti-

vated once there are no more fault codes detected.

The Steering Angle Sensor must be initialized. A

procedure is carried out using the DRBIIItto

ensure that the module detects the exact position of

the sensor. The sensor must be calibrated any time

wheel alignment is changed, the steering column is

removed and re-installed, or the sensor is replaced.

3.8 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading diagnostic trouble

codes, erasing diagnostic trouble codes and other

DRBIIItfunctions.

3.9 DRBIIITERROR MESSAGES

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

Ð User-Requested WARM Boot or User-Requested

COLD Boot.

If the DRBIIItshould display any other error

message, record the entire display and call the

STAR Center for information and assistance. This

is a sample of such an error message display:

4

GENERAL INFORMATION

Page 327 of 2305

4.2.4 DRBIIITSAFETY INFORMATION

WARNING: EXCEEDING THE LIMITS OF THE

DRBIIITMULTIMETER IS DANGEROUS. IT

CAN EXPOSE YOU TO SERIOUS OR

POSSIBLE FATAL INJURY. CAREFULLY

READ AND UNDERSTAND THE CAUTIONS

AND THE SPECIFICATION LIMITS.

²Follow the vehicle manufacturer 's service speci-

fications at all times.

²Do not use the DRBIIItif it has been damaged.

²Do not use the test leads if the insulation is

damaged or if metal is exposed.

²To avoid electrical shock, do not touch the test

leads, tips, or the circuit being tested.

²Choose the proper range and function for the

measurement. Do not try voltage or current mea-

surements that may exceed the rated capacity.

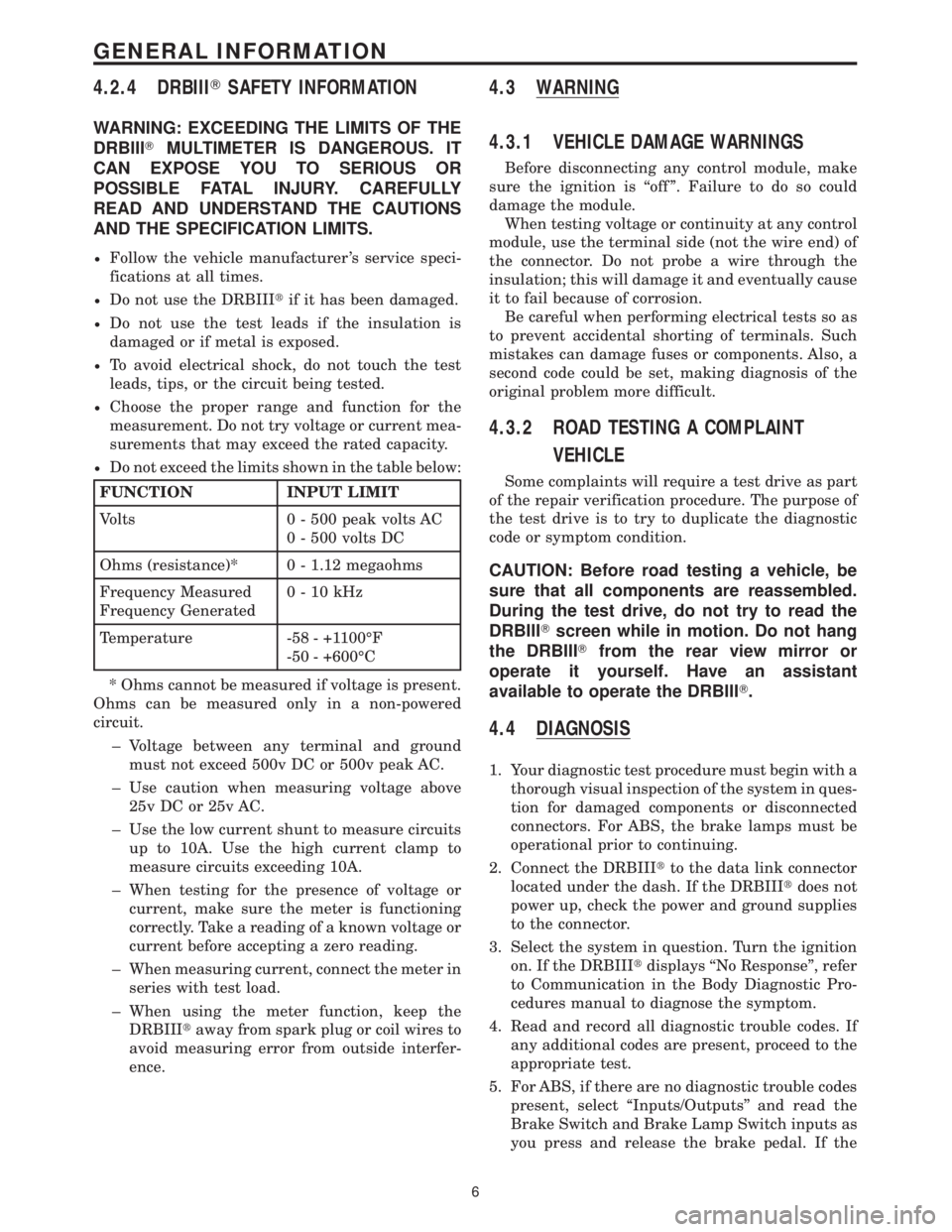

²Do not exceed the limits shown in the table below:

FUNCTION INPUT LIMIT

Volts 0 - 500 peak volts AC

0 - 500 volts DC

Ohms (resistance)* 0 - 1.12 megaohms

Frequency Measured

Frequency Generated0-10kHz

Temperature -58 - +1100ÉF

-50 - +600ÉC

* Ohms cannot be measured if voltage is present.

Ohms can be measured only in a non-powered

circuit.

± Voltage between any terminal and ground

must not exceed 500v DC or 500v peak AC.

± Use caution when measuring voltage above

25v DC or 25v AC.

± Use the low current shunt to measure circuits

up to 10A. Use the high current clamp to

measure circuits exceeding 10A.

± When testing for the presence of voltage or

current, make sure the meter is functioning

correctly. Take a reading of a known voltage or

current before accepting a zero reading.

± When measuring current, connect the meter in

series with test load.

± When using the meter function, keep the

DRBIIItaway from spark plug or coil wires to

avoid measuring error from outside interfer-

ence.

4.3 WARNING

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is ``off ''. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

4.3.2 ROAD TESTING A COMPLAINT

VEHICLE

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: Before road testing a vehicle, be

sure that all components are reassembled.

During the test drive, do not try to read the

DRBIIITscreen while in motion. Do not hang

the DRBIIITfrom the rear view mirror or

operate it yourself. Have an assistant

available to operate the DRBIIIT.

4.4 DIAGNOSIS

1. Your diagnostic test procedure must begin with a

thorough visual inspection of the system in ques-

tion for damaged components or disconnected

connectors. For ABS, the brake lamps must be

operational prior to continuing.

2. Connect the DRBIIItto the data link connector

located under the dash. If the DRBIIItdoes not

power up, check the power and ground supplies

to the connector.

3. Select the system in question. Turn the ignition

on. If the DRBIIItdisplays ``No Responseº, refer

to Communication in the Body Diagnostic Pro-

cedures manual to diagnose the symptom.

4. Read and record all diagnostic trouble codes. If

any additional codes are present, proceed to the

appropriate test.

5. For ABS, if there are no diagnostic trouble codes

present, select ``Inputs/Outputs'' and read the

Brake Switch and Brake Lamp Switch inputs as

you press and release the brake pedal. If the

6

GENERAL INFORMATION

Page 331 of 2305

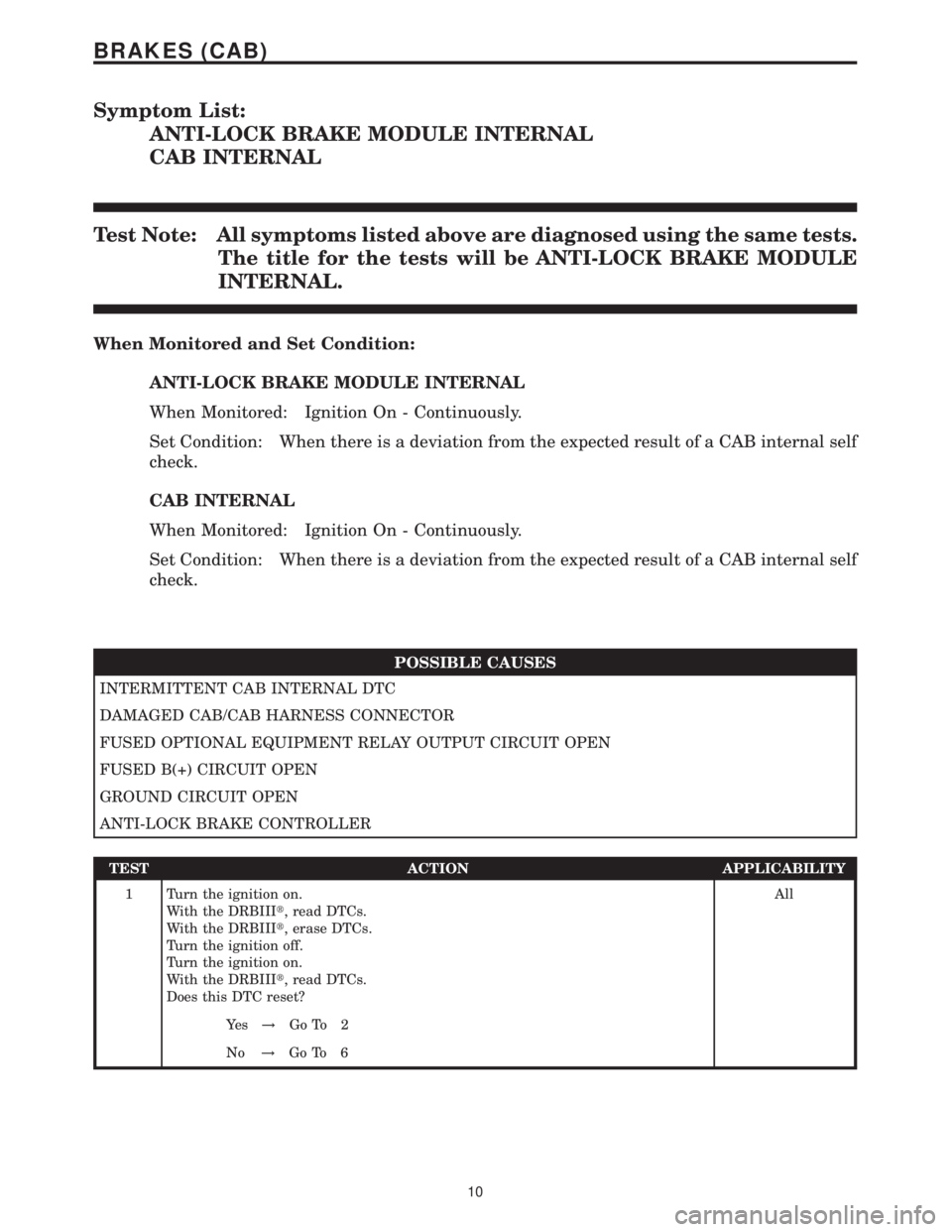

Symptom List:

ANTI-LOCK BRAKE MODULE INTERNAL

CAB INTERNAL

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be ANTI-LOCK BRAKE MODULE

INTERNAL.

When Monitored and Set Condition:

ANTI-LOCK BRAKE MODULE INTERNAL

When Monitored: Ignition On - Continuously.

Set Condition: When there is a deviation from the expected result of a CAB internal self

check.

CAB INTERNAL

When Monitored: Ignition On - Continuously.

Set Condition: When there is a deviation from the expected result of a CAB internal self

check.

POSSIBLE CAUSES

INTERMITTENT CAB INTERNAL DTC

DAMAGED CAB/CAB HARNESS CONNECTOR

FUSED OPTIONAL EQUIPMENT RELAY OUTPUT CIRCUIT OPEN

FUSED B(+) CIRCUIT OPEN

GROUND CIRCUIT OPEN

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 6

10

BRAKES (CAB)

Page 332 of 2305

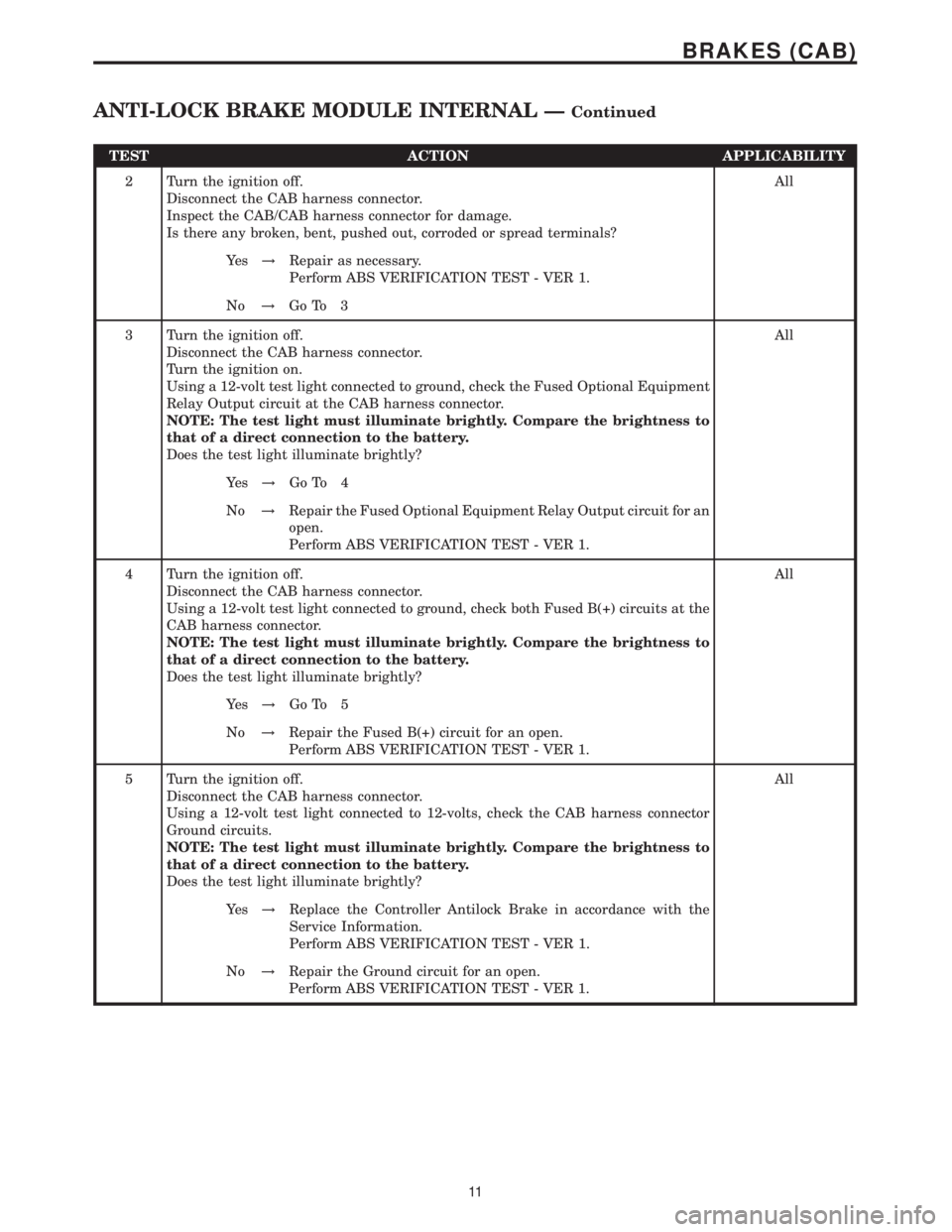

TEST ACTION APPLICABILITY

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Optional Equipment

Relay Output circuit at the CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 4

No!Repair the Fused Optional Equipment Relay Output circuit for an

open.

Perform ABS VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to ground, check both Fused B(+) circuits at the

CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 5

No!Repair the Fused B(+) circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to 12-volts, check the CAB harness connector

Ground circuits.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No!Repair the Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

11

BRAKES (CAB)

ANTI-LOCK BRAKE MODULE INTERNAL ÐContinued