radio MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1572 of 2305

OPERATION

All of the circuits entering and leaving the fuse

block do so through the instrument panel wire har-

ness. Internal connection of all of the fuse block cir-

cuits is accomplished by an intricate combination of

hard wiring and bus bars. Internal relays and micro

processors allow the vehicle electronics to control

some of the power distribution circuits throughout

the vehicle. Refer to the Wiring section for complete

circuit diagrams.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove fuse block cover by rotating locking

screw 90É.

(3) Remove the steering column cover. Refer to the

Body section for the procedure.

(4) Unscrew fuse block connections and disconnect

all electrical connectors from the fuse block.

(5) Remove the fuse block from the steering col-

umn.

INSTALLATION

(1) Position the fuse block in the steering column.

(2) Install fuse block connections and connect all

electrical connectors on the fuse block.

(3) Install the steering column cover. Refer to the

Body section for the procedure.

(4) Install fuse block cover by rotating locking

screw 90É.

(5) Connect the negative battery cable.

(6) Set time and radio stations.

FUSE BLOCK #2

DESCRIPTION

An electrical fuse block is concealed under the

driver side front seat. The fuse block serves to dis-

tribute electrical current to many of the electrical

systems in the vehicle. The fuse block houses blade-

type mini fuses, blade-type automatic resetting cir-

cuit breakers and International Standards

Organization relays. Additional provisions are avail-

able in the fuse block for additional fuses and ISO

relays.

The molded plastic fuse block housing has an inte-

gral mounting bracket that is secured with screws to

the seat base. The driver side seat base also has a

snap-fit fuse access panel that can be removed for

service of the fuses and the relays. A finger recess is

molded into one end for easy removal. A fuse layout

map is molded onto the back side of the panel to

ensure proper fuse identification.

The fuse block is integral to the body wire harness.

If any internal circuit or the fuse block housing isfaulty or damaged, the entire fuse block and body

wire harness unit must be replaced.

OPERATION

All of the circuits entering and leaving the fuse

block do so through the body wire harness. Internal

connection of all of the fuse block circuits is accom-

plished by an intricate combination of hard wiring

and bus bars.

POWER DISTRIBUTION CEN-

TER

DESCRIPTION

All of the electrical current distributed throughout

this vehicle is directed through the Power Distribu-

tion Center (PDC). The molded plastic PDC housing

is located in the left front corner of the engine com-

partment, on the battery positive cable. The PDC

housing has a molded plastic cover that slides over

the PDC housing. The PDC cover is easily opened or

removed for service access.

The PDC unit cannot be repaired and is only ser-

viced as a unit with the headlamp and dash wire

harness. If the internal circuits or the PDC housing

are faulty or damaged, the headlamp and dash wire

harness unit must be replaced.

OPERATION

All of the current from the battery and the gener-

ator output enters the PDC through the positive bat-

tery cable. The PDC cover is removed to access the

battery and generator output connection B(+) termi-

nal studs. Internal connection of all of the PDC cir-

cuits is accomplished by an intricate combination of

hard wiring and bus bars. Refer to Wiring Diagrams

for the location of complete PDC circuit diagrams.

POWER OUTLET

DESCRIPTION

The power outlet is installed in the instrument

panel accessory switch plate, which is located near

the center of the instrument panel. The power outlet

base is secured by a snap fit within the instrument

panel. A plastic protective cap snaps over the power

outlet base when the power outlet is not being used.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

The power outlet receptacle unit are available for

service. The power outlet receptacle cannot be

VA8W-97 POWER DISTRIBUTION 8W - 97 - 3

Page 1735 of 2305

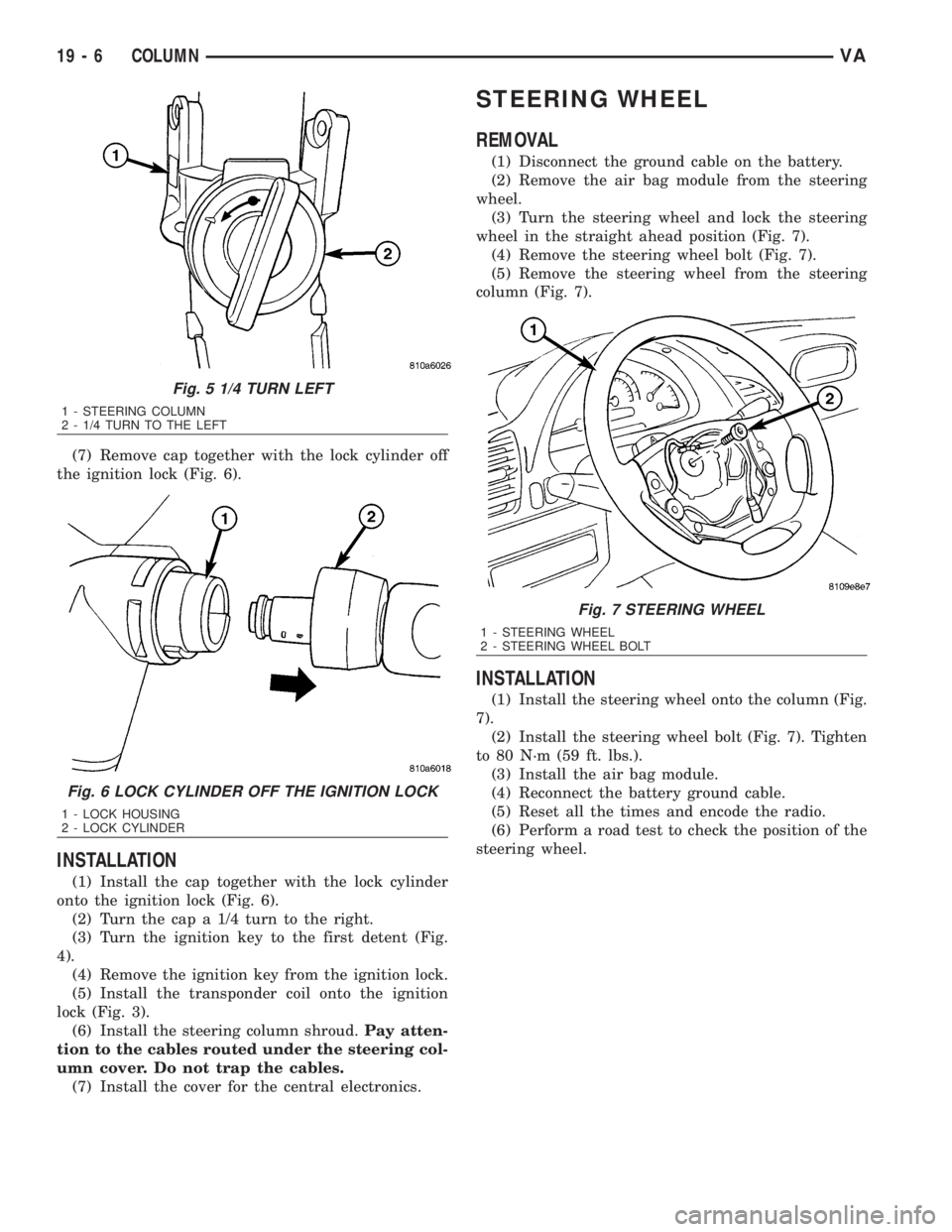

(7) Remove cap together with the lock cylinder off

the ignition lock (Fig. 6).

INSTALLATION

(1) Install the cap together with the lock cylinder

onto the ignition lock (Fig. 6).

(2) Turn the cap a 1/4 turn to the right.

(3) Turn the ignition key to the first detent (Fig.

4).

(4) Remove the ignition key from the ignition lock.

(5) Install the transponder coil onto the ignition

lock (Fig. 3).

(6) Install the steering column shroud.Pay atten-

tion to the cables routed under the steering col-

umn cover. Do not trap the cables.

(7) Install the cover for the central electronics.

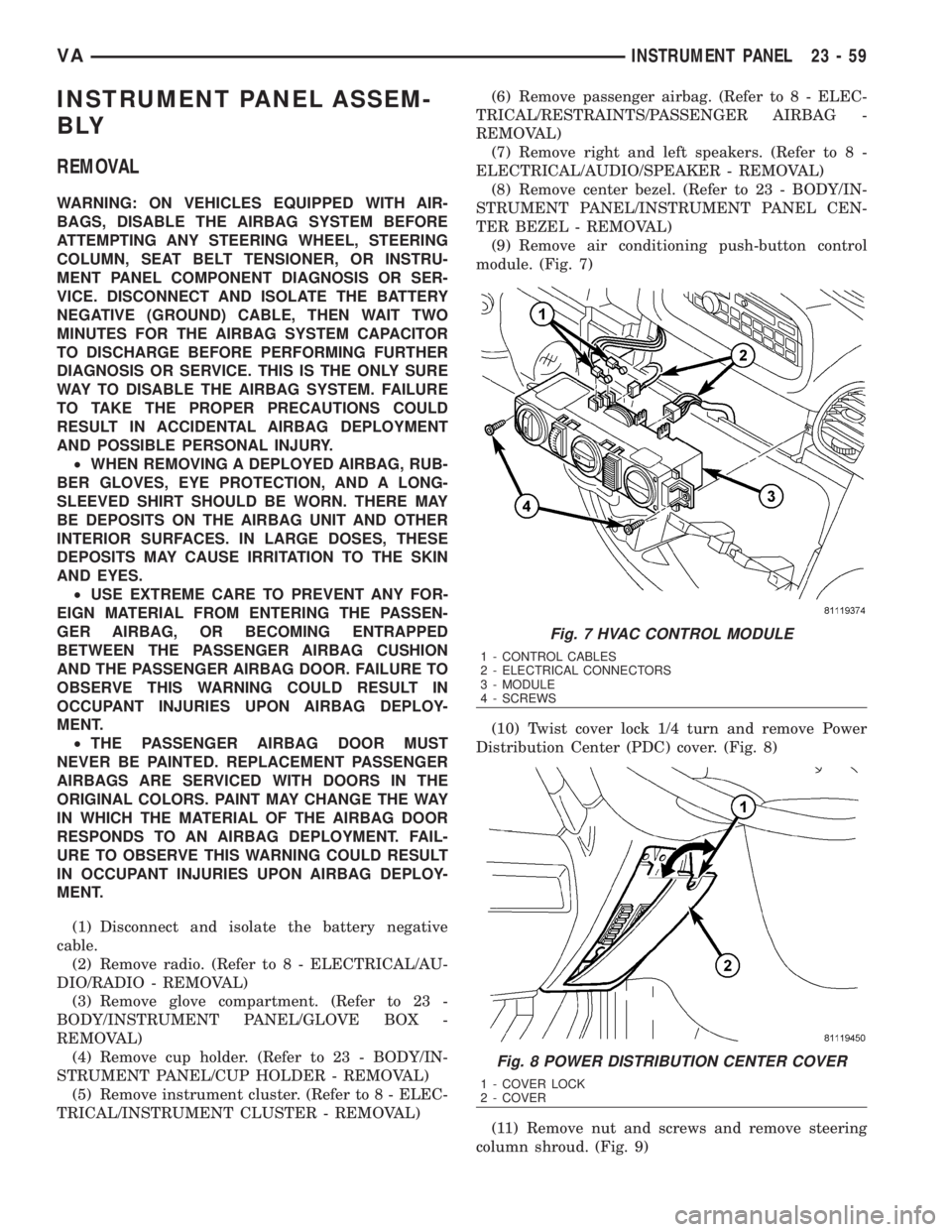

STEERING WHEEL

REMOVAL

(1) Disconnect the ground cable on the battery.

(2) Remove the air bag module from the steering

wheel.

(3) Turn the steering wheel and lock the steering

wheel in the straight ahead position (Fig. 7).

(4) Remove the steering wheel bolt (Fig. 7).

(5) Remove the steering wheel from the steering

column (Fig. 7).

INSTALLATION

(1) Install the steering wheel onto the column (Fig.

7).

(2) Install the steering wheel bolt (Fig. 7). Tighten

to 80 N´m (59 ft. lbs.).

(3) Install the air bag module.

(4) Reconnect the battery ground cable.

(5) Reset all the times and encode the radio.

(6) Perform a road test to check the position of the

steering wheel.

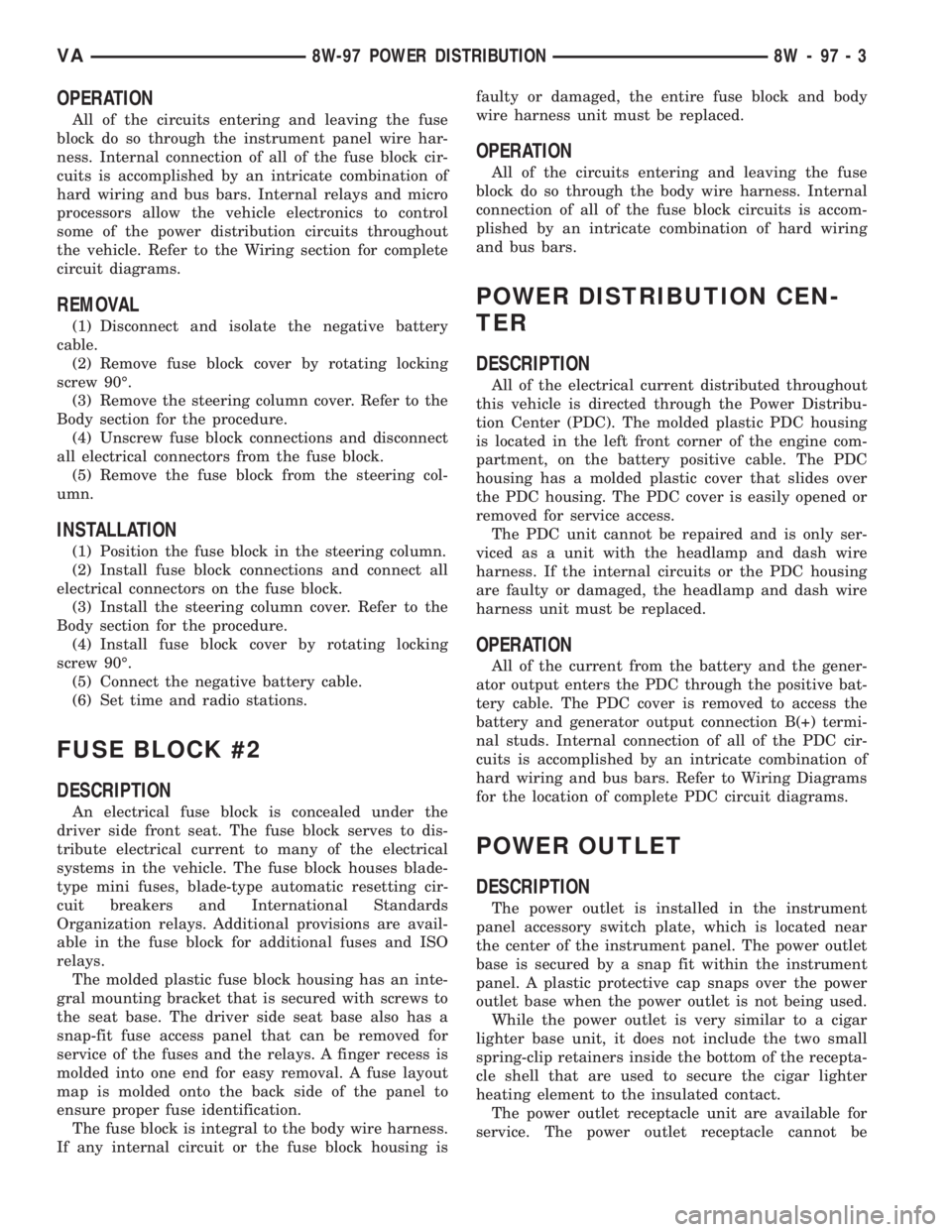

Fig. 5 1/4 TURN LEFT

1 - STEERING COLUMN

2 - 1/4 TURN TO THE LEFT

Fig. 6 LOCK CYLINDER OFF THE IGNITION LOCK

1 - LOCK HOUSING

2 - LOCK CYLINDER

Fig. 7 STEERING WHEEL

1 - STEERING WHEEL

2 - STEERING WHEEL BOLT

19 - 6 COLUMNVA

Page 2002 of 2305

INSTRUMENT PANEL ASSEM-

BLY

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

²WHEN REMOVING A DEPLOYED AIRBAG, RUB-

BER GLOVES, EYE PROTECTION, AND A LONG-

SLEEVED SHIRT SHOULD BE WORN. THERE MAY

BE DEPOSITS ON THE AIRBAG UNIT AND OTHER

INTERIOR SURFACES. IN LARGE DOSES, THESE

DEPOSITS MAY CAUSE IRRITATION TO THE SKIN

AND EYES.

²USE EXTREME CARE TO PREVENT ANY FOR-

EIGN MATERIAL FROM ENTERING THE PASSEN-

GER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

²THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAGS ARE SERVICED WITH DOORS IN THE

ORIGINAL COLORS. PAINT MAY CHANGE THE WAY

IN WHICH THE MATERIAL OF THE AIRBAG DOOR

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove radio. (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - REMOVAL)

(3) Remove glove compartment. (Refer to 23 -

BODY/INSTRUMENT PANEL/GLOVE BOX -

REMOVAL)

(4) Remove cup holder. (Refer to 23 - BODY/IN-

STRUMENT PANEL/CUP HOLDER - REMOVAL)

(5) Remove instrument cluster. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - REMOVAL)(6) Remove passenger airbag. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

REMOVAL)

(7) Remove right and left speakers. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(8) Remove center bezel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL CEN-

TER BEZEL - REMOVAL)

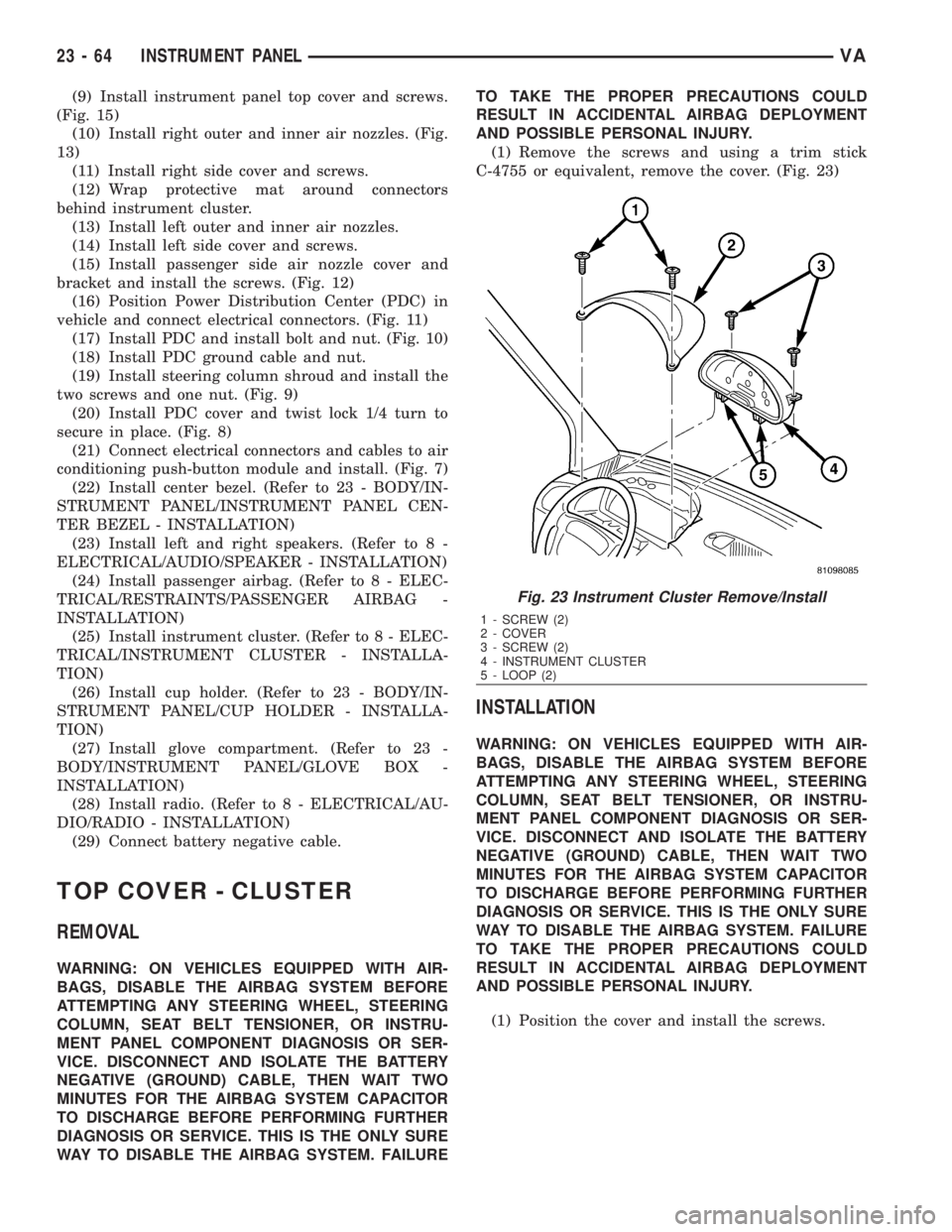

(9) Remove air conditioning push-button control

module. (Fig. 7)

(10) Twist cover lock 1/4 turn and remove Power

Distribution Center (PDC) cover. (Fig. 8)

(11) Remove nut and screws and remove steering

column shroud. (Fig. 9)

Fig. 7 HVAC CONTROL MODULE

1 - CONTROL CABLES

2 - ELECTRICAL CONNECTORS

3 - MODULE

4 - SCREWS

Fig. 8 POWER DISTRIBUTION CENTER COVER

1 - COVER LOCK

2 - COVER

VAINSTRUMENT PANEL 23 - 59

Page 2007 of 2305

(9) Install instrument panel top cover and screws.

(Fig. 15)

(10) Install right outer and inner air nozzles. (Fig.

13)

(11) Install right side cover and screws.

(12) Wrap protective mat around connectors

behind instrument cluster.

(13) Install left outer and inner air nozzles.

(14) Install left side cover and screws.

(15) Install passenger side air nozzle cover and

bracket and install the screws. (Fig. 12)

(16) Position Power Distribution Center (PDC) in

vehicle and connect electrical connectors. (Fig. 11)

(17) Install PDC and install bolt and nut. (Fig. 10)

(18) Install PDC ground cable and nut.

(19) Install steering column shroud and install the

two screws and one nut. (Fig. 9)

(20) Install PDC cover and twist lock 1/4 turn to

secure in place. (Fig. 8)

(21) Connect electrical connectors and cables to air

conditioning push-button module and install. (Fig. 7)

(22) Install center bezel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL CEN-

TER BEZEL - INSTALLATION)

(23) Install left and right speakers. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - INSTALLATION)

(24) Install passenger airbag. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

INSTALLATION)

(25) Install instrument cluster. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - INSTALLA-

TION)

(26) Install cup holder. (Refer to 23 - BODY/IN-

STRUMENT PANEL/CUP HOLDER - INSTALLA-

TION)

(27) Install glove compartment. (Refer to 23 -

BODY/INSTRUMENT PANEL/GLOVE BOX -

INSTALLATION)

(28) Install radio. (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION)

(29) Connect battery negative cable.

TOP COVER - CLUSTER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURETO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the screws and using a trim stick

C-4755 or equivalent, remove the cover. (Fig. 23)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the cover and install the screws.

Fig. 23 Instrument Cluster Remove/Install

1 - SCREW (2)

2 - COVER

3 - SCREW (2)

4 - INSTRUMENT CLUSTER

5 - LOOP (2)

23 - 64 INSTRUMENT PANELVA

Page 2010 of 2305

TOP COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

²WHEN REMOVING A DEPLOYED AIRBAG, RUB-

BER GLOVES, EYE PROTECTION, AND A LONG-

SLEEVED SHIRT SHOULD BE WORN. THERE MAY

BE DEPOSITS ON THE AIRBAG UNIT AND OTHER

INTERIOR SURFACES. IN LARGE DOSES, THESE

DEPOSITS MAY CAUSE IRRITATION TO THE SKIN

AND EYES.

²USE EXTREME CARE TO PREVENT ANY FOR-

EIGN MATERIAL FROM ENTERING THE PASSEN-

GER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

²THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAGS ARE SERVICED WITH DOORS IN THE

ORIGINAL COLORS. PAINT MAY CHANGE THE WAY

IN WHICH THE MATERIAL OF THE AIRBAG DOOR

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove radio. (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - REMOVAL)

(3) Remove passenger airbag. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

REMOVAL)

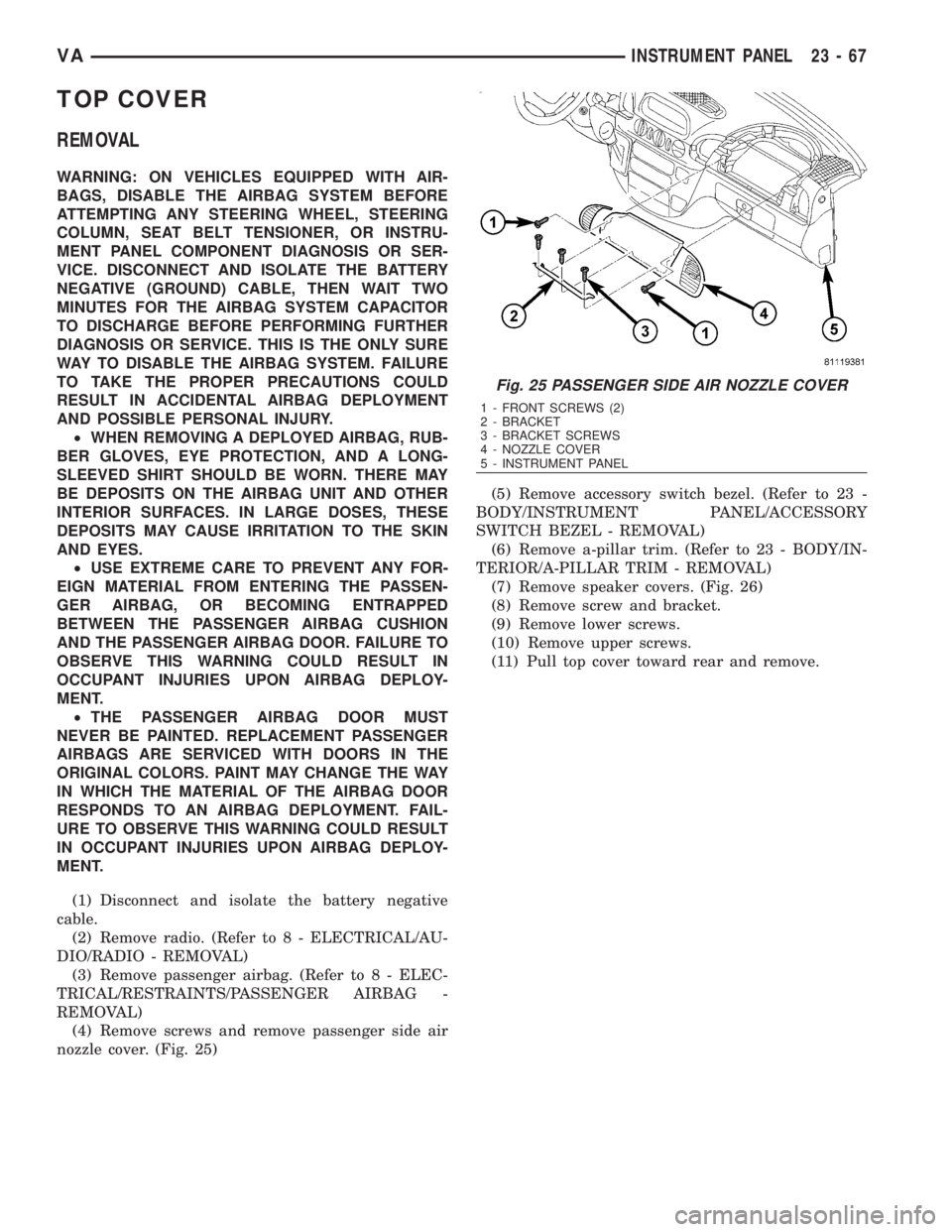

(4) Remove screws and remove passenger side air

nozzle cover. (Fig. 25)(5) Remove accessory switch bezel. (Refer to 23 -

BODY/INSTRUMENT PANEL/ACCESSORY

SWITCH BEZEL - REMOVAL)

(6) Remove a-pillar trim. (Refer to 23 - BODY/IN-

TERIOR/A-PILLAR TRIM - REMOVAL)

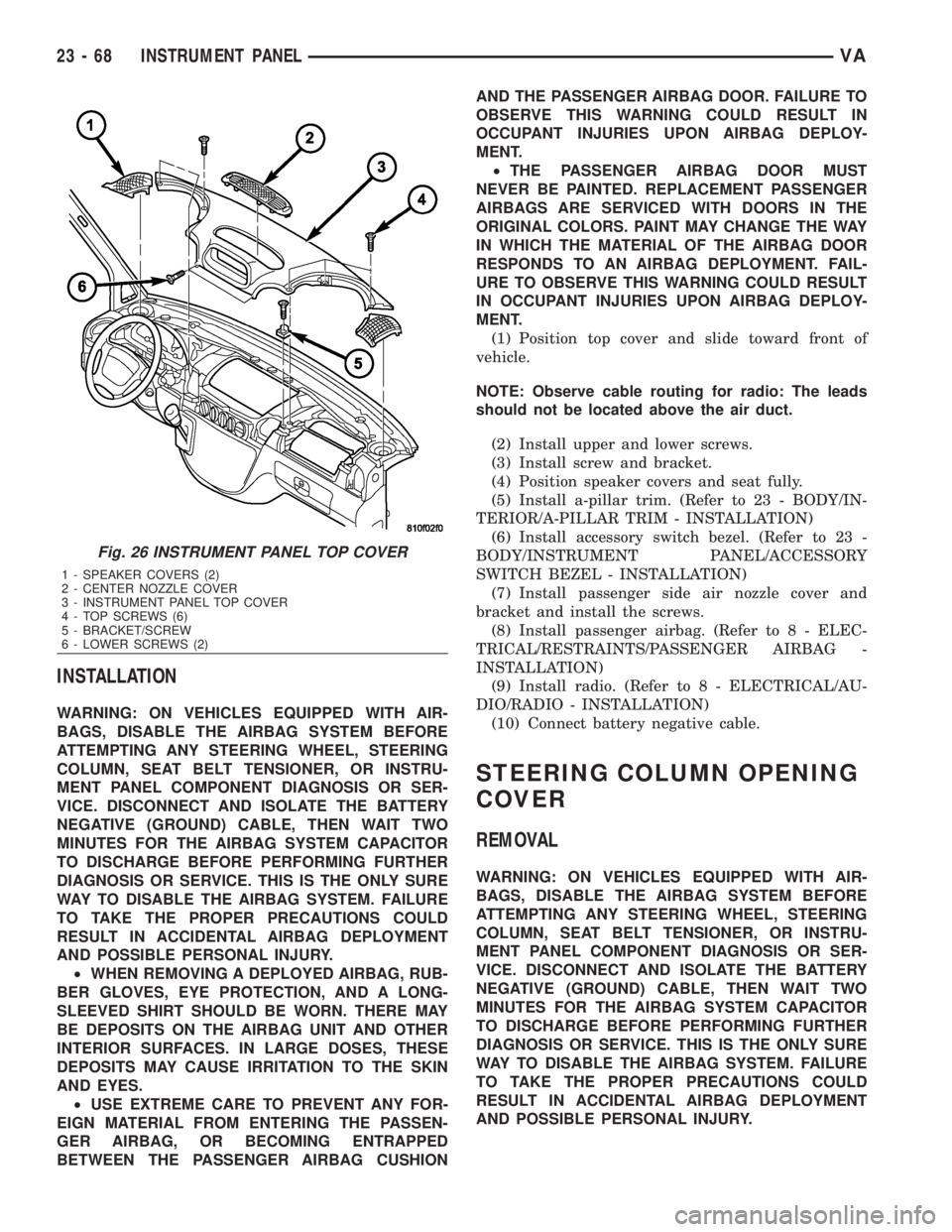

(7) Remove speaker covers. (Fig. 26)

(8) Remove screw and bracket.

(9) Remove lower screws.

(10) Remove upper screws.

(11) Pull top cover toward rear and remove.

Fig. 25 PASSENGER SIDE AIR NOZZLE COVER

1 - FRONT SCREWS (2)

2 - BRACKET

3 - BRACKET SCREWS

4 - NOZZLE COVER

5 - INSTRUMENT PANEL

VAINSTRUMENT PANEL 23 - 67

Page 2011 of 2305

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

²WHEN REMOVING A DEPLOYED AIRBAG, RUB-

BER GLOVES, EYE PROTECTION, AND A LONG-

SLEEVED SHIRT SHOULD BE WORN. THERE MAY

BE DEPOSITS ON THE AIRBAG UNIT AND OTHER

INTERIOR SURFACES. IN LARGE DOSES, THESE

DEPOSITS MAY CAUSE IRRITATION TO THE SKIN

AND EYES.

²USE EXTREME CARE TO PREVENT ANY FOR-

EIGN MATERIAL FROM ENTERING THE PASSEN-

GER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHIONAND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

²THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAGS ARE SERVICED WITH DOORS IN THE

ORIGINAL COLORS. PAINT MAY CHANGE THE WAY

IN WHICH THE MATERIAL OF THE AIRBAG DOOR

RESPONDS TO AN AIRBAG DEPLOYMENT. FAIL-

URE TO OBSERVE THIS WARNING COULD RESULT

IN OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Position top cover and slide toward front of

vehicle.

NOTE: Observe cable routing for radio: The leads

should not be located above the air duct.

(2) Install upper and lower screws.

(3) Install screw and bracket.

(4) Position speaker covers and seat fully.

(5) Install a-pillar trim. (Refer to 23 - BODY/IN-

TERIOR/A-PILLAR TRIM - INSTALLATION)

(6) Install accessory switch bezel. (Refer to 23 -

BODY/INSTRUMENT PANEL/ACCESSORY

SWITCH BEZEL - INSTALLATION)

(7) Install passenger side air nozzle cover and

bracket and install the screws.

(8) Install passenger airbag. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/PASSENGER AIRBAG -

INSTALLATION)

(9) Install radio. (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION)

(10) Connect battery negative cable.

STEERING COLUMN OPENING

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Fig. 26 INSTRUMENT PANEL TOP COVER

1 - SPEAKER COVERS (2)

2 - CENTER NOZZLE COVER

3 - INSTRUMENT PANEL TOP COVER

4 - TOP SCREWS (6)

5 - BRACKET/SCREW

6 - LOWER SCREWS (2)

23 - 68 INSTRUMENT PANELVA

Page 2050 of 2305

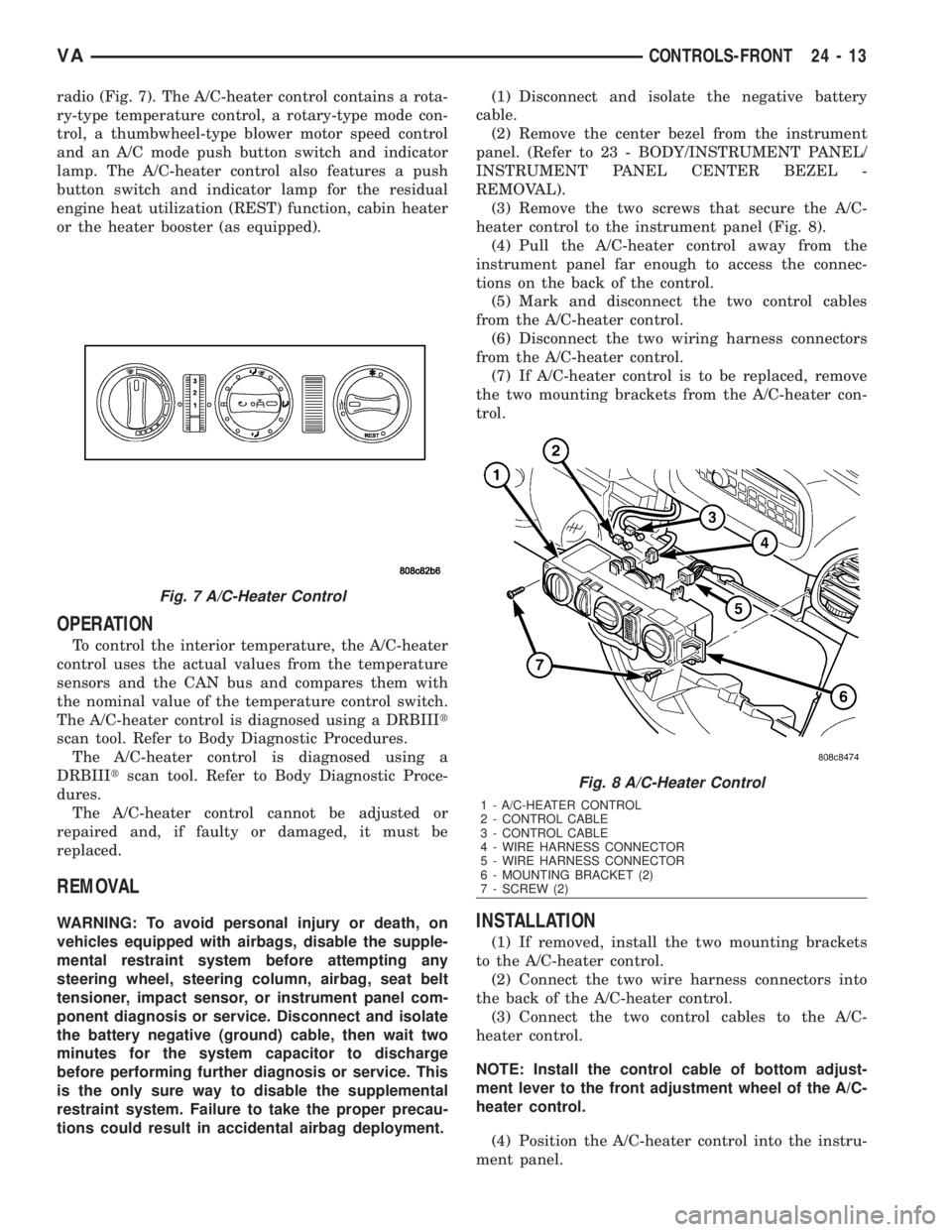

radio (Fig. 7). The A/C-heater control contains a rota-

ry-type temperature control, a rotary-type mode con-

trol, a thumbwheel-type blower motor speed control

and an A/C mode push button switch and indicator

lamp. The A/C-heater control also features a push

button switch and indicator lamp for the residual

engine heat utilization (REST) function, cabin heater

or the heater booster (as equipped).

OPERATION

To control the interior temperature, the A/C-heater

control uses the actual values from the temperature

sensors and the CAN bus and compares them with

the nominal value of the temperature control switch.

The A/C-heater control is diagnosed using a DRBIIIt

scan tool. Refer to Body Diagnostic Procedures.

The A/C-heater control is diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

The A/C-heater control cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

REMOVAL

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, impact sensor, or instrument panel com-

ponent diagnosis or service. Disconnect and isolate

the battery negative (ground) cable, then wait two

minutes for the system capacitor to discharge

before performing further diagnosis or service. This

is the only sure way to disable the supplemental

restraint system. Failure to take the proper precau-

tions could result in accidental airbag deployment.(1) Disconnect and isolate the negative battery

cable.

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(3) Remove the two screws that secure the A/C-

heater control to the instrument panel (Fig. 8).

(4) Pull the A/C-heater control away from the

instrument panel far enough to access the connec-

tions on the back of the control.

(5) Mark and disconnect the two control cables

from the A/C-heater control.

(6) Disconnect the two wiring harness connectors

from the A/C-heater control.

(7) If A/C-heater control is to be replaced, remove

the two mounting brackets from the A/C-heater con-

trol.INSTALLATION

(1) If removed, install the two mounting brackets

to the A/C-heater control.

(2) Connect the two wire harness connectors into

the back of the A/C-heater control.

(3) Connect the two control cables to the A/C-

heater control.

NOTE: Install the control cable of bottom adjust-

ment lever to the front adjustment wheel of the A/C-

heater control.

(4) Position the A/C-heater control into the instru-

ment panel.

Fig. 7 A/C-Heater Control

Fig. 8 A/C-Heater Control

1 - A/C-HEATER CONTROL

2 - CONTROL CABLE

3 - CONTROL CABLE

4 - WIRE HARNESS CONNECTOR

5 - WIRE HARNESS CONNECTOR

6 - MOUNTING BRACKET (2)

7 - SCREW (2)

VACONTROLS-FRONT 24 - 13

Page 2057 of 2305

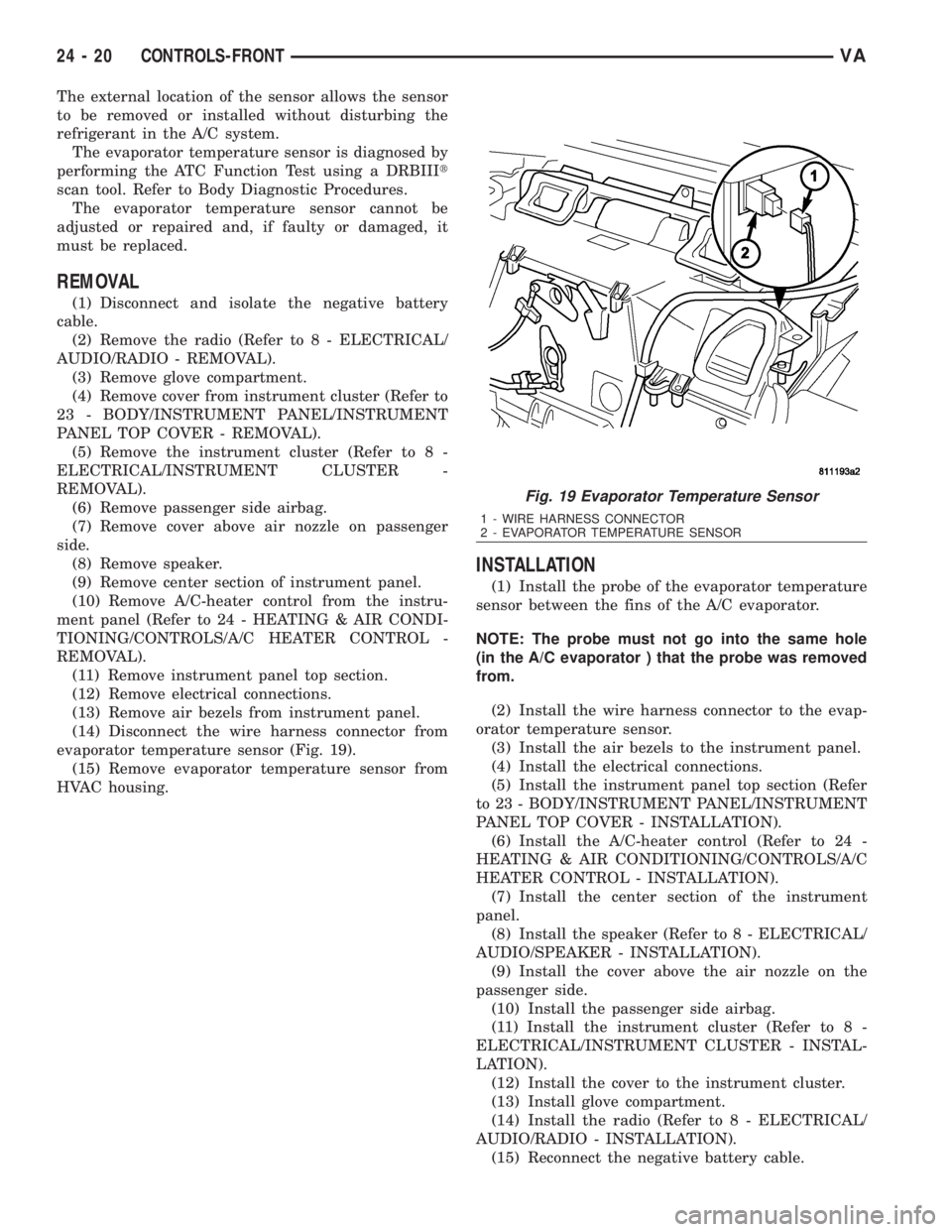

The external location of the sensor allows the sensor

to be removed or installed without disturbing the

refrigerant in the A/C system.

The evaporator temperature sensor is diagnosed by

performing the ATC Function Test using a DRBIIIt

scan tool. Refer to Body Diagnostic Procedures.

The evaporator temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the radio (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - REMOVAL).

(3) Remove glove compartment.

(4) Remove cover from instrument cluster (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - REMOVAL).

(5) Remove the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER -

REMOVAL).

(6) Remove passenger side airbag.

(7) Remove cover above air nozzle on passenger

side.

(8) Remove speaker.

(9) Remove center section of instrument panel.

(10) Remove A/C-heater control from the instru-

ment panel (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS/A/C HEATER CONTROL -

REMOVAL).

(11) Remove instrument panel top section.

(12) Remove electrical connections.

(13) Remove air bezels from instrument panel.

(14) Disconnect the wire harness connector from

evaporator temperature sensor (Fig. 19).

(15) Remove evaporator temperature sensor from

HVAC housing.

INSTALLATION

(1) Install the probe of the evaporator temperature

sensor between the fins of the A/C evaporator.

NOTE: The probe must not go into the same hole

(in the A/C evaporator ) that the probe was removed

from.

(2) Install the wire harness connector to the evap-

orator temperature sensor.

(3) Install the air bezels to the instrument panel.

(4) Install the electrical connections.

(5) Install the instrument panel top section (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION).

(6) Install the A/C-heater control (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - INSTALLATION).

(7) Install the center section of the instrument

panel.

(8) Install the speaker (Refer to 8 - ELECTRICAL/

AUDIO/SPEAKER - INSTALLATION).

(9) Install the cover above the air nozzle on the

passenger side.

(10) Install the passenger side airbag.

(11) Install the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - INSTAL-

LATION).

(12) Install the cover to the instrument cluster.

(13) Install glove compartment.

(14) Install the radio (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - INSTALLATION).

(15) Reconnect the negative battery cable.

Fig. 19 Evaporator Temperature Sensor

1 - WIRE HARNESS CONNECTOR

2 - EVAPORATOR TEMPERATURE SENSOR

24 - 20 CONTROLS-FRONTVA

Page 2078 of 2305

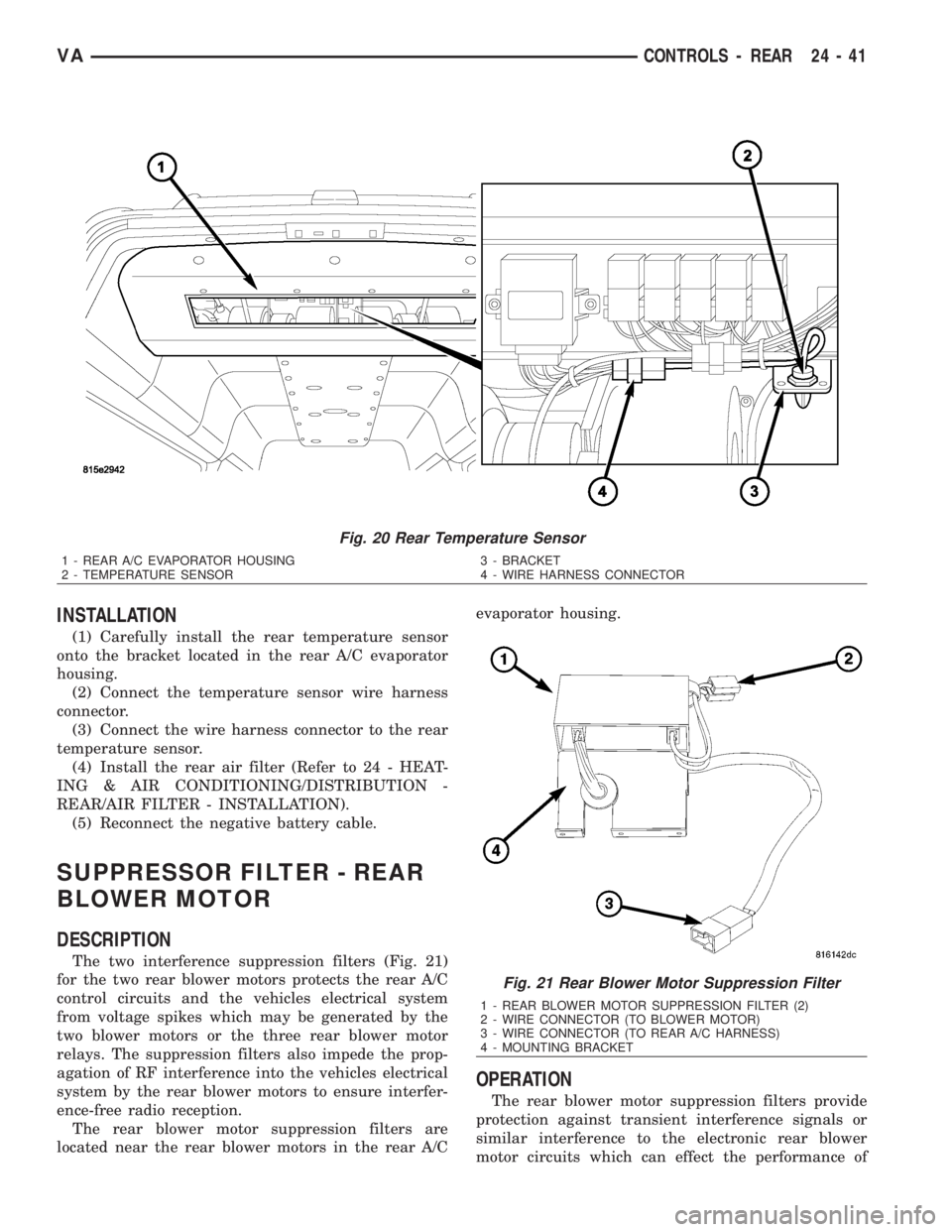

INSTALLATION

(1) Carefully install the rear temperature sensor

onto the bracket located in the rear A/C evaporator

housing.

(2) Connect the temperature sensor wire harness

connector.

(3) Connect the wire harness connector to the rear

temperature sensor.

(4) Install the rear air filter (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION -

REAR/AIR FILTER - INSTALLATION).

(5) Reconnect the negative battery cable.

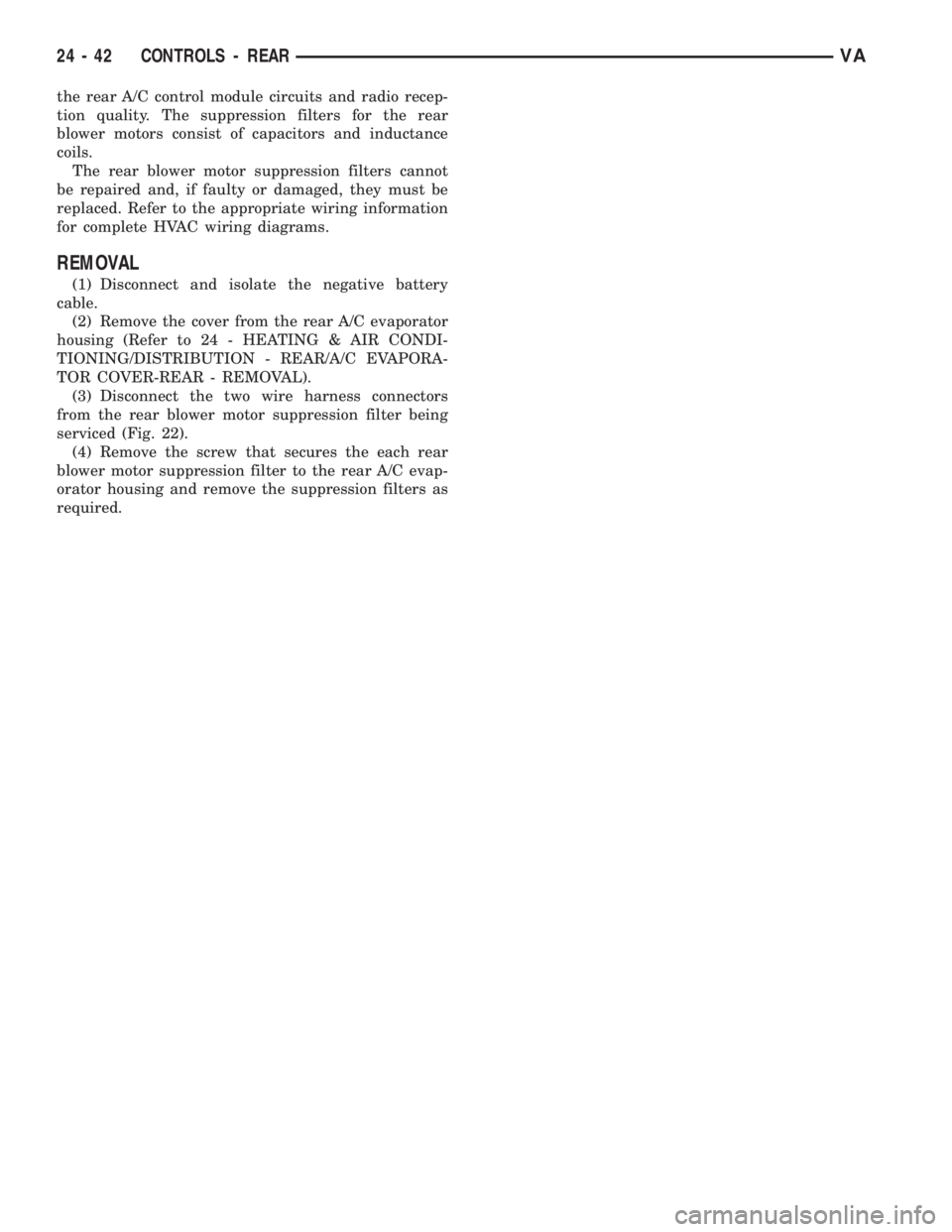

SUPPRESSOR FILTER - REAR

BLOWER MOTOR

DESCRIPTION

The two interference suppression filters (Fig. 21)

for the two rear blower motors protects the rear A/C

control circuits and the vehicles electrical system

from voltage spikes which may be generated by the

two blower motors or the three rear blower motor

relays. The suppression filters also impede the prop-

agation of RF interference into the vehicles electrical

system by the rear blower motors to ensure interfer-

ence-free radio reception.

The rear blower motor suppression filters are

located near the rear blower motors in the rear A/Cevaporator housing.

OPERATION

The rear blower motor suppression filters provide

protection against transient interference signals or

similar interference to the electronic rear blower

motor circuits which can effect the performance of

Fig. 20 Rear Temperature Sensor

1 - REAR A/C EVAPORATOR HOUSING

2 - TEMPERATURE SENSOR3 - BRACKET

4 - WIRE HARNESS CONNECTOR

Fig. 21 Rear Blower Motor Suppression Filter

1 - REAR BLOWER MOTOR SUPPRESSION FILTER (2)

2 - WIRE CONNECTOR (TO BLOWER MOTOR)

3 - WIRE CONNECTOR (TO REAR A/C HARNESS)

4 - MOUNTING BRACKET

VACONTROLS - REAR 24 - 41

Page 2079 of 2305

the rear A/C control module circuits and radio recep-

tion quality. The suppression filters for the rear

blower motors consist of capacitors and inductance

coils.

The rear blower motor suppression filters cannot

be repaired and, if faulty or damaged, they must be

replaced. Refer to the appropriate wiring information

for complete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(3) Disconnect the two wire harness connectors

from the rear blower motor suppression filter being

serviced (Fig. 22).

(4) Remove the screw that secures the each rear

blower motor suppression filter to the rear A/C evap-

orator housing and remove the suppression filters as

required.

24 - 42 CONTROLS - REARVA