door lock MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 309 of 2305

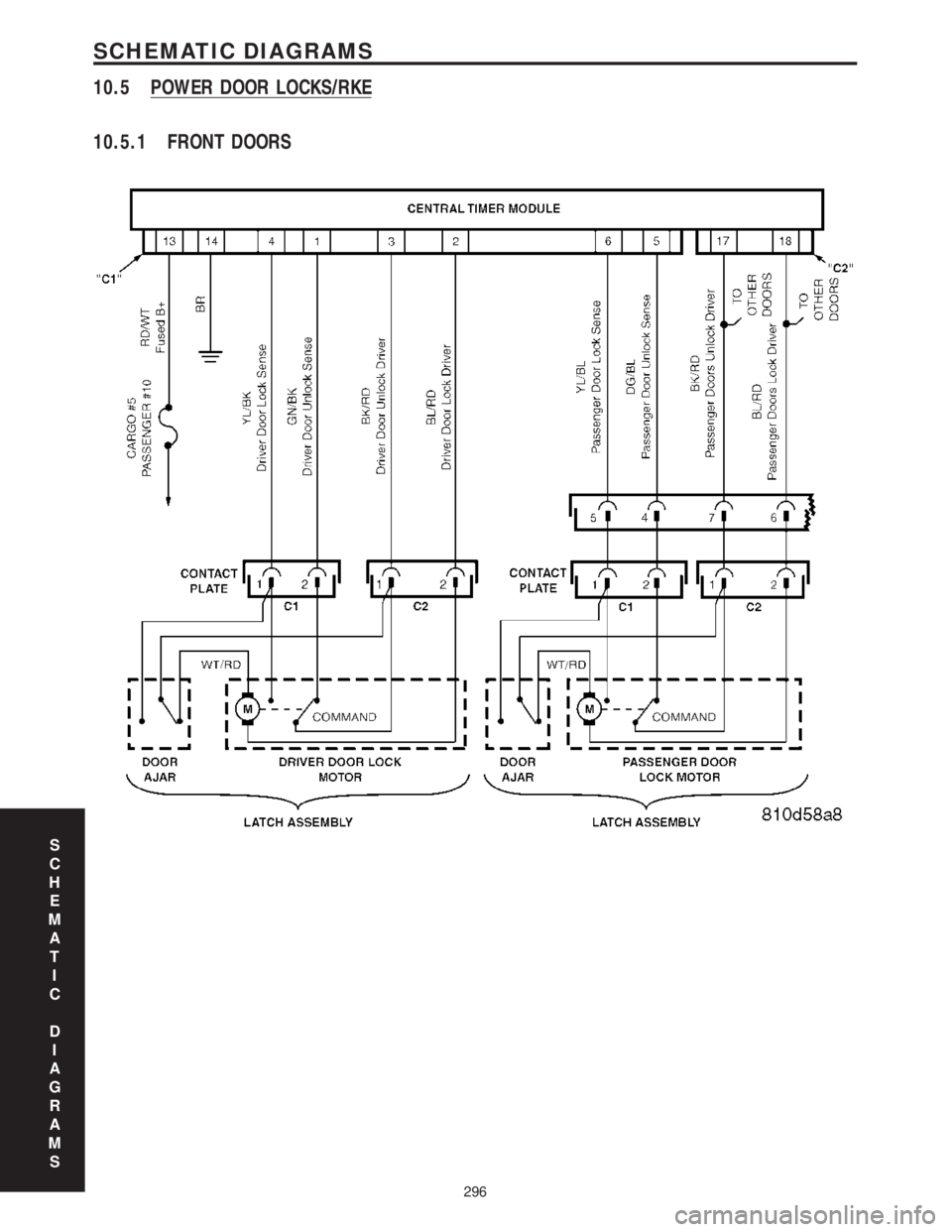

10.5 POWER DOOR LOCKS/RKE

10.5.1 FRONT DOORS

S

C

H

E

M

A

T

I

C

D

I

A

G

R

A

M

S

296

SCHEMATIC DIAGRAMS

Page 311 of 2305

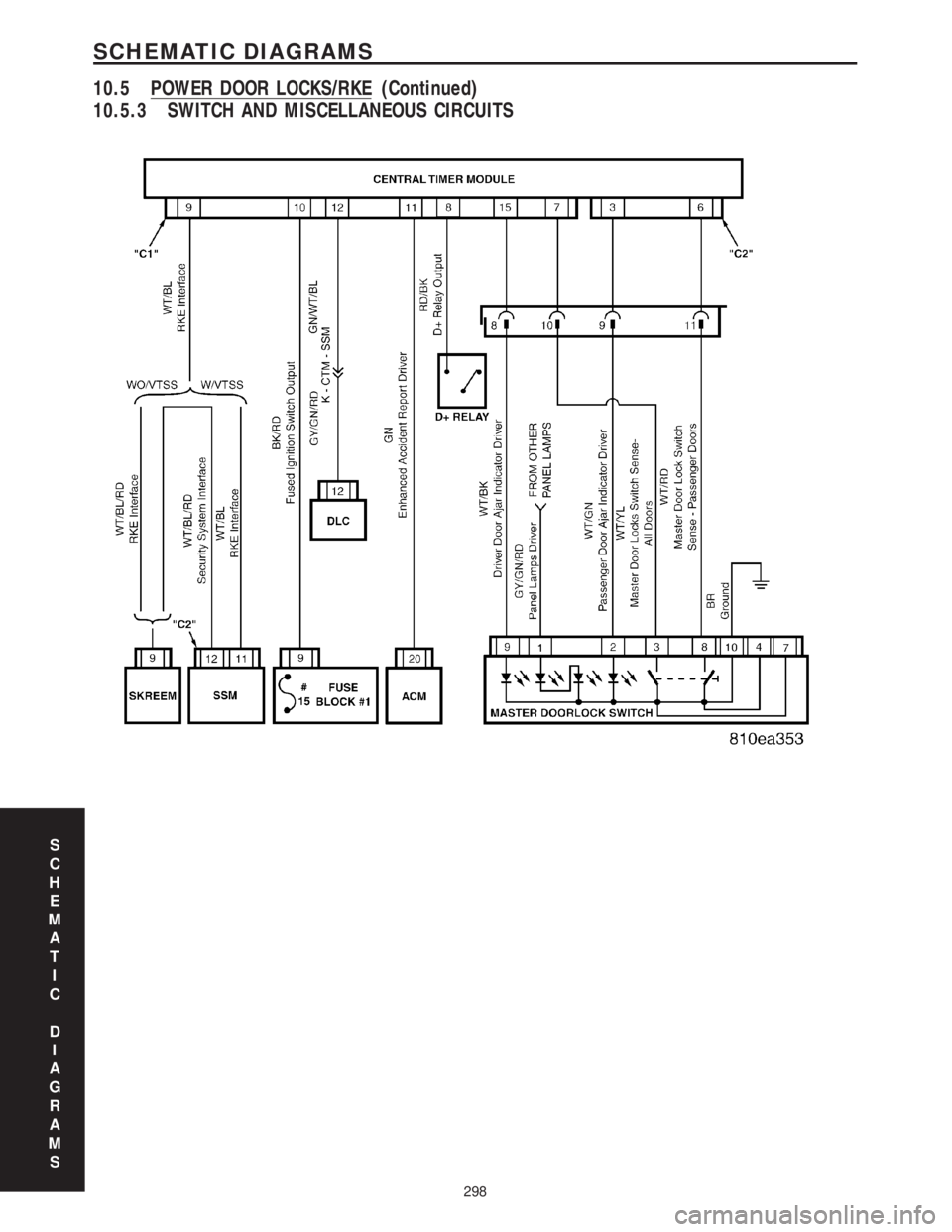

10.5.3 SWITCH AND MISCELLANEOUS CIRCUITS

S

C

H

E

M

A

T

I

C

D

I

A

G

R

A

M

S

298

SCHEMATIC DIAGRAMS

10.5 POWER DOOR LOCKS/RKE (Continued)

Page 855 of 2305

the status of the driver side front seat belt. This

audible warning occurs independent of the visual

warning provided by the EMIC ªSeatbeltº indicator.

²Lights-On Warning- The EMIC chime tone

generator will generate repetitive chime tones at a

fast rate when either front door is opened with the

ignition switch in any position except On, and the

exterior lights are turned On. The EMIC uses inter-

nal programming and hard wired inputs from the left

(lighting) control stalk of the multi-function switch,

the ignition switch, and both front door jamb

switches to determine the current status of these

switches. This chime will continue to sound until the

exterior lighting is turned Off, until the ignition

switch is turned to the On position, or until both

front doors are closed, whichever occurs first.

²Key-In-Ignition Warning- The EMIC chime

tone generator will generate repetitive chime tones at

a fast rate when the key is in the ignition lock cylin-

der, the ignition switch is in any position except On,

and either front door is opened. The EMIC uses

internal programming and hard wired inputs from

the key-in ignition switch, the ignition switch, and

both front door jamb switches to determine the cur-

rent status of these switches. The chime will con-

tinue to sound until the key is removed from the

ignition lock cylinder, until the ignition switch is

turned to the On position, or until both front doors

are closed, whichever occurs first.

²Audible Turn Signal/Hazard Warning Sup-

port- The EMIC contactless relay will generate

repetitive clicks at a slow rate during normal turn

signal/hazard warning operation, or at a fast rate

when a turn signal lamp bulb or circuit is inopera-

tive, in concert with the operation of the turn signal

indicators in the cluster. These clicks are designed to

emulate the sound of the opening and closing of the

contact points in a conventional electromechanical

turn signal or hazard warning flasher. The EMIC

uses a hard wired input received from the turn sig-

nal relay in the fuse block beneath the steering col-

umn through the turn signal or hazard warning

switch circuitry of the multi-function switch to deter-

mine when to flash the turn signal indicators and

activate the contactless relay on the cluster electronic

circuit board. The turn signal clicks will continue to

sound until the turn signal switch is turned Off, or

until the ignition switch is turned to the Off position,

whichever occurs first. The hazard warning clicks

will continue to sound until the hazard warning

switch is turned Off.

The EMIC provides chime service for all available

features in the chime warning system. The EMIC relies

upon its internal programming and hard wired inputs

from the front door ajar switches, the key-in ignition

switch, the ignition switch, the seat belt switch, and the

turn signal/hazard warning (multi-function) switches.

The EMIC relies upon electronic message inputsreceived from other electronic modules over the CAN

data bus network to provide chime service for the low

engine oil level warning. Upon receiving the proper

inputs, the EMIC activates the chime tone generator or

the contactless relay to provide the audible warning to

the vehicle operator. The internal programming of the

EMIC determines the priority of each chime request

input that is received, as well as the rate and duration

of each tone that is to be generated. See the owner's

manual in the vehicle glove box for more information on

the features provided by the chime warning system.

The hard wired chime warning system inputs to

the EMIC, as well as other hard wired circuits for

this system may be diagnosed and tested using con-

ventional diagnostic tools and procedures. However,

conventional diagnostic methods may not prove con-

clusive in the diagnosis of the EMIC, the CAN data

bus network, or the electronic message inputs used

by the EMIC to provide chime warning system ser-

vice. The most reliable, efficient, and accurate means

to diagnose the EMIC, the CAN data bus network,

and the electronic message inputs for the chime

warning system requires the use of a diagnostic scan

tool. Refer to the appropriate diagnostic information.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-

tem. Failure to take the proper precautions could

result in accidental airbag deployment.

The hard wired chime warning system inputs to

the ElectroMechanical Instrument Cluster (EMIC),

as well as other hard wired circuits for this system

may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods may not prove conclusive

in the diagnosis of the EMIC, the Controller Area

Network (CAN) data bus network, or the electronic

message inputs used by the EMIC to provide chime

warning system service. The most reliable, efficient,

and accurate means to diagnose the EMIC, the CAN

data bus network, and the electronic message inputs

for the chime warning system requires the use of a

diagnostic scan tool. Refer to the appropriate diag-

nostic information.

8B - 2 CHIME/BUZZERVA

Page 856 of 2305

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

CENTRAL TIMER MODULE

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE.............................2

REMOVAL.............................2

INSTALLATION..........................3

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................3

REMOVAL.............................3INSTALLATION..........................3

ENGINE CONTROL MODULE

DESCRIPTION..........................3

REMOVAL.............................6

INSTALLATION..........................6

TRANSMISSION CONTROL MODULE

DESCRIPTION..........................6

OPERATION............................7

STANDARD PROCEDURE - TCM ADAPTATION . 10

CENTRAL TIMER MODULE

DESCRIPTION

The central timer module (CTM) is located beneath

the driver seat. The CTM uses information carried on

the programmable communications interface (PCI)

data bus network along with many hard wired inputs

to monitor many sensor and switch inputs. In

response to those inputs, the circuitry and program-

ming of the CTM allow it to supply the vehicle occu-

pants with audible and visual information, and to

control and integrate many functions and features of

the vehicle through both hard wired outputs and the

transmission of message outputs to other modules in

the vehicle over the PCI data bus.

The features that the CTM supports or controls

include the following:

²Central Locking- The CTM on vehicles

equipped with the optional Vehicle Theft Security

System (VTSS) includes a central locking/unlocking

feature.

²Enhanced Accident Response- The CTM pro-

vides an optional enhanced accident response fea-

ture. This is a programmable feature.

²Panic Mode- The CTM provides support for

the optional RKE system panic mode including horn,

headlamp, and park lamp flash features.

²Power Lock Control- The CTM provides the

optional power lock system features, including sup-

port for the automatic door lock and door lock inhibit

modes.

²Programmable Features- The CTM provides

support for certain programmable features.

²Remote Keyless Entry- The CTM provides

the optional Remote Keyless Entry (RKE) system fea-

tures, including support for the RKE Lock (with

optional horn and park lamps flash), Unlock (with

park lamps flash, driver-door-only unlock, andunlock-all-doors), Panic, and illuminated entry

modes, as well as the ability to be programmed to

recognize up to four RKE transmitters. The RKE

horn, driver-door-only unlock, and unlock-all-doors

features are programmable.

²Vehicle Theft Security System- The CTM

provides control of the optional Vehicle Theft Secu-

rity System (VTSS) features, including support for

the central locking/unlocking mode and control of the

Security indicator in the instrument cluster.

Hard wired circuitry connects the CTM to the elec-

trical system of the vehicle. Refer to the appropriate

wiring information.

Many of the features in the vehicle controlled or

supported by the CTM are programmable using the

DRBIIItscan tool. However, if any of the CTM hard-

ware components are damaged or faulty, the entire

CTM unit must be replaced. The hard wired inputs

or outputs of all CTM versions can be diagnosed

using conventional diagnostic tools and methods;

however, for diagnosis of the CTM or the PCI data

bus, the use of a DRBIIItscan tool is required. Refer

to the appropriate diagnostic information.

OPERATION

The central timer module (CTM) monitors many

hard wired switch and sensor inputs as well as those

resources it shares with other modules in the vehicle

through its communication over the programmable

communications interface (PCI) data bus network.

The internal programming and all of these inputs

allow the CTM to determine the tasks it needs to

perform and their priorities, as well as both the stan-

dard and optional features that it should provide.

The CTM then performs those tasks and provides

those features through both PCI data bus communi-

cation with other modules and hard wired outputs

through a number of driver circuits, relays, and

VAELECTRONIC CONTROL MODULES 8E - 1

Page 857 of 2305

actuators.These outputs allow the CTM the ability to

control numerous accessory systems in the vehicle.

The CTM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the CTM include the fol-

lowing:

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (run-start)

²Ground

²Key-in ignition switch sense

²Sliding door switch sense

²Passenger door switch sense

²Driver door switch sense

²PCI bus circuit

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²Door lock relay output

²Door unlock relay output

²VTSS indicator driver

MESSAGING

The CTM uses the following messages received

from other electronic modules over the PCI data bus:

²Airbag Deploy (ACM)

²Beep request (CMTC)

²Charging System Failure (PCM)

²Chime request (EMIC)

²Engine RPM (PCM)

²OK to Arm VTSS (PCM)

²Security indicator request (SKIM)

²System Voltage (PCM)

²Valid/Invalid Key (SKIM)

²Vehicle Distance (PCM)

²Vehicle Speed (PCM)

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-tem. Failure to take the proper precautions could

result in accidental airbag deployment.

The hard wired inputs to and outputs from the

central timer module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the CTM. In

order to obtain conclusive testing of the CTM, the

programmable communications interface (PCI) data

bus network and all of the modules that provide

inputs to or receive outputs from the CTM must also

be checked. The most reliable, efficient, and accurate

means to diagnose the CTM, the PCI data bus net-

work, and the modules that provide inputs to, or

receive outputs from, the CTM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Slide the driver seat to the full forward posi-

tion.

(3) Disconnect the wire harness connector for the

seat belt latch. (Fig. 1).

(4) Remove the screws that secure the closeout

panel beneathe the driver seat cushion and remove

the panel.

(5) Remove the screws that secure the central

timer module to the bracket.

(6) Disconnect the wire harness connectors from

the central timer module.

(7) Remove the central timer module from the

vehicle.

8E - 2 ELECTRONIC CONTROL MODULESVA

Page 875 of 2305

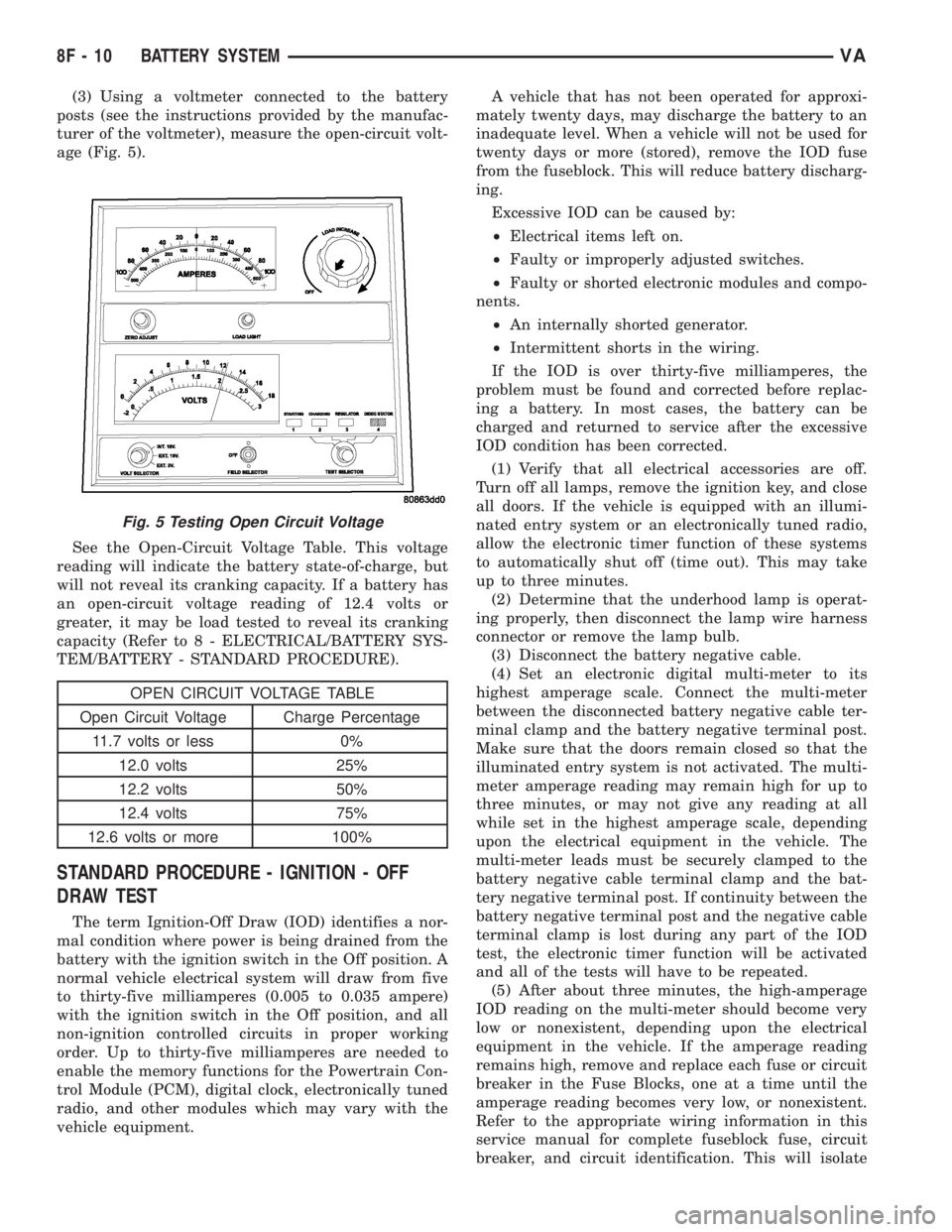

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 5).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - IGNITION - OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the fuseblock. This will reduce battery discharg-

ing.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes.

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Fuse Blocks, one at a time until the

amperage reading becomes very low, or nonexistent.

Refer to the appropriate wiring information in this

service manual for complete fuseblock fuse, circuit

breaker, and circuit identification. This will isolate

Fig. 5 Testing Open Circuit Voltage

8F - 10 BATTERY SYSTEMVA

Page 925 of 2305

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC elec-

tronic circuit board. The ambient temperature indica-

tor (optional), brake indicator, brake wear indicator,

charging indicator, coolant low indicator, high beam

indicator, low fuel indicator, park brake indicator,

seatbelt indicator, turn signal indicators, and washer

fluid indicator operate based upon hard wired inputs

to the EMIC. The airbag (SRS) indicator is normally

controlled by a hard wired input from the Airbag

Control Module (ACM); however, if the EMIC sees an

abnormal or no input from the ACM, it will automat-

ically turn the airbag indicator On until the hard

wired input from the ACM has been restored. The

Malfunction Indicator Lamp (MIL) is normally con-

trolled by CAN data bus messages from the Engine

Control Module (ECM); however, if the EMIC loses

CAN data bus communication, the EMIC circuitry

will automatically turn the MIL on until CAN data

bus communication is restored. The EMIC uses CAN

data bus messages from the ECM, the ACM, and the

Controller Antilock Brake to control all of the

remaining indicators.

The various EMIC indicators are controlled by dif-

ferent strategies; some receive battery feed from the

EMIC circuitry and have a switched ground, while

others are grounded through the EMIC circuitry and

have a switched battery feed. However, all indicators

are completely controlled by the EMIC microproces-

sor based upon various hard wired and electronic

message inputs. Except for the indications provided

by the multi-function indicator Liquid Crystal Dis-

play (LCD) unit, all indicators are illuminated at a

fixed intensity, which is not affected by the selected

illumination intensity of the EMIC general illumina-

tion lamps.

The hard wired indicator inputs may be diagnosed

using conventional diagnostic methods. However,

proper testing of the EMIC circuitry and the CAN

bus message controlled indicators requires the use of

a diagnostic scan tool. Refer to the appropriate diag-

nostic information. Specific details of the operation

for each indicator may be found elsewhere in this

service information.

CLUSTER ILLUMINATION

The EMIC has several general illumination lamps

that are illuminated when the exterior lighting is

turned on with the multi-function switch. The illumi-

nation intensity of these lamps is adjusted by a dim-

ming level input received from the multi-function

indicator ª+º (plus) and ª±º (minus) switch push but-

tons that extend through the lower edge of the clus-

ter lens below the right end of the multi-function

indicator. When the exterior lighting is turned Off,

the display is illuminated at maximum brightness.

When the exterior lighting is turned On and thetransmission gear selector is in the Park position,

depressing the plus switch push button brightens the

display lighting, and depressing the minus switch

push button dims the display lighting. The EMIC

also provides a Pulse-Width Modulated (PWM) panel

lamps dimmer output that can be used to synchro-

nize the illumination lighting levels of external illu-

mination lamps (up to about 23 to 30 watts) with

that of the EMIC.

The hard wired multi-function switch input and

the EMIC panel lamps dimmer output may be diag-

nosed using conventional diagnostic methods. How-

ever, proper testing of the PWM control of the EMIC

and the electronic dimming level inputs from the

multi-function indicator push buttons requires the

use of a diagnostic scan tool. Refer to the appropriate

diagnostic information.

INPUT AND OUTPUT CIRCUITS

HARD WIRED INPUTS

The hard wired inputs to the EMIC include the fol-

lowing:

NOTE: Final approved circuit names were not yet

available at the time this information was compiled.

²Airbag Indicator Driver

²Ambient Temperature Sensor Signal

(Optional)

²Brake Wear Indicator Sense

²Charging Indicator Driver

²Coolant Level Switch Sense

²Front Door Jamb Switch Sense

²Fuel Level Sensor Signal

²Fused B(+)

²Fused Ignition Switch Output

²High Beam Indicator Driver

²Key-In Ignition Switch Sense

²Left Turn Signal

²Park Brake Switch Sense

²Right Turn Signal

²Seat Belt Switch Sense

²Washer Fluid Switch Sense (Optional)

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS

The hard wired outputs of the EMIC include the

following:

²Engine Running Relay Control

²Panel Lamps Driver

Refer to the appropriate wiring information for

additional details.

8J - 6 INSTRUMENT CLUSTERVA

Page 951 of 2305

REAR TURN LAMP BULB

REMOVAL.............................23

INSTALLATION.........................23

REPEATER LAMP BULB

REMOVAL.............................23

INSTALLATION.........................24

REPEATER LAMP UNIT

REMOVAL.............................24INSTALLATION.........................25

TAIL LAMP UNIT

REMOVAL.............................25

INSTALLATION.........................26

TURN SIGNAL RELAY

REMOVAL.............................26

INSTALLATION.........................26

LAMPS / LIGHTING - EXTE-

RIOR

DESCRIPTION

The exterior lighting system for this model

includes the following exterior lamps:

²Backup Lamps- The backup (or reverse) lamps

are integral to the tail lamp units mounted to the

back of the quarter panel on each side of the tailgate

at the rear of the vehicle.

²Brake Lamps- The brake (or stop) lamps

include a bulb and reflector that are integral to the

tail lamp units mounted to the back of the quarter

panel on each side of the tailgate opening, and the

Center High Mounted Stop Lamp (CHMSL) that is

centered on the rear edge of the roof panel above the

tailgate opening.

²Daytime Running Lamps- Vehicles manufac-

tured for sale in Canada have a Daytime Running

Lamps (DRL) relay that illuminates the low beam

headlamp bulbs whenever the engine is running.

²Fog Lamps- Fog lamp bulbs and reflectors are

included in both front lamp units of vehicles

equipped with this option.

²Hazard Warning Lamps- The hazard warning

lamps include all of the right and left turn signal and

repeater lamps.

²Headlamps- Separate low beam and high

beam headlamp bulbs are installed in the front lamp

unit on each side of the front grille opening. A head-

lamp leveling actuator motor is also integral to each

front lamp unit.

²Park Lamps- The park lamps include the front

park/side marker lamps and front position lamps

that are integral to the front lamp units mounted on

either side of the front grille opening, as well as the

rear park lamps and rear side marker lamps that are

integral to the tail lamp units mounted to the back of

the quarter panel on each side of the tailgate open-

ing. Included in the park lamps circuit are two rear

license plate lamp units mounted on the left rear

tailgate door. The park lamps may also include

optional clearance lamps, which are located on each

side of a vehicle that is so equipped.

²Turn Signal Lamps- The turn signal lamps

include the front turn lamps that are integral to the

front lamp units, the rear turn lamps that are inte-

gral to the tail lamp units, and a repeater lampmounted to each front fender just above the front

wheel opening.

Other components of the exterior lighting system

for this model include:

²Brake Lamp Switch- A plunger-type brake

lamp switch is located on the steering column sup-

port bracket under the instrument panel and actu-

ated by the brake pedal arm.

²Daytime Running Lamp Relays- Vehicles

manufactured for sale in Canada have two Daytime

Running Lamps (DRL) relays. Dedicated right and

left side relays illuminate the low beam headlamp

bulb installed in each front lamp unit whenever the

engine is running. These relays are located in dedi-

cated vehicle wire harness connectors within the

driver side front seat riser.

²Fog Lamp Relay- Vehicles equipped with the

optional fog lamps have a fog lamp relay located in a

dedicated vehicle wire harness connector within the

driver side front seat riser.

²Fog Lamp Switch- A fog lamp switch is

mounted in the instrument cluster bezel, below the

cluster and outboard of the steering column on vehi-

cles equipped with this option.

²Headlamp Leveling Motor- A headlamp lev-

eling actuator motor is located on the back of each

headlamp housing and adjusts both the low beam

headlamp, high beam headlamp, and fog lamp (if

equipped) reflector frames in unison.

²Headlamp Leveling Switch- A thumbwheel

actuated headlamp leveling switch is mounted in the

instrument cluster bezel, below the cluster and out-

board of the steering column.

²Multi-Function Switch- The multi-function

switch is located on the top of the steering column,

just below the steering wheel. The multi-function

switch is connected directly to the fuse block located

below the steering column through an integral inter-

face connector. Only the left (lighting), right (wiper)

control stalks and the hazard warning switch button

for the multi-function switch are visible, the remain-

der of the switch is concealed beneath the steering

column shrouds. The multi-function switch includes a

left (lighting) control stalk and a right (wiper) control

stalk. The left control stalk is dedicated to providing

almost all of the driver controls for the exterior light-

ing system.

²Trailer Tow Connector- Vehicles equipped

with a factory-approved, field-installed trailer towing

8L - 2 LAMPS/LIGHTING - EXTERIORVA

Page 978 of 2305

right rear door is standard equipment on wagon mod-

els. The sliding and rear door jamb switches are not

available for van models.

²Entry/Exit Lamp- An entry/exit lamp to illu-

minate each front and sliding side door step well is

optional equipment on wagon models.

²Time Delay Relay- Vehicles equipped with the

optional remote cargo lamp switches also have a time

delay relay located in the electrical center within the

driver side front seat riser.

Hard wired circuitry connects the interior lighting

system components to the electrical system of the

vehicle. These hard wired circuits are integral to sev-

eral wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the interior lighting

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

The interior lighting systems can be divided into

two general classifications based upon the circuit

that controls their operation: The interior lighting

circuit, or the exterior lighting circuit. The hard

wired circuits and components of the interior lighting

systems may be diagnosed and tested using conven-

tional diagnostic tools and procedures.

INTERIOR LIGHTING CIRCUIT

Depending upon the vehicle model (van or wagon)

and the selected vehicle options the interior lighting

circuit may include dome/cargo lamps located over-

head in the front and rear of the vehicle, a dome/

reading lamp located in the header area above the

windshield between the sun visors, and entry/exit

lamps located in the front and sliding side door step

wells.

WAGON MODELS

In all wagon models, the lamps in the interior

lighting circuit are provided with battery current at

all times by a fuse in the fuse block beneath the

steering column. The front, side, and rear door jamb

switches control a ground path for each of these

lamps, except for the optional reading lamp. If the

lamp has an optional integral switch, that switch has

three separate positions. The first position provides a

ground path independent of the door jamb switches

to turn the lamp On. The second, or center position

allows the door jamb switches to control the lamp.The third position segregates that lamp from the

door jamb switch input, turning the lamp Off. In the

case of the optional dome/reading lamp, the integral

lamp switch has a fourth position which will illumi-

nate only the reading lamp bulb.

VAN MODELS

Unless a van model is equipped with an optional

remote cargo lamp switch, all of the lamps in the

interior lighting circuit operate the same way as the

wagon models except that there are only two door

jamb switches, one for each front door. If the vehicle

is equipped with an optional remote cargo lamp

switch, the lamps in the rear of the vehicle on the

interior lighting circuit are provided with battery

current by the time delay relay. The time delay relay

is a smart relay containing active electronic elements

that comprise an electronic timer logic circuit. When

the remote cargo lamp switches provide the proper

input to the time delay relay, the relay logic responds

by energizing the relay control coil. The energized

relay control coil provides battery current to all of

the lamps on the rear interior lighting circuit and to

the indicator Light-Emitting Diode (LED) units in

the remote cargo switches causing each to illuminate.

If a remote cargo lamp switch remains On for more

than about fifteen minutes, the time delay relay will

then automatically de-energize the rear interior

lighting circuits until the remote cargo lamp switch

is cycled Off and then back On.

EXTERIOR LIGHTING CIRCUIT

The exterior lighting circuit provides battery cur-

rent to the optional ash receiver/cigar lighter lamp

and to the illumination Light-Emitting Diode (LED)

unit within the remote cargo lamp switch in the

instrument panel accessory switch bezel whenever

the exterior lamps are turned On.

SPECIFICATIONS - INTERIOR LIGHTING

VALAMPS/LIGHTING - INTERIOR 8L - 29

Page 980 of 2305

CARGO / DOME LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

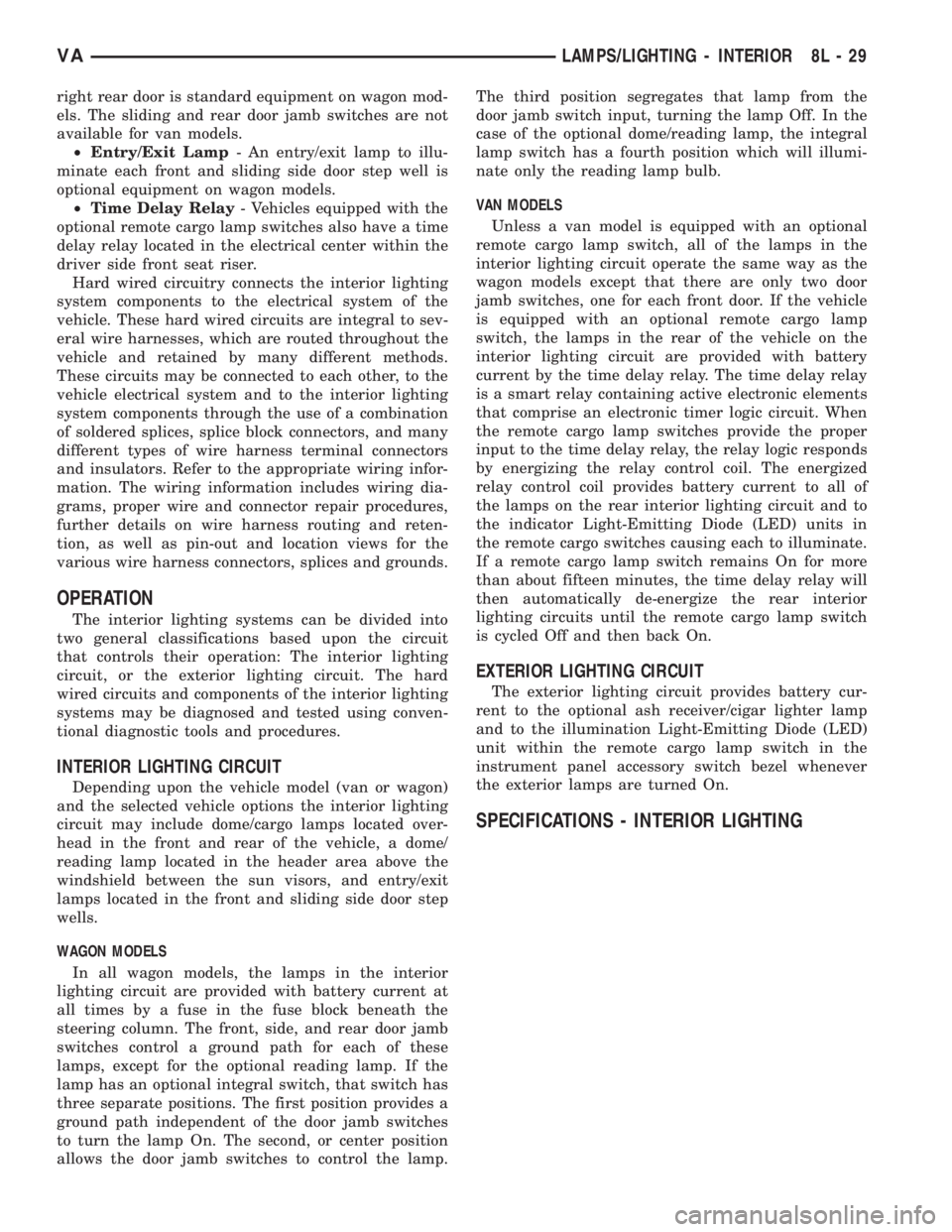

(2) Insert the tip of a small flat-bladed screwdriver

into the notch on one edge of the cargo/dome lamp

housing to depress the retainer clip and pull that

edge of the lamp away from its mounting location

(Fig. 3).

(3) Pull the cargo/dome lamp unit from its mount-

ing location far enough to access and disconnect the

vehicle wire harness from the lamp connector recep-

tacle.

(4) Remove the cargo/dome lamp unit from its

mounting location.

INSTALLATION

(1) Position the cargo/dome lamp unit to its

mounting location.

(2) Reconnect the vehicle wire harness connector

to the cargo/dome lamp connector receptacle (Fig. 3).

(3) Position the edge of the cargo/dome lamp hous-

ing opposite from the retainer clip into the mounting

hole.

(4) Push firmly and evenly on the notched edge of

the cargo/dome lamp housing until the retainer clip

latches into place.

(5) Reconnect the battery negative cable.

CARGO LAMP SWITCH

REMOVAL

REMOVAL - INSTRUMENT PANEL

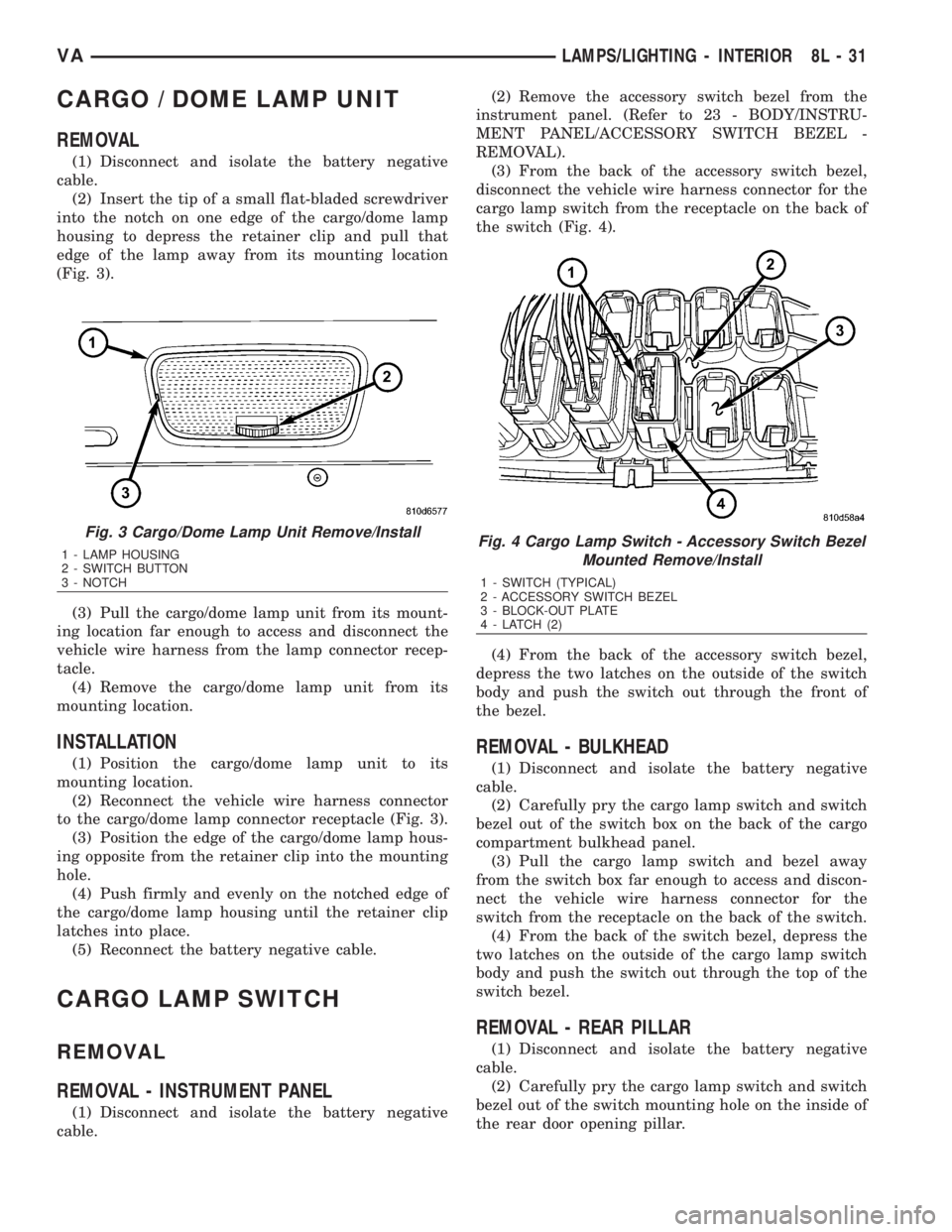

(1) Disconnect and isolate the battery negative

cable.(2) Remove the accessory switch bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/ACCESSORY SWITCH BEZEL -

REMOVAL).

(3) From the back of the accessory switch bezel,

disconnect the vehicle wire harness connector for the

cargo lamp switch from the receptacle on the back of

the switch (Fig. 4).

(4) From the back of the accessory switch bezel,

depress the two latches on the outside of the switch

body and push the switch out through the front of

the bezel.

REMOVAL - BULKHEAD

(1) Disconnect and isolate the battery negative

cable.

(2) Carefully pry the cargo lamp switch and switch

bezel out of the switch box on the back of the cargo

compartment bulkhead panel.

(3) Pull the cargo lamp switch and bezel away

from the switch box far enough to access and discon-

nect the vehicle wire harness connector for the

switch from the receptacle on the back of the switch.

(4) From the back of the switch bezel, depress the

two latches on the outside of the cargo lamp switch

body and push the switch out through the top of the

switch bezel.

REMOVAL - REAR PILLAR

(1) Disconnect and isolate the battery negative

cable.

(2) Carefully pry the cargo lamp switch and switch

bezel out of the switch mounting hole on the inside of

the rear door opening pillar.

Fig. 3 Cargo/Dome Lamp Unit Remove/Install

1 - LAMP HOUSING

2 - SWITCH BUTTON

3 - NOTCHFig. 4 Cargo Lamp Switch - Accessory Switch Bezel

Mounted Remove/Install

1 - SWITCH (TYPICAL)

2 - ACCESSORY SWITCH BEZEL

3 - BLOCK-OUT PLATE

4 - LATCH (2)

VALAMPS/LIGHTING - INTERIOR 8L - 31