ECU MERCEDES-BENZ SPRINTER 2006 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 824 of 2305

(5) Install the bracket with the control modules

(Fig. 9).

(6) Install the cover for the drivers seat (Fig. 8).

(7) Return the drivers seat to normal position.

(8) Reconnect the battery.

(9) Perform diagnosis quick check and road test

the vehicle.

YAW RATE SENSOR

DESCRIPTION

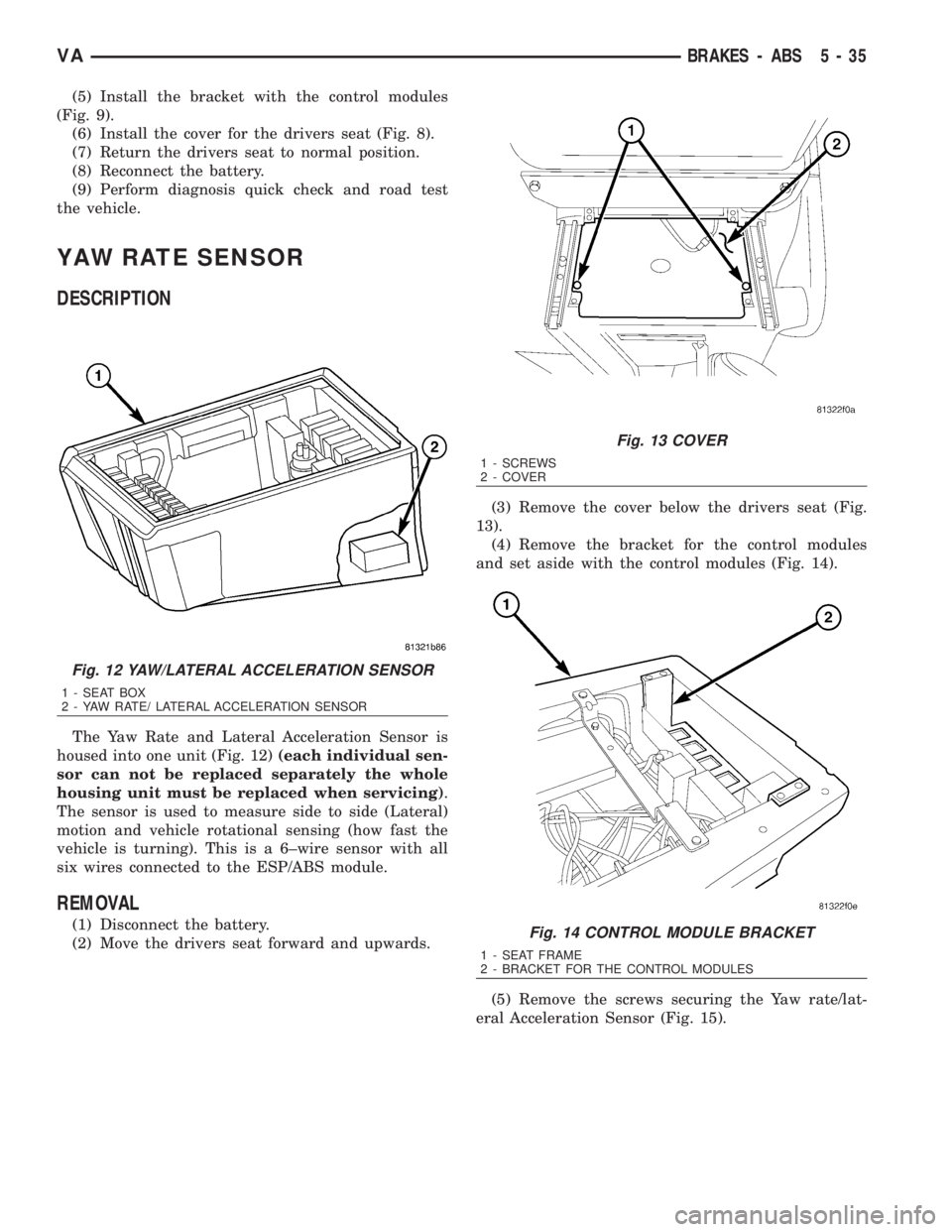

The Yaw Rate and Lateral Acceleration Sensor is

housed into one unit (Fig. 12)(each individual sen-

sor can not be replaced separately the whole

housing unit must be replaced when servicing).

The sensor is used to measure side to side (Lateral)

motion and vehicle rotational sensing (how fast the

vehicle is turning). This is a 6±wire sensor with all

six wires connected to the ESP/ABS module.

REMOVAL

(1) Disconnect the battery.

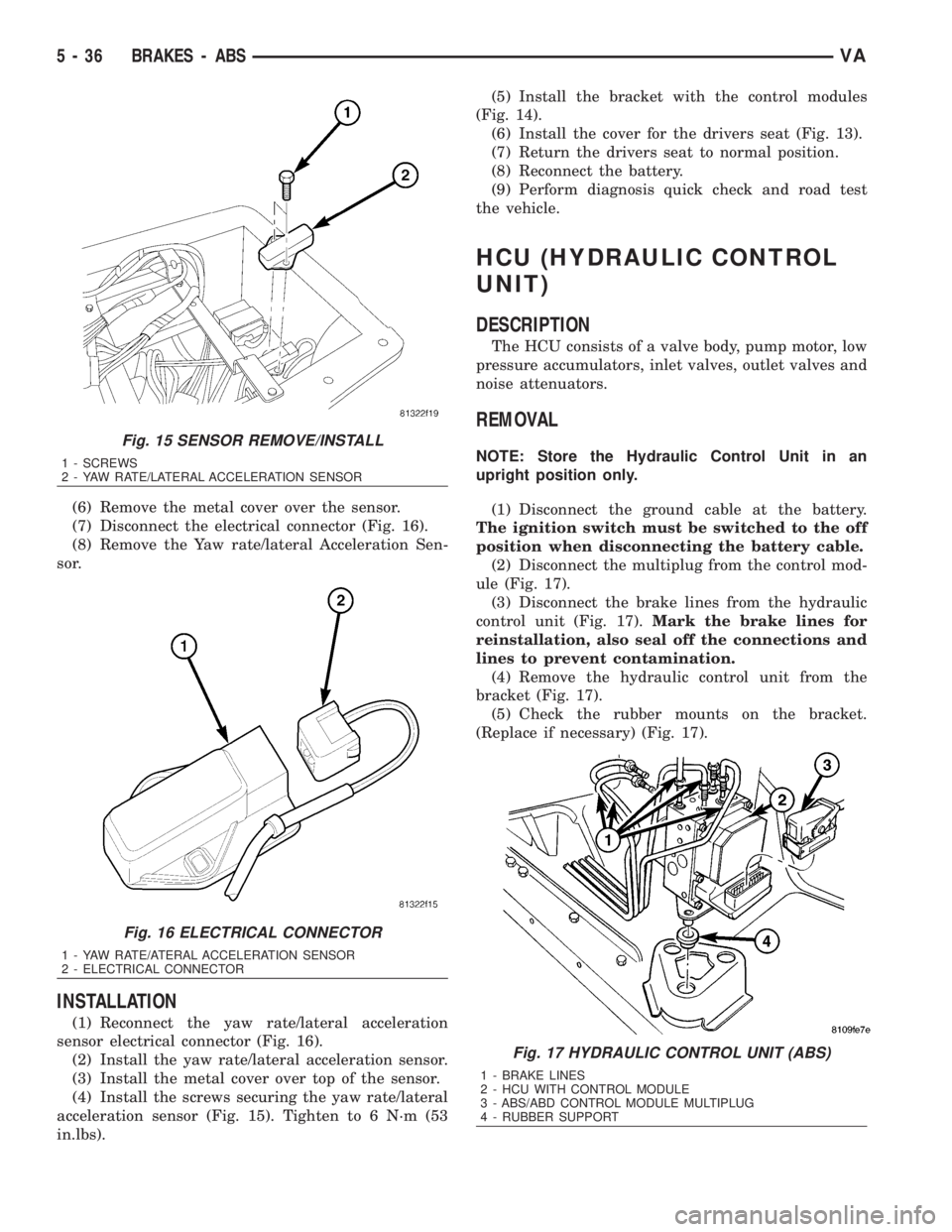

(2) Move the drivers seat forward and upwards.(3) Remove the cover below the drivers seat (Fig.

13).

(4) Remove the bracket for the control modules

and set aside with the control modules (Fig. 14).

(5) Remove the screws securing the Yaw rate/lat-

eral Acceleration Sensor (Fig. 15).

Fig. 12 YAW/LATERAL ACCELERATION SENSOR

1 - SEAT BOX

2 - YAW RATE/ LATERAL ACCELERATION SENSOR

Fig. 13 COVER

1 - SCREWS

2 - COVER

Fig. 14 CONTROL MODULE BRACKET

1 - SEAT FRAME

2 - BRACKET FOR THE CONTROL MODULES

VABRAKES - ABS 5 - 35

Page 825 of 2305

(6) Remove the metal cover over the sensor.

(7) Disconnect the electrical connector (Fig. 16).

(8) Remove the Yaw rate/lateral Acceleration Sen-

sor.

INSTALLATION

(1) Reconnect the yaw rate/lateral acceleration

sensor electrical connector (Fig. 16).

(2) Install the yaw rate/lateral acceleration sensor.

(3) Install the metal cover over top of the sensor.

(4) Install the screws securing the yaw rate/lateral

acceleration sensor (Fig. 15). Tighten to 6 N´m (53

in.lbs).(5) Install the bracket with the control modules

(Fig. 14).

(6) Install the cover for the drivers seat (Fig. 13).

(7) Return the drivers seat to normal position.

(8) Reconnect the battery.

(9) Perform diagnosis quick check and road test

the vehicle.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

REMOVAL

NOTE: Store the Hydraulic Control Unit in an

upright position only.

(1) Disconnect the ground cable at the battery.

The ignition switch must be switched to the off

position when disconnecting the battery cable.

(2) Disconnect the multiplug from the control mod-

ule (Fig. 17).

(3) Disconnect the brake lines from the hydraulic

control unit (Fig. 17).Mark the brake lines for

reinstallation, also seal off the connections and

lines to prevent contamination.

(4) Remove the hydraulic control unit from the

bracket (Fig. 17).

(5) Check the rubber mounts on the bracket.

(Replace if necessary) (Fig. 17).

Fig. 15 SENSOR REMOVE/INSTALL

1 - SCREWS

2 - YAW RATE/LATERAL ACCELERATION SENSOR

Fig. 16 ELECTRICAL CONNECTOR

1 - YAW RATE/ATERAL ACCELERATION SENSOR

2 - ELECTRICAL CONNECTOR

Fig. 17 HYDRAULIC CONTROL UNIT (ABS)

1 - BRAKE LINES

2 - HCU WITH CONTROL MODULE

3 - ABS/ABD CONTROL MODULE MULTIPLUG

4 - RUBBER SUPPORT

5 - 36 BRAKES - ABSVA

Page 842 of 2305

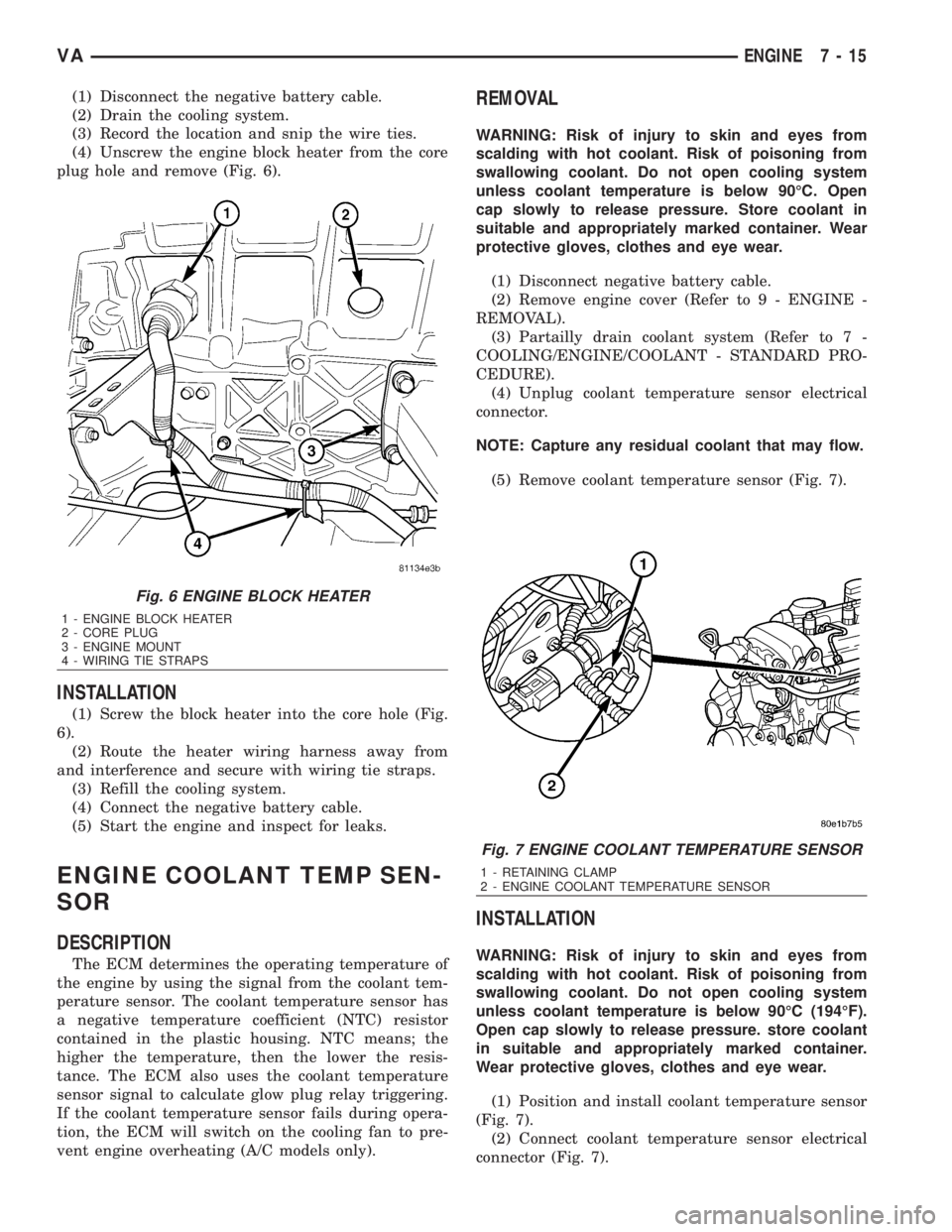

(1) Disconnect the negative battery cable.

(2) Drain the cooling system.

(3) Record the location and snip the wire ties.

(4) Unscrew the engine block heater from the core

plug hole and remove (Fig. 6).

INSTALLATION

(1) Screw the block heater into the core hole (Fig.

6).

(2) Route the heater wiring harness away from

and interference and secure with wiring tie straps.

(3) Refill the cooling system.

(4) Connect the negative battery cable.

(5) Start the engine and inspect for leaks.

ENGINE COOLANT TEMP SEN-

SOR

DESCRIPTION

The ECM determines the operating temperature of

the engine by using the signal from the coolant tem-

perature sensor. The coolant temperature sensor has

a negative temperature coefficient (NTC) resistor

contained in the plastic housing. NTC means; the

higher the temperature, then the lower the resis-

tance. The ECM also uses the coolant temperature

sensor signal to calculate glow plug relay triggering.

If the coolant temperature sensor fails during opera-

tion, the ECM will switch on the cooling fan to pre-

vent engine overheating (A/C models only).

REMOVAL

WARNING: Risk of injury to skin and eyes from

scalding with hot coolant. Risk of poisoning from

swallowing coolant. Do not open cooling system

unless coolant temperature is below 90ÉC. Open

cap slowly to release pressure. Store coolant in

suitable and appropriately marked container. Wear

protective gloves, clothes and eye wear.

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Partailly drain coolant system (Refer to 7 -

COOLING/ENGINE/COOLANT - STANDARD PRO-

CEDURE).

(4) Unplug coolant temperature sensor electrical

connector.

NOTE: Capture any residual coolant that may flow.

(5) Remove coolant temperature sensor (Fig. 7).

INSTALLATION

WARNING: Risk of injury to skin and eyes from

scalding with hot coolant. Risk of poisoning from

swallowing coolant. Do not open cooling system

unless coolant temperature is below 90ÉC (194ÉF).

Open cap slowly to release pressure. store coolant

in suitable and appropriately marked container.

Wear protective gloves, clothes and eye wear.

(1) Position and install coolant temperature sensor

(Fig. 7).

(2) Connect coolant temperature sensor electrical

connector (Fig. 7).

Fig. 6 ENGINE BLOCK HEATER

1 - ENGINE BLOCK HEATER

2 - CORE PLUG

3 - ENGINE MOUNT

4 - WIRING TIE STRAPS

Fig. 7 ENGINE COOLANT TEMPERATURE SENSOR

1 - RETAINING CLAMP

2 - ENGINE COOLANT TEMPERATURE SENSOR

VAENGINE 7 - 15

Page 845 of 2305

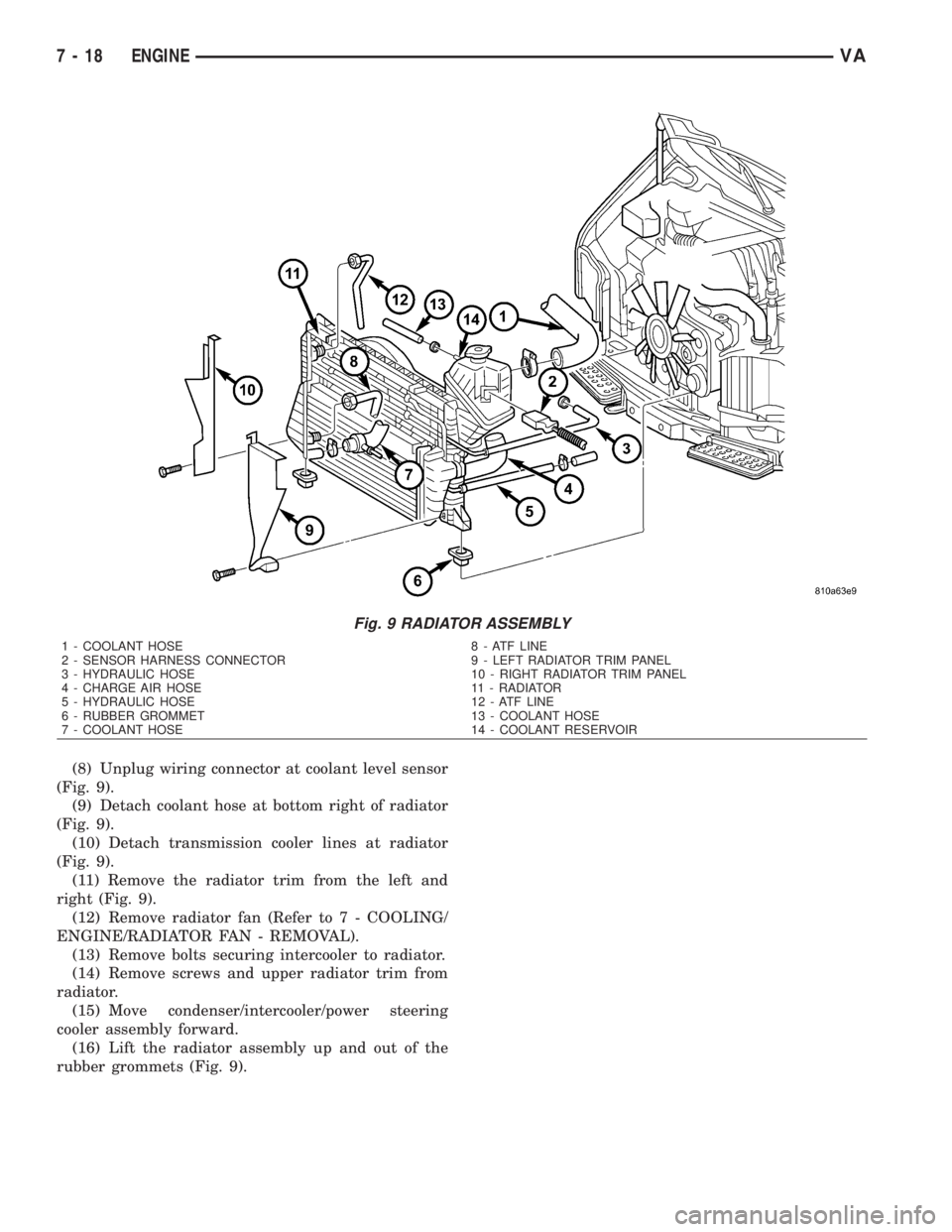

(8) Unplug wiring connector at coolant level sensor

(Fig. 9).

(9) Detach coolant hose at bottom right of radiator

(Fig. 9).

(10) Detach transmission cooler lines at radiator

(Fig. 9).

(11) Remove the radiator trim from the left and

right (Fig. 9).

(12) Remove radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

(13) Remove bolts securing intercooler to radiator.

(14) Remove screws and upper radiator trim from

radiator.

(15) Move condenser/intercooler/power steering

cooler assembly forward.

(16) Lift the radiator assembly up and out of the

rubber grommets (Fig. 9).

Fig. 9 RADIATOR ASSEMBLY

1 - COOLANT HOSE 8 - ATF LINE

2 - SENSOR HARNESS CONNECTOR 9 - LEFT RADIATOR TRIM PANEL

3 - HYDRAULIC HOSE 10 - RIGHT RADIATOR TRIM PANEL

4 - CHARGE AIR HOSE 11 - RADIATOR

5 - HYDRAULIC HOSE 12 - ATF LINE

6 - RUBBER GROMMET 13 - COOLANT HOSE

7 - COOLANT HOSE 14 - COOLANT RESERVOIR

7 - 18 ENGINEVA

Page 856 of 2305

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

CENTRAL TIMER MODULE

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE.............................2

REMOVAL.............................2

INSTALLATION..........................3

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................3

REMOVAL.............................3INSTALLATION..........................3

ENGINE CONTROL MODULE

DESCRIPTION..........................3

REMOVAL.............................6

INSTALLATION..........................6

TRANSMISSION CONTROL MODULE

DESCRIPTION..........................6

OPERATION............................7

STANDARD PROCEDURE - TCM ADAPTATION . 10

CENTRAL TIMER MODULE

DESCRIPTION

The central timer module (CTM) is located beneath

the driver seat. The CTM uses information carried on

the programmable communications interface (PCI)

data bus network along with many hard wired inputs

to monitor many sensor and switch inputs. In

response to those inputs, the circuitry and program-

ming of the CTM allow it to supply the vehicle occu-

pants with audible and visual information, and to

control and integrate many functions and features of

the vehicle through both hard wired outputs and the

transmission of message outputs to other modules in

the vehicle over the PCI data bus.

The features that the CTM supports or controls

include the following:

²Central Locking- The CTM on vehicles

equipped with the optional Vehicle Theft Security

System (VTSS) includes a central locking/unlocking

feature.

²Enhanced Accident Response- The CTM pro-

vides an optional enhanced accident response fea-

ture. This is a programmable feature.

²Panic Mode- The CTM provides support for

the optional RKE system panic mode including horn,

headlamp, and park lamp flash features.

²Power Lock Control- The CTM provides the

optional power lock system features, including sup-

port for the automatic door lock and door lock inhibit

modes.

²Programmable Features- The CTM provides

support for certain programmable features.

²Remote Keyless Entry- The CTM provides

the optional Remote Keyless Entry (RKE) system fea-

tures, including support for the RKE Lock (with

optional horn and park lamps flash), Unlock (with

park lamps flash, driver-door-only unlock, andunlock-all-doors), Panic, and illuminated entry

modes, as well as the ability to be programmed to

recognize up to four RKE transmitters. The RKE

horn, driver-door-only unlock, and unlock-all-doors

features are programmable.

²Vehicle Theft Security System- The CTM

provides control of the optional Vehicle Theft Secu-

rity System (VTSS) features, including support for

the central locking/unlocking mode and control of the

Security indicator in the instrument cluster.

Hard wired circuitry connects the CTM to the elec-

trical system of the vehicle. Refer to the appropriate

wiring information.

Many of the features in the vehicle controlled or

supported by the CTM are programmable using the

DRBIIItscan tool. However, if any of the CTM hard-

ware components are damaged or faulty, the entire

CTM unit must be replaced. The hard wired inputs

or outputs of all CTM versions can be diagnosed

using conventional diagnostic tools and methods;

however, for diagnosis of the CTM or the PCI data

bus, the use of a DRBIIItscan tool is required. Refer

to the appropriate diagnostic information.

OPERATION

The central timer module (CTM) monitors many

hard wired switch and sensor inputs as well as those

resources it shares with other modules in the vehicle

through its communication over the programmable

communications interface (PCI) data bus network.

The internal programming and all of these inputs

allow the CTM to determine the tasks it needs to

perform and their priorities, as well as both the stan-

dard and optional features that it should provide.

The CTM then performs those tasks and provides

those features through both PCI data bus communi-

cation with other modules and hard wired outputs

through a number of driver circuits, relays, and

VAELECTRONIC CONTROL MODULES 8E - 1

Page 857 of 2305

actuators.These outputs allow the CTM the ability to

control numerous accessory systems in the vehicle.

The CTM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the CTM include the fol-

lowing:

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (run-start)

²Ground

²Key-in ignition switch sense

²Sliding door switch sense

²Passenger door switch sense

²Driver door switch sense

²PCI bus circuit

HARD WIRED OUTPUTS

The hard wired outputs of the CTM include the fol-

lowing:

²Door lock relay output

²Door unlock relay output

²VTSS indicator driver

MESSAGING

The CTM uses the following messages received

from other electronic modules over the PCI data bus:

²Airbag Deploy (ACM)

²Beep request (CMTC)

²Charging System Failure (PCM)

²Chime request (EMIC)

²Engine RPM (PCM)

²OK to Arm VTSS (PCM)

²Security indicator request (SKIM)

²System Voltage (PCM)

²Valid/Invalid Key (SKIM)

²Vehicle Distance (PCM)

²Vehicle Speed (PCM)

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

WARNING: To avoid personal injury or death, on

vehicles equipped with airbags, disable the supple-

mental restraint system before attempting any

steering wheel, steering column, airbag, seat belt

tensioner, or instrument panel component diagno-

sis or service. Disconnect and isolate the battery

negative (ground) cable, then wait two minutes for

the system capacitor to discharge before perform-

ing further diagnosis or service. This is the only

sure way to disable the supplemental restraint sys-tem. Failure to take the proper precautions could

result in accidental airbag deployment.

The hard wired inputs to and outputs from the

central timer module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the CTM. In

order to obtain conclusive testing of the CTM, the

programmable communications interface (PCI) data

bus network and all of the modules that provide

inputs to or receive outputs from the CTM must also

be checked. The most reliable, efficient, and accurate

means to diagnose the CTM, the PCI data bus net-

work, and the modules that provide inputs to, or

receive outputs from, the CTM requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

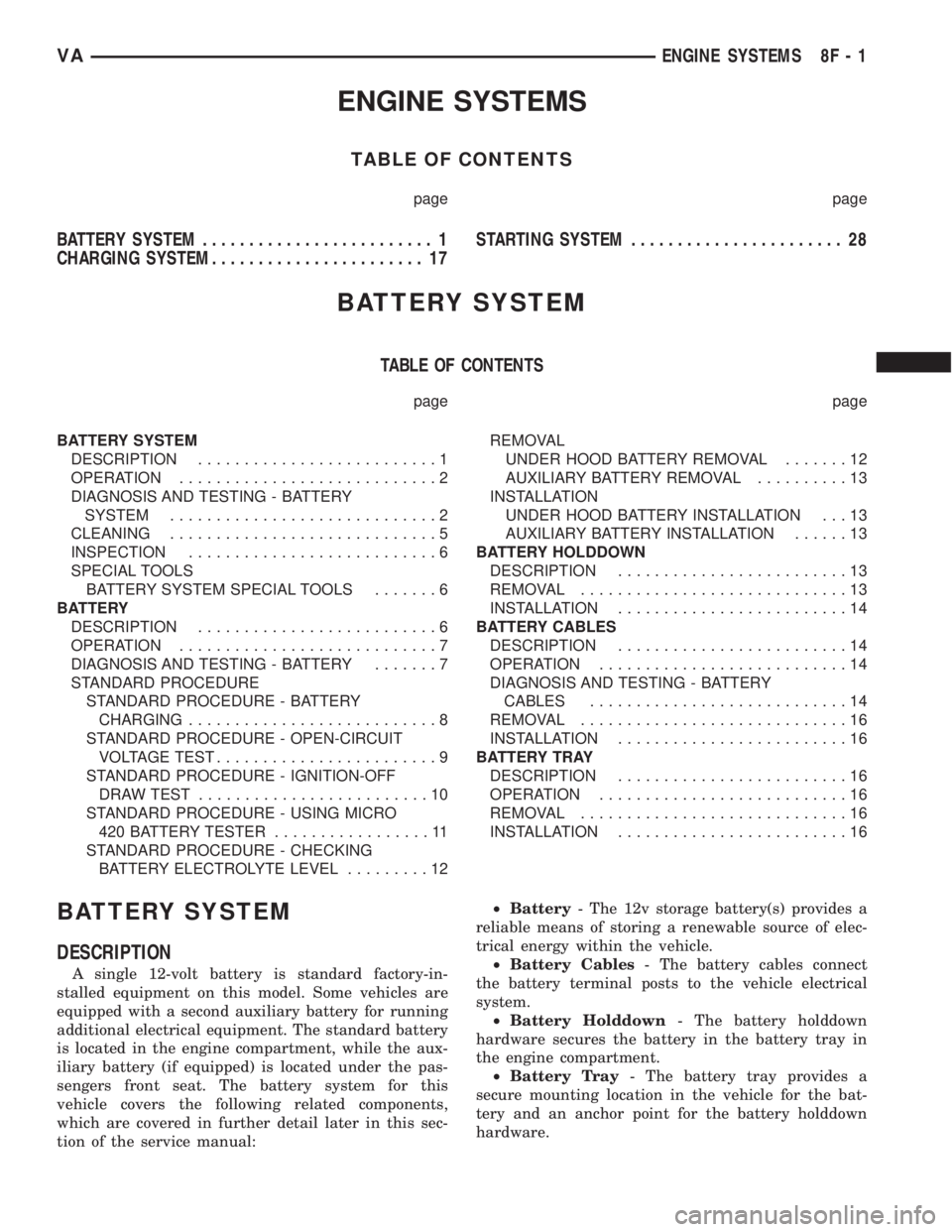

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Slide the driver seat to the full forward posi-

tion.

(3) Disconnect the wire harness connector for the

seat belt latch. (Fig. 1).

(4) Remove the screws that secure the closeout

panel beneathe the driver seat cushion and remove

the panel.

(5) Remove the screws that secure the central

timer module to the bracket.

(6) Disconnect the wire harness connectors from

the central timer module.

(7) Remove the central timer module from the

vehicle.

8E - 2 ELECTRONIC CONTROL MODULESVA

Page 858 of 2305

INSTALLATION

(1) Position the central timer module in the vehicle

(2) Connect the wire harness connectors to the

central timer module.

(3) Install the screws that secure the central timer

module. Tighten the screws securely.

(4) Route the seat belt latch wire lead through the

hole in the closeout panel and position the panel

beneath the driver seat cushion

(5) Install the screws that secure the closeout

panel beneath the driver seat cushion. Tighten the

screws securely.

(6) Connect the wire harness connector to the seat

belt latch connector.

(7) Slide the driver seat to back to its original posi-

tion.

(8) Reconnect the negative battery cable.

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system.

REMOVAL

(1) Remove the negative battery cable from the

battery.

(2) Pull up on the CAB harness connector release

and remove connector.

(3) Remove the CAB mounting bolts.

(4) Remove the CAB from the HCU.

INSTALLATION

(1) Install CAB to the HCU.

(2) Install mounting bolts. Tighten to 2 N´m (16 in.

lbs.).

(3) Install the wiring harness connector to the

CAB and push down on the release to secure the con-

nector.

(4) Install negative battery cable to the battery.

ENGINE CONTROL MODULE

DESCRIPTION

The electronic control module (ECM) is mounted to

the left lower dash panel and consists of an electronic

printed circuit board which is designed as a milliliter

board assembly fitted on both sides. The routing of

the wiring harness connector at the ECM connector

are split into interfering cables and sensitive cables

in order to achieve improved electromagnetic compat-

ibility. The smaller wiring harness connector is used

for the vehicle wiring harness and the larger harness

is used for the engine wiring harness. The ECM

stores engine specific data, monitors the connected

sensor and analyzes their measurement (Fig. 2).

Its task consists in controlling the following sys-

tems in line with the analysis of the input signals:

²Fuel Supply System

²Injected Quantity Control

²Emission Control System

²Charge Pressure Control

²Cruise Control

²A/C Compressor Shut-Off

²Pre-Heating Output Relay for the Glow Plugs

²Vehicle Theft

²Air Bag

²Monitors inputs/outputs, checks plausibility and

stores faults

²Share information with other control modules

²Diagnosis

If a sensor should fail, provided the fault is not

serious, the ECM will continue to operate the engine

in Limp-Home Mode (emergency mode) using a

default value for the missing signal. The ECM

ensures that, continuing to operate the engine will

not cause damage or effect safety, otherwise a Engine

shut-off process will be carried out (Fig. 3).Fig. 1 Central Timer Module

1 - DRIVER SEAT

2 - WIRE HARNESS CONNECTOR

3 - SCREW (2)

4 - CLOSEOUT PANEL

5 - CENTRAL TIMER MODULE

6 - WIRE HARNESS CONNECTOR (2)

7 - SCREW (2)

VAELECTRONIC CONTROL MODULES 8E - 3

Page 866 of 2305

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING SYSTEM....................... 17STARTING SYSTEM....................... 28

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - BATTERY

SYSTEM.............................2

CLEANING.............................5

INSPECTION...........................6

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS.......6

BATTERY

DESCRIPTION..........................6

OPERATION............................7

DIAGNOSIS AND TESTING - BATTERY.......7

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING...........................8

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST........................9

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST.........................10

STANDARD PROCEDURE - USING MICRO

420 BATTERY TESTER.................11

STANDARD PROCEDURE - CHECKING

BATTERY ELECTROLYTE LEVEL.........12REMOVAL

UNDER HOOD BATTERY REMOVAL.......12

AUXILIARY BATTERY REMOVAL..........13

INSTALLATION

UNDER HOOD BATTERY INSTALLATION . . . 13

AUXILIARY BATTERY INSTALLATION......13

BATTERY HOLDDOWN

DESCRIPTION.........................13

REMOVAL.............................13

INSTALLATION.........................14

BATTERY CABLES

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - BATTERY

CABLES............................14

REMOVAL.............................16

INSTALLATION.........................16

BATTERY TRAY

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

BATTERY SYSTEM

DESCRIPTION

A single 12-volt battery is standard factory-in-

stalled equipment on this model. Some vehicles are

equipped with a second auxiliary battery for running

additional electrical equipment. The standard battery

is located in the engine compartment, while the aux-

iliary battery (if equipped) is located under the pas-

sengers front seat. The battery system for this

vehicle covers the following related components,

which are covered in further detail later in this sec-

tion of the service manual:²Battery- The 12v storage battery(s) provides a

reliable means of storing a renewable source of elec-

trical energy within the vehicle.

²Battery Cables- The battery cables connect

the battery terminal posts to the vehicle electrical

system.

²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

VAENGINE SYSTEMS 8F - 1

Page 875 of 2305

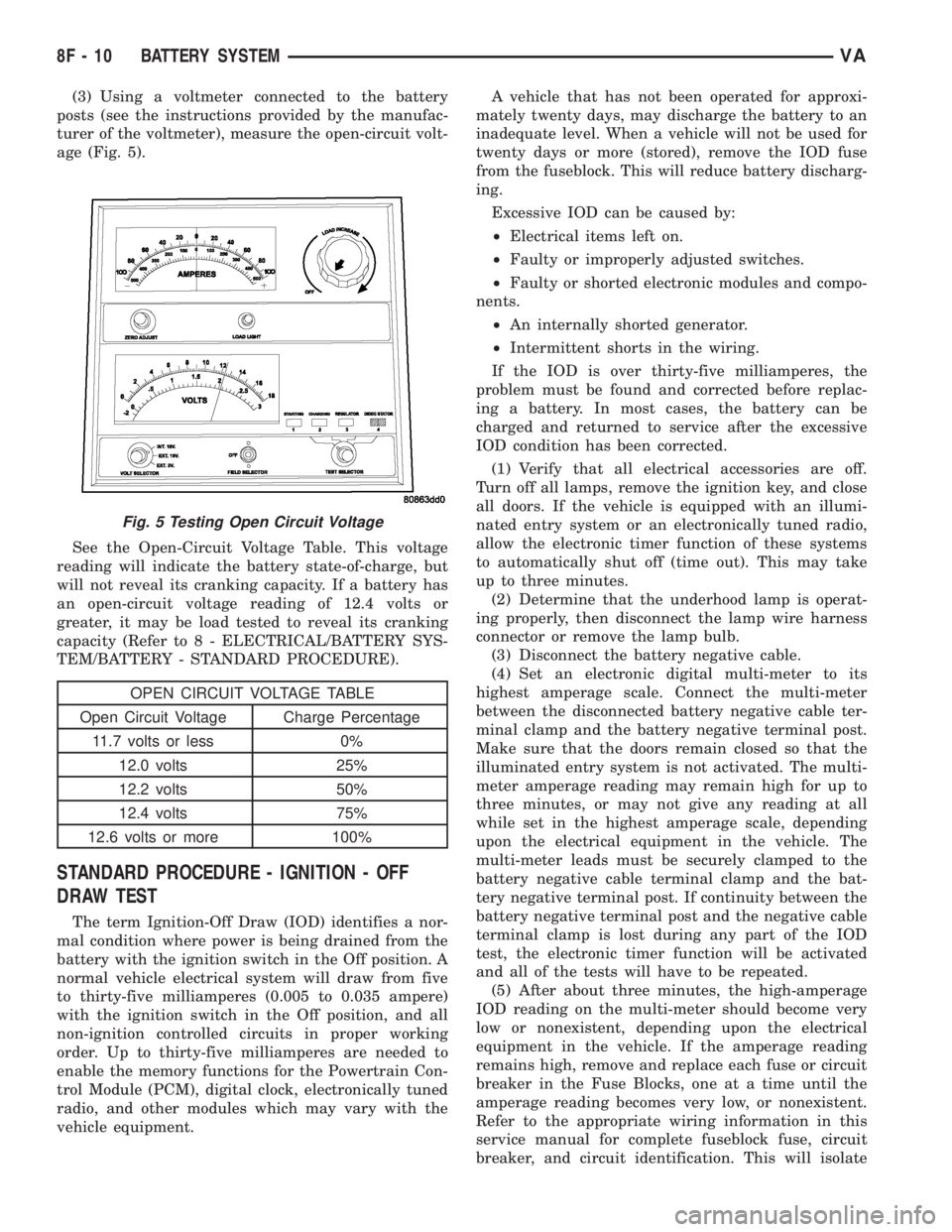

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 5).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

STANDARD PROCEDURE - IGNITION - OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the fuseblock. This will reduce battery discharg-

ing.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes.

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(5) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Fuse Blocks, one at a time until the

amperage reading becomes very low, or nonexistent.

Refer to the appropriate wiring information in this

service manual for complete fuseblock fuse, circuit

breaker, and circuit identification. This will isolate

Fig. 5 Testing Open Circuit Voltage

8F - 10 BATTERY SYSTEMVA

Page 878 of 2305

AUXILIARY BATTERY REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the passenger front seat assembly.

Refer to the Body section for procedure.

(3) Remove the top cover from the seat base

assembly.

(4) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post.

(6) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(7) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(8) Remove the battery hold downs from the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - REMOVAL).

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(9) Remove the battery from the battery tray.

INSTALLATION

UNDER HOOD BATTERY INSTALLATION

(1) Position the battery onto the battery tray.

Ensure that the battery positive and negative termi-

nal posts are correctly positioned. The battery cable

terminal clamps must reach the correct battery ter-

minal post without stretching the cables.

(2) Reinstall the battery hold downs onto the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - INSTALLATION).

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reverse battery polarity may damage

electrical components of the vehicle.

(3) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 11.8 N´m

(105 in. lbs.).

(4) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 7.9 N´m (70

in. lbs.).(5) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.

AUXILIARY BATTERY INSTALLATION

(1) Position the battery onto the battery tray.

Ensure that the battery positive and negative termi-

nal posts are correctly positioned. The battery cable

terminal clamps must reach the correct battery ter-

minal post without stretching the cables.

(2) Reinstall the battery hold downs onto the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - INSTALLATION).

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reverse battery polarity may damage

electrical components of the vehicle.

(3) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 11.8 N´m

(105 in. lbs.).

(4) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 7.9 N´m (70

in. lbs.).

(5) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.

(6) Install the top cover on the seat base assembly.

(7) Install the passenger front seat assembly. Refer

to the Body section for procedure.

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware includes two hex

nuts with washers and two hold down brackets. The

battery hold down brackets are formed of stamped

steel. The hold down assembly is coated for corrosion

protection.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the two nuts that secure the battery

hold down brackets to the battery tray.

(3) Remove the battery hold down brackets.

VABATTERY SYSTEM 8F - 13