ECU MERCEDES-BENZ SPRINTER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 704 of 2305

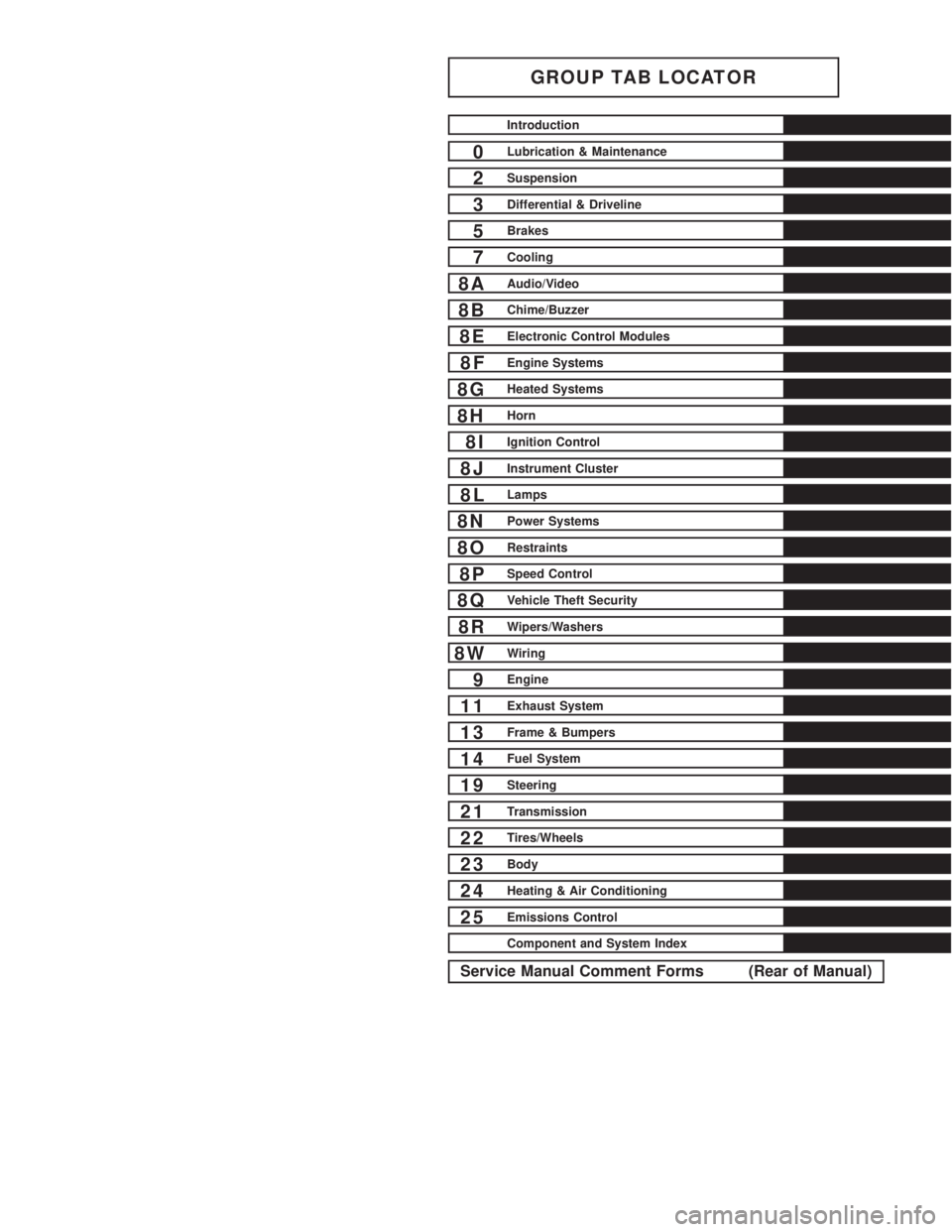

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 720 of 2305

Do not blend other specific fuel additives with die-

sel fuel. They only result in unnecessary cost, and

may be harmful to the engine operation.

POWER STEERING FLUID

No fluid service required. Filled with Power Steer-

ing Fluid approved to MB 236.3, such as Mobil

ATF-D (Exxon Mobil Corporation) or equivalent.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

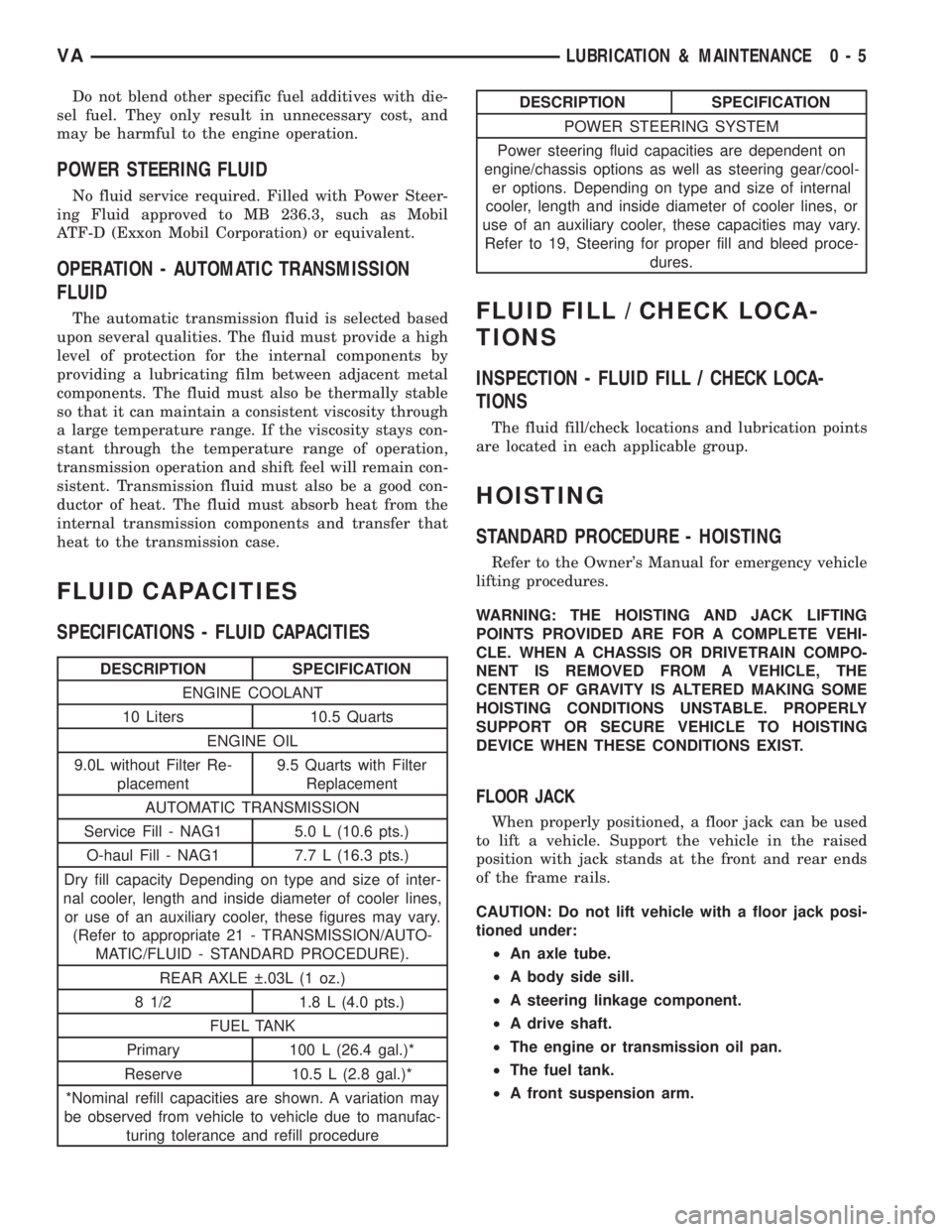

FLUID CAPACITIES

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

ENGINE COOLANT

10 Liters 10.5 Quarts

ENGINE OIL

9.0L without Filter Re-

placement9.5 Quarts with Filter

Replacement

AUTOMATIC TRANSMISSION

Service Fill - NAG1 5.0 L (10.6 pts.)

O-haul Fill - NAG1 7.7 L (16.3 pts.)

Dry fill capacity Depending on type and size of inter-

nal cooler, length and inside diameter of cooler lines,

or use of an auxiliary cooler, these figures may vary.

(Refer to appropriate 21 - TRANSMISSION/AUTO-

MATIC/FLUID - STANDARD PROCEDURE).

REAR AXLE .03L (1 oz.)

8 1/2 1.8 L (4.0 pts.)

FUEL TANK

Primary 100 L (26.4 gal.)*

Reserve 10.5 L (2.8 gal.)*

*Nominal refill capacities are shown. A variation may

be observed from vehicle to vehicle due to manufac-

turing tolerance and refill procedure

DESCRIPTION SPECIFICATION

POWER STEERING SYSTEM

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cool-

er options. Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these capacities may vary.

Refer to 19, Steering for proper fill and bleed proce-

dures.

FLUID FILL / CHECK LOCA-

TIONS

INSPECTION - FLUID FILL / CHECK LOCA-

TIONS

The fluid fill/check locations and lubrication points

are located in each applicable group.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT OR SECURE VEHICLE TO HOISTING

DEVICE WHEN THESE CONDITIONS EXIST.

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a vehicle. Support the vehicle in the raised

position with jack stands at the front and rear ends

of the frame rails.

CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

²An axle tube.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.

VALUBRICATION & MAINTENANCE 0 - 5

Page 722 of 2305

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

STANDARD PROCEDURE - TOWING

WARNING: Do not tow the vehicle if the key cannot

be turned in the ignition lock. If the key cannot be

turned, the ignition lock remains locked and the

vehicle cannot be steered. With the engine not run-

ning there is no power assistance for the braking

and steering systems. In this case, it is important to

keep in mind that a considerably higher degree of

effort is necessary to brake and steer the vehicle.

The vehicle must not be towed with the front axle

raised and the key in position 2 in the ignition lock

as the drive wheels could then lock due to the

acceleration skid control (ASR)

If the Engine is Damaged

For towing distances up to 30 miles (about 50

km)

²Shift selector lever in ªNº position.

²Do not exceed a towing speed of 30 m.p.h. (50

km/h).

For towing distances greater than 30 mile

(about 50 km)

²Remove the propeller shafts leading to the drive

axles. The vehicle can be towed without restriction.

If the Transmission is Damaged

²Remove the propeller shafts leading to the drive

axles. The vehicle can be towed without restriction.

If the Front Axle is Damaged

²Raise the front axle.

²Observe the same towing restrictions as for

engine damage.

If the Rear Axle is Damaged

²Raise the rear axle.

NOTE: Comply with local legal regulations regard-

ing towing vehicles.

SAFETY PRECAUTIONS

NOTE: The following safety precautions must be

observed when towing a vehicle.

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Remove exhaust pipe tips that interfere with the

tow sling and crossbar

²Padding should be placed between the tow sling/

crossbar and any painted surfaces

²When placing tow hooks on the rear axle, posi-

tion them so they do not damage the brake tubing or

hoses

²Do not tow the vehicle by connecting to the front

or rear shock absorbers

²Do not tow a heavily loaded vehicle. Damage to

the vehicle may result. Use a flatbed device to trans-

port a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain, steep rises in the road or if the vehicle

is equipped with air dams, spoilers, and/or ground

VALUBRICATION & MAINTENANCE 0 - 7

Page 743 of 2305

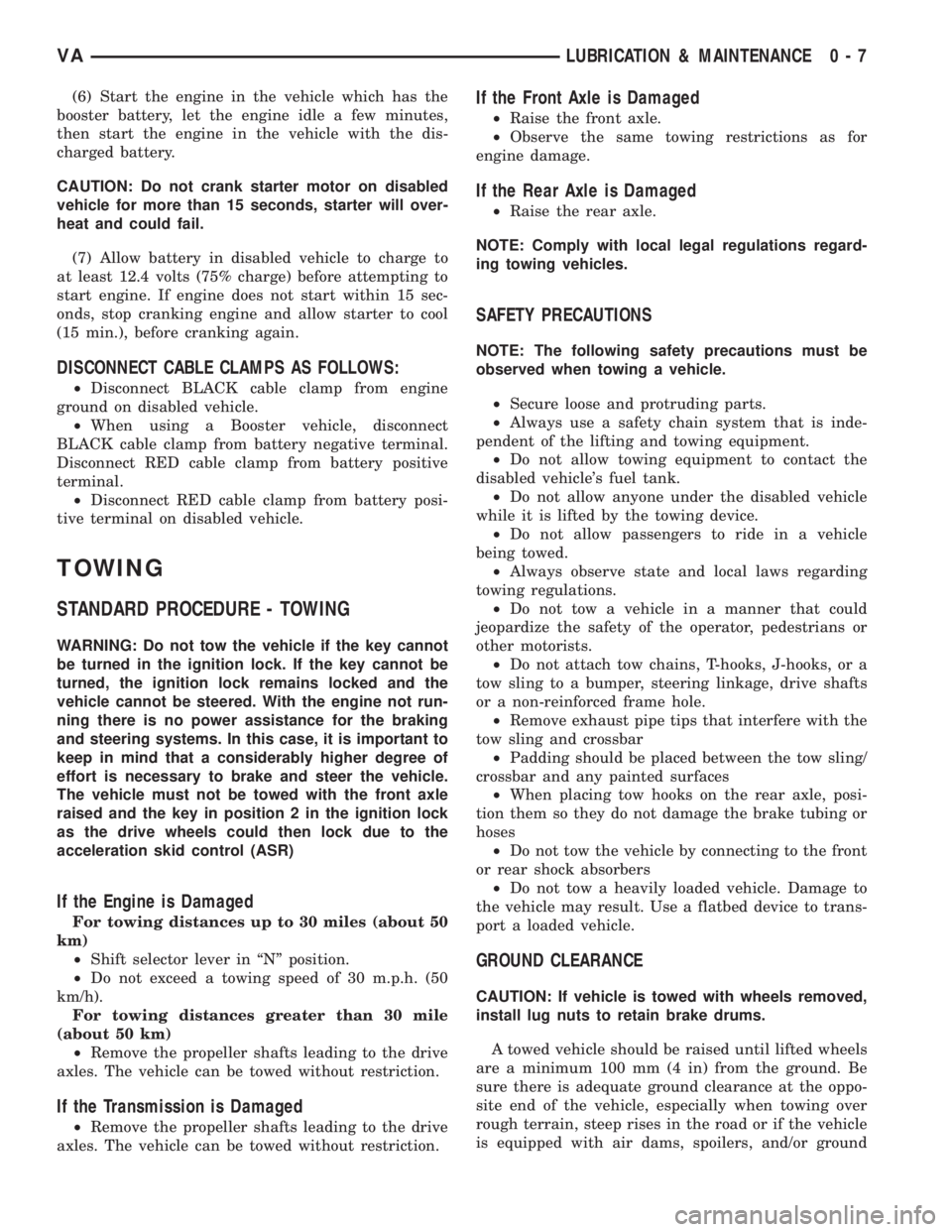

SUSPENSION AND STEERING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Loose or worn steering or sus-

pension components.3. Tighten or replace components as nec-

essary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Loose or worn steering gear. 3. Replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE INSTABILITY 1. Loose or worn wheel bearing. 1. Replace wheel bearing.

2. Loose or worn steering or sus-

pension components.2. Tighten or replace components as nec-

essary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Replace steering gear.

2. Column coupler binding. 2. Replace coupler.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

VEHICLE PULLS TO ONE

SIDE1. Tire pressure. 1. Adjust tire pressure.

2. Tire. 2. Criss-Cross Front Tires.

3. Alignment. 3. Align vehicle to specifications.

4. Loose or worn steering or sus-

pension components.4. Tighten or replace components as nec-

essary.

5. Radial tire lead. 5. Rotate or replace tire as necessary.

6. Brake pull. 6. Repair brake as necessary.

7. Weak or broken spring. 7. Replace spring.

STANDARD PROCEDURE - TOE ADJUSTMENT

CAMBER AND CASTER ARE NOT ADJUSTABLE

(TOE ONLY)..

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the

inner tie rod as necessary.

2 - 18 WHEEL ALIGNMENTVA

Page 752 of 2305

PROPELLER SHAFT

REMOVAL

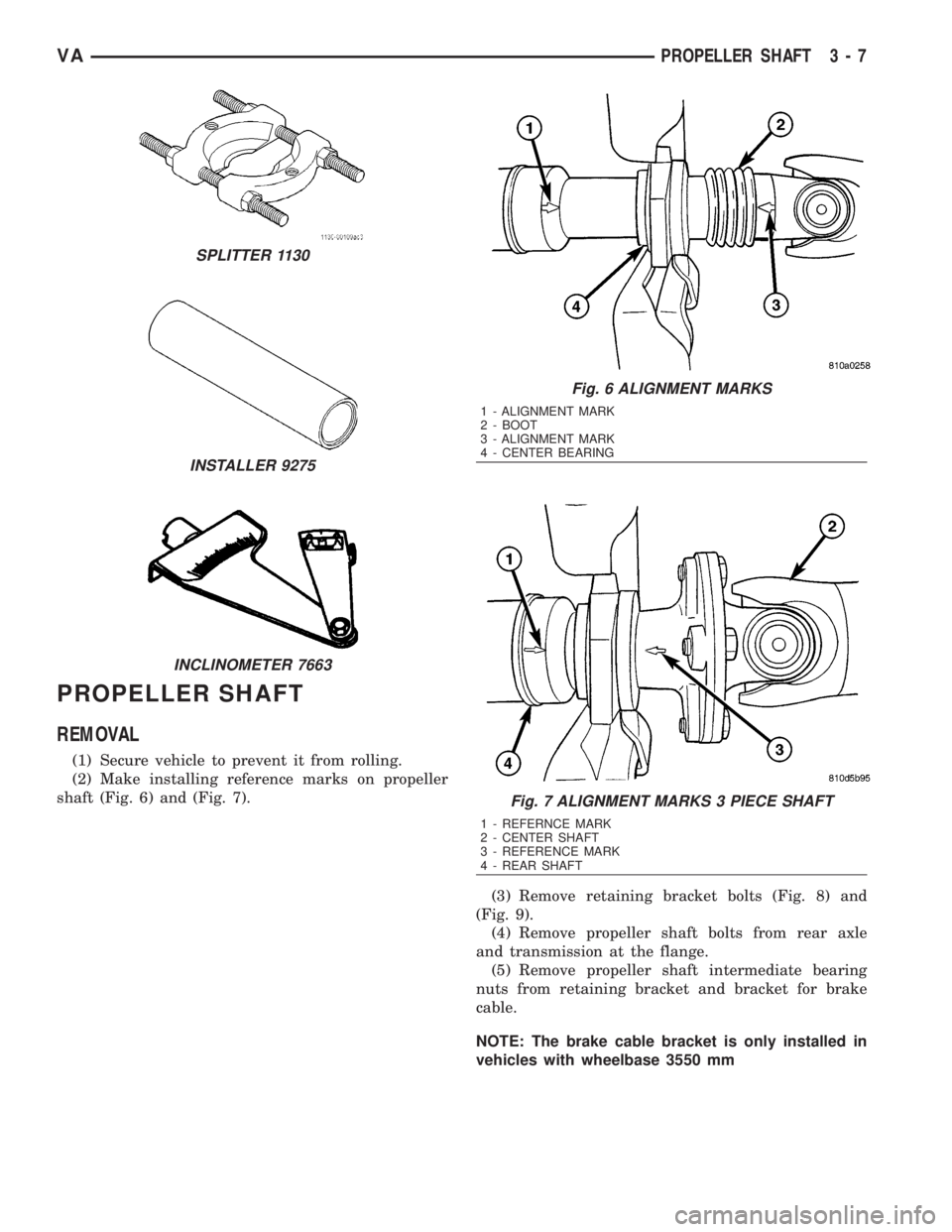

(1) Secure vehicle to prevent it from rolling.

(2) Make installing reference marks on propeller

shaft (Fig. 6) and (Fig. 7).

(3) Remove retaining bracket bolts (Fig. 8) and

(Fig. 9).

(4) Remove propeller shaft bolts from rear axle

and transmission at the flange.

(5) Remove propeller shaft intermediate bearing

nuts from retaining bracket and bracket for brake

cable.

NOTE: The brake cable bracket is only installed in

vehicles with wheelbase 3550 mm

SPLITTER 1130

INSTALLER 9275

INCLINOMETER 7663

Fig. 6 ALIGNMENT MARKS

1 - ALIGNMENT MARK

2 - BOOT

3 - ALIGNMENT MARK

4 - CENTER BEARING

Fig. 7 ALIGNMENT MARKS 3 PIECE SHAFT

1 - REFERNCE MARK

2 - CENTER SHAFT

3 - REFERENCE MARK

4 - REAR SHAFT

VAPROPELLER SHAFT 3 - 7

Page 760 of 2305

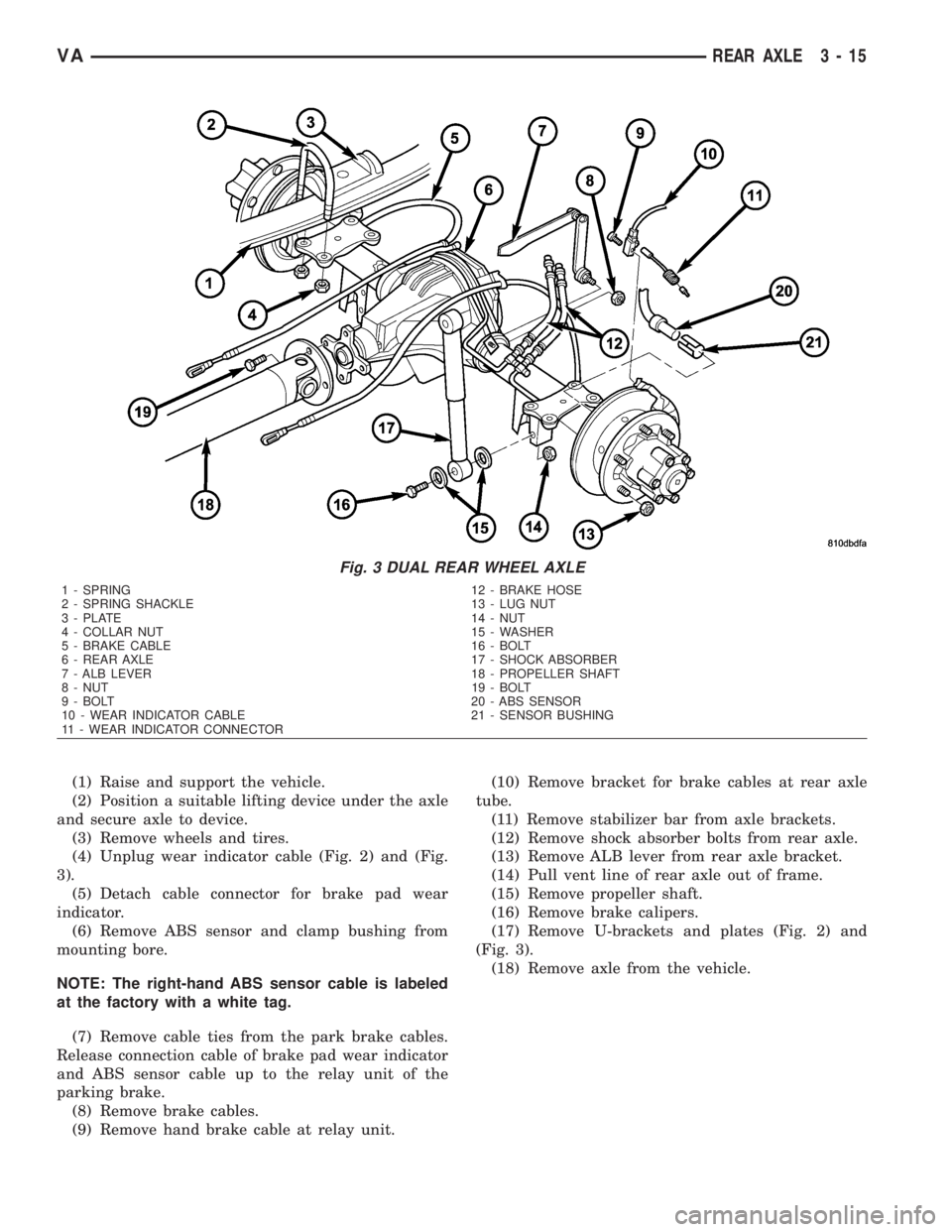

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the axle

and secure axle to device.

(3) Remove wheels and tires.

(4) Unplug wear indicator cable (Fig. 2) and (Fig.

3).

(5) Detach cable connector for brake pad wear

indicator.

(6) Remove ABS sensor and clamp bushing from

mounting bore.

NOTE: The right-hand ABS sensor cable is labeled

at the factory with a white tag.

(7) Remove cable ties from the park brake cables.

Release connection cable of brake pad wear indicator

and ABS sensor cable up to the relay unit of the

parking brake.

(8) Remove brake cables.

(9) Remove hand brake cable at relay unit.(10) Remove bracket for brake cables at rear axle

tube.

(11) Remove stabilizer bar from axle brackets.

(12) Remove shock absorber bolts from rear axle.

(13) Remove ALB lever from rear axle bracket.

(14) Pull vent line of rear axle out of frame.

(15) Remove propeller shaft.

(16) Remove brake calipers.

(17) Remove U-brackets and plates (Fig. 2) and

(Fig. 3).

(18) Remove axle from the vehicle.

Fig. 3 DUAL REAR WHEEL AXLE

1 - SPRING 12 - BRAKE HOSE

2 - SPRING SHACKLE 13 - LUG NUT

3 - PLATE 14 - NUT

4 - COLLAR NUT 15 - WASHER

5 - BRAKE CABLE 16 - BOLT

6 - REAR AXLE 17 - SHOCK ABSORBER

7 - ALB LEVER 18 - PROPELLER SHAFT

8 - NUT 19 - BOLT

9 - BOLT 20 - ABS SENSOR

10 - WEAR INDICATOR CABLE 21 - SENSOR BUSHING

11 - WEAR INDICATOR CONNECTOR

VAREAR AXLE 3 - 15

Page 793 of 2305

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE GRAB OR PULL

Rear grab or pull is usually caused by improperly

adjusted or seized parking brake cables, contami-

nated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is

involved. However, when both rear wheels are

affected, the master cylinder or proportioning valve

could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or worn seals, driving through deep

water puddles, or lining that has become covered

with grease and grit during repair. Contaminated lin-

ing should be replaced to avoid further brake prob-

lems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfacesafter a few brake applications causing the noise to

subside.

BRAKE SQUEAK / SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake pads in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors can become so scored that replacement is nec-

essary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

THUMP / CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise.

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL BLEEDING

Use approved brake fluid (Refer to LUBRICATION

& MAINTENANCE/FLUID TYPES - DESCRIP-

TION). Use fresh, clean fluid from a sealed container

at all times.

(1) Remove reservoir filler caps and fill reservoir.

(2) If calipers, or wheel cylinders were overhauled,

open all caliper and wheel cylinder bleed screws.

Then close each bleed screw as fluid starts to drip

from it. Top off master cylinder reservoir once more

before proceeding.

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

5 - 4 BRAKES - BASEVA

Page 809 of 2305

edge of the diaphragm is secured to the housing. The

booster push rod, which connects the booster to the

brake pedal and master cylinder, is attached to the

center of the diaphragm. A check valve is used in the

booster outlet connected to the engine intake mani-

fold. Power assist is generated by utilizing a combi-

nation of vacuum and atmospheric pressure to boost

brake assist.

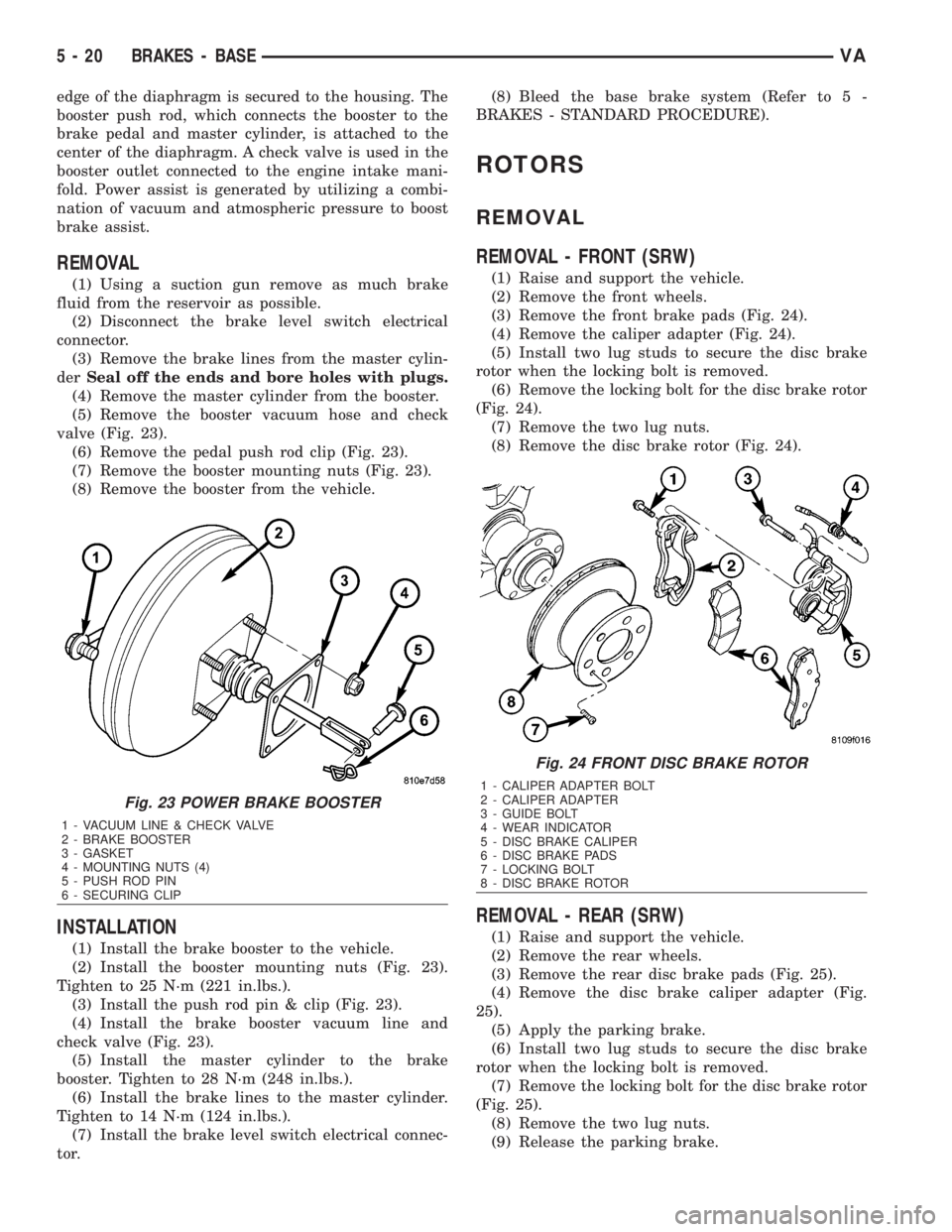

REMOVAL

(1) Using a suction gun remove as much brake

fluid from the reservoir as possible.

(2) Disconnect the brake level switch electrical

connector.

(3) Remove the brake lines from the master cylin-

derSeal off the ends and bore holes with plugs.

(4) Remove the master cylinder from the booster.

(5) Remove the booster vacuum hose and check

valve (Fig. 23).

(6) Remove the pedal push rod clip (Fig. 23).

(7) Remove the booster mounting nuts (Fig. 23).

(8) Remove the booster from the vehicle.

INSTALLATION

(1) Install the brake booster to the vehicle.

(2) Install the booster mounting nuts (Fig. 23).

Tighten to 25 N´m (221 in.lbs.).

(3) Install the push rod pin & clip (Fig. 23).

(4) Install the brake booster vacuum line and

check valve (Fig. 23).

(5) Install the master cylinder to the brake

booster. Tighten to 28 N´m (248 in.lbs.).

(6) Install the brake lines to the master cylinder.

Tighten to 14 N´m (124 in.lbs.).

(7) Install the brake level switch electrical connec-

tor.(8) Bleed the base brake system (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

ROTORS

REMOVAL

REMOVAL - FRONT (SRW)

(1) Raise and support the vehicle.

(2) Remove the front wheels.

(3) Remove the front brake pads (Fig. 24).

(4) Remove the caliper adapter (Fig. 24).

(5) Install two lug studs to secure the disc brake

rotor when the locking bolt is removed.

(6) Remove the locking bolt for the disc brake rotor

(Fig. 24).

(7) Remove the two lug nuts.

(8) Remove the disc brake rotor (Fig. 24).

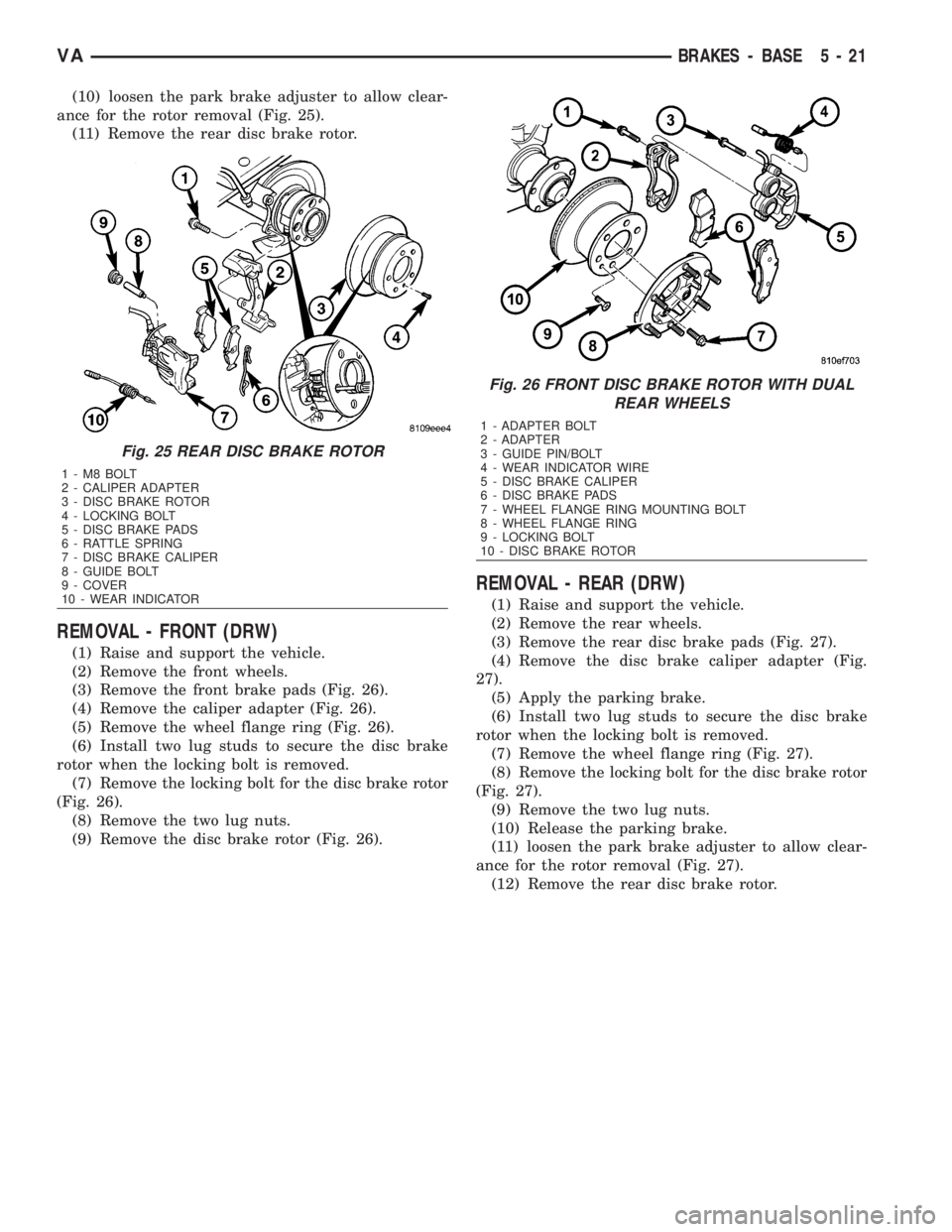

REMOVAL - REAR (SRW)

(1) Raise and support the vehicle.

(2) Remove the rear wheels.

(3) Remove the rear disc brake pads (Fig. 25).

(4) Remove the disc brake caliper adapter (Fig.

25).

(5) Apply the parking brake.

(6) Install two lug studs to secure the disc brake

rotor when the locking bolt is removed.

(7) Remove the locking bolt for the disc brake rotor

(Fig. 25).

(8) Remove the two lug nuts.

(9) Release the parking brake.

Fig. 23 POWER BRAKE BOOSTER

1 - VACUUM LINE & CHECK VALVE

2 - BRAKE BOOSTER

3 - GASKET

4 - MOUNTING NUTS (4)

5 - PUSH ROD PIN

6 - SECURING CLIP

Fig. 24 FRONT DISC BRAKE ROTOR

1 - CALIPER ADAPTER BOLT

2 - CALIPER ADAPTER

3 - GUIDE BOLT

4 - WEAR INDICATOR

5 - DISC BRAKE CALIPER

6 - DISC BRAKE PADS

7 - LOCKING BOLT

8 - DISC BRAKE ROTOR

5 - 20 BRAKES - BASEVA

Page 810 of 2305

(10) loosen the park brake adjuster to allow clear-

ance for the rotor removal (Fig. 25).

(11) Remove the rear disc brake rotor.

REMOVAL - FRONT (DRW)

(1) Raise and support the vehicle.

(2) Remove the front wheels.

(3) Remove the front brake pads (Fig. 26).

(4) Remove the caliper adapter (Fig. 26).

(5) Remove the wheel flange ring (Fig. 26).

(6) Install two lug studs to secure the disc brake

rotor when the locking bolt is removed.

(7) Remove the locking bolt for the disc brake rotor

(Fig. 26).

(8) Remove the two lug nuts.

(9) Remove the disc brake rotor (Fig. 26).

REMOVAL - REAR (DRW)

(1) Raise and support the vehicle.

(2) Remove the rear wheels.

(3) Remove the rear disc brake pads (Fig. 27).

(4) Remove the disc brake caliper adapter (Fig.

27).

(5) Apply the parking brake.

(6) Install two lug studs to secure the disc brake

rotor when the locking bolt is removed.

(7) Remove the wheel flange ring (Fig. 27).

(8) Remove the locking bolt for the disc brake rotor

(Fig. 27).

(9) Remove the two lug nuts.

(10) Release the parking brake.

(11) loosen the park brake adjuster to allow clear-

ance for the rotor removal (Fig. 27).

(12) Remove the rear disc brake rotor.

Fig. 25 REAR DISC BRAKE ROTOR

1-M8BOLT

2 - CALIPER ADAPTER

3 - DISC BRAKE ROTOR

4 - LOCKING BOLT

5 - DISC BRAKE PADS

6 - RATTLE SPRING

7 - DISC BRAKE CALIPER

8 - GUIDE BOLT

9 - COVER

10 - WEAR INDICATOR

Fig. 26 FRONT DISC BRAKE ROTOR WITH DUAL

REAR WHEELS

1 - ADAPTER BOLT

2 - ADAPTER

3 - GUIDE PIN/BOLT

4 - WEAR INDICATOR WIRE

5 - DISC BRAKE CALIPER

6 - DISC BRAKE PADS

7 - WHEEL FLANGE RING MOUNTING BOLT

8 - WHEEL FLANGE RING

9 - LOCKING BOLT

10 - DISC BRAKE ROTOR

VABRAKES - BASE 5 - 21

Page 823 of 2305

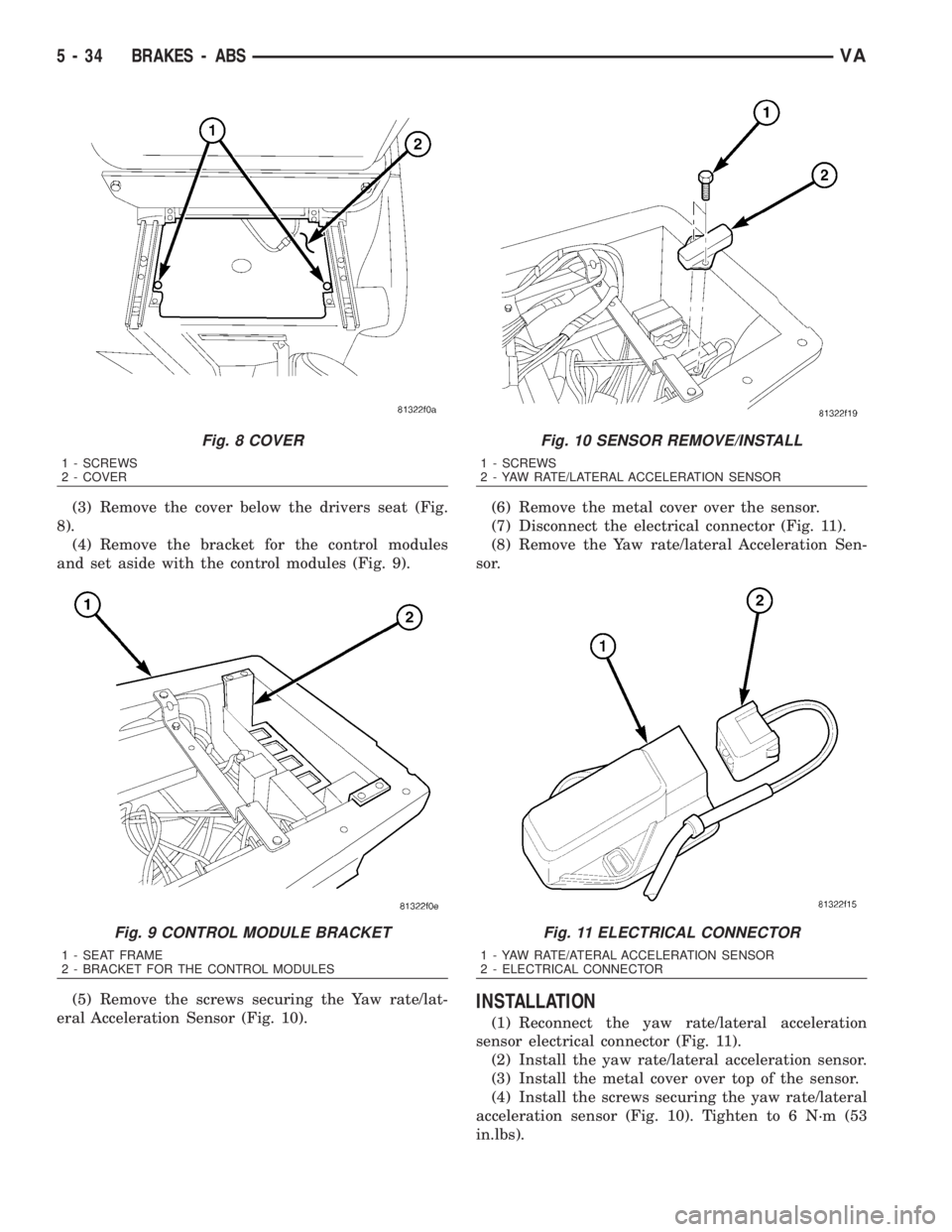

(3) Remove the cover below the drivers seat (Fig.

8).

(4) Remove the bracket for the control modules

and set aside with the control modules (Fig. 9).

(5) Remove the screws securing the Yaw rate/lat-

eral Acceleration Sensor (Fig. 10).(6) Remove the metal cover over the sensor.

(7) Disconnect the electrical connector (Fig. 11).

(8) Remove the Yaw rate/lateral Acceleration Sen-

sor.

INSTALLATION

(1) Reconnect the yaw rate/lateral acceleration

sensor electrical connector (Fig. 11).

(2) Install the yaw rate/lateral acceleration sensor.

(3) Install the metal cover over top of the sensor.

(4) Install the screws securing the yaw rate/lateral

acceleration sensor (Fig. 10). Tighten to 6 N´m (53

in.lbs).

Fig. 8 COVER

1 - SCREWS

2 - COVER

Fig. 9 CONTROL MODULE BRACKET

1 - SEAT FRAME

2 - BRACKET FOR THE CONTROL MODULES

Fig. 10 SENSOR REMOVE/INSTALL

1 - SCREWS

2 - YAW RATE/LATERAL ACCELERATION SENSOR

Fig. 11 ELECTRICAL CONNECTOR

1 - YAW RATE/ATERAL ACCELERATION SENSOR

2 - ELECTRICAL CONNECTOR

5 - 34 BRAKES - ABSVA