clock MERCEDES-BENZ SPRINTER 2006 Manual Online

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1877 of 2305

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Verify that the vehicle is parked on a level sur-

face.

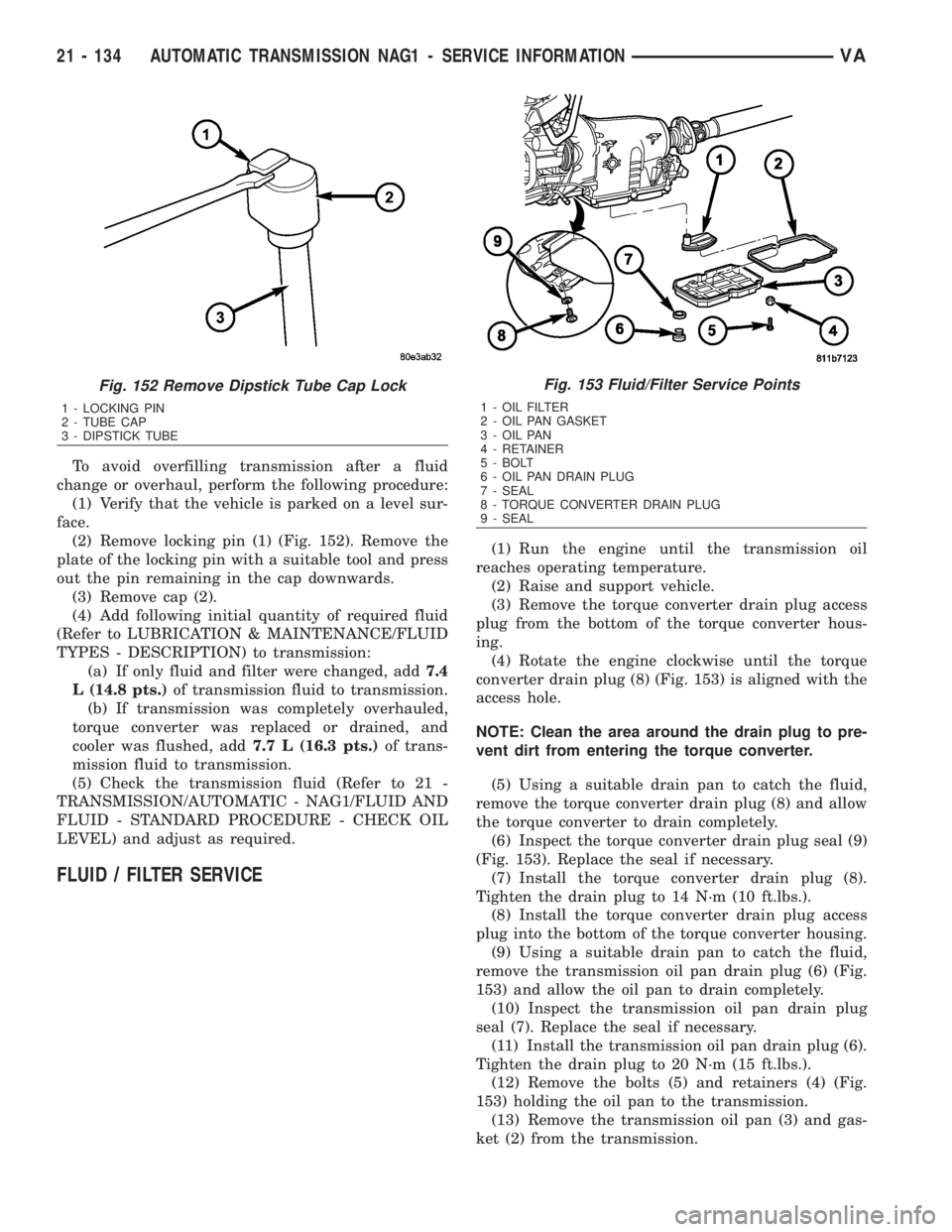

(2) Remove locking pin (1) (Fig. 152). Remove the

plate of the locking pin with a suitable tool and press

out the pin remaining in the cap downwards.

(3) Remove cap (2).

(4) Add following initial quantity of required fluid

(Refer to LUBRICATION & MAINTENANCE/FLUID

TYPES - DESCRIPTION) to transmission:

(a) If only fluid and filter were changed, add7.4

L (14.8 pts.)of transmission fluid to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add7.7 L (16.3 pts.)of trans-

mission fluid to transmission.

(5) Check the transmission fluid (Refer to 21 -

TRANSMISSION/AUTOMATIC - NAG1/FLUID AND

FLUID - STANDARD PROCEDURE - CHECK OIL

LEVEL) and adjust as required.

FLUID / FILTER SERVICE

(1) Run the engine until the transmission oil

reaches operating temperature.

(2) Raise and support vehicle.

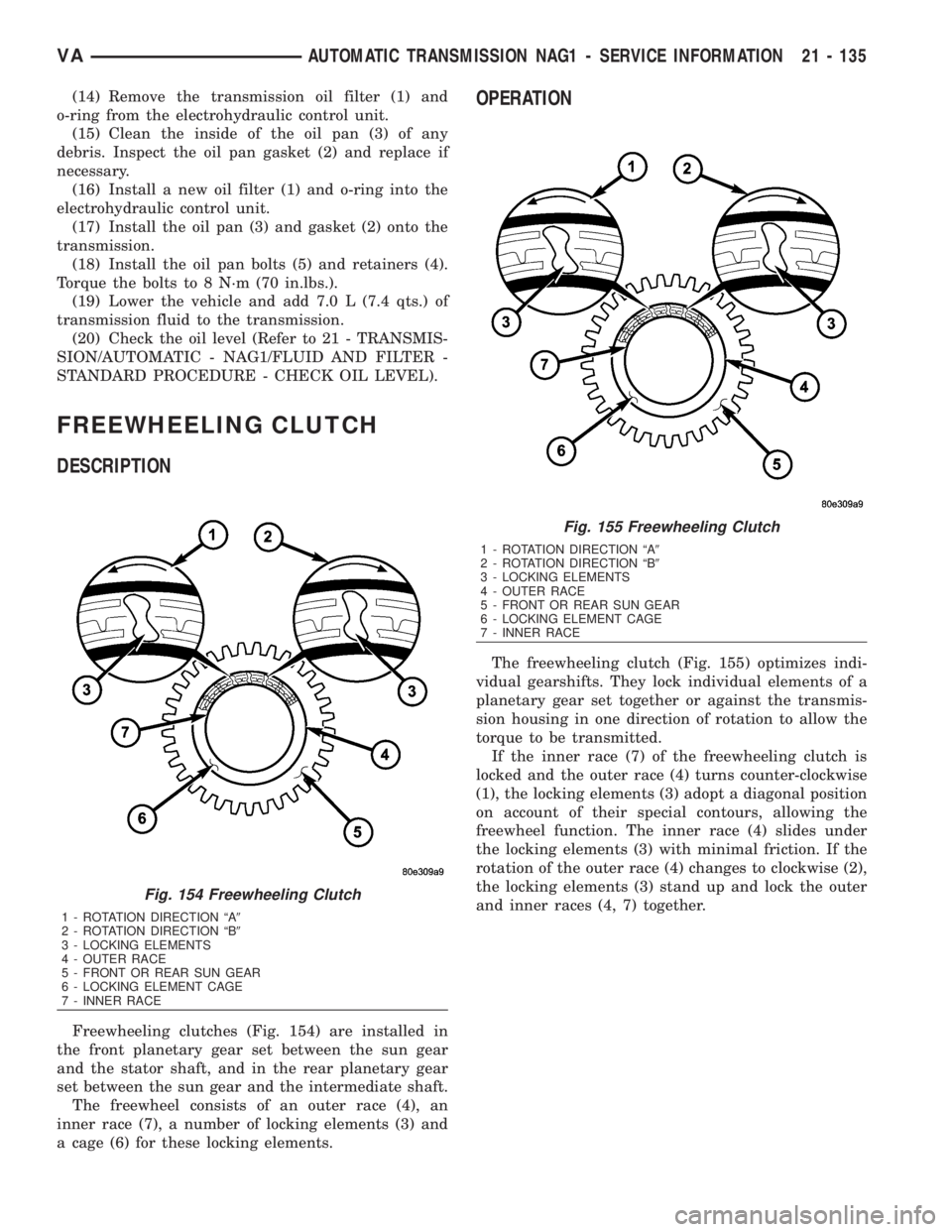

(3) Remove the torque converter drain plug access

plug from the bottom of the torque converter hous-

ing.

(4) Rotate the engine clockwise until the torque

converter drain plug (8) (Fig. 153) is aligned with the

access hole.

NOTE: Clean the area around the drain plug to pre-

vent dirt from entering the torque converter.

(5) Using a suitable drain pan to catch the fluid,

remove the torque converter drain plug (8) and allow

the torque converter to drain completely.

(6) Inspect the torque converter drain plug seal (9)

(Fig. 153). Replace the seal if necessary.

(7) Install the torque converter drain plug (8).

Tighten the drain plug to 14 N´m (10 ft.lbs.).

(8) Install the torque converter drain plug access

plug into the bottom of the torque converter housing.

(9) Using a suitable drain pan to catch the fluid,

remove the transmission oil pan drain plug (6) (Fig.

153) and allow the oil pan to drain completely.

(10) Inspect the transmission oil pan drain plug

seal (7). Replace the seal if necessary.

(11) Install the transmission oil pan drain plug (6).

Tighten the drain plug to 20 N´m (15 ft.lbs.).

(12) Remove the bolts (5) and retainers (4) (Fig.

153) holding the oil pan to the transmission.

(13) Remove the transmission oil pan (3) and gas-

ket (2) from the transmission.

Fig. 152 Remove Dipstick Tube Cap Lock

1 - LOCKING PIN

2 - TUBE CAP

3 - DIPSTICK TUBE

Fig. 153 Fluid/Filter Service Points

1 - OIL FILTER

2 - OIL PAN GASKET

3 - OIL PAN

4 - RETAINER

5 - BOLT

6 - OIL PAN DRAIN PLUG

7 - SEAL

8 - TORQUE CONVERTER DRAIN PLUG

9 - SEAL

21 - 134 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1878 of 2305

(14) Remove the transmission oil filter (1) and

o-ring from the electrohydraulic control unit.

(15) Clean the inside of the oil pan (3) of any

debris. Inspect the oil pan gasket (2) and replace if

necessary.

(16) Install a new oil filter (1) and o-ring into the

electrohydraulic control unit.

(17) Install the oil pan (3) and gasket (2) onto the

transmission.

(18) Install the oil pan bolts (5) and retainers (4).

Torque the bolts to 8 N´m (70 in.lbs.).

(19) Lower the vehicle and add 7.0 L (7.4 qts.) of

transmission fluid to the transmission.

(20) Check the oil level (Refer to 21 - TRANSMIS-

SION/AUTOMATIC - NAG1/FLUID AND FILTER -

STANDARD PROCEDURE - CHECK OIL LEVEL).

FREEWHEELING CLUTCH

DESCRIPTION

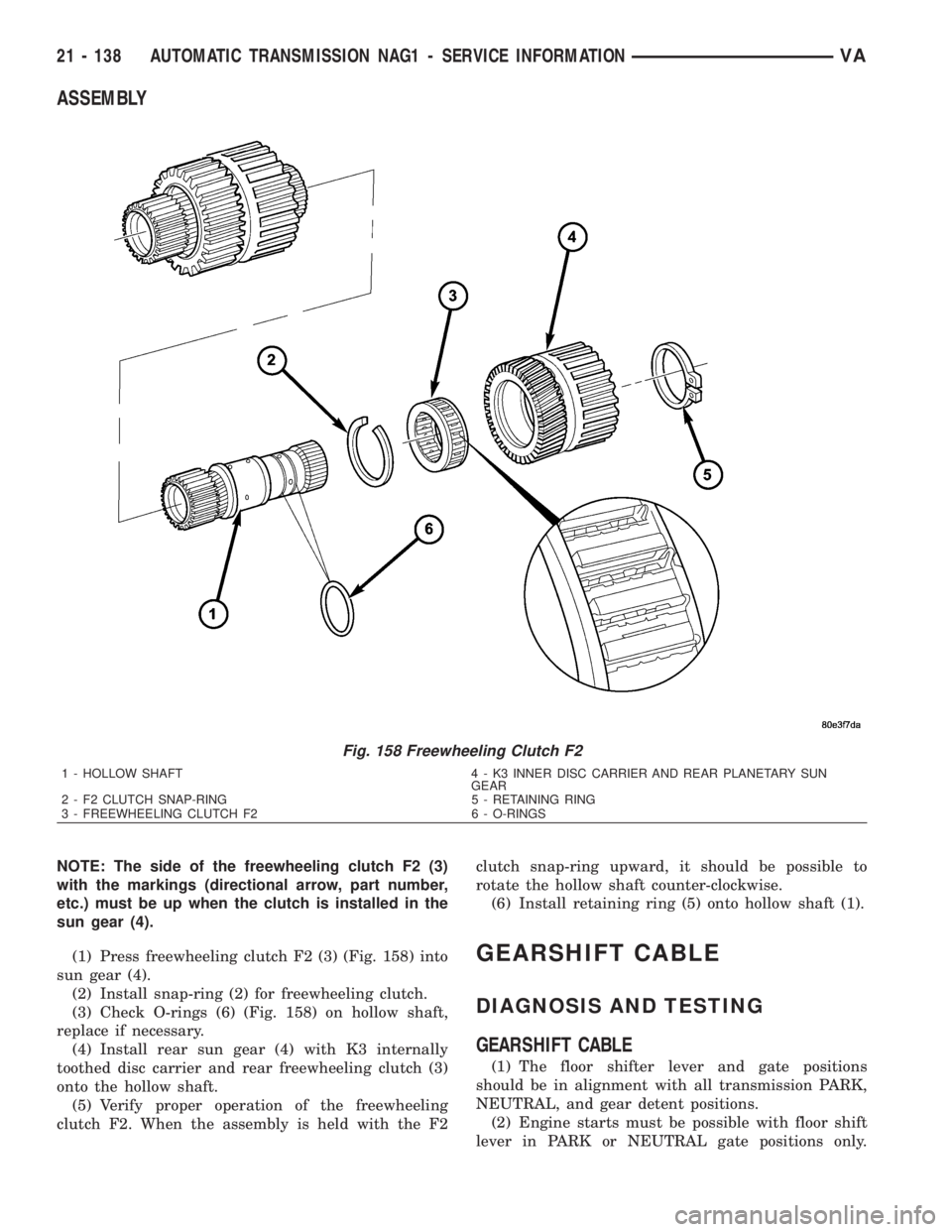

Freewheeling clutches (Fig. 154) are installed in

the front planetary gear set between the sun gear

and the stator shaft, and in the rear planetary gear

set between the sun gear and the intermediate shaft.

The freewheel consists of an outer race (4), an

inner race (7), a number of locking elements (3) and

a cage (6) for these locking elements.

OPERATION

The freewheeling clutch (Fig. 155) optimizes indi-

vidual gearshifts. They lock individual elements of a

planetary gear set together or against the transmis-

sion housing in one direction of rotation to allow the

torque to be transmitted.

If the inner race (7) of the freewheeling clutch is

locked and the outer race (4) turns counter-clockwise

(1), the locking elements (3) adopt a diagonal position

on account of their special contours, allowing the

freewheel function. The inner race (4) slides under

the locking elements (3) with minimal friction. If the

rotation of the outer race (4) changes to clockwise (2),

the locking elements (3) stand up and lock the outer

and inner races (4, 7) together.

Fig. 154 Freewheeling Clutch

1 - ROTATION DIRECTION ªA9

2 - ROTATION DIRECTION ªB9

3 - LOCKING ELEMENTS

4 - OUTER RACE

5 - FRONT OR REAR SUN GEAR

6 - LOCKING ELEMENT CAGE

7 - INNER RACE

Fig. 155 Freewheeling Clutch

1 - ROTATION DIRECTION ªA9

2 - ROTATION DIRECTION ªB9

3 - LOCKING ELEMENTS

4 - OUTER RACE

5 - FRONT OR REAR SUN GEAR

6 - LOCKING ELEMENT CAGE

7 - INNER RACE

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 135

Page 1881 of 2305

ASSEMBLY

NOTE: The side of the freewheeling clutch F2 (3)

with the markings (directional arrow, part number,

etc.) must be up when the clutch is installed in the

sun gear (4).

(1) Press freewheeling clutch F2 (3) (Fig. 158) into

sun gear (4).

(2) Install snap-ring (2) for freewheeling clutch.

(3) Check O-rings (6) (Fig. 158) on hollow shaft,

replace if necessary.

(4) Install rear sun gear (4) with K3 internally

toothed disc carrier and rear freewheeling clutch (3)

onto the hollow shaft.

(5) Verify proper operation of the freewheeling

clutch F2. When the assembly is held with the F2clutch snap-ring upward, it should be possible to

rotate the hollow shaft counter-clockwise.

(6) Install retaining ring (5) onto hollow shaft (1).

GEARSHIFT CABLE

DIAGNOSIS AND TESTING

GEARSHIFT CABLE

(1) The floor shifter lever and gate positions

should be in alignment with all transmission PARK,

NEUTRAL, and gear detent positions.

(2) Engine starts must be possible with floor shift

lever in PARK or NEUTRAL gate positions only.

Fig. 158 Freewheeling Clutch F2

1 - HOLLOW SHAFT 4 - K3 INNER DISC CARRIER AND REAR PLANETARY SUN

GEAR

2 - F2 CLUTCH SNAP-RING 5 - RETAINING RING

3 - FREEWHEELING CLUTCH F2 6 - O-RINGS

21 - 138 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1924 of 2305

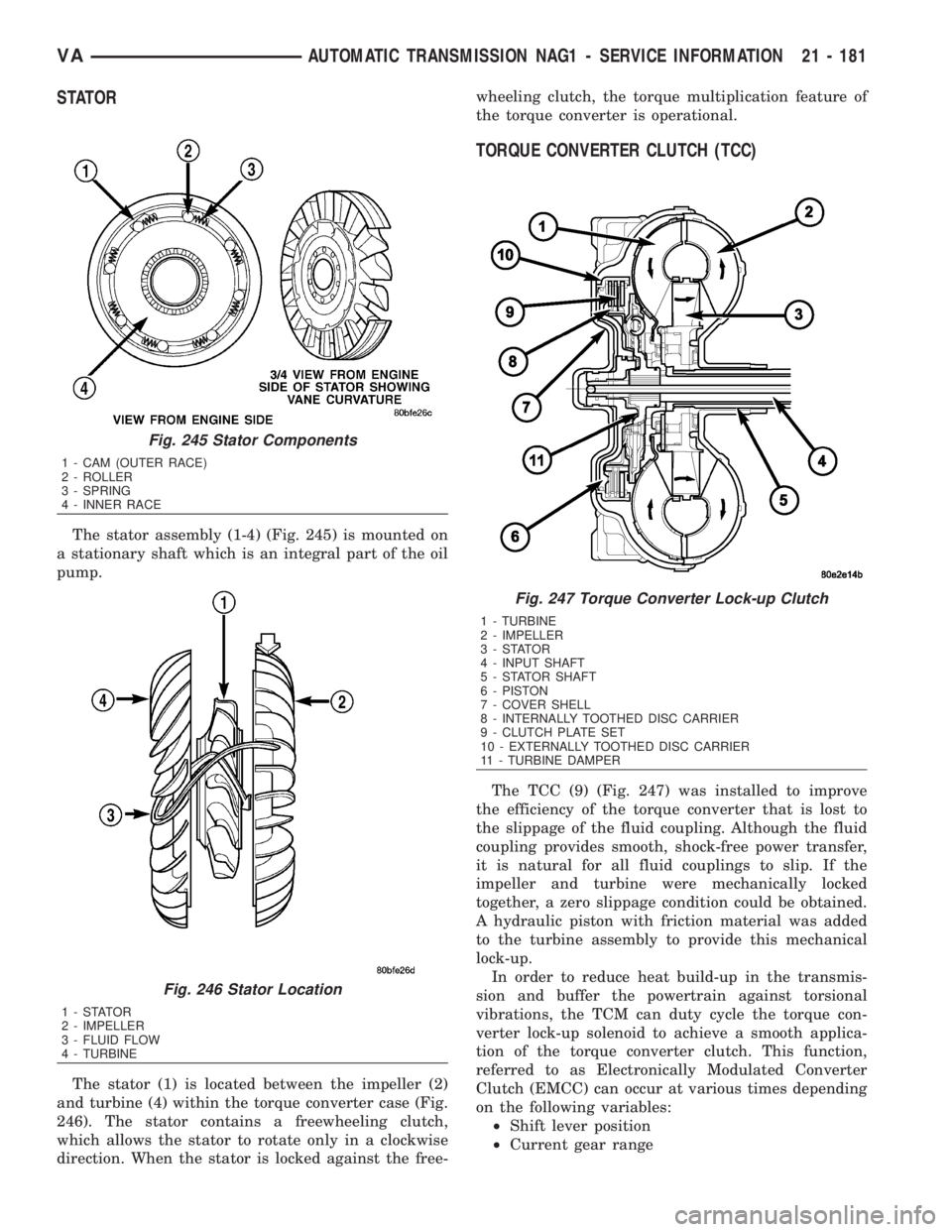

STATOR

The stator assembly (1-4) (Fig. 245) is mounted on

a stationary shaft which is an integral part of the oil

pump.

The stator (1) is located between the impeller (2)

and turbine (4) within the torque converter case (Fig.

246). The stator contains a freewheeling clutch,

which allows the stator to rotate only in a clockwise

direction. When the stator is locked against the free-wheeling clutch, the torque multiplication feature of

the torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (9) (Fig. 247) was installed to improve

the efficiency of the torque converter that is lost to

the slippage of the fluid coupling. Although the fluid

coupling provides smooth, shock-free power transfer,

it is natural for all fluid couplings to slip. If the

impeller and turbine were mechanically locked

together, a zero slippage condition could be obtained.

A hydraulic piston with friction material was added

to the turbine assembly to provide this mechanical

lock-up.

In order to reduce heat build-up in the transmis-

sion and buffer the powertrain against torsional

vibrations, the TCM can duty cycle the torque con-

verter lock-up solenoid to achieve a smooth applica-

tion of the torque converter clutch. This function,

referred to as Electronically Modulated Converter

Clutch (EMCC) can occur at various times depending

on the following variables:

²Shift lever position

²Current gear range

Fig. 245 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 246 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 247 Torque Converter Lock-up Clutch

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

6 - PISTON

7 - COVER SHELL

8 - INTERNALLY TOOTHED DISC CARRIER

9 - CLUTCH PLATE SET

10 - EXTERNALLY TOOTHED DISC CARRIER

11 - TURBINE DAMPER

VAAUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATION 21 - 181

Page 1925 of 2305

²Transmission fluid temperature

²Engine coolant temperature

²Input speed

²Throttle angle

²Engine speed

OPERATION

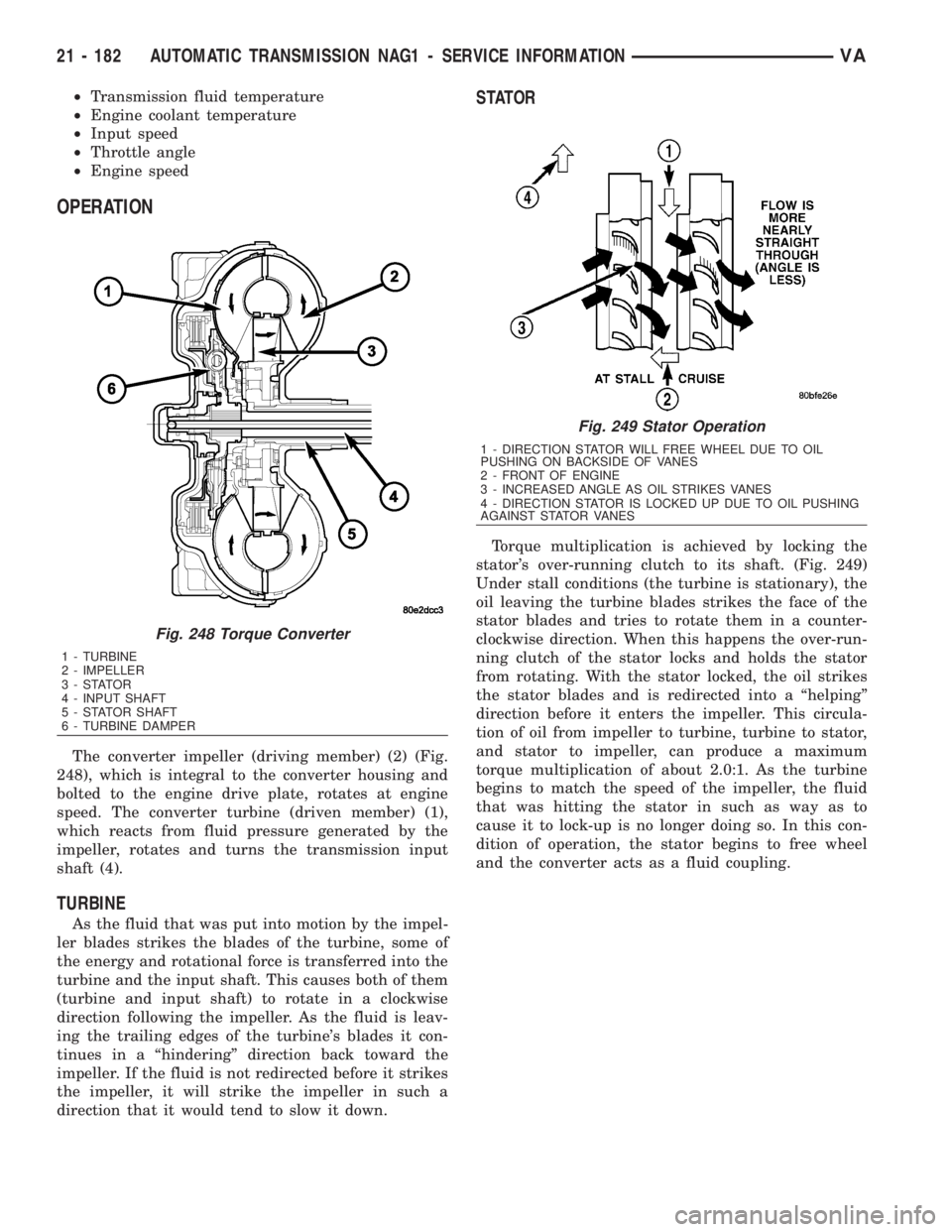

The converter impeller (driving member) (2) (Fig.

248), which is integral to the converter housing and

bolted to the engine drive plate, rotates at engine

speed. The converter turbine (driven member) (1),

which reacts from fluid pressure generated by the

impeller, rotates and turns the transmission input

shaft (4).

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

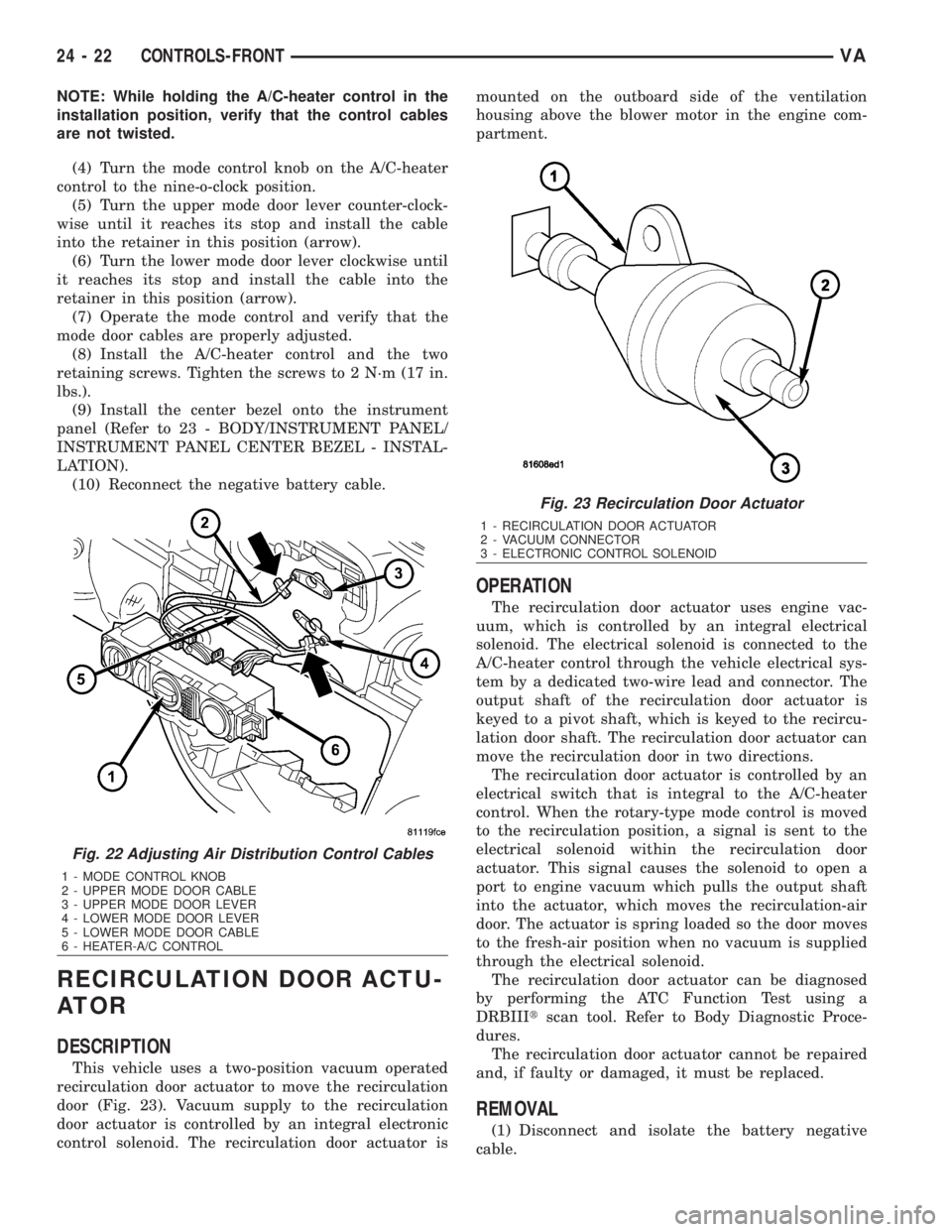

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft. (Fig. 249)

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over-run-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.0:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

Fig. 248 Torque Converter

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

6 - TURBINE DAMPER

Fig. 249 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

21 - 182 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 2059 of 2305

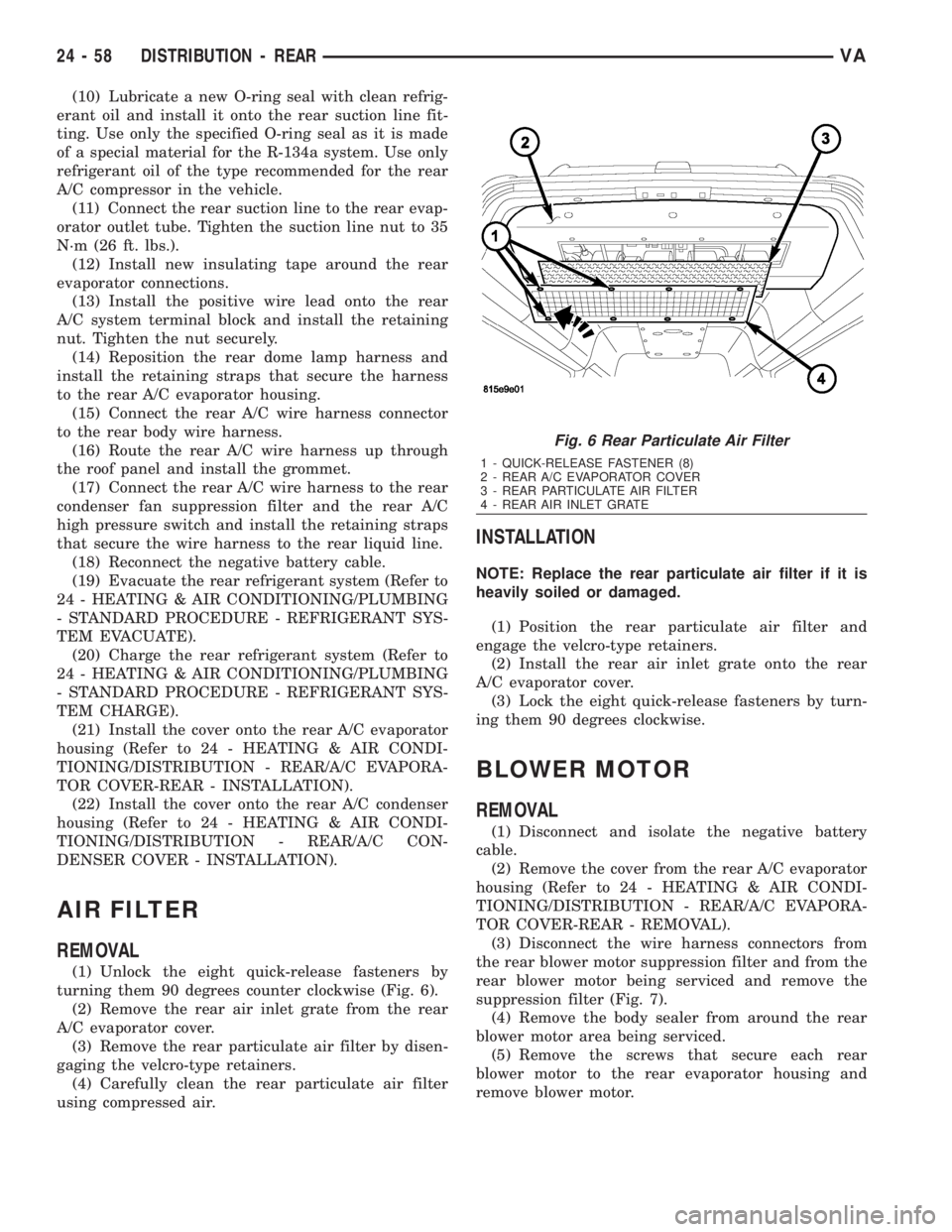

NOTE: While holding the A/C-heater control in the

installation position, verify that the control cables

are not twisted.

(4) Turn the mode control knob on the A/C-heater

control to the nine-o-clock position.

(5) Turn the upper mode door lever counter-clock-

wise until it reaches its stop and install the cable

into the retainer in this position (arrow).

(6) Turn the lower mode door lever clockwise until

it reaches its stop and install the cable into the

retainer in this position (arrow).

(7) Operate the mode control and verify that the

mode door cables are properly adjusted.

(8) Install the A/C-heater control and the two

retaining screws. Tighten the screws to 2 N´m (17 in.

lbs.).

(9) Install the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(10) Reconnect the negative battery cable.

RECIRCULATION DOOR ACTU-

ATOR

DESCRIPTION

This vehicle uses a two-position vacuum operated

recirculation door actuator to move the recirculation

door (Fig. 23). Vacuum supply to the recirculation

door actuator is controlled by an integral electronic

control solenoid. The recirculation door actuator ismounted on the outboard side of the ventilation

housing above the blower motor in the engine com-

partment.

OPERATION

The recirculation door actuator uses engine vac-

uum, which is controlled by an integral electrical

solenoid. The electrical solenoid is connected to the

A/C-heater control through the vehicle electrical sys-

tem by a dedicated two-wire lead and connector. The

output shaft of the recirculation door actuator is

keyed to a pivot shaft, which is keyed to the recircu-

lation door shaft. The recirculation door actuator can

move the recirculation door in two directions.

The recirculation door actuator is controlled by an

electrical switch that is integral to the A/C-heater

control. When the rotary-type mode control is moved

to the recirculation position, a signal is sent to the

electrical solenoid within the recirculation door

actuator. This signal causes the solenoid to open a

port to engine vacuum which pulls the output shaft

into the actuator, which moves the recirculation-air

door. The actuator is spring loaded so the door moves

to the fresh-air position when no vacuum is supplied

through the electrical solenoid.

The recirculation door actuator can be diagnosed

by performing the ATC Function Test using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

The recirculation door actuator cannot be repaired

and, if faulty or damaged, it must be replaced.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 22 Adjusting Air Distribution Control Cables

1 - MODE CONTROL KNOB

2 - UPPER MODE DOOR CABLE

3 - UPPER MODE DOOR LEVER

4 - LOWER MODE DOOR LEVER

5 - LOWER MODE DOOR CABLE

6 - HEATER-A/C CONTROL

Fig. 23 Recirculation Door Actuator

1 - RECIRCULATION DOOR ACTUATOR

2 - VACUUM CONNECTOR

3 - ELECTRONIC CONTROL SOLENOID

24 - 22 CONTROLS-FRONTVA

Page 2095 of 2305

(10) Lubricate a new O-ring seal with clean refrig-

erant oil and install it onto the rear suction line fit-

ting. Use only the specified O-ring seal as it is made

of a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the rear

A/C compressor in the vehicle.

(11) Connect the rear suction line to the rear evap-

orator outlet tube. Tighten the suction line nut to 35

N´m (26 ft. lbs.).

(12) Install new insulating tape around the rear

evaporator connections.

(13) Install the positive wire lead onto the rear

A/C system terminal block and install the retaining

nut. Tighten the nut securely.

(14) Reposition the rear dome lamp harness and

install the retaining straps that secure the harness

to the rear A/C evaporator housing.

(15) Connect the rear A/C wire harness connector

to the rear body wire harness.

(16) Route the rear A/C wire harness up through

the roof panel and install the grommet.

(17) Connect the rear A/C wire harness to the rear

condenser fan suppression filter and the rear A/C

high pressure switch and install the retaining straps

that secure the wire harness to the rear liquid line.

(18) Reconnect the negative battery cable.

(19) Evacuate the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(20) Charge the rear refrigerant system (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(21) Install the cover onto the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - INSTALLATION).

(22) Install the cover onto the rear A/C condenser

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C CON-

DENSER COVER - INSTALLATION).

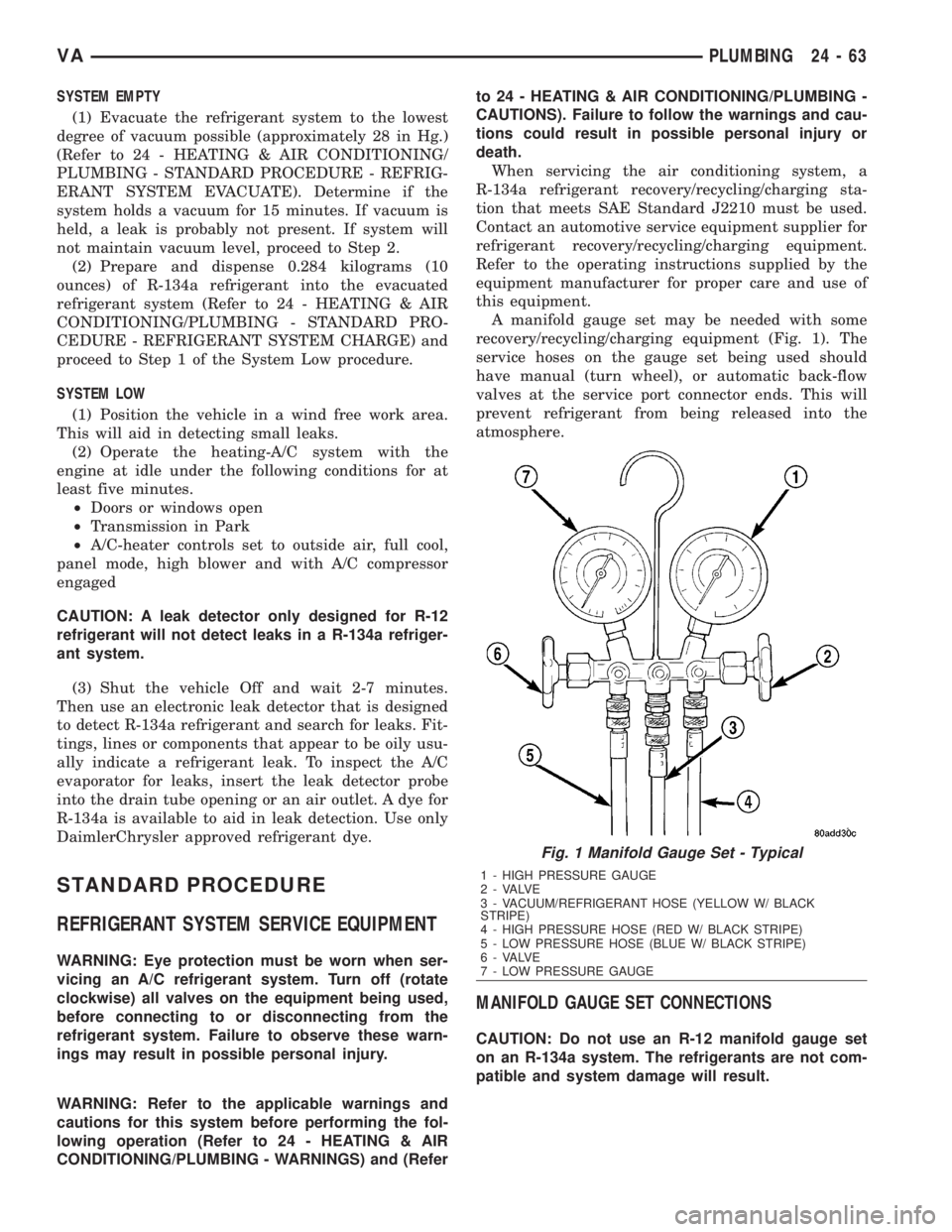

AIR FILTER

REMOVAL

(1) Unlock the eight quick-release fasteners by

turning them 90 degrees counter clockwise (Fig. 6).

(2) Remove the rear air inlet grate from the rear

A/C evaporator cover.

(3) Remove the rear particulate air filter by disen-

gaging the velcro-type retainers.

(4) Carefully clean the rear particulate air filter

using compressed air.

INSTALLATION

NOTE: Replace the rear particulate air filter if it is

heavily soiled or damaged.

(1) Position the rear particulate air filter and

engage the velcro-type retainers.

(2) Install the rear air inlet grate onto the rear

A/C evaporator cover.

(3) Lock the eight quick-release fasteners by turn-

ing them 90 degrees clockwise.

BLOWER MOTOR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the rear A/C evaporator

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C EVAPORA-

TOR COVER-REAR - REMOVAL).

(3) Disconnect the wire harness connectors from

the rear blower motor suppression filter and from the

rear blower motor being serviced and remove the

suppression filter (Fig. 7).

(4) Remove the body sealer from around the rear

blower motor area being serviced.

(5) Remove the screws that secure each rear

blower motor to the rear evaporator housing and

remove blower motor.

Fig. 6 Rear Particulate Air Filter

1 - QUICK-RELEASE FASTENER (8)

2 - REAR A/C EVAPORATOR COVER

3 - REAR PARTICULATE AIR FILTER

4 - REAR AIR INLET GRATE

24 - 58 DISTRIBUTION - REARVA

Page 2100 of 2305

SYSTEM EMPTY

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approximately 28 in Hg.)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM EVACUATE). Determine if the

system holds a vacuum for 15 minutes. If vacuum is

held, a leak is probably not present. If system will

not maintain vacuum level, proceed to Step 2.

(2) Prepare and dispense 0.284 kilograms (10

ounces) of R-134a refrigerant into the evacuated

refrigerant system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE) and

proceed to Step 1 of the System Low procedure.

SYSTEM LOW

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Operate the heating-A/C system with the

engine at idle under the following conditions for at

least five minutes.

²Doors or windows open

²Transmission in Park

²A/C-heater controls set to outside air, full cool,

panel mode, high blower and with A/C compressor

engaged

CAUTION: A leak detector only designed for R-12

refrigerant will not detect leaks in a R-134a refriger-

ant system.

(3) Shut the vehicle Off and wait 2-7 minutes.

Then use an electronic leak detector that is designed

to detect R-134a refrigerant and search for leaks. Fit-

tings, lines or components that appear to be oily usu-

ally indicate a refrigerant leak. To inspect the A/C

evaporator for leaks, insert the leak detector probe

into the drain tube opening or an air outlet. A dye for

R-134a is available to aid in leak detection. Use only

DaimlerChrysler approved refrigerant dye.

STANDARD PROCEDURE

REFRIGERANT SYSTEM SERVICE EQUIPMENT

WARNING: Eye protection must be worn when ser-

vicing an A/C refrigerant system. Turn off (rotate

clockwise) all valves on the equipment being used,

before connecting to or disconnecting from the

refrigerant system. Failure to observe these warn-

ings may result in possible personal injury.

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Referto 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-

tions could result in possible personal injury or

death.

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

equipment manufacturer for proper care and use of

this equipment.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 1). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

Fig. 1 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/ BLACK

STRIPE)

4 - HIGH PRESSURE HOSE (RED W/ BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/ BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

VAPLUMBING 24 - 63

Page 2121 of 2305

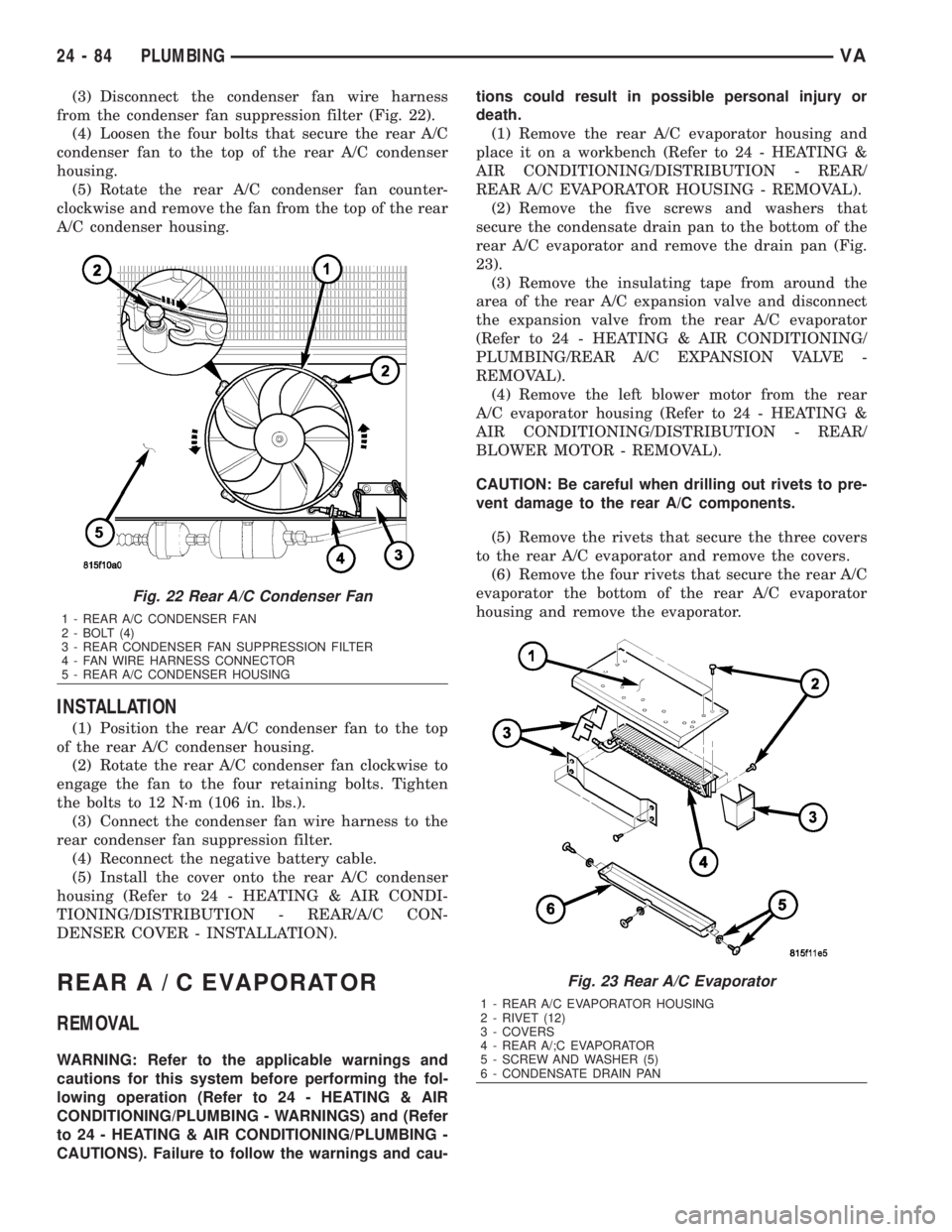

(3) Disconnect the condenser fan wire harness

from the condenser fan suppression filter (Fig. 22).

(4) Loosen the four bolts that secure the rear A/C

condenser fan to the top of the rear A/C condenser

housing.

(5) Rotate the rear A/C condenser fan counter-

clockwise and remove the fan from the top of the rear

A/C condenser housing.

INSTALLATION

(1) Position the rear A/C condenser fan to the top

of the rear A/C condenser housing.

(2) Rotate the rear A/C condenser fan clockwise to

engage the fan to the four retaining bolts. Tighten

the bolts to 12 N´m (106 in. lbs.).

(3) Connect the condenser fan wire harness to the

rear condenser fan suppression filter.

(4) Reconnect the negative battery cable.

(5) Install the cover onto the rear A/C condenser

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/A/C CON-

DENSER COVER - INSTALLATION).

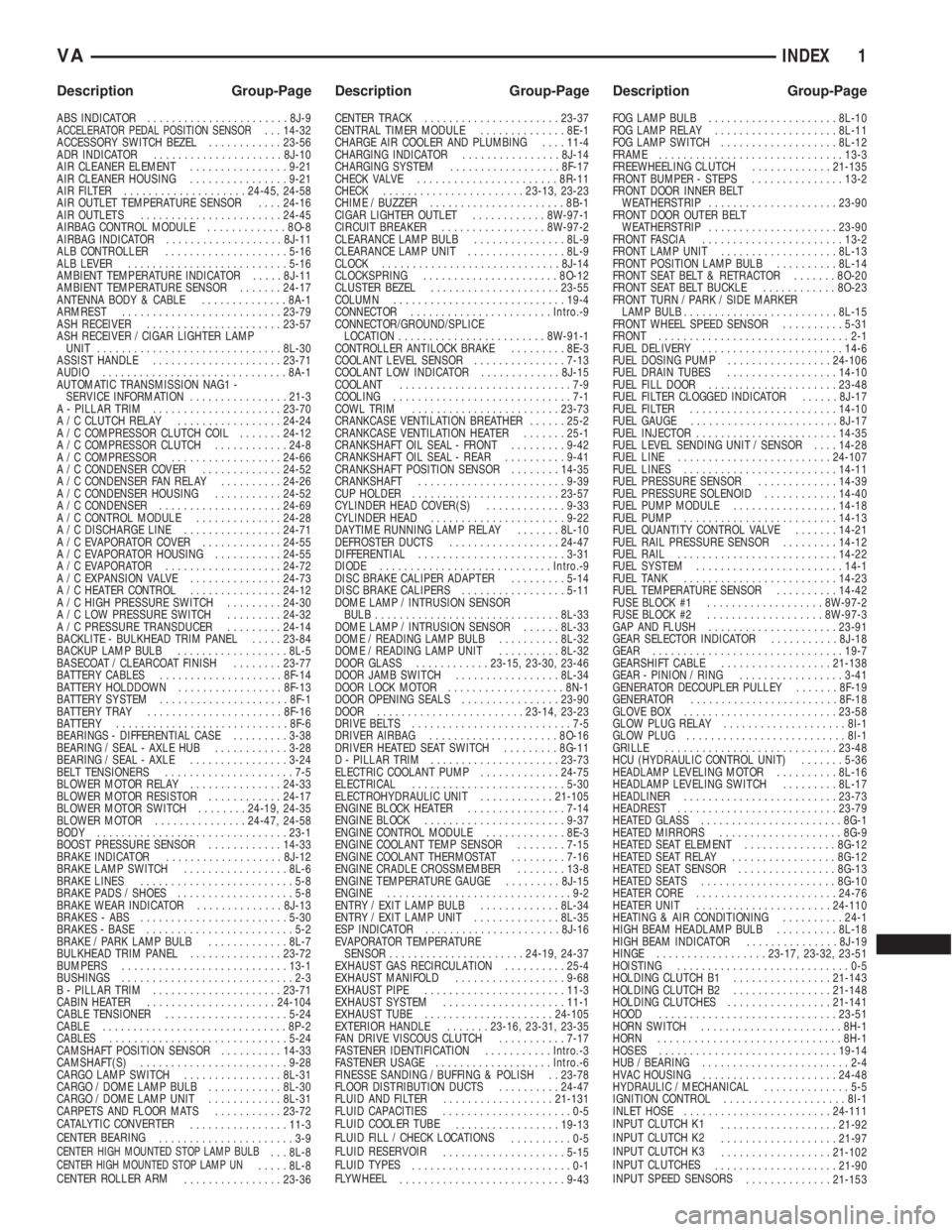

REARA/CEVAPORATOR

REMOVAL

WARNING: Refer to the applicable warnings and

cautions for this system before performing the fol-

lowing operation (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNINGS) and (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTIONS). Failure to follow the warnings and cau-tions could result in possible personal injury or

death.

(1) Remove the rear A/C evaporator housing and

place it on a workbench (Refer to 24 - HEATING &

AIR CONDITIONING/DISTRIBUTION - REAR/

REAR A/C EVAPORATOR HOUSING - REMOVAL).

(2) Remove the five screws and washers that

secure the condensate drain pan to the bottom of the

rear A/C evaporator and remove the drain pan (Fig.

23).

(3) Remove the insulating tape from around the

area of the rear A/C expansion valve and disconnect

the expansion valve from the rear A/C evaporator

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REAR A/C EXPANSION VALVE -

REMOVAL).

(4) Remove the left blower motor from the rear

A/C evaporator housing (Refer to 24 - HEATING &

AIR CONDITIONING/DISTRIBUTION - REAR/

BLOWER MOTOR - REMOVAL).

CAUTION: Be careful when drilling out rivets to pre-

vent damage to the rear A/C components.

(5) Remove the rivets that secure the three covers

to the rear A/C evaporator and remove the covers.

(6) Remove the four rivets that secure the rear A/C

evaporator the bottom of the rear A/C evaporator

housing and remove the evaporator.

Fig. 22 Rear A/C Condenser Fan

1 - REAR A/C CONDENSER FAN

2 - BOLT (4)

3 - REAR CONDENSER FAN SUPPRESSION FILTER

4 - FAN WIRE HARNESS CONNECTOR

5 - REAR A/C CONDENSER HOUSING

Fig. 23 Rear A/C Evaporator

1 - REAR A/C EVAPORATOR HOUSING

2 - RIVET (12)

3 - COVERS

4 - REAR A/;C EVAPORATOR

5 - SCREW AND WASHER (5)

6 - CONDENSATE DRAIN PAN

24 - 84 PLUMBINGVA

Page 2158 of 2305

INDEX

ABS INDICATOR.......................8J-9ACCELERATOR PEDAL POSITION SENSOR. . . 14-32

ACCESSORY SWITCH BEZEL............23-56

ADR INDICATOR.....................8J-10

AIR CLEANER ELEMENT................9-21

AIR CLEANER HOUSING................9-21

AIR FILTER ....................24-45, 24-58

AIR OUTLET TEMPERATURE SENSOR....24-16

AIR OUTLETS.......................24-45

AIRBAG CONTROL MODULE.............8O-8

AIRBAG INDICATOR...................8J-11

ALB CONTROLLER....................5-16

ALB LEVER..........................5-16

AMBIENT TEMPERATURE INDICATOR.....8J-11

AMBIENT TEMPERATURE SENSOR.......24-17

ANTENNA BODY & CABLE..............8A-1

ARMREST..........................23-79

ASH RECEIVER......................23-57

ASH RECEIVER / CIGAR LIGHTER LAMP

UNIT..............................8L-30

ASSIST HANDLE.....................23-71

AUDIO..............................8A-1

AUTOMATIC TRANSMISSION NAG1 -

SERVICE INFORMATION................21-3

A - PILLAR TRIM.....................23-70

A / C CLUTCH RELAY.................24-24

A / C COMPRESSOR CLUTCH COIL.......24-12

A / C COMPRESSOR CLUTCH............24-8

A / C COMPRESSOR..................24-66

A / C CONDENSER COVER.............24-52

A / C CONDENSER FAN RELAY..........24-26

A / C CONDENSER HOUSING...........24-52

A / C CONDENSER....................24-69

A / C CONTROL MODULE..............24-28

A / C DISCHARGE LINE................24-71

A / C EVAPORATOR COVER.............24-55

A / C EVAPORATOR HOUSING...........24-55

A / C EVAPORATOR...................24-72

A / C EXPANSION VALVE...............24-73

A / C HEATER CONTROL...............24-12

A / C HIGH PRESSURE SWITCH.........24-30

A / C LOW PRESSURE SWITCH.........24-32

A / C PRESSURE TRANSDUCER.........24-14

BACKLITE - BULKHEAD TRIM PANEL.....23-84

BACKUP LAMP BULB..................8L-5

BASECOAT / CLEARCOAT FINISH........23-77

BATTERY CABLES....................8F-14

BATTERY HOLDDOWN.................8F-13

BATTERY SYSTEM.....................8F-1

BATTERY TRAY......................8F-16

BATTERY............................8F-6

BEARINGS - DIFFERENTIAL CASE.........3-38

BEARING / SEAL - AXLE HUB............3-28

BEARING / SEAL - AXLE................3-24

BELT TENSIONERS.....................7-5

BLOWER MOTOR RELAY...............24-33

BLOWER MOTOR RESISTOR............24-17

BLOWER MOTOR SWITCH........24-19, 24-35

BLOWER MOTOR...............24-47, 24-58

BODY...............................23-1

BOOST PRESSURE SENSOR............14-33

BRAKE INDICATOR...................8J-12

BRAKE LAMP SWITCH.................8L-6

BRAKE LINES.........................5-8

BRAKE PADS / SHOES...................5-8

BRAKE WEAR INDICATOR..............8J-13

BRAKES - ABS........................5-30

BRAKES - BASE........................5-2

BRAKE / PARK LAMP BULB.............8L-7

BULKHEAD TRIM PANEL...............23-72

BUMPERS...........................13-1

BUSHINGS............................2-3

B - PILLAR TRIM.....................23-71

CABIN HEATER.....................24-104

CABLE TENSIONER....................5-24

CABLE..............................8P-2

CABLES.............................5-24

CAMSHAFT POSITION SENSOR..........14-33

CAMSHAFT(S)........................9-28

CARGO LAMP SWITCH................8L-31

CARGO / DOME LAMP BULB............8L-30

CARGO / DOME LAMP UNIT............8L-31

CARPETS AND FLOOR MATS...........23-72

CATALYTIC CONVERTER

................11-3

CENTER BEARING

......................3-9

CENTER HIGH MOUNTED STOP LAMP BULB. . . 8L-8CENTER HIGH MOUNTED STOP LAMP UN.....8L-8

CENTER ROLLER ARM

................23-36CENTER TRACK......................23-37

CENTRAL TIMER MODULE..............8E-1

CHARGE AIR COOLER AND PLUMBING....11-4

CHARGING INDICATOR................8J-14

CHARGING SYSTEM..................8F-17

CHECK VALVE.......................8R-11

CHECK.......................23-13, 23-23

CHIME / BUZZER......................8B-1

CIGAR LIGHTER OUTLET............8W-97-1

CIRCUIT BREAKER.................8W-97-2

CLEARANCE LAMP BULB...............8L-9

CLEARANCE LAMP UNIT................8L-9

CLOCK.............................8J-14

CLOCKSPRING......................8O-12

CLUSTER BEZEL.....................23-55

COLUMN............................19-4

CONNECTOR.......................Intro.-9

CONNECTOR/GROUND/SPLICE

LOCATION........................8W-91-1

CONTROLLER ANTILOCK BRAKE.........8E-3

COOLANT LEVEL SENSOR...............7-13

COOLANT LOW INDICATOR.............8J-15

COOLANT............................7-9

COOLING.............................7-1

COWL TRIM........................23-73

CRANKCASE VENTILATION BREATHER......25-2

CRANKCASE VENTILATION HEATER.......25-1

CRANKSHAFT OIL SEAL - FRONT.........9-42

CRANKSHAFT OIL SEAL - REAR..........9-41

CRANKSHAFT POSITION SENSOR........14-35

CRANKSHAFT........................9-39

CUP HOLDER........................23-57

CYLINDER HEAD COVER(S).............9-33

CYLINDER HEAD......................9-22

DAYTIME RUNNING LAMP RELAY.......8L-10

DEFROSTER DUCTS..................24-47

DIFFERENTIAL........................3-31

DIODE............................Intro.-9

DISC BRAKE CALIPER ADAPTER.........5-14

DISC BRAKE CALIPERS.................5-11

DOME LAMP / INTRUSION SENSOR

BULB..............................8L-33

DOME LAMP / INTRUSION SENSOR......8L-33

DOME / READING LAMP BULB..........8L-32

DOME / READING LAMP UNIT..........8L-32

DOOR GLASS............23-15, 23-30, 23-46

DOOR JAMB SWITCH.................8L-34

DOOR LOCK MOTOR...................8N-1

DOOR OPENING SEALS................23-90

DOOR........................23-14, 23-23

DRIVE BELTS..........................7-5

DRIVER AIRBAG.....................8O-16

DRIVER HEATED SEAT SWITCH.........8G-11

D - PILLAR TRIM.....................23-73

ELECTRIC COOLANT PUMP.............24-75

ELECTRICAL.........................5-30

ELECTROHYDRAULIC UNIT............21-105

ENGINE BLOCK HEATER................7-14

ENGINE BLOCK.......................9-37

ENGINE CONTROL MODULE.............8E-3

ENGINE COOLANT TEMP SENSOR........7-15

ENGINE COOLANT THERMOSTAT.........7-16

ENGINE CRADLE CROSSMEMBER........13-8

ENGINE TEMPERATURE GAUGE.........8J-15

ENGINE..............................9-2

ENTRY / EXIT LAMP BULB.............8L-34

ENTRY / EXIT LAMP UNIT..............8L-35

ESP INDICATOR......................8J-16

EVAPORATOR TEMPERATURE

SENSOR......................24-19, 24-37

EXHAUST GAS RECIRCULATION..........25-4

EXHAUST MANIFOLD..................9-68

EXHAUST PIPE.......................11-3

EXHAUST SYSTEM....................11-1

EXHAUST TUBE.....................24-105

EXTERIOR HANDLE.......23-16, 23-31, 23-35

FAN DRIVE VISCOUS CLUTCH...........7-17

FASTENER IDENTIFICATION...........Intro.-3

FASTENER USAGE...................Intro.-6

FINESSE SANDING / BUFFING & POLISH . . 23-78

FLOOR DISTRIBUTION DUCTS..........24-47

FLUID AND FILTER..................21-131

FLUID CAPACITIES.....................0-5

FLUID COOLER TUBE

.................19-13

FLUID FILL / CHECK LOCATIONS

..........0-5

FLUID RESERVOIR

....................5-15

FLUID TYPES

..........................0-1

FLYWHEEL

...........................9-43FOG LAMP BULB.....................8L-10

FOG LAMP RELAY....................8L-11

FOG LAMP SWITCH...................8L-12

FRAME..............................13-3

FREEWHEELING CLUTCH.............21-135

FRONT BUMPER - STEPS...............13-2

FRONT DOOR INNER BELT

WEATHERSTRIP.....................23-90

FRONT DOOR OUTER BELT

WEATHERSTRIP.....................23-90

FRONT FASCIA.......................13-2

FRONT LAMP UNIT...................8L-13

FRONT POSITION LAMP BULB..........8L-14

FRONT SEAT BELT & RETRACTOR.......8O-20

FRONT SEAT BELT BUCKLE............8O-23

FRONT TURN / PARK / SIDE MARKER

LAMP BULB.........................8L-15

FRONT WHEEL SPEED SENSOR..........5-31

FRONT...............................2-1

FUEL DELIVERY.......................14-6

FUEL DOSING PUMP.................24-106

FUEL DRAIN TUBES..................14-10

FUEL FILL DOOR.....................23-48

FUEL FILTER CLOGGED INDICATOR......8J-17

FUEL FILTER........................14-10

FUEL GAUGE........................8J-17

FUEL INJECTOR.......................14-35

FUEL LEVEL SENDING UNIT / SENSOR....14-28

FUEL LINE.........................24-107

FUEL LINES.........................14-11

FUEL PRESSURE SENSOR.............14-39

FUEL PRESSURE SOLENOID............14-40

FUEL PUMP MODULE.................14-18

FUEL PUMP.........................14-13

FUEL QUANTITY CONTROL VALVE.......14-21

FUEL RAIL PRESSURE SENSOR.........14-12

FUEL RAIL..........................14-22

FUEL SYSTEM........................14-1

FUEL TANK.........................14-23

FUEL TEMPERATURE SENSOR..........14-42

FUSE BLOCK #1...................8W-97-2

FUSE BLOCK #2...................8W-97-3

GAP AND FLUSH.....................23-91

GEAR SELECTOR INDICATOR...........8J-18

GEAR...............................19-7

GEARSHIFT CABLE..................21-138

GEAR - PINION / RING.................3-41

GENERATOR DECOUPLER PULLEY.......8F-19

GENERATOR........................8F-18

GLOVE BOX.........................23-58

GLOW PLUG RELAY....................8I-1

GLOW PLUG..........................8I-1

GRILLE............................23-48

HCU (HYDRAULIC CONTROL UNIT).......5-36

HEADLAMP LEVELING MOTOR..........8L-16

HEADLAMP LEVELING SWITCH.........8L-17

HEADLINER.........................23-73

HEADREST..........................23-79

HEATED GLASS.......................8G-1

HEATED MIRRORS....................8G-9

HEATED SEAT ELEMENT...............8G-12

HEATED SEAT RELAY.................8G-12

HEATED SEAT SENSOR................8G-13

HEATED SEATS ......................8G-10

HEATER CORE.......................24-76

HEATER UNIT......................24-110

HEATING & AIR CONDITIONING..........24-1

HIGH BEAM HEADLAMP BULB..........8L-18

HIGH BEAM INDICATOR...............8J-19

HINGE..................23-17, 23-32, 23-51

HOISTING............................0-5

HOLDING CLUTCH B1................21-143

HOLDING CLUTCH B2................21-148

HOLDING CLUTCHES.................21-141

HOOD.............................23-51

HORN SWITCH.......................8H-1

HORN..............................8H-1

HOSES.............................19-14

HUB / BEARING........................2-4

HVAC HOUSING......................24-48

HYDRAULIC / MECHANICAL..............5-5

IGNITION CONTROL....................8I-1

INLET HOSE........................24-111

INPUT CLUTCH K1

...................21-92

INPUT CLUTCH K2

...................21-97

INPUT CLUTCH K3

..................21-102

INPUT CLUTCHES

....................21-90

INPUT SPEED SENSORS

..............21-153

VAINDEX 1

Description Group-Page Description Group-Page Description Group-Page