clock MERCEDES-BENZ SPRINTER 2006 Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 1650 of 2305

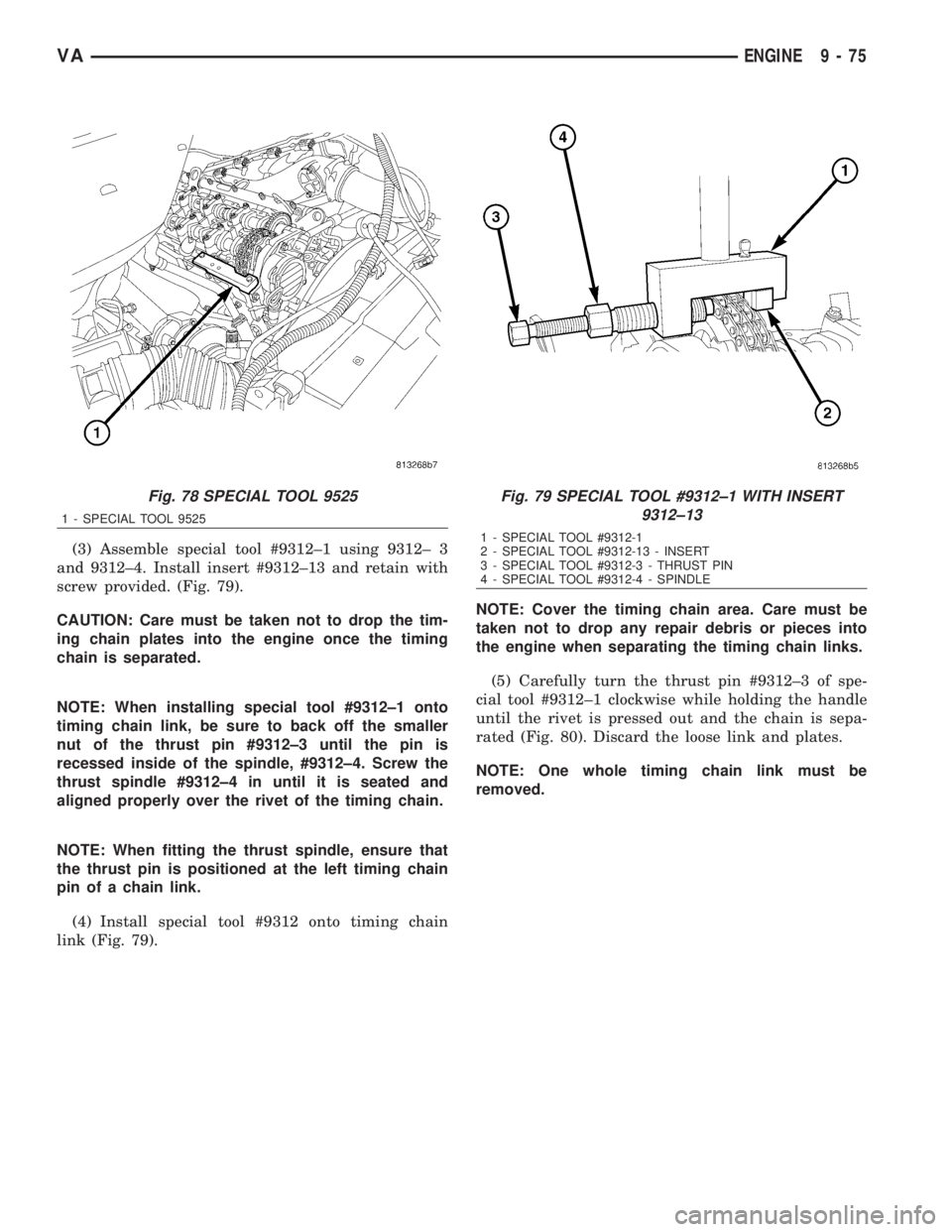

(3) Assemble special tool #9312±1 using 9312± 3

and 9312±4. Install insert #9312±13 and retain with

screw provided. (Fig. 79).

CAUTION: Care must be taken not to drop the tim-

ing chain plates into the engine once the timing

chain is separated.

NOTE: When installing special tool #9312±1 onto

timing chain link, be sure to back off the smaller

nut of the thrust pin #9312±3 until the pin is

recessed inside of the spindle, #9312±4. Screw the

thrust spindle #9312±4 in until it is seated and

aligned properly over the rivet of the timing chain.

NOTE: When fitting the thrust spindle, ensure that

the thrust pin is positioned at the left timing chain

pin of a chain link.

(4) Install special tool #9312 onto timing chain

link (Fig. 79).NOTE: Cover the timing chain area. Care must be

taken not to drop any repair debris or pieces into

the engine when separating the timing chain links.

(5) Carefully turn the thrust pin #9312±3 of spe-

cial tool #9312±1 clockwise while holding the handle

until the rivet is pressed out and the chain is sepa-

rated (Fig. 80). Discard the loose link and plates.

NOTE: One whole timing chain link must be

removed.

Fig. 78 SPECIAL TOOL 9525

1 - SPECIAL TOOL 9525

Fig. 79 SPECIAL TOOL #9312±1 WITH INSERT

9312±13

1 - SPECIAL TOOL #9312-1

2 - SPECIAL TOOL #9312-13 - INSERT

3 - SPECIAL TOOL #9312-3 - THRUST PIN

4 - SPECIAL TOOL #9312-4 - SPINDLE

VAENGINE 9 - 75

Page 1653 of 2305

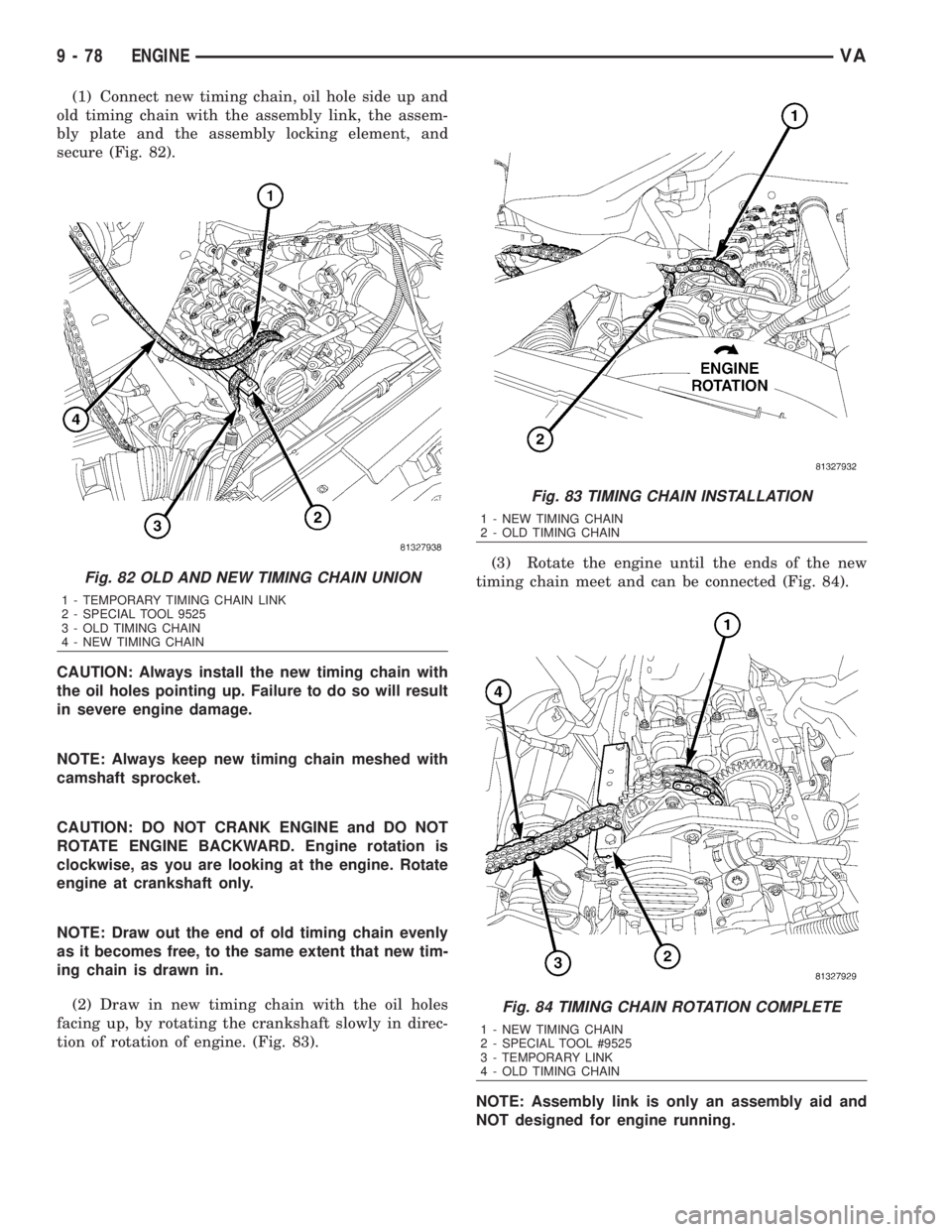

(1) Connect new timing chain, oil hole side up and

old timing chain with the assembly link, the assem-

bly plate and the assembly locking element, and

secure (Fig. 82).

CAUTION: Always install the new timing chain with

the oil holes pointing up. Failure to do so will result

in severe engine damage.

NOTE: Always keep new timing chain meshed with

camshaft sprocket.

CAUTION: DO NOT CRANK ENGINE and DO NOT

ROTATE ENGINE BACKWARD. Engine rotation is

clockwise, as you are looking at the engine. Rotate

engine at crankshaft only.

NOTE: Draw out the end of old timing chain evenly

as it becomes free, to the same extent that new tim-

ing chain is drawn in.

(2) Draw in new timing chain with the oil holes

facing up, by rotating the crankshaft slowly in direc-

tion of rotation of engine. (Fig. 83).(3) Rotate the engine until the ends of the new

timing chain meet and can be connected (Fig. 84).

NOTE: Assembly link is only an assembly aid and

NOT designed for engine running.

Fig. 82 OLD AND NEW TIMING CHAIN UNION

1 - TEMPORARY TIMING CHAIN LINK

2 - SPECIAL TOOL 9525

3 - OLD TIMING CHAIN

4 - NEW TIMING CHAIN

Fig. 83 TIMING CHAIN INSTALLATION

1 - NEW TIMING CHAIN

2 - OLD TIMING CHAIN

Fig. 84 TIMING CHAIN ROTATION COMPLETE

1 - NEW TIMING CHAIN

2 - SPECIAL TOOL #9525

3 - TEMPORARY LINK

4 - OLD TIMING CHAIN

9 - 78 ENGINEVA

Page 1656 of 2305

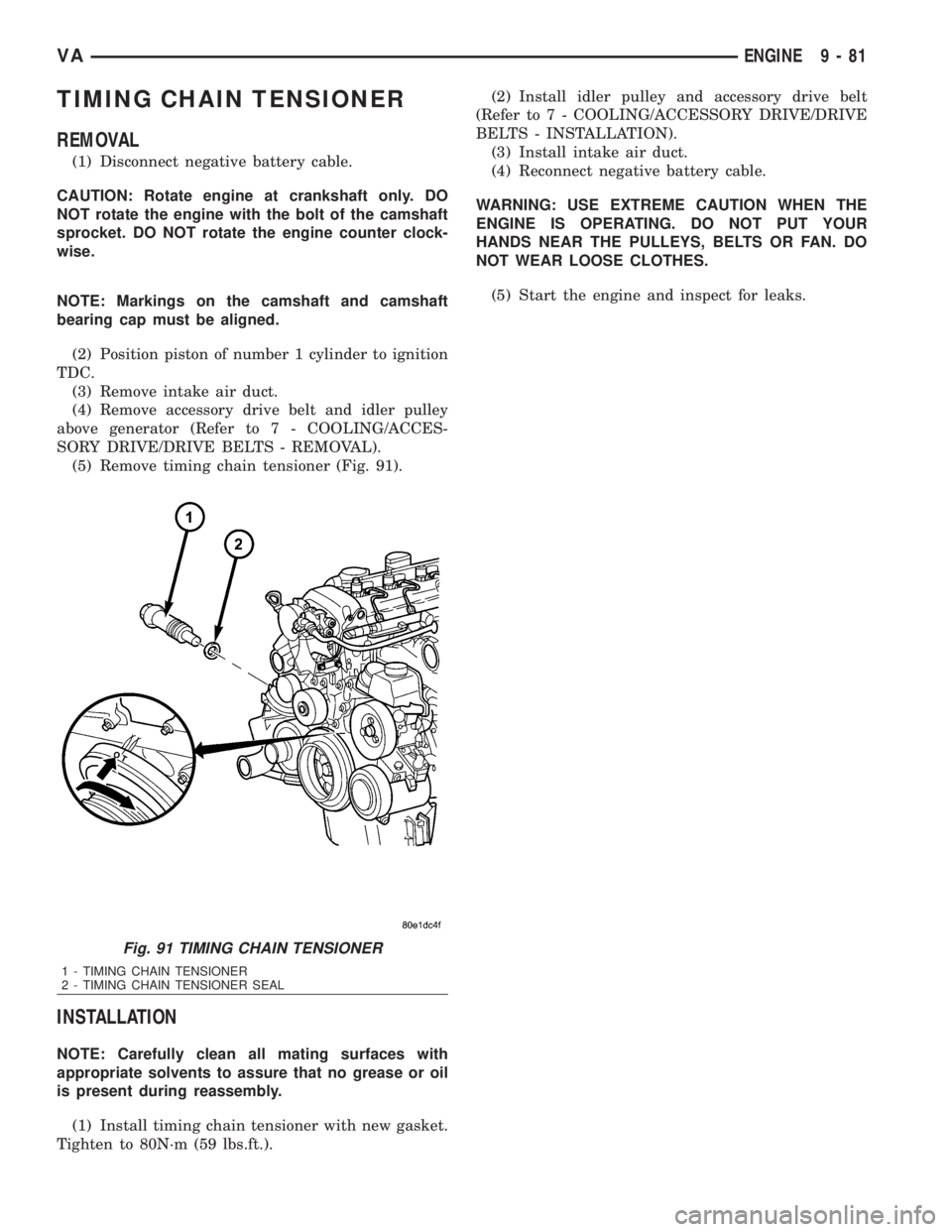

TIMING CHAIN TENSIONER

REMOVAL

(1) Disconnect negative battery cable.

CAUTION: Rotate engine at crankshaft only. DO

NOT rotate the engine with the bolt of the camshaft

sprocket. DO NOT rotate the engine counter clock-

wise.

NOTE: Markings on the camshaft and camshaft

bearing cap must be aligned.

(2) Position piston of number 1 cylinder to ignition

TDC.

(3) Remove intake air duct.

(4) Remove accessory drive belt and idler pulley

above generator (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

(5) Remove timing chain tensioner (Fig. 91).

INSTALLATION

NOTE: Carefully clean all mating surfaces with

appropriate solvents to assure that no grease or oil

is present during reassembly.

(1) Install timing chain tensioner with new gasket.

Tighten to 80N´m (59 lbs.ft.).(2) Install idler pulley and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(3) Install intake air duct.

(4) Reconnect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(5) Start the engine and inspect for leaks.

Fig. 91 TIMING CHAIN TENSIONER

1 - TIMING CHAIN TENSIONER

2 - TIMING CHAIN TENSIONER SEAL

VAENGINE 9 - 81

Page 1684 of 2305

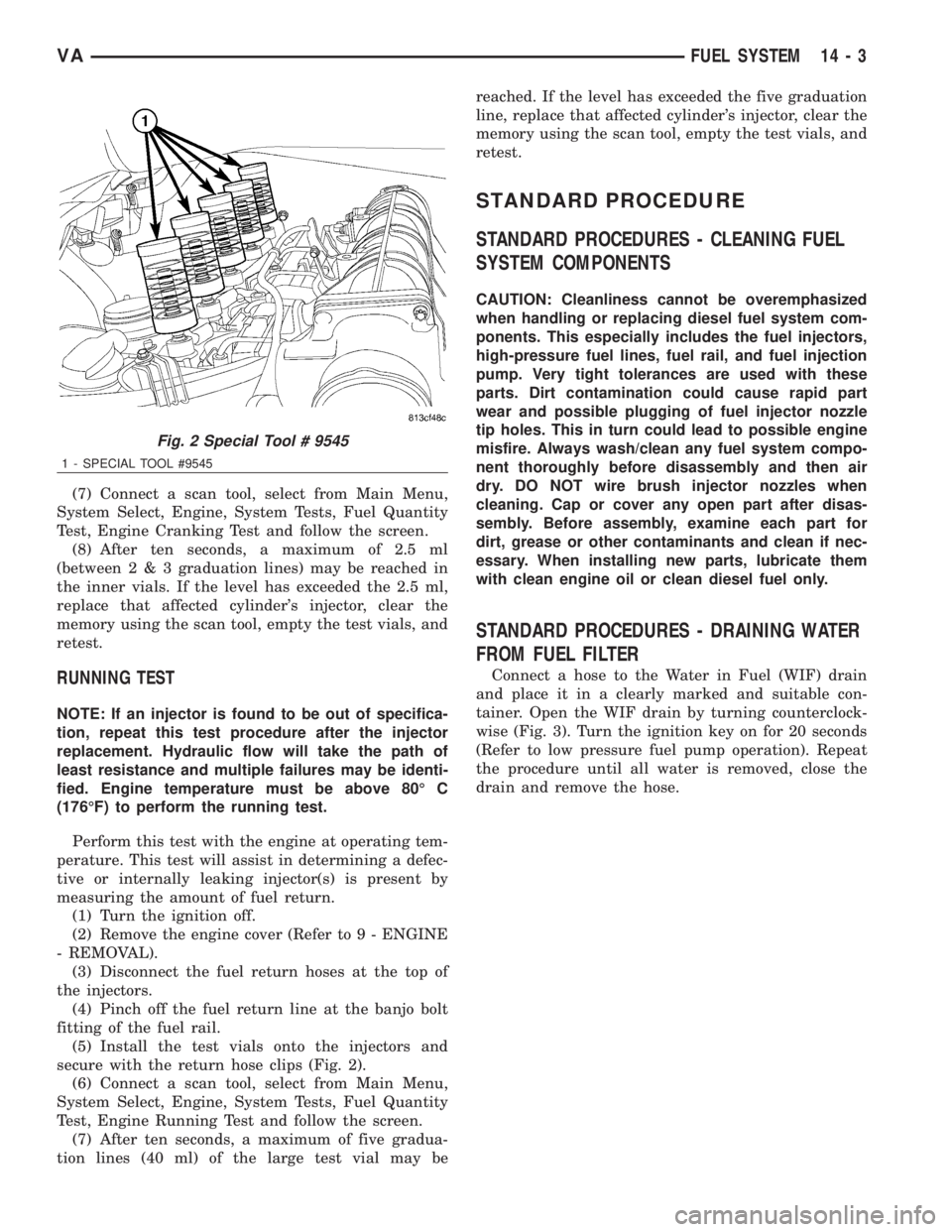

(7) Connect a scan tool, select from Main Menu,

System Select, Engine, System Tests, Fuel Quantity

Test, Engine Cranking Test and follow the screen.

(8) After ten seconds, a maximum of 2.5 ml

(between2&3graduation lines) may be reached in

the inner vials. If the level has exceeded the 2.5 ml,

replace that affected cylinder's injector, clear the

memory using the scan tool, empty the test vials, and

retest.

RUNNING TEST

NOTE: If an injector is found to be out of specifica-

tion, repeat this test procedure after the injector

replacement. Hydraulic flow will take the path of

least resistance and multiple failures may be identi-

fied. Engine temperature must be above 80É C

(176ÉF) to perform the running test.

Perform this test with the engine at operating tem-

perature. This test will assist in determining a defec-

tive or internally leaking injector(s) is present by

measuring the amount of fuel return.

(1) Turn the ignition off.

(2) Remove the engine cover (Refer to 9 - ENGINE

- REMOVAL).

(3) Disconnect the fuel return hoses at the top of

the injectors.

(4) Pinch off the fuel return line at the banjo bolt

fitting of the fuel rail.

(5) Install the test vials onto the injectors and

secure with the return hose clips (Fig. 2).

(6) Connect a scan tool, select from Main Menu,

System Select, Engine, System Tests, Fuel Quantity

Test, Engine Running Test and follow the screen.

(7) After ten seconds, a maximum of five gradua-

tion lines (40 ml) of the large test vial may bereached. If the level has exceeded the five graduation

line, replace that affected cylinder's injector, clear the

memory using the scan tool, empty the test vials, and

retest.

STANDARD PROCEDURE

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM COMPONENTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines, fuel rail, and fuel injection

pump. Very tight tolerances are used with these

parts. Dirt contamination could cause rapid part

wear and possible plugging of fuel injector nozzle

tip holes. This in turn could lead to possible engine

misfire. Always wash/clean any fuel system compo-

nent thoroughly before disassembly and then air

dry. DO NOT wire brush injector nozzles when

cleaning. Cap or cover any open part after disas-

sembly. Before assembly, examine each part for

dirt, grease or other contaminants and clean if nec-

essary. When installing new parts, lubricate them

with clean engine oil or clean diesel fuel only.

STANDARD PROCEDURES - DRAINING WATER

FROM FUEL FILTER

Connect a hose to the Water in Fuel (WIF) drain

and place it in a clearly marked and suitable con-

tainer. Open the WIF drain by turning counterclock-

wise (Fig. 3). Turn the ignition key on for 20 seconds

(Refer to low pressure fuel pump operation). Repeat

the procedure until all water is removed, close the

drain and remove the hose.

Fig. 2 Special Tool # 9545

1 - SPECIAL TOOL #9545

VAFUEL SYSTEM 14 - 3

Page 1733 of 2305

COLUMN

TABLE OF CONTENTS

page page

COLUMN

SPECIFICATIONS - TORQUE CHART.........4

INTERMEDIATE SHAFT

REMOVAL.............................4

INSTALLATION..........................5

KEY/LOCK CYLINDER

REMOVAL.............................5INSTALLATION..........................6

STEERING WHEEL

REMOVAL.............................6

INSTALLATION..........................6

COLUMN

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel With Air-

bag To Steering Shaft80 59 Ð

Jacket Tube For Steering

Shaft To Waist Rail25 18 221

U-Joint To Steering Gear

Shaft24 18 212

INTERMEDIATE SHAFT

REMOVAL

(1) Disconnect the ground cable from the battery.

(2) Remove the air bag module from the steering

wheel.

(3) Turn the steering wheel and lock the steering

wheel in the straight ahead position.The position

of the steering gear must not be altered again

for the entire duration of the work procedure.

(4) Remove the electrical center.

(5) Remove the steering wheel bolt.

(6) Remove the steering wheel from the steering

column.

(7) Remove the clockspring.Unscrew the retain-

ing bolts just enough to be able to remove the

clockspring. Do not twist or disassemble the

clockspring.

(8) Remove the combination switch.

(9) Disconnect the electrical connector for the igni-

tion lock.

(10) Remove the spring for the brake pedal from

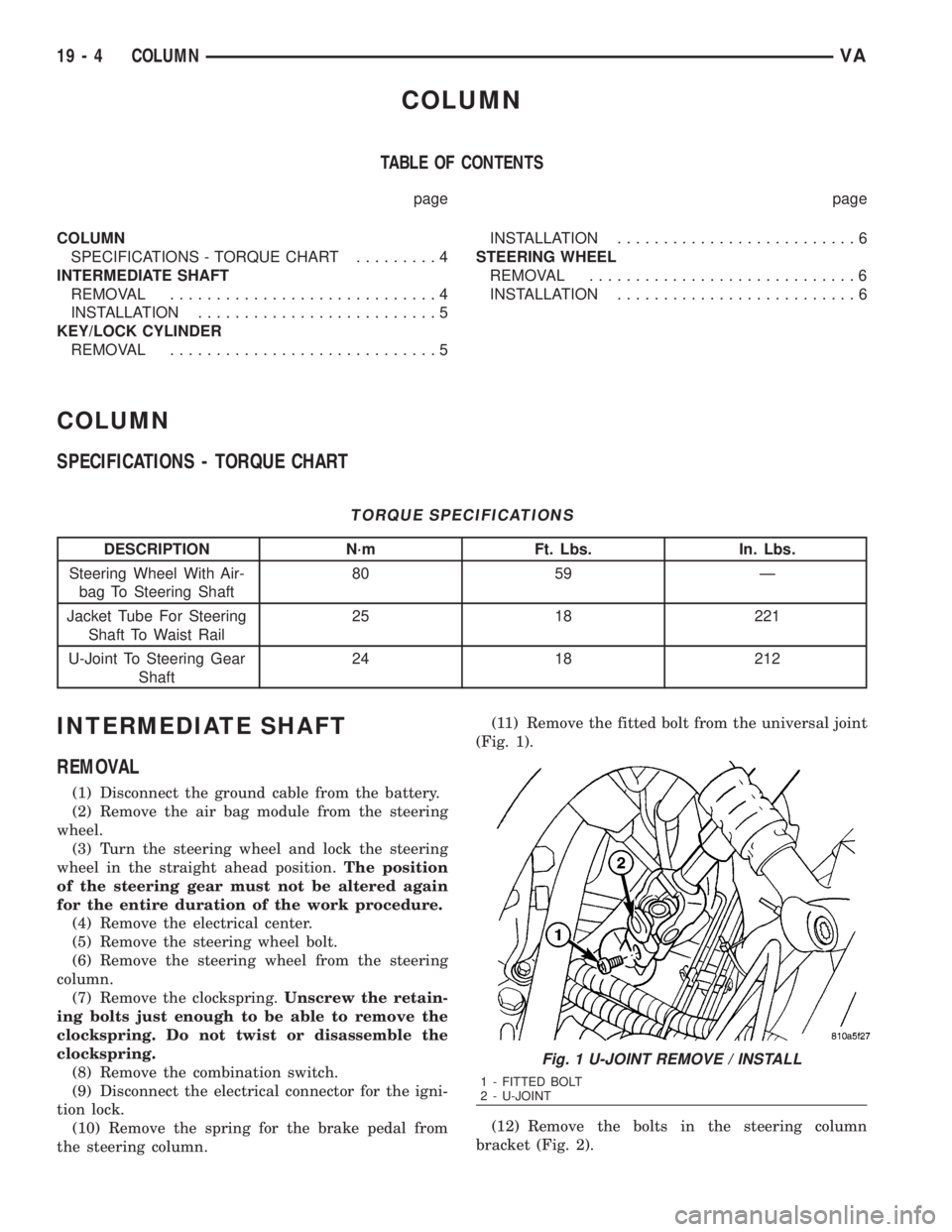

the steering column.(11) Remove the fitted bolt from the universal joint

(Fig. 1).

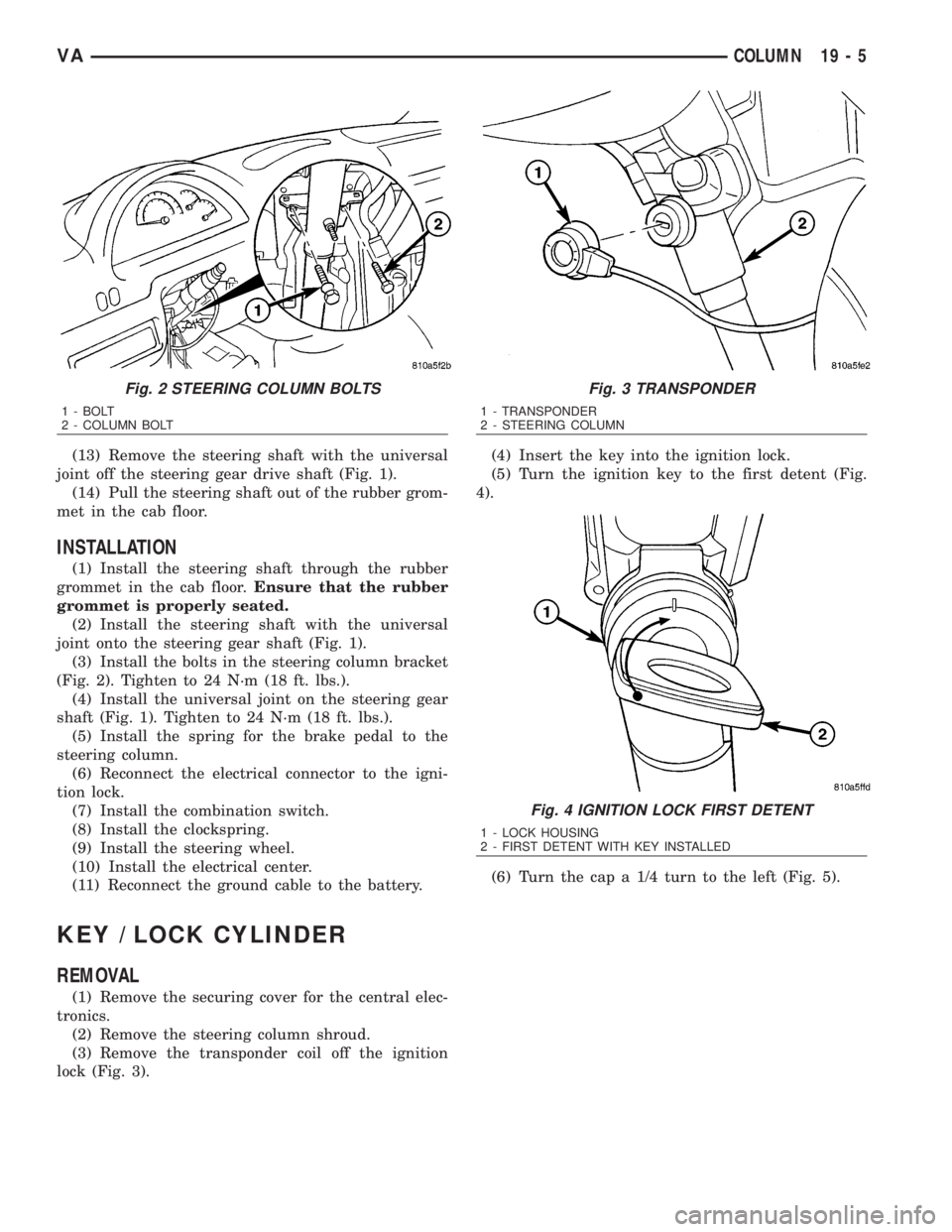

(12) Remove the bolts in the steering column

bracket (Fig. 2).

Fig. 1 U-JOINT REMOVE / INSTALL

1 - FITTED BOLT

2 - U-JOINT

19 - 4 COLUMNVA

Page 1734 of 2305

(13) Remove the steering shaft with the universal

joint off the steering gear drive shaft (Fig. 1).

(14) Pull the steering shaft out of the rubber grom-

met in the cab floor.

INSTALLATION

(1) Install the steering shaft through the rubber

grommet in the cab floor.Ensure that the rubber

grommet is properly seated.

(2) Install the steering shaft with the universal

joint onto the steering gear shaft (Fig. 1).

(3) Install the bolts in the steering column bracket

(Fig. 2). Tighten to 24 N´m (18 ft. lbs.).

(4) Install the universal joint on the steering gear

shaft (Fig. 1). Tighten to 24 N´m (18 ft. lbs.).

(5) Install the spring for the brake pedal to the

steering column.

(6) Reconnect the electrical connector to the igni-

tion lock.

(7) Install the combination switch.

(8) Install the clockspring.

(9) Install the steering wheel.

(10) Install the electrical center.

(11) Reconnect the ground cable to the battery.

KEY / LOCK CYLINDER

REMOVAL

(1) Remove the securing cover for the central elec-

tronics.

(2) Remove the steering column shroud.

(3) Remove the transponder coil off the ignition

lock (Fig. 3).(4) Insert the key into the ignition lock.

(5) Turn the ignition key to the first detent (Fig.

4).

(6) Turn the cap a 1/4 turn to the left (Fig. 5).

Fig. 2 STEERING COLUMN BOLTS

1 - BOLT

2 - COLUMN BOLT

Fig. 3 TRANSPONDER

1 - TRANSPONDER

2 - STEERING COLUMN

Fig. 4 IGNITION LOCK FIRST DETENT

1 - LOCK HOUSING

2 - FIRST DETENT WITH KEY INSTALLED

VACOLUMN 19 - 5

Page 1787 of 2305

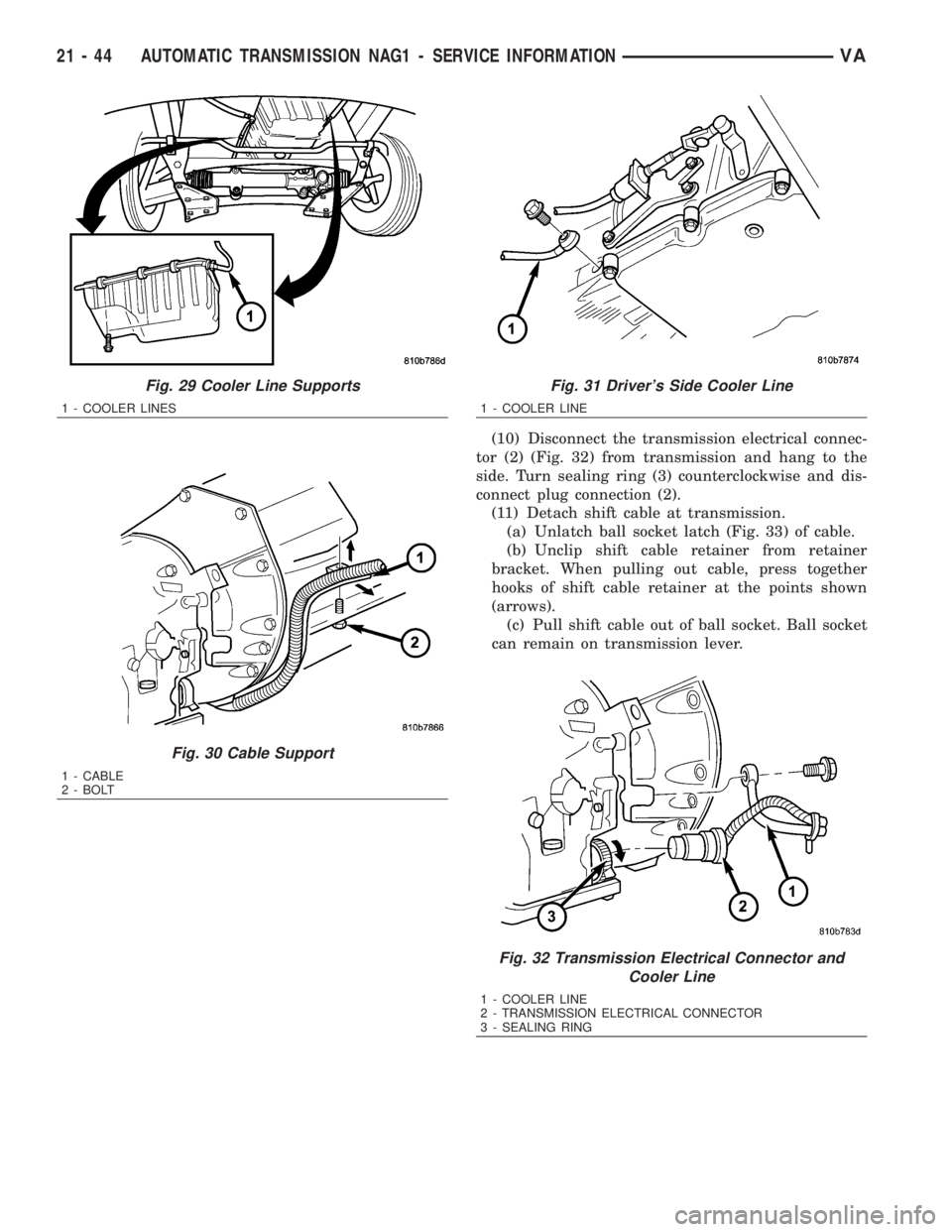

(10) Disconnect the transmission electrical connec-

tor (2) (Fig. 32) from transmission and hang to the

side. Turn sealing ring (3) counterclockwise and dis-

connect plug connection (2).

(11) Detach shift cable at transmission.

(a) Unlatch ball socket latch (Fig. 33) of cable.

(b) Unclip shift cable retainer from retainer

bracket. When pulling out cable, press together

hooks of shift cable retainer at the points shown

(arrows).

(c) Pull shift cable out of ball socket. Ball socket

can remain on transmission lever.

Fig. 29 Cooler Line Supports

1 - COOLER LINES

Fig. 30 Cable Support

1 - CABLE

2 - BOLT

Fig. 31 Driver's Side Cooler Line

1 - COOLER LINE

Fig. 32 Transmission Electrical Connector and

Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

21 - 44 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1805 of 2305

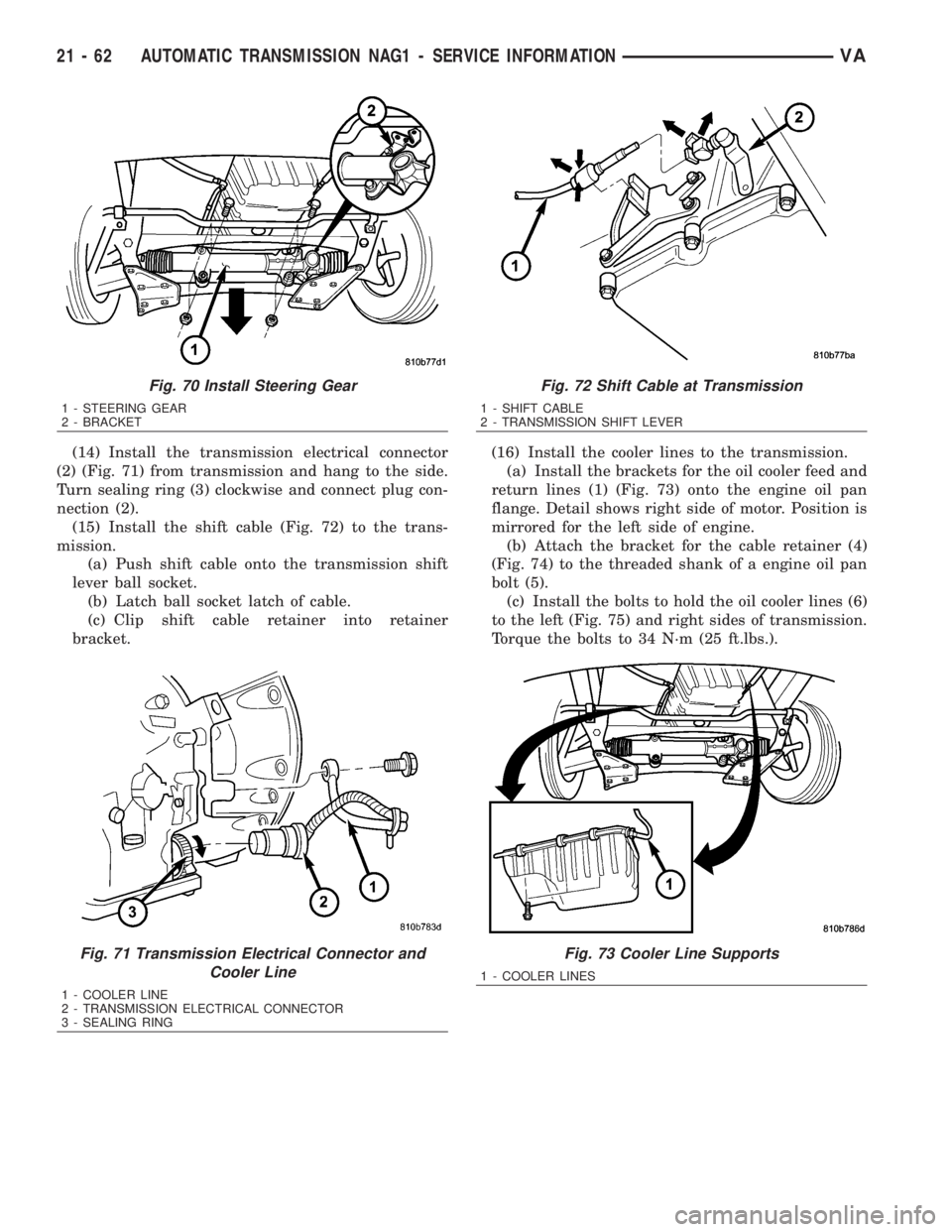

(14) Install the transmission electrical connector

(2) (Fig. 71) from transmission and hang to the side.

Turn sealing ring (3) clockwise and connect plug con-

nection (2).

(15) Install the shift cable (Fig. 72) to the trans-

mission.

(a) Push shift cable onto the transmission shift

lever ball socket.

(b) Latch ball socket latch of cable.

(c) Clip shift cable retainer into retainer

bracket.(16) Install the cooler lines to the transmission.

(a) Install the brackets for the oil cooler feed and

return lines (1) (Fig. 73) onto the engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Attach the bracket for the cable retainer (4)

(Fig. 74) to the threaded shank of a engine oil pan

bolt (5).

(c) Install the bolts to hold the oil cooler lines (6)

to the left (Fig. 75) and right sides of transmission.

Torque the bolts to 34 N´m (25 ft.lbs.).

Fig. 70 Install Steering Gear

1 - STEERING GEAR

2 - BRACKET

Fig. 71 Transmission Electrical Connector and

Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

Fig. 72 Shift Cable at Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 73 Cooler Line Supports

1 - COOLER LINES

21 - 62 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1863 of 2305

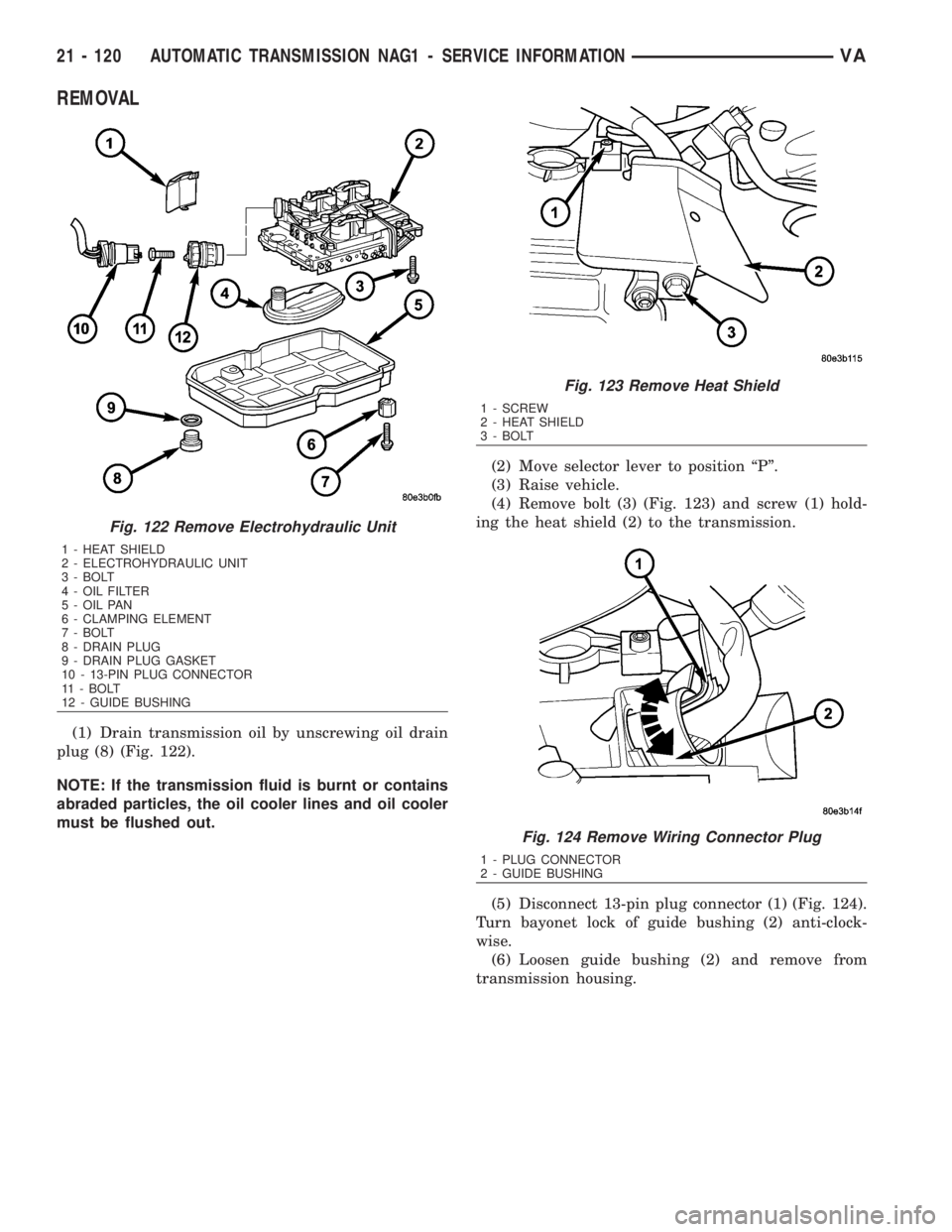

REMOVAL

(1) Drain transmission oil by unscrewing oil drain

plug (8) (Fig. 122).

NOTE: If the transmission fluid is burnt or contains

abraded particles, the oil cooler lines and oil cooler

must be flushed out.(2) Move selector lever to position ªPº.

(3) Raise vehicle.

(4) Remove bolt (3) (Fig. 123) and screw (1) hold-

ing the heat shield (2) to the transmission.

(5) Disconnect 13-pin plug connector (1) (Fig. 124).

Turn bayonet lock of guide bushing (2) anti-clock-

wise.

(6) Loosen guide bushing (2) and remove from

transmission housing.

Fig. 122 Remove Electrohydraulic Unit

1 - HEAT SHIELD

2 - ELECTROHYDRAULIC UNIT

3 - BOLT

4 - OIL FILTER

5 - OIL PAN

6 - CLAMPING ELEMENT

7 - BOLT

8 - DRAIN PLUG

9 - DRAIN PLUG GASKET

10 - 13-PIN PLUG CONNECTOR

11 - BOLT

12 - GUIDE BUSHING

Fig. 123 Remove Heat Shield

1 - SCREW

2 - HEAT SHIELD

3 - BOLT

Fig. 124 Remove Wiring Connector Plug

1 - PLUG CONNECTOR

2 - GUIDE BUSHING

21 - 120 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA

Page 1873 of 2305

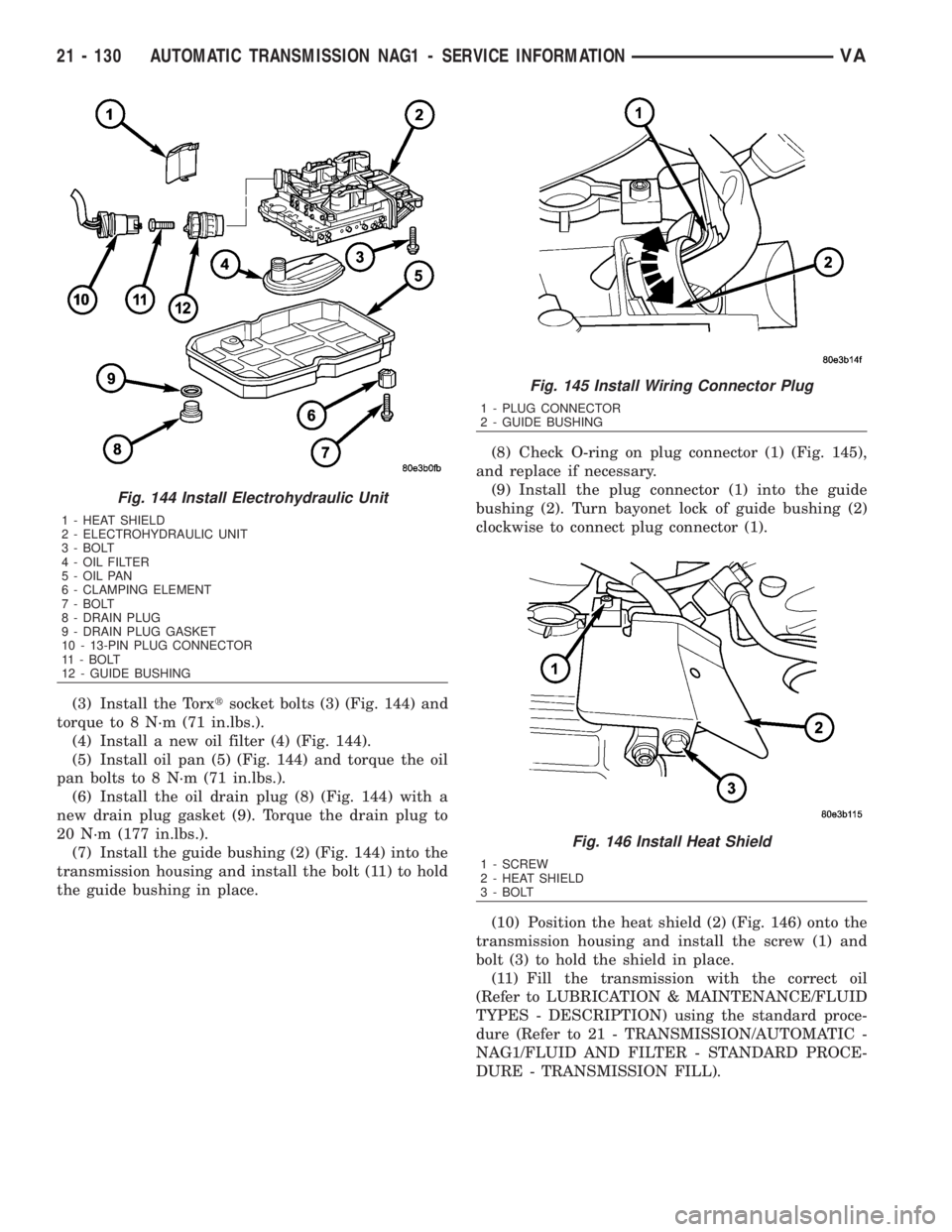

(3) Install the Torxtsocket bolts (3) (Fig. 144) and

torque to 8 N´m (71 in.lbs.).

(4) Install a new oil filter (4) (Fig. 144).

(5) Install oil pan (5) (Fig. 144) and torque the oil

pan bolts to 8 N´m (71 in.lbs.).

(6) Install the oil drain plug (8) (Fig. 144) with a

new drain plug gasket (9). Torque the drain plug to

20 N´m (177 in.lbs.).

(7) Install the guide bushing (2) (Fig. 144) into the

transmission housing and install the bolt (11) to hold

the guide bushing in place.(8) Check O-ring on plug connector (1) (Fig. 145),

and replace if necessary.

(9) Install the plug connector (1) into the guide

bushing (2). Turn bayonet lock of guide bushing (2)

clockwise to connect plug connector (1).

(10) Position the heat shield (2) (Fig. 146) onto the

transmission housing and install the screw (1) and

bolt (3) to hold the shield in place.

(11) Fill the transmission with the correct oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

TYPES - DESCRIPTION) using the standard proce-

dure (Refer to 21 - TRANSMISSION/AUTOMATIC -

NAG1/FLUID AND FILTER - STANDARD PROCE-

DURE - TRANSMISSION FILL).

Fig. 144 Install Electrohydraulic Unit

1 - HEAT SHIELD

2 - ELECTROHYDRAULIC UNIT

3 - BOLT

4 - OIL FILTER

5 - OIL PAN

6 - CLAMPING ELEMENT

7 - BOLT

8 - DRAIN PLUG

9 - DRAIN PLUG GASKET

10 - 13-PIN PLUG CONNECTOR

11 - BOLT

12 - GUIDE BUSHING

Fig. 145 Install Wiring Connector Plug

1 - PLUG CONNECTOR

2 - GUIDE BUSHING

Fig. 146 Install Heat Shield

1 - SCREW

2 - HEAT SHIELD

3 - BOLT

21 - 130 AUTOMATIC TRANSMISSION NAG1 - SERVICE INFORMATIONVA