charging MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 109 of 2305

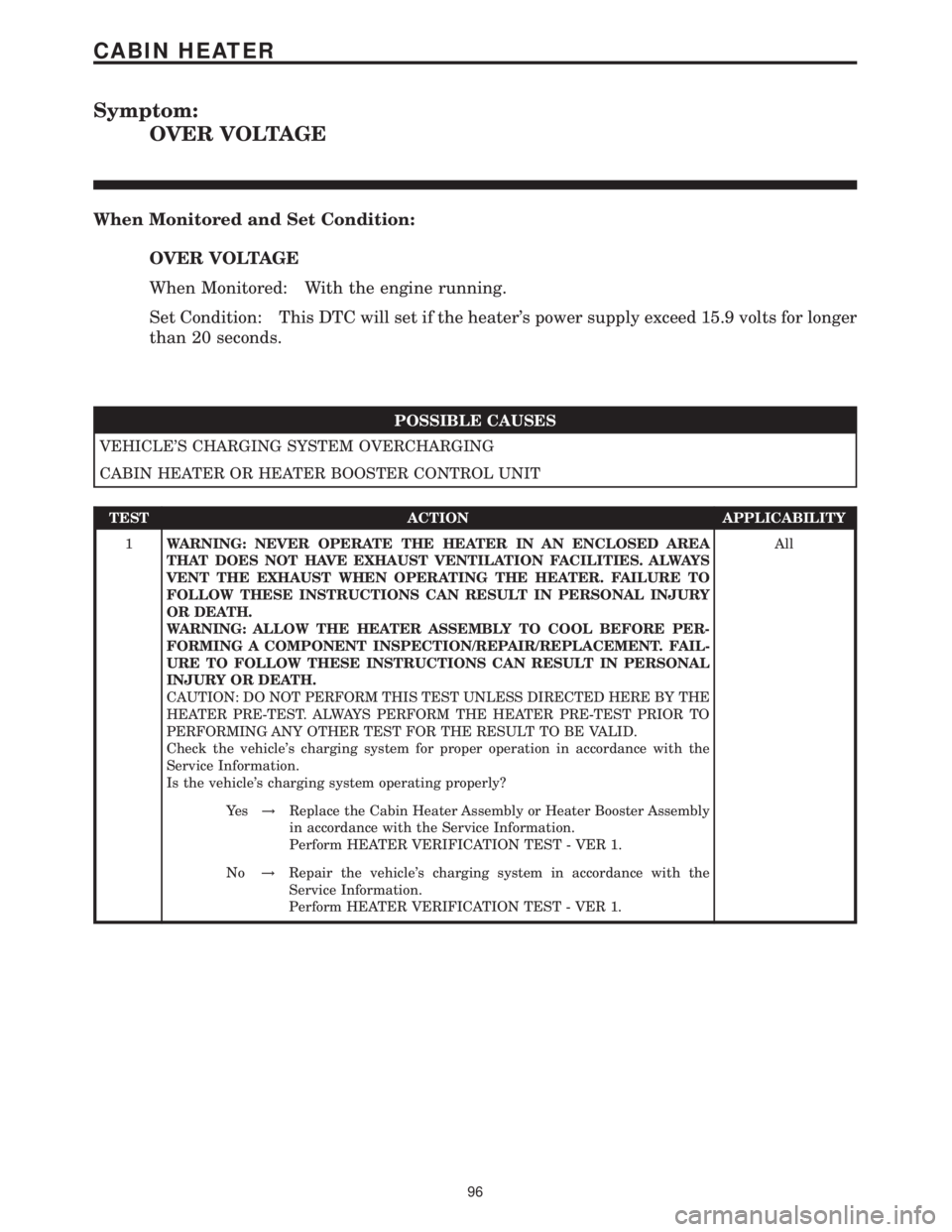

Symptom:

OVER VOLTAGE

When Monitored and Set Condition:

OVER VOLTAGE

When Monitored: With the engine running.

Set Condition: This DTC will set if the heater's power supply exceed 15.9 volts for longer

than 20 seconds.

POSSIBLE CAUSES

VEHICLE'S CHARGING SYSTEM OVERCHARGING

CABIN HEATER OR HEATER BOOSTER CONTROL UNIT

TEST ACTION APPLICABILITY

1WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

WARNING: ALLOW THE HEATER ASSEMBLY TO COOL BEFORE PER-

FORMING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL

INJURY OR DEATH.

CAUTION: DO NOT PERFORM THIS TEST UNLESS DIRECTED HERE BY THE

HEATER PRE-TEST. ALWAYS PERFORM THE HEATER PRE-TEST PRIOR TO

PERFORMING ANY OTHER TEST FOR THE RESULT TO BE VALID.

Check the vehicle's charging system for proper operation in accordance with the

Service Information.

Is the vehicle's charging system operating properly?All

Ye s!Replace the Cabin Heater Assembly or Heater Booster Assembly

in accordance with the Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

No!Repair the vehicle's charging system in accordance with the

Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

96

CABIN HEATER

Page 112 of 2305

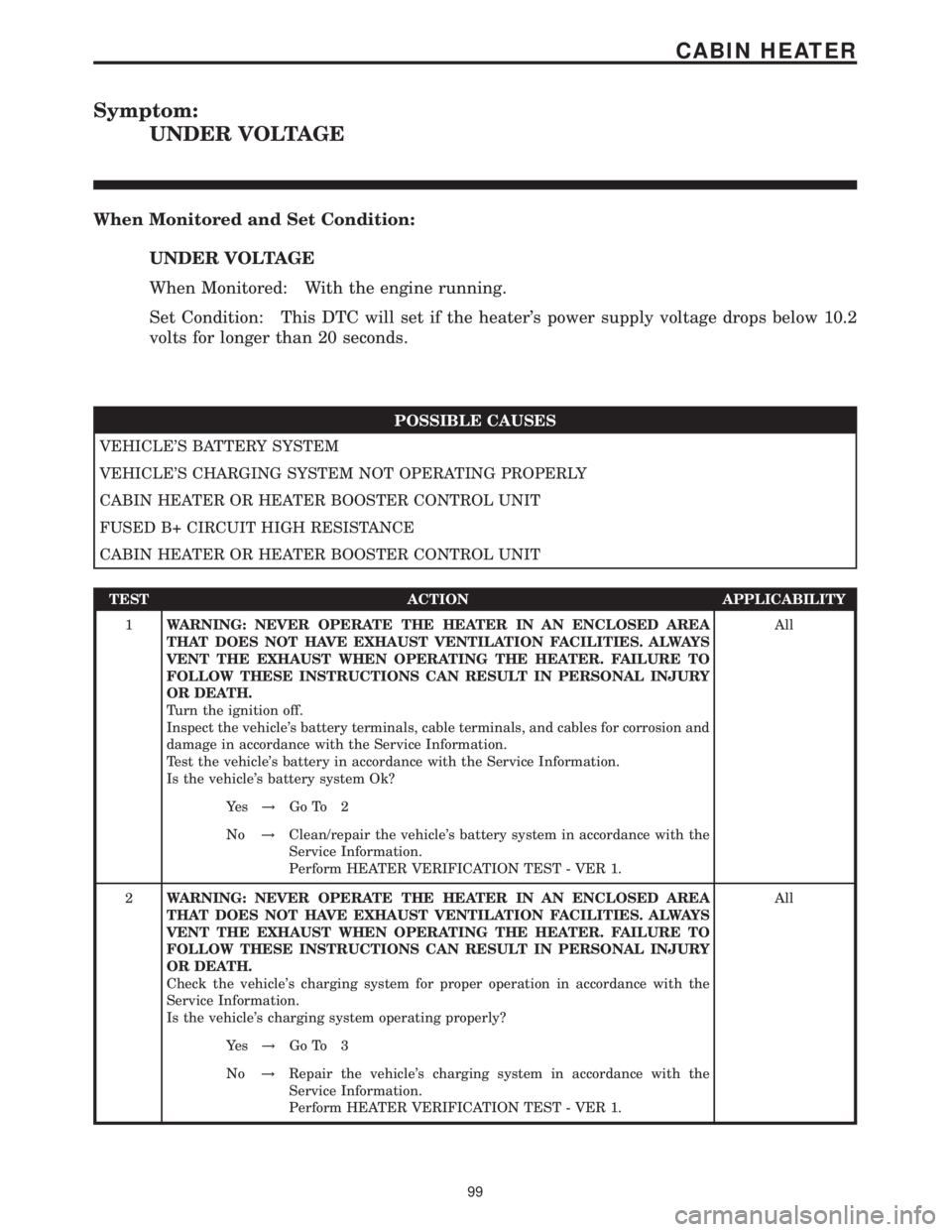

Symptom:

UNDER VOLTAGE

When Monitored and Set Condition:

UNDER VOLTAGE

When Monitored: With the engine running.

Set Condition: This DTC will set if the heater's power supply voltage drops below 10.2

volts for longer than 20 seconds.

POSSIBLE CAUSES

VEHICLE'S BATTERY SYSTEM

VEHICLE'S CHARGING SYSTEM NOT OPERATING PROPERLY

CABIN HEATER OR HEATER BOOSTER CONTROL UNIT

FUSED B+ CIRCUIT HIGH RESISTANCE

CABIN HEATER OR HEATER BOOSTER CONTROL UNIT

TEST ACTION APPLICABILITY

1WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

Turn the ignition off.

Inspect the vehicle's battery terminals, cable terminals, and cables for corrosion and

damage in accordance with the Service Information.

Test the vehicle's battery in accordance with the Service Information.

Is the vehicle's battery system Ok?All

Ye s!Go To 2

No!Clean/repair the vehicle's battery system in accordance with the

Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

2WARNING: NEVER OPERATE THE HEATER IN AN ENCLOSED AREA

THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE EXHAUST WHEN OPERATING THE HEATER. FAILURE TO

FOLLOW THESE INSTRUCTIONS CAN RESULT IN PERSONAL INJURY

OR DEATH.

Check the vehicle's charging system for proper operation in accordance with the

Service Information.

Is the vehicle's charging system operating properly?All

Ye s!Go To 3

No!Repair the vehicle's charging system in accordance with the

Service Information.

Perform HEATER VERIFICATION TEST - VER 1.

99

CABIN HEATER

Page 200 of 2305

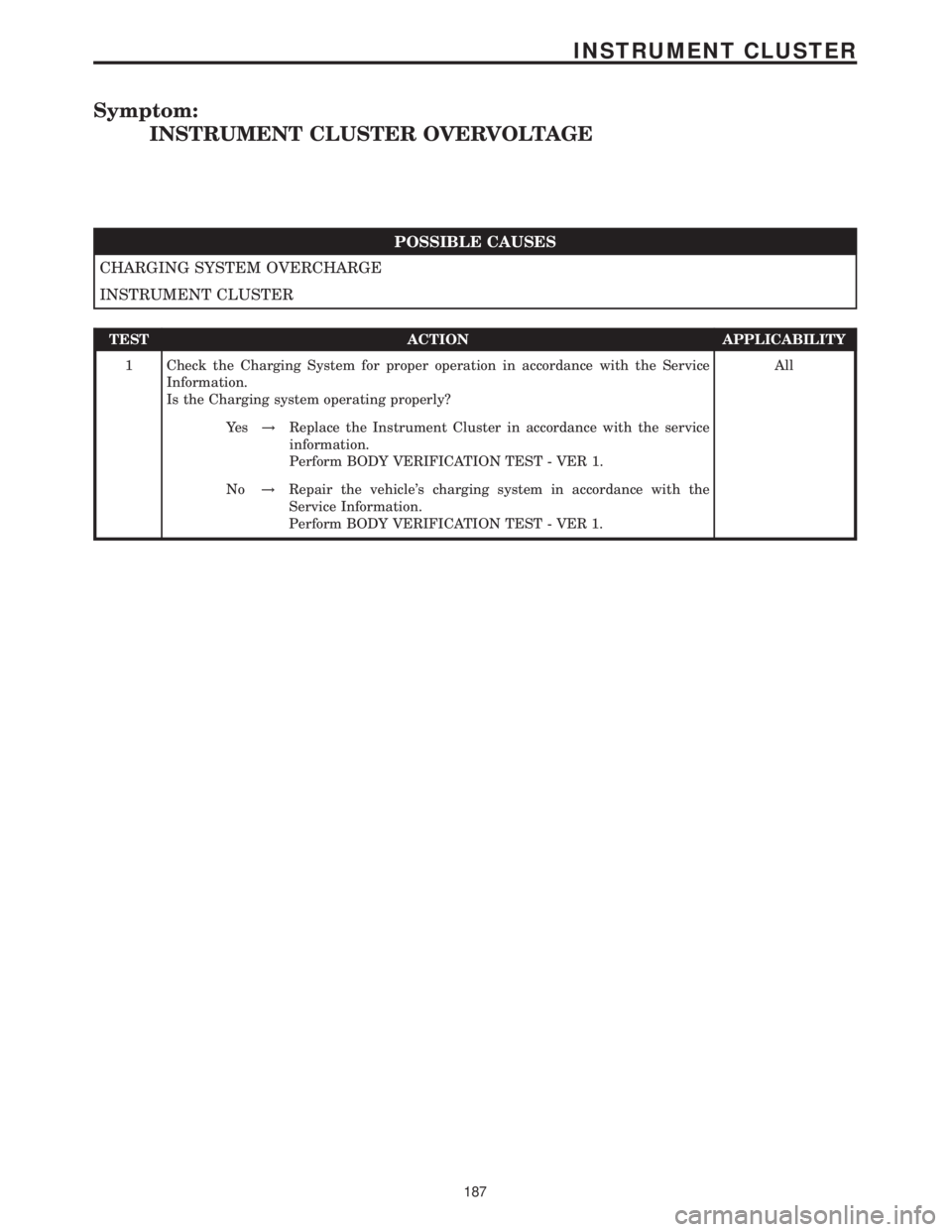

Symptom:

INSTRUMENT CLUSTER OVERVOLTAGE

POSSIBLE CAUSES

CHARGING SYSTEM OVERCHARGE

INSTRUMENT CLUSTER

TEST ACTION APPLICABILITY

1 Check the Charging System for proper operation in accordance with the Service

Information.

Is the Charging system operating properly?All

Ye s!Replace the Instrument Cluster in accordance with the service

information.

Perform BODY VERIFICATION TEST - VER 1.

No!Repair the vehicle's charging system in accordance with the

Service Information.

Perform BODY VERIFICATION TEST - VER 1.

187

INSTRUMENT CLUSTER

Page 381 of 2305

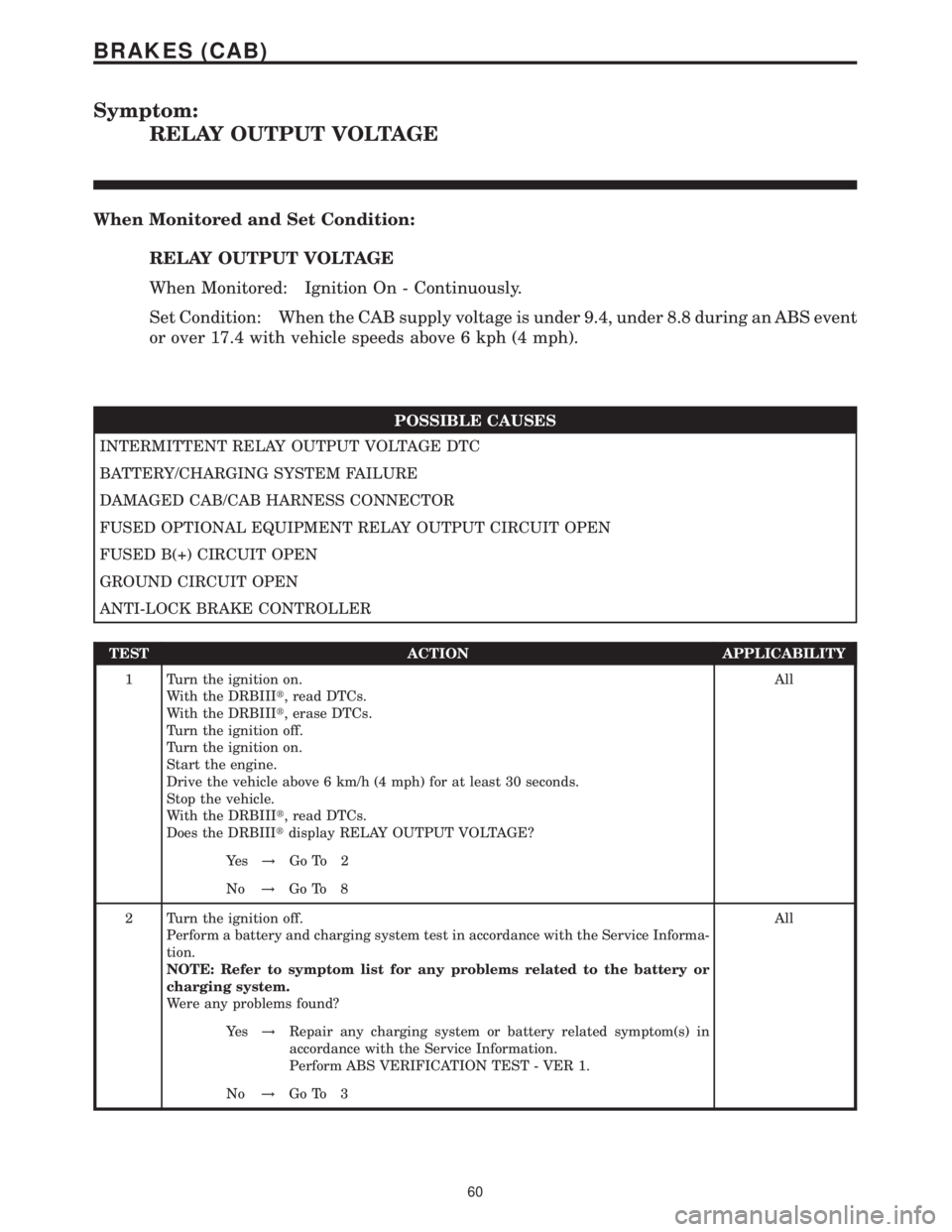

Symptom:

RELAY OUTPUT VOLTAGE

When Monitored and Set Condition:

RELAY OUTPUT VOLTAGE

When Monitored: Ignition On - Continuously.

Set Condition: When the CAB supply voltage is under 9.4, under 8.8 during an ABS event

or over 17.4 with vehicle speeds above 6 kph (4 mph).

POSSIBLE CAUSES

INTERMITTENT RELAY OUTPUT VOLTAGE DTC

BATTERY/CHARGING SYSTEM FAILURE

DAMAGED CAB/CAB HARNESS CONNECTOR

FUSED OPTIONAL EQUIPMENT RELAY OUTPUT CIRCUIT OPEN

FUSED B(+) CIRCUIT OPEN

GROUND CIRCUIT OPEN

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Start the engine.

Drive the vehicle above 6 km/h (4 mph) for at least 30 seconds.

Stop the vehicle.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay RELAY OUTPUT VOLTAGE?All

Ye s!Go To 2

No!Go To 8

2 Turn the ignition off.

Perform a battery and charging system test in accordance with the Service Informa-

tion.

NOTE: Refer to symptom list for any problems related to the battery or

charging system.

Were any problems found?All

Ye s!Repair any charging system or battery related symptom(s) in

accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

60

BRAKES (CAB)

Page 383 of 2305

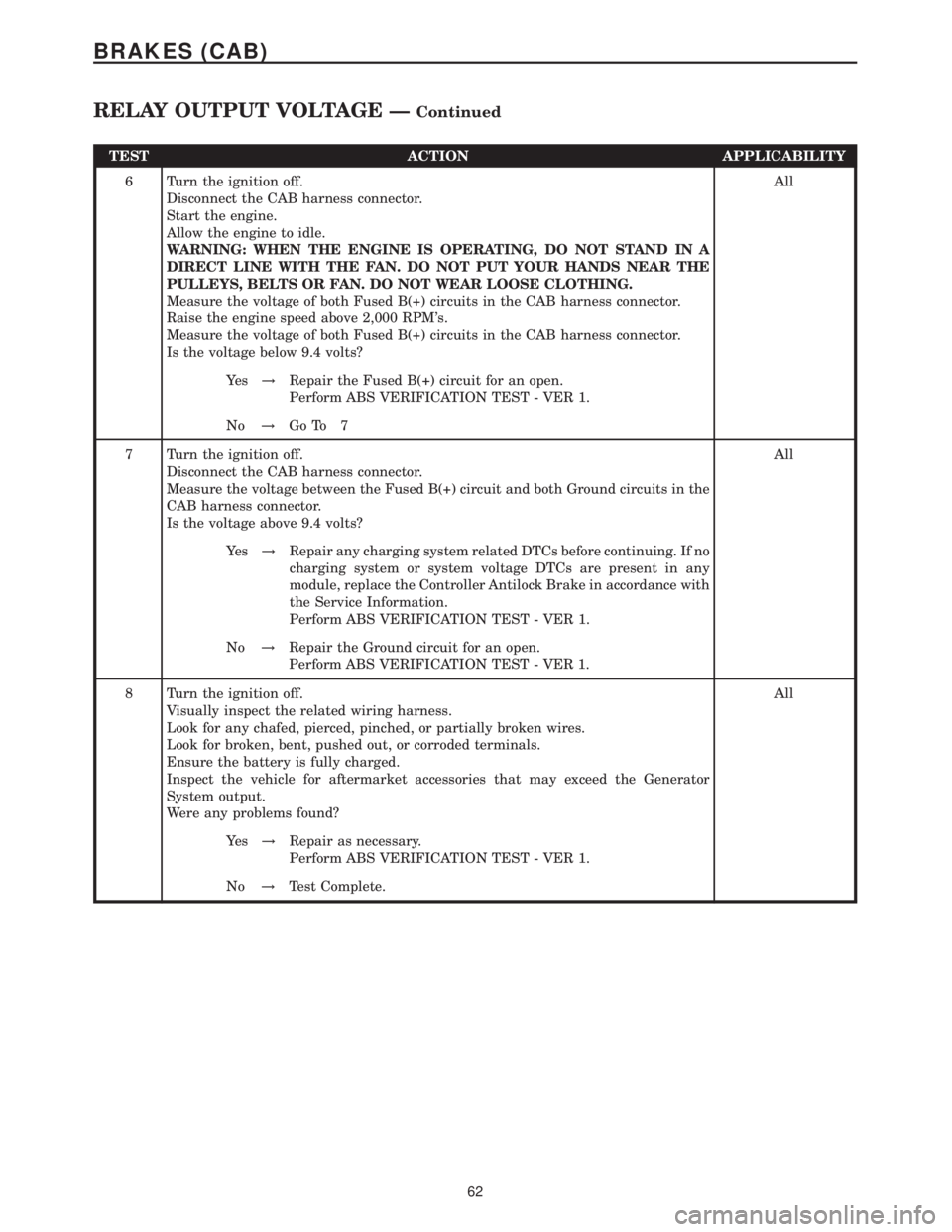

TEST ACTION APPLICABILITY

6 Turn the ignition off.

Disconnect the CAB harness connector.

Start the engine.

Allow the engine to idle.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Measure the voltage of both Fused B(+) circuits in the CAB harness connector.

Raise the engine speed above 2,000 RPM's.

Measure the voltage of both Fused B(+) circuits in the CAB harness connector.

Is the voltage below 9.4 volts?All

Ye s!Repair the Fused B(+) circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 7

7 Turn the ignition off.

Disconnect the CAB harness connector.

Measure the voltage between the Fused B(+) circuit and both Ground circuits in the

CAB harness connector.

Is the voltage above 9.4 volts?All

Ye s!Repair any charging system related DTCs before continuing. If no

charging system or system voltage DTCs are present in any

module, replace the Controller Antilock Brake in accordance with

the Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No!Repair the Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

8 Turn the ignition off.

Visually inspect the related wiring harness.

Look for any chafed, pierced, pinched, or partially broken wires.

Look for broken, bent, pushed out, or corroded terminals.

Ensure the battery is fully charged.

Inspect the vehicle for aftermarket accessories that may exceed the Generator

System output.

Were any problems found?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Test Complete.

62

BRAKES (CAB)

RELAY OUTPUT VOLTAGE ÐContinued

Page 396 of 2305

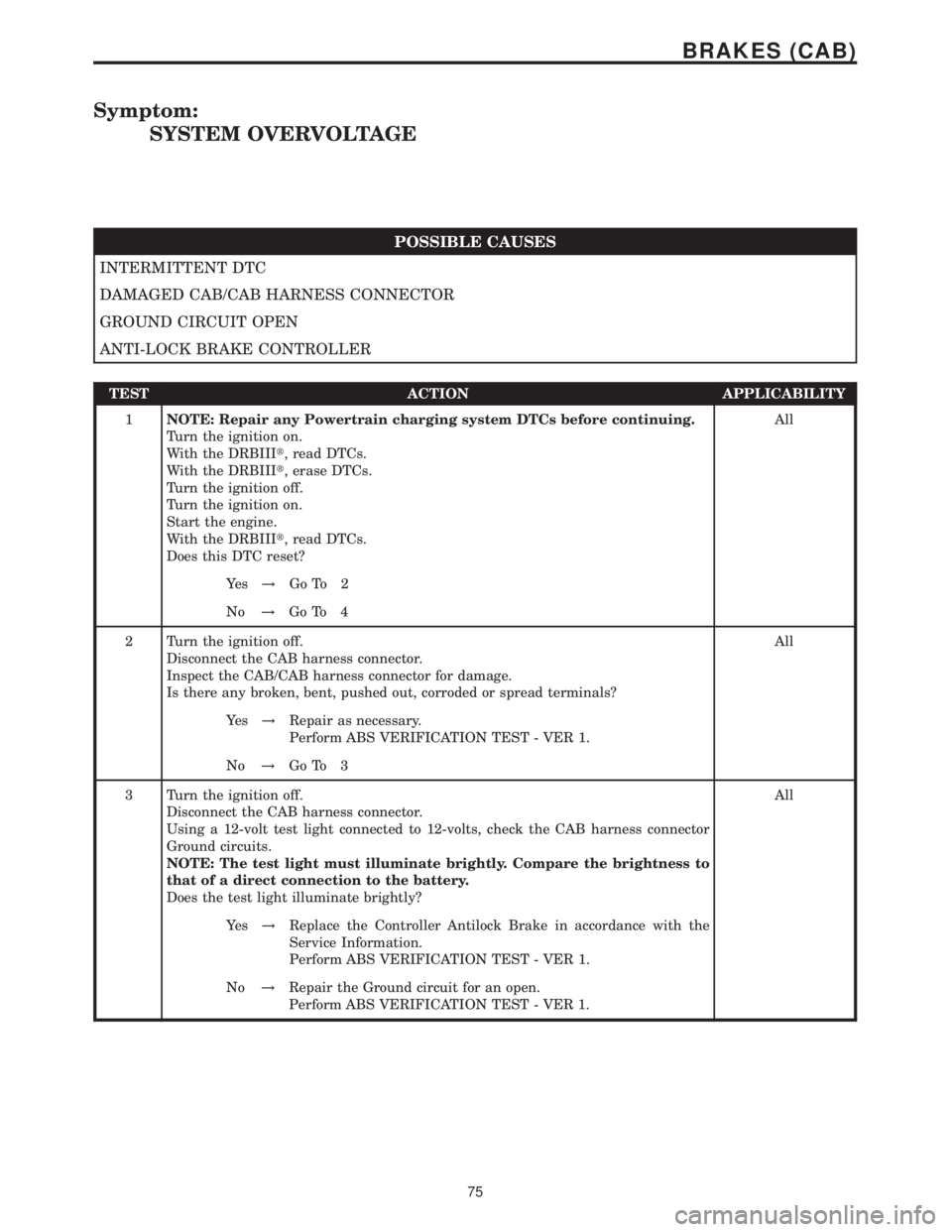

Symptom:

SYSTEM OVERVOLTAGE

POSSIBLE CAUSES

INTERMITTENT DTC

DAMAGED CAB/CAB HARNESS CONNECTOR

GROUND CIRCUIT OPEN

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1NOTE: Repair any Powertrain charging system DTCs before continuing.

Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Start the engine.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 4

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Using a 12-volt test light connected to 12-volts, check the CAB harness connector

Ground circuits.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No!Repair the Ground circuit for an open.

Perform ABS VERIFICATION TEST - VER 1.

75

BRAKES (CAB)

Page 398 of 2305

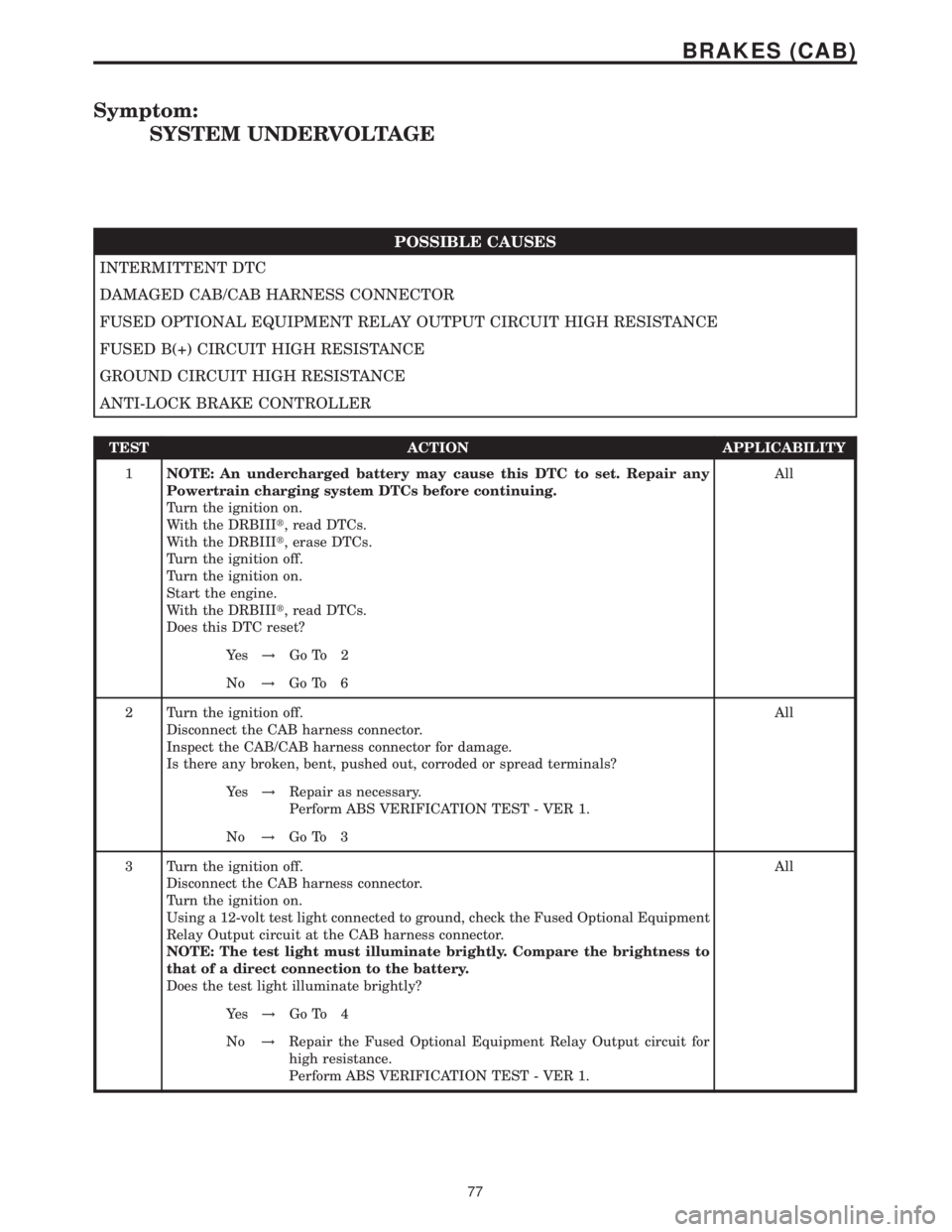

Symptom:

SYSTEM UNDERVOLTAGE

POSSIBLE CAUSES

INTERMITTENT DTC

DAMAGED CAB/CAB HARNESS CONNECTOR

FUSED OPTIONAL EQUIPMENT RELAY OUTPUT CIRCUIT HIGH RESISTANCE

FUSED B(+) CIRCUIT HIGH RESISTANCE

GROUND CIRCUIT HIGH RESISTANCE

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1NOTE: An undercharged battery may cause this DTC to set. Repair any

Powertrain charging system DTCs before continuing.

Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Start the engine.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 6

2 Turn the ignition off.

Disconnect the CAB harness connector.

Inspect the CAB/CAB harness connector for damage.

Is there any broken, bent, pushed out, corroded or spread terminals?All

Ye s!Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1.

No!Go To 3

3 Turn the ignition off.

Disconnect the CAB harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the Fused Optional Equipment

Relay Output circuit at the CAB harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s!Go To 4

No!Repair the Fused Optional Equipment Relay Output circuit for

high resistance.

Perform ABS VERIFICATION TEST - VER 1.

77

BRAKES (CAB)

Page 523 of 2305

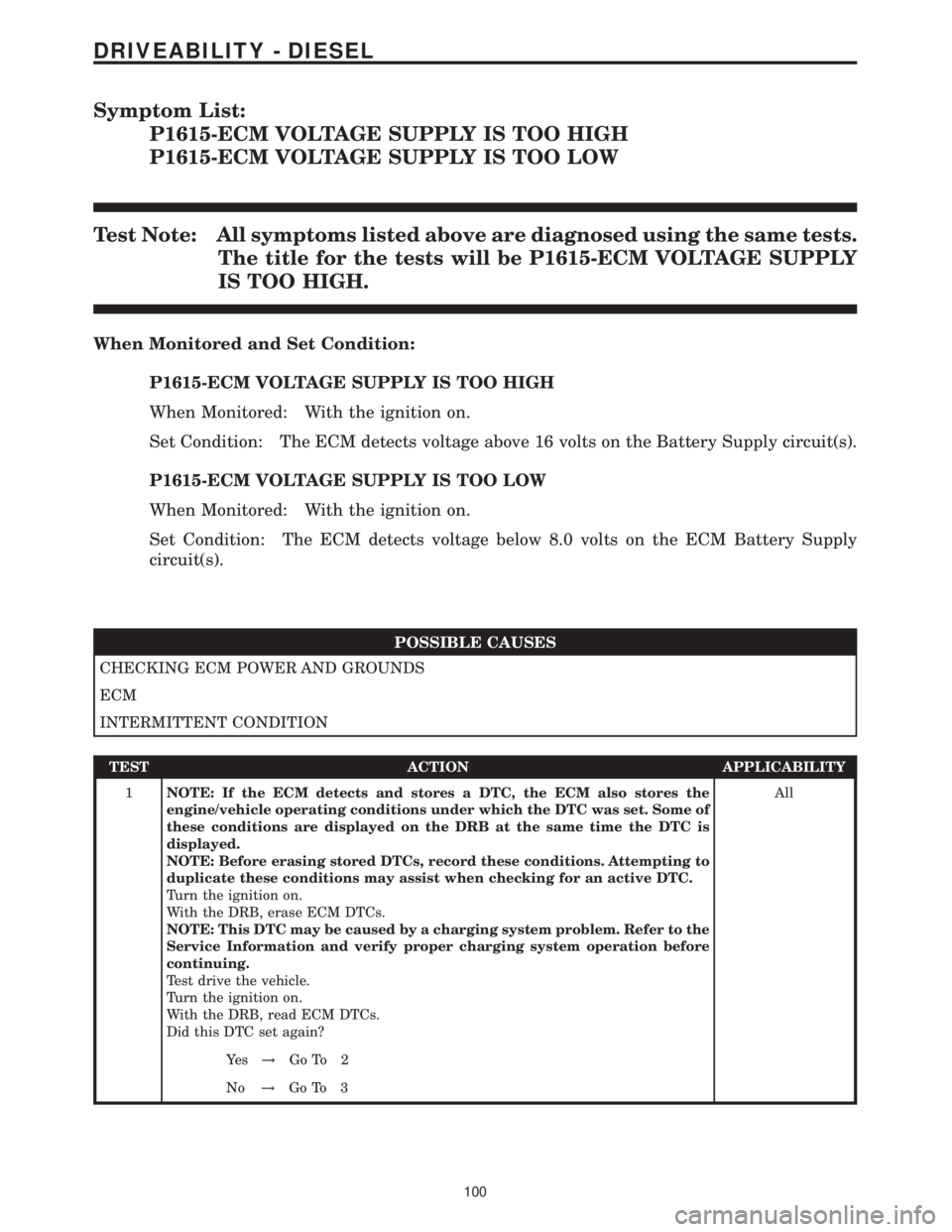

Symptom List:

P1615-ECM VOLTAGE SUPPLY IS TOO HIGH

P1615-ECM VOLTAGE SUPPLY IS TOO LOW

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P1615-ECM VOLTAGE SUPPLY

IS TOO HIGH.

When Monitored and Set Condition:

P1615-ECM VOLTAGE SUPPLY IS TOO HIGH

When Monitored: With the ignition on.

Set Condition: The ECM detects voltage above 16 volts on the Battery Supply circuit(s).

P1615-ECM VOLTAGE SUPPLY IS TOO LOW

When Monitored: With the ignition on.

Set Condition: The ECM detects voltage below 8.0 volts on the ECM Battery Supply

circuit(s).

POSSIBLE CAUSES

CHECKING ECM POWER AND GROUNDS

ECM

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1NOTE: If the ECM detects and stores a DTC, the ECM also stores the

engine/vehicle operating conditions under which the DTC was set. Some of

these conditions are displayed on the DRB at the same time the DTC is

displayed.

NOTE: Before erasing stored DTCs, record these conditions. Attempting to

duplicate these conditions may assist when checking for an active DTC.

Turn the ignition on.

With the DRB, erase ECM DTCs.

NOTE: This DTC may be caused by a charging system problem. Refer to the

Service Information and verify proper charging system operation before

continuing.

Test drive the vehicle.

Turn the ignition on.

With the DRB, read ECM DTCs.

Did this DTC set again?All

Ye s!Go To 2

No!Go To 3

100

DRIVEABILITY - DIESEL

Page 708 of 2305

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 2) and (Fig. 3).

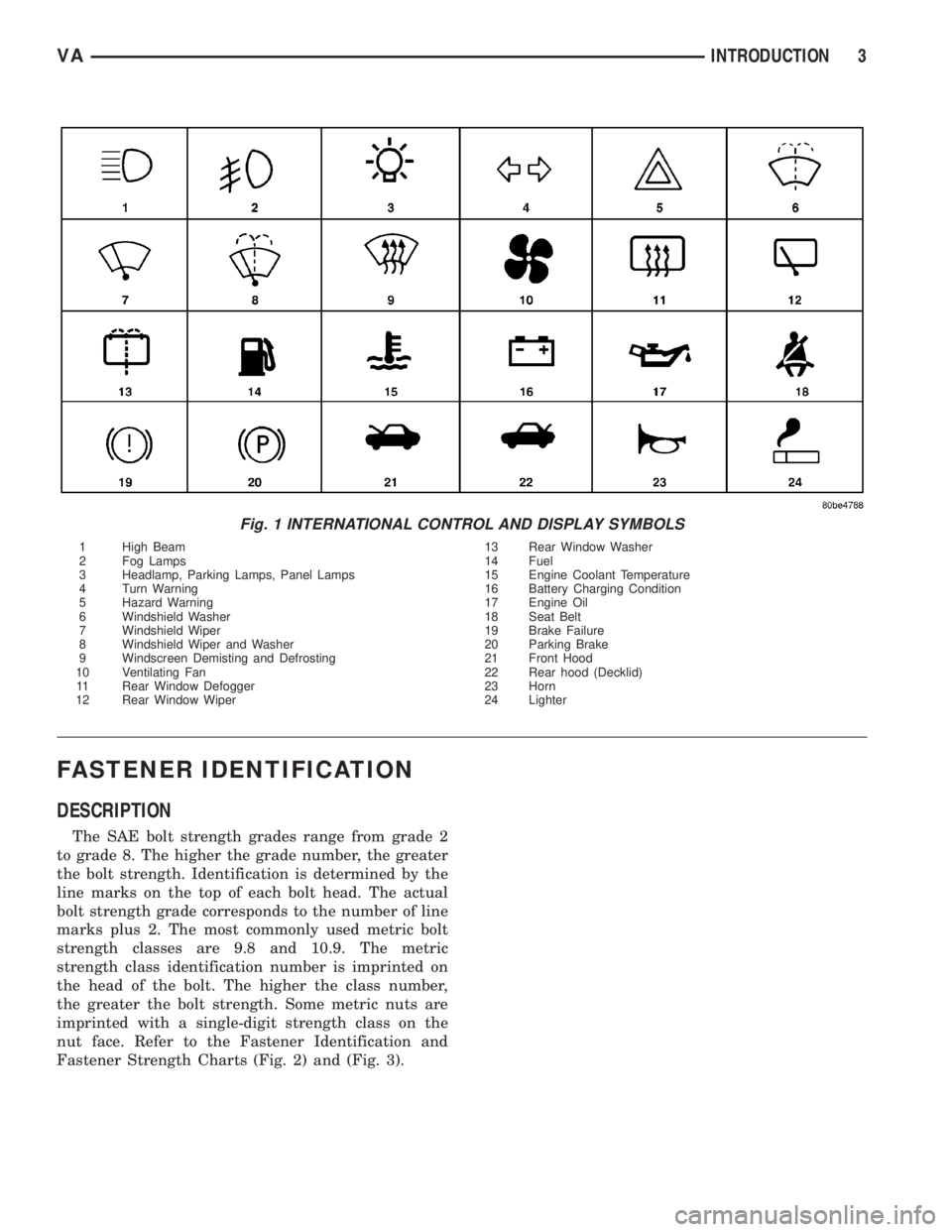

Fig. 1 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

VAINTRODUCTION 3

Page 721 of 2305

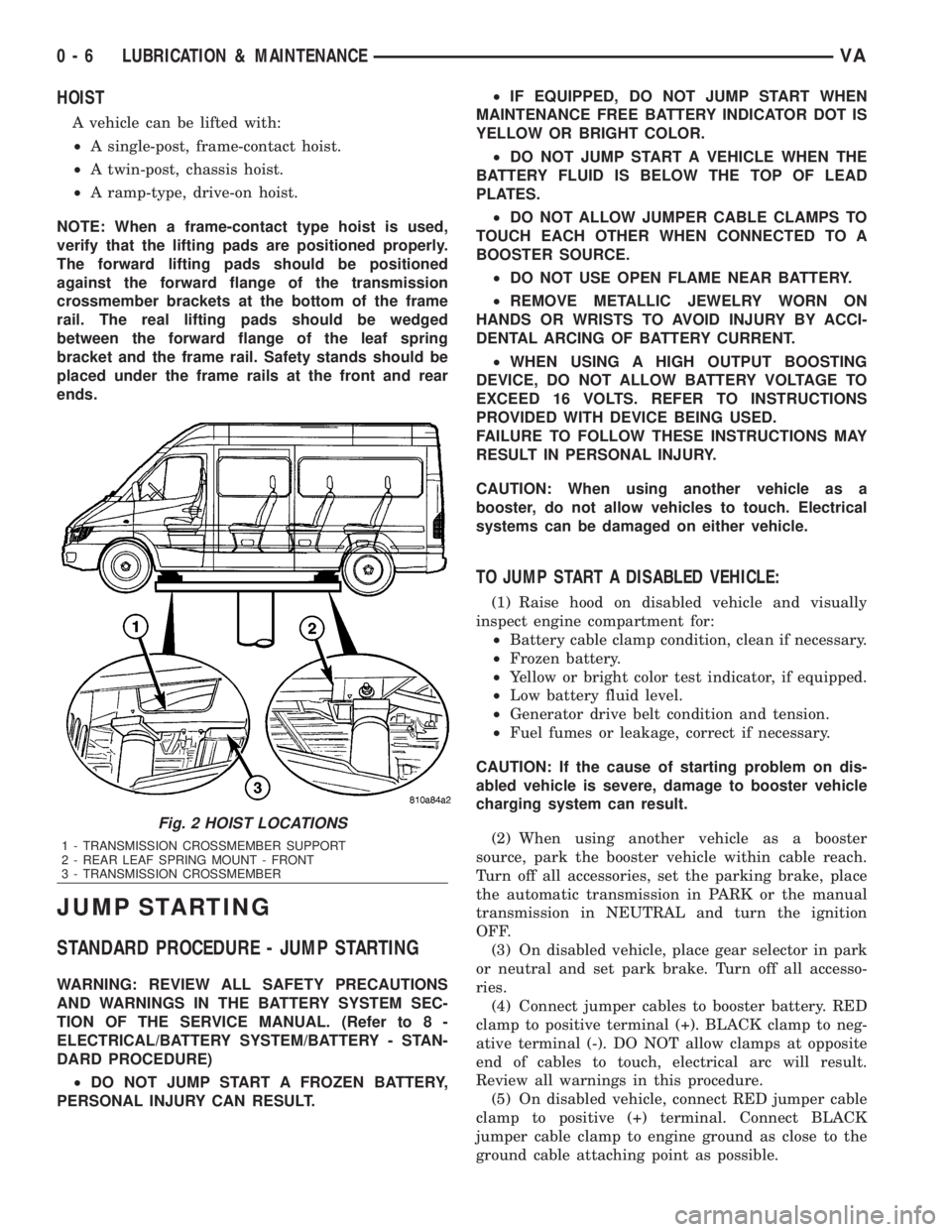

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly.

The forward lifting pads should be positioned

against the forward flange of the transmission

crossmember brackets at the bottom of the frame

rail. The real lifting pads should be wedged

between the forward flange of the leaf spring

bracket and the frame rail. Safety stands should be

placed under the frame rails at the front and rear

ends.

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN THE BATTERY SYSTEM SEC-

TION OF THE SERVICE MANUAL. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY - STAN-

DARD PROCEDURE)

²DO NOT JUMP START A FROZEN BATTERY,

PERSONAL INJURY CAN RESULT.²IF EQUIPPED, DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR.

²DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

²DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

²DO NOT USE OPEN FLAME NEAR BATTERY.

²REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT.

²WHEN USING A HIGH OUTPUT BOOSTING

DEVICE, DO NOT ALLOW BATTERY VOLTAGE TO

EXCEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible.

Fig. 2 HOIST LOCATIONS

1 - TRANSMISSION CROSSMEMBER SUPPORT

2 - REAR LEAF SPRING MOUNT - FRONT

3 - TRANSMISSION CROSSMEMBER

0 - 6 LUBRICATION & MAINTENANCEVA