tires MERCEDES-BENZ SPRINTER 2006 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2006, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2006Pages: 2305, PDF Size: 48.12 MB

Page 323 of 2305

enable the HCU to perform the brake fluid manage-

ment control as the combination/proportioning

valves.

The Bosch 5.7 system uses the CAB/HCU/Pump

Motor to make an integral electronic/hydraulic unit

which shares data with other electronic modules on

the vehicle via the CAN C Bus network. To access

DTCs from the CAB, the DRBIIItuses the K-ABS

line located in the Data Link Connector (DLC).

3.3 BRAKE ASSIST SYSTEM (HBA)

The Brake Assist System (HBA) analyzes how

hard and fast the driver wants to brake. It monitors

the brake pressure via a pressure sensor. The

passenger car brake assist system uses a vacuum

booster solenoid. The Sprinter uses the hydraulic

control unit to develop the brake pressure.

3.4 TCS (ASR)

The primary function of the Traction Control System

is to reduce wheel slip and maintain traction at the

driven wheels when the road surfaces are slippery. The

Traction Control System reduces wheel slip by applying

the brake that has lost traction. The system is designed

to operate at speeds below 50 km/h (30 mph). The

engine's torque can be reduced by the ECM via the CAN

C Bus, if necessary. The TCS can be deactivated with

switch on the dash. The Traction Control System uses

the ABS to indicate spinning tires to enable the traction

control function. The TCS software is in the CAB.

The TCS (ASR) performs the following functions:

1. Engine power derate

2. Engine deceleration regulation. If the vehicle is

on a patch of ice, the simple action of releasing

the throttle is enough to cause the rear wheels to

slip. To avoid this, the throttle input is regulated

so power drops slowly instead of abruptly. The

engine power is reduced (decelerated) as neces-

sary.

3.5 ELECTRONIC BRAKE DISTRIBUTION

(EBD)

The system was enhanced and eliminates the

need for the ALB system (load sensing valve). All

ESP equipped models will not have ALB. The EBV

system self-adapts to operating conditions. It de-

tects the vehicle's payload when the vehicle starts

and pulls away. Based on the acceleration rate

when the vehicle first pulls away from a standstill,

the system is able to calculate the actual payload.

This is a rough estimate which is used initially.

Later on, the system gathers more precise informa-

tion by monitoring the brake pressure and wheel

speed and negative slip when the driver applies thebrakes. The system will then produce a more accu-

rate calculation of payload depending on brake

retardation. The adaptation is erased when the

ignition is switched off. A new adaptation will occur

on the next driving cycle. By default, the system

acts upon the vehicle as if in an unloaded condition

(safe mode).

Once a new driving cycle begins with the vehicle

in a fully loaded condition (without having gathered

more precise information) the system will detect

ABS actuation in the front wheels and will allow

enough pressure to be applied to the rear axle, to an

extent where the wheels are just about to lock up

(maximum braking possible).

The system calculates the braking force at the

front and rear axles. If the driver applies the brakes

gently and then realizes he needs to apply the

brakes further, the EBV allows the proper pressure

to be applied to the front and rear brakes.

The EBV also contains a feature called ªcorner

brake systemº (CBS) which operates when the ve-

hicle is braked while cornering to avoid a possible

oversteering condition. The EBV monitors the

wheel speed of both rear wheels to detect when the

vehicle is cornering and allows precise brake pres-

sure application to the front and rear brakes. Also

when the brakes are applied during cornering, the

outer wheels get more of the vehicle's weight while

the inner wheels get less weight and could lose

traction (wheel lock up). The EBV system splits the

pressure between left and right sides in addition to

front and rear brakes.

3.6 VEHICLE CONTROLLING (FZR)

Vehicle controlling (FZR)requires additional

sensors to operate. The term ESP refers to the

software of the system. The term FZR refers to the

system controller. The TCS (ASR) system requires

wheel speed sensors to monitor wheel slip and CAN

bus communications to regulate engine power. In

addition to these inputs, the vehicle controlling

(FZR) requires a steering angle sensor, and a lateral

acceleration/yaw rate sensor.

The ESP system does not take the vehicle load

into account. Instead, the coefficient of friction is

calculated in a 20 millisecond period, where the

controller measures the rate at which the wheel

speed is decelerated, as brake pressure is applied to

the wheel.

3.7 SYSTEM COMPONENTS

²Controller Antilock Brake (CAB)

²Hydraulic Control Unit (HCU)

²Pump Motor

2

GENERAL INFORMATION

Page 325 of 2305

read opposite switch states.Note: The BS and

BLS are in the same switch housing.

BRAKE LAMP SWITCH (BLS):This switch pre-

pares the CAB for a possible antilock event. The

CAB uses an output state voltage from the BLS

when the brake pedal is either depressed/released.

The Fused Ignition Switch Output circuit supplies

12 volts to the BLS. A depressed brake pedal will

close the BLS circuit and the BLS Output circuit

supplies 12 volts at the CAB. When the driver

releases the brake pedal, the BLS Output circuit

voltage drops to 0 volts and the CAB senses the

brake pedal state. This tells the CAB what position

the brake pedal is currently in to make an ABS

event possible. When using the DRBIIItin Inputs/

Outputs, the BS and BLS will read opposite switch

states.Note: The BS and BLS are in the same

switch housing.

TRACTION CONTROL SYSTEM SWITCH

(TCSS):This switch signals the CAB to either turn

ON or OFF the TCS. The driver can toggle the

TCSS, which receives 12 volts from the D (+) Relay

Output circuit. Depending on the position of the

TCSS, open or closed, the CAB receives the TCSS

state voltage on the TCS Switch Sense circuit.

When 12 volts are applied to the TCS Switch Sense

circuit, the TCS is OFF. When no voltage is present,

the TCS is ON.

WHEEL SPEED SENSORS AND TONE

WHEELS:The Bosch 5.7 system uses one passive

WSS on each wheel. The sensor measures the wheel

speed by monitoring a rotating tone wheel. As the

teeth of the tone wheel move through the magnetic

field of the sensor an AC voltage and amperage is

generated. This signal frequency increases or de-

creases proportionally to the speed of the wheel.

The CAB monitors this signal to check for a sudden

change in single or multiple wheel decelerations. If

the deceleration of one or more wheels is not within

a predetermined amount, the CAB takes control for

antilock action through the HCU. Each WSS has a

magnetic inductive pick up coil (WSS) that is

mounted to a fixed component. There is an air gap

between the tone wheel and the speed sensor as-

sembly. Diagnostically, the coils of the Wheel Speed

Sensors have the same amount of resistance. When

measured across the CAB harness connector termi-

nals, the resistance should be between 1100 - 1800

ohms. Refer to service manual for WSS replacement

and air gap specifications.

Correct ABS operation is dependent on Tone

Wheel speed signal from the WSS. The vehicle

wheels and tires should all be the same size and

type to get accurate signals. In addition, all tires

should be at recommended tire pressures.3.7.5 SELF TESTS

The system software includes several self tests

that are performed every time the ignition is turned

on and the vehicle is driven. Some of the self tests

occur immediately, while others occur under normal

driving conditions while not in antilock operation.

The CAB checks continuously for a missing or

erratic WSS signals/circuits, tone wheels, solenoids,

pump motor or solenoid relay by performing several

tests such as: dynamic, static, ohmic, voltage drop,

and timed response. If any component exhibits a

fault during testing, the CAB will request to illumi-

nate the ABS and TCS warning indicators.

As an additional check of the ESP system, a road

test procedure is available on the DRBIIIt. This

test should be carried out when any ESP component

is replaced in order to ensure proper function. Since

the wheel speed sensors are required inputs to the

ESP, this test should also be performed if the wheel

speed sensors are replaced.

First, the brakes are applied with the vehicle

stationary. Then, the vehicle is driven at approxi-

mately 6 MPH. The driver has to make left and

right turns, with a minimum 90 degree steering

turning angle. If the indicator lamp goes out, every-

thing is in order. If the lamp remains illuminated,

the DRBIIItwill display the fault codes that are

causing the test to fail. The road test function is set

in the ESP control module, and can only be deacti-

vated once there are no more fault codes detected.

The Steering Angle Sensor must be initialized. A

procedure is carried out using the DRBIIItto

ensure that the module detects the exact position of

the sensor. The sensor must be calibrated any time

wheel alignment is changed, the steering column is

removed and re-installed, or the sensor is replaced.

3.8 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading diagnostic trouble

codes, erasing diagnostic trouble codes and other

DRBIIItfunctions.

3.9 DRBIIITERROR MESSAGES

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

Ð User-Requested WARM Boot or User-Requested

COLD Boot.

If the DRBIIItshould display any other error

message, record the entire display and call the

STAR Center for information and assistance. This

is a sample of such an error message display:

4

GENERAL INFORMATION

Page 350 of 2305

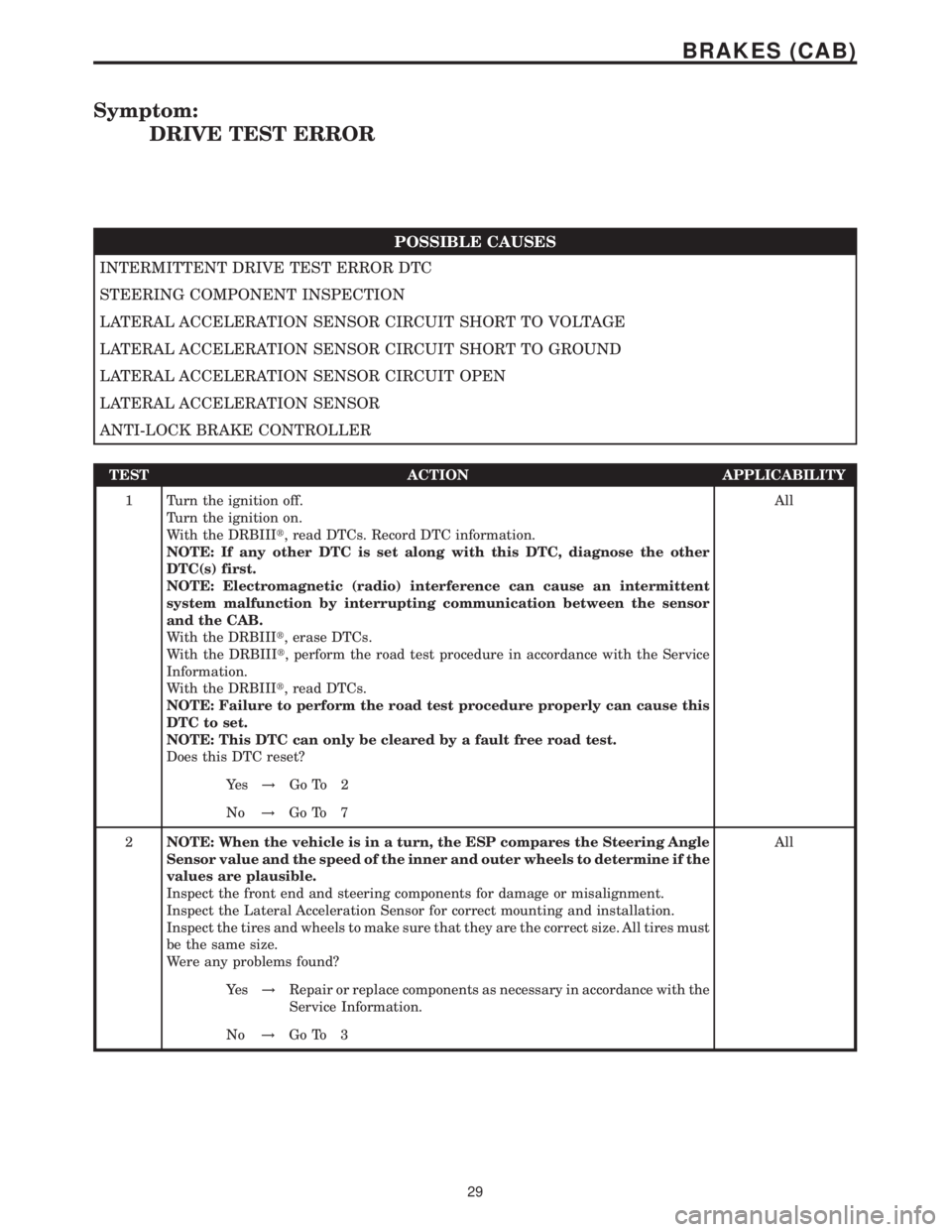

Symptom:

DRIVE TEST ERROR

POSSIBLE CAUSES

INTERMITTENT DRIVE TEST ERROR DTC

STEERING COMPONENT INSPECTION

LATERAL ACCELERATION SENSOR CIRCUIT SHORT TO VOLTAGE

LATERAL ACCELERATION SENSOR CIRCUIT SHORT TO GROUND

LATERAL ACCELERATION SENSOR CIRCUIT OPEN

LATERAL ACCELERATION SENSOR

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Turn the ignition on.

With the DRBIIIt, read DTCs. Record DTC information.

NOTE: If any other DTC is set along with this DTC, diagnose the other

DTC(s) first.

NOTE: Electromagnetic (radio) interference can cause an intermittent

system malfunction by interrupting communication between the sensor

and the CAB.

With the DRBIIIt, erase DTCs.

With the DRBIIIt, perform the road test procedure in accordance with the Service

Information.

With the DRBIIIt, read DTCs.

NOTE: Failure to perform the road test procedure properly can cause this

DTC to set.

NOTE: This DTC can only be cleared by a fault free road test.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 7

2NOTE: When the vehicle is in a turn, the ESP compares the Steering Angle

Sensor value and the speed of the inner and outer wheels to determine if the

values are plausible.

Inspect the front end and steering components for damage or misalignment.

Inspect the Lateral Acceleration Sensor for correct mounting and installation.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Were any problems found?All

Ye s!Repair or replace components as necessary in accordance with the

Service Information.

No!Go To 3

29

BRAKES (CAB)

Page 353 of 2305

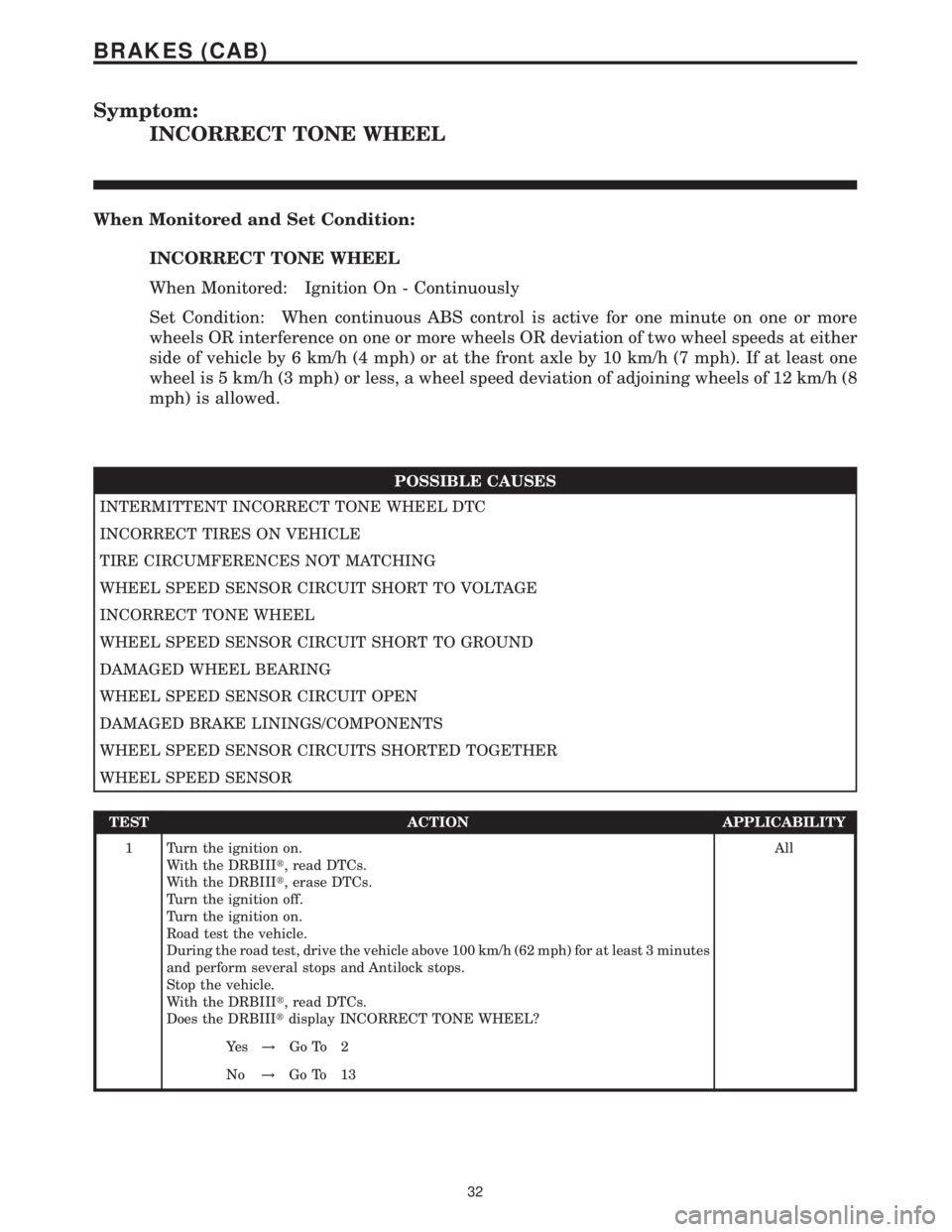

Symptom:

INCORRECT TONE WHEEL

When Monitored and Set Condition:

INCORRECT TONE WHEEL

When Monitored: Ignition On - Continuously

Set Condition: When continuous ABS control is active for one minute on one or more

wheels OR interference on one or more wheels OR deviation of two wheel speeds at either

side of vehicle by 6 km/h (4 mph) or at the front axle by 10 km/h (7 mph). If at least one

wheel is 5 km/h (3 mph) or less, a wheel speed deviation of adjoining wheels of 12 km/h (8

mph) is allowed.

POSSIBLE CAUSES

INTERMITTENT INCORRECT TONE WHEEL DTC

INCORRECT TIRES ON VEHICLE

TIRE CIRCUMFERENCES NOT MATCHING

WHEEL SPEED SENSOR CIRCUIT SHORT TO VOLTAGE

INCORRECT TONE WHEEL

WHEEL SPEED SENSOR CIRCUIT SHORT TO GROUND

DAMAGED WHEEL BEARING

WHEEL SPEED SENSOR CIRCUIT OPEN

DAMAGED BRAKE LININGS/COMPONENTS

WHEEL SPEED SENSOR CIRCUITS SHORTED TOGETHER

WHEEL SPEED SENSOR

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTCs.

With the DRBIIIt, erase DTCs.

Turn the ignition off.

Turn the ignition on.

Road test the vehicle.

During the road test, drive the vehicle above 100 km/h (62 mph) for at least 3 minutes

and perform several stops and Antilock stops.

Stop the vehicle.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay INCORRECT TONE WHEEL?All

Ye s!Go To 2

No!Go To 13

32

BRAKES (CAB)

Page 357 of 2305

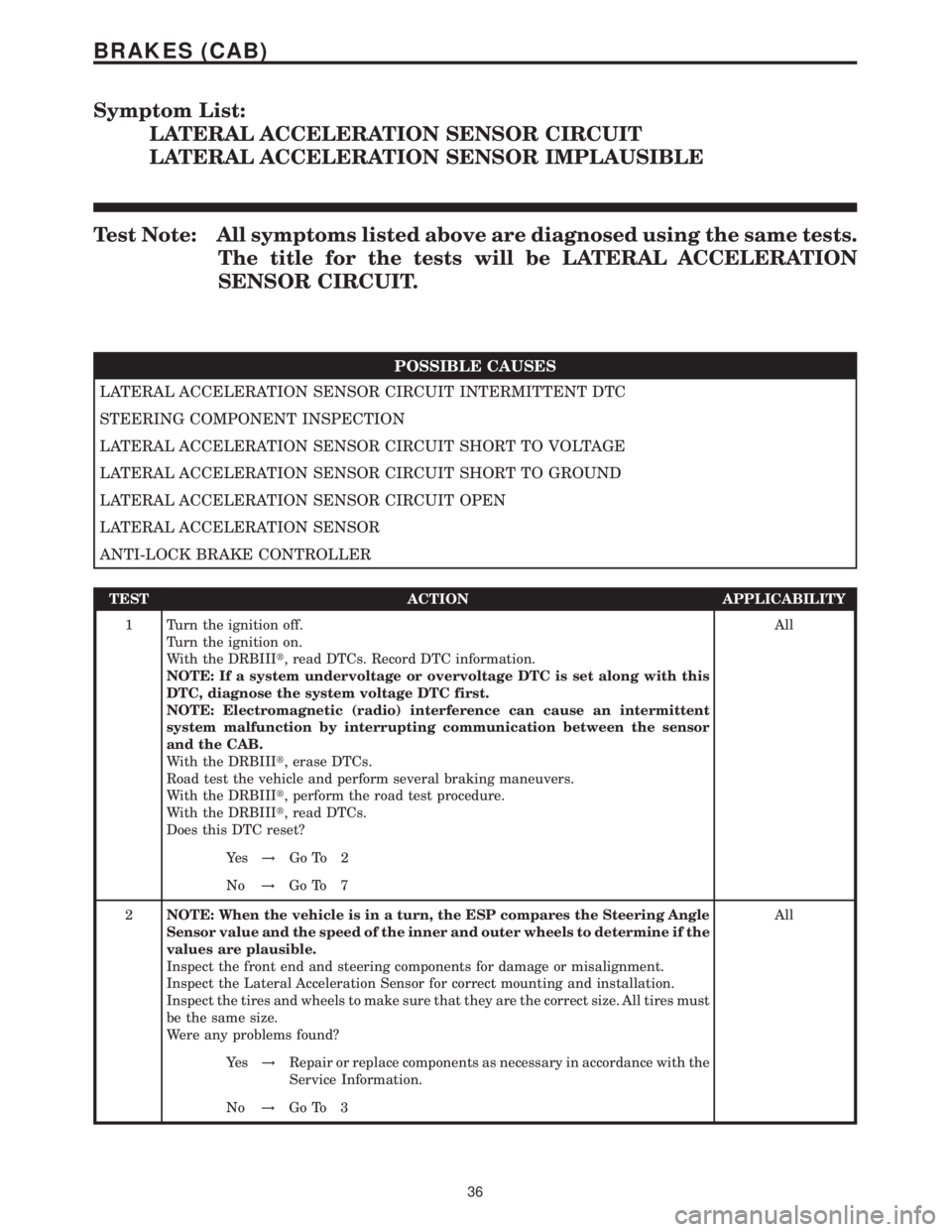

Symptom List:

LATERAL ACCELERATION SENSOR CIRCUIT

LATERAL ACCELERATION SENSOR IMPLAUSIBLE

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be LATERAL ACCELERATION

SENSOR CIRCUIT.

POSSIBLE CAUSES

LATERAL ACCELERATION SENSOR CIRCUIT INTERMITTENT DTC

STEERING COMPONENT INSPECTION

LATERAL ACCELERATION SENSOR CIRCUIT SHORT TO VOLTAGE

LATERAL ACCELERATION SENSOR CIRCUIT SHORT TO GROUND

LATERAL ACCELERATION SENSOR CIRCUIT OPEN

LATERAL ACCELERATION SENSOR

ANTI-LOCK BRAKE CONTROLLER

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Turn the ignition on.

With the DRBIIIt, read DTCs. Record DTC information.

NOTE: If a system undervoltage or overvoltage DTC is set along with this

DTC, diagnose the system voltage DTC first.

NOTE: Electromagnetic (radio) interference can cause an intermittent

system malfunction by interrupting communication between the sensor

and the CAB.

With the DRBIIIt, erase DTCs.

Road test the vehicle and perform several braking maneuvers.

With the DRBIIIt, perform the road test procedure.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 7

2NOTE: When the vehicle is in a turn, the ESP compares the Steering Angle

Sensor value and the speed of the inner and outer wheels to determine if the

values are plausible.

Inspect the front end and steering components for damage or misalignment.

Inspect the Lateral Acceleration Sensor for correct mounting and installation.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Were any problems found?All

Ye s!Repair or replace components as necessary in accordance with the

Service Information.

No!Go To 3

36

BRAKES (CAB)

Page 387 of 2305

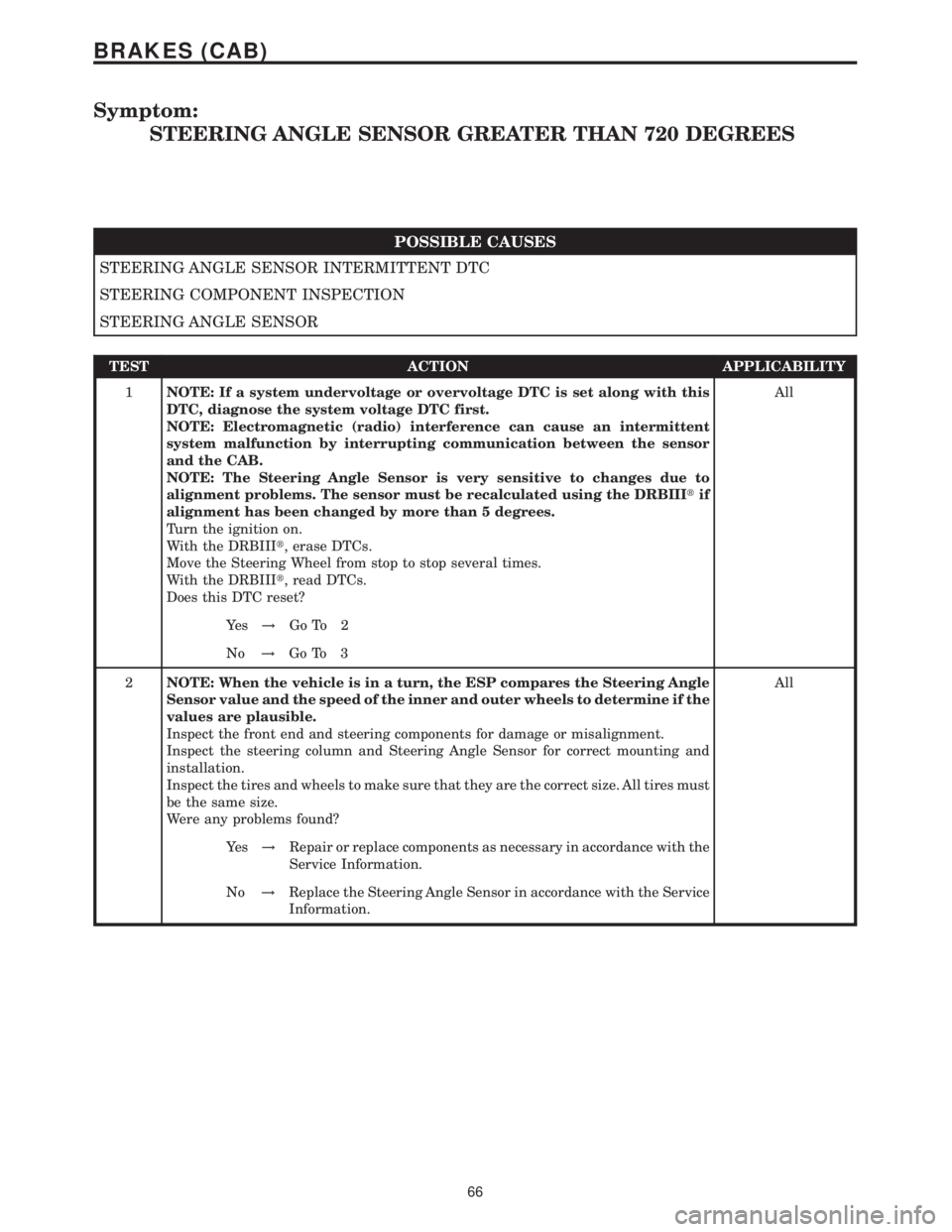

Symptom:

STEERING ANGLE SENSOR GREATER THAN 720 DEGREES

POSSIBLE CAUSES

STEERING ANGLE SENSOR INTERMITTENT DTC

STEERING COMPONENT INSPECTION

STEERING ANGLE SENSOR

TEST ACTION APPLICABILITY

1NOTE: If a system undervoltage or overvoltage DTC is set along with this

DTC, diagnose the system voltage DTC first.

NOTE: Electromagnetic (radio) interference can cause an intermittent

system malfunction by interrupting communication between the sensor

and the CAB.

NOTE: The Steering Angle Sensor is very sensitive to changes due to

alignment problems. The sensor must be recalculated using the DRBIIItif

alignment has been changed by more than 5 degrees.

Turn the ignition on.

With the DRBIIIt, erase DTCs.

Move the Steering Wheel from stop to stop several times.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 3

2NOTE: When the vehicle is in a turn, the ESP compares the Steering Angle

Sensor value and the speed of the inner and outer wheels to determine if the

values are plausible.

Inspect the front end and steering components for damage or misalignment.

Inspect the steering column and Steering Angle Sensor for correct mounting and

installation.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Were any problems found?All

Ye s!Repair or replace components as necessary in accordance with the

Service Information.

No!Replace the Steering Angle Sensor in accordance with the Service

Information.

66

BRAKES (CAB)

Page 388 of 2305

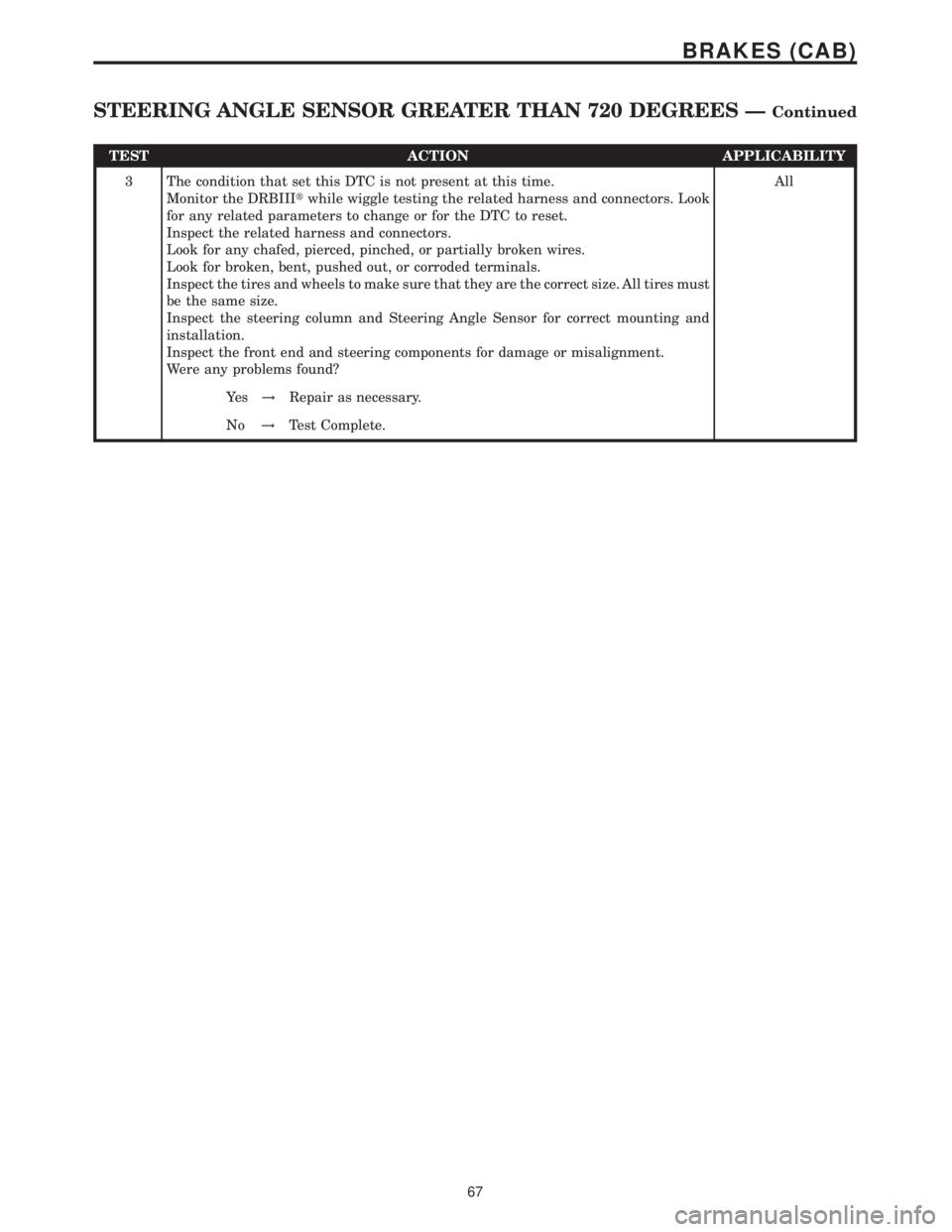

TEST ACTION APPLICABILITY

3 The condition that set this DTC is not present at this time.

Monitor the DRBIIItwhile wiggle testing the related harness and connectors. Look

for any related parameters to change or for the DTC to reset.

Inspect the related harness and connectors.

Look for any chafed, pierced, pinched, or partially broken wires.

Look for broken, bent, pushed out, or corroded terminals.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Inspect the steering column and Steering Angle Sensor for correct mounting and

installation.

Inspect the front end and steering components for damage or misalignment.

Were any problems found?All

Ye s!Repair as necessary.

No!Test Complete.

67

BRAKES (CAB)

STEERING ANGLE SENSOR GREATER THAN 720 DEGREES ÐContinued

Page 391 of 2305

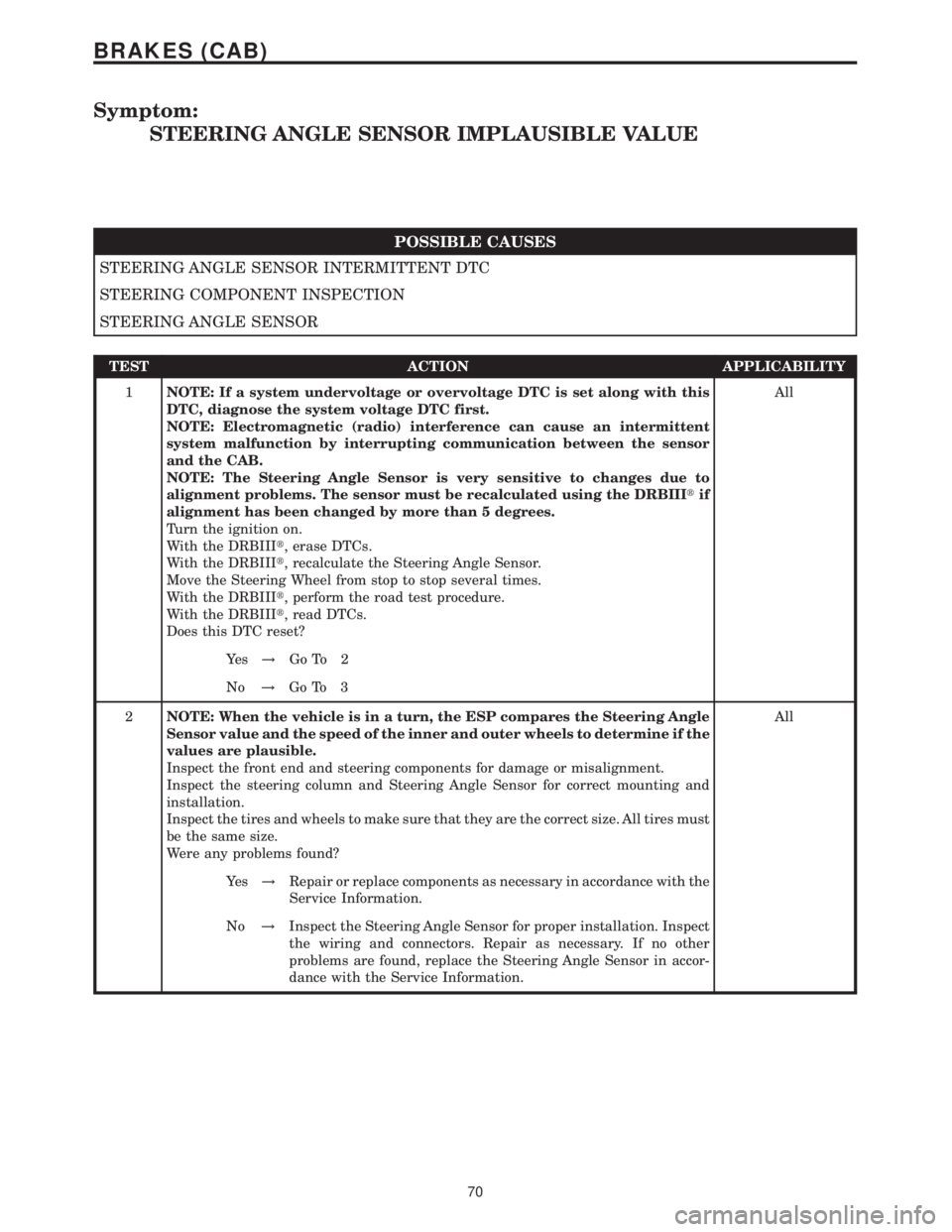

Symptom:

STEERING ANGLE SENSOR IMPLAUSIBLE VALUE

POSSIBLE CAUSES

STEERING ANGLE SENSOR INTERMITTENT DTC

STEERING COMPONENT INSPECTION

STEERING ANGLE SENSOR

TEST ACTION APPLICABILITY

1NOTE: If a system undervoltage or overvoltage DTC is set along with this

DTC, diagnose the system voltage DTC first.

NOTE: Electromagnetic (radio) interference can cause an intermittent

system malfunction by interrupting communication between the sensor

and the CAB.

NOTE: The Steering Angle Sensor is very sensitive to changes due to

alignment problems. The sensor must be recalculated using the DRBIIItif

alignment has been changed by more than 5 degrees.

Turn the ignition on.

With the DRBIIIt, erase DTCs.

With the DRBIIIt, recalculate the Steering Angle Sensor.

Move the Steering Wheel from stop to stop several times.

With the DRBIIIt, perform the road test procedure.

With the DRBIIIt, read DTCs.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 3

2NOTE: When the vehicle is in a turn, the ESP compares the Steering Angle

Sensor value and the speed of the inner and outer wheels to determine if the

values are plausible.

Inspect the front end and steering components for damage or misalignment.

Inspect the steering column and Steering Angle Sensor for correct mounting and

installation.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Were any problems found?All

Ye s!Repair or replace components as necessary in accordance with the

Service Information.

No!Inspect the Steering Angle Sensor for proper installation. Inspect

the wiring and connectors. Repair as necessary. If no other

problems are found, replace the Steering Angle Sensor in accor-

dance with the Service Information.

70

BRAKES (CAB)

Page 392 of 2305

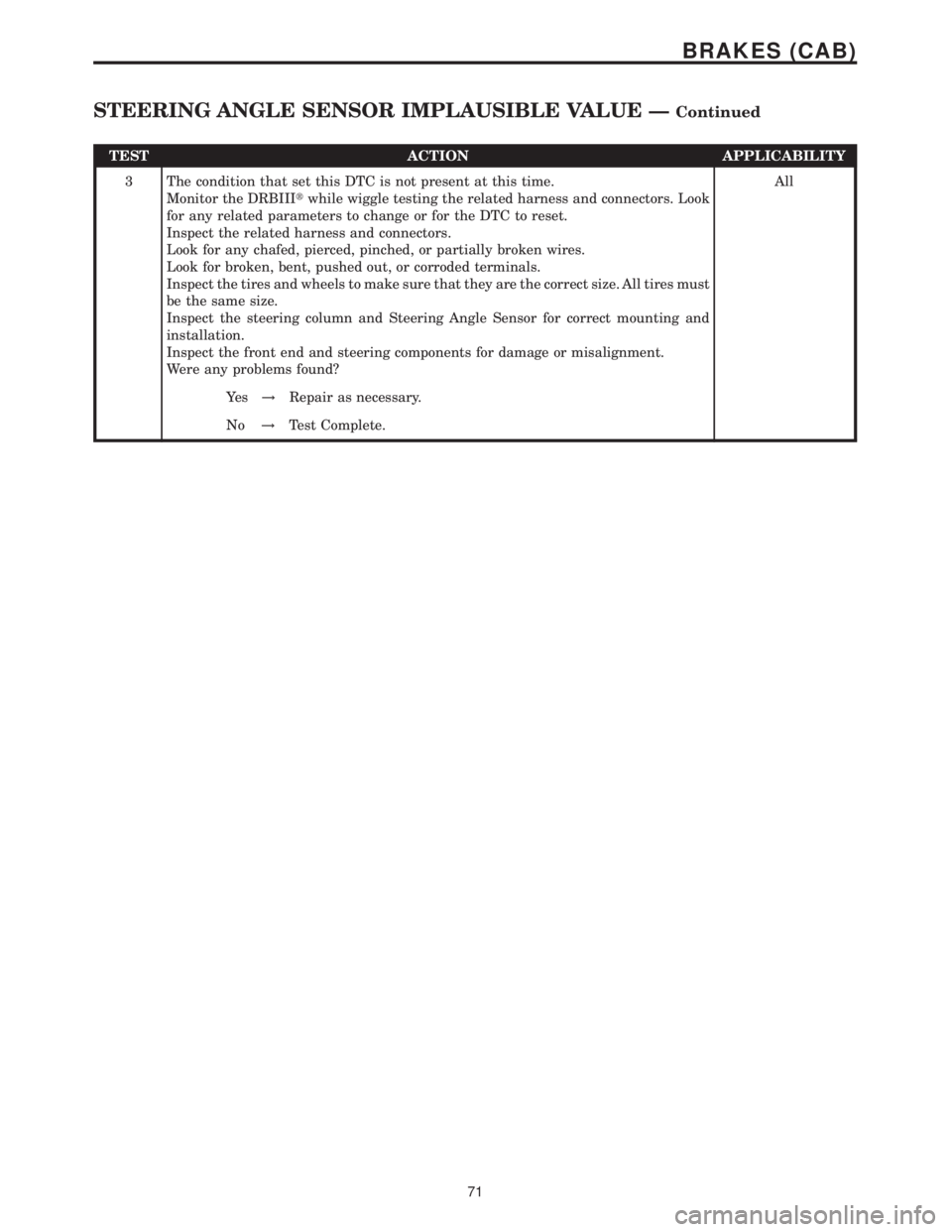

TEST ACTION APPLICABILITY

3 The condition that set this DTC is not present at this time.

Monitor the DRBIIItwhile wiggle testing the related harness and connectors. Look

for any related parameters to change or for the DTC to reset.

Inspect the related harness and connectors.

Look for any chafed, pierced, pinched, or partially broken wires.

Look for broken, bent, pushed out, or corroded terminals.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Inspect the steering column and Steering Angle Sensor for correct mounting and

installation.

Inspect the front end and steering components for damage or misalignment.

Were any problems found?All

Ye s!Repair as necessary.

No!Test Complete.

71

BRAKES (CAB)

STEERING ANGLE SENSOR IMPLAUSIBLE VALUE ÐContinued

Page 393 of 2305

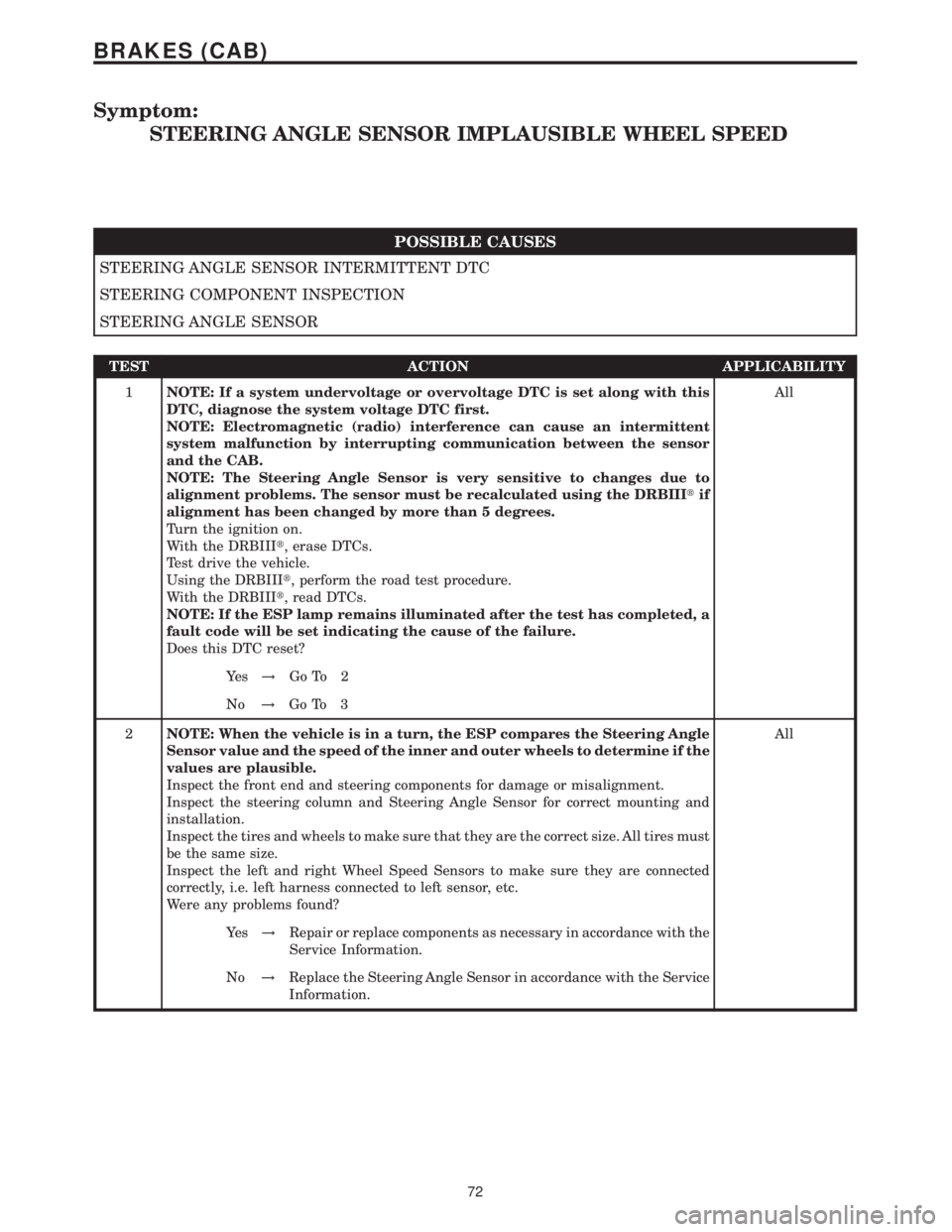

Symptom:

STEERING ANGLE SENSOR IMPLAUSIBLE WHEEL SPEED

POSSIBLE CAUSES

STEERING ANGLE SENSOR INTERMITTENT DTC

STEERING COMPONENT INSPECTION

STEERING ANGLE SENSOR

TEST ACTION APPLICABILITY

1NOTE: If a system undervoltage or overvoltage DTC is set along with this

DTC, diagnose the system voltage DTC first.

NOTE: Electromagnetic (radio) interference can cause an intermittent

system malfunction by interrupting communication between the sensor

and the CAB.

NOTE: The Steering Angle Sensor is very sensitive to changes due to

alignment problems. The sensor must be recalculated using the DRBIIItif

alignment has been changed by more than 5 degrees.

Turn the ignition on.

With the DRBIIIt, erase DTCs.

Test drive the vehicle.

Using the DRBIIIt, perform the road test procedure.

With the DRBIIIt, read DTCs.

NOTE: If the ESP lamp remains illuminated after the test has completed, a

fault code will be set indicating the cause of the failure.

Does this DTC reset?All

Ye s!Go To 2

No!Go To 3

2NOTE: When the vehicle is in a turn, the ESP compares the Steering Angle

Sensor value and the speed of the inner and outer wheels to determine if the

values are plausible.

Inspect the front end and steering components for damage or misalignment.

Inspect the steering column and Steering Angle Sensor for correct mounting and

installation.

Inspect the tires and wheels to make sure that they are the correct size. All tires must

be the same size.

Inspect the left and right Wheel Speed Sensors to make sure they are connected

correctly, i.e. left harness connected to left sensor, etc.

Were any problems found?All

Ye s!Repair or replace components as necessary in accordance with the

Service Information.

No!Replace the Steering Angle Sensor in accordance with the Service

Information.

72

BRAKES (CAB)