roof MERCEDES-BENZ SPRINTER 2011 MY11 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2011Pages: 292, PDF Size: 6.75 MB

Page 147 of 292

Always make sure that the distribution of the

load is correct and adapt your driving style

according to the load. G

Warning

If you have installed a roof carrier, the

vehicle’s handling, steering and braking

characteristics may change

due to the higher

center of gravity. This is the case particularly

if the roof carrier is laden. Adapt your driving

style according to the vehicle load.

Observe the manufacturer's installation

instructions. An incorrectly secured roof

carrier and/or load could come loose, fall off

and thereby endanger you or others.

Observe the maximum roof load and

maximum roof carrier load. Loads transported

on the roof must always be secured with

particular care.

Do not allow the load, including passengers,

to exceed the permissible gross vehicle

weight or the gross axle weight rating for your

vehicle. G

Warning

When using suitable load securing aids and

lashing material, always follow the

manufacturer's operating instructions, in

particular the notes on discard criteria

contained therein.

Load securing aids and lashing material may

not be used, for example, if:

R identification marks are

missing or illegible

R there are yarn breakages, damage to

bearing seams or other signs of tearing

R there are signs of shearing, deformation,

pinching or other damage

R there is damage to clamping or connecting

elements

Load securing aids and lashing material in this

condition are ready for discard and must be

replaced.

If you use load securing aids or lashing

materials that are ready for discard, the load

is not correctly secured and could cause serious injuries to you and others and cause

material damage.

G

Warning!

After an

accident, have a damaged cargo floor

or cargo area, lashing eyelets and lashing

material checked at a qualified specialist

workshop that has the necessary specialist

knowledge and tools to carry out the work

required. The cargo could otherwise be

insufficiently secured during the next

transport and could lead to serious injury to

you and other persons or material damage.

For this reason,

we recommend an authorized

Sprinter Dealer. In particular, all work relevant

to safety or on safety-related systems must

be carried out at a qualified specialist

workshop.

! If you are using a roof carrier, observe the

maximum roof load and maximum roof

carrier load.

You will find information about the maximum

roof load in the "Technical data" section

(Y page 283) and information about roof

carriers in the "Carrier systems" section

(Y page 149).

Before loading X

Tire pressure: check the

tire pressure and

correct if necessary ( Y page 281).

X Cargo floor: clean the cargo floor.

The cargo floor must be free from oil and

dust, dry and clean swept to prevent the

load from slipping.

X Place non-slip mats (anti-slip mats) on the

cargo floor if necessary.

! As soon as the non-slip mats show signs

of deformation or

develop squashed areas,

or traces of cracking/cutting, they can no

longer be used to secure a load and must

be replaced. Transporting loads with the vehicle

145

Operation Z

Page 151 of 292

Make sure that locking mechanism 0046 is

always engaged in a recess.

G

Warning

If not firmly anchored in the loading rail, the

cargo tie-down ring

may slip or be torn out of

the loading rail in the event of sudden braking.

The load would no longer be secured,

resulting in a risk of serious injury being

caused by the load slipping. For this reason,

always check the cargo tie-down ring for firm

seating after installing.

X Check the cargo tie-down ring for firm

seating.

X To remove:

pull locking

mechanism 0046 up

and pull the cargo tie-down ring towards

the locking mechanism and out of the

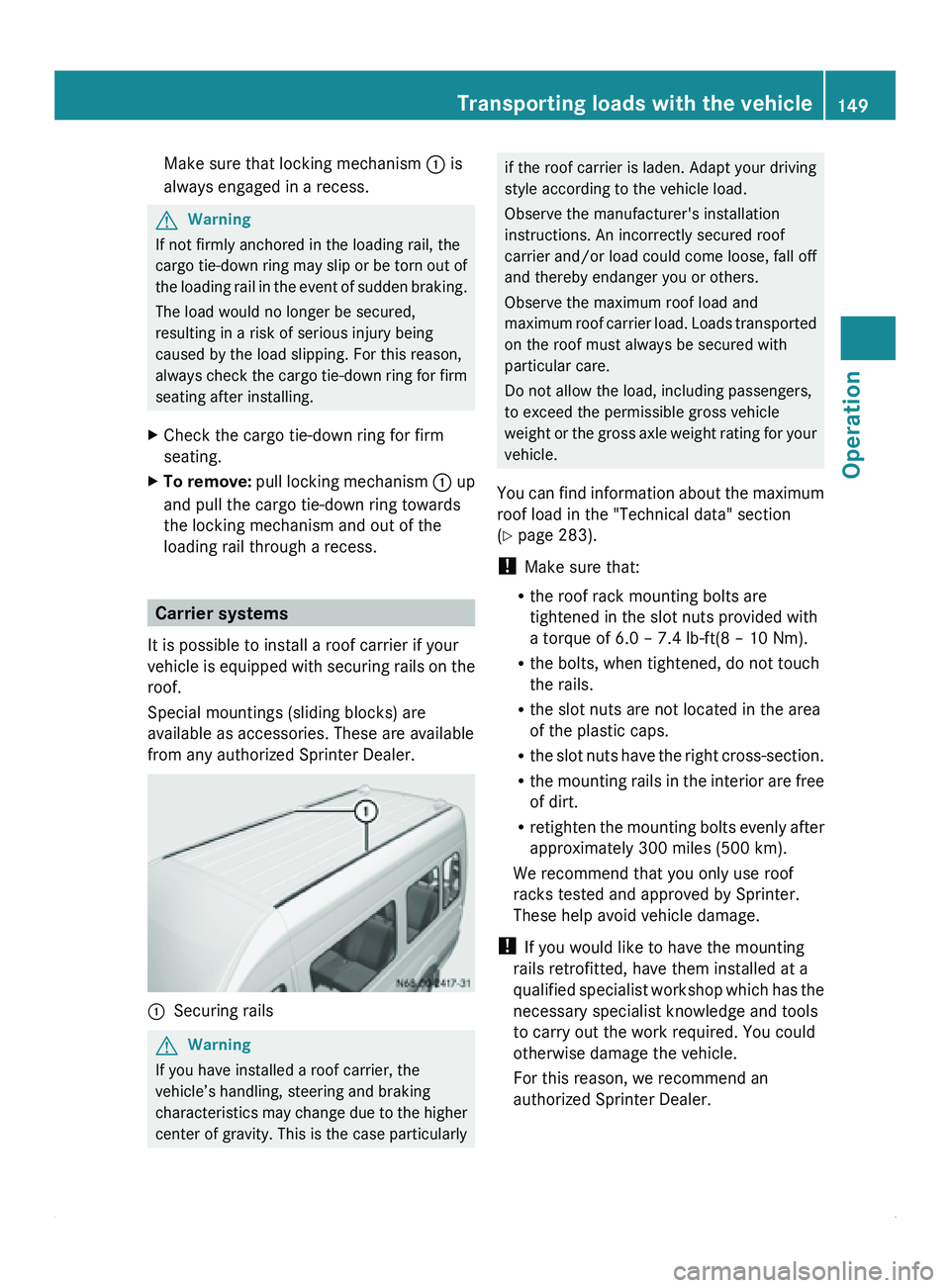

loading rail through a recess. Carrier systems

It is possible to install a roof carrier if your

vehicle is equipped

with securing rails on the

roof.

Special mountings (sliding blocks) are

available as accessories. These are available

from any authorized Sprinter Dealer. 0046

Securing rails G

Warning

If you have installed a roof carrier, the

vehicle’s handling, steering and braking

characteristics may change

due to the higher

center of gravity. This is the case particularly if the roof carrier is laden. Adapt your driving

style according to the vehicle load.

Observe the manufacturer's installation

instructions. An incorrectly secured roof

carrier and/or

load

could come loose, fall off

and thereby endanger you or others.

Observe the maximum roof load and

maximum roof carrier load. Loads transported

on the roof must always be secured with

particular care.

Do not allow the load, including passengers,

to exceed the permissible gross vehicle

weight or the gross axle weight rating for your

vehicle.

You can find information about the maximum

roof load in the "Technical data" section

(Y page 283).

! Make sure that:

R the roof rack mounting bolts are

tightened in the slot nuts provided with

a torque of 6.0 – 7.4 lb-ft(8 – 10 Nm).

R the bolts, when tightened, do not touch

the rails.

R the slot nuts are not located in the area

of the plastic caps.

R the slot nuts have the right cross-section.

R the mounting rails in the interior are free

of dirt.

R retighten the mounting bolts evenly after

approximately 300 miles (500 km).

We recommend that you only use roof

racks tested and approved by Sprinter.

These help avoid vehicle damage.

! If you would like to have the mounting

rails retrofitted, have them installed at a

qualified specialist workshop which has the

necessary specialist knowledge and tools

to carry out the work required. You could

otherwise damage the vehicle.

For this reason, we recommend an

authorized Sprinter Dealer. Transporting loads with the vehicle

149

Operation Z

Page 165 of 292

!

In order to avoid consequential damage,

repair damage caused by loose chippings

and remove any dirt immediately, in

particular:

R insect remains

R bird droppings

R flash rust

R tree resin

R oils and grease

R fuels

R tar stains

R salt residue

Wash your vehicle

more frequently if it gets

dirty more often.

! Do not park the vehicle for an extended

period right after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. Generally, park the

vehicle at operating temperature after

cleaning.

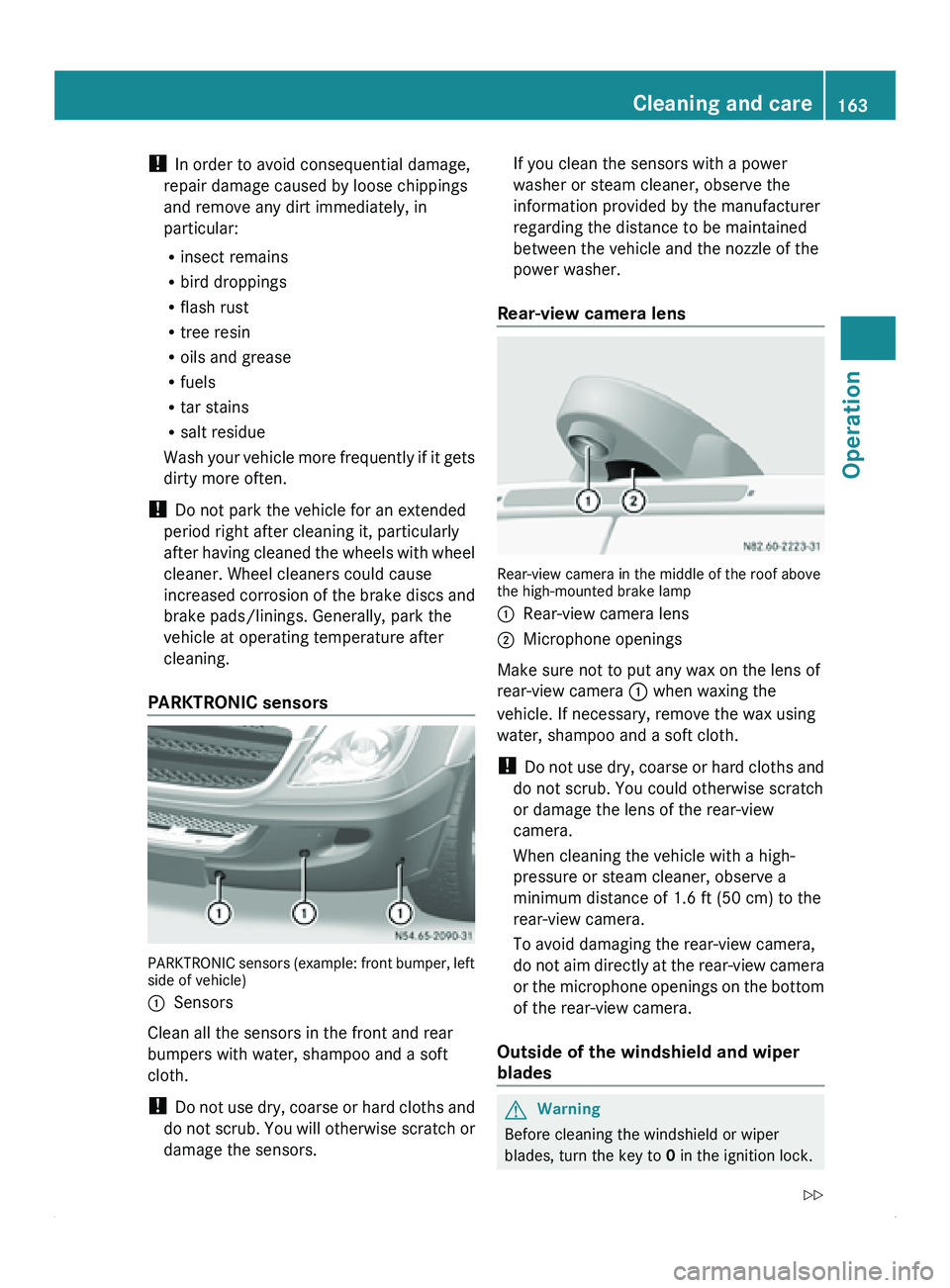

PARKTRONIC sensors PARKTRONIC sensors (example: front bumper, left

side of vehicle)

0046

Sensors

Clean all the sensors in the front and rear

bumpers with water, shampoo and a soft

cloth.

! Do not

use

dry, coarse or hard cloths and

do not scrub. You will otherwise scratch or

damage the sensors. If you clean the sensors with a power

washer or steam cleaner, observe the

information provided by the manufacturer

regarding the distance to be maintained

between the vehicle and the nozzle of the

power washer.

Rear-view camera lens Rear-view camera in the middle of the roof above

the high-mounted brake lamp

0046

Rear-view camera lens

0047 Microphone openings

Make sure not to put any wax on the lens of

rear-view camera 0046 when waxing the

vehicle. If necessary, remove the wax using

water, shampoo and a soft cloth.

! Do not

use

dry, coarse or hard cloths and

do not scrub. You could otherwise scratch

or damage the lens of the rear-view

camera.

When cleaning the vehicle with a high-

pressure or steam cleaner, observe a

minimum distance of 1.6 ft (50 cm) to the

rear-view camera.

To avoid damaging the rear-view camera,

do not aim directly at the rear-view camera

or the microphone openings on the bottom

of the rear-view camera.

Outside of the windshield and wiper

blades G

Warning

Before cleaning the windshield or wiper

blades, turn the key to 0 in the ignition lock. Cleaning and care

163

Operation

Z

Page 175 of 292

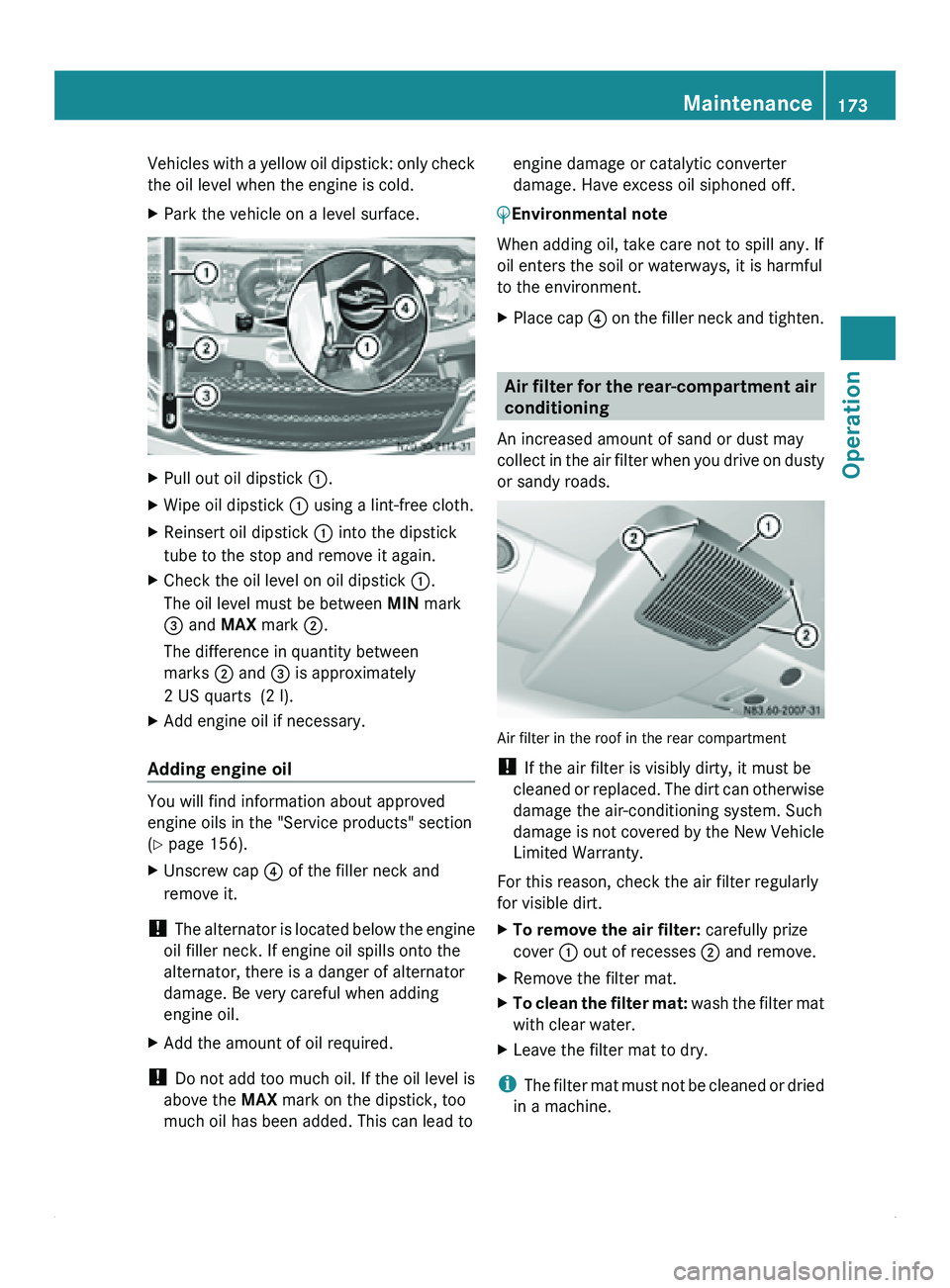

Vehicles with a yellow oil dipstick: only check

the oil level when the engine is cold.

X

Park the vehicle on a level surface. X

Pull out oil dipstick 0046.

X Wipe oil dipstick 0046 using a lint-free cloth.

X Reinsert oil dipstick 0046 into the dipstick

tube to the stop and remove it again.

X Check the oil level on oil dipstick 0046.

The oil level must be between MIN mark

008A and MAX mark 0047.

The difference in quantity between

marks 0047 and 008A is approximately

2 US quarts (2 l).

X Add engine oil if necessary.

Adding engine oil You will find information about approved

engine oils in the "Service products" section

(Y page 156).

X

Unscrew cap 0088 of the filler neck and

remove it.

! The alternator

is

located below the engine

oil filler neck. If engine oil spills onto the

alternator, there is a danger of alternator

damage. Be very careful when adding

engine oil.

X Add the amount of oil required.

! Do not add

too much oil. If the oil level is

above the MAX mark on the dipstick, too

much oil has been added. This can lead to engine damage or catalytic converter

damage. Have excess oil siphoned off.

0040Environmental note

When adding oil, take care not to spill any. If

oil enters the soil or waterways, it is harmful

to the environment.

X Place cap 0088 on the

filler neck and tighten. Air filter for the rear-compartment air

conditioning

An increased amount of sand or dust may

collect in the

air filter when you drive on dusty

or sandy roads. Air filter in the roof in the rear compartment

!

If the air filter is visibly dirty, it must be

cleaned or replaced.

The dirt can otherwise

damage the air-conditioning system. Such

damage is not covered by the New Vehicle

Limited Warranty.

For this reason, check the air filter regularly

for visible dirt.

X To remove the air filter: carefully prize

cover 0046 out of recesses 0047 and remove.

X Remove the filter mat.

X To clean the filter mat:

wash the

filter mat

with clear water.

X Leave the filter mat to dry.

i The filter mat

must not be cleaned or dried

in a machine. Maintenance

173

Operation Z

Page 177 of 292

Batteries

G

Warning Risk of explosion.

Explosive oxyhydrogen is

produced when batteries

are being charged. Only

charge batteries in well-

ventilated areas.

Risk of explosion. Avoid

creating sparks. Avoid

naked flames and do not

smoke in

the

vicinity of the

battery. Battery acid is caustic.

Wear acid-proof protective

gloves. If skin or clothes

are splashed with acid,

neutralize the splashes

immediately with soapy

water or an acid

neutralizer, and then clean

the affected areas with

water.

Wear eye

protection. When

mixing water and acid, the

liquid can splash into your

eyes. Rinse acid splashes

to the eyes immediately

with clean water and

contact a doctor

immediately. Keep children at a safe

distance. Children are not

able to assess the dangers

posed by batteries and

acid.

When handling batteries,

observe the safety

precautions and special

protective measures

contained in these

Operating Instructions. 0040Environmental note Batteries contain pollutants. It is

against the law to dispose of them

with the household garbage. They

must be collected separately and

recycled to protect the

environment.

Dispose of batteries in an

environmentally responsible

manner. Take discharged batteries

to a qualified specialist workshop,

e.g. an authorized Sprinter Dealer,

or to a special collection point for

old batteries.

In order for the batteries to achieve their

maximum possible service life, they must

always be sufficiently charged.

Have the battery charge checked more

frequently if you use the vehicle mainly for

short trips or if you leave it parked up for a

lengthy period.

If you intend to leave your vehicle parked up

for a long period, seek advice from an

authorized Sprinter Dealer or switch off the

electrical system using the battery isolating

switch (Y page 87).

Your vehicle may be equipped with two

batteries, depending on the equipment

version:

R a starter battery in the battery case in the

driver's footwell

R an additional battery in the engine

compartment

Have the batteries removed at a qualified

specialist workshop which

has the necessary

specialist knowledge and tools to carry out

the work required. We recommend that you

use an authorized Sprinter Dealer for this

purpose. Maintenance

175Operation Z

Page 246 of 292

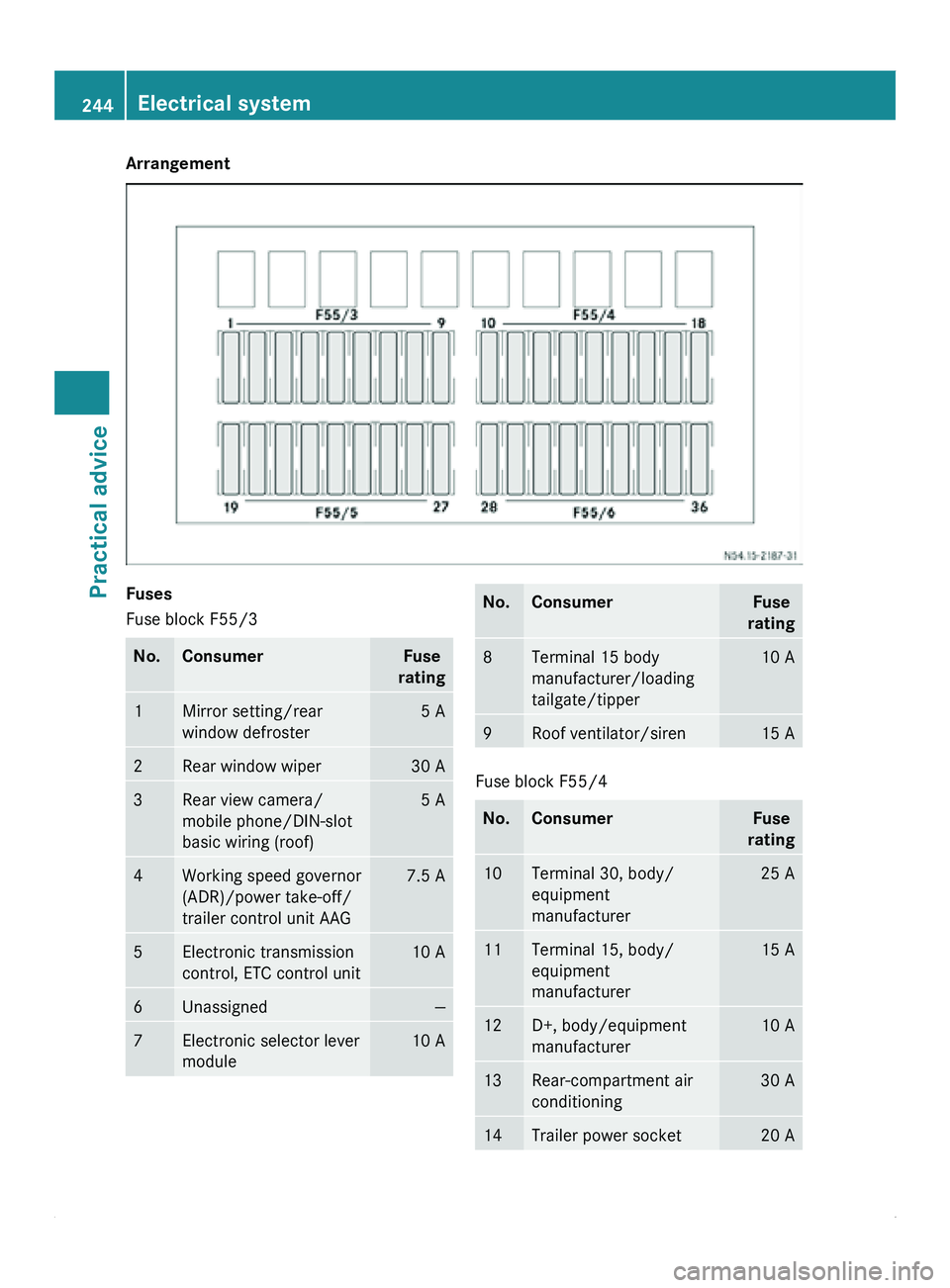

Arrangement

Fuses

Fuse block F55/3

No. Consumer Fuse

rating 1 Mirror setting/rear

window defroster 5 A

2 Rear window wiper 30 A

3 Rear view camera/

mobile phone/DIN-slot

basic wiring (roof) 5 A

4 Working speed governor

(ADR)/power take-off/

trailer control unit AAG 7.5 A

5 Electronic transmission

control, ETC control unit 10 A

6 Unassigned —

7 Electronic selector lever

module 10 A No. Consumer Fuse

rating 8 Terminal 15 body

manufacturer/loading

tailgate/tipper 10 A

9 Roof ventilator/siren 15 A

Fuse block F55/4

No. Consumer Fuse

rating 10 Terminal 30, body/

equipment

manufacturer 25 A

11 Terminal 15, body/

equipment

manufacturer 15 A

12 D+, body/equipment

manufacturer 10 A

13 Rear-compartment air

conditioning 30 A

14 Trailer power socket 20 A244

Electrical systemPractical advice

Page 256 of 292

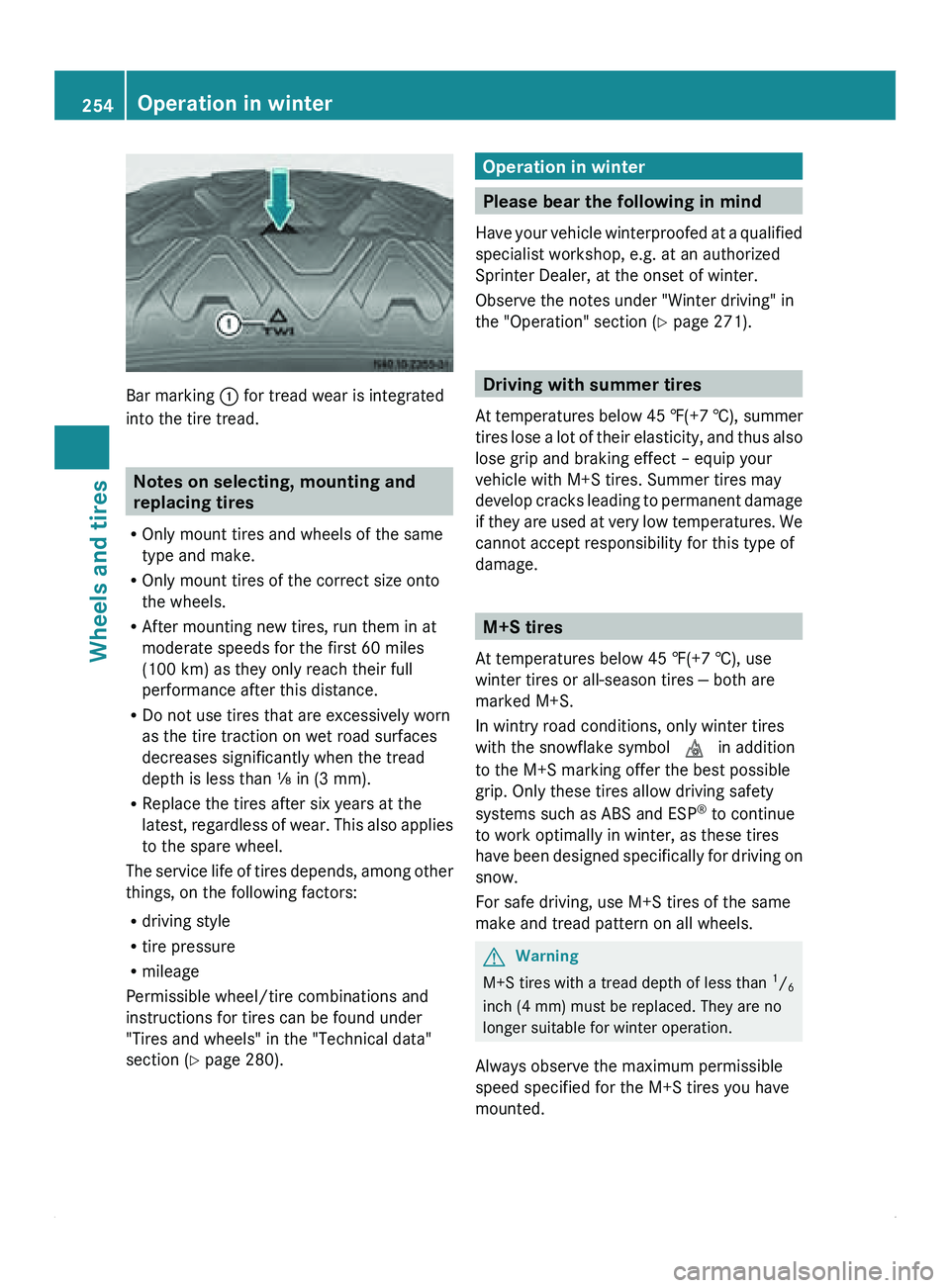

Bar marking 0046 for tread wear is integrated

into the tire tread.

Notes on selecting, mounting and

replacing tires

R Only mount tires and wheels of the same

type and make.

R Only mount tires of the correct size onto

the wheels.

R After mounting new tires, run them in at

moderate speeds for the first 60 miles

(100 km) as they only reach their full

performance after this distance.

R Do not use tires that are excessively worn

as the tire traction on wet road surfaces

decreases significantly when the tread

depth is less than ⅛ in (3 mm).

R Replace the tires after six years at the

latest, regardless of

wear. This also applies

to the spare wheel.

The service life of tires depends, among other

things, on the following factors:

R driving style

R tire pressure

R mileage

Permissible wheel/tire combinations and

instructions for tires can be found under

"Tires and wheels" in the "Technical data"

section ( Y page 280). Operation in winter

Please bear the following in mind

Have your vehicle

winterproofed at a qualified

specialist workshop, e.g. at an authorized

Sprinter Dealer, at the onset of winter.

Observe the notes under "Winter driving" in

the "Operation" section (Y page 271). Driving with summer tires

At temperatures below

45 ‡(+7 †), summer

tires lose a lot of their elasticity, and thus also

lose grip and braking effect – equip your

vehicle with M+S tires. Summer tires may

develop cracks leading to permanent damage

if they are used at very low temperatures. We

cannot accept responsibility for this type of

damage. M+S tires

At temperatures below 45 ‡(+7 †), use

winter tires or all-season tires — both are

marked M+S.

In wintry road conditions, only winter tires

with the snowflake symbol 004D in addition

to the M+S marking offer the best possible

grip. Only these tires allow driving safety

systems such as ABS and ESP ®

to continue

to work optimally in winter, as these tires

have been

designed specifically for driving on

snow.

For safe driving, use M+S tires of the same

make and tread pattern on all wheels. G

Warning

M+S tires with a tread depth of less than 1

/ 6

inch (4 mm) must be replaced. They are no

longer suitable for winter operation.

Always observe the maximum permissible

speed specified for the M+S tires you have

mounted. 254

Operation in winter

Wheels and tires

Page 272 of 292

Maximum weight of the laden vehicle

The maximum weight is the sum of the

unladen weight of the vehicle, the weight of

the accessories, the maximum load and the

weight of the

optional equipment installed at

the factory. Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa is

equivalent to

1 psi. Another tire pressure unit

is bar. 100 kilopascal (kPa) is equivalent to

1 bar. Unladen weight

The weight of a vehicle with standard

equipment including the maximum filling

capacity of fuel, oil, and coolant. It also

includes the air-conditioning system and

optional equipment if these are installed on

the vehicle, but does not include passengers

or luggage. Maximum tire load

The maximum tire load in kilograms or

pounds is the maximum weight for which a

tire is approved. Maximum permissible tire pressure

Maximum permissible tire pressure for one

tire. Maximum load on one tire

Maximum load on one tire. This is calculated

by dividing the

maximum axle load of one axle

by two. PSI (Pounds per square inch)

Standard unit of measurement for tire

pressure. Aspect ratio

Relationship between tire

height and width in

percent. Tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's

surface. Tire pressure is specified in pounds

per square inch

(psi), in kilopascal (kPa) or in

bar. Tire pressure should only be corrected

when the tires are cold. For this, the vehicle

must have been stationary for at least three

hours or not have traveled more than 1.6 km

(1 mile) in this time. Tire tread

The part of the tire that comes into contact

with the road. Tire bead

The tire bead ensures that the tire sits

securely on the

wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim. Sidewall

The part of

the tire between the tread and the

tire bead. Weight of optional extras

The combined weight

of those optional extras

that weigh more than the replaced standard

part and more than 2.3 kilograms (5 lbs).

These optional extras, such as a roof rack or 270

Definition for tires and loading

Wheels and tires

Page 286 of 292

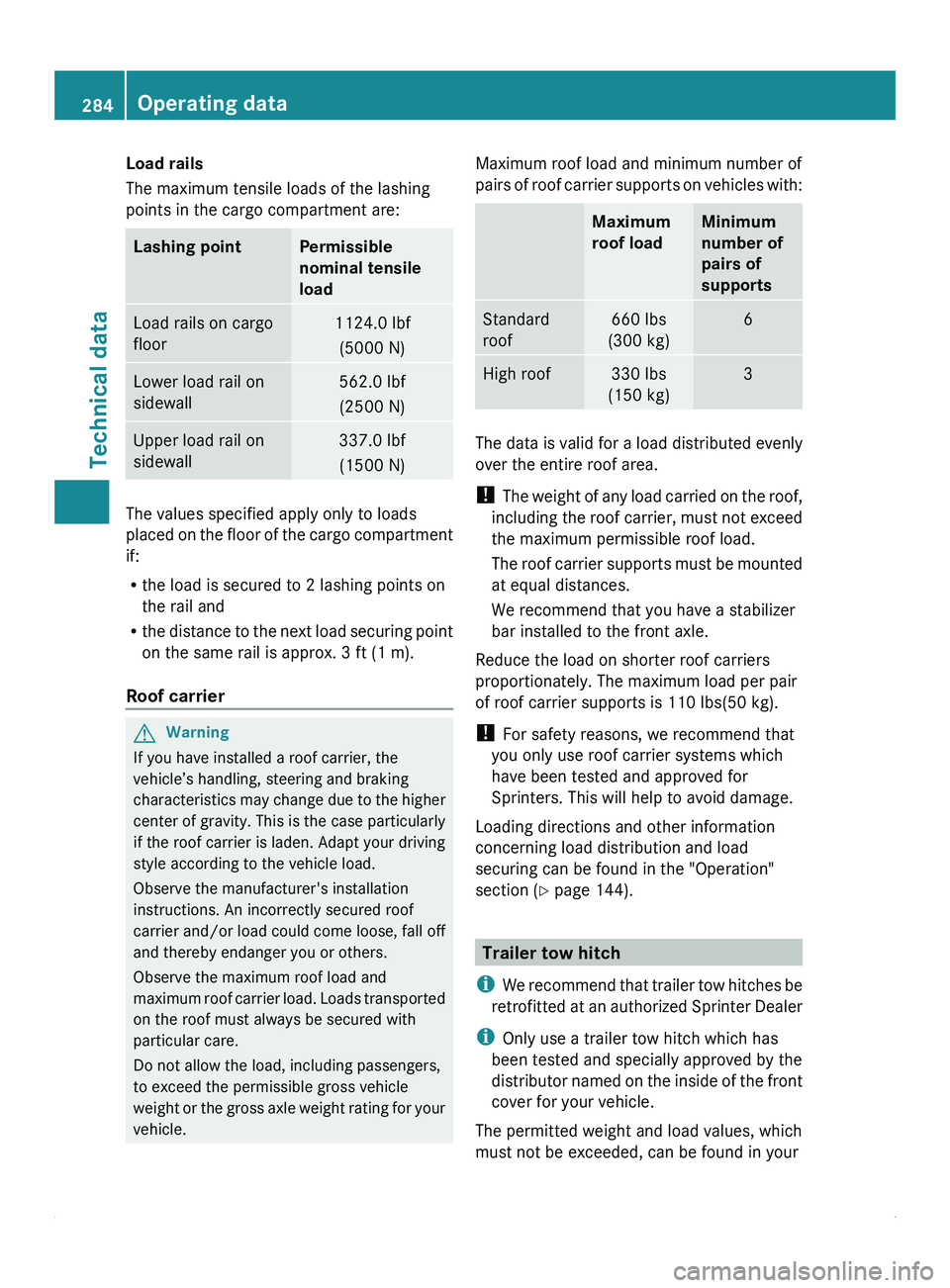

Load rails

The maximum tensile loads of the lashing

points in the cargo compartment are:

Lashing point Permissible

nominal tensile

load

Load rails on cargo

floor 1124.0 lbf

(5000 N) Lower load rail on

sidewall 562.0 lbf

(2500 N) Upper load rail on

sidewall 337.0 lbf

(1500 N) The values specified apply only to loads

placed on

the

floor of the cargo compartment

if:

R the load is secured to 2 lashing points on

the rail and

R the distance to the next load securing point

on the same rail is approx. 3 ft (1 m).

Roof carrier G

Warning

If you have installed a roof carrier, the

vehicle’s handling, steering and braking

characteristics may change

due to the higher

center of gravity. This is the case particularly

if the roof carrier is laden. Adapt your driving

style according to the vehicle load.

Observe the manufacturer's installation

instructions. An incorrectly secured roof

carrier and/or load could come loose, fall off

and thereby endanger you or others.

Observe the maximum roof load and

maximum roof carrier load. Loads transported

on the roof must always be secured with

particular care.

Do not allow the load, including passengers,

to exceed the permissible gross vehicle

weight or the gross axle weight rating for your

vehicle. Maximum roof load and minimum number of

pairs of

roof

carrier supports on vehicles with: Maximum

roof load Minimum

number of

pairs of

supports

Standard

roof 660 lbs

(300 kg) 6

High roof 330 lbs

(150 kg) 3

The data is valid for a load distributed evenly

over the entire roof area.

!

The weight of

any load carried on the roof,

including the roof carrier, must not exceed

the maximum permissible roof load.

The roof carrier supports must be mounted

at equal distances.

We recommend that you have a stabilizer

bar installed to the front axle.

Reduce the load on shorter roof carriers

proportionately. The maximum load per pair

of roof carrier supports is 110 lbs(50 kg).

! For safety reasons, we recommend that

you only use roof carrier systems which

have been tested and approved for

Sprinters. This will help to avoid damage.

Loading directions and other information

concerning load distribution and load

securing can be found in the "Operation"

section ( Y page 144). Trailer tow hitch

i We recommend that

trailer tow hitches be

retrofitted at an authorized Sprinter Dealer

i Only use a trailer tow hitch which has

been tested and specially approved by the

distributor named on the inside of the front

cover for your vehicle.

The permitted weight and load values, which

must not be exceeded, can be found in your 284

Operating data

Technical data