battery MERCEDES-BENZ SPRINTER 2011 MY11 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2011Pages: 292, PDF Size: 6.75 MB

Page 219 of 292

Problem Possible causes/consequences and

0050 SolutionsThe auxiliary heating

does not switch on. The outside temperature is above 39 ‡ (4 †).

The auxiliary heating

switches off automatically. The auxiliary heating

does not switch on. Lack of fuel

The tank is less than one quarter full. The auxiliary heating

switches off automatically.

X

Refuel at the nearest gas station.

X Then, start the auxiliary heating several times until the fuel lines

are full. The auxiliary heating

does not switch on. The undervoltage protection circuit integrated in the control unit

switches off the

auxiliary heating because the on-board voltage is

less than 10 V.

X Have the alternator and battery checked. The auxiliary heating

does not switch on. The fuse is blown.

X

Replace the fuse ( Y page 239).

X Have the cause of the blown fuse determined at a qualified

specialist workshop. The auxiliary heating

does not switch on. The heater is faulty.

X

Have the auxiliary heating checked at a qualified specialist

workshop. The auxiliary heating is

overheated. The coolant level is too low.

X

Check the coolant level and top up if necessary (Y page 169). Central locking system

G

Warning

The operating safety of your vehicle could be jeopardized if maintenance work is carried out

incorrectly. As a

result, you could lose control of the vehicle and cause an accident. In addition,

the safety systems may no longer be able to protect you or others as they are designed to do.

Always have maintenance work carried out at a qualified specialist workshop. The qualified

specialist workshop must have the necessary specialist knowledge and tools to carry out the

work required. We recommend visiting an authorized Sprinter Dealer. In particular, work relevant

to safety or on safety-related systems must be carried out at a qualified specialist workshop. Troubleshooting

217

Practical advice Z

Page 221 of 292

Problem Possible causes/consequences and

0050 SolutionsThe key cannot be

turned in the ignition

lock. The vehicle voltage is too low.

X

Switch off all non-essential consumers, e.g. the seat heating,

interior lighting, and try to turn the key again.

If this does not work:

X Check and, if necessary, replace the starter battery.

or

X Jump-start the vehicle.

or

X Consult a qualified specialist workshop. The key cannot be

turned in the ignition

lock. The steering lock has jammed mechanically.

X

Remove the key and insert it again into the ignition lock. Turn

the steering wheel from side to side while doing so. Headlamps and turn signals

G

Warning

The operating safety of your vehicle could be jeopardized if maintenance work is carried out

incorrectly. As a

result, you could lose control of the vehicle and cause an accident. In addition,

the safety systems may no longer be able to protect you or others as they are designed to do.

Always have maintenance work carried out at a qualified specialist workshop. The qualified

specialist workshop must have the necessary specialist knowledge and tools to carry out the

work required. We recommend visiting an authorized Sprinter Dealer. In particular, work relevant

to safety or on safety-related systems must be carried out at a qualified specialist workshop. Problem Possible causes/consequences and

0050 SolutionsThe headlamps are

fogged up

on

the inside. Air humidity is very high.

X

Drive with the headlamps switched on.

The headlamps are clear after a short distance. The headlamps are

fogged up

on

the inside. The headlamp housing is not sealed and moisture has been able

to enter.

X

Have the headlamps checked at a qualified specialist workshop. Windshield wipers

G

Warning

The operating safety of your vehicle could be jeopardized if maintenance work is carried out

incorrectly. As a

result, you could lose control of the vehicle and cause an accident. In addition,

the safety systems may no longer be able to protect you or others as they are designed to do. Troubleshooting

219

Practical advice

Z

Page 244 of 292

No. Consumer Fuse

rating 22 Brake system (ABS) 5 A

23 Starter motor 20 A

24 Engine components 10 A

25 12 V socket in the center

console 25 A

Fuse block F55/1

No. Consumer Fuse

rating 1 Left door control unit 25 A

2 Diagnostics socket 10 A

3 Brake system (valves) 25 A

4 Brake system (delivery

pump) 40 A

5 Terminal 87 (5) engine 7.5/10 A

6 Terminal 87 (6) engine 7.5/10 A

7 Headlamp cleaning

system 30 A

8 Anti-theft alarm system

(ATA) 15 A

9 Additional turn signal

module 10 A

Fuse block F55/2

No. Consumer Fuse

rating 10 Radio 15 A

11 Mobile phone 7.5 A

12 Blower, front/auxiliary

heating blower setting 1 30 A

13 Auxiliary heating digital

timer, radio receiver/

basic wiring DIN-

slot 7.5 A No. Consumer Fuse

rating 14 Seat heating 30 A

15 Unassigned —

16 Heating, rear-

compartment heating/

front-compartment air

conditioning/CD player 10 A

17 Motion detector/

convenience lighting 10 A

18 Rear-compartment air-

conditioning system 7.5 A

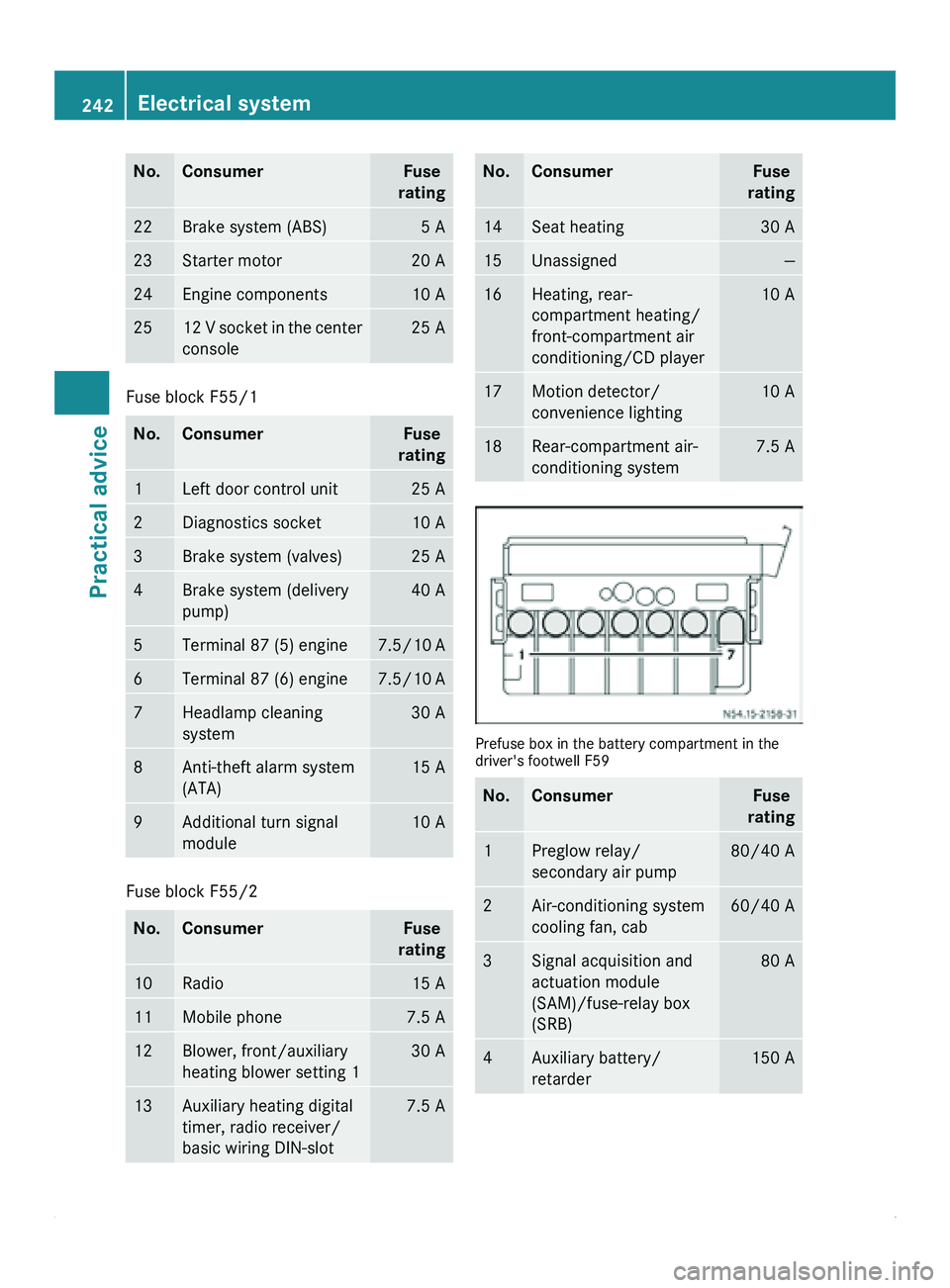

Prefuse box in the battery compartment in the

driver's footwell F59

No. Consumer Fuse

rating 1 Preglow relay/

secondary air pump 80/40 A

2 Air-conditioning system

cooling fan, cab 60/40 A

3 Signal acquisition and

actuation module

(SAM)/fuse-relay box

(SRB) 80 A

4 Auxiliary battery/

retarder 150 A242

Electrical systemPractical advice

Page 247 of 292

No. Consumer Fuse

rating 15 Trailer recognition unit 25 A

16 Tire pressure monitor/

PARKTRONIC 7.5 A

17 PSM control unit 25 A

18 PSM control unit 25 A

Fuse block F55/5

No. Consumer Fuse

rating 19 Overhead control panel 5 A

20 Perimeter lamp 7.5 A

21 Rear window defroster 1 30 A

22 Rear window defroster 2 15 A

23 12 V socket rear left,

cargo compartment/

passenger

compartment/non-MB

body electrics 15 A

24 12 V socket under the

base of driver's seat 15 A

25 12 V socket rear right,

cargo compartment/

passenger compartment 15 A

26 Auxiliary heating 25 A

27 Heater booster system 25 A

Fuse block F55/6

No. Consumer Fuse

rating 28 Exhaust gas

aftertreatment – SCR

10

control unit 10 A

29 Unassigned — No. Consumer Fuse

rating 30 Brake booster 30 A

31 Rear-compartment

heating blower/sliding

door closing assistance,

left 30/15 A

32 Exhaust gas

aftertreatment – SCR

10

relay power supply 10 A

33 Sliding door closing

assistance, right 15 A

34 Exhaust gas

aftertreatment – SCR

10

heater 1 tank 15 A

35 Exhaust gas

aftertreatment – SCR

10

heater 2 hose 15 A

36 Exhaust gas

aftertreatment – SCR

10

heater 3 delivery pump 10 A

Batteries for the remote control

Notes on changing the batteries

G

Warning!

Batteries are toxic and contain caustic

substances. For this reason, keep batteries

out of the reach of children.

If a battery

has been swallowed, visit a doctor

immediately.

0040Environmental note Batteries contain toxic substances.

It is illegal to dispose of them with

household

waste. Batteries

must be

collected separately and be

10 Selective Catalytic Reduction. Batteries for the remote control

245

Practical advice Z

Page 248 of 292

recycled in an environmentally

responsible manner.

Dispose of old batteries in an

environmentally responsible

manner. Take discharged batteries

to a qualified specialist workshop,

e.g. an authorized Sprinter Dealer,

or to a special collection point for

old batteries.

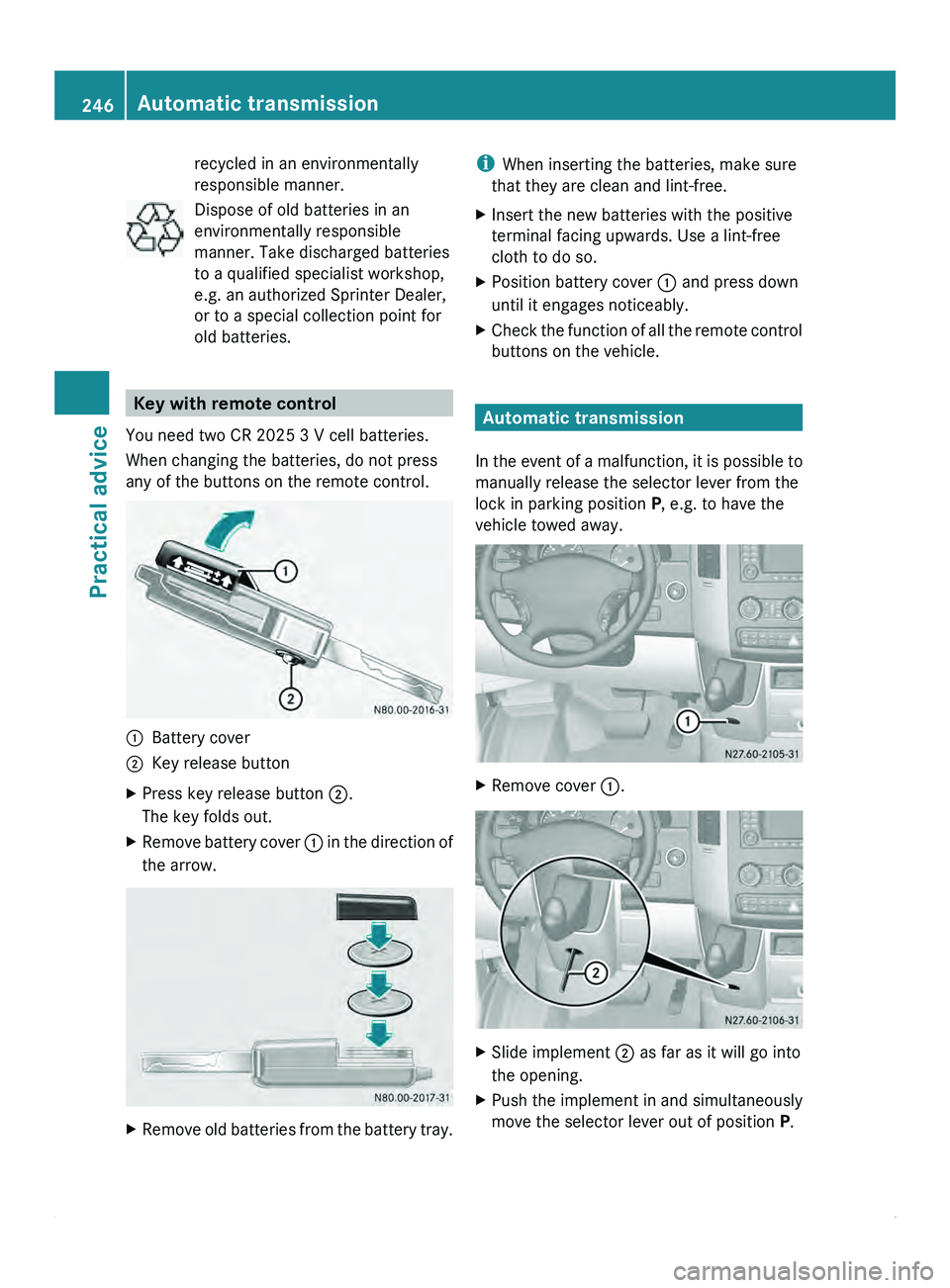

Key with remote control

You need two CR 2025 3 V cell batteries.

When changing the batteries, do not press

any of the buttons on the remote control. 0046

Battery cover

0047 Key release button

X Press key release button 0047.

The key folds out.

X Remove battery cover 0046 in

the direction of

the arrow. X

Remove old batteries from the battery tray. i

When inserting the batteries, make sure

that they are clean and lint-free.

X Insert the new batteries with the positive

terminal facing upwards. Use a lint-free

cloth to do so.

X Position battery cover 0046 and press down

until it engages noticeably.

X Check the function of all the remote control

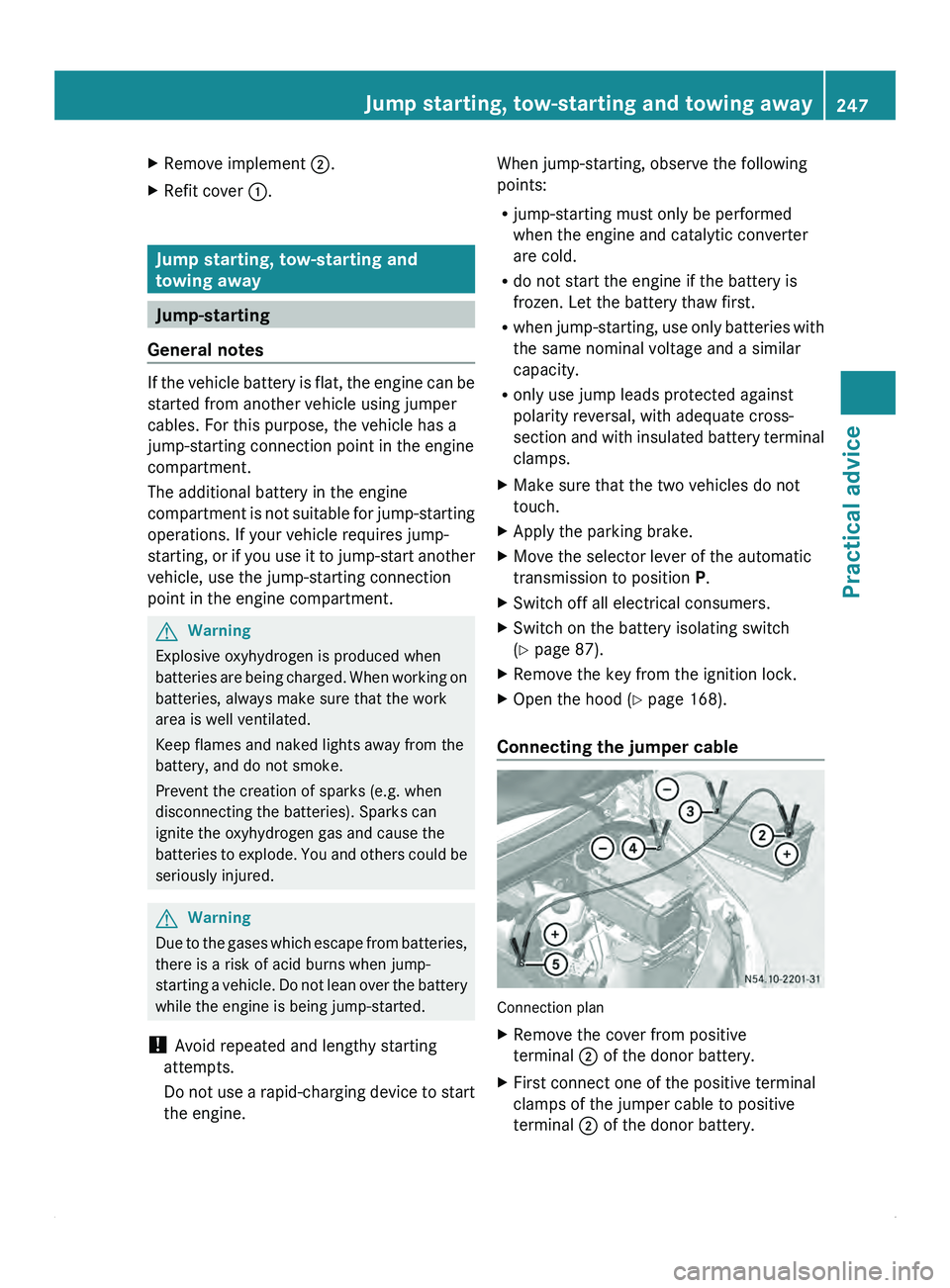

buttons on the vehicle. Automatic transmission

In the event

of a malfunction, it is possible to

manually release the selector lever from the

lock in parking position P, e.g. to have the

vehicle towed away. X

Remove cover 0046. X

Slide implement 0047 as far as it will go into

the opening.

X Push the implement in and simultaneously

move the selector lever out of position P.246

Automatic transmission

Practical advice

Page 249 of 292

X

Remove implement 0047.

X Refit cover 0046. Jump starting, tow-starting and

towing away

Jump-starting

General notes If the vehicle battery is flat, the engine can be

started from another vehicle using jumper

cables. For this purpose, the vehicle has a

jump-starting connection point in the engine

compartment.

The additional battery in the engine

compartment is

not

suitable for jump-starting

operations. If your vehicle requires jump-

starting, or if you use it to jump-start another

vehicle, use the jump-starting connection

point in the engine compartment. G

Warning

Explosive oxyhydrogen is produced when

batteries are being

charged. When working on

batteries, always make sure that the work

area is well ventilated.

Keep flames and naked lights away from the

battery, and do not smoke.

Prevent the creation of sparks (e.g. when

disconnecting the batteries). Sparks can

ignite the oxyhydrogen gas and cause the

batteries to explode. You and others could be

seriously injured. G

Warning

Due to the gases which escape from batteries,

there is a risk of acid burns when jump-

starting a vehicle.

Do not lean over the battery

while the engine is being jump-started.

! Avoid repeated and lengthy starting

attempts.

Do not use a rapid-charging device to start

the engine. When jump-starting, observe the following

points:

R

jump-starting must only be performed

when the engine and catalytic converter

are cold.

R do not start the engine if the battery is

frozen. Let the battery thaw first.

R when jump-starting, use

only batteries with

the same nominal voltage and a similar

capacity.

R only use jump leads protected against

polarity reversal, with adequate cross-

section and with insulated battery terminal

clamps.

X Make sure that the two vehicles do not

touch.

X Apply the parking brake.

X Move the selector lever of the automatic

transmission to position P.

X Switch off all electrical consumers.

X Switch on the battery isolating switch

(Y page 87).

X Remove the key from the ignition lock.

X Open the hood (Y page 168).

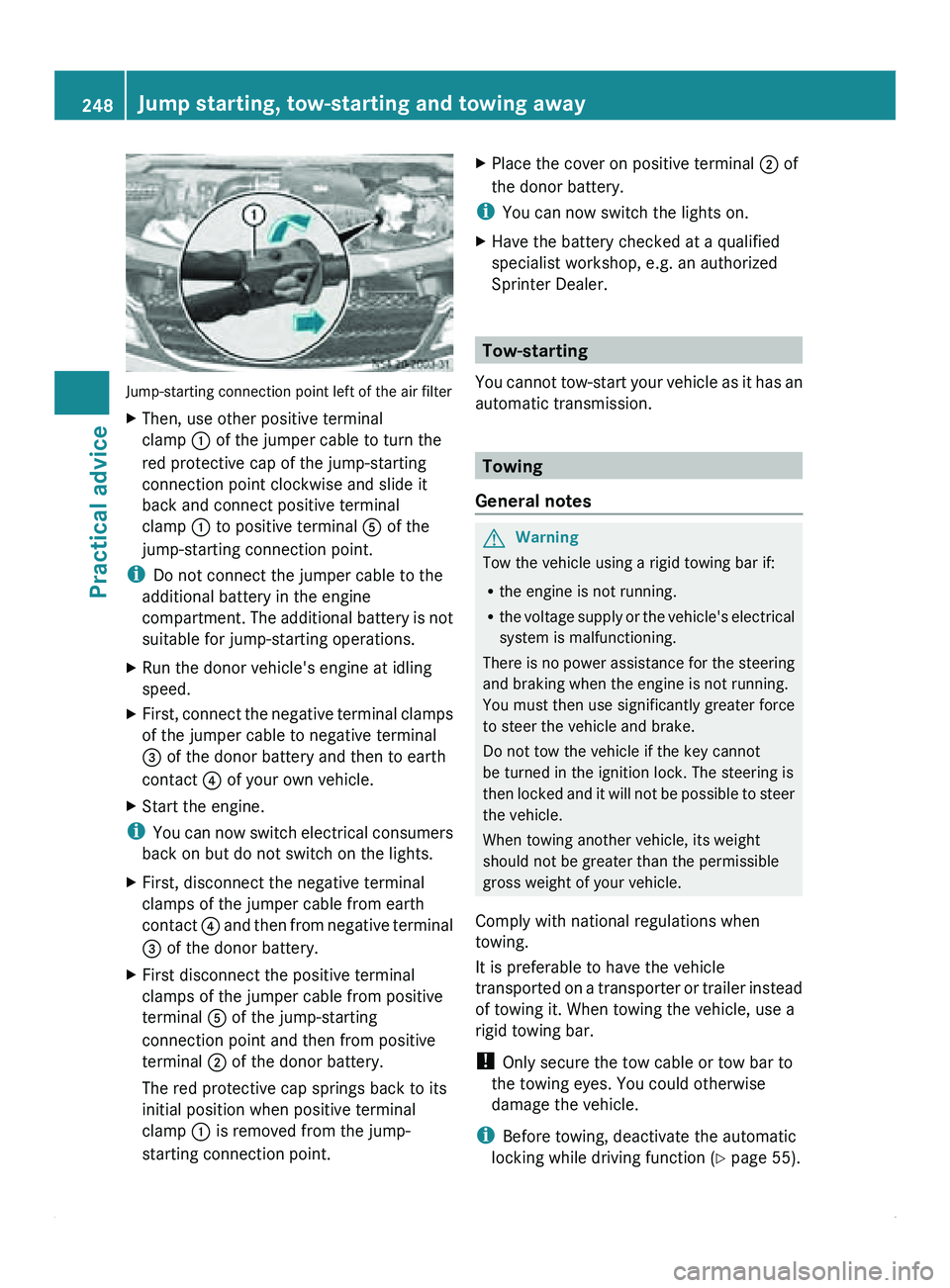

Connecting the jumper cable Connection plan

X

Remove the cover from positive

terminal 0047 of the donor battery.

X First connect one of the positive terminal

clamps of the jumper cable to positive

terminal 0047 of the donor battery. Jump starting, tow-starting and towing away

247

Practical advice Z

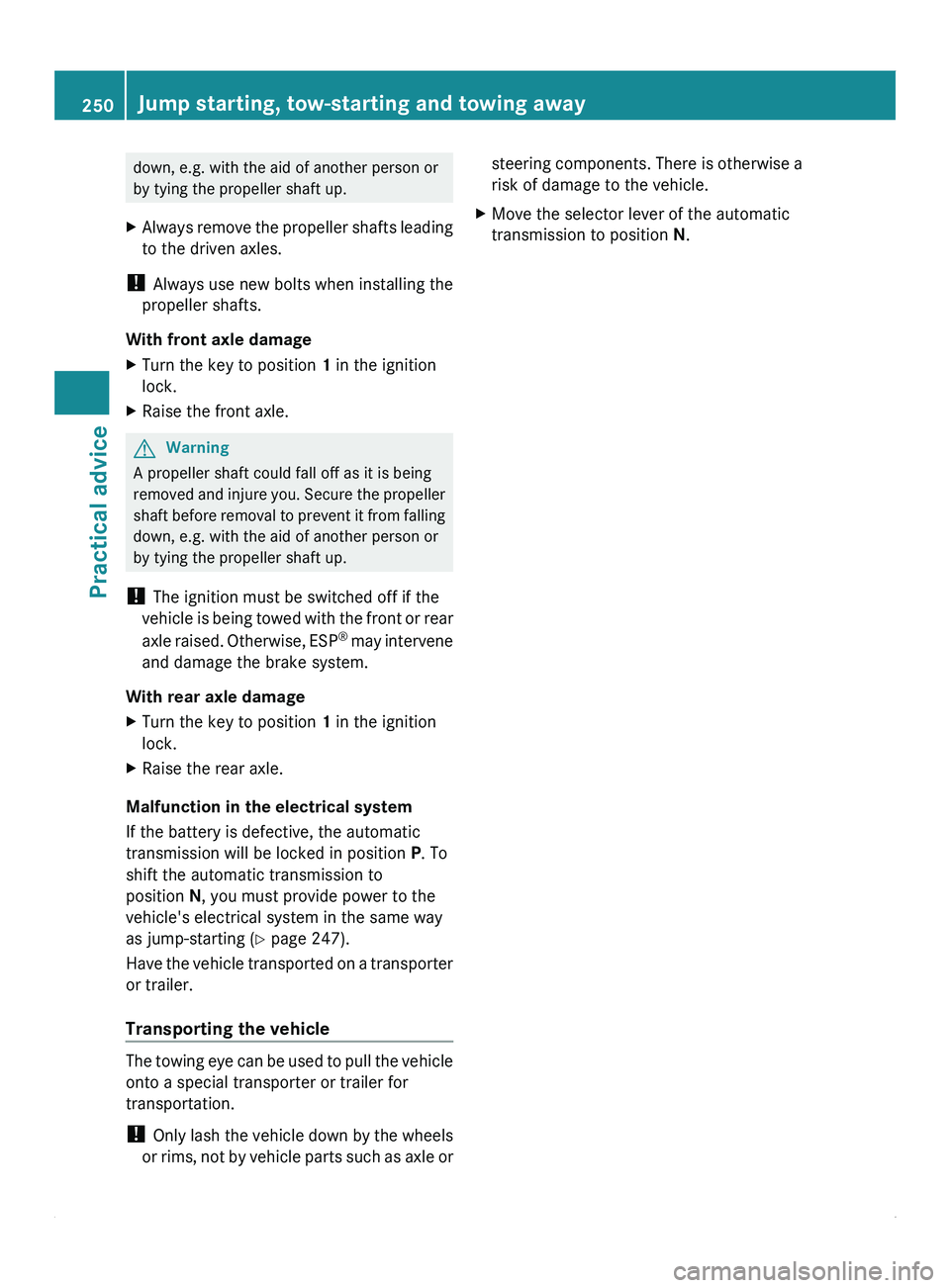

Page 250 of 292

Jump-starting connection point left of the air filter

X

Then, use other positive terminal

clamp 0046 of the jumper cable to turn the

red protective cap of the jump-starting

connection point clockwise and slide it

back and connect positive terminal

clamp 0046 to positive terminal 0086 of the

jump-starting connection point.

i Do not connect the jumper cable to the

additional battery in the engine

compartment. The

additional

battery is not

suitable for jump-starting operations.

X Run the donor vehicle's engine at idling

speed.

X First, connect the negative terminal clamps

of the jumper cable to negative terminal

008A of the donor battery and then to earth

contact 0088 of your own vehicle.

X Start the engine.

i You can

now

switch electrical consumers

back on but do not switch on the lights.

X First, disconnect the negative terminal

clamps of the jumper cable from earth

contact 0088 and then

from negative terminal

008A of the donor battery.

X First disconnect the positive terminal

clamps of the jumper cable from positive

terminal 0086 of the jump-starting

connection point and then from positive

terminal 0047 of the donor battery.

The red protective cap springs back to its

initial position when positive terminal

clamp 0046 is removed from the jump-

starting connection point. X

Place the cover on positive terminal 0047 of

the donor battery.

i You can now switch the lights on.

X Have the battery checked at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. Tow-starting

You cannot tow-start

your vehicle as it has an

automatic transmission. Towing

General notes G

Warning

Tow the vehicle using a rigid towing bar if:

R the engine is not running.

R the voltage supply

or the vehicle's electrical

system is malfunctioning.

There is no power assistance for the steering

and braking when the engine is not running.

You must then use significantly greater force

to steer the vehicle and brake.

Do not tow the vehicle if the key cannot

be turned in the ignition lock. The steering is

then locked and it will not be possible to steer

the vehicle.

When towing another vehicle, its weight

should not be greater than the permissible

gross weight of your vehicle.

Comply with national regulations when

towing.

It is preferable to have the vehicle

transported on a transporter or trailer instead

of towing it. When towing the vehicle, use a

rigid towing bar.

! Only secure the tow cable or tow bar to

the towing eyes. You could otherwise

damage the vehicle.

i Before towing, deactivate the automatic

locking while driving function (Y page 55). 248

Jump starting, tow-starting and towing away

Practical advice

Page 252 of 292

down, e.g. with the aid of another person or

by tying the propeller shaft up.

X Always remove the propeller shafts leading

to the driven axles.

! Always use new bolts when installing the

propeller shafts.

With front axle damage

X Turn the key to position 1 in the ignition

lock.

X Raise the front axle. G

Warning

A propeller shaft could fall off as it is being

removed and injure

you. Secure the propeller

shaft before removal to prevent it from falling

down, e.g. with the aid of another person or

by tying the propeller shaft up.

! The ignition must be switched off if the

vehicle is being towed with the front or rear

axle raised. Otherwise, ESP ®

may intervene

and damage the brake system.

With rear axle damage

X Turn the key to position 1 in the ignition

lock.

X Raise the rear axle.

Malfunction in the electrical system

If the battery is defective, the automatic

transmission will be locked in position P. To

shift the automatic transmission to

position N, you must provide power to the

vehicle's electrical system in the same way

as jump-starting ( Y page 247).

Have the vehicle

transported on a transporter

or trailer.

Transporting the vehicle The towing

eye can be used to pull the vehicle

onto a special transporter or trailer for

transportation.

! Only lash the

vehicle down by the wheels

or rims, not by vehicle parts such as axle or steering components. There is otherwise a

risk of damage to the vehicle.

X Move the selector lever of the automatic

transmission to position N.250

Jump starting, tow-starting and towing away

Practical advice

Page 273 of 292

a high-capacity battery, are not included in

the unladen weight and the weight of the

accessories.

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires,

for example for a product recall, and thus

identify the purchasers.

The TIN is composed

of the manufacturer identification code, tire

size, tire model code and manufacturing date. Load bearing index

The load bearing index (also load index) is a

code that contains

the maximum load bearing

capacity of a tire. Traction

Traction is the result of friction between the

tires and the road surface. Wear indicator

Narrow bars (tread wear bars) that are

distributed over the

tire tread. If the tire tread

is level with the bars, the wear limit of 1

/ 16 in

(1.6 mm) has been reached. Distribution of the vehicle occupants

The distribution of vehicle occupants over

designated seat positions in a vehicle. Maximum permissible payload

weight

Nominal load and cargo/luggage load plus

68 kilograms (150 lb) multiplied by the

number of seats in the vehicle. Changing wheels

Flat tire

The "Flat tire"

section in the "Practical advice"

chapter (Y page 221) contains information

and notes on how to deal with a flat tire. It

also provides instructions on changing a

wheel or mounting the spare wheel. Replacing wheels

G

Warning

Rotate front and rear wheels only if the tires

are of the same dimension.

If your vehicle is equipped with mixed-size

tires (different tire

dimensions front vs. rear),

tire rotation is not possible. G

Warning

After changing a wheel, for safety reasons you

must:

R have the tightening torque checked. For

wheel bolts, the tightening torque is

177 lb-ft (240 Nm) (steel wheel)/ 133 lb-ft

(180

Nm) (alloy wheel). For wheel nuts, the

tightening torque is 133 lb-ft (180 Nm). The

wheels could otherwise work loose.

R check the tire pressure and correct it if

necessary.

R have the wheel bolts/wheel nuts

retightened after driving a distance of 30

miles (50 km). The tightening torque for

wheel bolts is 177 lb-ft (240 Nm)(steel

wheel)/133 lb-ft (180 Nm) (alloy wheel).

The tightening torque for wheel nuts is

133 lb-ft (180 Nm).

R if using new or painted rims, have the wheel

bolts and wheel nuts retightened at the

specified tightening torque after the vehicle

has been driven for approximately 600 to

3000 miles (1000 to 5000 km).

R have the direction of rotation corrected, if

reversed, as soon as possible at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. The vehicle handling Changing wheels

271

Wheels and tires

Z