spare tire MERCEDES-BENZ SPRINTER 2011 MY11 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2011, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2011Pages: 292, PDF Size: 6.75 MB

Page 17 of 292

Troubleshooting

Automatic transmission .................214

Driving systems

............................. 215

Turn signals ......................................... 90

Changing bulbs .............. 235, 236, 237

Two-way radio

Installation ..................................... 277U

Unlocking With button ...................................... 55

With key ........................................... 52V

Vehicle Assemblies .................................... 174

Cleaning ......................................... 162

Dimensions .................................... 280

Electronics

..................................... 276

Individual settings (vehicles with

steering wheel buttons) ................... 78

Loading .......................................... 261

Towing ........................................... 248

Tow-starting ................................... 248

Transporting .................................. 250

Weights .......................................... 280

Vehicle identification number .......... 277

Vehicle identification plates ............277

Vehicle key Malfunction .................................... 217

Vehicle tool kit .................................. 182

Voltage supply Fuses ............................................. 239W

Warning and indicator lamp Diesel Exhaust Fluid (DEF) ............. 190

Warning and indicator lamps .............24

PARKTRONIC ................................. 215

Seat belt ........................................ 196

Warning lamp .................................... 183

Warning tones ................................... 212

Warning triangle ................................ 183

Washer fluid Display message ............................ 208

Indicator lamp ................................

196Topping up .....................................

171

Wiping with ...................................... 95

Wheel

Changing ....................................... 229

Rim size ......................................... 280

Spare wheel ................................... 185

Wheel chock

...................................... 229

Wheel nuts/wheel bolts Retightening .................................. 233

Tightening torque ........................... 232

Wheels

Changing/replacing .......................271

Checking ........................................ 253

Storing ........................................... 273

Wheel size/tire size ....................... 280

Window curtain air bag ....................... 41

Windows

Cleaning ......................................... 162

Cleaning the windshield ................. 163

Washing system ....................... 95, 171

Windshield

Cleaning ......................................... 163

Windshield heater ............................... 95

windshield heating Malfunction .................................... 211

Windshield washer fluid

Indicator lamp ................................ 196

Windshield wipers ............................... 94

Malfunction .................................... 219

Rain/light sensor ............................. 94

Replacing the wiper blades ............ 174

Setting the sensitivity (vehicles

with steering wheel buttons and

rain/light sensor) ............................. 84

Winter diesel ..................................... 154

Winter operation ....................... 153, 254

Winter tires M+S tires ....................................... 254

Working speed governor (ADR) ........ 117 X

Xenon headlamps see Bi-Xenon headlamps

Index

15

Page 51 of 292

G

Warning

Never switch off ASR when you see the

0067 warning lamp

flashing in the instrument

cluster. In this case proceed as follows:

R when driving off, apply as little throttle as

possible.

R while driving, ease off the accelerator

pedal.

R adapt your speed and driving style to the

prevailing road conditions.

Failure to observe these guidelines could

cause the vehicle to skid. ESP ®

cannot

prevent accidents resulting from excessive

speed.

If, taking tires, cargo load and gradient into

consideration, the surface driven on still

provides insufficient traction, you may

experience difficulties in pulling away despite

ASR.

Vehicles without steering-wheel buttons:

the 003D indicator lamp in the instrument

cluster lights up when you switch on the

ignition. It goes out when the engine is

running.

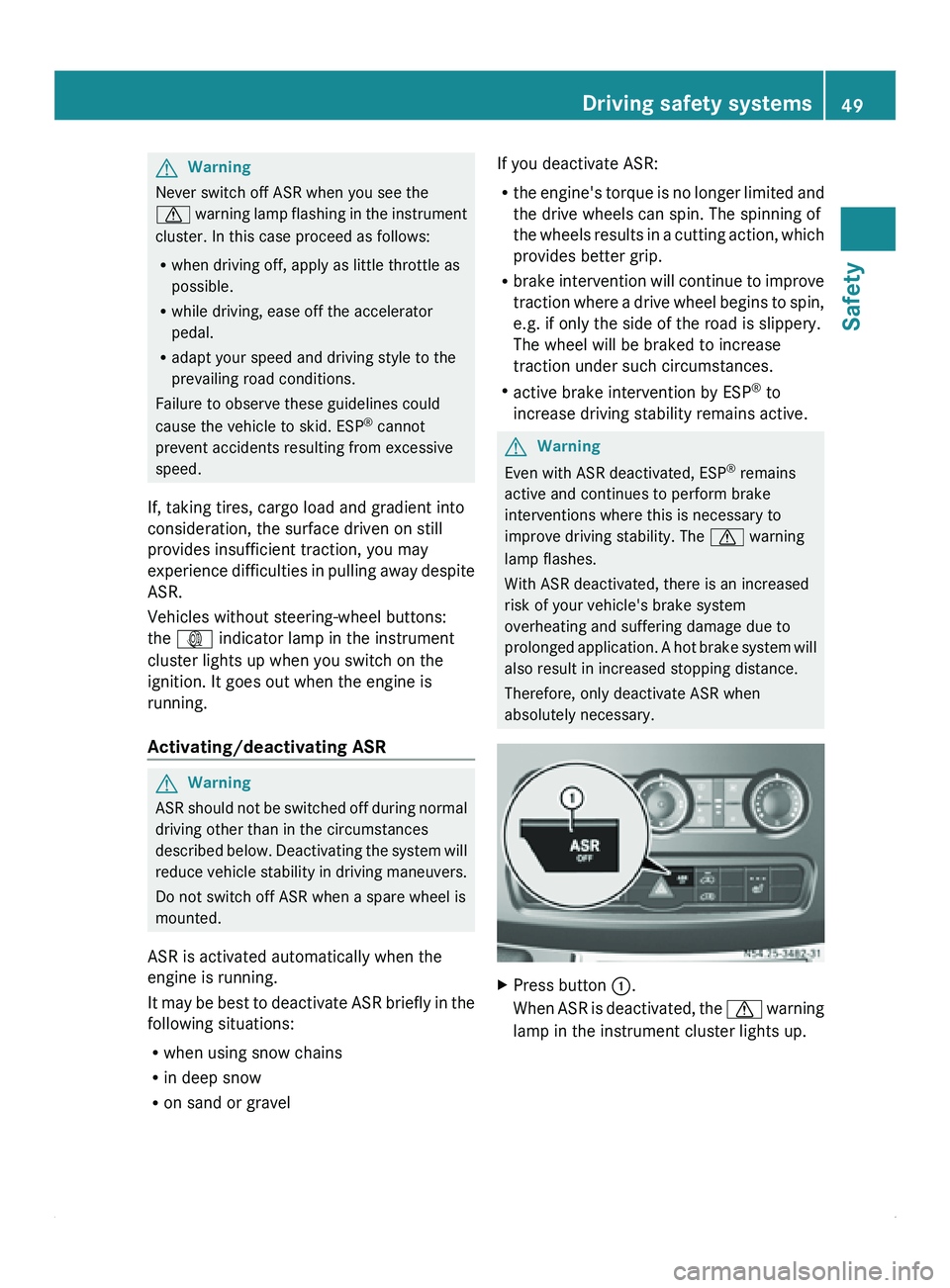

Activating/deactivating ASR G

Warning

ASR should

not be switched off during normal

driving other than in the circumstances

described below. Deactivating

the system will

reduce vehicle stability in driving maneuvers.

Do not switch off ASR when a spare wheel is

mounted.

ASR is activated automatically when the

engine is running.

It may be best to deactivate ASR briefly in the

following situations:

R when using snow chains

R in deep snow

R on sand or gravel If you deactivate ASR:

R

the engine's torque

is no longer limited and

the drive wheels can spin. The spinning of

the wheels results in a cutting action, which

provides better grip.

R brake intervention will continue to improve

traction where a drive wheel begins to spin,

e.g. if only the side of the road is slippery.

The wheel will be braked to increase

traction under such circumstances.

R active brake intervention by ESP ®

to

increase driving stability remains active. G

Warning

Even with ASR deactivated, ESP ®

remains

active and continues to perform brake

interventions where this is necessary to

improve driving stability. The 0067 warning

lamp flashes.

With ASR deactivated, there is an increased

risk of your vehicle's brake system

overheating and suffering damage due to

prolonged application. A

hot brake system will

also result in increased stopping distance.

Therefore, only deactivate ASR when

absolutely necessary. X

Press button 0046

.

When ASR is

deactivated, the 0067 warning

lamp in the instrument cluster lights up. Driving safety systems

49

Safety Z

Page 187 of 292

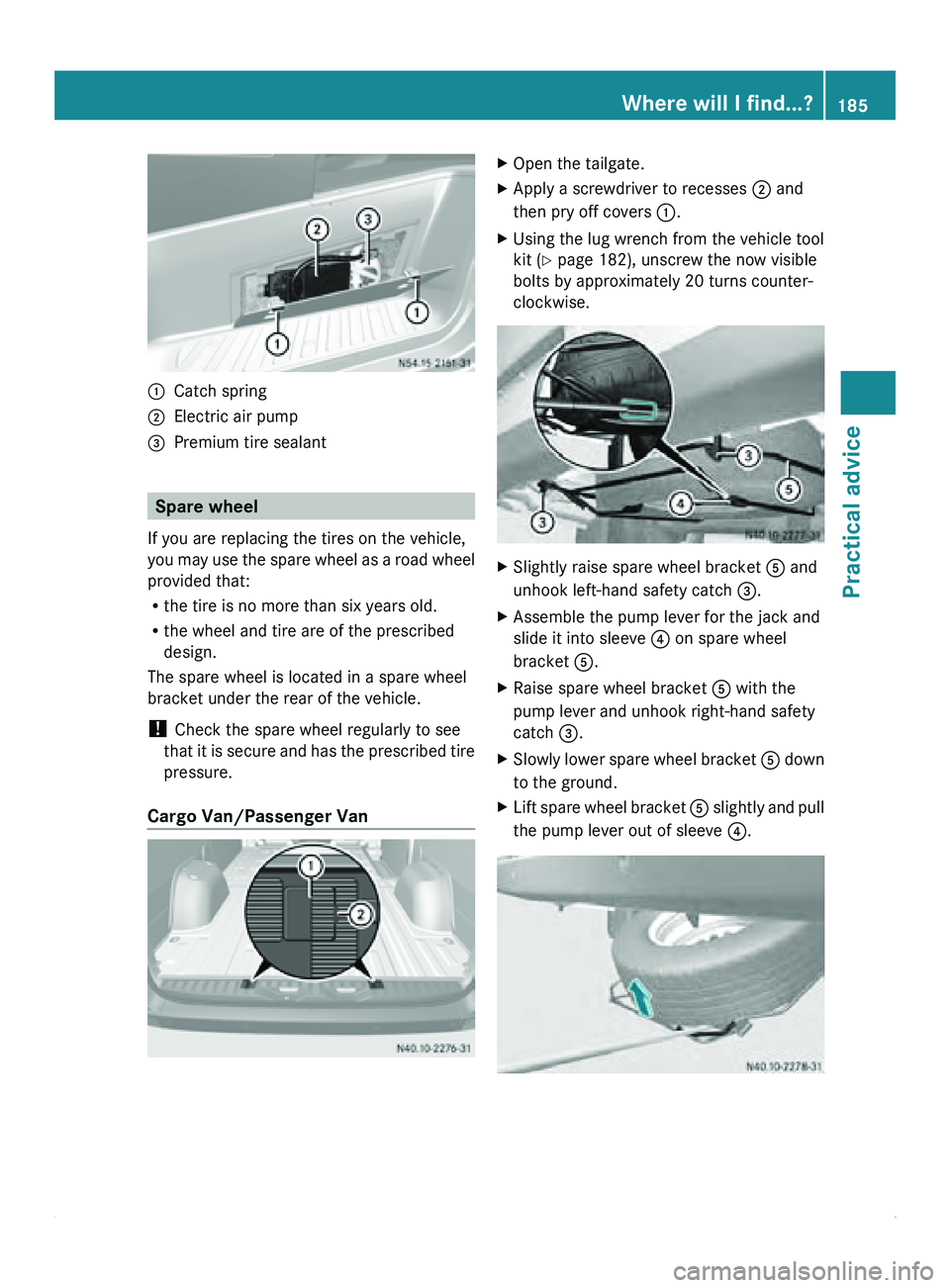

0046

Catch spring

0047 Electric air pump

008A Premium tire sealant Spare wheel

If you are replacing the tires on the vehicle,

you may use

the spare wheel as a road wheel

provided that:

R the tire is no more than six years old.

R the wheel and tire are of the prescribed

design.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

Cargo Van/Passenger Van X

Open the tailgate.

X Apply a screwdriver to recesses 0047 and

then pry off covers 0046.

X Using the lug wrench from the vehicle tool

kit ( Y page 182), unscrew the now visible

bolts by approximately 20 turns counter-

clockwise. X

Slightly raise spare wheel bracket 0086 and

unhook left-hand safety catch 008A.

X Assemble the pump lever for the jack and

slide it into sleeve 0088 on spare wheel

bracket 0086.

X Raise spare wheel bracket 0086 with the

pump lever and unhook right-hand safety

catch 008A.

X Slowly lower spare wheel bracket 0086 down

to the ground.

X Lift spare

wheel bracket 0086 slightly and

pull

the pump lever out of sleeve 0088. Where will I find...?

185

Practical advice Z

Page 201 of 292

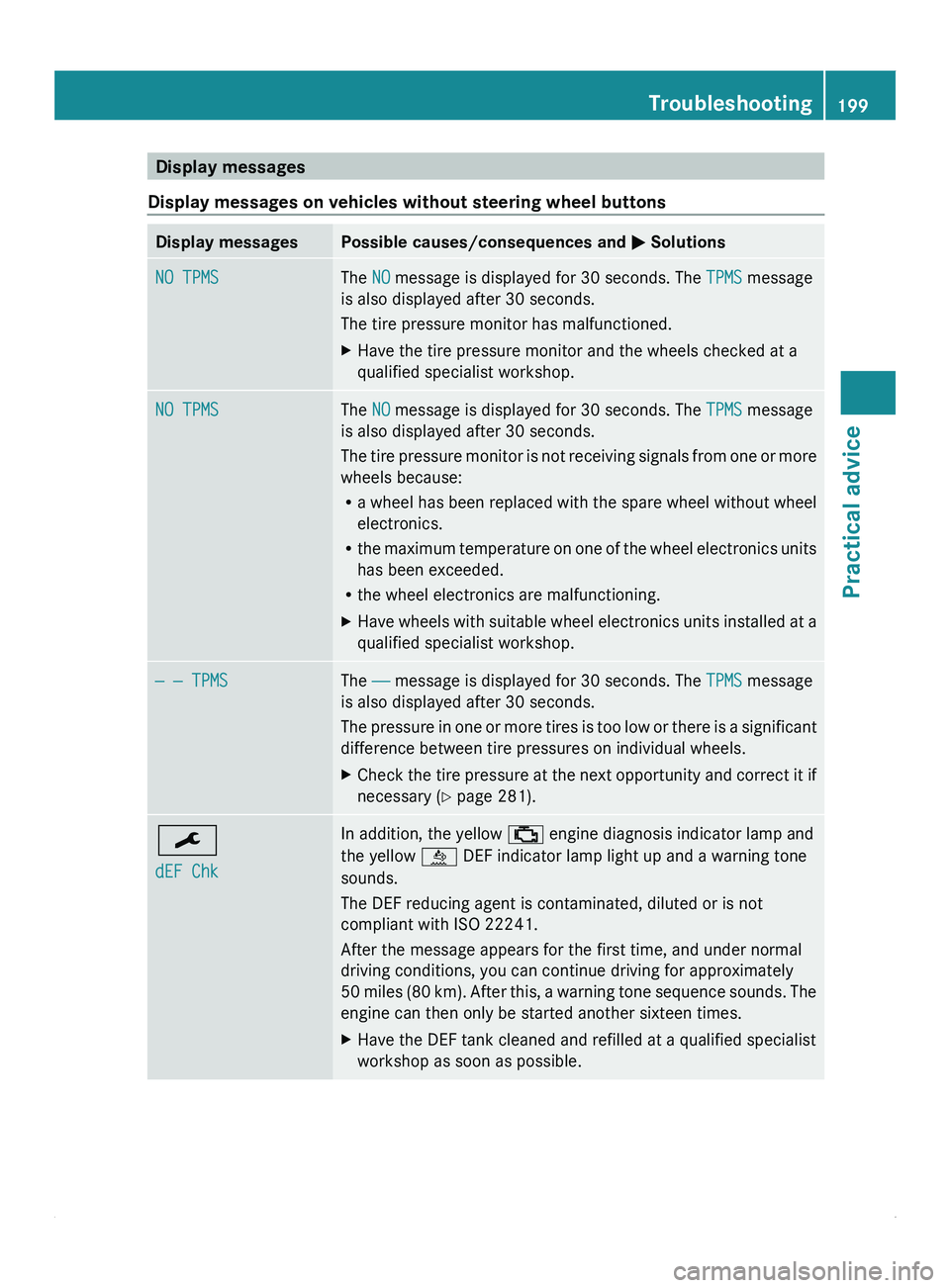

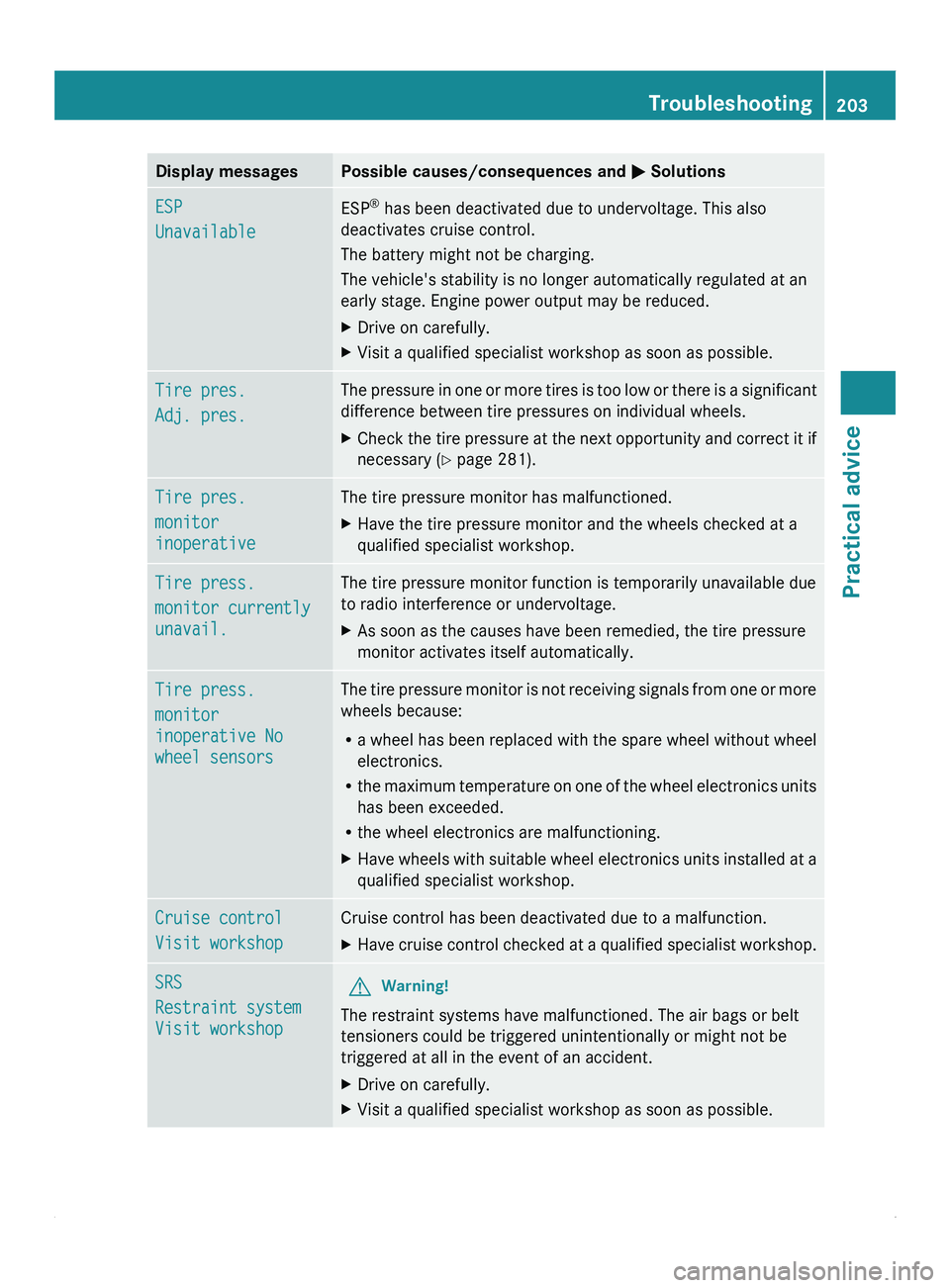

Display messages

Display messages on vehicles without steering wheel buttons Display messages Possible causes/consequences and

0050 SolutionsNO TPMS The NO message is displayed for 30 seconds. The

TPMS message

is also displayed after 30 seconds.

The tire pressure monitor has malfunctioned.

X Have the tire pressure monitor and the wheels checked at a

qualified specialist workshop. NO TPMS The NO message is displayed for 30 seconds. The

TPMS message

is also displayed after 30 seconds.

The tire pressure

monitor is not receiving signals from one or more

wheels because:

R a wheel has been replaced with the spare wheel without wheel

electronics.

R the maximum temperature on one of the wheel electronics units

has been exceeded.

R the wheel electronics are malfunctioning.

X Have wheels with suitable wheel electronics units installed at a

qualified specialist workshop. — — TPMS The ——

message is displayed for 30 seconds. The

TPMS message

is also displayed after 30 seconds.

The pressure in

one or more tires is too low or there is a significant

difference between tire pressures on individual wheels.

X Check the tire pressure at the next opportunity and correct it if

necessary ( Y page 281). 009B

dEF Chk In addition, the yellow

00BB engine diagnosis indicator lamp and

the yellow 00E4

DEF indicator lamp light up and a warning tone

sounds.

The DEF reducing agent is contaminated, diluted or is not

compliant with ISO 22241 .

After the message appears for the first time, and under normal

driving conditions, you can continue driving for approximately

50 miles

(80 km). After this, a warning tone sequence sounds. The

engine can then only be started another sixteen times.

X Have the DEF tank cleaned and refilled at a qualified specialist

workshop as soon as possible. Troubleshooting

199

Practical advice Z

Page 205 of 292

Display messages Possible causes/consequences and

0050 SolutionsESP

Unavailable

ESP

®

has been deactivated due to undervoltage. This also

deactivates cruise control.

The battery might not be charging.

The vehicle's stability is no longer automatically regulated at an

early stage. Engine power output may be reduced.

X Drive on carefully.

X Visit a qualified specialist workshop as soon as possible. Tire pres.

Adj. pres. The pressure in one or more tires is too low or there is a significant

difference between tire pressures on individual wheels.

X

Check the tire pressure at the next opportunity and correct it if

necessary ( Y page 281). Tire pres.

monitor

inoperative The tire pressure monitor has malfunctioned.

X

Have the tire pressure monitor and the wheels checked at a

qualified specialist workshop. Tire press.

monitor currently

unavail. The tire pressure monitor function is temporarily unavailable due

to radio interference or undervoltage.

X

As soon as the causes have been remedied, the tire pressure

monitor activates itself automatically. Tire press.

monitor

inoperative No

wheel sensors The tire pressure monitor is not receiving signals from one or more

wheels because:

R

a wheel has

been replaced with the spare wheel without wheel

electronics.

R the maximum temperature on one of the wheel electronics units

has been exceeded.

R the wheel electronics are malfunctioning.

X Have wheels with suitable wheel electronics units installed at a

qualified specialist workshop. Cruise control

Visit workshop Cruise control has been deactivated due to a malfunction.

X

Have cruise control checked at a qualified specialist workshop. SRS

Restraint system

Visit workshop

G

Warning!

The restraint systems have malfunctioned. The air bags or belt

tensioners could be triggered unintentionally or might not be

triggered at all in the event of an accident.

X Drive on carefully.

X Visit a qualified specialist workshop as soon as possible. Troubleshooting

203

Practical advice Z

Page 223 of 292

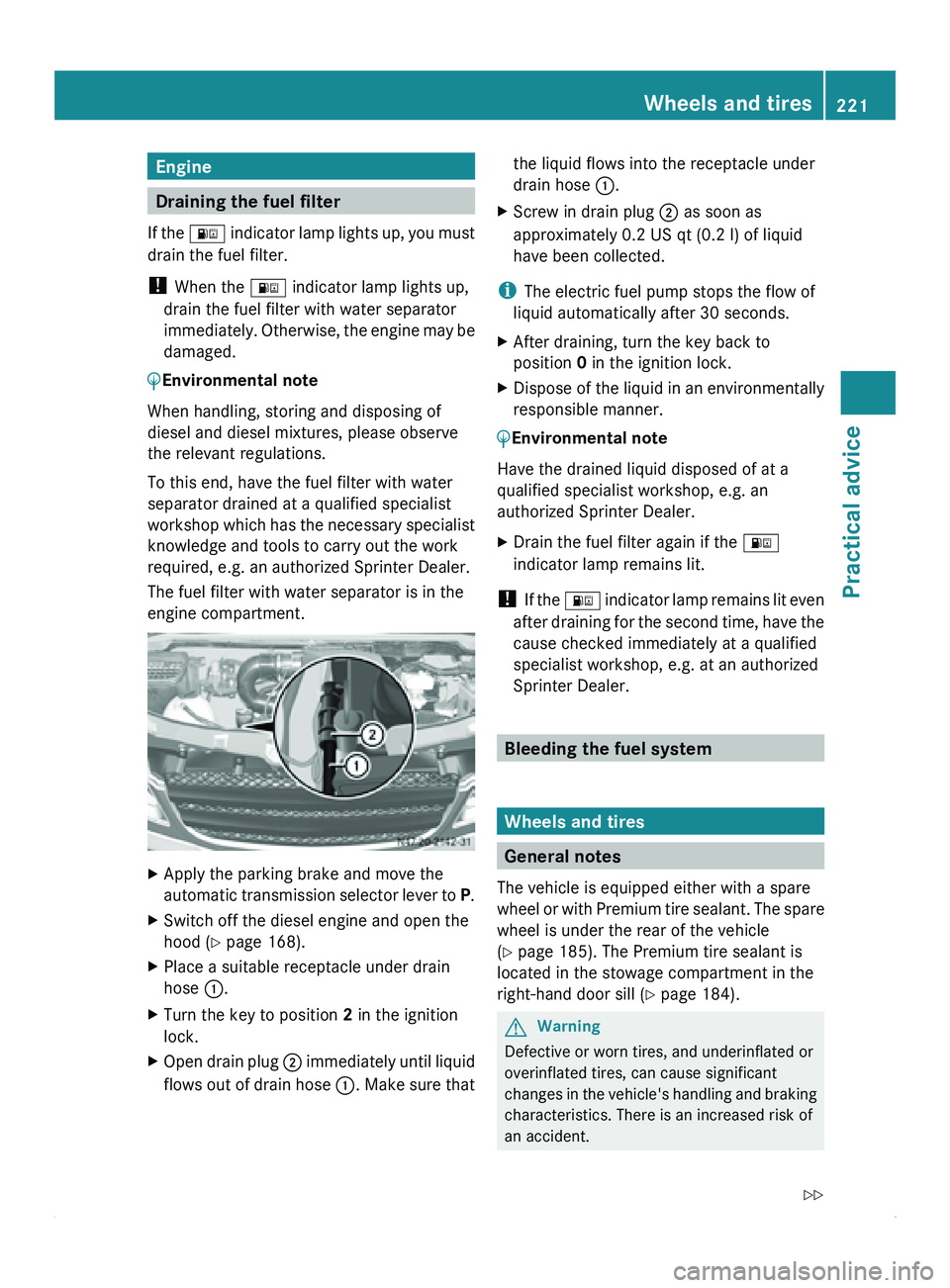

Engine

Draining the fuel filter

If the 00BA

indicator lamp lights up, you must

drain the fuel filter.

! When the 00BA indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged.

0040Environmental note

When handling, storing and disposing of

diesel and diesel mixtures, please observe

the relevant regulations.

To this end, have the fuel filter with water

separator drained at a qualified specialist

workshop which

has

the necessary specialist

knowledge and tools to carry out the work

required, e.g. an authorized Sprinter Dealer.

The fuel filter with water separator is in the

engine compartment. X

Apply the parking brake and move the

automatic

transmission selector

lever to P.

X Switch off the diesel engine and open the

hood ( Y page 168).

X Place a suitable receptacle under drain

hose 0046.

X Turn the key to position 2 in the ignition

lock.

X Open drain plug 0047

immediately until

liquid

flows out of drain hose 0046. Make sure that the liquid flows into the receptacle under

drain hose

0046.

X Screw in drain plug 0047 as soon as

approximately 0.2 US qt (0.2 l) of liquid have been collected.

i The electric fuel pump stops the flow of

liquid automatically after 30 seconds.

X After draining, turn the key back to

position

0 in the ignition lock.

X Dispose of the liquid in an environmentally

responsible manner.

0040Environmental note

Have the drained liquid disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

X Drain the fuel filter again if the 00BA

indicator lamp remains lit.

! If the

00BA

indicator lamp remains lit even

after draining for the second time, have the

cause checked immediately at a qualified

specialist workshop, e.g. at an authorized

Sprinter Dealer. Bleeding the fuel system

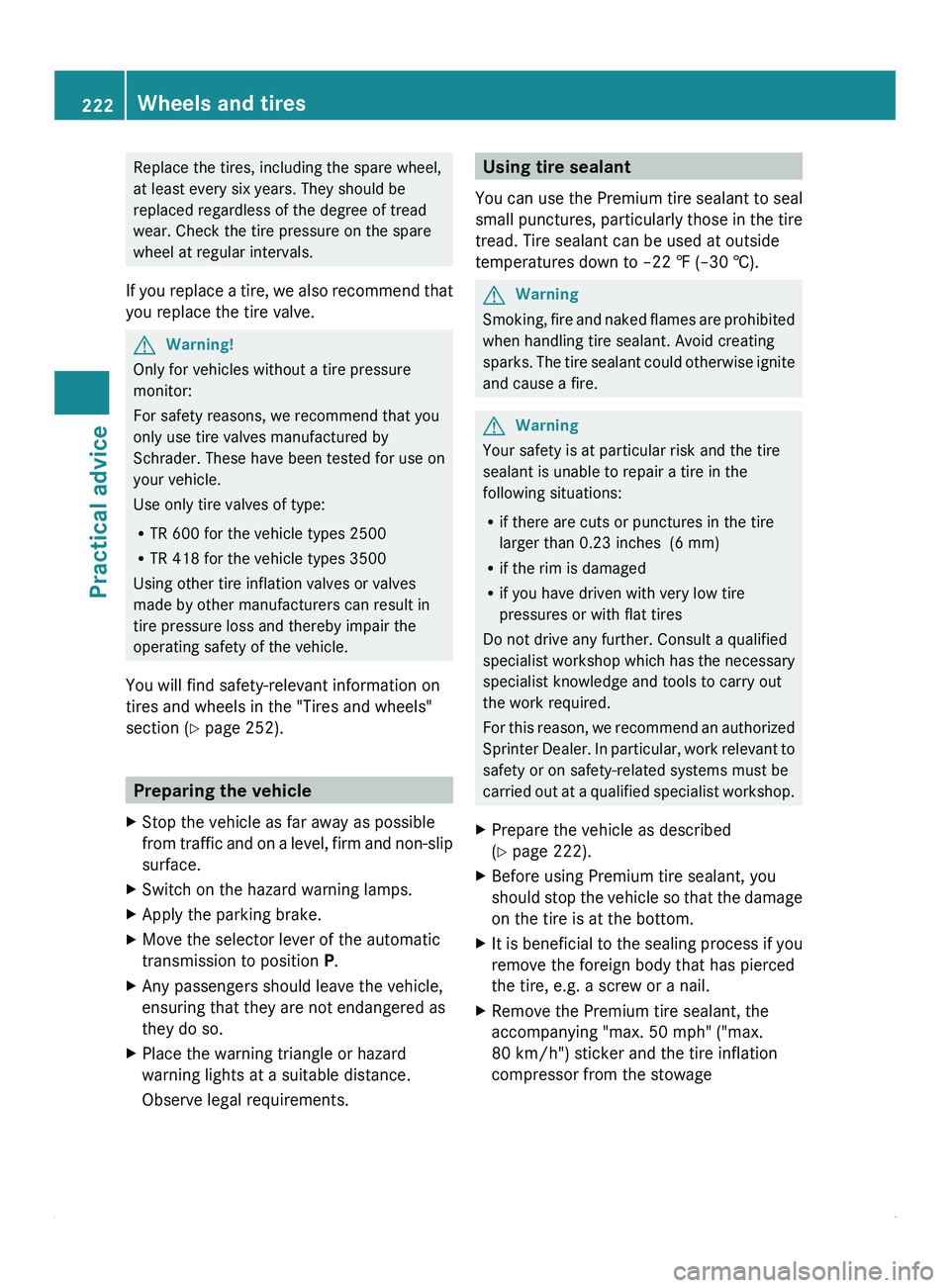

Wheels and tires

General notes

The vehicle is equipped either with a spare

wheel or with

Premium tire sealant. The spare

wheel is under the rear of the vehicle

(Y page 185). The Premium tire sealant is

located in the stowage compartment in the

right-hand door sill ( Y page 184). G

Warning

Defective or worn tires, and underinflated or

overinflated tires, can cause significant

changes in the

vehicle's handling and braking

characteristics. There is an increased risk of

an accident. Wheels and tires

221

Practical advice

Z

Page 224 of 292

Replace the tires, including the spare wheel,

at least every six years. They should be

replaced regardless of the degree of tread

wear. Check the tire pressure on the spare

wheel at regular intervals.

If you replace

a tire, we also recommend that

you replace the tire valve. G

Warning!

Only for vehicles without a tire pressure

monitor:

For safety reasons, we recommend that you

only use tire valves manufactured by

Schrader. These have been tested for use on

your vehicle.

Use only tire valves of type:

R TR 600 for the vehicle types 2500

R TR 418 for the vehicle types 3500

Using other tire inflation valves or valves

made by other manufacturers can result in

tire pressure loss and thereby impair the

operating safety of the vehicle.

You will find safety-relevant information on

tires and wheels in the "Tires and wheels"

section ( Y page 252).Preparing the vehicle

X Stop the vehicle as far away as possible

from traffic and

on a level, firm and non-slip

surface.

X Switch on the hazard warning lamps.

X Apply the parking brake.

X Move the selector lever of the automatic

transmission to position P.

X Any passengers should leave the vehicle,

ensuring that they are not endangered as

they do so.

X Place the warning triangle or hazard

warning lights at a suitable distance.

Observe legal requirements. Using tire sealant

You can use

the Premium tire sealant to seal

small punctures, particularly those in the tire

tread. Tire sealant can be used at outside

temperatures down to –22 ‡ (–30 †). G

Warning

Smoking, fire

and naked flames are prohibited

when handling tire sealant. Avoid creating

sparks. The tire

sealant could otherwise ignite

and cause a fire. G

Warning

Your safety is at particular risk and the tire

sealant is unable to repair a tire in the

following situations:

R if there are cuts or punctures in the tire

larger than 0.23 inches (6 mm)

R if the rim is damaged

R if you have driven with very low tire

pressures or with flat tires

Do not drive any further. Consult a qualified

specialist workshop which

has the necessary

specialist knowledge and tools to carry out

the work required.

For this reason, we recommend an authorized

Sprinter Dealer. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

X Prepare the vehicle as described

(Y page 222).

X Before using Premium tire sealant, you

should stop the

vehicle so that the damage

on the tire is at the bottom.

X It is beneficial to the sealing process if you

remove the foreign body that has pierced

the tire, e.g. a screw or a nail.

X Remove the Premium tire sealant, the

accompanying "max. 50 mph" ("max.

80 km/h") sticker and the tire inflation

compressor from the stowage222

Wheels and tires

Practical advice

Page 231 of 292

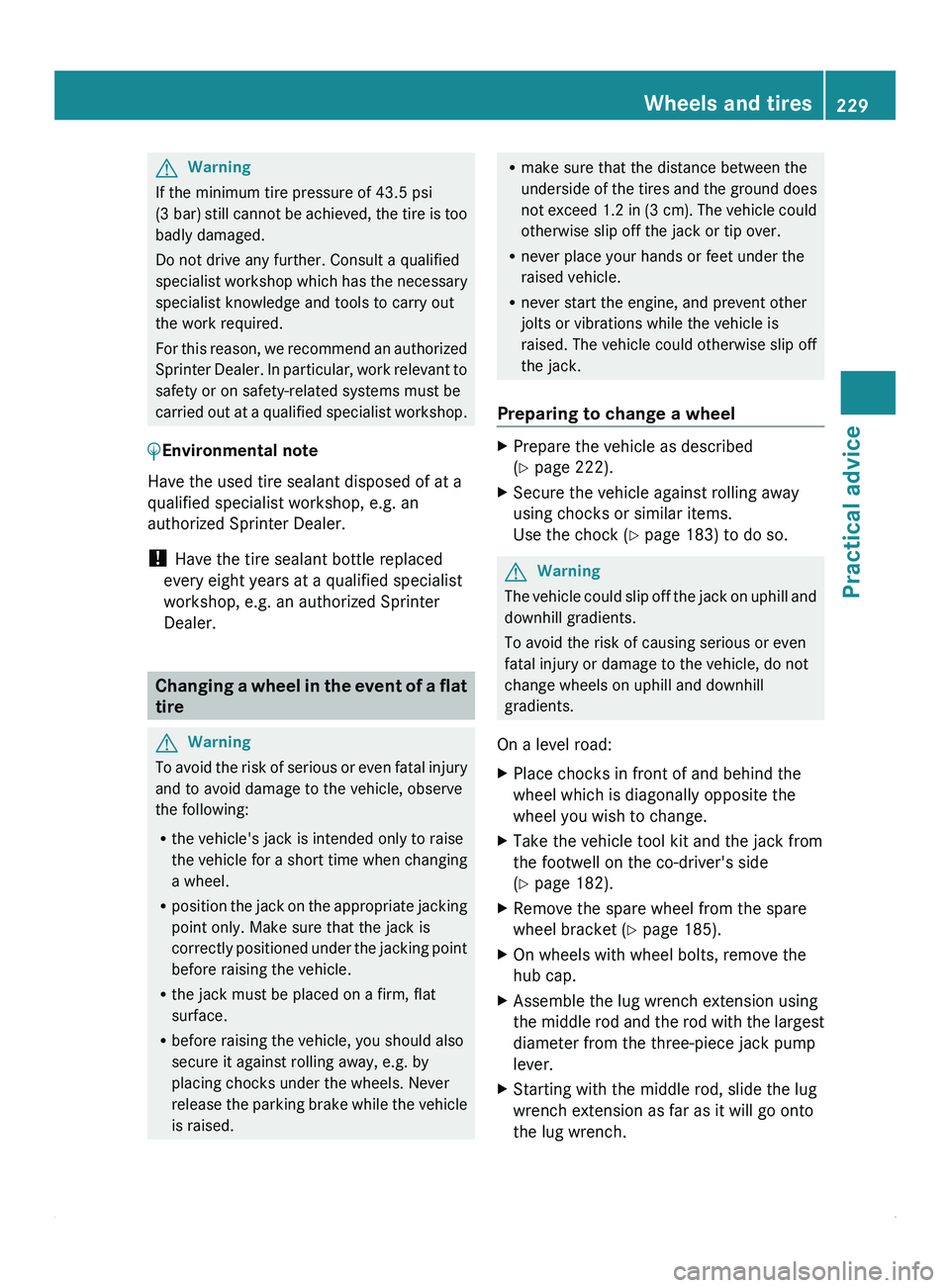

G

Warning

If the minimum tire pressure of 43.5 psi

(3 bar) still cannot

be achieved, the tire is too

badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the necessary

specialist knowledge and tools to carry out

the work required.

For this reason, we recommend an authorized

Sprinter Dealer. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

0040Environmental note

Have the used tire sealant disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

! Have the tire sealant bottle replaced

every eight years at a qualified specialist

workshop, e.g. an authorized Sprinter

Dealer. Changing a

wheel in the event of a flat

tire G

Warning

To avoid the risk of serious or even fatal injury

and to avoid damage to the vehicle, observe

the following:

R the vehicle's jack is intended only to raise

the vehicle for

a short time when changing

a wheel.

R position the jack on the appropriate jacking

point only. Make sure that the jack is

correctly positioned under the jacking point

before raising the vehicle.

R the jack must be placed on a firm, flat

surface.

R before raising the vehicle, you should also

secure it against rolling away, e.g. by

placing chocks under the wheels. Never

release the parking brake while the vehicle

is raised. R

make sure that the distance between the

underside

of the

tires and the ground does

not exceed 1.2 in (3 cm). The vehicle could

otherwise slip off the jack or tip over.

R never place your hands or feet under the

raised vehicle.

R never start the engine, and prevent other

jolts or vibrations while the vehicle is

raised. The vehicle could otherwise slip off

the jack.

Preparing to change a wheel X

Prepare the vehicle as described

(Y

page 222).

X Secure the vehicle against rolling away

using chocks or similar items.

Use the chock ( Y

page 183) to do so. G

Warning

The vehicle

could slip off the jack on uphill and

downhill gradients.

To avoid the risk of causing serious or even

fatal injury or damage to the vehicle, do not

change wheels on uphill and downhill

gradients.

On a level road:

X Place chocks in front of and behind the

wheel which is diagonally opposite the

wheel you wish to change.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 182).

X Remove the spare wheel from the spare

wheel bracket ( Y page 185).

X On wheels with wheel bolts, remove the

hub cap.

X Assemble the lug wrench extension using

the middle rod

and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench. Wheels and tires

229

Practical advice Z

Page 233 of 292

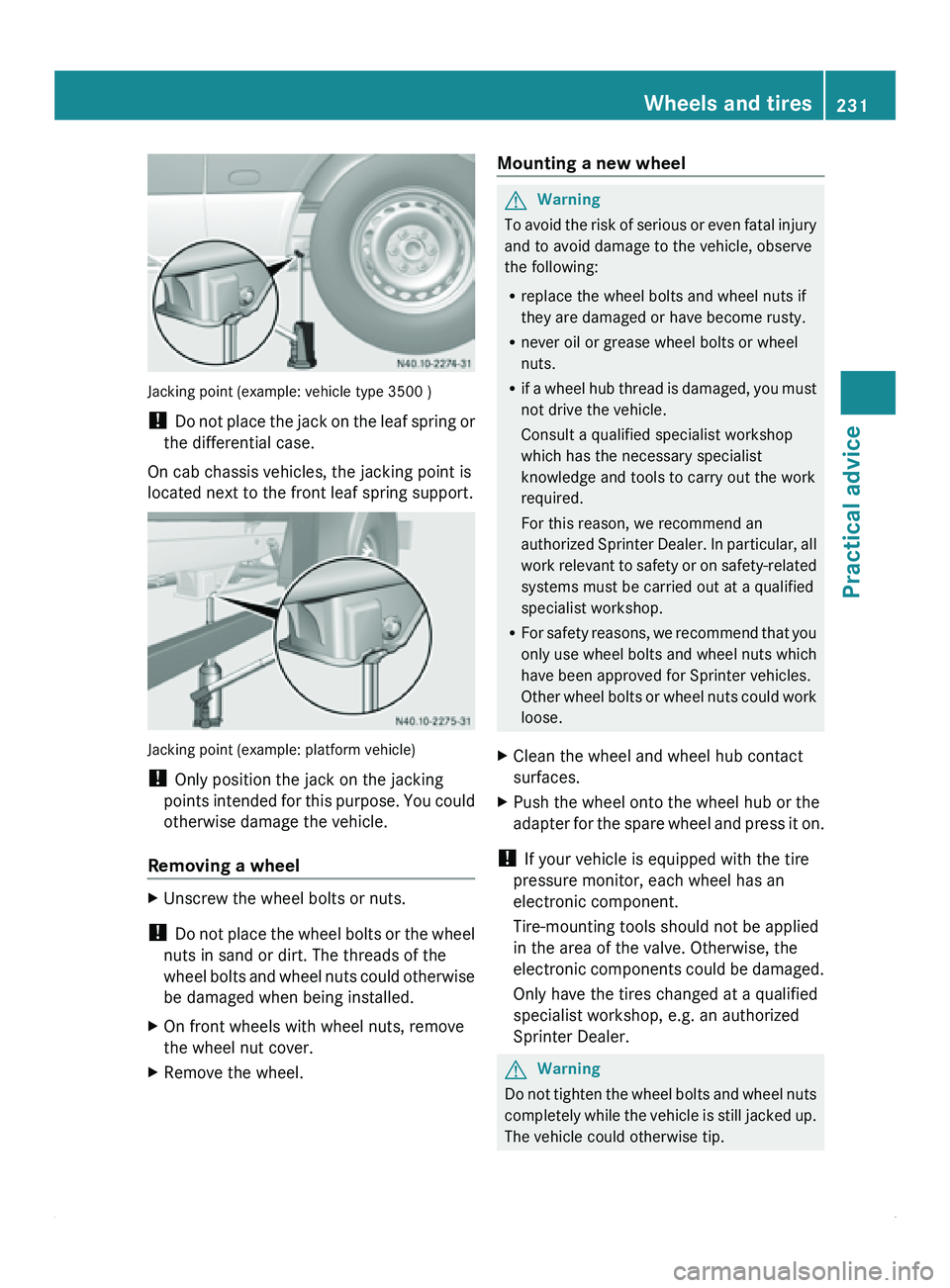

Jacking point (example: vehicle type 3500 )

!

Do not place

the jack on the leaf spring or

the differential case.

On cab chassis vehicles, the jacking point is

located next to the front leaf spring support. Jacking point (example: platform vehicle)

!

Only position the jack on the jacking

points intended for

this purpose. You could

otherwise damage the vehicle.

Removing a wheel X

Unscrew the wheel bolts or nuts.

! Do not place

the wheel bolts or the wheel

nuts in sand or dirt. The threads of the

wheel bolts and wheel nuts could otherwise

be damaged when being installed.

X On front wheels with wheel nuts, remove

the wheel nut cover.

X Remove the wheel. Mounting a new wheel G

Warning

To avoid the risk of serious or even fatal injury

and to avoid damage to the vehicle, observe

the following:

R replace the wheel bolts and wheel nuts if

they are damaged or have become rusty.

R never oil or grease wheel bolts or wheel

nuts.

R if a wheel

hub thread is damaged, you must

not drive the vehicle.

Consult a qualified specialist workshop

which has the necessary specialist

knowledge and tools to carry out the work

required.

For this reason, we recommend an

authorized Sprinter Dealer. In particular, all

work relevant to safety or on safety-related

systems must be carried out at a qualified

specialist workshop.

R For safety reasons, we recommend that you

only use wheel bolts and wheel nuts which

have been approved for Sprinter vehicles.

Other wheel bolts or wheel nuts could work

loose.

X Clean the wheel and wheel hub contact

surfaces.

X Push the wheel onto the wheel hub or the

adapter for the

spare wheel and press it on.

! If your vehicle is equipped with the tire

pressure monitor, each wheel has an

electronic component.

Tire-mounting tools should not be applied

in the area of the valve. Otherwise, the

electronic components could

be damaged.

Only have the tires changed at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. G

Warning

Do not tighten the wheel bolts and wheel nuts

completely while the

vehicle is still jacked up.

The vehicle could otherwise tip. Wheels and tires

231

Practical advice Z

Page 234 of 292

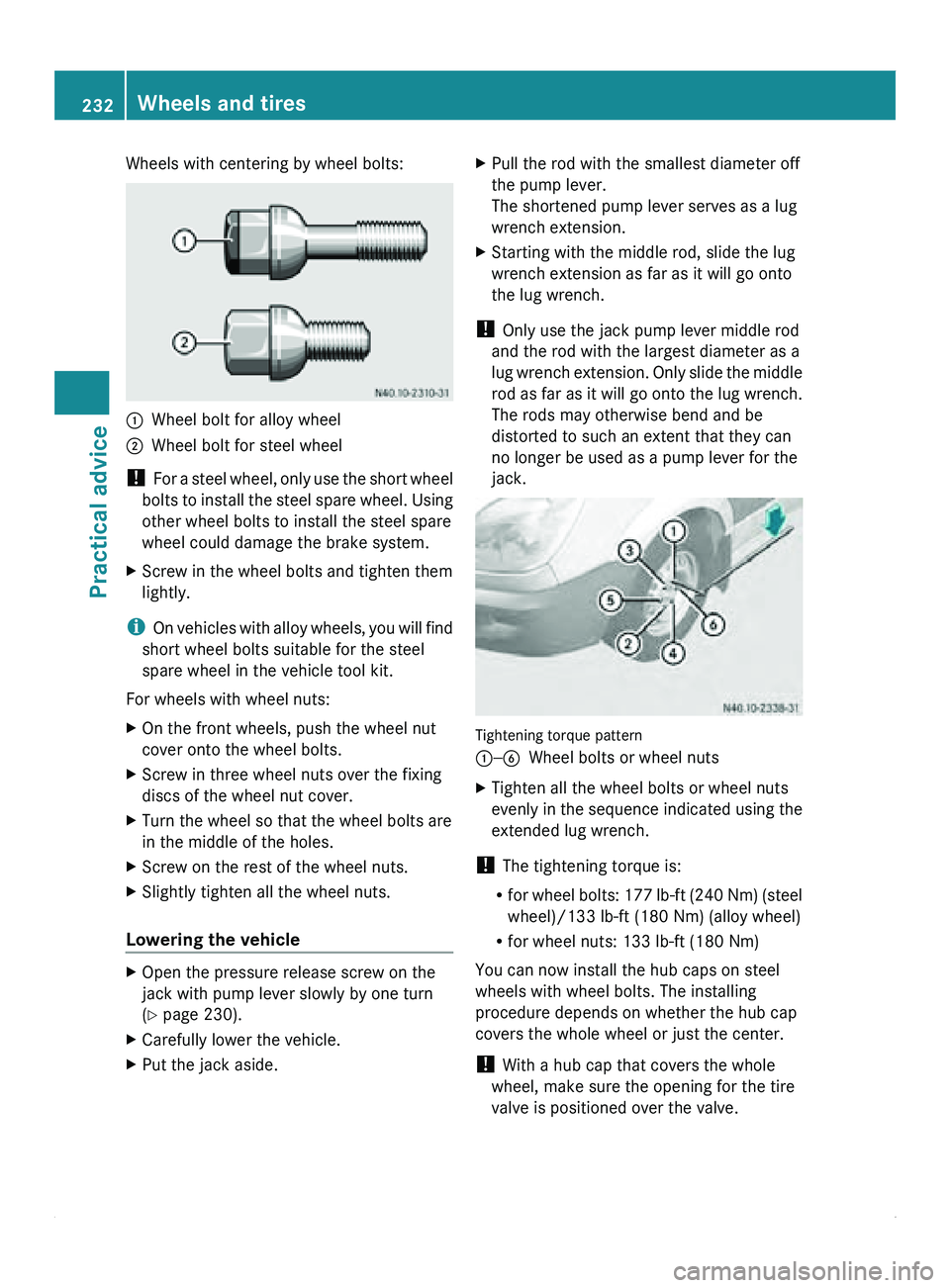

Wheels with centering by wheel bolts:

0046

Wheel bolt for alloy wheel

0047 Wheel bolt for steel wheel

! For a

steel

wheel, only use the short wheel

bolts to install the steel spare wheel. Using

other wheel bolts to install the steel spare

wheel could damage the brake system.

X Screw in the wheel bolts and tighten them

lightly.

i On vehicles with

alloy wheels, you will find

short wheel bolts suitable for the steel

spare wheel in the vehicle tool kit.

For wheels with wheel nuts:

X On the front wheels, push the wheel nut

cover onto the wheel bolts.

X Screw in three wheel nuts over the fixing

discs of the wheel nut cover.

X Turn the wheel so that the wheel bolts are

in the middle of the holes.

X Screw on the rest of the wheel nuts.

X Slightly tighten all the wheel nuts.

Lowering the vehicle X

Open the pressure release screw on the

jack with pump lever slowly by one turn

(Y page 230).

X Carefully lower the vehicle.

X Put the jack aside. X

Pull the rod with the smallest diameter off

the pump lever.

The shortened pump lever serves as a lug

wrench extension.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

! Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension.

Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be

distorted to such an extent that they can

no longer be used as a pump lever for the

jack. Tightening torque pattern

0046—0087

Wheel bolts or wheel nuts

X Tighten all the wheel bolts or wheel nuts

evenly in the

sequence indicated using the

extended lug wrench.

! The tightening torque is:

R for wheel bolts:

177 lb-ft (240 Nm) (steel

wheel)/133 lb-ft (180 Nm) (alloy wheel)

R for wheel nuts: 133 lb-ft (180 Nm)

You can now install the hub caps on steel

wheels with wheel bolts. The installing

procedure depends on whether the hub cap

covers the whole wheel or just the center.

! With a hub cap that covers the whole

wheel, make sure the opening for the tire

valve is positioned over the valve. 232

Wheels and tires

Practical advice