engine MERCEDES-BENZ SPRINTER 2012 MY12 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2012Pages: 292, PDF Size: 6.75 MB

Page 222 of 292

Always have maintenance work carried out at a qualified specialist workshop. The qualified

specialist workshop must have the necessary specialist knowledge and tools to carry out the

work required.

We

recommend visiting an authorized Sprinter Dealer. In particular, work relevant

to safety or on safety-related systems must be carried out at a qualified specialist workshop. Problem Possible causes/consequences and

0050 SolutionsThe windshield wipers

are jammed. The wiper movement is obstructed, e.g. by leaves or snow. The

wiper motor has been deactivated.

X

Stop the

vehicle as soon as possible. For safety reasons, remove

the key from the ignition lock.

X Remove the cause of the obstruction.

X Switch on the windshield wipers again. The windshield wipers

have stopped working

completely. There is a malfunction in the windshield wiper drive.

X

Select another wiper speed on the combination switch.

X Have the windshield wipers checked at a qualified specialist

workshop. Fuel and fuel tank

G

Warning

The operating safety of your vehicle could be jeopardized if maintenance work is carried out

incorrectly. As a

result, you could lose control of the vehicle and cause an accident. In addition,

the safety systems may no longer be able to protect you or others as they are designed to do.

Always have maintenance work carried out at a qualified specialist workshop. The qualified

specialist workshop must have the necessary specialist knowledge and tools to carry out the

work required. We recommend visiting an authorized Sprinter Dealer. In particular, work relevant

to safety or on safety-related systems must be carried out at a qualified specialist workshop. Problem Possible causes/consequences and

0050 SolutionsThe fuel tank has run

completely dry. There is air in the fuel system.

X

Bleed the fuel system . Fuel is

leaking from the

vehicle. G

Warning!

The fuel line or the fuel tank is damaged.

Leaking fuel creates a risk of fire or explosion.

X Switch off the ignition immediately.

X Remove the key from the ignition lock.

X Do not restart the engine under any circumstances.

X Consult a qualified specialist workshop.220

Troubleshooting

Practical advice

Page 223 of 292

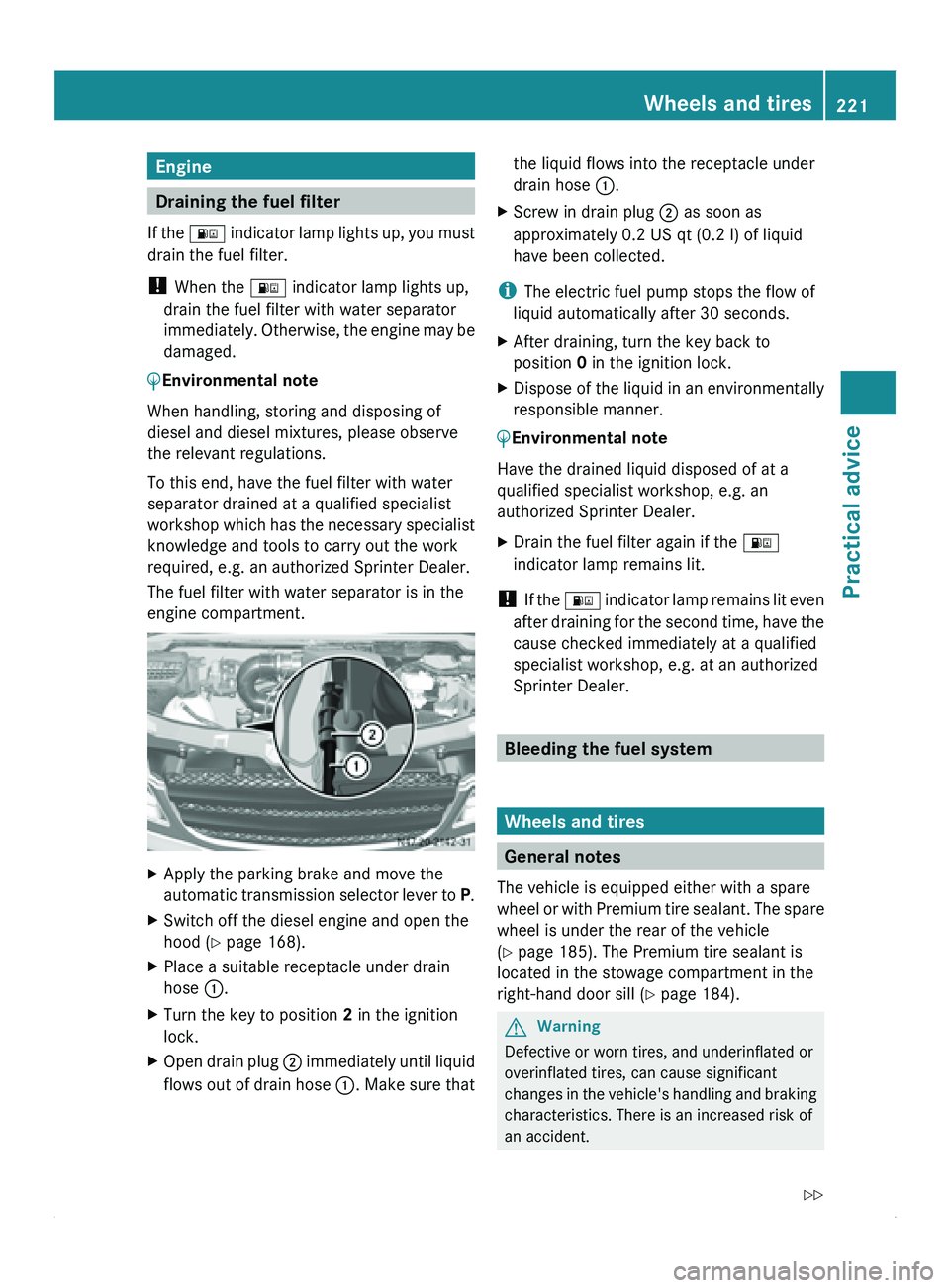

Engine

Draining the fuel filter

If the 00BA

indicator lamp lights up, you must

drain the fuel filter.

! When the 00BA indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged.

0040Environmental note

When handling, storing and disposing of

diesel and diesel mixtures, please observe

the relevant regulations.

To this end, have the fuel filter with water

separator drained at a qualified specialist

workshop which

has

the necessary specialist

knowledge and tools to carry out the work

required, e.g. an authorized Sprinter Dealer.

The fuel filter with water separator is in the

engine compartment. X

Apply the parking brake and move the

automatic

transmission selector

lever to P.

X Switch off the diesel engine and open the

hood ( Y page 168).

X Place a suitable receptacle under drain

hose 0046.

X Turn the key to position 2 in the ignition

lock.

X Open drain plug 0047

immediately until

liquid

flows out of drain hose 0046. Make sure that the liquid flows into the receptacle under

drain hose

0046.

X Screw in drain plug 0047 as soon as

approximately 0.2 US qt (0.2 l) of liquid have been collected.

i The electric fuel pump stops the flow of

liquid automatically after 30 seconds.

X After draining, turn the key back to

position

0 in the ignition lock.

X Dispose of the liquid in an environmentally

responsible manner.

0040Environmental note

Have the drained liquid disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

X Drain the fuel filter again if the 00BA

indicator lamp remains lit.

! If the

00BA

indicator lamp remains lit even

after draining for the second time, have the

cause checked immediately at a qualified

specialist workshop, e.g. at an authorized

Sprinter Dealer. Bleeding the fuel system

Wheels and tires

General notes

The vehicle is equipped either with a spare

wheel or with

Premium tire sealant. The spare

wheel is under the rear of the vehicle

(Y page 185). The Premium tire sealant is

located in the stowage compartment in the

right-hand door sill ( Y page 184). G

Warning

Defective or worn tires, and underinflated or

overinflated tires, can cause significant

changes in the

vehicle's handling and braking

characteristics. There is an increased risk of

an accident. Wheels and tires

221

Practical advice

Z

Page 226 of 292

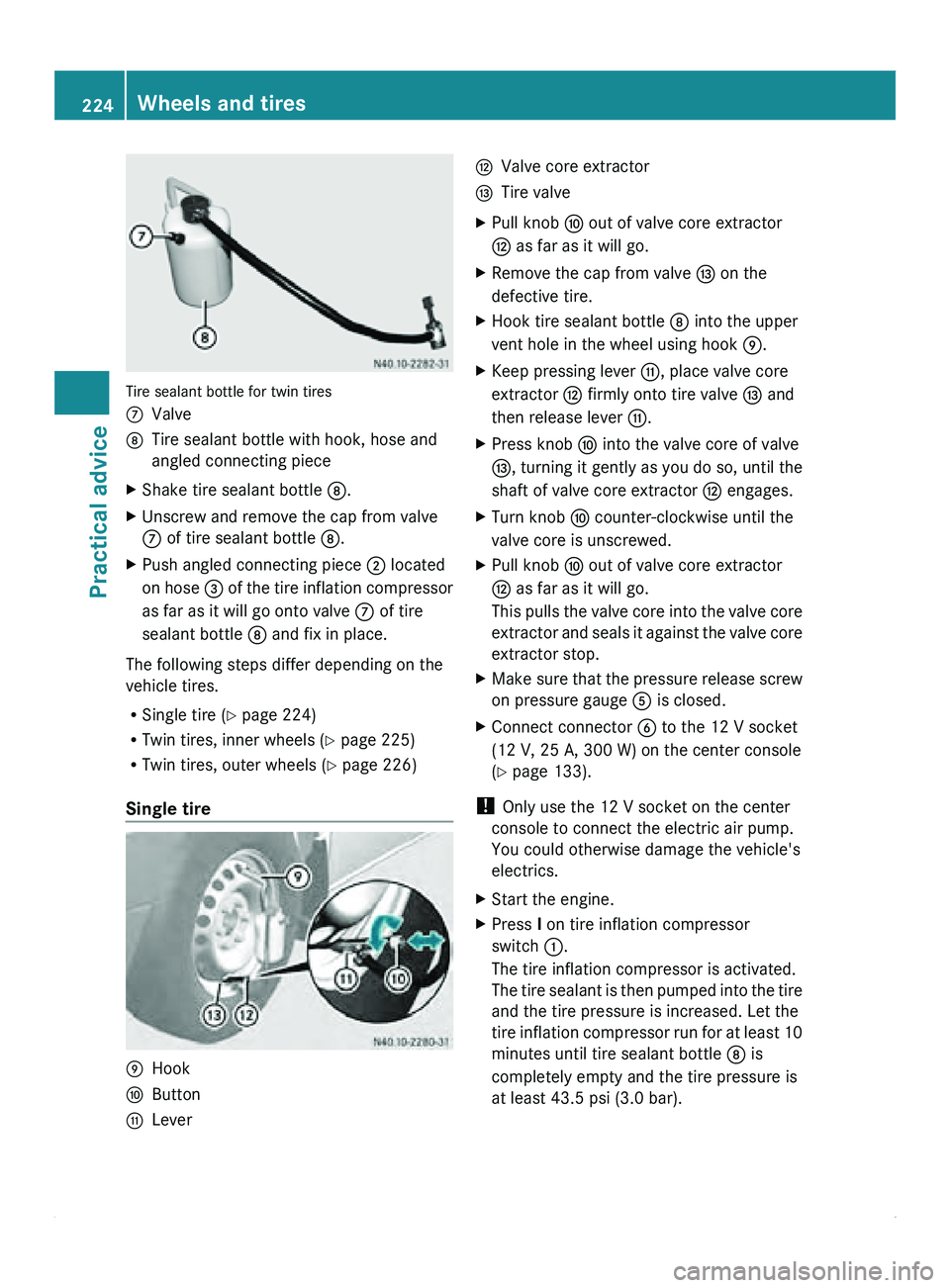

Tire sealant bottle for twin tires

006E

Valve

006F Tire sealant bottle with hook, hose and

angled connecting piece

X Shake tire sealant bottle 006F.

X Unscrew and remove the cap from valve

006E of tire sealant bottle 006F.

X Push angled connecting piece 0047 located

on hose 008A

of the tire inflation compressor

as far as it will go onto valve 006E of tire

sealant bottle 006F and fix in place.

The following steps differ depending on the

vehicle tires.

R Single tire (Y page 224)

R Twin tires, inner wheels ( Y page 225)

R Twin tires, outer wheels (

Y page 226)

Single tire 0070

Hook

0071 Button

0072 Lever 0073

Valve core extractor

0074 Tire valve

X Pull knob 0071 out of valve core extractor

0073 as far as it will go.

X Remove the cap from valve 0074 on the

defective tire.

X Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0070.

X Keep pressing lever 0072, place valve core

extractor 0073 firmly onto tire valve 0074 and

then release lever 0072.

X Press knob 0071 into the valve core of valve

0074, turning it gently as you do so, until the

shaft of valve core extractor 0073 engages.

X Turn knob 0071 counter-clockwise until the

valve core is unscrewed.

X Pull knob 0071 out of valve core extractor

0073 as far as it will go.

This pulls

the

valve core into the valve core

extractor and seals it against the valve core

extractor stop.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar). 224

Wheels and tires

Practical advice

Page 228 of 292

X

Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0072.

X Push angled connecting piece 0074 located

on the hose of tire sealant filler bottle 006F

as far

as

it will go on to valve core extractor

0071 and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on tire inflation compressor

switch 0046.

The tire inflation compressor is activated.

The tire

sealant

is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run for at least 10

minutes until tire sealant bottle 006F is

completely empty and the tire pressure is

at least 43.5 psi (3.0 bar).

! Do not

run

the electric air pump for longer

than 20 minutes without a break; otherwise

it may overheat.

The air pump can be used again once it has

cooled down.

X Inflate the tire using the tire inflation

compressor until the recommended tire

pressure ( Y page 281) is reached.

X Then, press 0 on tire inflation compressor

switch 0046.

The tire inflation compressor is

deactivated.

X Slide knob 0073 quickly to the stop in valve

core extractor 0071.

X Turn knob 0073 clockwise

until

the valve core

is firmly screwed into tire valve 0075.i

Do not pull the valve core extractor from

the tire valve while the valve core is

unscrewed from the

tire valve. Tire sealant

could otherwise escape and make you

dirty.

The tire sealant is water-soluble. If tire

sealant escapes, you can wash it away with

water.

X Pull knob 0073 out of valve core extractor

0071 as far as it will go.

X Unscrew valve core extractor 0071 counter-

clockwise from tire valve 0075.

X Screw valve extension 0070 onto tire valve

0075 and tighten it.

X Screw the valve cap onto valve extension

0070.

After filling with tire sealant, ( Y page 228).

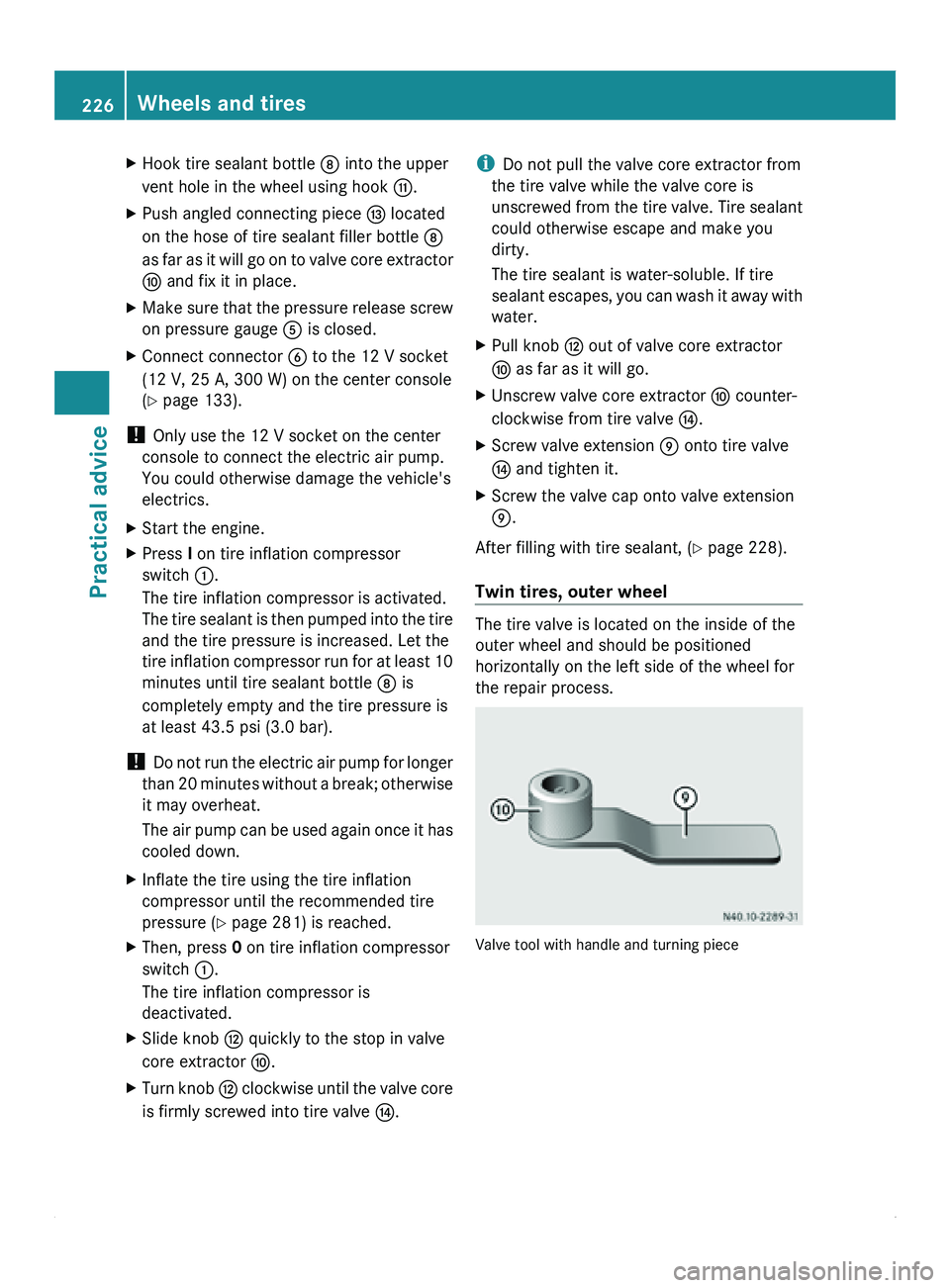

Twin tires, outer wheel The tire valve is located on the inside of the

outer wheel and should be positioned

horizontally on the left side of the wheel for

the repair process.

Valve tool with handle and turning piece226

Wheels and tires

Practical advice

Page 229 of 292

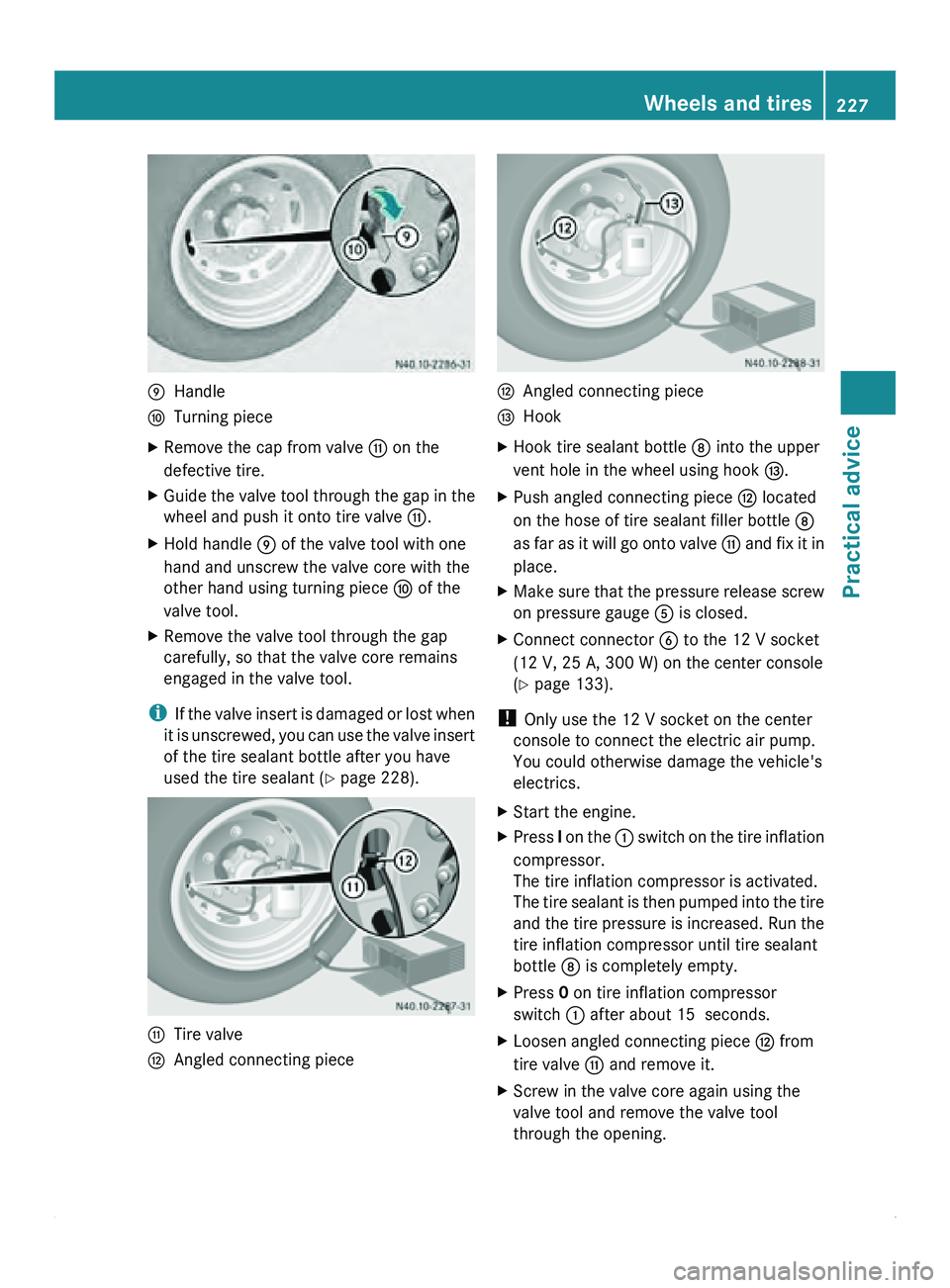

0070

Handle

0071 Turning piece

X Remove the cap from valve 0072 on the

defective tire.

X Guide the valve tool through the gap in the

wheel and push it onto tire valve 0072.

X Hold handle 0070 of the valve tool with one

hand and unscrew the valve core with the

other hand using turning piece 0071 of the

valve tool.

X Remove the valve tool through the gap

carefully, so that the valve core remains

engaged in the valve tool.

i If the

valve

insert is damaged or lost when

it is unscrewed, you can use the valve insert

of the tire sealant bottle after you have

used the tire sealant ( Y page 228).0072

Tire valve

0073 Angled connecting piece 0073

Angled connecting piece

0074 Hook

X Hook tire sealant bottle 006F into the upper

vent hole in the wheel using hook 0074.

X Push angled connecting piece 0073 located

on the hose of tire sealant filler bottle 006F

as far

as

it will go onto valve 0072 and fix it in

place.

X Make sure that the pressure release screw

on pressure gauge 0086 is closed.

X Connect connector 0087 to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 133).

! Only use the 12 V socket on the center

console to connect the electric air pump.

You could otherwise damage the vehicle's

electrics.

X Start the engine.

X Press I on the 0046

switch on the tire inflation

compressor.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Run the

tire inflation compressor until tire sealant

bottle 006F is completely empty.

X Press 0 on tire inflation compressor

switch 0046 after about 15 seconds.

X Loosen angled connecting piece 0073 from

tire valve 0072 and remove it.

X Screw in the valve core again using the

valve tool and remove the valve tool

through the opening. Wheels and tires

227

Practical advice Z

Page 231 of 292

G

Warning

If the minimum tire pressure of 43.5 psi

(3 bar) still cannot

be achieved, the tire is too

badly damaged.

Do not drive any further. Consult a qualified

specialist workshop which has the necessary

specialist knowledge and tools to carry out

the work required.

For this reason, we recommend an authorized

Sprinter Dealer. In particular, work relevant to

safety or on safety-related systems must be

carried out at a qualified specialist workshop.

0040Environmental note

Have the used tire sealant disposed of at a

qualified specialist workshop, e.g. an

authorized Sprinter Dealer.

! Have the tire sealant bottle replaced

every eight years at a qualified specialist

workshop, e.g. an authorized Sprinter

Dealer. Changing a

wheel in the event of a flat

tire G

Warning

To avoid the risk of serious or even fatal injury

and to avoid damage to the vehicle, observe

the following:

R the vehicle's jack is intended only to raise

the vehicle for

a short time when changing

a wheel.

R position the jack on the appropriate jacking

point only. Make sure that the jack is

correctly positioned under the jacking point

before raising the vehicle.

R the jack must be placed on a firm, flat

surface.

R before raising the vehicle, you should also

secure it against rolling away, e.g. by

placing chocks under the wheels. Never

release the parking brake while the vehicle

is raised. R

make sure that the distance between the

underside

of the

tires and the ground does

not exceed 1.2 in (3 cm). The vehicle could

otherwise slip off the jack or tip over.

R never place your hands or feet under the

raised vehicle.

R never start the engine, and prevent other

jolts or vibrations while the vehicle is

raised. The vehicle could otherwise slip off

the jack.

Preparing to change a wheel X

Prepare the vehicle as described

(Y

page 222).

X Secure the vehicle against rolling away

using chocks or similar items.

Use the chock ( Y

page 183) to do so. G

Warning

The vehicle

could slip off the jack on uphill and

downhill gradients.

To avoid the risk of causing serious or even

fatal injury or damage to the vehicle, do not

change wheels on uphill and downhill

gradients.

On a level road:

X Place chocks in front of and behind the

wheel which is diagonally opposite the

wheel you wish to change.

X Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 182).

X Remove the spare wheel from the spare

wheel bracket ( Y page 185).

X On wheels with wheel bolts, remove the

hub cap.

X Assemble the lug wrench extension using

the middle rod

and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench. Wheels and tires

229

Practical advice Z

Page 243 of 292

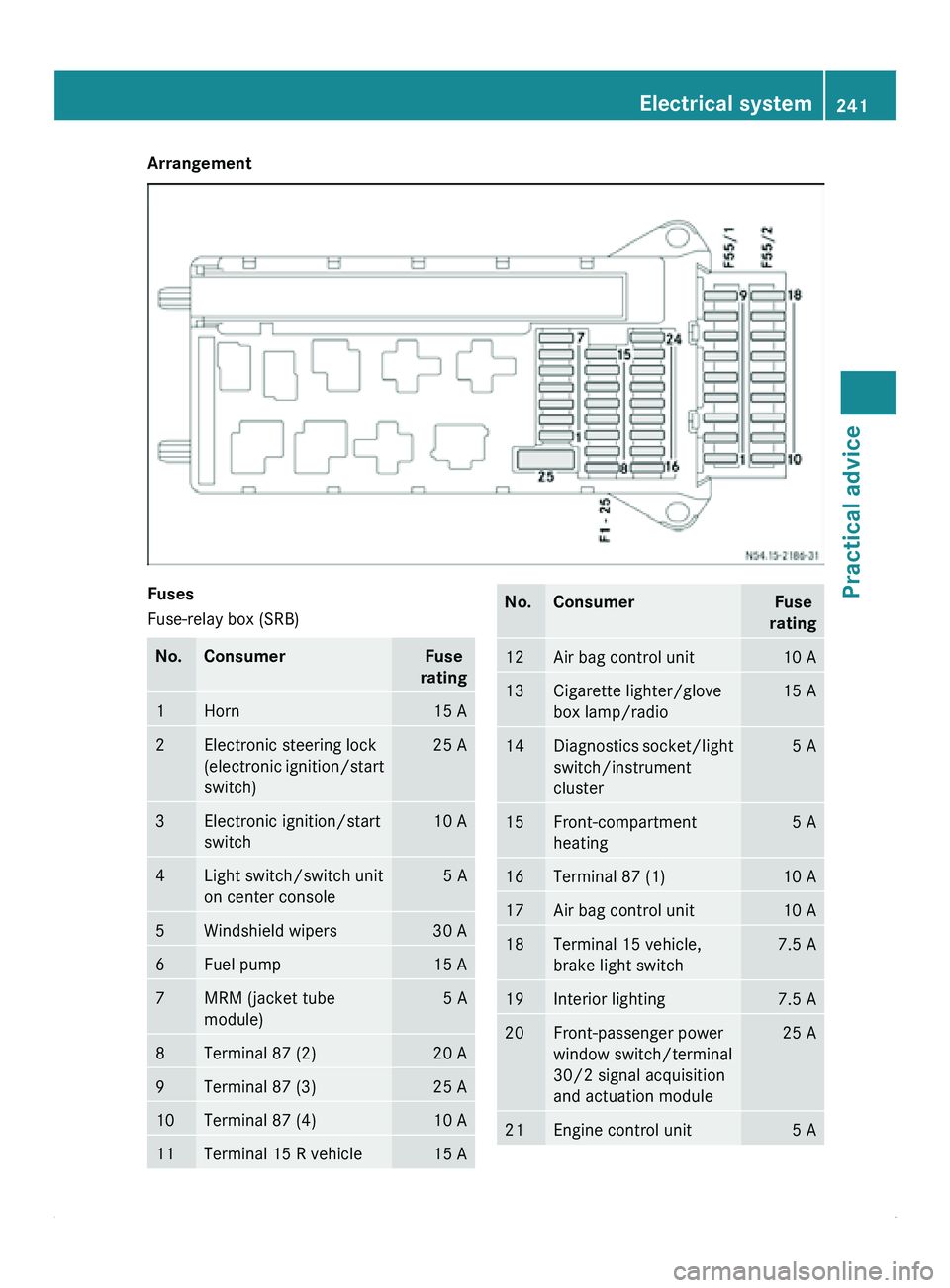

Arrangement

Fuses

Fuse-relay box (SRB)

No. Consumer Fuse

rating 1 Horn 15 A

2 Electronic steering lock

(electronic ignition/start

switch) 25 A

3 Electronic ignition/start

switch 10 A

4 Light switch/switch unit

on center console 5 A

5 Windshield wipers 30 A

6 Fuel pump 15 A

7 MRM (jacket tube

module) 5 A

8 Terminal 87 (2) 20 A

9 Terminal 87 (3) 25 A

10 Terminal 87 (4) 10 A

11 Terminal 15 R vehicle 15 A No. Consumer Fuse

rating 12 Air bag control unit 10 A

13 Cigarette lighter/glove

box lamp/radio 15 A

14 Diagnostics socket/light

switch/instrument

cluster 5 A

15 Front-compartment

heating 5 A

16 Terminal 87 (1) 10 A

17 Air bag control unit 10 A

18 Terminal 15 vehicle,

brake light switch 7.5 A

19 Interior lighting 7.5 A

20 Front-passenger power

window switch/terminal

30/2 signal acquisition

and actuation module 25 A

21 Engine control unit 5 AElectrical system

241Practical advice Z

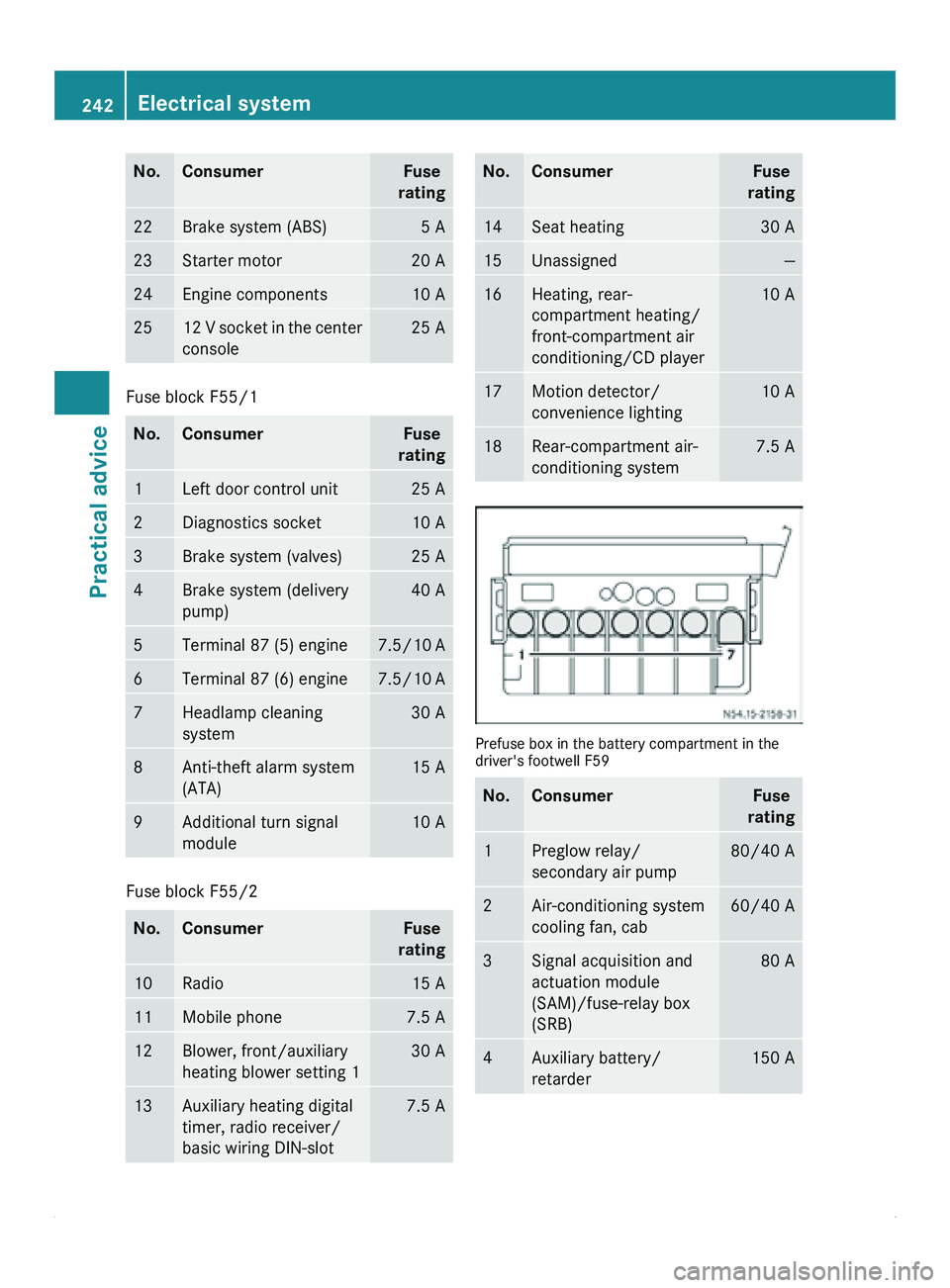

Page 244 of 292

No. Consumer Fuse

rating 22 Brake system (ABS) 5 A

23 Starter motor 20 A

24 Engine components 10 A

25 12 V socket in the center

console 25 A

Fuse block F55/1

No. Consumer Fuse

rating 1 Left door control unit 25 A

2 Diagnostics socket 10 A

3 Brake system (valves) 25 A

4 Brake system (delivery

pump) 40 A

5 Terminal 87 (5) engine 7.5/10 A

6 Terminal 87 (6) engine 7.5/10 A

7 Headlamp cleaning

system 30 A

8 Anti-theft alarm system

(ATA) 15 A

9 Additional turn signal

module 10 A

Fuse block F55/2

No. Consumer Fuse

rating 10 Radio 15 A

11 Mobile phone 7.5 A

12 Blower, front/auxiliary

heating blower setting 1 30 A

13 Auxiliary heating digital

timer, radio receiver/

basic wiring DIN-

slot 7.5 A No. Consumer Fuse

rating 14 Seat heating 30 A

15 Unassigned —

16 Heating, rear-

compartment heating/

front-compartment air

conditioning/CD player 10 A

17 Motion detector/

convenience lighting 10 A

18 Rear-compartment air-

conditioning system 7.5 A

Prefuse box in the battery compartment in the

driver's footwell F59

No. Consumer Fuse

rating 1 Preglow relay/

secondary air pump 80/40 A

2 Air-conditioning system

cooling fan, cab 60/40 A

3 Signal acquisition and

actuation module

(SAM)/fuse-relay box

(SRB) 80 A

4 Auxiliary battery/

retarder 150 A242

Electrical systemPractical advice

Page 249 of 292

X

Remove implement 0047.

X Refit cover 0046. Jump starting, tow-starting and

towing away

Jump-starting

General notes If the vehicle battery is flat, the engine can be

started from another vehicle using jumper

cables. For this purpose, the vehicle has a

jump-starting connection point in the engine

compartment.

The additional battery in the engine

compartment is

not

suitable for jump-starting

operations. If your vehicle requires jump-

starting, or if you use it to jump-start another

vehicle, use the jump-starting connection

point in the engine compartment. G

Warning

Explosive oxyhydrogen is produced when

batteries are being

charged. When working on

batteries, always make sure that the work

area is well ventilated.

Keep flames and naked lights away from the

battery, and do not smoke.

Prevent the creation of sparks (e.g. when

disconnecting the batteries). Sparks can

ignite the oxyhydrogen gas and cause the

batteries to explode. You and others could be

seriously injured. G

Warning

Due to the gases which escape from batteries,

there is a risk of acid burns when jump-

starting a vehicle.

Do not lean over the battery

while the engine is being jump-started.

! Avoid repeated and lengthy starting

attempts.

Do not use a rapid-charging device to start

the engine. When jump-starting, observe the following

points:

R

jump-starting must only be performed

when the engine and catalytic converter

are cold.

R do not start the engine if the battery is

frozen. Let the battery thaw first.

R when jump-starting, use

only batteries with

the same nominal voltage and a similar

capacity.

R only use jump leads protected against

polarity reversal, with adequate cross-

section and with insulated battery terminal

clamps.

X Make sure that the two vehicles do not

touch.

X Apply the parking brake.

X Move the selector lever of the automatic

transmission to position P.

X Switch off all electrical consumers.

X Switch on the battery isolating switch

(Y page 87).

X Remove the key from the ignition lock.

X Open the hood (Y page 168).

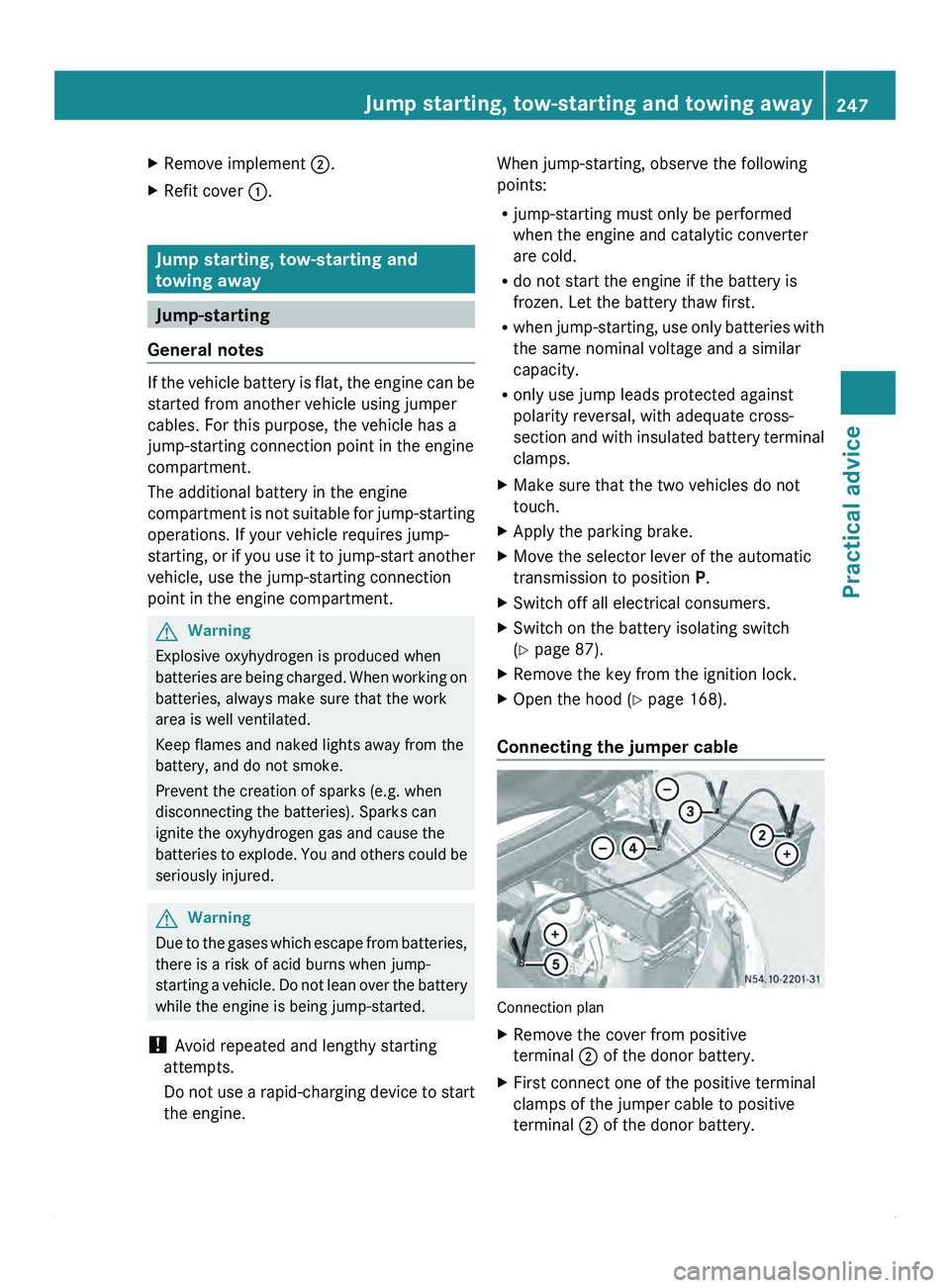

Connecting the jumper cable Connection plan

X

Remove the cover from positive

terminal 0047 of the donor battery.

X First connect one of the positive terminal

clamps of the jumper cable to positive

terminal 0047 of the donor battery. Jump starting, tow-starting and towing away

247

Practical advice Z

Page 250 of 292

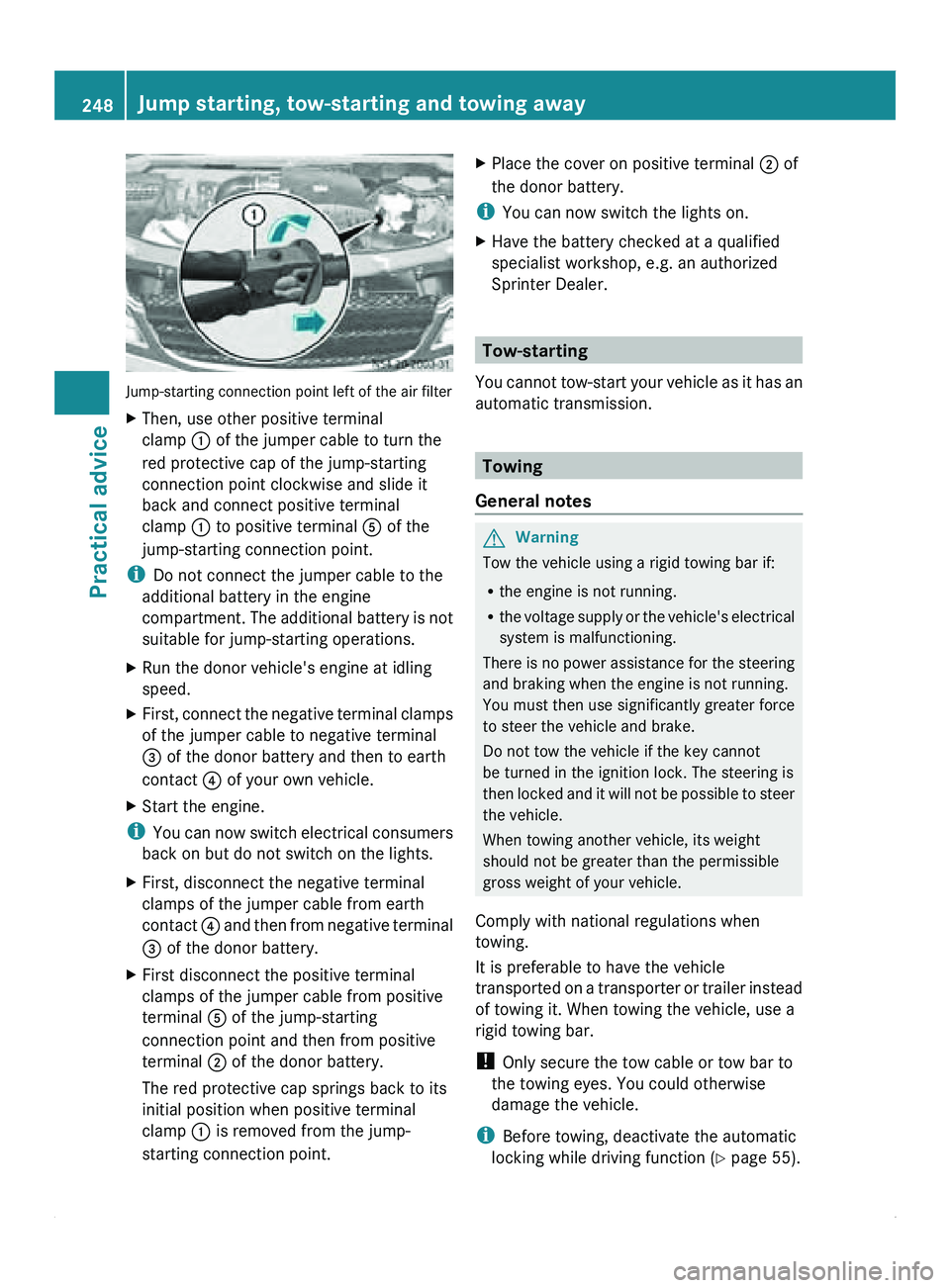

Jump-starting connection point left of the air filter

X

Then, use other positive terminal

clamp 0046 of the jumper cable to turn the

red protective cap of the jump-starting

connection point clockwise and slide it

back and connect positive terminal

clamp 0046 to positive terminal 0086 of the

jump-starting connection point.

i Do not connect the jumper cable to the

additional battery in the engine

compartment. The

additional

battery is not

suitable for jump-starting operations.

X Run the donor vehicle's engine at idling

speed.

X First, connect the negative terminal clamps

of the jumper cable to negative terminal

008A of the donor battery and then to earth

contact 0088 of your own vehicle.

X Start the engine.

i You can

now

switch electrical consumers

back on but do not switch on the lights.

X First, disconnect the negative terminal

clamps of the jumper cable from earth

contact 0088 and then

from negative terminal

008A of the donor battery.

X First disconnect the positive terminal

clamps of the jumper cable from positive

terminal 0086 of the jump-starting

connection point and then from positive

terminal 0047 of the donor battery.

The red protective cap springs back to its

initial position when positive terminal

clamp 0046 is removed from the jump-

starting connection point. X

Place the cover on positive terminal 0047 of

the donor battery.

i You can now switch the lights on.

X Have the battery checked at a qualified

specialist workshop, e.g. an authorized

Sprinter Dealer. Tow-starting

You cannot tow-start

your vehicle as it has an

automatic transmission. Towing

General notes G

Warning

Tow the vehicle using a rigid towing bar if:

R the engine is not running.

R the voltage supply

or the vehicle's electrical

system is malfunctioning.

There is no power assistance for the steering

and braking when the engine is not running.

You must then use significantly greater force

to steer the vehicle and brake.

Do not tow the vehicle if the key cannot

be turned in the ignition lock. The steering is

then locked and it will not be possible to steer

the vehicle.

When towing another vehicle, its weight

should not be greater than the permissible

gross weight of your vehicle.

Comply with national regulations when

towing.

It is preferable to have the vehicle

transported on a transporter or trailer instead

of towing it. When towing the vehicle, use a

rigid towing bar.

! Only secure the tow cable or tow bar to

the towing eyes. You could otherwise

damage the vehicle.

i Before towing, deactivate the automatic

locking while driving function (Y page 55). 248

Jump starting, tow-starting and towing away

Practical advice