clock MERCEDES-BENZ SPRINTER 2014 MY14 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2014Pages: 338, PDF Size: 6.78 MB

Page 257 of 338

X

Place cap 0043on the filler neck and tighten.

When doing so, make sure that the cap

engages correctly.

X Check the oil level with the oil dipstick

(Y page 253) or on the display

(Y page 252).

X Close the hood. Coolant

G

WARNING

The engine cooling system is pressurized, par-

ticularly when the engine is warm. When

opening the cap, you could be scalded by hot

coolant spraying out. There is a risk of injury.

Let the engine cool down before opening the

cap. Wear eye and hand protection when

opening the cap. Open the cap slowly half a

turn to allow pressure to escape.

Only check the coolant level and/or fill the

coolant if the vehicle is on a level surface and

the engine has cooled down. The coolant tem-

perature must be below 122 ‡ (50 †).

! Check the engine cooling and heating sys-

tem regularly for leaks.

If a large quantity of coolant is lost, have

the cause traced and rectified at a qualified

specialist workshop. G

WARNING

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant. See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact with skin, eyes or clothing. In case of

contact with eyes, rinse immediately with

plenty of clean water. Clean affected areas of

skin and clothing with soap and water imme-

diately. Change any affected clothing imme-

diately. G

WARNING

If antifreeze comes into contact with hot com-

ponents in the engine compartment, it may

ignite. There is a risk of fire and injury.

Let the engine cool down before you add anti-

freeze. Make sure that antifreeze is not spilled

next to the filler neck. Thoroughly clean the

antifreeze from components before starting

the engine.

! Take care not to spill any coolant on

painted surfaces. You could otherwise

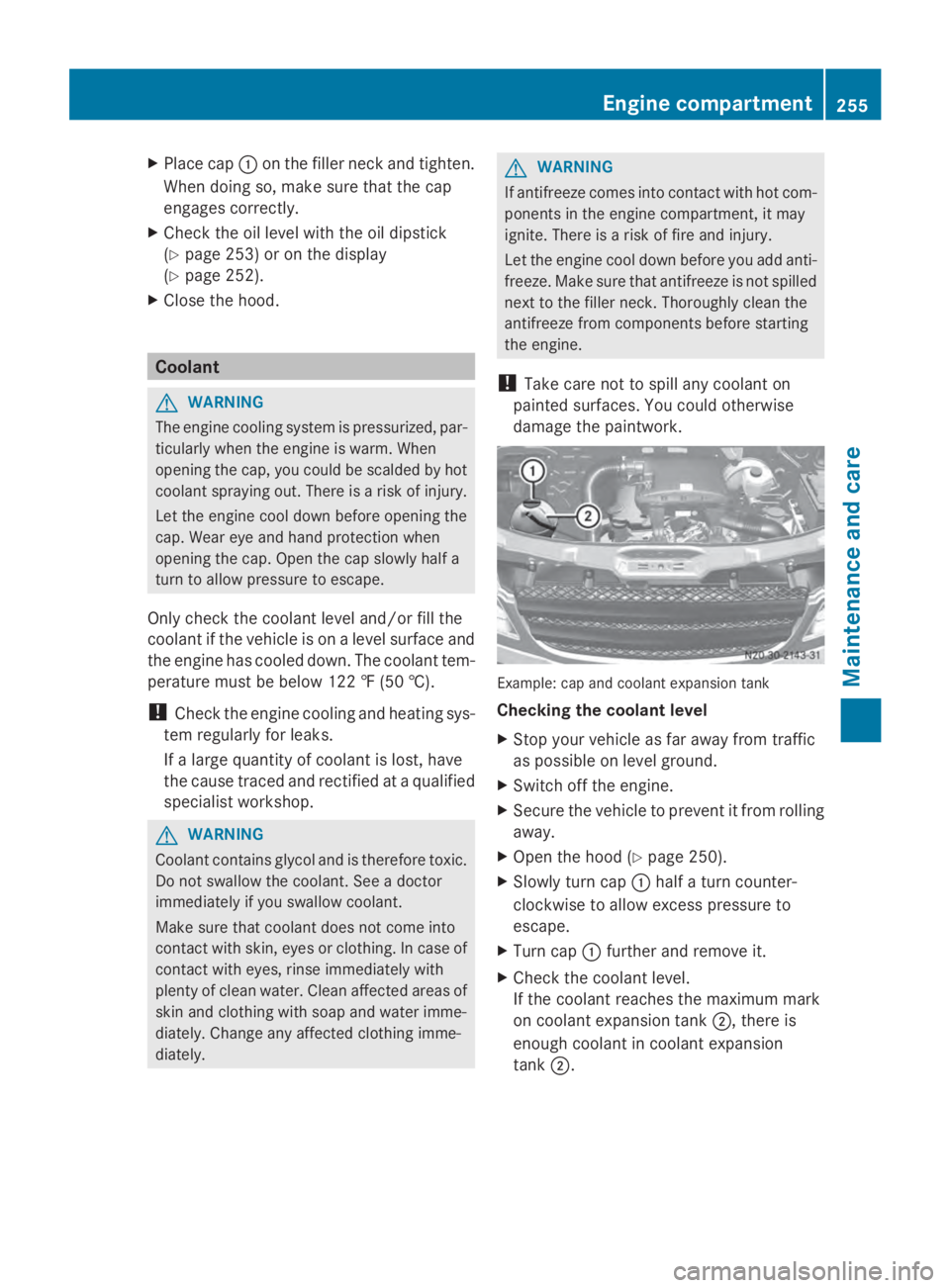

damage the paintwork. Example: cap and coolant expansion tank

Checking the coolant level

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 250).

X Slowly turn cap 0043half a turn counter-

clockwise to allow excess pressure to

escape.

X Turn cap 0043further and remove it.

X Check the coolant level.

If the coolant reaches the maximum mark

on coolant expansion tank 0044, there is

enough coolant in coolant expansion

tank 0044. Engine compartment

255Maintenance and care Z

Page 258 of 338

Adding coolant

X

If the coolant drops under the minimum

mark on coolant expansion tank 0044, add

coolant to the maximum mark.

Observe the information on coolant mix-

ture ratio and water quality in the "Techni-

cal data" section ( Ypage 329). To prevent

damage to the engine cooling system, use

only approved corrosion inhibitor/anti-

freeze that comply with the Mercedes-Benz

Specifications for Service Products.

X Replace cap 0043and turn it clockwise to

tighten.

X Start the engine.

X After approximately 5 minutes, switch off

the engine and allow it to cool down.

X Check the coolant level again and add cool-

ant if necessary.

X Close the hood. Brake fluid

G

WARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

Brake fluid is hazardous to health. Also

observe the safety notes in the "Service prod-

ucts and capacities" section (Y page 320).G

WARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident. You should have the brake fluid renewed at

the specified intervals.

! Brake fluid corrodes paint, plastic and

rubber. If paint, plastic or rubber has come

into contact with brake fluid, rinse with

water immediately.

Have the brake fluid renewed every 2 years

at a qualified specialist workshop. Observe

the information on brake fluid in the "Techni-

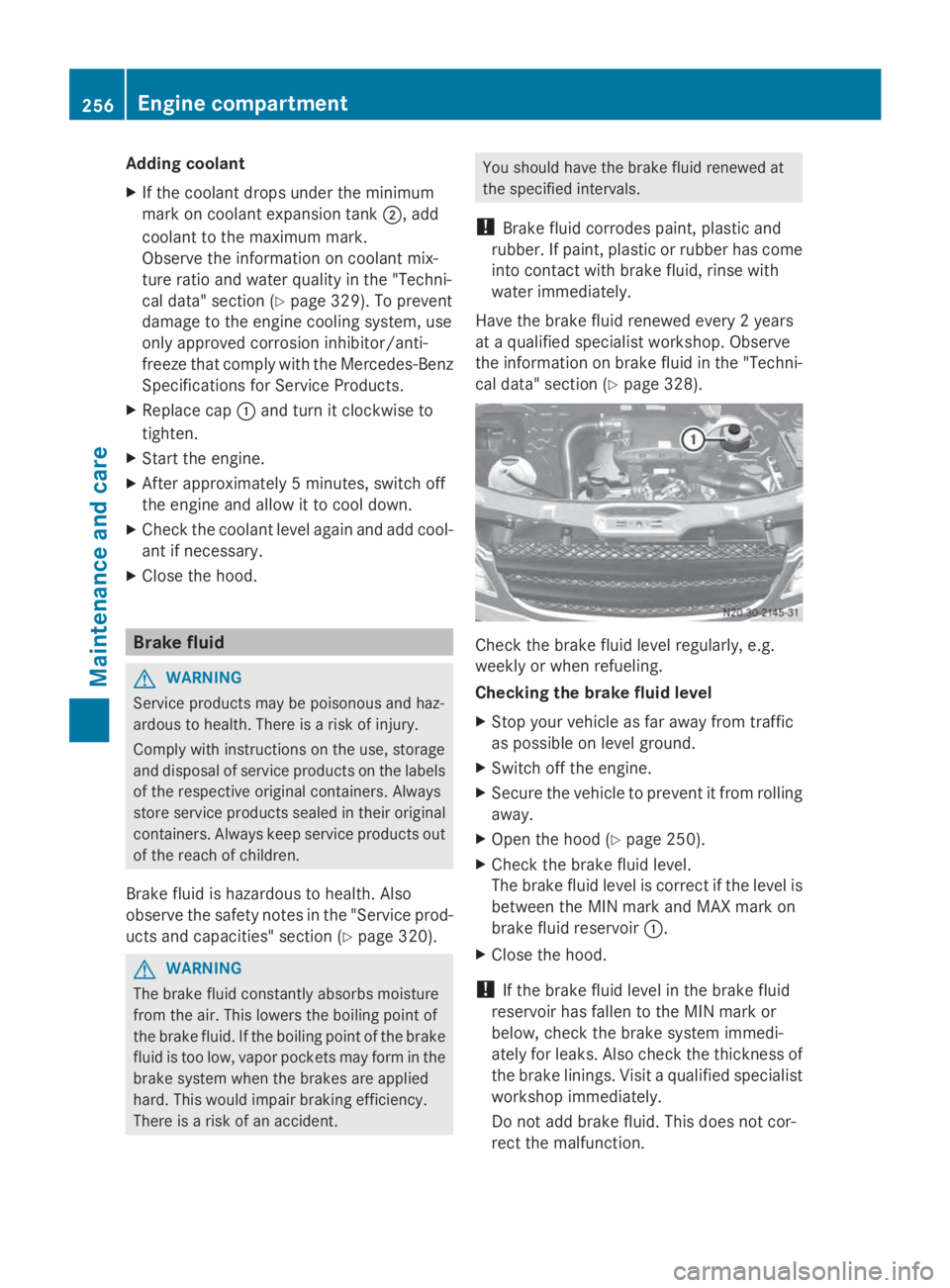

cal data" section ( Ypage 328). Check the brake fluid level regularly, e.g.

weekly or when refueling.

Checking the brake fluid level

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 250).

X Check the brake fluid level.

The brake fluid level is correct if the level is

between the MIN mark and MAX mark on

brake fluid reservoir 0043.

X Close the hood.

! If the brake fluid level in the brake fluid

reservoir has fallen to the MIN mark or

below, check the brake system immedi-

ately for leaks. Also check the thickness of

the brake linings. Visit a qualified specialist

workshop immediately.

Do not add brake fluid. This does not cor-

rect the malfunction. 256

Engine compartmentMaintenance and care

Page 278 of 338

Useful information

This Operator's Manual describes all models

as well as standard and optional equipment

of your vehicle that were available at the time

of going to print. Country-specific variations

are possible. Note that your vehicle may not

be equipped with all of the described func-

tions. This also applies to systems and func-

tions relevant to safety.

Read the information on qualified specialist

workshops (Y page 26). Where will I find...?

Vehicle tool kit

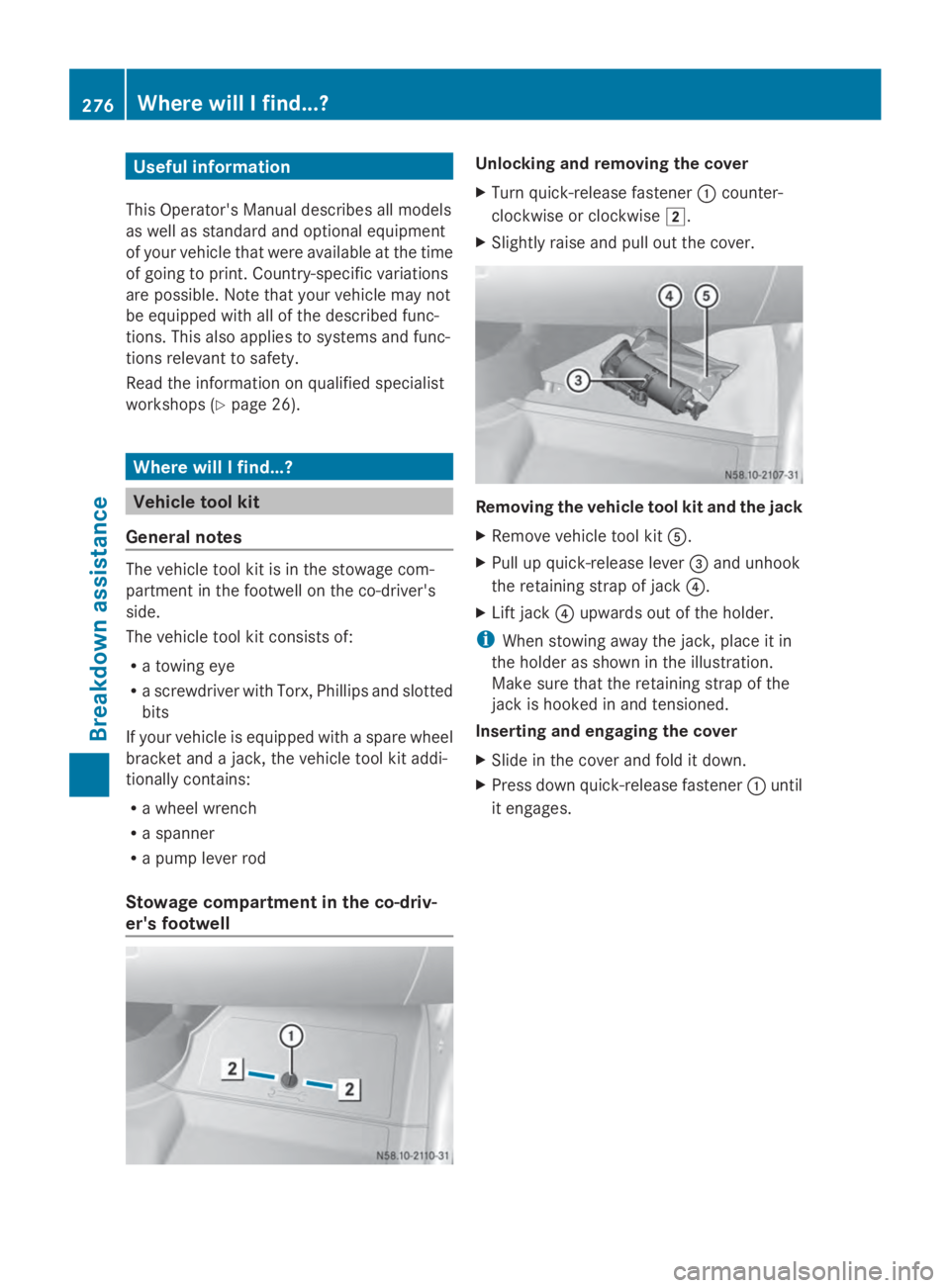

General notes The vehicle tool kit is in the stowage com-

partment in the footwell on the co-driver's

side.

The vehicle tool kit consists of:

R a towing eye

R a screwdriver with Torx, Phillips and slotted

bits

If your vehicle is equipped with a spare wheel

bracket and a jack, the vehicle tool kit addi-

tionally contains:

R a wheel wrench

R a spanner

R a pump lever rod

Stowage compartment in the co-driv-

er's footwell Unlocking and removing the cover

X

Turn quick-release fastener 0043counter-

clockwise or clockwise 0048.

X Slightly raise and pull out the cover. Removing the vehicle tool kit and the jack

X

Remove vehicle tool kit 0083.

X Pull up quick-release lever 0087and unhook

the retaining strap of jack 0085.

X Lift jack 0085upwards out of the holder.

i When stowing away the jack, place it in

the holder as shown in the illustration.

Make sure that the retaining strap of the

jack is hooked in and tensioned.

Inserting and engaging the cover

X Slide in the cover and fold it down.

X Press down quick-release fastener 0043until

it engages. 276

Where will I find...?Breakdown assistance

Page 282 of 338

!

Observe the following points when towing

with a tow rope:

R Secure the tow rope on the same side on

both vehicles.

R Ensure that the tow cable is not longer

than legally permitted. Mark the tow

cable in the middle, e.g. with a white

cloth (30 x 30 cm). This will make other

road users aware that the vehicle is being

towed.

R Only secure the tow cable to the towing

eye.

R Observe the brake lamps of the towing

vehicle while driving. Always maintain a

distance so that the tow rope does not

sag.

R Do not use steel cables or chains to tow

your vehicle. You could otherwise dam-

age the vehicle.

! Do not use the towing eye for recovery,

this could damage the vehicle. If in doubt,

recover the vehicle with a crane.

! When towing, pull away slowly and

smoothly. If the tractive power is too high,

the vehicles could be damaged.

Observe the legal requirements for the rele-

vant country when towing.

It is preferable to have the vehicle trans-

ported on a transporter or trailer instead of

towing it.

The automatic transmission selector lever

must be in the Nposition when towing the

vehicle.

The battery must be connected and charged.

Otherwise, you:

R cannot turn the key in the ignition lock to

position 2

R cannot move the selector lever to position

N on vehicles with automatic transmission.

i Switch off the automatic locking feature

before the vehicle is towed (Y page 71). You

could otherwise lock yourself out of the

vehicle when pushing or towing away the

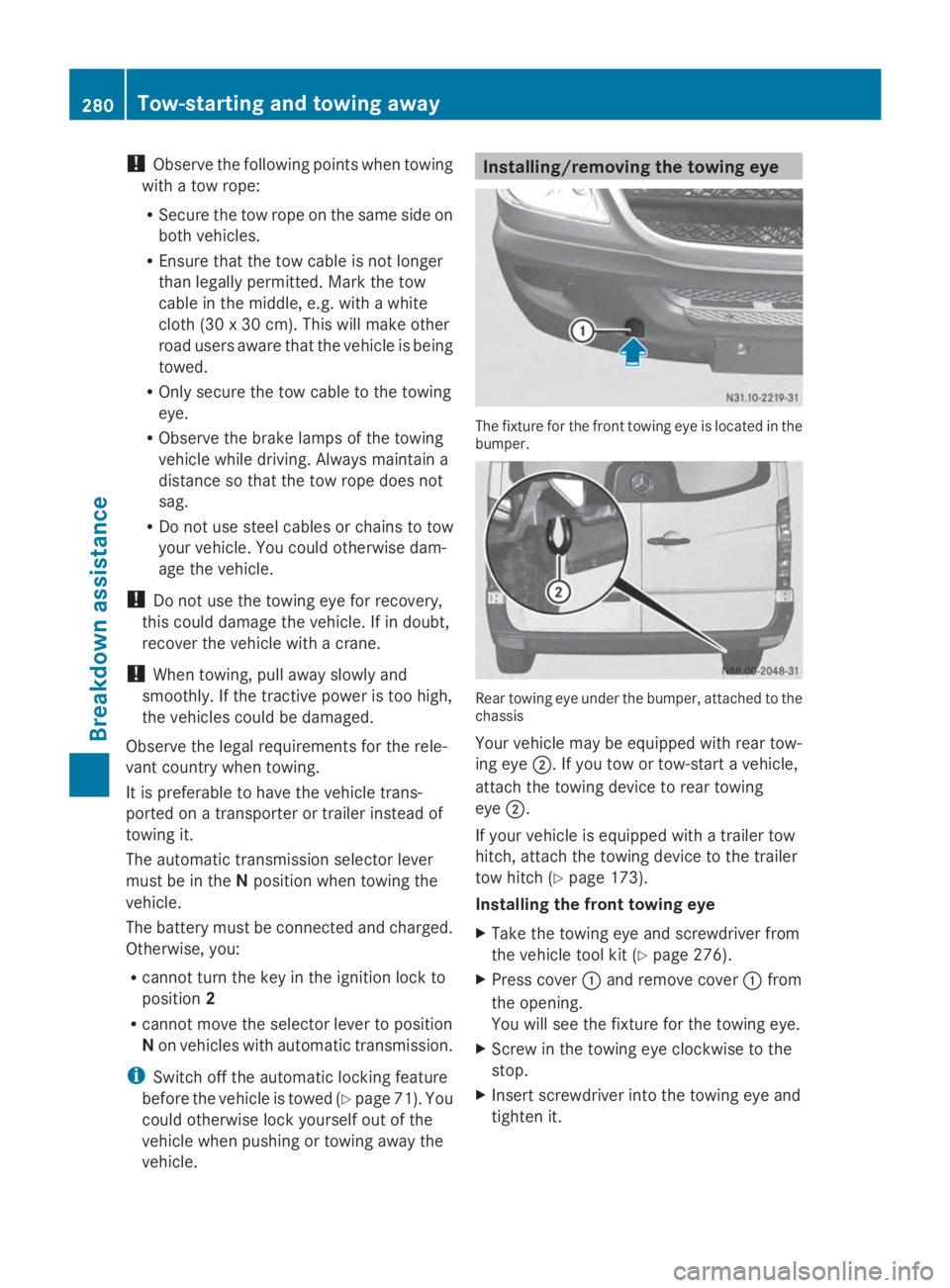

vehicle. Installing/removing the towing eye

The fixture for the front towing eye is located in the

bumper.

Rear towing eye under the bumper, attached to the

chassis

Your vehicle may be equipped with rear tow-

ing eye 0044. If you tow or tow-start a vehicle,

attach the towing device to rear towing

eye 0044.

If your vehicle is equipped with a trailer tow

hitch, attach the towing device to the trailer

tow hitch (Y page 173).

Installing the front towing eye

X Take the towing eye and screwdriver from

the vehicle tool kit (Y page 276).

X Press cover 0043and remove cover 0043from

the opening.

You will see the fixture for the towing eye.

X Screw in the towing eye clockwise to the

stop.

X Insert screwdriver into the towing eye and

tighten it. 280

Tow-starting and towing awayBreakdown assistance

Page 283 of 338

Removing the front towing eye

X

Remove the screwdriver from the vehicle

tool kit.

X Insert the screwdriver into the towing eye

and turn the screwdriver counter-clock-

wise.

X Unscrew the towing eye.

X Insert cover 0043with the lug at the bottom

and press it in at the top until it engages.

X Place the towing eye and screwdriver back

in the vehicle tool kit. Towing in the event of malfunctions

With transmission damage !

Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed at a qualified specialist workshop.

If the vehicle has transmission damage, have

the propeller shaft removed before towing

away.

In the event of damage to the electrical

system If the battery is defective, the automatic

transmission will be locked in position P. In

order to be able to shift the automatic trans-

mission to position N, you must provide

power to the vehicle's 12 V electrical system

in the same way as when jump-starting

(Y page 278).

Have the vehicle transported on a transporter

or trailer. Towing with the front or rear axle

raised

General notes !

The ignition must be switched off if the

vehicle is being towed with the front or rear axle raised. Otherwise, ESP

®

may intervene

and damage the brake system.

! Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed at a qualified specialist workshop.

Observe the following before towing a vehicle

with a raised front or rear axle:

R the information on towing in the event of

malfunctions (Y page 281) and

R the important safety notes (Y page 279).

If the front axle is damaged, raise the vehicle

at the front axle and if the rear axle is dam-

aged, raise the vehicle at the rear axle.

Towing If the front axle is raised, the vehicle may be

towed a maximum of 30 miles

(50 km). For a

towing distance of over 30 miles (50 km), you

must remove the propeller shafts to the

driven axles.

X Turn the key to position 2in the ignition

lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake.

X Turn the key to position 1in the ignition

lock and leave it in this position.

X Switch on the hazard warning lamps

(Y page 96).

X If the front axle is raised, do not exceed the

towing speed of 30 mph (50 km/h) and the

towing distance of 30 miles (50 km). Tow-starting and towing away

281Breakdown assistance Z

Page 312 of 338

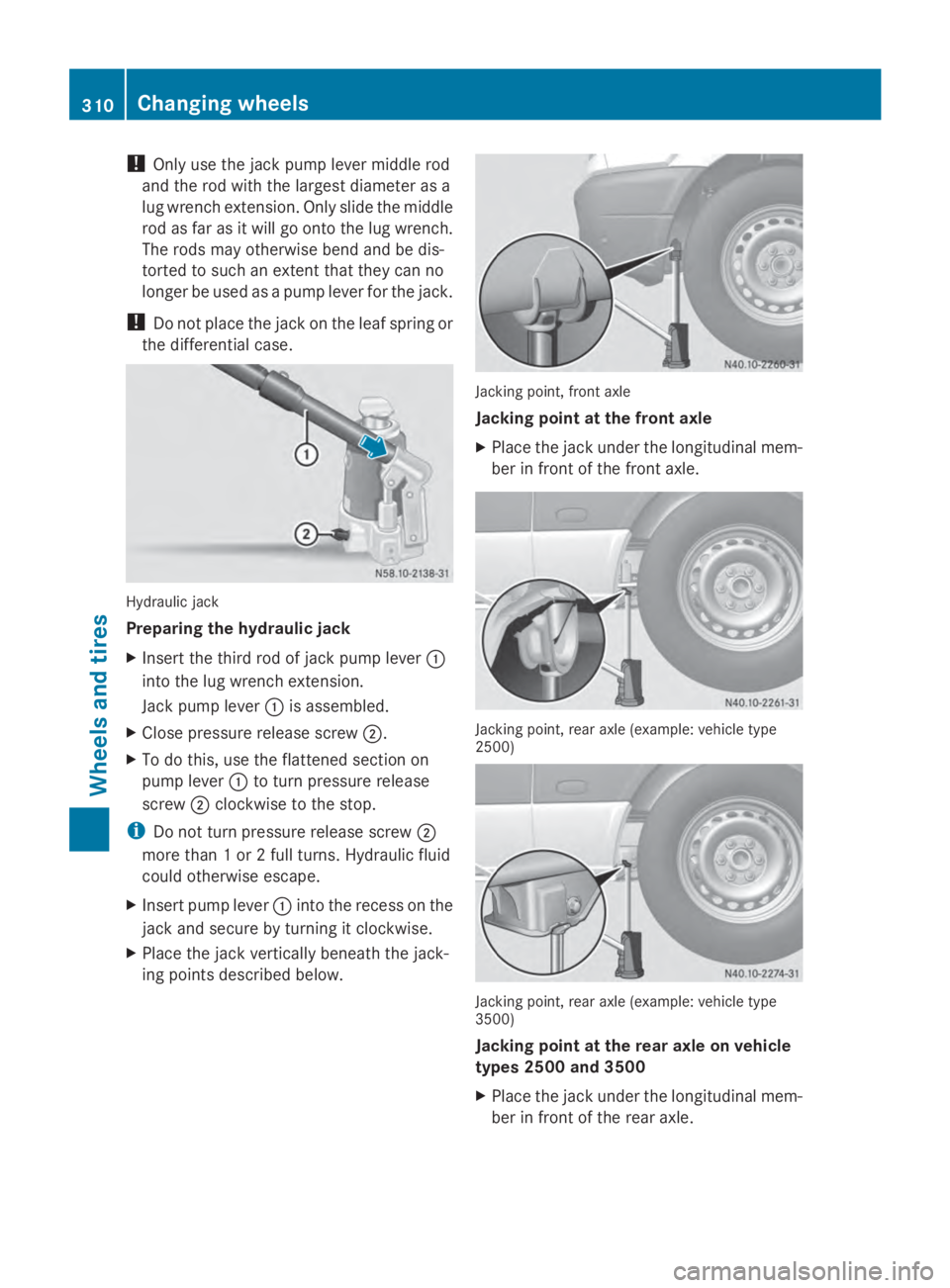

!

Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be dis-

torted to such an extent that they can no

longer be used as a pump lever for the jack.

! Do not place the jack on the leaf spring or

the differential case. Hydraulic jack

Preparing the hydraulic jack

X

Insert the third rod of jack pump lever 0043

into the lug wrench extension.

Jack pump lever 0043is assembled.

X Close pressure release screw 0044.

X To do this, use the flattened section on

pump lever 0043to turn pressure release

screw 0044clockwise to the stop.

i Do not turn pressure release screw 0044

more than 1 or 2 full turns. Hydraulic fluid

could otherwise escape.

X Insert pump lever 0043into the recess on the

jack and secure by turning it clockwise.

X Place the jack vertically beneath the jack-

ing points described below. Jacking point, front axle

Jacking point at the front axle

X

Place the jack under the longitudinal mem-

ber in front of the front axle. Jacking point, rear axle (example: vehicle type

2500)

Jacking point, rear axle (example: vehicle type

3500)

Jacking point at the rear axle on vehicle

types 2500 and 3500

X Place the jack under the longitudinal mem-

ber in front of the rear axle. 310

Changing wheelsWheels and tires

Page 316 of 338

R

only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum speed of

80 km/h. General notes

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

The procedure for mounting the spare wheel

is described in "Mounting a wheel"

(Y page 308).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 290).

R the fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6 years at the latest,

regardless of wear. This also applies to the

spare wheel.

i If you have mounted a spare wheel, the

tire pressure monitor (Y page 293) will not

function for this wheel. The spare wheel is

not equipped with a sensor for monitoring

tire pressure. Removing and installing the spare

wheel

Cargo Van/Passenger Van Bolt covers for the safety catches (example: Cargo

Van)

Removing

X

Open the rear doors.

X Place a screwdriver into recesses 0044and

then prise off covers 0043.

X Using the lug wrench from the vehicle tool

kit (Y page 276), unscrew the now visible

bolts counter-clockwise by approximately

20 turns. Spare wheel carrier under the vehicle

X Slightly raise spare wheel bracket 0083and

unhook left-hand retaining hook 0087.

X Assemble the pump lever for the jack and

slide it into sleeve 0085on spare wheel

bracket 0083.

X Raise spare wheel bracket 0083with the

pump lever and unhook right-hand retain-

ing hook 0087. 314

Spare wheelWheels and tires

Page 317 of 338

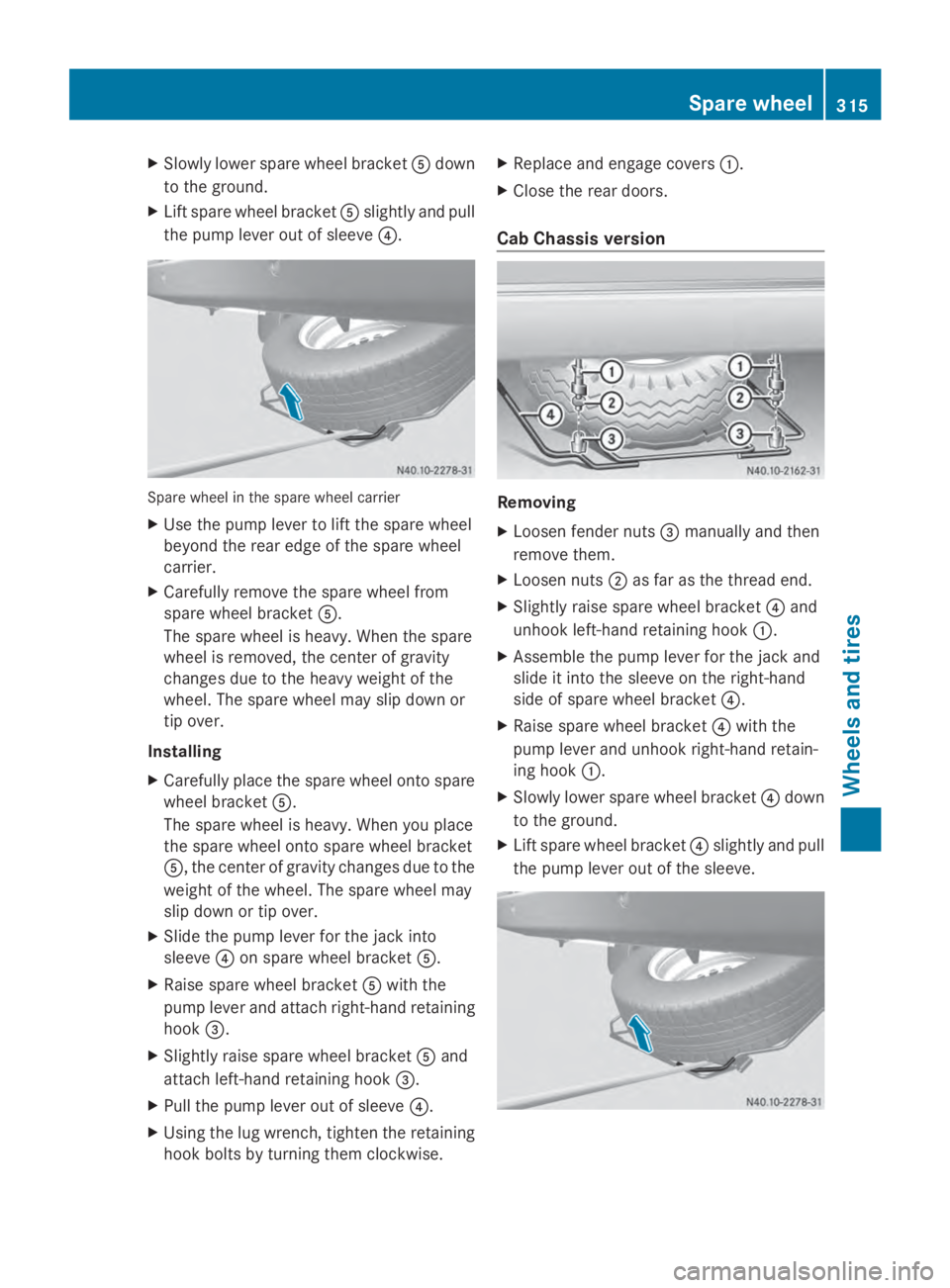

X

Slowly lower spare wheel bracket 0083down

to the ground.

X Lift spare wheel bracket 0083slightly and pull

the pump lever out of sleeve 0085.Spare wheel in the spare wheel carrier

X Use the pump lever to lift the spare wheel

beyond the rear edge of the spare wheel

carrier.

X Carefully remove the spare wheel from

spare wheel bracket 0083.

The spare wheel is heavy. When the spare

wheel is removed, the center of gravity

changes due to the heavy weight of the

wheel. The spare wheel may slip down or

tip over.

Installing

X Carefully place the spare wheel onto spare

wheel bracket 0083.

The spare wheel is heavy. When you place

the spare wheel onto spare wheel bracket

0083, the center of gravity changes due to the

weight of the wheel. The spare wheel may

slip down or tip over.

X Slide the pump lever for the jack into

sleeve 0085on spare wheel bracket 0083.

X Raise spare wheel bracket 0083with the

pump lever and attach right-hand retaining

hook 0087.

X Slightly raise spare wheel bracket 0083and

attach left-hand retaining hook 0087.

X Pull the pump lever out of sleeve 0085.

X Using the lug wrench, tighten the retaining

hook bolts by turning them clockwise. X

Replace and engage covers 0043.

X Close the rear doors.

Cab Chassis version Removing

X

Loosen fender nuts 0087manually and then

remove them.

X Loosen nuts 0044as far as the thread end.

X Slightly raise spare wheel bracket 0085and

unhook left-hand retaining hook 0043.

X Assemble the pump lever for the jack and

slide it into the sleeve on the right-hand

side of spare wheel bracket 0085.

X Raise spare wheel bracket 0085with the

pump lever and unhook right-hand retain-

ing hook 0043.

X Slowly lower spare wheel bracket 0085down

to the ground.

X Lift spare wheel bracket 0085slightly and pull

the pump lever out of the sleeve. Spare wheel

315Wheels and tires Z