ESP MERCEDES-BENZ SPRINTER 2014 MY14 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2014Pages: 338, PDF Size: 6.78 MB

Page 245 of 338

Always observe the operating instructions of

the respective manufacturer when using suit-

able load securing aids or tie downs. In par-

ticular, the information on service life.

Load securing aids and tie downs may not be

used, for example, if:

R identification marks are missing or illegible

R there are yarn breakages, damage to bear-

ing seams or other signs of tearing

R there are signs of shearing, deformation,

pinching or other damage

R there is damage to clamping or connecting

elements

Such load securing aids and tie downs are

worn; they should not be used and must be

replaced. If you use load securing aids or tie

downs which are worn, the load may not be

sufficiently secured and could cause damage

to property.

After an accident, the following must be

checked at a specialist workshop:

R Cargo compartment floor

R Load surface

R Cargo tie-down rings

R Tie downs

Otherwise, the load may not be correctly

secured the next time anything is stowed.

Even if you follow all loading guidelines, the

load increases the risk of injury in the event

of an accident. Observe the tips in the "Secur-

ing luggage/loads" (Y page 244) and "Load

distribution" (Y page 244) sections. Before loading

! The anti-slip mats cannot be used for

securing goods and must be replaced when

they show signs of:

R Permanent deformation and crushing

R Crack formation

R Cuts X

Tire pressure: check the tire pressure and

correct if necessary ( Ypage 290).

X Cargo compartment floor: clean the

cargo compartment floor.

The cargo compartment floor must be free

from oil and dust, dry and swept clean to

prevent the load from slipping.

X Place non-slip mats (anti-slip mats) on the

cargo compartment floor if necessary. During loading

! On passenger van versions with maxi-

mum seating layout, the permissible rear

axle load would be exceeded if the full pay-

load were to be loaded in the cargo com-

partment.

X Observe the gross axle weight rating and

permissible gross vehicle weight for your

vehicle.

Take into account that your vehicle's curb

weight is increased if accessories or

optional equipment are installed. The max-

imum payload is thus reduced.

X Observe the notes on load distribution

(Y page 244).

The overall center of gravity of the load

should always be as low as possible, cen-

tered and between the axles near the rear

axle.

X Secure the load (Y page 244).

Always observe the relevant country-spe-

cific legal requirements, laws and regula-

tions. Checks after loading

G

WARNING

Combustion engines emit poisonous exhaust

gases, such as carbon monoxide. If the sliding

door or rear door is open when the engine is

running, exhaust gases can enter the vehicle

interior, especially during the journey. There

is a risk of poisoning. Loading guidelines

243Transporting loads

Z

Page 247 of 338

maximum loading capacity of the weakest

cargo tie-down point into account.

If you brake hard, for example, the forces

acting could be up to several times the

weight force of the load. Always use multi-

ple cargo tie-down points in order to dis-

tribute the force absorption. Load the

anchorages evenly.

Spread the load evenly between the cargo tie-

down points or tie-down rings.

Please also refer to the notes about qualified

specialist workshops (Y page 26).

Always observe the operating instructions or

the notes of the lashing strap manufacturer

for the operation of the lashing strap.

Information about the maximum loading

capacity of the cargo tie-down points can be

found in the "Technical data" section

(Y page 331).

As the driver, you are responsible for ensuring

that:

R The applicable requirements and guide-

lines relating to load-securing practices

must be met.

If this is not the case, this may constitute a

punishable offense, depending on local leg-

islation and any ensuing consequences.

You should therefore observe the respec-

tive legal requirements for the relevant

country.

Make sure that the load is secure before every

journey and at regular intervals during a long

journey. Correct an incorrectly or inade-

quately secured load if necessary.

You can obtain information about securing

the load correctly from the manufacturer of

the load securing aids or tie down for securing

the load.

X Fill spaces between the load and the cargo

compartment walls or wheel housings

(form-locking). Use rigid load securing aids,

such as wedges, wooden fixings or pad-

ding.

X Attach secured and stabilized loads in all

directions. Use the cargo tie-down points or cargo tie-down rings and the loading rails

in the cargo compartment or on the cargo

area.

Only use tie downs, such as lashing rods or

lashing nets and lashing straps, that have

been tested in accordance with current

standards (e.g. DIN EN).

Always use the cargo tie-down rings closest

to the load to secure it and pad sharp edges

for protection.

Loads, and heavy loads in particular, should

preferably be secured using the cargo tie-

down rings.

i Tie downs tested in accordance with cur-

rent standards (e.g. DIN EN) are available

at any qualified specialist workshop. Cargo tie-down point (example: Passenger Van)

0043

Cargo tie-down rings Securing loads

245Transporting loads Z

Page 258 of 338

Adding coolant

X

If the coolant drops under the minimum

mark on coolant expansion tank 0044, add

coolant to the maximum mark.

Observe the information on coolant mix-

ture ratio and water quality in the "Techni-

cal data" section ( Ypage 329). To prevent

damage to the engine cooling system, use

only approved corrosion inhibitor/anti-

freeze that comply with the Mercedes-Benz

Specifications for Service Products.

X Replace cap 0043and turn it clockwise to

tighten.

X Start the engine.

X After approximately 5 minutes, switch off

the engine and allow it to cool down.

X Check the coolant level again and add cool-

ant if necessary.

X Close the hood. Brake fluid

G

WARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

Brake fluid is hazardous to health. Also

observe the safety notes in the "Service prod-

ucts and capacities" section (Y page 320).G

WARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident. You should have the brake fluid renewed at

the specified intervals.

! Brake fluid corrodes paint, plastic and

rubber. If paint, plastic or rubber has come

into contact with brake fluid, rinse with

water immediately.

Have the brake fluid renewed every 2 years

at a qualified specialist workshop. Observe

the information on brake fluid in the "Techni-

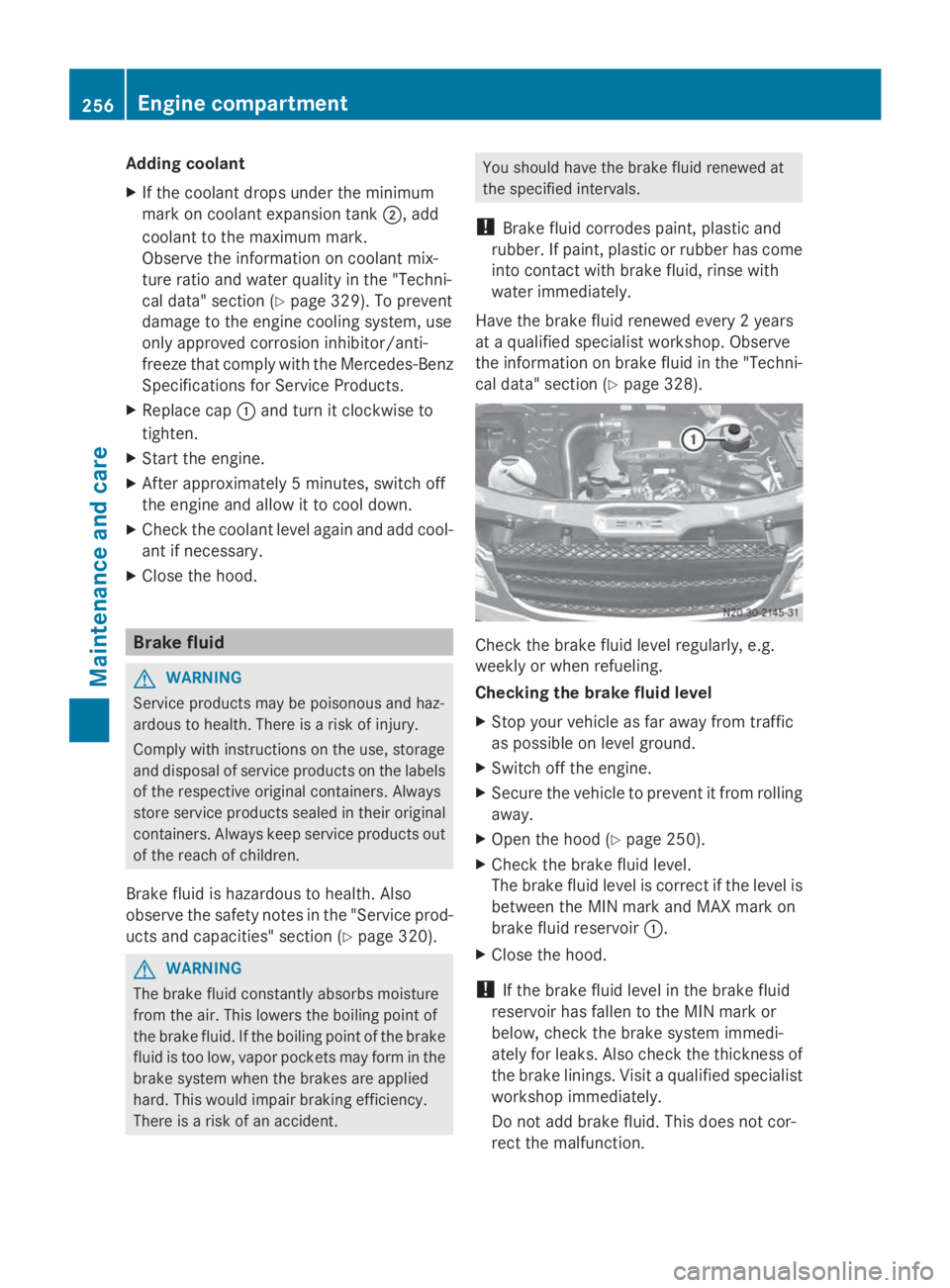

cal data" section ( Ypage 328). Check the brake fluid level regularly, e.g.

weekly or when refueling.

Checking the brake fluid level

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 250).

X Check the brake fluid level.

The brake fluid level is correct if the level is

between the MIN mark and MAX mark on

brake fluid reservoir 0043.

X Close the hood.

! If the brake fluid level in the brake fluid

reservoir has fallen to the MIN mark or

below, check the brake system immedi-

ately for leaks. Also check the thickness of

the brake linings. Visit a qualified specialist

workshop immediately.

Do not add brake fluid. This does not cor-

rect the malfunction. 256

Engine compartmentMaintenance and care

Page 259 of 338

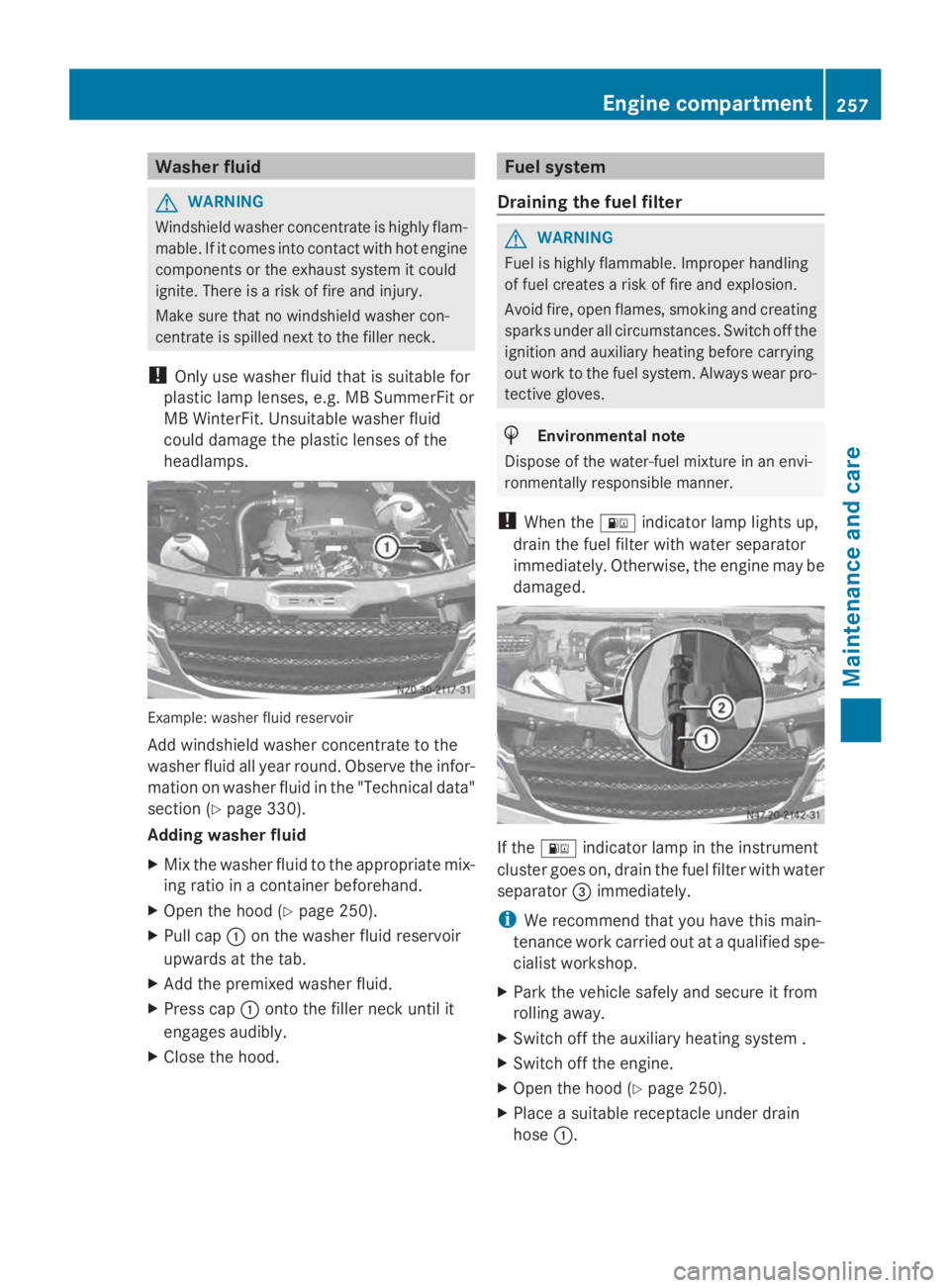

Washer fluid

G

WARNING

Windshield washer concentrate is highly flam-

mable. If it comes into contact with hot engine

components or the exhaust system it could

ignite. There is a risk of fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of the

headlamps. Example: washer fluid reservoir

Add windshield washer concentrate to the

washer fluid all year round. Observe the infor-

mation on washer fluid in the "Technical data"

section (Y

page 330).

Adding washer fluid

X Mix the washer fluid to the appropriate mix-

ing ratio in a container beforehand.

X Open the hood (Y page 250).

X Pull cap 0043on the washer fluid reservoir

upwards at the tab.

X Add the premixed washer fluid.

X Press cap 0043onto the filler neck until it

engages audibly.

X Close the hood. Fuel system

Draining the fuel filter G

WARNING

Fuel is highly flammable. Improper handling

of fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

ignition and auxiliary heating before carrying

out work to the fuel system. Always wear pro-

tective gloves. H

Environmental note

Dispose of the water-fuel mixture in an envi-

ronmentally responsible manner.

! When the 00B8indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged. If the

00B8 indicator lamp in the instrument

cluster goes on, drain the fuel filter with water

separator 0087immediately.

i We recommend that you have this main-

tenance work carried out at a qualified spe-

cialist workshop.

X Park the vehicle safely and secure it from

rolling away.

X Switch off the auxiliary heating system .

X Switch off the engine.

X Open the hood (Y page 250).

X Place a suitable receptacle under drain

hose 0043. Engine compartment

257Maintenance and care Z

Page 260 of 338

X

Turn the key to position 2in the ignition

lock.

X Open drain plug 0044immediately until the

water/fuel mixture flows out of drain

hose 0043.

X Screw in drain plug 0044as soon as approx-

imately 0.2 US qt (0.2 l) of the water/fuel

mixture have been collected.

i The electrical fuel pump halts the flow of

the water/fuel mixture after 30 seconds.

X After draining, turn the key back to posi-

tion 0in the ignition lock.

X Dispose of the collected water/fuel mix-

ture in an environmentally responsible

manner, e.g. at a qualified specialist work-

shop.

X Check drain plug 0044. The drain plug must

be closed.

When the engine is running and drain

hose 0044is open, fuel is lost through drain

hose 0043.

X Close the hood.

If the 00B8 indicator lamp does not go out

after draining:

X Drain the fuel filter again.

X If the 00B8 indicator lamp does not go out

after draining for the second time, have the

cause checked immediately at a qualified

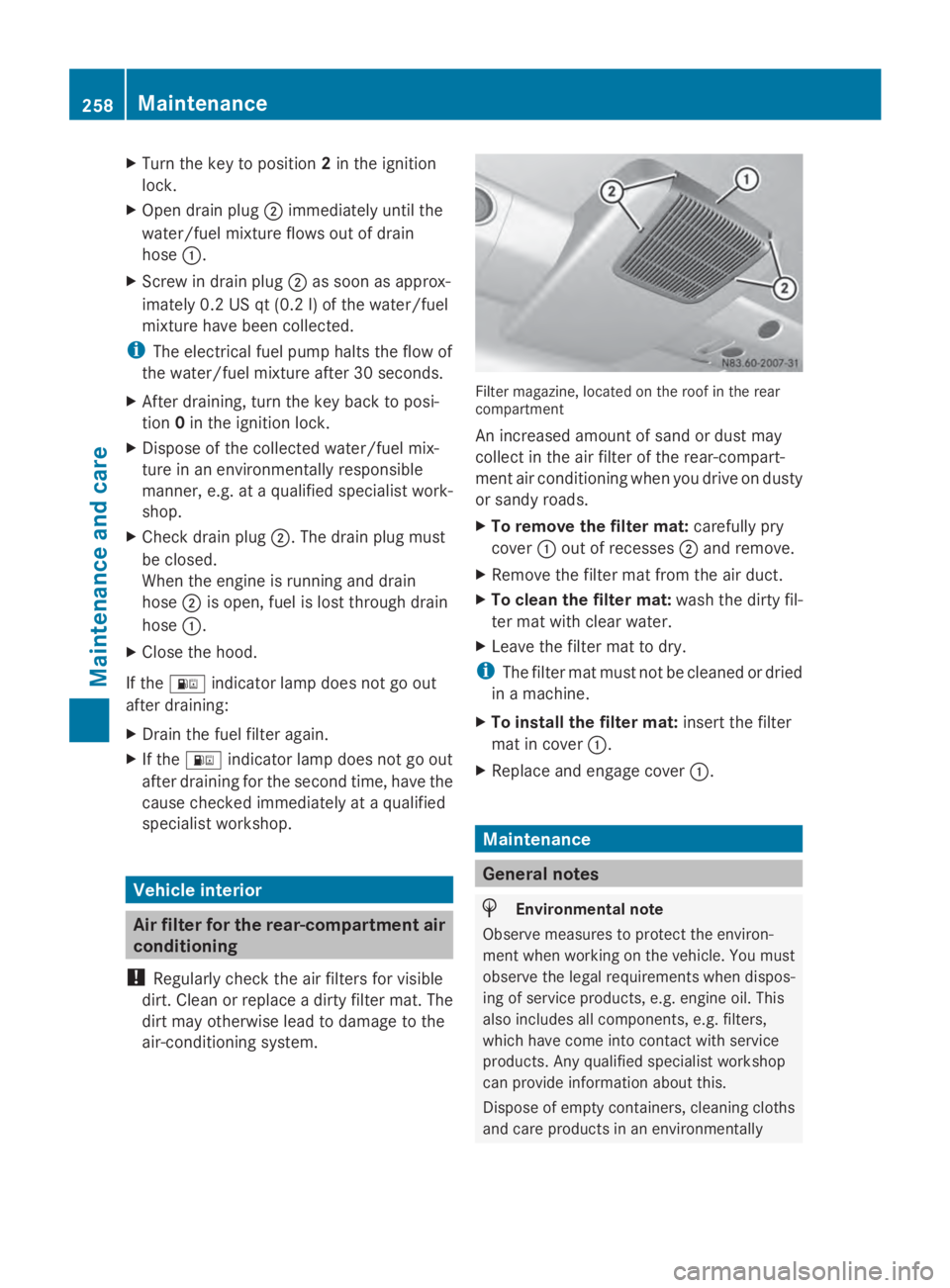

specialist workshop. Vehicle interior

Air filter for the rear-compartment air

conditioning

! Regularly check the air filters for visible

dirt. Clean or replace a dirty filter mat. The

dirt may otherwise lead to damage to the

air-conditioning system. Filter magazine, located on the roof in the rear

compartment

An increased amount of sand or dust may

collect in the air filter of the rear-compart-

ment air conditioning when you drive on dusty

or sandy roads.

X

To remove the filter mat: carefully pry

cover 0043out of recesses 0044and remove.

X Remove the filter mat from the air duct.

X To clean the filter mat: wash the dirty fil-

ter mat with clear water.

X Leave the filter mat to dry.

i The filter mat must not be cleaned or dried

in a machine.

X To install the filter mat: insert the filter

mat in cover 0043.

X Replace and engage cover 0043. Maintenance

General notes

H

Environmental note

Observe measures to protect the environ-

ment when working on the vehicle. You must

observe the legal requirements when dispos-

ing of service products, e.g. engine oil. This

also includes all components, e.g. filters,

which have come into contact with service

products. Any qualified specialist workshop

can provide information about this.

Dispose of empty containers, cleaning cloths

and care products in an environmentally 258

MaintenanceMaintenance and care

Page 261 of 338

responsible manner. Comply with the instruc-

tions for use of the care products.

Do not run the engine for longer than neces-

sary when the vehicle is stationary.

Before having maintenance and repairs per-

formed, it is essential to read the materials

related to the maintenance and repairs:

R the applicable sections of the technical

documentation, e.g. the Operator's Manual

and workshop information.

R regulations such as industrial safety regu-

lations and accident prevention regula-

tions.

While working under the vehicle, you must

secure the vehicle on jack stands with suffi-

cient load capacity.

Never use the jack as a substitute. the vehi-

cle's jack is intended only to raise the vehicle

for a short time when changing a wheel. It is

not suited for performing maintenance work

under the vehicle.

Please also refer to the notes about qualified

specialist workshops (Y page 26).

The scope and regularity of the inspection

and maintenance work primarily depend on

the often diverse operating conditions. Spe-

cialist knowledge beyond the scope of this

Operator's Manual is required when carrying

out testing and maintenance work. This work

should only be carried out by trained staff.

The vehicle's Maintenance Booklet describes

the extent and frequency of the maintenance

work and contains additional information on

the New Vehicle Limited Warranty and on the

service products.

i Maintenance services must be carried out

in accordance with the provisions and rec-

ommendations in the Maintenance Book-

let.

Not doing so could void the warranty claim

and lead to refusal of goodwill gestures

after the manufacturer has submitted a

damage report. i

Observe the information on Sprinter orig-

inal parts in the "Technical data" section

(Y page 318). Service interval display

General notes A service that is due is displayed in the service

interval display about 1 month in advance. A

message is then displayed while the vehicle

is in motion or when the ignition is switched

on.

i

The service interval display does not pro-

vide information about the oil level. The

service interval display should therefore

not be confused with the 00B3engine oil

level display.

The service due date is displayed in days or

miles (kilometers), depending on the total

distance driven.

The symbols or letters on the service display

show the type of service that is due.

0099 orA

A for a minor service

009A orB B for a major service

Service due date display Vehicles with steering wheel buttons:

the

following messages may be displayed.

R 0099 Service A due in ... days

Service A due in ... days

R 0099 Service A due in ... mi Service A due in ... mi (kmkm)

R 0099 Service A Carry out now

Service A Carry out now

Vehicles without steering wheel buttons:

the following messages may be displayed.

R 0099 for service A

R 009A for Service B

Additionally, you will see the remaining dis-

tance in miles (mi mi) or kilometers (km km) or the

remaining time in days (d d). Maintenance

259Maintenance and care Z

Page 269 of 338

If you do not unscrew the caps for cleaning,

there is a risk of short circuit.

The breathers in the caps and the cell ven-

tilation tubes must be open. Otherwise, gas

cannot escape.

X Only clean the battery casing with a com-

mercially available cleaning product. Care

Notes on care

G

WARNING

If you use openings in the bodywork or

detachable parts as steps, you could:

R slip and/or fall

R damage the vehicle and cause yourself to

fall.

There is a risk of injury.

Always use secure climbing aids, e.g. a suita-

ble ladder.

! For cleaning your vehicle, do not use any

of the following:

R dry, rough or hard cloths

R abrasive cleaning agents

R solvents

R cleaning agents containing solvents

Do not scrub.

Do not touch the surfaces or protective

films with hard objects, e.g. a ring or ice

scraper. You could otherwise scratch or

damage the surfaces and protective film.

! Do not park the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after clean-

ing. Braking heats the brake discs and the

brake pads/linings, thus drying them. The

vehicle can then be parked. H

Environmental note

Only clean your vehicle at specially designed

wash bays. Dispose of empty containers and

used cleaning products in an environmentally

responsible manner. H

Environmental note

Dispose of empty packaging and cleaning

cloths in an environmentally responsible man-

ner.

Regular care of your vehicle is a condition for

retaining the quality in the long term.

Use care products and cleaning agents rec-

ommended and approved for Sprinter vehi-

cles. Washing the vehicle and cleaning the

paintwork

Automatic car wash G

WARNING

Braking efficiency is reduced after washing

the vehicle. There is a risk of an accident.

After the vehicle has been washed, brake

carefully while paying attention to the traffic

conditions until full braking power is restored.

! Never clean your vehicle in a Touchless

Automatic Car Wash as these use special

cleaning agents. These cleaning agents can

damage the paintwork or plastic parts.

! Make sure that the automatic car wash is

suitable for the size of the vehicle.

Before washing the vehicle in an automatic

car wash, fold in the exterior mirrors and

remove any additional antennas. Other-

wise, the exterior mirror, antenna or the

vehicle itself could be damaged.

Make sure that the exterior mirrors are fully

folded out again and that any additional

antennas are re-installed when you leave

the automatic car wash. Care

267Maintenance and care Z

Page 270 of 338

!

Make sure that:

R the side windows and the roof are com-

pletely closed

R the climate control blower is switched off

R the windshield wiper switch is at position

0

The vehicle could otherwise be damaged.

You can wash the vehicle in an automatic car

wash from the very start.

Wash off excess dirt before cleaning the vehi-

cle in an automatic car wash.

After putting the vehicle through an auto-

matic car wash, wipe off wax from:

R the rear view camera lens (Y page 271)

R the windshield

R the windshield wiper blades

This will prevent smears and reduce wiping

noises caused by residue on the wind-

shield.

Washing by hand In some countries, washing by hand is only

allowed at specially equipped washing bays.

Observe the legal requirements for each indi-

vidual country.

X Do not use hot water and do not wash the

vehicle in direct sunlight.

X Use a soft car sponge.

X Use a mild cleaning agent, e.g. a car sham-

poo approved for use with Sprinter vehi-

cles.

X Thoroughly hose down the vehicle with a

gentle jet of water.

X Do not point the water jet directly towards

the air inlets.

X Use plenty of water and rinse out the

sponge frequently.

X Rinse the vehicle with clean water and dry

thoroughly with a chamois.

X Do not let the cleaning agents dry on the

paintwork. When using the vehicle in winter, remove all

traces of road salt deposits carefully and as

soon as possible.

High-pressure cleaning equipment G

WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage

to the tires or chassis components. Compo-

nents damaged in this way may fail unexpect-

edly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced imme-

diately.

! Under no circumstances use power wash-

ers in the vehicle interior. The pressurized

water and associated spray produced by

the power washer could cause extensive

damage to the vehicle.

! Observe the minimum distance to be

maintained between the nozzle of the

power washer and object to be cleaned, as

outlined below:

R approximately 2.2 ft(70 cm) when using

round-jet nozzles

R approximately 1 ft (30 cm) when using

25°flat-spray jets and dirt blasters

Keep the water jet moving while cleaning.

To avoid causing damage, do not point the

water jet directly at:

R door joints

R brake hoses

R electrical components

R electrical connections

R seals

R drive train, especially not at the inter-

mediate bearing of the propeller shaft

R rear view camera (camera lens and

microphone opening on the bottom)

Keep a minimum distance of

1.6 ft(50 cm). 268

CareMaintenance and care

Page 283 of 338

Removing the front towing eye

X

Remove the screwdriver from the vehicle

tool kit.

X Insert the screwdriver into the towing eye

and turn the screwdriver counter-clock-

wise.

X Unscrew the towing eye.

X Insert cover 0043with the lug at the bottom

and press it in at the top until it engages.

X Place the towing eye and screwdriver back

in the vehicle tool kit. Towing in the event of malfunctions

With transmission damage !

Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed at a qualified specialist workshop.

If the vehicle has transmission damage, have

the propeller shaft removed before towing

away.

In the event of damage to the electrical

system If the battery is defective, the automatic

transmission will be locked in position P. In

order to be able to shift the automatic trans-

mission to position N, you must provide

power to the vehicle's 12 V electrical system

in the same way as when jump-starting

(Y page 278).

Have the vehicle transported on a transporter

or trailer. Towing with the front or rear axle

raised

General notes !

The ignition must be switched off if the

vehicle is being towed with the front or rear axle raised. Otherwise, ESP

®

may intervene

and damage the brake system.

! Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed at a qualified specialist workshop.

Observe the following before towing a vehicle

with a raised front or rear axle:

R the information on towing in the event of

malfunctions (Y page 281) and

R the important safety notes (Y page 279).

If the front axle is damaged, raise the vehicle

at the front axle and if the rear axle is dam-

aged, raise the vehicle at the rear axle.

Towing If the front axle is raised, the vehicle may be

towed a maximum of 30 miles

(50 km). For a

towing distance of over 30 miles (50 km), you

must remove the propeller shafts to the

driven axles.

X Turn the key to position 2in the ignition

lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake.

X Turn the key to position 1in the ignition

lock and leave it in this position.

X Switch on the hazard warning lamps

(Y page 96).

X If the front axle is raised, do not exceed the

towing speed of 30 mph (50 km/h) and the

towing distance of 30 miles (50 km). Tow-starting and towing away

281Breakdown assistance Z

Page 284 of 338

Towing the vehicle with both axles on

the ground

Important safety notes G

WARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged. There

is a risk of an accident.

Always switch off the ignition when towing the

vehicle with a tow cable or a tow bar.

! Do not exceed a towing speed of

31 mph (50 km/h). You could otherwise

damage the transmission.

! Always use new bolts when installing the

propeller shafts.

i Only have the propeller shafts fitted/

removed at a qualified specialist workshop.

Before towing the vehicle, observe the fol-

lowing:

R the information on towing in the event of

malfunctions (Y page 281) and

R the important safety notes (Y page 279).

Towing You may only tow the vehicle a maximum dis-

tance of 30 miles (50 km). For a towing dis-

tance of over 30 miles (50 km), you must

remove the propeller shafts to the driven

axles.

X Turn the key to position 2in the ignition

lock.

X Depress the brake pedal and keep it

depressed.

X Shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake.

X Leave the key in position 2in the ignition

lock. X

Switch on the hazard warning lamps

(Y page 96).

X Do not exceed the towing speed of

30 mph (50 km/h) and the towing distance

of 30 miles (50 km). Recovering a vehicle that is stuck

! When recovering a vehicle that has

become stuck, pull it as smoothly and

evenly as possible. Excessive tractive

power could damage the vehicles.

If the drive wheels get trapped on loose or

muddy ground, recover the vehicle with the

utmost care. This is especially the case if the

vehicle is laden.

Never attempt to recover a vehicle with a

trailer attached.

Pull out the vehicle backwards, if possible,

using the tracks it made when it became

stuck. Transporting the vehicle

! You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise,

the vehicle could be damaged. Tow-starting (emergency engine

starting)

Vehicles with automatic transmission !

Vehicles with automatic transmission

must not be tow-started. You could other-

wise damage the automatic transmission.

Information on "Jump-starting" can be found

at the beginning of the "Breakdown assis-

tance" section ( Ypage 278). 282

Tow-starting and towing awayBreakdown assistance