oil pressure MERCEDES-BENZ SPRINTER 2016 MY16 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2016, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2016Pages: 290, PDF Size: 6.44 MB

Page 239 of 290

XClean camera lens:with clean water and a

soft cloth.

Make sure that you donot apply any wax to

camera lens :when waxing the veh icle.If nec-

essary, remove the wax using water, shampoo

and a soft cloth.

Cleaning the sliding door

XRemove foreign objects from the vicinity of

the contact surfaces and contact pins of the

slidin g door.

XClean the contact surfaces and contact pins

wit h a mild cleaning agent and a soft cloth.

Do not oil or grease the contact plates and con-

tact pins.

Steps

Cleaning the electrical step

Clean the electrical step at least once a month.

Make sure that no dirtaccumulates inthe hous-

ing or on the step.

XExtend the electrical step (Ypage 66).

XClose the sliding door unt ilthe door lock

engages.

The electrical step remains extended for

cleaning.

XClean the electrical step and the housing with

a power washer.

XAfter cleaning, spray the step guides on each

side wit h silicone spray when the housing and

electrical step are dry.

Do not use oil or grease as a lubricant.

XRetract the electrical step.

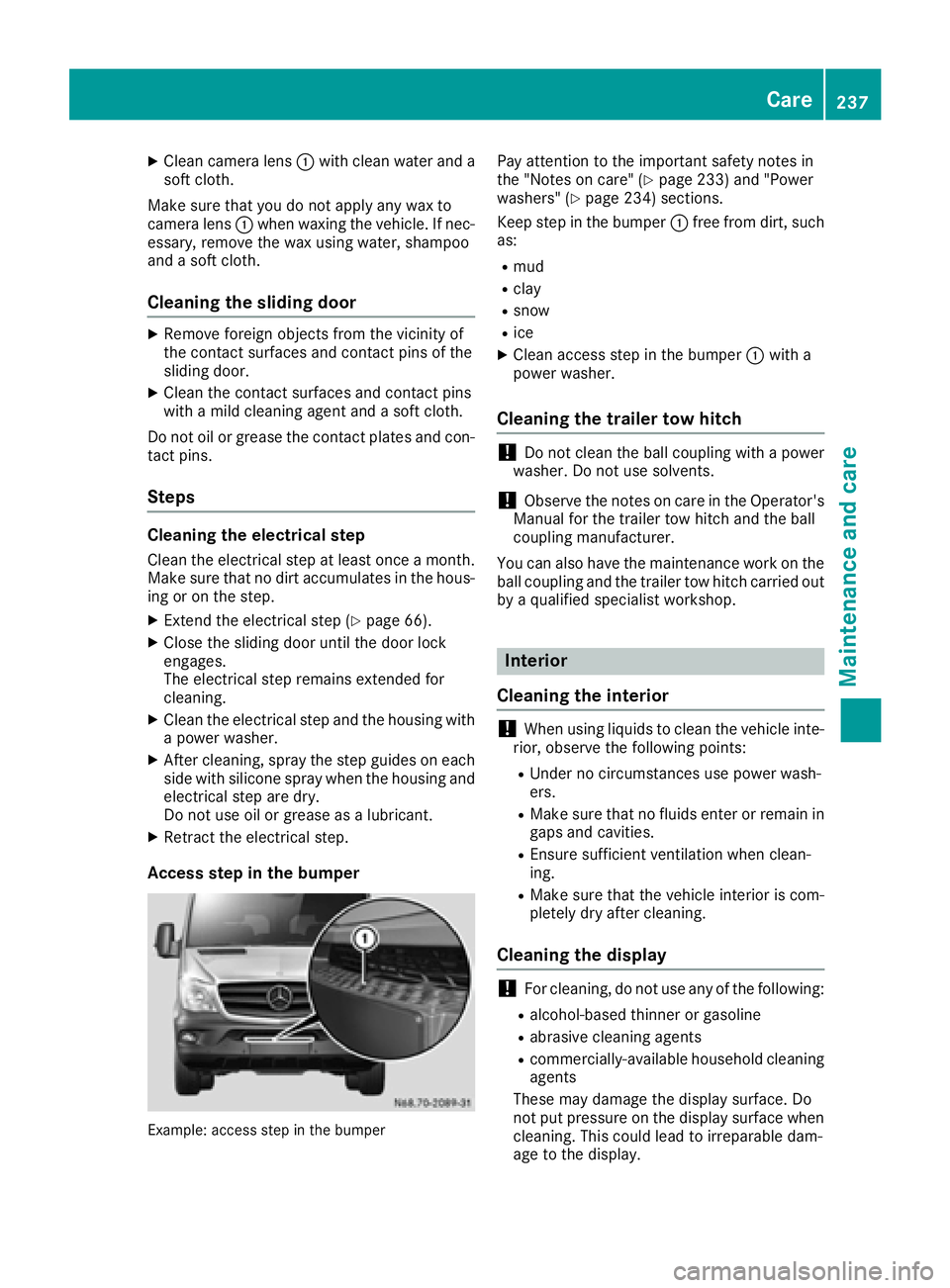

Access step in the bumper

Example :access step in th ebumpe r

Pay attention to the important safety notes in

the "Notes on care" (Ypage 233) and "Power

washers" (Ypage 234) sections.

Keep step in the bumper :free from dirt, such

as:

Rmud

Rclay

Rsnow

Rice

XClean access step in the bumper :with a

power washer.

Cleaning the trailer tow hitch

!Do not clean the ball coupling with a power

washer. Do not use solvents.

!Observe the notes on care in the Operator's

Manual for the trailer tow hitch and the ball

coupling manufacturer.

You can also have the maintenance work on the

ball coupling and the trailer tow hitch carried out

by a qualified specialist workshop.

Interior

Cleaning the interior

!When using liquids to clean the vehicle inte-

rior, observe the foll owing points:

RUnder no circumstances use power wash-

ers.

RMake sure that no fluids enter or remain in

gaps and cavities.

REnsure sufficient ventilation when clean-

ing.

RMake sure that the vehicle interior is com-

pletely dry after cleaning.

Cleaning the display

!For cleaning, do not use any of the foll owing:

Ralcohol-based thinner or gasoline

Rabrasive cleaning agents

Rcommercially-availab lehousehold cleaning

agents

These may damage the display surface. Do

not put pressure on the display surface when cleaning. This could lead to irreparable dam-

age to the display.

Care237

Maintenance and care

Z

Page 267 of 290

cle weight rating (GVWR) specified on the vehi-

cle identification plate at the base of the driver's

seat (

Ypage 276).

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permitted gross

weight of the fully laden vehicle (weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight if

applicable). The Gross Vehicle Weight Rating is

specified on the vehicle identification plate on

the driver seat frame (

Ypage 276).

Maximum weight of the laden vehicle

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1 psi. Another tire pressure unit is

bar. 100 kilopascals(kPa) are the equivalent of

1 bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of the

tire more precisely.

Curb weight

The weight of a vehicle with standard equipment

including the maximum filling capacity of fuel,

oil, and coolant. It also includes the air-condi-

tioning system and optional equipme nt i

f these

are installed on the vehicle, but does not include

passengers or luggage.

Maximum tire load

The maximum tire load in kilograms or pounds is

the maximum weight for which a tire is

approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pressure.

Aspect ratio

Relationship between tire height and width in

percent.

tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

Tire pressure is specified in pounds per square

inch (psi), in kilopascal (kPa) or in bar. Tire pres-

sure should only be corrected when the tires are

cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact with the road.

Tire bead

The tire bead ensures that the tire sits securely

on the wheel. There are several stee l wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and the

weight of the accessories.

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is composed of the

manufacturer identification code, tire size, tire

model code and manufacturing date.

What you should know about wheels and tires265

Wheels and tires

Z

Page 272 of 290

wide tire at a qualified specialist workshop

immediately.

!Vehicles with Super Single tires:if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

On vehicles with Super Single tires, you must

attach the narrow spare wheel to the rear axle by

means of an adapter. The adapter is bolted to

the spare wheel using the adapter bolts for

transportation.

The handling characteristics of your vehicle are affected when driving with a spare wheel instal-

led. After changing a wheel, drive to the nearest

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that hasa Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter boltsevenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of 177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 266).

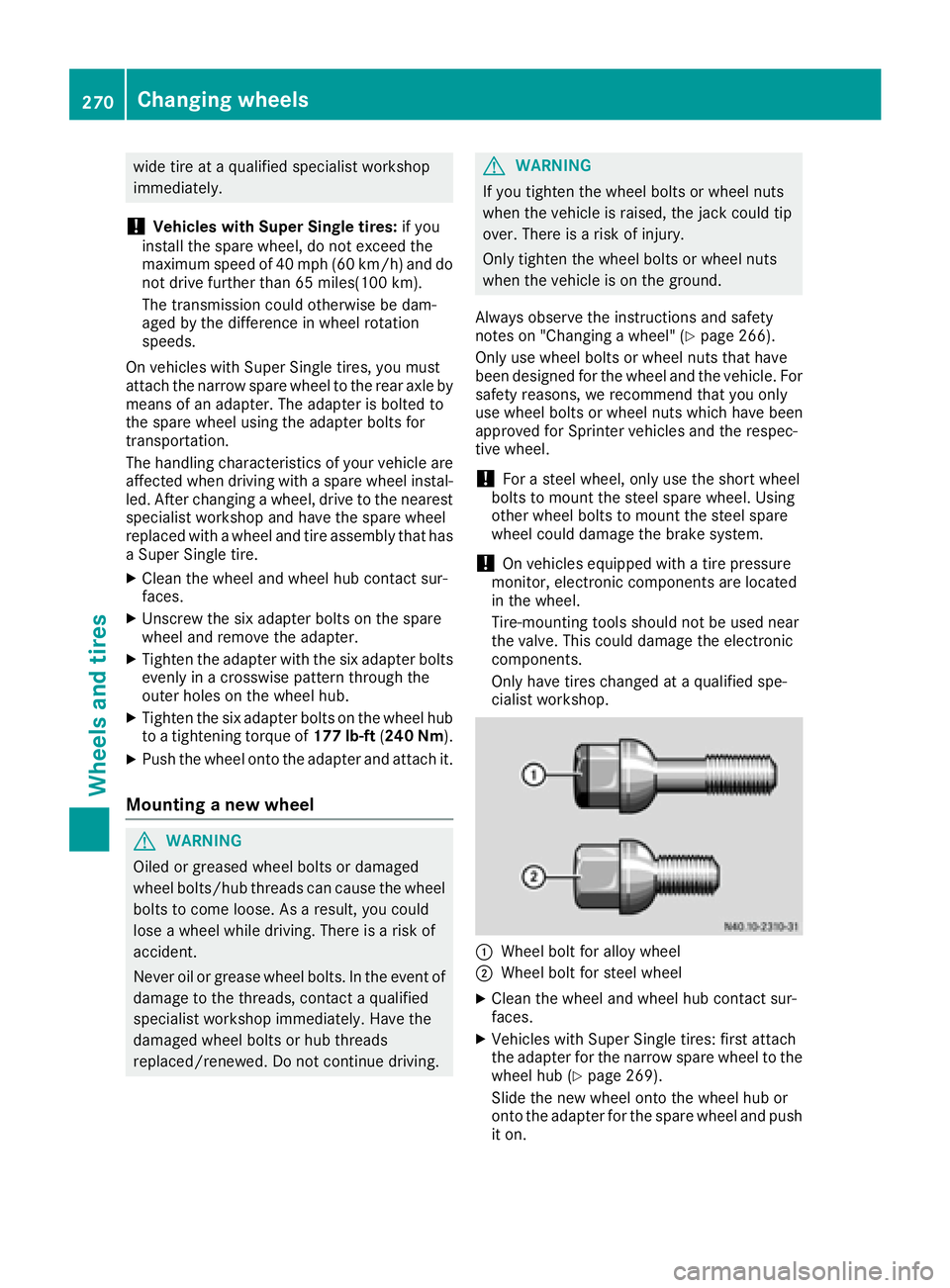

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 269).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

270Changing wheels

Wheels and tires