spare wheel MERCEDES-BENZ SPRINTER 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2017Pages: 286, PDF Size: 4.36 MB

Page 247 of 286

RDo not drive with tires which have too little

tread depth, as this significantly reduces the

traction on wet roads (hydroplaning).

RReplace the tires after 6 years at the latest,

regardless of wear. This also applies to the

spare wheel.

Operation in winter

General notes

Have your vehicle winterproofed at a qualified

specialist workshop at the onset of winter.

Prior to the onset of winter, ensure that snow

chains are stowed in the vehicle (

Ypage 246).

Also observe the notes in the "Changing a

wheel" section (

Ypage 262).

Regularly check the vehicle and remove snow or ice when traveling in wintry conditions.

An accumulation of snow and ice, particularly

when frozen, caught in the area around the air

intake slots, moving parts, the axles and the

wheel arches may:

Rrestrict air intake

Rdamage vehicle parts

Rcause malfunctions by restricting the mobility

intended by the design (e.g. reduced possible

steering input).

If there is any damage, inform a qualified spe-

cialist workshop.

Driving with summer tires

At temperatures below 45 ‡ (+7 †), summer

tires lose elasticity and therefore traction and

braking power. Change the tires on your vehicle

to M+S tire. Using summer tires at very cold

temperatures could cause tears to form,

thereby damaging the tires permanently. We

cannot accept responsibility for this type of

damage.

M+S tires

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may

be severely affected. There is a risk of an acci- dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

GWARNING

M+S tires with a tire tread depth of less than

ã in (4 mm) are not suitable for use in winter

and do not provide sufficient traction. There is

a risk of an accident.

M+S tires with a tread depth of less than ãin

(4 mm) must be replaced immediately.

Use winter tires or all-season tires at tempera-

tures below 45 ‡ (+7 †). Both types of tire are

identified by the M+S marking.

Only winter tires bearing the isnowflake

symbol in addition to the M+S marking provide

the best possible grip in wintry road conditions.

Only these tires will allow driving safety systems

such as ABS and ESP

®to function optimally in

winter. These tires have been developed specif-

ically for driving in snow.

For safe driving, use M+S tire sof the same make

and tread pattern on all wheels.

Always observe the maximum permissible

speed specified for the M+S tires you have

mounted.

If you install M+S tires that have a lower maxi-

mum permissible speed than the maximum per-

missible speed of the vehicle, affix an appropri-

ate warning sign in the driver's field of vision.

You can obtain this at a qualified specialist work-

shop.

Operation in winter245

Wheels and tires

Z

Page 249 of 286

There is a risk of an accident.

Follow recommended tire inflation pressures

and check the pressure of all the tires includ-

ing the spare wheel:

Rmonthly, at least

Rif the load changes

Rbefore beginning a long journey

Runder different operating conditions, e.g.

off-road driving

If necessary, correct the tire pressure.

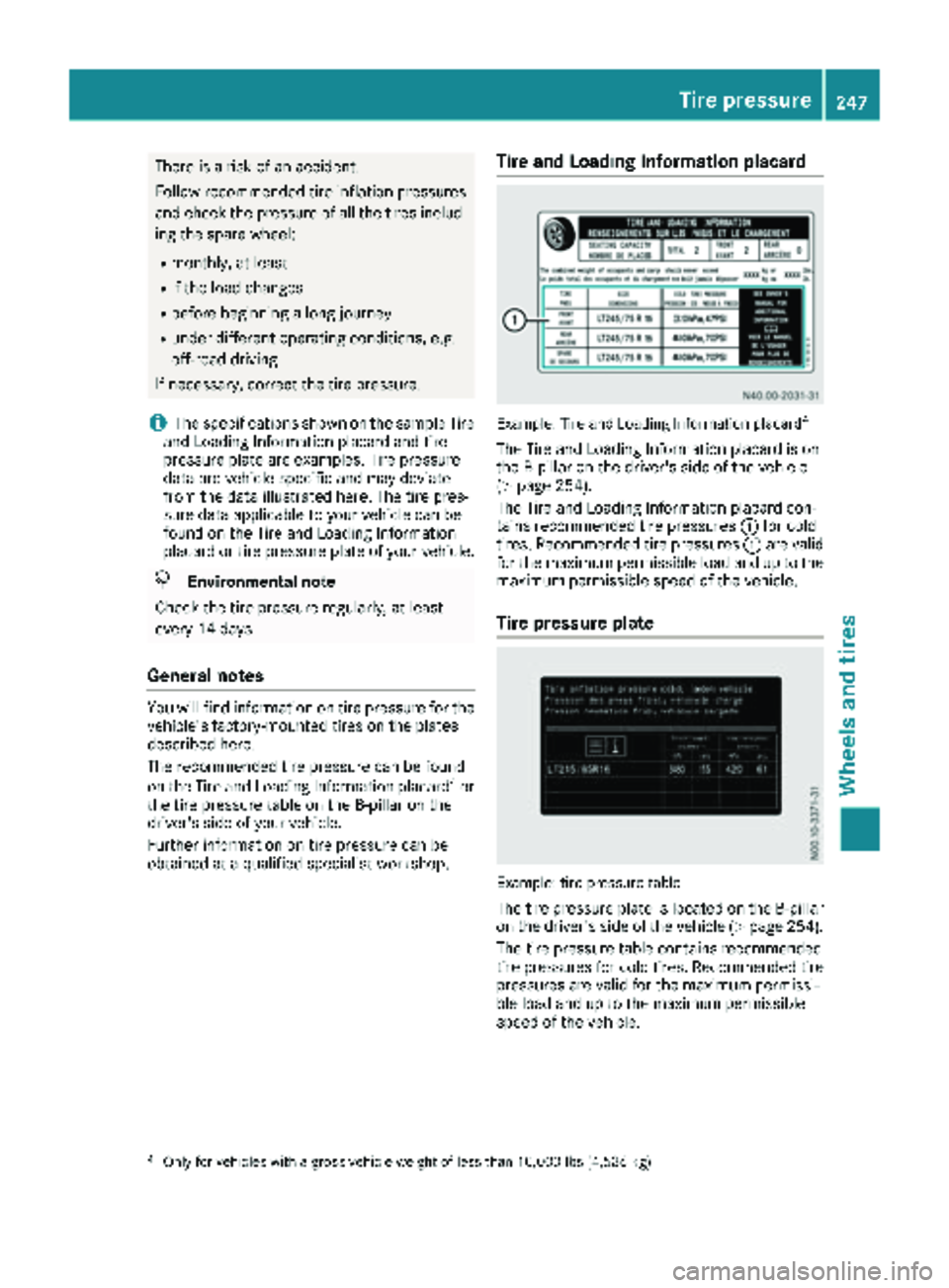

iThe specifications shown on the sample Tire

and Loading Information placard and tire

pressure plate are examples. Tire pressure

data are vehicle-specific and may deviate

from the data illustrated here. The tire pres-

sure data applicable to your vehicle can be

found on the Tire and Loading Information

placard or tire pressure plate of your vehicle.

HEnvironmental note

Check the tire pressure regularly, at least

every 14 days.

General notes

You will find information on tire pressure for the

vehicle's factory-mounted tires on the plates

described here.

The recommended tire pressure can be found

on the Tire and Loading Information placard

4or

the tire pressure table on the B-pillar on the

driver's side of your vehicle.

Further information on tire pressure can be

obtained at a qualified specialist workshop.

Tire and Loading Information placard

Example: Tire and Loading Information placard4

The Tire and Loading Information placard is on

the B-pillar on the driver's side of the vehicle

(

Ypage 254).

The Tire and Loading Information placard con-

tains recommended tire pressures :for cold

tires. Recommended tire pressures :are valid

for the maximum permissible load and up to the

maximum permissible speed of the vehicle.

Tire pressure plate

Example: tire pressure table

The tire pressure plate is located on the B-pillar

on the driver's side of the vehicle (Ypage 254).

The tire pressure table contains recommended

tire pressures for cold tires. Recommended tire pressures are valid for the maximum permissi-

ble load and up to the maximum permissible

speed of the vehicle.

4Only for vehicles with a gross vehicle weight of less than 10,000 lbs (4,536 kg)

Tire pressure247

Wheels and tires

Z

Page 250 of 286

Important notes on tire pressure

GWARNING

If th etire pressur edrops repeatedly, th e

wheel, valv eor tire may be damaged. Tir e

pressur ethat is to olow may result in atire

blow-out .Ther eis aris kof an accident.

RChec kth etire for foreign objects .

RCheckwhether th ewhee lis losing air or th e

valv eis leaking .

If you are unable to rectify th edamage, con-

tac t a qualified specialist workshop.

Use asuitable pressur egage to chec kth etire

pressure. The outer appearanc eof atire does

no tpermit any reliable conclusio nabout th etire

pressure. On vehicles equipped wit hth eelec -

tronic tire pressur emonitor, th etire pressur e

can be checke dusin gth eon-board computer.

The tire temperature and pressur eincreas e

when th evehicl eis in motion .This is dependen t

on th edriving spee dand th eload.

Therefore, you should only correc ttire pressur e

when th etires are cold.

The tires are cold:

Rif th evehicl ehas been parked for at least

three hour swithout direct sunligh ton th e

tires ,and

Rif th evehicl ehas no tbeen driven further than

1 mile (1.6 km )

Tire temper ature changes depending on the

ambient temperature, driving speed and tire

load. If the tire temperature changes by 18 ‡

(10 †), the tire pressure ch anges by approx

-

imately 10 kPa (0.1 bar/1.5 psi). Take this into

account when checking the pressure of warm

tires. Only correct the tire pressure if it is too low

for the current operating conditions. If you

check the tire pressure when the tires are warm,

it results in a higher value than when the tires

are cold. This is normal. Do not under any cir-

cumstances release the air in order to adjust the

pressure to the prescribed value for cold tires.

The tire pressure would otherwise be too low. Observe the recommended tire pressures for

cold tires:

Ron the Tire and Loading Information placard5

on the B-pillar on the driver's side, or

Ron the tire pressure plate on the B-pillar on the

driver's side of the vehicle

Underinflated or overinflated tires

Underinflated tires:

GWARNING

Tires with pressure that is too low can over-

heat and burst as a consequence. In addition, they also suffer from excessive and/or irreg-

ular wear, which can severely impair the brak-

ing properties and the driving characteristics.

There is a risk of an accident.

Avoid tire pressures that are too low in all the

tires, including the spare wheel.

Underinflated tires can:

Rfail from being overheated

Radversely affect handling

Rwear excessively and/or unevenly

Rhave an adverse effect on fuel consumption

Overinflated tires

GWARNING

Tires with excessively high pressure can burst

because they are damaged more easily by

road debris, potholes etc. In addition, they

also suffer from irregular wear, which can

severely impair the braking properties and the driving characteristics. There is a risk of an

accident.

Avoid tire pressures that are too high in all the

tires, including the spare wheel.

Overinflated tires can:

Rincrease the braking distance

Radversely affect handling

Rwear excessively and/or unevenly

5Only for vehicle swith agross weigh tof less than 10,00 0lbs (4,536 kg).

248Tire pressure

Wheels and tires

Page 251 of 286

Radversely affect ride comfort

Rbe more susceptible to damage

Maximum tire pressures

:Maximum permitted tire pressure (example)

Never exceed the maximum permissible tire

inflation pressure. When adjusting the tire pres-

sures always observe the recommended tire

pressure for your vehicle (

Ypage 246).

iThe actual values for tires are specific to

each vehicle and may deviate from the values in the illustration.

Tire valve

GWARNING

Tire valve that are not approved for your vehi-

cle by the distributor named on the inside

cover page may result in a loss of tire pres-

sure. This may affect road safety. There is a

risk of an accident.

Only use tire valve that are approved for your

vehicle by the distributor named on the inside

cover page. Always make sure you have the

correct tire valve type for the tires on your

vehicle.

!Do not screw additional weights (check

valves, etc.) onto the tire valves. The elec-

tronic components could thus be damaged.

Only for vehicles without a tire pressure moni-

tor:

For safety reasons, Mercedes-Benz recom-

mends that you only use tire valves that have

been tested for use on your vehicle.

Checking the tire pressure manually

In order to determine and adjust the tire pres-

sures, proceed as follows:

XRemove the valve cap of the tire you wish to

check.

XPress the tire pressure gauge securely onto

the valve.

XRead the tire pressure and compare it with the

recommended value on the loading informa-

tion table or the tire pressure table

(

Ypage 246).

XIf the tire pressure is too low, increase it to the

recommended value.

XIf the tire pressure is too high, release air by

pressing down the metal pin in the valve. Use

the tip of a pen, for example. Then, check the

tire pressure again using the tire pressure

gauge.

XScrew the valve cap onto the valve.

XRepeat the steps for the other tires.

Tire pressure monitor

Important safety notes

GWARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure rec-

ommended by the vehicle manufacturer on

the Tire and Loading Information placard on

the driver's door B-pillar or the tire pressure

label on the inside of the fuel filler flap. If your

vehicle has tires of a different size than the

size indicated on the Tire and Loading Infor-

mation placard or the tire pressure label, you

should determine the proper tire pressure for

those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire pres-

sure telltale when one or more of your tires

are significantly underinflated. Accordingly,

when the low tire pressure telltale illuminates,

you should stop and check your tires as soon

as possible, and inflate them to the proper

pressure. Driving on a significantly underin-

Tire pressure249

Wheels and tires

Z

Page 255 of 286

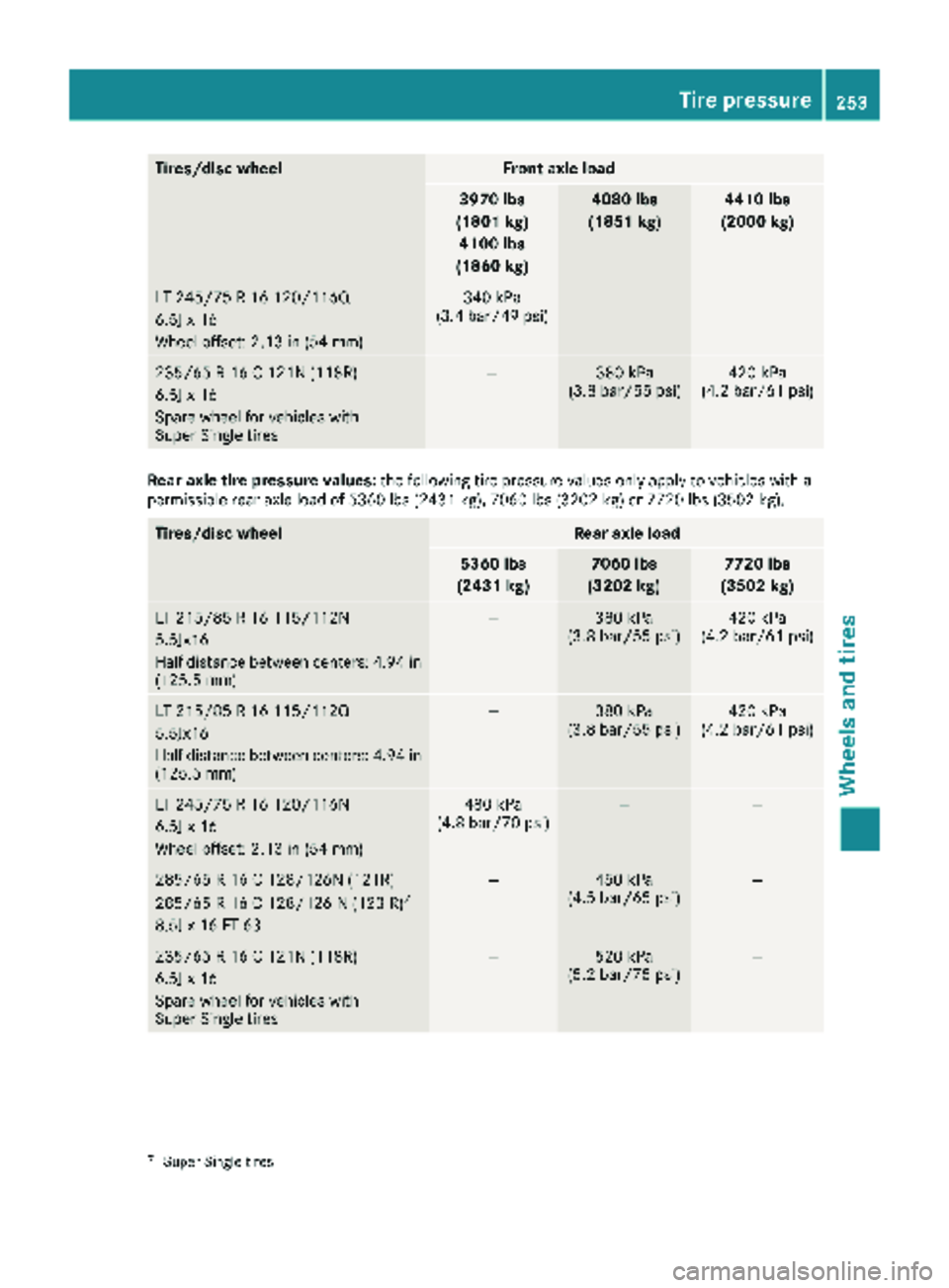

Tires/disc wheelFront axle load

3970 lbs

(1801 kg) 4100 lbs

(1860 kg)4080 lbs

(1851 kg)4410 lbs

(2000 kg)

LT 245/75 R 16 120/116Q

6.5J x 16

Wheel offset: 2.13 in (54 mm)340 kPa

(3.4 bar/49 psi)——

235/65 R 16 C 121N (118R)

6.5J x 16

Spare wheel for vehicles with

Super Single tires—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

Rear axle tire pressure values: the following tire pressure values only apply to vehicles with a

permissible rear axle load of 5360 lbs (2431 kg), 7060 lbs (3202 kg) or 7720 lbs (3502 kg).

Tires/disc wheelRear axle load

5360 lbs

(2431 kg)7060 lbs

(3202 kg)7720 lbs

(3502 kg)

LT 215/85 R 16 115/112N

5.5Jx16

Half distance between centers: 4.94 in

(125.5 mm)—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

LT 215/85 R 16 115/112Q

5.5Jx16

Half distance between centers: 4.94 in

(125.5 mm)—380 kPa

(3.8 bar/55 psi)420 kPa

(4.2 bar/61 psi)

LT 245/75 R 16 120/116N

6.5J x 16

Wheel offset: 2.13 in (54 mm)480 kPa

(4.8 ba r/70 psi)——

285/65 R16 C128/126N (121R)

285/65 R16 C128/12 6 N(123 R)7

8.5J x 16 ET 63

—450 kPa

(4.5 bar/65 psi)—

235/65 R 16 C 121N (118R)

6.5J x 16

Spare wheel for vehicles with

Super Single tires—520 kPa

(5.2 bar/75 psi)—

7Super Single tires

Tire pressure253

Wheels and tires

Z

Page 262 of 286

Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals (kPa)

are the equivalent of 1 bar.

DOT (Department of Transportation)

DOT marked tires fulfill the requirements of the

United States Department of Transportation.

Average weight of vehicle occupants

The number of occupants for which the vehicle

is designed multiplied by 68 kilograms (150 lbs).

Uniform Tire Quality Grading Standards

A uniform standard to grade the quality of tires

with regard to tread quality, traction and tem-

perature characteristics. The quality grading

assessment is made by the manufacturer fol-

lowing specifications from the U.S government.

The quality grade of a tire is imprinted on the

sidewall of the tire.

Recommended tire pressure

The recommended tire pressures are the pres-

sures specified for the tires mounted on the

vehicle at the factory.

The tire and load information table

8contains the

recommended tire pressures for cold tires, the

maximum permissible load and the maximum

permissible vehicle speed.

The tire pressure table contains the recommen- ded tire pressure for cold tires under various

operating conditions, i.e. loading and/or speed

of the vehicle.

Increased vehicle weight due to optional

equipment

The combined weight of all standard and

optional equipment available for the vehicle,

regardless of whether it is actually installed on

the vehicle or not.

Wheel rim

The part of the wheel on which the tire is moun-

ted.

GAWR (Gross Axle Weight Rating)

GAWR is the maximum gross axle weight rating.

The actual load on an axle must never exceed

the gross axle weight rating. The Gross Axle

Weight Rating can be found on the vehicle iden- tification plate on the driver seat frame

(

Ypage 272).

Speed index

The speed index is part of the tire identification.

It specifies the speed range for which the tire is

approved.

GTW (Gross Trailer Weight)

GTW is the total of weight of a trailer and the

weight of the load, accessories etc. on the

trailer.

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight of

the vehicle including fuel, tools, spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight if applicable. The gross

vehicle weight may never exceed the gross vehi-

cle weight rating (GVWR) specified on the vehi-

cle i

dentification plate at the base of the driver's

seat (Ypage 272).

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permitted gross

weight of the fully laden vehicle (weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight if

applicable). The Gross Vehicle Weight Rating is

specified on the vehicle identification plate on

the driver seat frame (

Ypage 272).

Maximum weight of the laden vehicle

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1 ps i.Another tire pressure unit is

bar. 100 kilopascal s(kPa) are the equivalent of

1 bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of the

tire more precisely.

8Only for vehicles with a gross weight of less than 10,000 lbs (4536 kg).

260What you should know about wheels and tires

Wheels and tires

Page 265 of 286

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XMove the selector lever of the automatic

transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel

change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe legal requirements.

XSecure the vehicle to prevent it from rolling

away.

iObserve the safety notes on parking in the

section on "Driving and parking"

(

Ypage 127).

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitable objects under the wheels on the front and rear axles opposite the wheel to be

changed.

XTake the vehicle tool kit and the jack from the

footwell on the front-passenger side

(

Ypage 236).

XRemove the spare wheel from the spare wheel

bracket (Ypage 269). Observe the safety

notes in the "Spare wheel" section

(

Ypage 268).

XOn wheels with wheel bolts, remove the hub

caps.

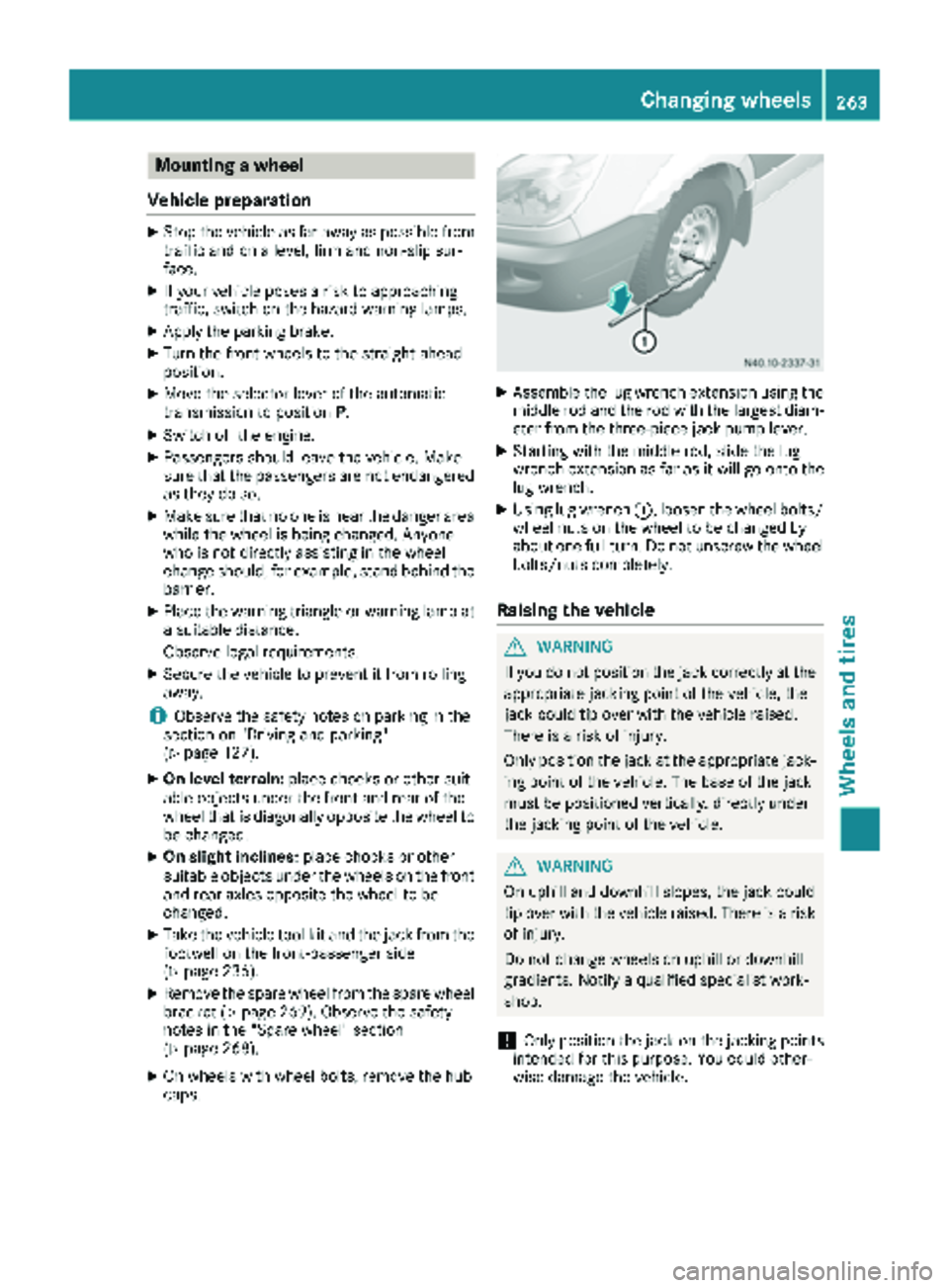

XAssemble the lug wrench extension using the

middle rod and the rod with the largest diam-

eter from the three-piece jack pump lever.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing lug wrench :, loosen the wheel bolts/

wheel nuts on the wheel to be changed by

about one full turn. Do not unscrew the wheel bolts/nuts completely.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Changing wheels263

Wheels and tires

Z

Page 267 of 286

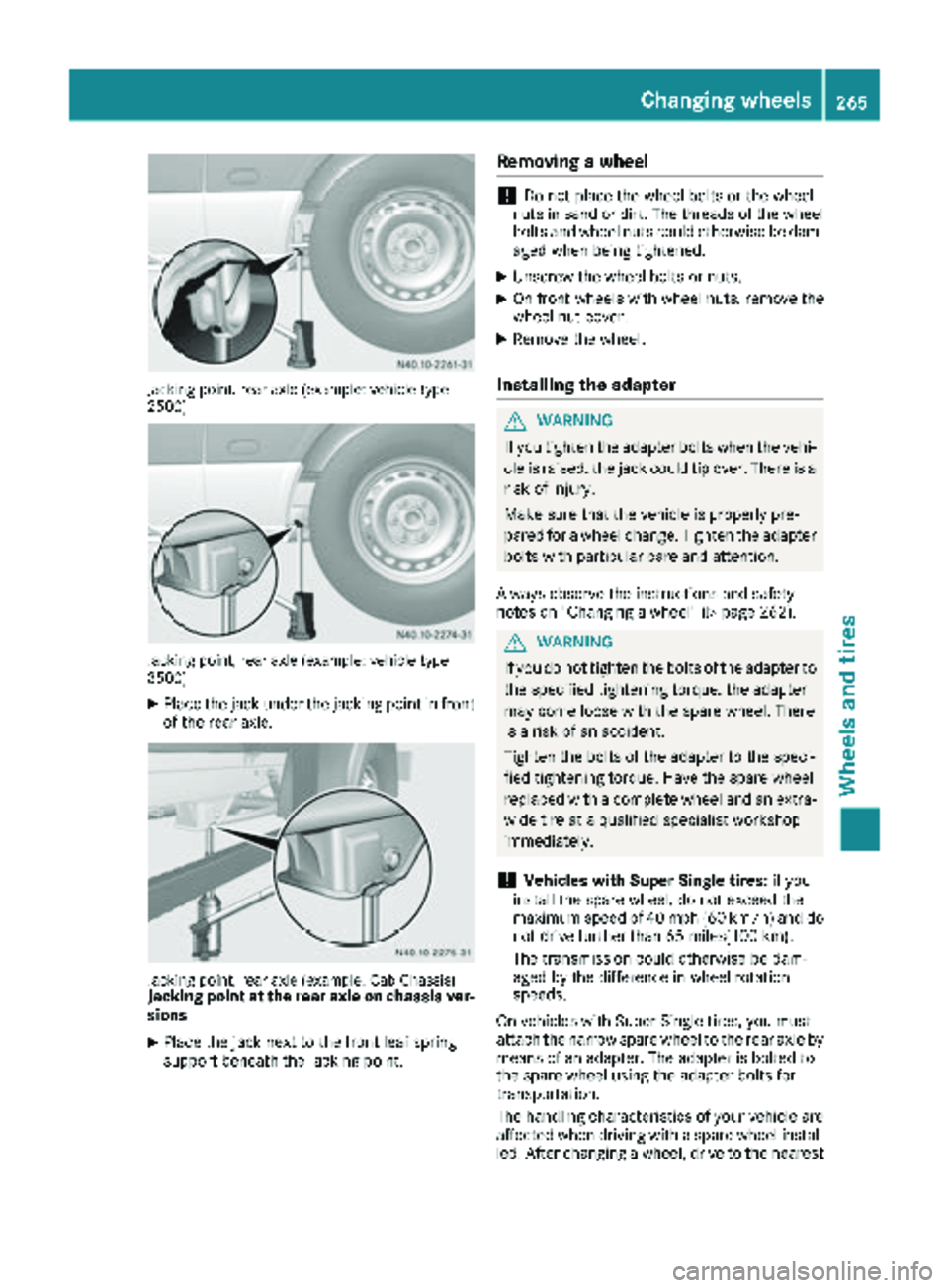

Jacking point, rear axle (example: vehicle type

2500)

Jacking point, rear axle (example: vehicle type

3500)

XPlace the jack under the jacking point in front

of the rear axle.

Jacking point, rear axle (example: Cab Chassis)Jacking point at the rear axle on chassis ver-

sions

XPlace the jack next to the front leaf spring

support beneath the jacking point.

Removing a wheel

!Do not place the wheel bolts or the wheel

nuts in sand or dirt. The threads of the wheel

bolts and wheel nuts could otherwise be dam-

aged when being tightened.

XUnscrew the wheel bolts or nuts.

XOn front wheels with wheel nuts, remove the

wheel nut cover.

XRemove the wheel.

Installing the adapter

GWARNING

If you tighten the adapter bolts when the vehi-

cle is raised, the jack could tip over. There is a risk of injury.

Make sure that the vehicle is properly pre-

pared for a wheel change. Tighten the adapter

bolts with particular care and attention.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 262).

GWARNING

If you do not tighten the bolts of the adapter to

the specified tightening torque, the adapter

may come loose with the spare wheel. There

is a risk of an accident.

Tighten the bolts of the adapter to the speci-

fied tightening torque. Have the spare wheel

replaced with a complete wheel and an extra- wide tire at a qualified specialist workshop

immediately.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h)and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

On vehicles with Super Single tires, you must

attach the narrow spare wheel to the rear axle by means of an adapter. The adapter is bolted to

the spare wheel using the adapter bolts for

transportation.

The handling characteristics of your vehicle are

affected when driving with a spare wheel instal-

led. After changing a wheel, drive to the nearest

Changing wheels265

Wheels and tires

Z

Page 268 of 286

specialist workshop and have the spare wheel

replaced with a wheel and tire assembly that has

a Super Single tire.

XClean the wheel and wheel hub contact sur-

faces.

XUnscrew the six adapter bolts on the spare

wheel and remove the adapter.

XTighten the adapter with the six adapter bolts

evenly in a crosswise pattern through the

outer holes on the wheel hub.

XTighten the six adapter bolts on the wheel hub

to a tightening torque of177 lb-ft(240 Nm).

XPush the wheel onto the adapter and attach it.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 262).

Only use wheel bolts or wheel nuts that have

been designed for the wheel and the vehicle. For safety reasons, we recommend that you only

use wheel bolts or wheel nuts which have been

approved for Sprinter vehicles and the respec-

tive wheel.

!For a steel wheel, only use the short wheel

bolts to mount the steel spare wheel. Using

other wheel bolts to mount the steel spare

wheel could damage the brake system.

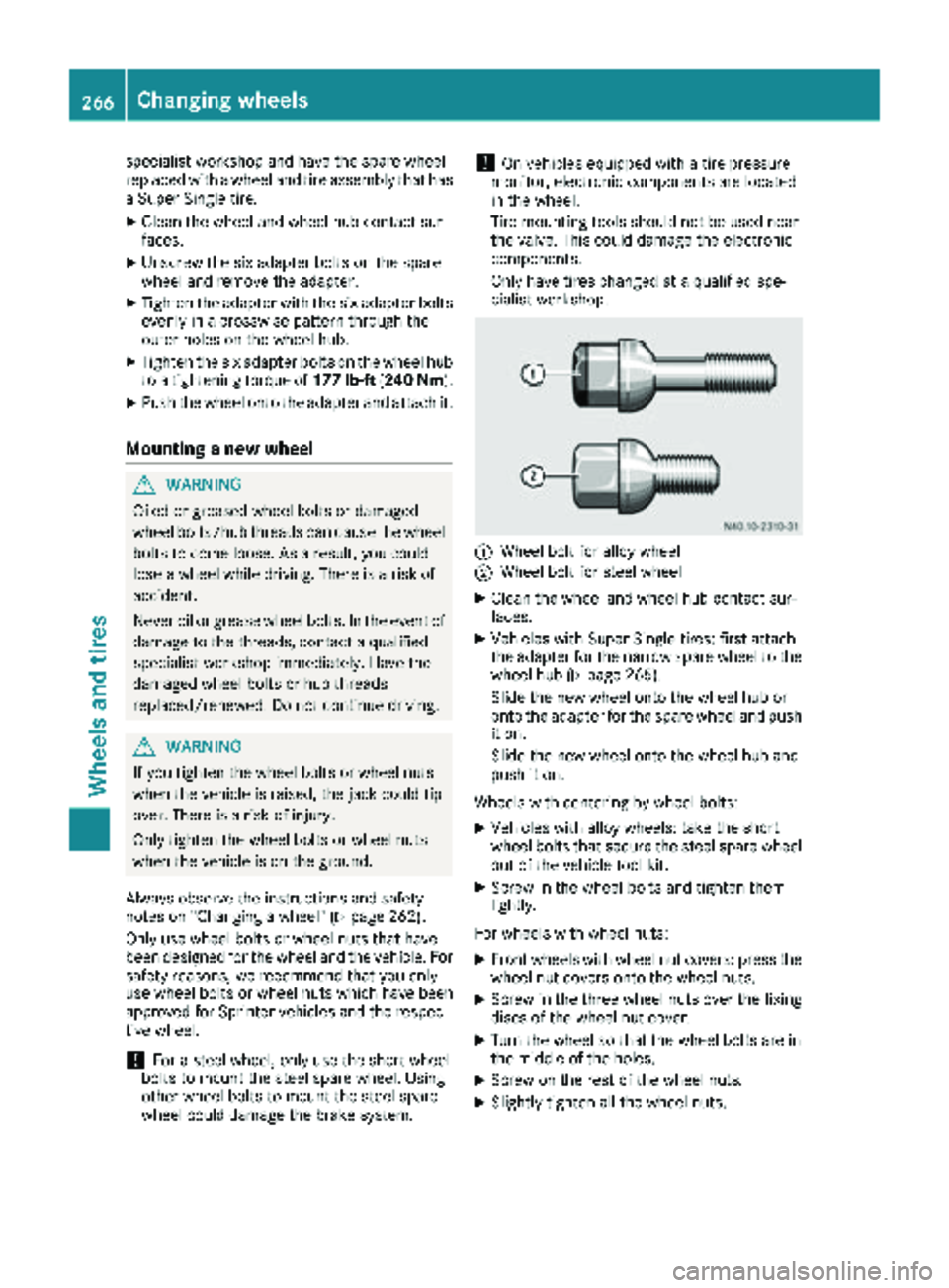

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

:Wheel bolt for alloy wheel

;Wheel bolt for steel wheel

XClean the wheel and wheel hub contact sur-

faces.

XVehicles with Super Single tires: first attach

the adapter for the narrow spare wheel to the

wheel hub (

Ypage 265).

Slide the new wheel onto the wheel hub or

onto the adapter for the spare wheel and push

it on.

Slide the new wheel onto the wheel hub and

push it on.

Wheels with centering by wheel bolts:

XVehicles with alloy wheels: take the short

wheel bolts that secure the steel spare wheel

out of the vehicle tool kit.

XScrew in the wheel bolts and tighten them

lightly.

For wheels with wheel nuts:

XFront wheels with wheel nut covers: press the wheel nut covers onto the wheel nuts.

XScrew in the three wheel nuts over the fixing

discs of the wheel nut cover.

XTurn the wheel so that the wheel bolts are in

the middle of the holes.

XScrew on the rest of the wheel nuts.

XSlightly tighten all the wheel nuts.

266Changing wheels

Wheels and tires

Page 269 of 286

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Only use the jack pump lever middle rod and

the rod with the largest diameter as a lug

wrench extension. Only slide the middle rod

as far as it will go onto the lug wrench. The

rods may otherwise bend and be distorted to

such an extent that they can no longer be

used as a pump lever for the jack.

!Vehicles with Super Single tires: if you

install the spare wheel, do not exceed the

maximum speed of 40 mph (60 km/h) and do

not drive further than 65 miles(100 km).

The transmission could otherwise be dam-

aged by the difference in wheel rotation

speeds.

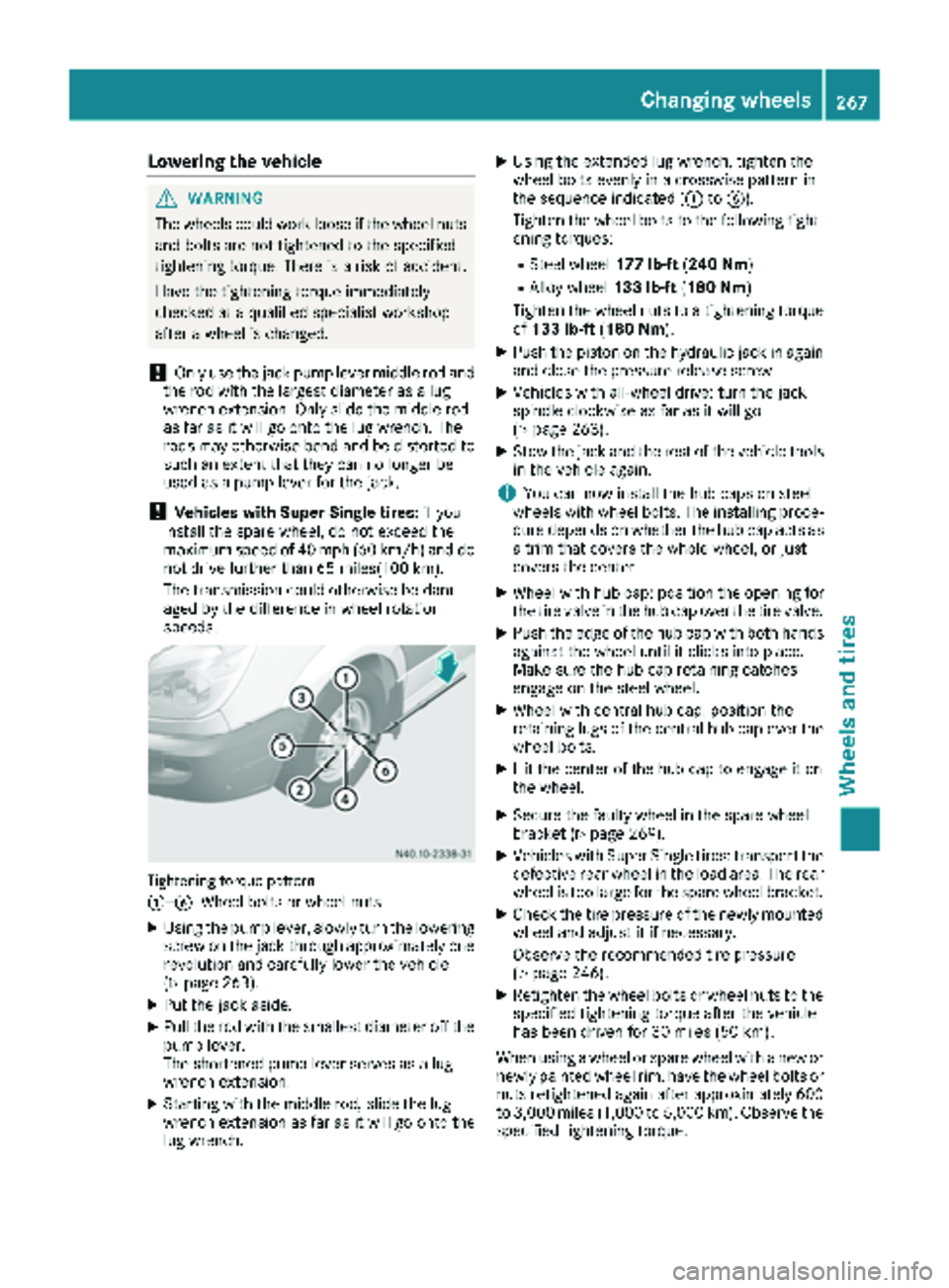

Tightening torque pattern

:— B

Wheel bolts or wheel nuts

XUsing the pump lever, slowly turn the lowering

screw on the jack through approximately one

revolution and carefully lower the vehicle

(

Ypage 263).

XPut the jack aside.

XPull the rod with the smallest diameter off the

pump lever.

The shortened pump lever serves as a lug

wrench extension.

XStarting with the middle rod, slide the lug

wrench extension as far as it will go onto the

lug wrench.

XUsing the extended lug wrench, tighten the

wheel bolts evenly in a crosswise pattern in

the sequence indicated ( :toB).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 177 lb-ft(240 Nm )

RAlloy wheel 133 lb-ft(180 Nm )

Tighten the wheel nuts to a tightening torque

of 133 lb-ft (180 Nm).

XPush the piston on the hydraulic jack in again

and close the pressure release screw.

XVehicles with all-wheel drive: turn the jack

spindle clockwise as far as it will go

(

Ypage 263).

XStow the jack and the rest of the vehicle tools

in the vehicle again.

iYou can now install the hub caps on steel

wheels with wheel bolts. The installing proce-

dure depends on whether the hub cap acts as

a trim that covers the whole wheel, or just

covers the center.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XWheel with central hub cap: position the

retaining lugs of the central hub cap over the

wheel bolts.

XHit the center of the hub cap to engage it on

the wheel.

XSecure the faulty wheel in the spare wheel

bracket (Ypage 269).

XVehicles with Super Single tires: transport the

defective rear wheel in the load area. The rear wheel is too large for the spare wheel bracket.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 246).

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

When using a wheel or spare wheel with a new or newly painted wheel rim, have the wheel bolts or

nuts retightened again after approximately 600

to 3,000 miles (1,000 to 5,000 km). Observe the

specified tightening torque.

Changing wheels267

Wheels and tires

Z