technical data MERCEDES-BENZ SPRINTER 2018 MY18 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2018Pages: 294, PDF Size: 4.36 MB

Page 217 of 294

Load distribution

General notes

!

Excessive loads on individual points of the

cargo floor or on the load surface impair vehi-

cle handling characteristics and could cause

damage to the floor covering.

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle.

On Cargo Vans and Passenger Vans:

XAlways transport loads in the cargo compart-

ment.

XAlways place the load against the backrests of the rear bench seat.

XMove large and heavy loads as far towards the

front of the vehicle as possible against the

rear bench seat. Stow the load flush with the

rear bench seat.

XAlways additionally secure the load with suit-

able load-securing aids or tie downs.

Observe the following notes:

RDo not stack loads higher than the upper edge

of the backrests.

RTransport loads behind seats that are not

occupied.

RIf the rear bench seat is not occupied, insert

the seat belts crosswise into the buckle of the

opposite seat belt.

Securing loads

Important safety notes

GWARNING

If you attach the tie-down incorrectly when

securing the load, the following may occur in

the event of abrupt changes in direction, brak- ing maneuvers or an accident:

Rthe cargo tie-down rings may become

detached or the tie-down may tear if the

permissible load is exceeded

Rthe load may not be restrained.

This may cause the load to slip, tip over or be

tossed about, striking vehicle occupants.

There is a risk of an accident and injury.

Always tension the tie-downs in the proper

manner and only between the described

cargo tie-down rings. Always use tie-downs

designed specifically for the loads.

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act- ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force

absorption. Load the anchorages evenly.

Spread the load evenly between the cargo tie-

down points or tie-down rings.

Please also refer to the notes about qualified

specialist workshops (

Ypage 27).

Always observe the operating instructions or the

notes of the lashing strap manufacturer for the

operation of the lashing strap.

Information about the maximum loading capa-

city of the cargo tie-down points can be found in

the "Technical data" section (

Ypage 287).

As the driver, you are responsible for ensuring

that:

RThe load is secured against slipping, tipping,

rolling or falling off. This applies both in nor-

mal traffic conditions and if the vehicle must

swerve to avoid an obstacle, in the event of

full brake application and on poor road sur

fa-

ces.

RThe applicable requirements and guidelines

relating to load-securing practices must be

met.

If this is not the case, this may constitute a

punishable offense, depending on local legis-

lation and any ensuing consequences.

You should therefore observe the respective

legal requirements for the relevant country.

Make sure that the load is secure before every

journey and at regular intervals during a long

journey. Correct an incorrectly or inadequately

secured load if necessary.

You can obtain information about securing the

load correctly from the manufacturer of the load

securing aids or tie down for securing the load.

Securing loads215

Transporting loads

Z

Page 219 of 294

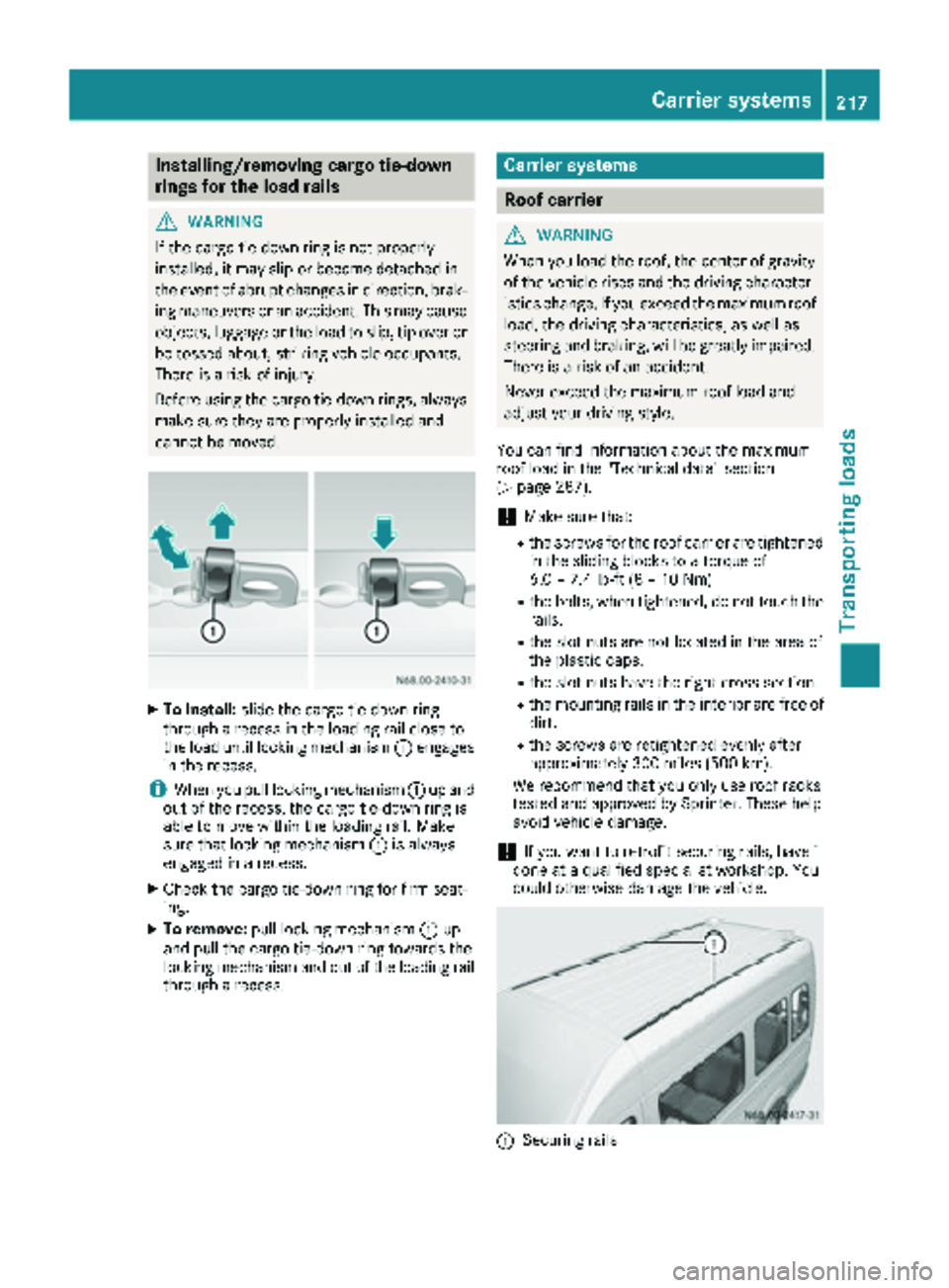

Installing/removing cargo tie-down

rings for the load rails

GWARNING

If th ecargo tie-down rin gis no tproperly

installed, it may slip or become detached in

th eevent of abrup tchanges in direction ,brak -

ing maneuvers or an accident. This may caus e

objects ,luggag eor th eload to slip, ti pove ror

be tosse dabout ,striking vehicl eoccupants.

Ther eis aris kof injury.

Before usin gth ecargo tie-down rings, always

mak esur ethey are properly installed and

canno tbe moved.

XTo install: slide thecargo tie-down rin g

throug h arecess in th eloadin grail close to

th eload until lockin gmechanism :engage s

in th erecess .

iWhen you pull lockin gmechanism :up and

out of th erecess ,th ecargo tie-down rin gis

able to mov ewithin th eloadin grail. Mak e

sur ethat lockin gmechanism :is always

engage din arecess .

XCheckth ecargo tie-down rin gfor fir mseat -

ing .

XTo remove: pull lockingmechanism :up

and pull th ecargo tie-down rin gtowards th e

lockin gmechanism and out of th eloadin grail

throug h arecess .

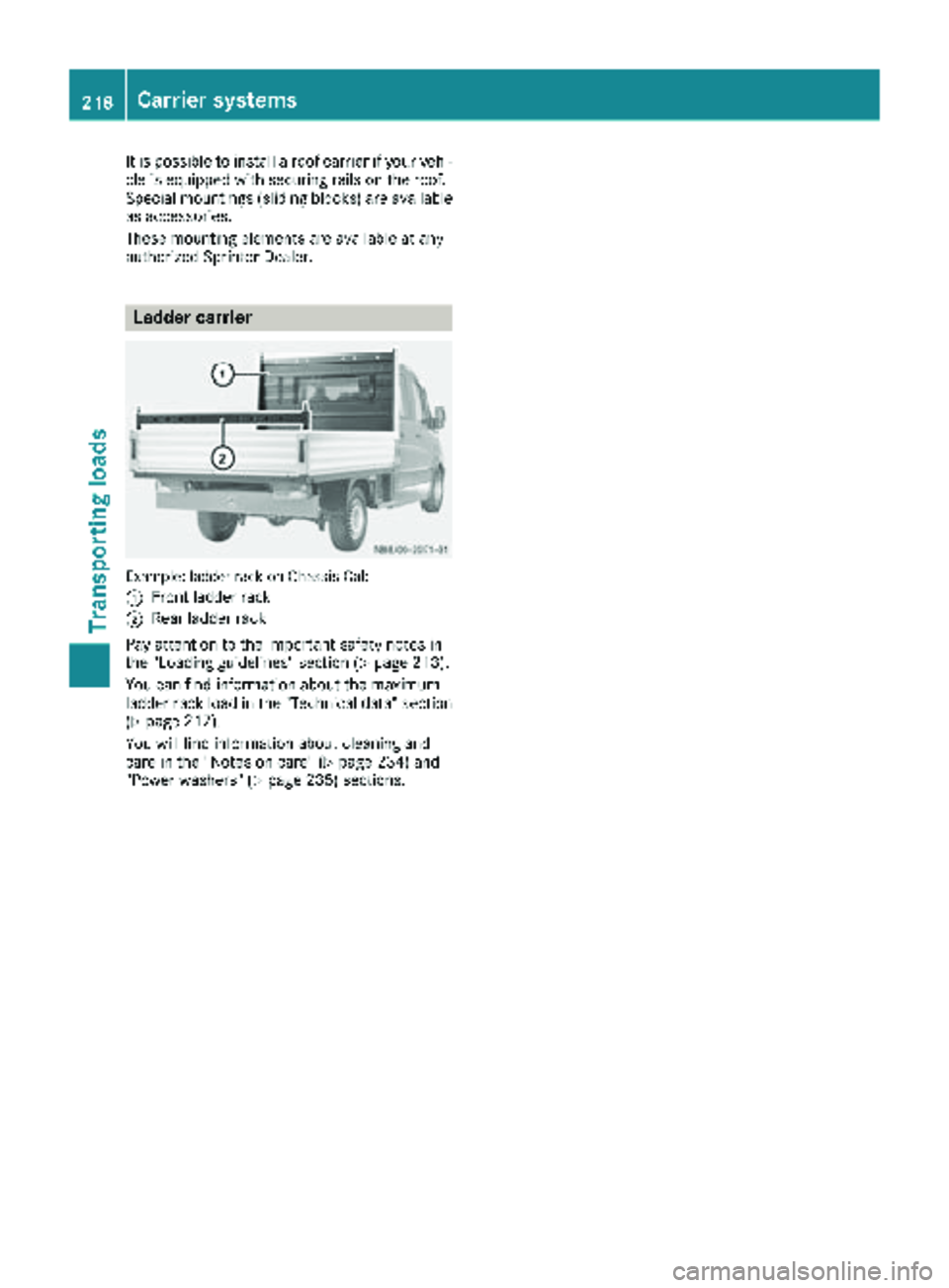

Carrier systems

Roof carrier

GWARNIN G

When you load th eroof, th ecenter of gravit y

of th evehicl erises and th edriving character-

istics change. If you exceed th emaximum roo f

load, th edriving characteristics ,as well as

steering and braking ,will be greatl yimpaired.

Ther eis aris kof an accident.

Never exceed th emaximum roo fload and

adjust your driving style.

You can fin dinformation about th emaximum

roo fload in th e"Technical data" section

(

Ypage 287).

!Mak esur ethat:

Rth escrews for th eroo fcarrie rare tightened

in th esliding blocks to atorque of

6. 0 – 7.4lb-ft (8 –10 Nm)

Rth ebolts, when tightened, do no ttouch th e

rails .

Rtheslot nut sare no tlocate din th earea of

th eplastic caps.

Rth eslot nut shav eth eright cross-section .

Rthemounting rails in th einterior are free of

dirt .

Rthescrews are retightened evenly after

approximately 30 0mile s(50 0km).

We recommen dtha tyou only use roo fracks

tested and approve dby Sprinter. These help

avoid vehicl edamage.

!If you wan tto retrofit securin grails, hav eit

don eat aqualified specialist workshop .You

could otherwise damage th evehicle.

:Securin grail s

Carrier systems217

Transporting loads

Z

Page 220 of 294

It is possible to install a roof carrier if your vehi-

cle is equipped with securing rails on the roof.

Special mountings (sliding blocks) are available

as accessories.

These mounting elements are available at any

authorized Sprinter Dealer.

Ladder carrier

Example: ladder rack on Chassis Cab

:

Front ladder rack

;Rear ladder rack

Pay attention to the important safety notes in

the "Loading guidelines" section (

Ypage 213).

You can find information about the maximum

ladder rack load in the "Technical data" section

(

Ypage 217).

You will find information about cleaning and

care in the "Notes on care" (

Ypage 234) and

"Power washers" (Ypage 235) sections.

218Carrier systems

Transporting loads

Page 223 of 294

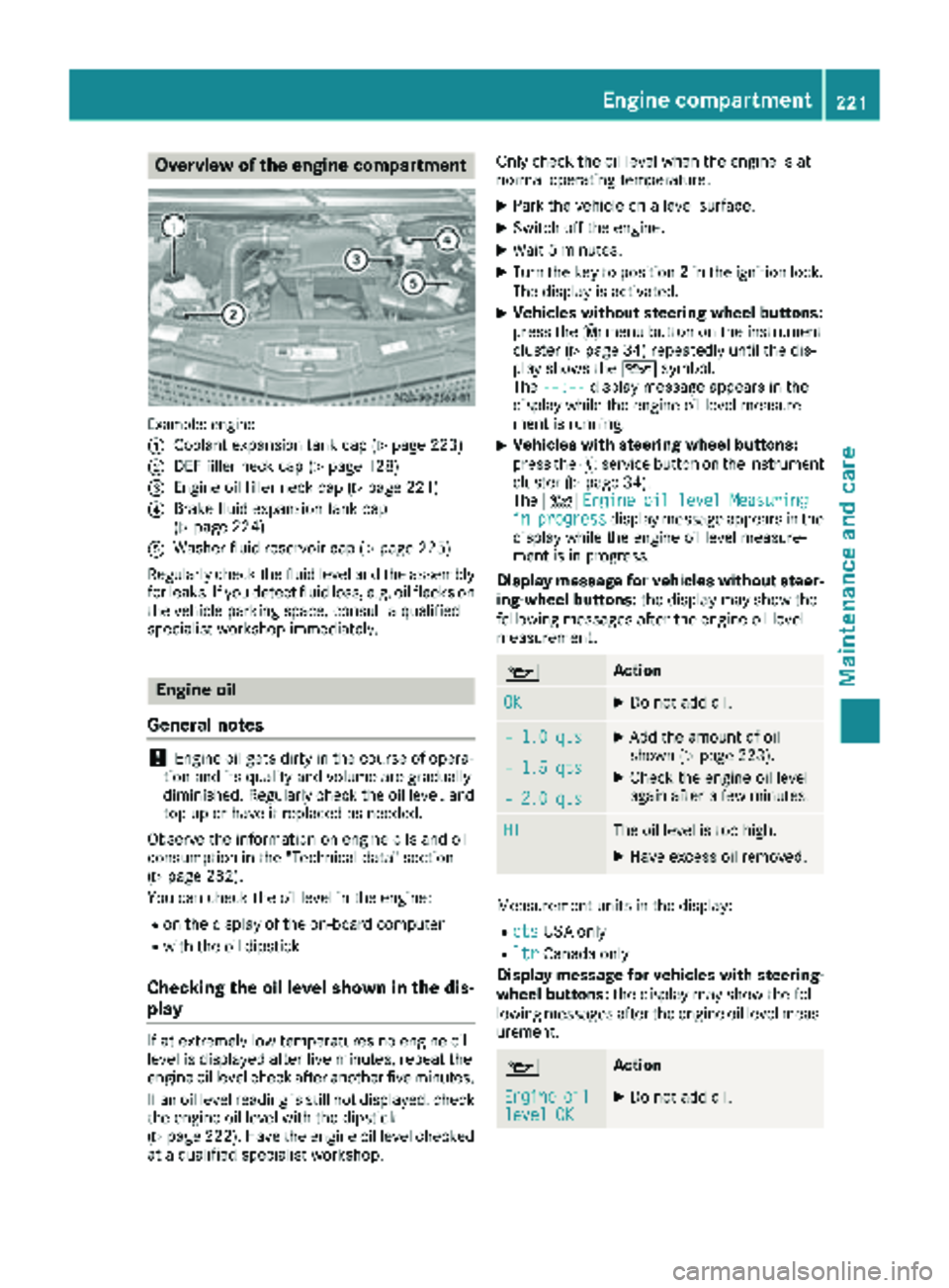

Overview of the engine compartment

Example: engine

:

Coolant expansion tank cap (Ypage 223)

;DEF filler neck cap (Ypage 128)

=Engine oil filler neck cap (Ypage 221)

?Brake fluid expansion tank cap

(Ypage 224)

AWasher fluid reservoir cap (Ypage 225)

Regularly check the fluid level and the assembly

for leaks. If you detect fluid loss, e.g. oil flecks on

the vehicle parking space, consult a qualified

specialist workshop immediately.

Engine oil

General notes

!Engine oil gets dirty in the course of opera-

tion and its quality and volume are gradually

diminished. Regularly check the oil level, and

top up or have it replaced as needed.

Observe the information on engine oils and oil

consumption in the "Technical data" section

(

Ypage 282).

You can check the oil level in the engine:

Ron the display of the on-board computer

Rwith the oil dipstick

Checking the oil level shown in the dis-

play

If at extremely low temperatures no engine oil

level is displayed after five minutes, repeat the

engine oil level check after another five minutes.

If an oil level reading is still not displayed, check

the engine oil level with the dipstick

(

Ypage 222). Have the engine oil level checked

at a qualified specialist workshop. Only check the oil level when the engine is at

normal operating temperature.

XPark the vehicle on a level surface.

XSwitch off the engine.

XWait 5 minutes.

XTurn the key to position

2in the ignition lock.

The display is activated.

XVehicles without steering wheel buttons:

press the 4menu button on the instrument

cluster (

Ypage 34) repeatedly until the dis-

play shows the 1symbol.

The --:--

display message appears in the

display while the engine oil level measure-

ment is running.

XVehicles with steering wheel buttons:

press the Ëservice button on the instrument

cluster (

Ypage 34).

The 4 Engine oil level Measuring

inprogressdisplay message appears in the

display while the engine oil level measure-

ment is in progress.

Display message for vehicles without steer-

ing-wheel buttons: the display may show the

following messages after the engine oil level

measurement.

1Action

OKXDo not add oil.

– 1.0 qtsXAdd the amount of oil

shown (Ypage 223).

XCheck the engine oil level

again after a few minutes.– 1.5 qts

– 2.0 qts

HIThe oil level is too high.

XHave excess oil removed.

Measurement units in the display:

RqtsUSA only

RltrCanada only

Display message for vehicles with steering- wheel buttons: the display may show the fol-

lowing messages after the engine oil level meas-

urement.

1Action

Engineoillevel OKXDo not add oil.

Engine compartment221

Maintenance and care

Z

Page 226 of 294

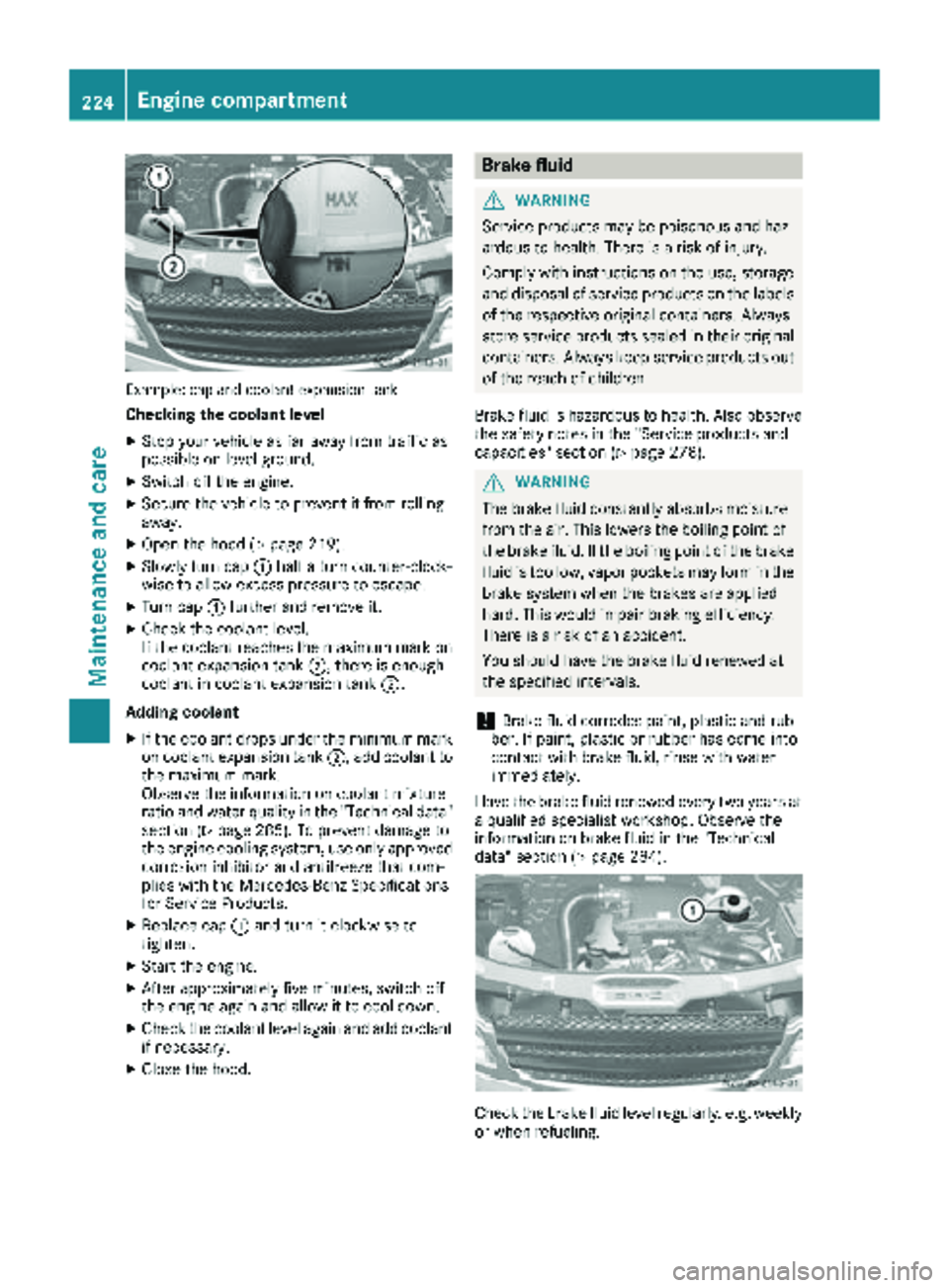

Example: cap and coolant expansion tank

Checking the coolant level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 219).

XSlowly turn cap:half a turn counter-clock-

wise to allow excess pressure to escape.

XTurn cap :further and remove it.

XCheck the coolant level.

If the coolant reaches the maximum mark on

coolant expansion tank ;, there is enough

coolant in coolant expansion tank ;.

Adding coolant

XIf the coolant drops under the minimum mark

on coolant expansion tank ;, add coolant to

the maximum mark.

Observe the information on coolant mixture

ratio and water quality in the "Technical data"

section (

Ypage 285). To prevent damage to

the engine cooling system, use only approved

corrosion inhibitor and antifreeze that com-

plies with the Mercedes-Benz Specifications

for Service Products.

XReplace cap :and turn it clockwise to

tighten.

XStart the engine.

XAfter approximately five minutes, switch off

the engine again and allow it to cool down.

XCheck the coolant level again and add coolant

if necessa ry.

XClose the hood.

Brake fluid

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

Brake fluid is hazardous to health. Also observe

the safety notes in the "Service products and

capacities" section (

Ypage 278).

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!Brake fluid corrodes paint, plastic and rub-

ber. If paint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Have the brake fluid renewed every two years at

a qualified specialist workshop. Observe the

information on brake fluid in the "Technical

data" section (

Ypage 284).

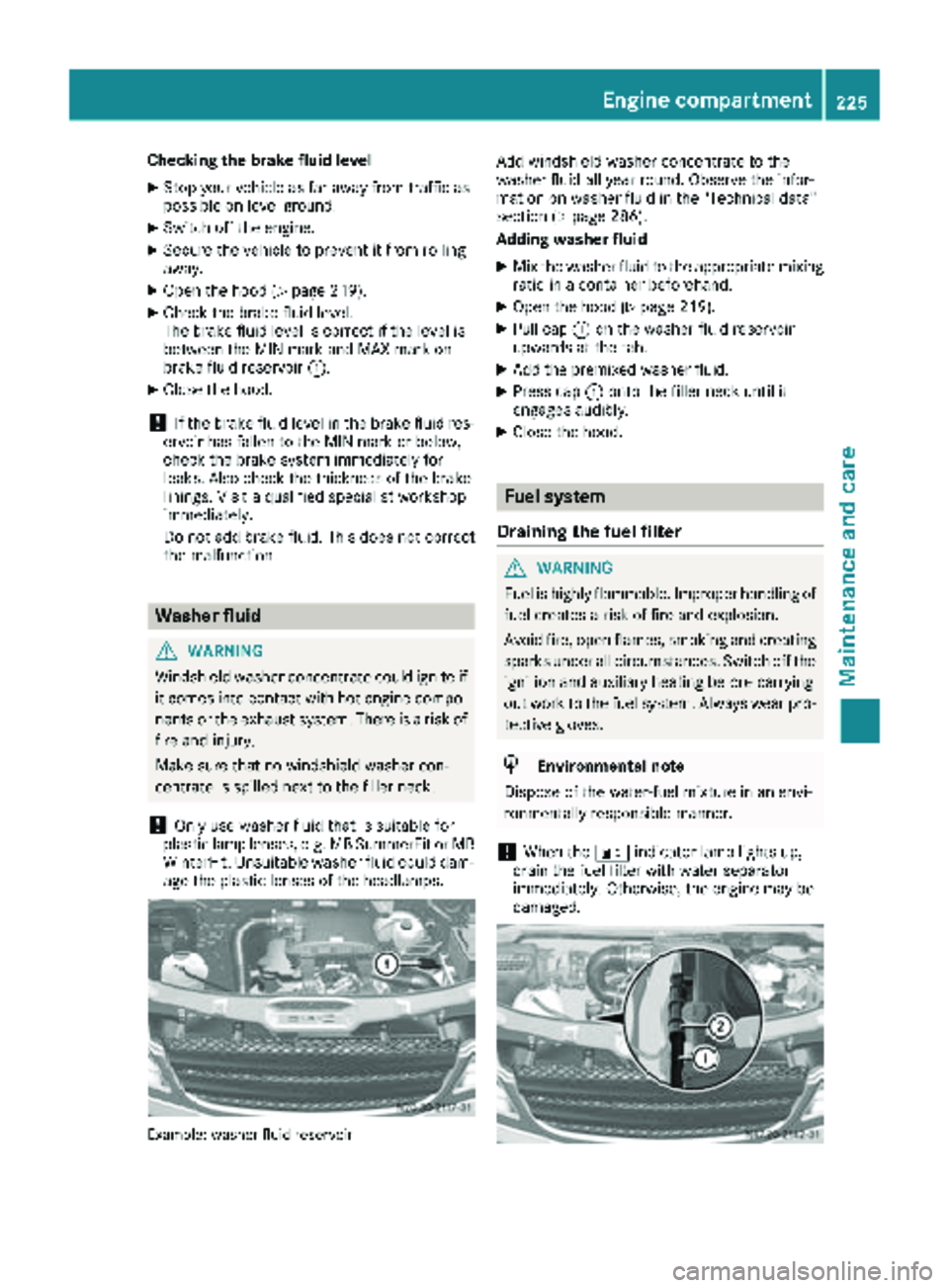

Check the brake fluid level regularly, e.g. weekly

or when refueling.

224Engine compartment

Maintenance and care

Page 227 of 294

Checking the brake fluid level

XStop your vehicle as far away from traffic as

possible on level ground.

XSwitch off the engine.

XSecure the vehicle to prevent it from rolling

away.

XOpen the hood (Ypage 219).

XCheck the brake fluid level.

The brake fluid level is correct if the level is

between the MIN mark and MAX mark on

brake fluid reservoir:.

XClose the hood.

!If the brake fluid level in the brake fluid res-

ervoir has fallen to the MIN mark or below,

check the brake system immediately for

leaks. Also check the thickness of the brake

linings. Visit a qualified specialist workshop

immediately.

Do not add brake fluid. This does not correct

the malfunction.

Washer fluid

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

Example: washer fluid reservoir

Add windshield washer concentrate to the

washer fluid all year round. Observe the infor-

mation on washer fluid in the "Technical data"

section (

Ypage 286).

Adding washer fluid

XMix the washer fluid to the appropriate mixing ratio in a container beforehand.

XOpen the hood (Ypage 219).

XPull cap :on the washer fluid reservoir

upwards at the tab.

XAdd the premixed washer fluid.

XPress cap :onto the filler neck until it

engages audibly.

XClose the hood.

Fuel system

Draining the fuel filter

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

ignition and auxiliary heating before carrying

out work to the fuel system. Always wear pro-

tective gloves.

HEnvironmental note

Dispose of the water-fuel mixture in an envi-

ronmentally responsible manner.

!When the :indicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged.

Engine compartment225

Maintenance and care

Z

Page 278 of 294

Useful information

This Operator's Manual describes all models as

well as standard and optional equipment of your

vehicle that were available at the time of going

to print. Country-specific variations are possi-

ble. Note that your vehicle may not be equipped

with all of the described functions. This also

applies to systems and functions relevant to

safety.

Read the information on qualified specialist

workshops (

Ypage 27).

Vehicle electronics

Tampering with the engine electron-

ics

!

Only have engine electronics and the corre-

sponding parts, such as control units, actua-

tors, sensors or connector leads, serviced at a

qualified specialist workshop. Otherwise, the

vehicle parts may wear more quickly. This can

lead to loss of the New Vehicle Limited War-

ranty.

Installing electrical or electronic

equipment

You and others can suffer health-related dam-

age through electromagnetic radiation. By using

an exterior antenna, a possible health risk

caused by electromagnetic fields, as discussed

in scientific circles, is taken into account. Only

have the exterior antenna installed by a qualified specialist workshop.

Electrical and electronic devices may have a

detrimental effect on both the comfort and the

operating safety of the vehicle. If equipment of

this kind is installed, its electromagnetic com-

patibility must be checked and verified.

If these devices are linked to functions associ-

ated with resistance to interference, they must

have type approval. This applies to the device or

its interfaces to the vehicle electronics, e.g.

charging brackets.

A telephone or two-way radio to be installed in

the vehicle must be approved. Further informa-

tion can be obtained from any Sprinter Dealer.

For operation of mobile phones and two-way

radios, Mercedes-Benz recommends connec- tion to an approved exterior antenna. This is the

only way to ensure optimum reception quality

inside the vehicle and to minimize mutual inter-

ference between the vehicle electronics, mobile

phones and two-way radios.

The transmission output of the mobile phone or

two-way radio may not exceed the following

maximum transmission output (PEAK):

Frequency rangeMaximum trans-

mission output

(PEAK)

Shortwave

(f < 50 MHz)100 W

4 m waveband30 W

2 m waveband50 W

Trunked radio/Tetra35 W

70 cm waveband35 W

GSM/UMTS/LTE10 W

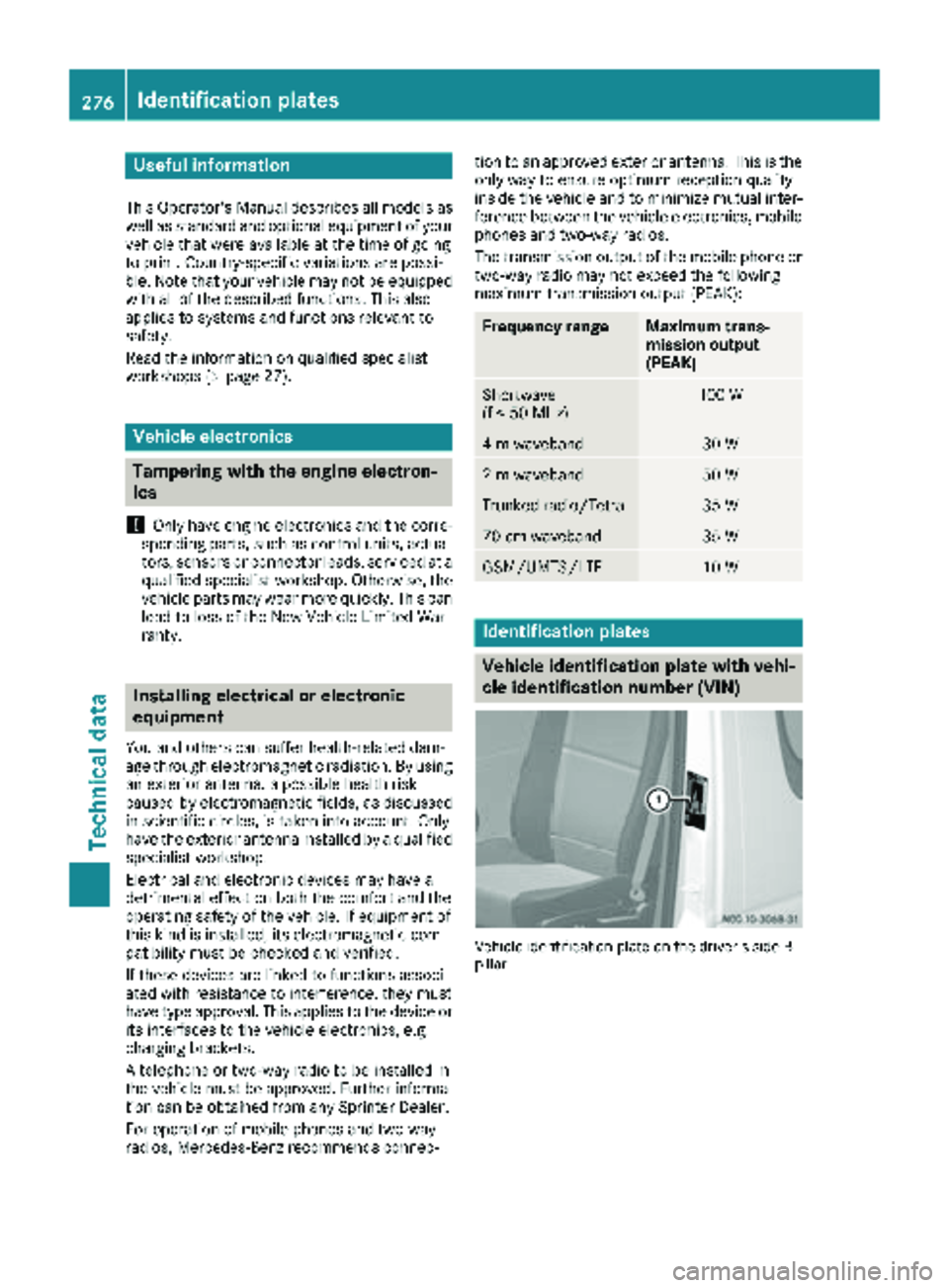

Identification plates

Vehicle identification plate with vehi-

cle identification number (VIN)

Vehicle identification plate on the driver's side B-

pillar

276Identification plates

Technical data

Page 279 of 294

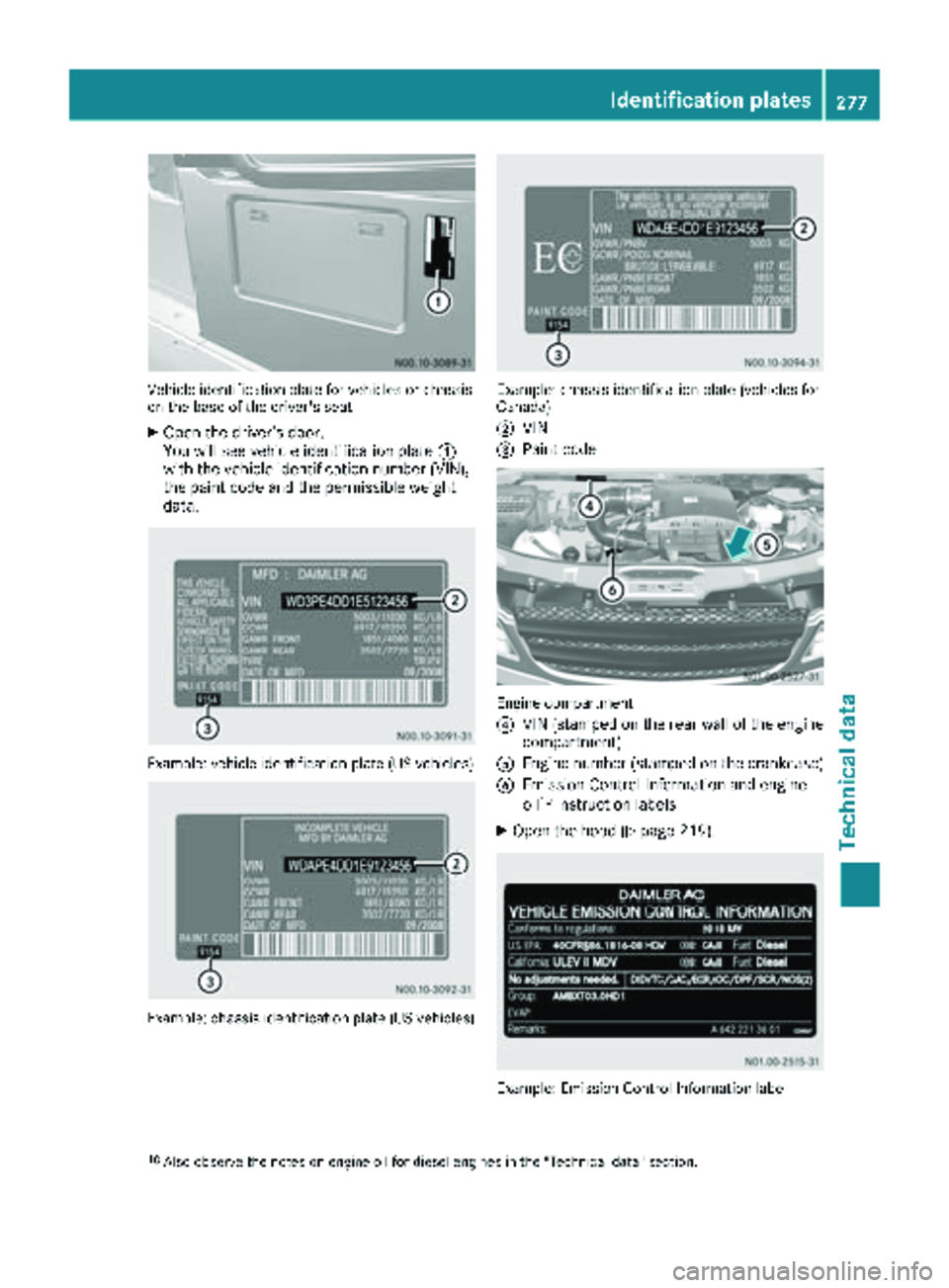

Vehicle identification plate for vehicles or chassis

on the base of the driver's seat

XOpen the driver’s door.

You will see vehicle identification plate:

with the vehicle identification number (VIN),

the paint code and the permissible weight

data.

Example: vehicle identification plate (US vehicles)

Example: chassis identification plate (US vehicles)

Example: chassis identification plate (vehicles for

Canada)

;

VIN

=Paint code

Engine compartment

?

VIN (stamped on the rear wall of the engine

compartment)

AEngine number (stamped on the crankcase)

BEmission Control Information and engine

oil10instruction labels

XOpen the hood (Ypage 219).

Example: Emission Control Information label

10Also observe the notes on engine oil for diesel engines in the "Technical data" section.

Identification plates277

Technical data

Page 280 of 294

iSuch data is vehicle-specific and may differ

from that shown. Always observe the specifi-

cations on your vehicle's identification plate.

Engine number

The engine number is stamped on the crank-

case. More information may be obtained at any

qualified specialist workshop.

Service products and capacities

Important safety notes

GWARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels

of the respective original containers. Always

store service products sealed in their original

containers. Always keep service products out

of the reach of children.

HEnvironmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

RFuels, e.g. diesel

RAdditives for the exhaust gas aftertreatment,

e.g. Diesel Exhaust Fluid (DEF)

RLubricants, e.g. engine oil, transmission oil

RCoolant

RBrake fluid

RWasher fluid

RClimate control system refrigerants

Approved service products comply with the

highest quality standards and are listed in the

MB Specifications for Service Products. Only

use service products approved for the vehicle.

This is an important condition for the warranty.

You will recognize the approved service prod-

ucts by the inscription on the container: MB

Approval (e.g. MB Approval 228.5)

Other identifications and recommendations

refer to quality level or a specification according to an MB Sheet Number (e.g. MB 228.5). They

are therefore not necessarily approved.

More information can be obtained at any quali-

fied specialist workshop.

Additives for approved service products are nei-

ther required nor permitted. Approved fuel addi- tives are the exception. Additives can cause

engine damage and must therefore not be

added to the service products.

The use of additives is always the responsibility

of the vehicle operator. The use of additives may

result in the restriction or loss of you

r Limited

Warranty entitlements.

Fuel

Important safety notes

GWARNING

Fuel is highly flammable. Improper handling of

fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creating

sparks under all circumstances. Switch off the

engine and, if applicable, the auxiliary heating

before refueling.

GWARNING

Fuel is poisonous and hazardous to health.

There is a risk of injury.

You must make sure that fuel does not come into contact with your skin, eyes or clothing

and that it is not swallowed. Do not inhale fuel

vapors. Keep fuel away from children.

If you or others come into contact with fuel,

observe the following:

RWash away fuel from skin immediately

using soap and water.

RIf fuel comes into contact with your eyes,

immediately rinse them thoroughly with

clean water. Seek medical assistance with-

out delay.

RIf fuel is swallowed, seek medical assis-

tance without delay. Do not induce vomit-

ing.

RImmediately change out of clothing which

has come into contact with fuel.

278Service products and capacities

Technical data

Page 281 of 294

When handling, storing and disposing of fuels,

please observe the relevant regulations.

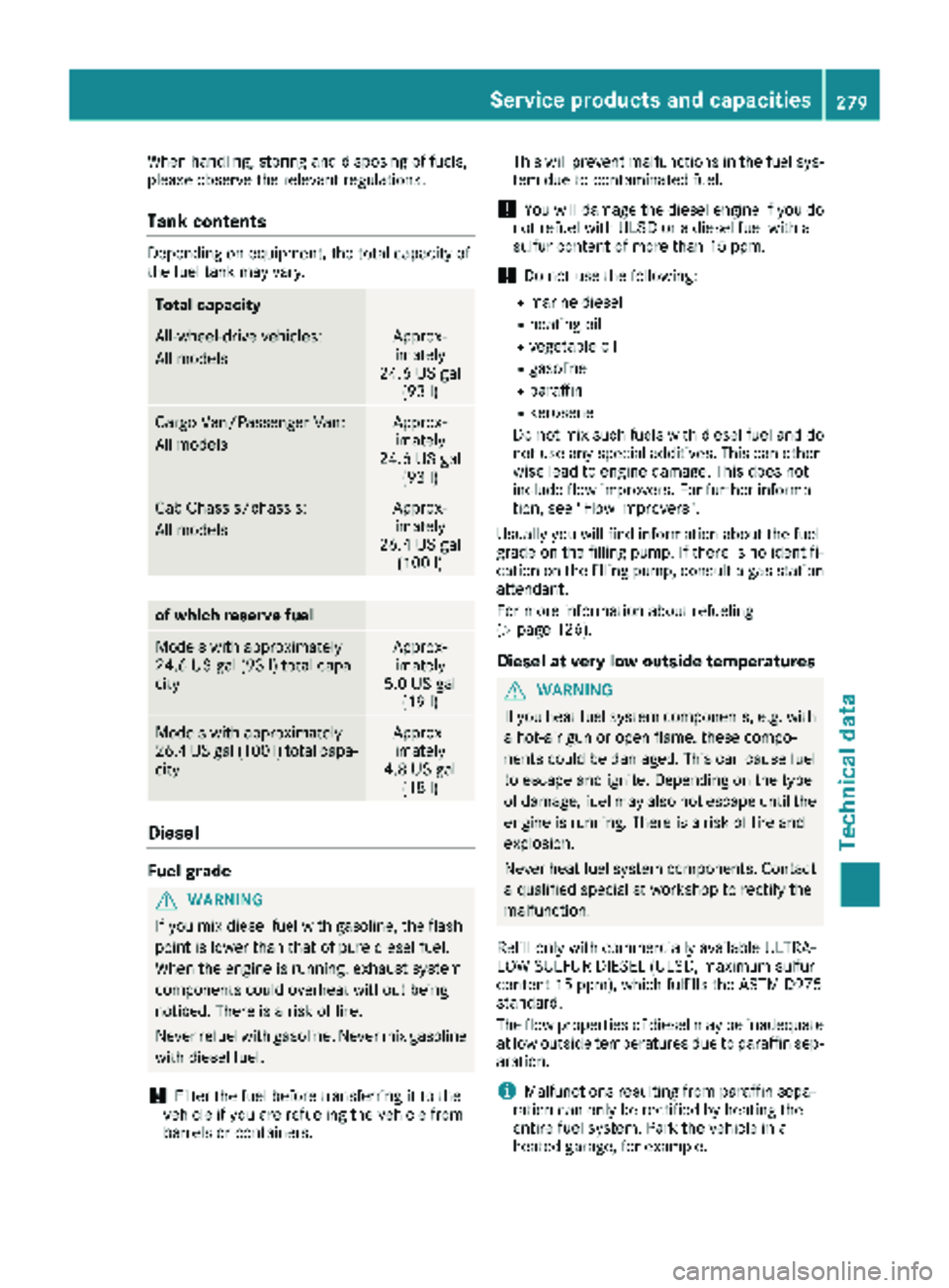

Tank contents

Depending on equipment, the total capacity of

the fuel tank may vary.

Total capacity

All-wheel-drive vehicles:

All modelsApprox-imately

24.6 US gal (93 l)

Cargo Van/Passenger Van:

All modelsApprox-imately

24.6 US gal (93 l)

Cab Chassis/chassis:

All modelsApprox-imately

26.4 US gal (100 l)

of which reserve fuel

Models with approximately

24.6 US gal (93 l) total capa-

cityApprox-imately

5.0 US gal (19 l)

Models with approximately

26.4 US gal (100 l)total capa-

cityApprox- imately

4.8 US gal (18 l)

Diesel

Fuel grade

GWARNING

If you mix diesel fuel with gasoline, the flash

point is lower than that of pure diesel fuel.

When the engine is running, exhaust system

components could overheat without being

noticed. There is a risk of fire.

Never refuel with gasoline. Never mix gasoline with diesel fuel.

!Filter the fuel before transferring it to the

vehicle if you are refueling the vehicle from

barrels or containers. This will prevent malfunctions in the fuel sys-

tem due to contaminated fuel.

!You will damage the diesel engine if you do

not refuel with ULSD or a diesel fuel with a

sulfur content of more than 15 ppm.

!Do not use the following:

Rmarine diesel

Rheating oil

Rvegetable oil

Rgasoline

Rparaffin

Rkerosene

Do not mix such fuels with diesel fuel and do

not use any special additives. This can other-

wise lead to engine damage. This does not

include flow improvers. For further informa-

tion, see "Flow improvers".

Usually you will find information about the fuel

grade on the filling pump. If there is no identifi-

cation on the filling pump, consult a gas station

attendant.

For mo

re information about refueling

(Ypage 126).

Diesel at very low outside temperatures

GWARNING

If you heat fuel system components, e.g. with

a hot-air gun or open flame, these compo-

nents could be damaged. This can cause fuel

to escape and ignite. Depending on the type

of damage, fuel may also not escape until the

engine is running. There is a risk of fire and

explosion.

Never heat fuel system components. Contact

a qualified specialist workshop to rectify the

malfunction.

Refill only with commercially available ULTRA-

LOW SULFUR DIESEL (ULSD, maximum sulfur

content 15 ppm), which fulfills the ASTM D975

standard.

The flow properties of diesel may be inadequate

at low outside temperatures due to paraffin sep-

aration.

iMalfunctions resulting from paraffin sepa-

ration can only be rectified by heating the

entire fuel system. Park the vehicle in a

heated garage, for example.

Service products and capacities279

Technical data

Z