tow MERCEDES-BENZ SPRINTER 2020 MY20 with Base Radio Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2020Pages: 324, PDF Size: 5.45 MB

Page 220 of 324

Installing/removing

thet ow ing eye Ins

talling and removing thef ront towing eye #

Toinstall thef ront towing eye: press the

to poft he co vera nd remo vethec over. #

Screw intowing eye1clockwise tothes top

and tighten. #

Toremo vethef ront towing eye: unsc rew

to wing eye1counter-clockwise. #

Inser tthe co verw itht he tabs at thet op and

push in at theb otto muntilthec ove rengages. Re

ar towing eye( vehicles wit hpassenger vehicle

appr oval)

% Re

ar towing eye2is permanentl yattached

to thev ehicle.

* NO

TEDama getothev ehicle due to

incor rect use of thet ow ing eye When

atow ing eyeisu sedtoreco verav ehi‐

cle, thev ehicle ma ybedamaged in thep roc‐

ess. #

Onlyusethet ow ing eyetot ow aw ayor

to ws tartthe vehicle. To

ws tarting vehicl e(eme rgency engine start) Ve

hicles with automatic transmission

* NO

TEDama getothea utomatic trans‐

mission due to towstarting The automatic transmissio

nmaybe damaged

in thep rocess of tows tartin gv ehicles with

automatic transmission. #

Vehicles wit hautomatic transmission

mus tnotbe tows tarted. #

Do no ttow st artv ehicles wit hautomatic

transmission. Electrical fuses

Note

sone lectrical fuses &

WARNING Risk of accident and injury

du etoo verloaded lines

If yo um anipulat eorbridg eaf aulty fuse or if

yo ur eplace it wit hafuse wit hahigher

amperage, thee lectric line could be overloa‐

ded.

This could result in afire. #

Alwa ys replace faulty fuse swiths peci‐

fi ed ne wfuses containing thec orrect

amperage. *

NO

TEDama gedue toincor rect fuses Electrica

lcomponents or sy stems could be

damaged byincor rect fuses. #

Only use fuses whi chhave been

appr ovedbyM ercedes-Benza nd which

ha ve thec orrect fus erating. Th

ee lectrica lfus es in your vehicle switc hoff

defectiv ecircuits. If afuse blo ws,allth ec ompo‐

nent sont he circuit and their functions will cease

to operate.

Blown fuses mus tbereplaced wit hfuses of an

equivalent specification ,whic hyou can de ter‐

mine bythec olor and fuse rating .The fuse allo‐

cation charta nd fur ther information on thee lec‐

tric fuses and relays can be found in the" Fuse

allocation chart" supplement. 218

Breakdown assis tance

Page 221 of 324

*

NO

TEDama geor malfunction scaused by

moisture Moistur

emaycause dama getothee lectrical

sy stem or cause it tomalfunction. #

When thef use bo xisopen, mak esure

th at no moistur ecan enter thef use box. #

When closing thef use box, mak esure

th at thes eal of thel id is positioned cor‐

re ctly on thef use box. If

th en ew fuse whic hhas been inser teda lso

blo ws,have thec ause traced and rectified at a

qu alified specialis tworks hop.

Mak esureoft hefollowing befor ereplacing a

fuse:

R thev ehicle is secured suc hthat it does not

ro llaw ay

R all electrical consume rsares wit ched off

R thei gnition is switched off

The fuses ar elocated in various fuse bo xes:

R fuse bo xinthe front-passenger foot we ll

(/ page219 )

R fuse bo xinthe seat base of thed rive r's seat

(/ page219 ) Opening

thef useb oxinthes eat base of the

dr iver's seat #

Toopen: press down and unclip fasteners 1

on thec over. #

Remo vethec ove r. #

Toclose: pressthec over firm ly in tothes eat

base until fasteners 1clip in. Opening and closing

thef useb oxinthec o-

driver's foot we ll Opening

thef useb ox #

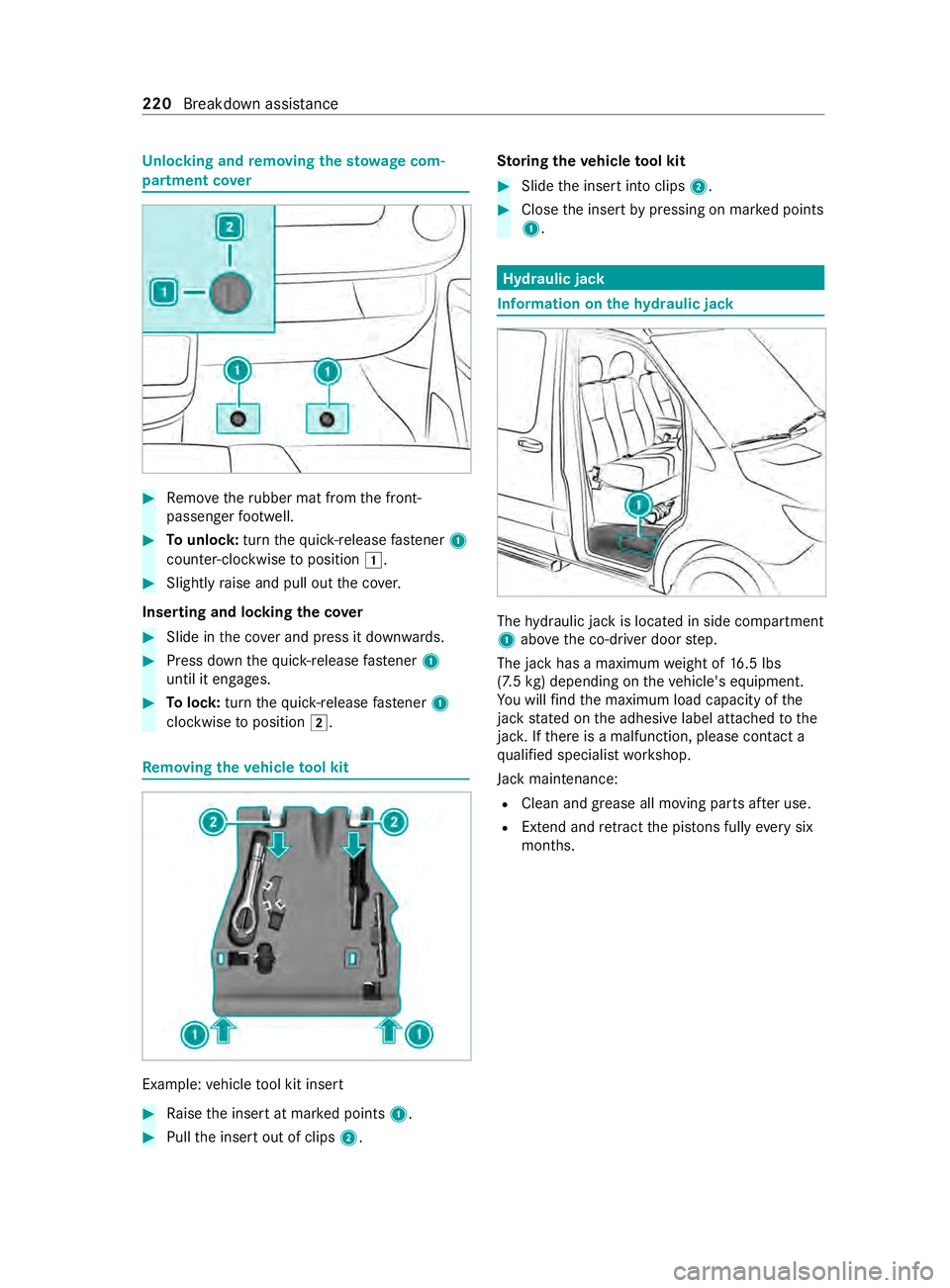

Unlocking andremoving thes towa ge com‐

partment co verint he co-driver's foot we ll

(/ page220). Example:

vehicle tool kit insert #

Liftthe inser tatmarke dp ositions 1. #

Pull thei nser tout of clips 2.

Closing thef useb ox #

Slide thei nser tint oc lips 2. #

Close thei nser tbyp ressing on mar kedp osi‐

tions 1. #

Put on thes towa ge compartment co verint he

co-d rive r's foot we ll and loc kit(/pag e220). Ve

hicl etool kit Information on

thev ehicle tool kit The

vehicle tool kit is located in thes towa ge com‐

partment in thef ootwell on thef ront-passenger

side (/ page220).

The vehicle tool kit contains:

R atow ing eye

R ascrew driver wit hTorx, Phillips and slotted

bits

The vehicle tool kit ma yalso contain thef ollow‐

ing, fore xamp le:

R an open-en dwrench

R awheel wrench Breakd

owna ssis tance 219

Page 222 of 324

Un

locking and removing the stowage com‐

pa rtmen tcover #

Remo vether ubber mat from thef ront-

passenger foot we ll. #

Tounlo ck:turnthe quick- re lease fastener 1

counter-clockwise toposition 0047. #

Slightly raise and pull out thec over.

Inserting and locking thec over #

Slide in thec over and press it down wards. #

Press down theq uick-re lease fastener 1

until it engages. #

Tolock: turnthe quick- re lease fastener 1

clockwise toposition 0048. Re

moving the vehicl etool kit Example:

vehicle tool kit insert #

Raise thei nser tatm arke dp oints 1. #

Pull thei nser tout of clips 2. St

oring thev ehicle tool kit #

Slide thei nser tint oc lips 2. #

Close thei nser tbyp ressing on mar kedp oints

1. Hydraulic jack

Information on

theh ydraulic jack The

hydraulic jac kislocated in side compartment

1 abo vethec o-driver door step.

The jac khasam aximum weight of 16.5 lbs

(7.5 kg)d epending on thev ehicle's equipment.

Yo uw illfind them aximum load capacity of the

jac kstatedont he adhesiv elabel attached tothe

jac k.Ifth er eisam alfunction, please contact a

qu alified specialis tworks hop.

Jac km aintenance:

R Cleana nd grease all moving parts af teru se.

R Extend and retract thep isto ns ful lyeve rysix

months. 220

Breakdown assis tance

Page 223 of 324

Re

moving the pum pleve rrod an dthe jack Re

quirements:

R The co-driver door is open. #

Toopen: press down and unclip fasteners 1

on thec over. #

Remo vethec ove r. #

Pull out theh older comple tely and place it on

th es tep. #

Remo vejack 2and unclip thep um plever

ro d.

% It is

recommended towe arglove sfor this

wo rk. #

Toclose: pressthec over firm ly in tothed oor

sill so that fast eners 1engage. Breakdown assis

tance 221

Page 243 of 324

Information on

thed irection of th etires' rota‐

tion Ti

re sw ithas pecified direction of rotatio nh ave

additional benefits ,e.g.ift hereisar isk ofhydro‐

planing. Youw ill on lyga in these benefits if the

cor rect directio nofrotation is obser ved.

An ar rowonthes ide wall of thet irei ndicates its

cor rect directio nofrotation.

Yo um ayalso ins tallas par ew heel agains tthe

direction of rotation. Obser vethet ime restriction

on use as well as thes peed limitation specified

on thes par ew heel. Information on

storing wheels Obser

vethef ollowing when storing wheels:

R Wheels that ha vebeen remo veds hould be

st ored in acool, dr yand, if possible, dark

place.

R Protect thet ires from oil, grease and fuel. Overvie

wofthe tire-chang etool kit Necessar

ytire-changing tools ma yinclude, for

ex ample:

R Jack

R Wheel wrench

% Yo

uw illfind them aximum load capacity of

th ej acks tatedont he adhesiv elabel

attached tothej ack.

The jac kismaintenance-free. If ther eisa

malfunction, please contact aqualified spe‐

cialis tworks hop.

Ve hicles with rear wheel drive The tire-chang

etool kit is located in stowage

compartment 1abo vethes tepoft he co-driv‐

er's door and in thes towa ge compartment in the

fo ot we ll on thec o-driver side. Preparing

thev ehicle foraw heelchange Re

quirements:

R The requ ired tire-chang etool is available.

R The vehicle is no tonaslope.

R The vehicle is on solid, non-slipper yand le vel

ground. #

Appl ythe parking brake. #

Movethef ront wheels tothes traight-ahead

position. #

Vehicles with automatic transmission:

shif tthe transmission toposition 005D. #

Switc hoffthee ngine. #

Mak esuret hat thee ngine cann otbe star ted. #

Take thev ehicle tool kit from thef ootwell on

th ec o-driver side (/ page219). Ve

hicles with rear-wheel drive #

Take thej acka nd thet ire-chang etool kit out

of thes towa ge compartment (/ page241). #

Ifnecessa ry,r emo vetheh ub cab. #

Assemble thel ug wrenc hextensio nusing the

middl erod and ther od wit hthe lar gest diam‐

et er from thet hree-piece jac kpum pleve r. #

Startin gwitht he middle rod, slide thel ug

wrenc hextensio nasfar as it will go ont othe

lug wrench. #

Using thel ug wrench, loosen thew heel nuts

or bolts on thew heel youw ish tochang eby Wheels and tires

241

Page 253 of 324

Information on

technical data

The given dat aonlya pplies tovehicles with

st andar dequipment. Further information can be

obtained at aqualified specialis tworks hop. On-board electronics

Note

sonw orkont he engine electronics *

NO

TES Premature wearthro ugh

improper main tenance Imprope

rmaintenance ma ycause vehicle

components towe ar mor equickl yand the

ve hicle's operating permit ma ybeinvalidated. #

Alwaysh ave workon thee ngine elec‐

tronics and related components car ried

out at aqualified specialis tworks hop. Tw

o-w ayradios In

stallation no tesf or two- wayradios &

WARNING Risk of accident du eto

improper workon two-w ayradios

The electromagnetic radiation from two-w ay

ra dios can inter fere wit hthe on-boar delec‐

tronics if RF transmit ters arem anipulated or

re trofitted inco rrectl y.

This could jeopardize theo perating saf etyof

th ev ehicle. #

Yous houl dhave allworkon electrical

and electronic component scarried out

at aq ualified specialis tworks hop. &

WARNING Risk of accident from incor‐

re ct ope ratio noft wo-way radios

If yo uo perat etwo -way radios incor rectl yin

th ev ehicle, thee lectromagnetic radiation

could inter fere wit hthe on-boar delectronics,

e.g.:

R ifth et wo -way radio is no tconnected to

an exterior antenna

R ifth ee xterio rantenna is no tcorrectly

mounted or is no toflowreflection

This could jeopardies theo perating saf etyof

th ev ehicle. #

Have thel ow -reflection exterior antenna

ins talled at aqualified specialis twork‐

shop. #

When operating two-w ayradios in the

ve hicle, alw aysc onnectt hemtothe

lo w- reflection exterior antenna. *

NO

TEInva lidation of theo perating per‐

mit due tofailur etoc omply wi th the

instructions fori ns tallation and use The operatin

gpermit ma ybeinvalidated if the

instructions fori ns tallation and use of two-

wa yradios ar enotobser ved. #

Onlyuse appr oved frequency bands. #

Obser vethem aximum permissible out‐

put po werint hese frequency bands. #

Onlyuse appr oved antenna positions. Use

Tech nica lSpecification ISO/T S21609 (Road

Ve hicles -EMC guidelines fori ns tallation of af ter‐

mar ketradio frequency transmitting equipmen t)

when retrofitting two-w ayradios. Comply wit hthe

legal requirements ford etachable parts.

If yo ur vehicle has ins talling fort wo -way radio

equipment ,use thep ower suppl yorantenna con‐

nections intended foru se wit hthe ins talling.

Obser vethem anufacturer's supplement during

ins tallation.

Information on two-w ayradio transmission

output

The maximum transmission outputs (PEAK) at the

base of thea ntenna mus tnotexc eed thev alues

in thef ollowing table:

Fr equency band and maximum transmission

output Fr

equency band Maximu mtransmis‐

sion output

Sho rtwa ve

3—54M Hz 10

0W

4—m—w aveband

74 —88M Hz 30 W

2—m—w aveband

14 4—1 74MHz 50 W

Tr unked radio sys‐

te m/T etra

380 —460 MHz 10 W Te

ch nica ldata 251

Page 265 of 324

Tr

aile rhitch Note

sont he trailer hitch &

WARNING Risk of accident du etoafter‐

mar ketins tallation of atrailer hitc hthat

is no tpermissible

If af term arke tins tallation of atrailer hitc his

no tp ermissible and youi nstallat railer hitch

or other assembly parts, thel ongitudinal

frame member will be weakene dand may

break .Inthis case, thet railer ma ycome

loose from thev ehicle.

Ther eisar isk of an accident.

Only ins tallat railer hitc haftermar ketifitis

pe rm issible. Obser

vethen otes on trailer operation

(/ page162).

Re trofitting atrailer hitchiso nly pe rmissible if a

to wing capacity is specified in your vehicle docu‐

ments.

Yo uc an obtain fur ther information on thet railer

hitc hataq ualified specialis tworks hop.

Mercedes-Benz recommends that youh ave a

traile rhitch retrofitted at an au thorized

Mercedes-Benz Center.

Onl yuseatrailer hitc hwhichh as been tested

and speciall yappr ove dbyM ercedes-Benzf or

yo ur vehicle.

Use onl yaball nec kthat has been appr ovedfor

yo ur vehicle and fory our Sprinter trailer hitch.

No tesont he permissible dimensions of theb all

nec kcan also be found on thei dentification plate

of thet railer hitch.

The maximum permissible towing capacity for

traile rswithout aseparat ebrakin gsystemis

1, 653 lbs (750 kg). Tr

aile rloads The permissible

weight sand loads whic hmust

no tbee xceeded can also be obtained from the

fo llowing sources of information:

R Vehicle documents

R The identification plates of thet railer hitch,

trailer and vehicle

The values appr ovedbyt he manufacturer can be

fo und in thef ollowing table. If thev alues dif fer,

th el ow estv alue applies. Use acalibrated weigh‐ ing machine

tocheckt he weight restrictions ha ve

been complied wit hbefor eyou star ty our journe y. Te

ch nica ldata 263

Page 268 of 324

Ve

hicl etype 3500 with amax. permissible gross weight of 9,900 lbs (4.490 t) (For Canad aonly) Pe

rm issible gross

we ight of vehicle/trailer

combination GCWR 6), 9)Pe

rm issible trailer load

GT W, braked 6) Pe

rm issible nose weight TWR

14 900 lbs (6.759 t) 2)

,o nly

fo rm odel series 90 7.657 8)5000 lbs (2.268 t)

2)

,o nly

fo rm odel series 90 7.657 8)500 lbs (0.22

7t)2)

,o nly form odel series

90 7.657 8)

15 250 lbs (6.9 17t)3)

,n ot

fo rm odel series 90 7.657 8)75

00 lbs (3.402 t) 3)

,n ot

fo rm odel series 90 7.657 8)75

0lbs (0.340 t) 3)

,n ot fo rmodel series

90 7.657 8) Ve

hicl etype 3500 with amax. permissible gross weight of 9,990 lbs (4.53 1t)(Fo rU SA only) Pe

rm issible gross

we ight of vehicle/trailer

combination GCWR 6), 9)Pe

rm issible trailer load

GT W, braked 6) Pe

rm issible nose weight TWR

14 990 lbs (6.799 t) 2)

,o nly

fo rm odel series 90 7.657 8)5004 lbs (2.270 t)

2)

,o nly

fo rm odel series 90 7.657 8)500 lbs (0.22

7t)2)

,o nlyf or model series

90 7.657 8)

15 250 lbs (6.9 17t)3)

,n ot

fo rm odel series 90 7.657 8)75

00 lbs (3.402 t) 3)

,n ot

fo rm odel series 90 7.657 8)75

0lbs (0.340 t) 3)

,n ot form odel series

90 7.657 8) Ve

hicl etype 3500 XD with amax. permissible gross weight of 11,03 0lbs (5.00 3t) Pe

rm issible gross

we ight of vehicle/trailer

combination GCWR 6), 9)Pe

rm issible trailer load

GT W, braked 6) Pe

rm issible nose weight TWR

15 250 lbs (6.9 17t)4)

5004 lbs(2.270 t) 2)

,o nly

fo rm odel series 90 7.657 8)500 lbs (0.22

7t)2)

,o nly form odel series

90 7.657 8)

optional :7500 lbs

(3.402 t) 3)

,n ot form odel

series 90 7.657 8) optional

:750 lbs (0.340 t) 3)

,n ot for

model series 90 7.657 8) Ve

hicl etype 4500 with amax. permissible gross weight of 12,125 lbs (5.500 t) Pe

rm issible gross

we ight of vehicle/trailer

combination GCWR 6), 9)Pe

rm issible trailer load

GT W, braked 6) Pe

rm issible nose weight TWR

15 250 lbs (6.9 17t)4)

5004 lbs(2.270 t) 2)

,o nly

fo rm odel series 90 7.657 8)500 lbs (0.22

7t)2)

,o nly form odel series

90 7.657 8)

optional :7500 lbs

(3.400 t) 3)

,n ot form odel

series 90 7.657 8) optional

:750 lbs (0.340 t) 3)

,n ot for

model series 90 7.657 8) 2)

Only NAFTAt rail er cross member ,tow ing capa‐

cit y5 ,000 lbs. 3)

Onl yNAFT Atrail er cross member ,tow ing capa‐

cit y7 ,500 lbs. 266

Tech nica ldata

Page 269 of 324

4)

Only NAFTAt rail er cross member ,tow ing capa‐

cit y5 ,000 or 7,500 lbs.

6) In trailer operation, no individual maximu mper‐

missible gross weight of those specified in the

ta ble ma ybeexceeded.

8) The vehicle lengt hfor vehicles wit hthe model

series 90 7.65 7( Ca rgoV an) is 29 0in(7,36 7m m).

9) It is no tpossible to towat railer on vehicles

whic hhaven otbeen equipped wi thatrailer cou‐

plin gass tandard. In this case, them aximum per‐

missible gross vehicle weight cor responds tothe

maximu mpermissible gross weight of thev ehicle

combination.

% If

th et railer coupling is retrofitted ,the identi‐

fi cation pla tess hould be adap teda ccording ly

wit hthe altered, maximum permissible

we ights. Please consult an authorized

Mercedes-Benz Center if youh ave anyf ur‐

th er questions. The body builder label is

found on thef ront-end

module abo vether adiator and con tains them axi‐

mum permissible curb weight fort he vehicles. Lashing points and car

rier sy stems Information abou

tthe cargo tie-down points *

NO

TERisk of accident if them aximum

loading capacity of thec argo tie-down

point is exceeded If

yo uc ombin evarious cargo tie-down points

to secur eaload, alw ayst aket he maximum

loading capacity of thew eakes tcargo tie-

down poin tint oa ccount.

During maximum full- stop braking, forc es may

act whic hcan multipl ythe weight of thel oad. #

Alwaysu se se veralc argo tie-down

point stod istribut eand spread thel oad.

Distribut ethe load on thec argo tie-

down points evenly. The nominal

tensil estrengt histhe maximum per‐

missible tensil eforce.

Fu rther information on thec argo tie-down points

and tie-down eyes can be obtained in the" Trans‐

po rting" section (/ page 186).

Ti e-d owne yes

No minal tensile stre ngt hoft he tie-down eyes Ti

e-d owne yesN ominaltensile

st re ngth

Pa ssenger Van3 50 daN

Cargo Van8 00 daN Loading

rails

No minal tensile stre ngth of thec argo tie-

down point sinthe cargo compartment Cargo tie-down

point

No

minal tensile

st re ngth

Loading rails on cargo

compartment floor 500 daN

Lo we rloading rail on

side wall 200 daN

Up per loading rail on

side wall 12

5d aN The

values specified appl yonlytol oads resting

on thec argo compartmen tfloor if youo bse rve

th ef ollowing:

R The load is secured totwoc argo tie-down

points on ther ail

R The dis tance tothen eares tload-securing

point on thes ame rail is appr oximately 1m Information about

roof racks &

WARNING Risk of inju ryif maximum roof

load is exceeded

If yo up laceal oad on ther oof as well as any

ex tern al and internal attachments ,the vehi‐

cle's center of gr avity will be raised and the

usual drivin gcharacteristics, as well as the

st eering and braking characteristics, will

ch ange. During cornering ,the vehicle will tilt

mor eseve rely an dmayreact mor esluggishly

to steering mo vements.

If yo ue xceed them aximum roof load, the

driving characteristics, as well as thes teering Te

ch nica ldata 267

Page 303 of 324

Anti-thef

tprotection

see ATA( Anti -Thef tAlarms ystem)

Ashtr ays

In thew indshield stowagec om‐

partment ............................................ 79

ASR (acceleration skid cont rol) .......... .147

Assistance graphic (on-board com‐

puter) ..................................................... 172

ASS YSTP LUS ........................................ 19 2

Batter ydisconnection period s.......... 19 2

Displ aying thes ervice due dat e........ 19 2

Fu nction/no tes. ............................... 19 2

Re gular maintenance work ............... 19 2

Special service requirements .......... .192

ATA (Anti-Thef tAlarms ystem) .............. .61

Ac tivating/deactivating thei nterior

motion sensor .................................... 63

Fu nctio n.............................................. 61

Interior motion sensor function .......... 63

St opping thea larm. ............................ 62

Switching thet ow -awa ya larm

on/of f............................................... .62

To w- aw ay alar mfunction .................... 62

At tachments .......................................... .21

AT TENTION ASSI ST............................... 15 6

Ac tivating/deactivating .................... 157

Fu nctio n........................................... 15 6

Sy stem limitations ............................1 56

Au dio settings

Balance and fader ............................ 180

Equalizer ........................................... 180

Playbac koptions .............................. 182

Au thorized workshop

see Qualified specialis tworks hop

Au tomatic distanc econtrol

se eA ctiv eDista nce Assi stDISTRONIC

Au tomatic drivin glights ........................ 84

Au tomatic transmission

DIRECT SELEC Tleve r........................ 12 2

Engaging driv eposit ion. ................... 12 3

Engaging neutral ............................... 12 2

Engaging reve rseg ear ...................... 12 2

Kickdown .......................................... 124

Re stricting thes hiftrang e................ 124

Selecting pa rkposition .....................1 23

Tr ansmission position displa y........... 12 2

Tr ansmission position s..................... 12 2

Au xiliar yheating ..................................1 05

Fu nctio n........................................... 105

Axle load .............................................. .252 B

Bac ksupport

see Lumbar suppor t(4-w ay)

BA S(Brak eAssis tSystem) .................. 14 6

Battery Charging ........................................... 209

Charging avehicle batter y................2 09

Disconnecting thea uxiliar ybattery

in thee ngine compartmen t.............. 214

Disconnecting thes tarter batter y..... 212

Jump-s tarting (vehicle) ..................... 209

Ke y. .................................................... 47

No tes( vehicle) ................................. 208

Re moving or ins talling thes tarter

batter y.............................................. 213

St arterb atter y.................................. 211

Batter ymain switch

No tes. ............................................... 12 0

Switching po wersupply on/of f......... 121

Belt see Sea tbelt

Bel twarning

see Sea tbelt

Blind Spo tAssist .................................. 157

Ac tivating/deactivating .................... 15 9

Fu nctio n........................................... 157

Re ar Cross Traf ficA lert. ................... 15 9

Sy stem limitations ............................1 57

Blue tooth ®

audio equipment

St artin gplaybac k............................. .181

Bottle holder ........................................... 78

Brake ABS (Anti-lo ckBraking Sy stem) ........ 14 6

Ac tivating/deactivating theH OLD

function ............................................ 15 5

Ac tiveB rake Assi st........................... 14 8

BA S(Brak eAssistSystem) ............... 14 6

Braking wi thparkin gbrake :. ............ .114

Downhil lgradien t.............................. 11 4

Driving no tes. ............................ 111,114

EBD (electroni cbrake forc ed istri‐

bution) ..............................................1 48

Heavy and light loads ........................ 11 4

HOLD functio n.................................. 154

Ne wb rake discs and brak epads/

linings ............................................... 11 4

Re stricted braking ef fect (salt-trea‐

te dr oads) .........................................1 14

We troad sur faces ............................ .114

Brak eAssis tSystem

see BAS(Brak eAssistSystem) Index

301